Abstract

This study presents a novel self-healing mechanism for porcelain ceramics using UV-curable resin to address the inherent brittleness of ceramic materials. A biomimetic double-layered structure was designed, consisting of a high-density outer layer for mechanical strength and a highly porous inner layer for resin storage. The porous layer, achieved through nylon microparticle addition and subsequent volatilization during sintering, reached a porosity of 67%. As confirmed by FT-IR spectroscopy and EDS analysis, UV-curable acrylic resin was successfully incorporated into the porous structure. Three-point bending tests demonstrated efficient healing with a recovery rate of 56% after 5 min of UV irradiation. Both cured resin weight and post-healing bending strength increased logarithmically with UV irradiation time. The bending strength after healing was strongly dependent on the cured resin weight and polymerization depth within the specimen, as evidenced by the correlation between increased polymerization area and higher bending strength. This approach offers a promising solution for developing more reliable and durable ceramic materials, which will be particularly beneficial for aerospace and medical applications where maintenance cost reduction and extended product life are crucial.

1. Introduction

The development of self-healing materials represents one of the most significant advancements in materials science over the past two decades, offering the ability to autonomously recover functionality after damage without external intervention [1,2,3,4]. This innovation draws inspiration from biological systems, where living organisms can heal wounds and repair damaged tissues through intrinsic mechanisms [5,6,7,8]. In engineering applications, particularly in the construction industry, self-healing materials are used to enhance the durability and sustainability of building materials. They can autonomously repair damage caused by wear, weathering, and structural stress, thereby extending the lifespan of structures and reducing maintenance requirements [9,10,11]. This technological innovation is expected to bring significant economic benefits while contributing to environmental sustainability by extending material lifespans and reducing waste [12,13,14].

Ceramic materials, especially porcelain, have become indispensable in modern industrial society due to their exceptional combination of properties, including high hardness, excellent heat resistance, and chemical stability [15,16,17,18,19]. Their applications span crucial sectors from electrical equipment [20,21] and medical implants [22,23] to advanced electronics [24,25] and energy systems [26,27]. However, the inherent brittleness of ceramics presents a significant challenge to their reliability and durability. Unlike metals or polymers that can undergo plastic deformation to absorb energy, ceramics typically fail catastrophically when microscopic cracks propagate rapidly through the material [28,29]. This characteristic is particularly concerning in certain applications, such as dental restorations and structural components, where sudden failure could have severe consequences [30,31,32,33].

Recent research in ceramic self-healing has explored various approaches, each with distinct mechanisms and limitations. High-temperature oxidation-based healing, exemplified by systems utilizing zirconium dioxide, requires temperatures exceeding 1000 °C [34] and healing times ranging from hours to days [35]. While effective in specialized applications, these conditions severely limit practical implementation [36]. Alternative methods employing glass phase fluidity, such as those using borosilicate glass, enable healing within minutes to hours at relatively lower temperatures (600–800 °C) [35,37]. However, these systems still demand considerable energy input and may compromise the material’s original properties.

Room-temperature healing strategies have emerged as a promising direction, primarily through the incorporation of healing agents in microcapsules or vascular networks. These systems have demonstrated success in polymeric materials, but their application to ceramics faces unique challenges. The size of healing agent carriers must be carefully controlled to prevent them from acting as defect initiation sites [38], and incomplete polymerization often limits healing efficiency [39]. Additionally, most existing room-temperature approaches offer limited healing capability [40,41].

The integration of UV-curable resins into ceramic matrices represents a novel approach that could potentially overcome these limitations. UV-curable systems offer several distinct advantages, including (1) rapid polymerization kinetics, with cure times typically under 10 s, enabling immediate on-site repair [42]; (2) low energy requirements, with irradiation intensities of 1–10 mW/cm2 sufficient for curing, potentially allowing utilization of natural UV-A radiation [43]; (3) excellent dimensional stability with shrinkage rates below 1% [42]; (4) high chemical resistance [44]; and (5) low viscosity (approximately 20 mPa·s) [45] ensuring good penetration into damaged regions.

However, implementing UV-curable resins in ceramics presents unique challenges, particularly regarding the storage and transport of the healing agent within the ceramic matrix. Previous attempts using traditional sintered ceramics (with porosity around 35% [46]) achieved only limited success, with the resin volume filling reaching just 29% of the total volume. This insufficient filling prevented effective transport of the healing agent to fracture surfaces, resulting in inadequate repair. To address this limitation, we explored the use of nylon microparticles (approximately 10 µm in diameter) mixed into the ceramic slurry, utilizing their volatilization at around 165 °C during sintering to create additional porosity. While this approach successfully increased porosity, it initially led to surface macro-cracks and significant degradation of mechanical properties.

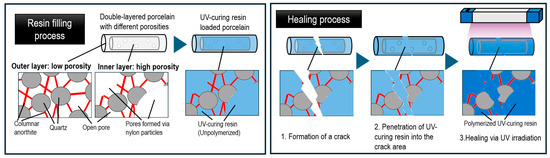

Drawing inspiration from biological systems, particularly bone structure, we propose a novel “biomimetic” approach to resolve this strength–storage capacity trade-off. Natural bone achieves its remarkable combination of strength and self-healing capability through a hierarchical structure comprising a dense outer layer (cortical bone) and a porous inner region (cancellous bone) [47,48]. We apply this principle to create a double-layered ceramic structure where the outer layer maintains mechanical integrity while the inner layer serves as both a reservoir and transport network for the healing agent (Figure 1).

Figure 1.

Schematic illustration of the resin-filling and self-healing processes in a double-layered porcelain with distinct porosities. The left panels depict the outer (low-porosity) and inner (high-porosity) layers, showing columnar anorthite grains, quartz particles, and the open pores formed by nylon burnout. UV-curing resin is introduced into the interconnected pores of the inner layer, enabling storage and transport of the healing agent. The right panels show the three-step self-healing mechanism: (1) crack formation, (2) spontaneous infiltration of the UV-curing resin into the crack via capillary action, and (3) rapid resin polymerization and structural recovery under UV irradiation.

This research aims to (1) establish a manufacturing method for double-layered porcelain with controlled porosity gradients (60–70% inner layer, 30% outer layer); (2) successfully incorporate UV-curable resin for self-healing functionality; and (3) evaluate the mechanical properties of the healed ceramic. To achieve these objectives, we investigated the relationship between UV exposure time and maximum post-healing stress (bending strength), correlating this with UV resin curing rates. Pore size distribution was characterized using mercury porosimetry, while scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) and FT-IR spectroscopy were employed to confirm UV resin coverage of fracture surfaces.

2. Materials and Methods

2.1. Materials

For fabricating the double-layered porcelain consisting of outer (dense) and inner (porous) layers, non-shrinking clay from Fuchinotodo Co., Ltd. (Ureshino, Japan) was used as the raw material. This non-shrinking clay, primarily composed of SiO2-Al2O3, exhibits minimal dimensional changes even after high-temperature (1300 °C) firing. A carboxylic acid copolymer, Alon A-6114 (Toagosei Co., Ltd., Tokyo, Japan), was used as a dispersant for the slurry. For pore formation in the inner (porous) layer, nylon microparticles (SP-10, TORAY, Tokyo, Japan) with a diameter of 10 µm were added. These nylon particles volatilize at approximately 165 °C, forming internal pores during high-temperature firing. To adjust the porosity of the porous structure, the nylon microparticle content was set at 20 wt% and thoroughly mixed with the porcelain slurry. UV-curable resin (UV resin sky blue, DAISO, Hiroshima, Japan) was used to fill the porous structure. This resin cures rapidly under 365 nm UV irradiation and enhances mechanical adhesion strength. Plaster molds in rectangular and cylindrical shapes were used for specimen formation. The cylindrical specimens were 10 mm in diameter and 55 mm in height.

2.2. Fabrication of Double-Layered Specimens and UV-Curable Resin Impregnation

Clay, water, and dispersant were mixed using a mixer (TESCOM, TM8200) at 12,000 rpm to obtain a porcelain slurry with 32% water content. Figure 2 illustrates the specimen formation and double-layer fabrication process. The double-layered ceramic samples consist of a dense outer layer and a highly porous inner layer. The outer layer, contributing to mechanical strength, was formed by pouring the porcelain slurry (1st slurry) into a plaster mold to create a cylindrical shape. After preparing the porcelain slurry, it was poured into a cylindrical plaster mold with the dimensions of a 10 mm diameter and 43 mm length. After leaving the slurry in the mold for approximately 4 min, the mold was inverted to drain the remaining liquid portion. After 24 h of setting, the specimen was demolded to obtain a cylindrical clay piece. Next, a second slurry (2nd slurry) containing 20 wt% nylon microparticles (approximately 10 μm in diameter) was prepared similarly to the 1st slurry and poured into the interior of the dried cylindrical clay piece. After 24 h of drying, the cylinder was bisque-fired at 800 °C for 12 h to volatilize the nylon microparticles and form interconnected pores in the inner region. Finally, the specimen was fired at 1300 °C for 12 h to form a dense outer layer and highly porous inner layer, resulting in a double-layered cylindrical porcelain. This process yielded a double-layered cylindrical porcelain where the outer layer provides mechanical strength and protection while the inner layer provides resin storage capacity.

Figure 2.

A schematic diagram illustrating the fabrication process for a double-layered porcelain specimen, from casting to UV-curing resin penetration.

UV-curable resin was vacuum-impregnated (0.8 kPa for 30 min) into the porous inner layer of the sintered double-layered porcelain using a diaphragm pump (FTP-20A; KNF Co. Ltd., Tokyo, Japan). The suction and discharge ports of the diaphragm pump were connected to one end of 9 mm inner diameter vacuum-grade thermoplastic polyurethane tubes (UD1290; Nihon Pisco Co., Ltd., Nagano, Japan), and the other ends of the tubes were attached to the cylindrical porcelain specimens. UV-curable resin was introduced into the sintered double-layered porcelain from the discharge side. Excess resin on the outer surface was removed by wiping with a cloth. In this study, complete curing under strong UV irradiation was performed only when artificially initiating the self-healing process after fracturing the porcelain into two pieces using a three-point bending test machine.

2.3. FT-IR

To verify the uniform distribution of UV-curable resin within the porcelain, FT-IR (Fourier transform infrared) analysis was conducted using the total reflection measurement method. A Bruker FT-IR spectrometer (Vertex 70, Bruker, Ettlingen, Germany) was used with the ATR (attenuated total reflection) mode. The wavenumber range was set to 4000–500 cm−1 with a resolution of 4 cm−1. Three types of samples were measured: fired porcelain, porcelain filled with UV-curable resin, and the UV-curable resin itself, to compare their characteristics. Measurements were conducted with samples in close contact with the diamond crystal plate, performing 32 scans at room temperature (25 °C).

2.4. Mechanical Property Testing by Three-Point Bending

The mechanical properties of the double-layered porcelain samples were evaluated using three-point bending tests on a universal testing machine (Shimadzu, AGS-X 10 kN, Kyoto, Japan). Cylindrical or bar-shaped specimens were placed on two support points, and a load was applied at a constant crosshead speed (0.5 mm/min) with a support span of 4 cm until fracture. The maximum stress recorded before failure was considered the specimen’s bending strength. This test was used for both the 1st bending test of unbroken specimens with UV-curable resin and the 2nd bending test in healing experiments. Five tests (n = 5) were conducted for each condition.

2.5. Healing Procedure and Recovery Evaluation

To evaluate the self-healing capability of the porcelain–resin composite, specimens were first fractured using the three-point bending test. Immediately after fracture, the two pieces were carefully aligned to ensure close contact between the fracture surfaces. Then, the fractured area was exposed to UV radiation (365 nm) using a UV irradiation device (OmniCure LX 505, Lumen Dynamics; Mississauga, ON, Canada) positioned 0.5 cm above the specimen. To ensure uniform UV exposure to the fractured area, the specimen was rotated (112 rpm) on a rolling device (mix rotor VMR-5R, AS ONE Co., Osaka, Japan) during irradiation. Irradiation times were set at 1, 3, 5, and 10 min to investigate the effect of exposure duration on resin curing and adhesion strength. The irradiation intensity at the specimen surface was 14 mW/cm2, and the rotation speed was maintained constantly throughout the exposure period. After the UV curing process, three-point bending was performed again under the same test conditions as the unbroken specimens to measure the post-repair bending strength. Healing efficiency was calculated according to the following equation by comparing the post-repair bending strength with the same specimen’s pre-fracture bending strength:

where σhealed is the bending strength after self-healing and σoriginal is the bending strength before fracture.

2.6. Evaluation of Porous Structure and Resin Distribution

SEM structural analysis and EDS composition analysis were performed on specimens without UV-curable resin and on specimens after the first fracture with UV-curable resin. For SEM observation, specimens were mounted on aluminum stubs using conductive carbon tape and coated with an approximately 10 nm-thick platinum layer to prevent charging. SEM observations were conducted using an S-3000 N (Hitachi, Tokyo, Japan) at an acceleration voltage of 15 kV. EDS was performed at 20 kV using the same equipment to map the distribution of surface elements (oxygen, carbon, silicon, and aluminum) in both specimens and to verify sufficient infiltration of UV-curable resin into the fracture surface after breakage.

Mercury intrusion porosimetry (AutoPore IV 9520, Micromeritics, Norcross, GA, USA) was used to quantify pore volume and pore size distribution in both specimens with and without UV-curable resin. For specimens without UV-curable resin, both dense and porous layer sections were examined. Samples were dried at 100 °C for 24 h before testing, and analysis was conducted over a pressure range of approximately 0.1–200 MPa.

2.7. Evaluation of Resin Weight Cured by UV Irradiation

To investigate the relationship between UV irradiation time and resin curing amount, resin alone was exposed to UV radiation for specified times, and the mass of the solidified portion was measured. Specifically, UV-curable resin was introduced to a depth of 2 cm in the same polyurethane tubes used for resin filling in porcelain and then irradiated under the same UV conditions used in self-healing tests (365 nm, 1, 3, 5, 10, and 30 min, irradiation intensity 14 mW/cm2) from directly above the tube’s circular face. After irradiation, the solidified resin was removed from the polyurethane tube and thoroughly washed with acetone to dissolve and remove uncured portions. The remaining cured resin was dried at room temperature, and its mass was measured using an electronic balance to determine the cured resin weight. Representative images of the cured samples were recorded using a digital camera. These measurements were conducted to elucidate the effect of UV irradiation time on mechanical recovery by correlating the degree of resin curing with post-healing bending strength results.

2.8. Analysis of UV-Cured Resin Polymerization Depth

Cross-sectional observations using a USB microscope (LPE-07W, Sanwa Supply, Okayama, Japan) were conducted to observe polymerization regions in specimens repaired with different UV irradiation times. Observation samples were those that had been fractured in actual three-point bending tests after receiving repair treatment (1, 3, 5, and 10 min). Cross-sections were ground with #320 sandpaper until visible surface irregularities were eliminated, then finished with #1500 sandpaper. Areas were observed using 2× zoom. UV-cured resin polymerization regions could be identified as white areas due to their different light reflectivity compared to uncured portions. Representative images were recorded for each sample. The polymerization area proportion was evaluated using image analysis software (ImageJ, version ver.1.54h, NIH, Bethesda, MD, USA). This method enabled the evaluation of polymerization depth from the UV-irradiated surface and investigation of correlations between polymerization depth and mechanical properties, as discussed in Section 3.6.

3. Results and Discussion

This section presents results and discussion for (1) the fabrication and porosity evaluation of double-layered porcelain, (2) UV-curable resin filling and internal structure changes, (3) chemical confirmation of resin filling by FT-IR, (4) mechanical property evaluation by three-point bending tests, (5) measurement of cured resin weight versus UV irradiation time, and (6) observation of polymerization regions by optical microscopy.

3.1. Fabrication and Porosity Evaluation of Double-Layered Porcelain

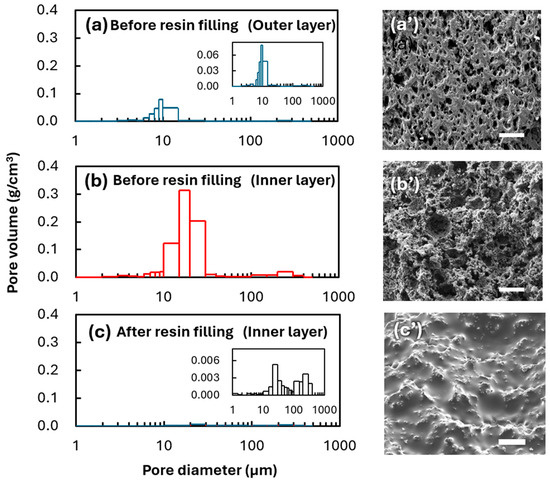

Double-layered porcelain with a porous layer was obtained through firing with added nylon microparticles (20 wt%). Mercury intrusion porosimetry measurements showed that the outer layer without nylon microparticles (Figure 3a) exhibited a relatively narrow pore size distribution with a peak around 10 µm and 39% porosity. This porosity was similar to that of porcelain from non-shrinking clay in previous studies [46,49]. In contrast, the inner layer with nylon microparticles (Figure 3b) showed a distribution peak around 10 µm with some spread up to 20 µm, reaching 67% porosity. Notably, the pore volume distribution revealed that the inner layer demonstrated 1.7 times the pore volume compared to the outer layer. These results indicate that the volatilization of nylon microparticles during the firing process formed larger interconnected pores.

Figure 3.

Mercury porosimetry measurements of pore size distributions (left) with corresponding SEM micrographs (right, scale bar = 10 µm) for (a,a’) outer layer before resin filling, with inset showing magnified view of the pore volume distribution; (b,b’) inner layer before resin filling; and (c,c’) inner layer after UV-curing resin filling, with inset showing magnified view of the pore volume distribution. Both insets display the same data at smaller pore volume ranges.

SEM observations revealed that the inner layer before resin filling (Figure 3b’) showed numerous macropores of 10–50 µm compared to the outer layer sample (Figure 3a’), consistent with the pore size distribution obtained by mercury intrusion. These SEM images directly demonstrate porous structure formation through nylon microparticle volatilization, confirming this as an appropriate method for achieving high porosity.

After resin filling, the inner layer samples (Figure 3c) showed significantly reduced pore volume, with porosity decreasing to 6%. The inset image at an expanded scale shows an extremely small remaining pore volume. Corresponding SEM images (Figure 3c’) confirm that the resin had sufficiently penetrated the pores, filling the internal structure and resulting in a smoother surface.

These results demonstrate that nylon microparticle addition and the firing process are highly effective for controlling porous layer structure in porcelain. Furthermore, the size and distribution of formed pores were confirmed as suitable for subsequent resin filling. This double-layer structure achieved the goal of maintaining structural stability in the outer layer while securing sufficient space for resin filling in the inner layer, creating a foundation for self-healing functionality.

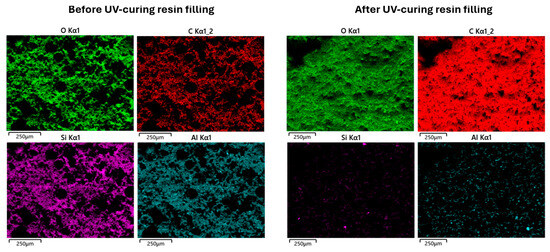

3.2. UV-Curable Resin Filling and Internal Structure Changes

Figure 4 shows the results of the elemental mapping before and after UV-curable resin filling. In the pre-filling samples (Figure 4, left column), Si and Al constituents of the porcelain were widely distributed, while O and C signals were limited. In contrast, after filling (Figure 4, right column), O and C were observed to spread throughout the sample. This indicates the penetration of acrylate-based resin, the main component of the UV-curable resin, confirming that the porcelain’s pores were filled with resin. Furthermore, the significant reduction in Si and Al signals after filling suggests that detection became difficult due to the resin coverage. This implies that the resin penetrated not only near the surface but deep into the internal pores, consistent with SEM observations (Figure 3, right). The EDS elemental mapping clearly demonstrates that the UV-curable resin not only penetrated the porous layer but spread uniformly within the pores, forming good interfaces with the porcelain components. These results confirm that vacuum filling effectively distributes UV-curable resin throughout the ceramic interior.

Figure 4.

EDS elemental mapping images comparing the distribution of Si, Al, O, and C elements in the double-layered porcelain specimens before (left column) and after (right column) UV-curing resin impregnation. Color intensity indicates relative elemental concentration.

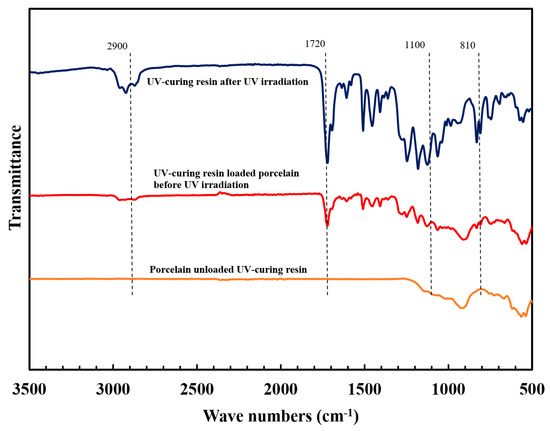

3.3. Chemical Confirmation of Resin Filling by FT-IR

FT-IR spectroscopy was used primarily to evaluate whether UV-curable resin uniformly penetrated the porcelain matrix and to confirm the basic polymerization progress (Figure 5). Three samples were measured, namely (i) UV-curable resin without porcelain, (ii) porcelain filled with UV-curable resin before UV irradiation, and (iii) porcelain filled with UV-curable resin after UV irradiation. An absorption at around 2900 cm−1, attributed to C–H stretching vibrations, served as an indicator of the resin’s presence within the porcelain. Additionally, a strong peak at 1720 cm−1, corresponding to the carbonyl group (C=O) of acrylate resin, suggested that the resin maintained its chemical characteristics after infiltration [50,51]. Furthermore, peaks around 1100 cm−1 were observed, potentially attributable to C–O–C stretching vibrations. Some references associate these bands with ether or epoxy-related structures [52], but in our study, we have not acquired sufficient data to clarify whether any epoxy functionality in the resin participates in the UV-induced polymerization. Notably, the C=C bending vibration peak clearly visible at around 810 cm−1 in the pre-UV irradiation resin sample significantly decreased after UV irradiation. This peak reduction indicates consumption of the acrylate vinyl groups and serves as an important indicator of radical polymerization progression [53]. Subtle shifts in the C=O stretching and C–O–C stretching vibration peaks after UV irradiation may reflect minor molecular structural changes upon curing.

Figure 5.

FT−IR spectra of three samples: UV−curing resin before incorporation into porcelain (porcelain-unloaded UV−curing resin), UV−curing resin−loaded porcelain before UV irradiation, and UV−curing resin after UV irradiation. Key vibrational modes are indicated on the spectra for chemical bond identification.

Overall, these FT-IR results confirm both the uniform distribution of UV-curable resin within the porous porcelain and the fact that the primary curing reaction—associated with acrylate groups—proceeds upon UV exposure. In particular, the significant reduction in the 810 cm−1 band strongly supports acrylate-based radical polymerization. A more detailed analysis of epoxy group reactivity—if any—would require additional spectroscopic data across different UV exposure times, which lies beyond the current scope. Nevertheless, combined with SEM and EDS observations, the FT-IR findings indicate that the resin not only covers the pore surfaces but also penetrates deep into the ceramic matrix and undergoes sufficient polymerization for self-healing functionality.

3.4. Mechanical Property Evaluation by Three-Point Bending

UV irradiation achieved shape recovery, or adhesion, with as little as 1 min of exposure, suggesting that UV light penetrated beyond the porcelain surface to promote resin polymerization to some depth. To clarify the influence of UV irradiation time on healing degree, the relationship between UV exposure time and post-healing mechanical strength was examined in detail.

Figure 6 shows (a) stress–strain curves and (b) bending strength for porcelain samples filled with UV-curable resin (1st bending: before healing) and samples repaired by UV irradiation after fracture (2nd bending: after healing). These results clearly demonstrate the effect of UV irradiation time on mechanical properties. Specifically, longer UV exposure times corresponded to increased post-healing maximum stress (bending strength), with 1 min of irradiation yielding 17 ± 4 MPa compared to 28 ± 4 MPa after 10 min of exposure, achieving a healing rate exceeding 50%. This suggests that extended UV exposure promotes resin curing and improves adhesion strength at fracture surfaces.

Figure 6.

(a) Representative stress–strain curves obtained from three-point bending tests comparing original specimens (1st bending) and healed specimens (2nd bending) after various UV exposure times. (b) Comparison of bending strength values before and after healing treatment, showing the relationship between UV exposure time and mechanical recovery. Error bars represent standard deviation (n = 5).

Comparing stress–strain curves, healed specimens showed increased strain before reaching maximum stress. Furthermore, the stress–strain curve slope (elastic modulus) remained nearly constant regardless of UV exposure time and showed similar behavior to pre-healing samples. This result suggests that resin encapsulation in pores does not significantly alter the elastic modulus, indicating that the elastic modulus of the harder phase—the porcelain matrix—remains dominant.

Evaluating the relationship between UV exposure time and healing rate revealed efficiencies of 37 ± 8% at 1 min, 40 ± 11% at 3 min, 56 ± 9% at 5 min, and 52 ± 7% at 10 min. These results suggest that UV-curable resin effectively adheres to fracture surfaces and contributes to mechanical strength recovery. However, healing rate improvement tended to plateau with UV exposure times beyond 10 min. UV light penetration depth depends on resin type and porcelain composition but is generally limited to several millimeters [54]. Given that the porcelain samples used in this study were approximately 5 mm thick, 10 min of UV exposure may not achieve complete curing in deeper regions. Additionally, shrinkage during resin curing could accumulate internal stress, potentially leading to reduced adhesion strength or crack reinitiation [55,56]. These factors may explain why healing rate improvement plateaus with extended UV exposure times. These results demonstrate that optimizing UV exposure time is essential for improving mechanical properties in UV-curable resin-based porcelain self-healing.

Furthermore, the slope of the stress–strain curves in Figure 6a shows that the elastic modulus remains nearly unchanged among all samples, regardless of UV-curable resin filling or varying UV irradiation times. This implies that the bulk stiffness of the composite is governed by the porcelain matrix, and that the resin in the porous layer does not significantly affect the overall elastic modulus. In contrast, although direct fracture toughness measurements (e.g., a single-edge notched beam) were not conducted in this study, improvements in bending strength and examination of the fracture surfaces indicate that the penetration and subsequent polymerization of the resin helps bridge cracks and impede their propagation. Therefore, we infer that fracture toughness likely follows the same trend as the bending strength. These observations demonstrate that the presence of the self-healing resin enhances the damage tolerance of the ceramic without negatively affecting the intrinsic stiffness of the porcelain matrix.

When compared with existing ceramic healing technologies (see Table S1), our approach offers distinct advantages in processing speed and temperature requirements, though with currently lower healing efficiency than high-temperature methods. This trade-off suggests promising applications in scenarios where rapid, room-temperature repair is prioritized over maximum strength recovery.

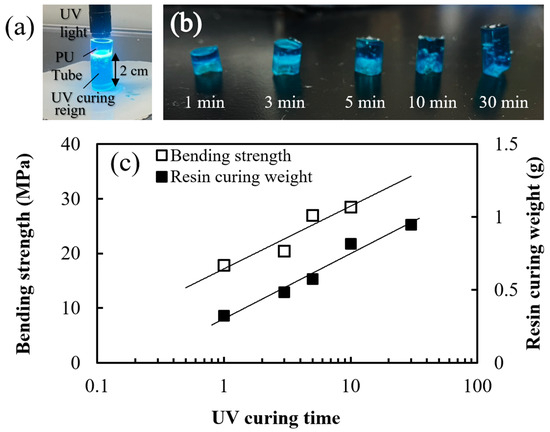

3.5. Evaluation of Cured Resin Weight vs. UV Irradiation Time

To evaluate UV-curable resin polymerization behavior, resin curing experiments were conducted in polyurethane tubes using the setup shown in Figure 7a. UV light was irradiated from above with a 2 cm UV curing region. Figure 7b shows the appearance of cured resin under different UV exposure times (1–30 min). Visual inspection confirmed increased cured resin volume with longer exposure times. Figure 7c shows the relationship between UV exposure time and both cured resin weight and bending strength. With the horizontal axis displayed on a logarithmic scale, both parameters showed linear increasing trends with exposure time. Cured resin weight increased from approximately 0.3 g at 1 min of exposure to about 1.0 g at 30 min. Similarly, bending strength increased from approximately 15 MPa at 1 min of exposure to about 30 MPa at 30 min. This trend correlates with increased cured resin weight, suggesting that extended UV exposure enables polymerization to progress deeper, leading to improved mechanical strength. Furthermore, the continued increase in cured weight beyond 10 min indicates that complete resin curing requires substantial time. These results align with the healing efficiency improvement trends shown in Section 3.4, confirming that extended UV exposure promotes complete resin curing and enhances post-healing mechanical properties.

Figure 7.

(a) Schematic and photographic illustration of the UV-curing setup, showing the polyurethane tube containing resin and the UV irradiation configuration. (b) Visual appearance of samples cured under various UV irradiation times (1–30 min), demonstrating progressive changes in cured volume. (c) Relationship between UV curing time and both bending strength (□, left axis) and cured resin weight (■, right axis), plotted on a logarithmic time scale with trend lines indicating approximate data fitting.

The logarithmic increase in both cured resin mass and bending strength with exposure time can be attributed to several interrelated factors affecting the UV curing process. This behavior is influenced by UV light penetration depth and curing reaction kinetics [57,58]. Initially, rapid crosslinking occurs in the resin surface layer, with monomer-to-polymer conversion significantly increasing cured volume. However, since the resin itself absorbs UV light, UV penetration decreases exponentially with depth, delaying deeper curing [58]. Additionally, curing reaction kinetics contribute to the logarithmic volume increase behavior. Initially, the high unreacted monomer concentration enables rapid polymerization [59]. However, as the unreacted monomers decrease and the polymer crosslink density increases, the curing rate decreases [60]. These effects result in volume increase slowing with extended exposure time, producing the observed logarithmic relationship. These results demonstrate that UV exposure time significantly influences resin curing characteristics and mechanical property recovery.

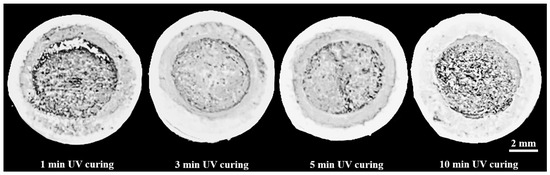

3.6. Observation of Polymerization Regions by Optical Microscopy

Figure 8 shows optical microscope observations of cross-sections from samples healed with different UV exposure times (1, 3, 5, and 10 min). In the cross-sectional images, white regions indicate areas where polymerization was completed by UV exposure. Observations revealed polymerization regions expanding from the specimen periphery toward the center with increased UV exposure time. With 1 min of exposure, only a thin polymerization layer formed at the specimen periphery, while extending the exposure time to 3 and 5 min showed polymerization regions progressing inward. Notably, 10 min of exposure achieved polymerization reaching deeper into the specimen. The polymerization area ratios were 18%, 26%, 30%, and 46% for 1, 3, 5, and 10 min exposures, respectively. These results approximately correspond to the cured resin weight increase trend shown in Section 3.5. Furthermore, expansion of the polymerization regions correlates with improved bending strength, confirming that more extensive resin curing is crucial for mechanical property recovery.

Figure 8.

Optical micrographs showing cross-sectional views of the double-layered porcelain specimens after brake and UV curing for different irradiation times (1, 3, 5, and 10 min). Scale bar = 2 mm.

4. Conclusions

This study successfully developed a novel self-healing ceramic system using UV-curable resin in a biomimetic double-layered structure. Our key findings include the following:

- A double-layered porcelain structure was successfully fabricated with distinct porosity levels (67% inner layer, 39% outer layer) using nylon microparticle addition and subsequent volatilization during sintering.

- FT-IR spectroscopy and EDS analysis confirmed the successful incorporation and uniform distribution of UV-curable resin throughout the porous structure.

- Three-point bending tests demonstrated effective healing with recovery rates exceeding 50% after 5 min of UV exposure, significantly faster than conventional ceramic healing methods.

- Both cured resin weight and post-healing bending strength increased logarithmically with UV exposure time, indicating a direct correlation between polymerization extent and mechanical recovery.

- Cross-sectional analysis revealed progressive polymerization from the surface inward with increased UV exposure time, providing insight into the healing mechanism.

These results demonstrate the potential of this approach for developing more reliable and durable ceramic materials, particularly beneficial for applications where maintenance cost reduction and extended product life are crucial, such as aerospace and medical applications.

Future work should focus on optimizing UV penetration depth, investigating the potential for multiple healing cycles, and evaluating long-term durability under various environmental conditions.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/jcs9030099/s1, Table S1: Comprehensive comparison of self-healing ceramic technologies [61,62,63,64,65].

Author Contributions

Conceptualization, R.T. and T.N.; methodology, R.T. and T.N.; formal analysis, R.T. and T.N.; investigation, R.T. and T.N.; resources, R.T. and T.N.; data curation, R.T. and T.N.; writing—original draft preparation, T.N.; writing—review and editing, T.N., M.Y., H.I. and Y.O.; visualization, R.T. and T.N.; supervision, T.N., M.Y., H.I. and Y.O.; project administration, T.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Ministry of Education, Culture, Sports, Science, and Technology of Japan (MEXT) through the Advanced Research Infrastructure Sharing Promotion Program (Support Program for Introduction of New Shared Systems) under grant number JPMXS0422400020.

Data Availability Statement

Data is contained within the article or Supplementary Material.

Acknowledgments

The FT-IR data were obtained at the Analytical Research Center for Experimental Sciences of Saga University. This research was supported by the Ministry of Education, Culture, Sports, Science, and Technology of Japan (MEXT) through the Advanced Research Infrastructure Sharing Promotion Program (Support Program for Introduction of New Shared Systems) under grant number JPMXS0422400020.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Islam, S.; Bhat, G. Progress and challenges in self-healing composite materials. Mater. Adv. 2021, 2, 1896–1926. [Google Scholar] [CrossRef]

- Song, T.; Jiang, B.; Li, Y.; Ji, Z.; Zhou, H.; Jiang, D.; Seok, I.; Murugadoss, V.; Wen, N.; Colorado, H. Self-healing materials: A review of recent developments. ES Mater. Manuf. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Bekas, D.G.; Tsirka, K.; Baltzis, D.; Paipetis, A.S. Self-healing materials: A review of advances in materials, evaluation, characterization and monitoring techniques. Compos. Part B Eng. 2016, 87, 92–119. [Google Scholar] [CrossRef]

- Zhong, J.; Tian, X.; Shi, B.; Zhang, Z.; Liu, X.; Yang, Y. Bio-inspired self-healing polyurethane system: Mimicking connective tissue with hydrogen-bonding mechanism. Chem. Eng. J. 2024, 498, 155416. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, F.; Xu, J.; Zhao, Z.H.; Fu, J. Research Progress of Human Biomimetic Self-Healing Materials. Small 2025, 21, 2408199. [Google Scholar] [CrossRef]

- Zhu, D.Y.; Rong, M.Z.; Zhang, M.Q. Self-Healing Polymeric Materials Based on Microencapsulated Healing Agents: From Design to Preparation. Prog. Polym. Sci. 2015, 49–50, 175–220. [Google Scholar] [CrossRef]

- Speck, O.; Speck, T. An overview of bioinspired and biomimetic self-repairing materials. Biomimetics 2019, 4, 26. [Google Scholar] [CrossRef]

- Chen, Y.; Kushner, A.M.; Williams, G.A.; Guan, Z. Multiphase design of autonomic self-healing thermoplastic elastomers. Nat. Chem. 2012, 4, 467–472. [Google Scholar] [CrossRef]

- Shields, Y.; Van Mullem, T.; De Belie, N.; Van Tittelboom, K. An investigation of suitable healing agents for vascular-based self-healing in cementitious materials. Sustainability 2021, 13, 12948. [Google Scholar] [CrossRef]

- Davies, R.; Jefferson, T.; Gardner, D. Development and testing of vascular networks for self-healing cementitious materials. J. Mater. Civ. Eng. 2021, 33, 04021164. [Google Scholar] [CrossRef]

- Kaushal, V.; Saeed, E. Sustainable and Innovative Self-Healing Concrete Technologies to Mitigate Environmental Impacts in Construction. CivilEng 2024, 5, 549–558. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, A. Advancing Sustainability in Construction and Environmental Management About Innovative Materials, Technologies, and Policy Frameworks. Appl. Comput. Eng. 2024, 66, 107–112. [Google Scholar] [CrossRef]

- Li, G.; Xiao, P.; Hou, S.; Huang, Y. Graphene based self-healing materials. Carbon 2019, 146, 371–387. [Google Scholar] [CrossRef]

- Sun, H.; Zou, B.; Wang, X.; Chen, W.; Zhang, G.; Quan, T.; Huang, C. Advancements in multi-material additive manufacturing of advanced ceramics: A review of strategies, techniques and equipment. Mater. Chem. Phys. 2024, 319, 129337. [Google Scholar] [CrossRef]

- Zhang, W.; Yamashita, S.; Kita, H. Progress in tribological research of SiC ceramics in unlubricated sliding—A review. Mater. Des. 2020, 190, 108528. [Google Scholar] [CrossRef]

- Belmonte, M. Advanced ceramic materials for high temperature applications. Adv. Eng. Mater. 2006, 8, 693–703. [Google Scholar] [CrossRef]

- Mohammed, B.; Afram, B.; Nazar, Z. An evaluation of the effect of different surface treatment on hardness and smoothness of pressable ceramic (in vitro study). IOSR J. Dent. Med. Sci. IOSR 2015, 14, 84–89. [Google Scholar]

- Boyraz, T.; Akkuş, A. Investigation of wear properties of mullite and aluminium titanate added porcelain ceramics. J. Ceram. Process. Res. 2021, 22, 226–231. [Google Scholar]

- Cherney, E.A.; Hackam, R.; Kim, S.H. Porcelain insulator maintenance with RTV silicone rubber coatings. IEEE Trans. Power Deliv. 1991, 6, 1177–1181. [Google Scholar] [CrossRef]

- Chaudhuri, S.P.; Sarkar, P.; Chakraborty, A.K. Electrical resistivity of porcelain in relation to constitution. Ceram. Int. 1999, 25, 91–99. [Google Scholar] [CrossRef]

- Hench, L.L. Bioceramics: From concept to clinic. J. Am. Ceram. Soc. 1991, 74, 1487–1510. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, X.; Qiao, S.; Qian, S.J.; Mo, J.-J. Hardware Complications and Failure of Three-unit Zirconia-based and Porcelain-fused-metal Implant-supported Fixed Dental Prostheses: A Retrospective Cohort Study with Up to 8 years. Clin. Oral Implant. Res. 2016, 28, 571–575. [Google Scholar] [CrossRef] [PubMed]

- Zakaly, H.M.H.; Saudi, H.A.; Tekin, H.O.; Rashad, M.; Issa, S.A.M.; Rammah, Y.S.; Elazaka, A.I.; Hessien, M.M.; Ene, A. Glass fabrication using ceramic and porcelain recycled waste and lithium niobate: Physical, structural, optical and nuclear radiation attenuation properties. J. Mater. Res. Technol. 2021, 15, 4074–4085. [Google Scholar] [CrossRef]

- Woda, C.; Greilich, S.; Beerten, K. On the OSL Curve Shape and Preheat Treatment of Electronic Components from Portable Electronic Devices. Radiat. Meas. 2010, 45, 746–748. [Google Scholar] [CrossRef]

- Belussi, L.; Mariotto, M.; Meroni, I.; Zevi, C.; Dei Svaldi, S. LCA study and testing of a photovoltaic ceramic tile prototype. Renew. Energy 2015, 74, 263–270. [Google Scholar] [CrossRef]

- Xiu, D.; Zhao, G.; Zhou, J.; Zhang, S. Black Porcelain Solar Plate and Its Thermal Performance. Int. J. Appl. Ceram. Technol. 2019, 16, 2385–2392. [Google Scholar] [CrossRef]

- Ewart, L.; Suresh, S. Crack propagation in ceramics under cyclic loads. J. Mater. Sci. 1987, 22, 1173–1192. [Google Scholar] [CrossRef]

- Evans, A.G. The role of inclusions in the fracture of ceramic materials. J. Mater. Sci. 1974, 9, 1145–1152. [Google Scholar] [CrossRef]

- Capobianco, V.; Baroudi, K.; Santos, M.J.M.C.; Rubo, J.H.; Rizkalla, A.S.; Piva, A.M.d.O.D.; Vitti, R.P.; Tribst, J.P.M.; Santos, G.C. Post-Fatigue Fracture Load, Stress Concentration and Mechanical Properties of Feldspathic, Leucite- and Lithium Disilicate-Reinforced Glass Ceramics. Heliyon 2023, 9, e17787. [Google Scholar] [CrossRef] [PubMed]

- Alwaqeet, M. Inter-Proximal Space Management Using Indirect Ceramic Veneers. J. Med. Sci. Clin. Res. 2017, 05, 15845–15849. [Google Scholar] [CrossRef]

- Wielage, B.; Nestler, D.; Roder, K. Investigation of Mechanical Properties and Failure Behaviour of CFRP, C/C and C/C-SiC Materials Fabricated by the Liquid-Silicon Infiltration Process in Dependence on the Matrix Chemistry. In Integrated Systems, Design and Technology 2010; Springer: Berlin/Heidelberg, Germany, 2011; pp. 59–66. [Google Scholar] [CrossRef]

- Bolten, M.; Gottschalk, H.; Hahn, C.; Saadi, M. Numerical Shape Optimization to Decrease Failure Probability of Ceramic Structures. Comput. Vis. Sci. 2019, 21, 1–10. [Google Scholar] [CrossRef]

- Osada, T.; Kamoda, K.; Mitome, M.; Hara, T.; Abe, T.; Tamagawa, Y.; Nakao, W.; Ohmura, T. A novel design approach for self-crack-healing structural ceramics with 3D networks of healing activator. Sci. Rep. 2017, 7, 17853. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, T.; Fang, X.; Zhang, Y.; Liu, D.; Wang, Y.; Feng, S.; Zhou, T.; Cai, S.; Suo, J. Enhancement of high temperature oxidation resistance and spallation resistance of SiC-self-healing thermal barrier coatings. Surf. Coat. Technol. 2016, 286, 365–375. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, L.; Du, S.; Han, W.; Han, J. Crack-healing behavior of zirconium diboride composite reinforced with silicon carbide whiskers. Scr. Mater. 2008, 59, 1222–1225. [Google Scholar] [CrossRef]

- Cluzel, C.; Baranger, E.; Ladeveze, P.; Mouret, A. Mechanical behaviour and lifetime modelling of self-healing ceramic-matrix composites subjected to thermomechanical loading in air. Compos. Part A Appl. Sci. Manuf. 2009, 40, 976–984. [Google Scholar] [CrossRef]

- McDonald, S.A.; Coban, S.B.; Sottos, N.R.; Withers, P.J. Tracking capsule activation and crack healing in a microcapsule-based self-healing polymer. Sci. Rep. 2019, 9, 17773. [Google Scholar] [CrossRef] [PubMed]

- Paladugu, S.R.M.; Sreekanth, P.S.R.; Sahu, S.K.; Naresh, K.; Karthick, S.A.; Venkateshwaran, N.; Ramoni, M.; Mensah, R.A.; Das, O.; Shanmugam, R. A comprehensive review of self-healing polymer, metal, and ceramic matrix composites and their modeling aspects for aerospace applications. Materials 2022, 15, 8521. [Google Scholar] [CrossRef]

- Zhang, H.; Ling, T.C.; Shi, X.; Wang, H. Influence of Curing Condition on Compressive Strength of Low-Calcium Fly Ash-Based Geopolymer Concrete. J. Residuals Sci. Technol. 2017, 14, S79–S83. [Google Scholar] [CrossRef]

- Mahdi, S.; Gama, B.A.; Yarlagadda, S.; Gillespie, J.W. Structural Repair of Composite Structural Armor. J. Compos. Mater. 2005, 39, 1695–1717. [Google Scholar] [CrossRef]

- Masson, F.; Decker, C.; Andre, S.; Andrieu, X. UV-curable formulations for UV-transparent optical fiber coatings: I. Acrylic resins. Prog. Org. Coat. 2004, 49, 1–12. [Google Scholar] [CrossRef]

- Noè, C.; Hakkarainen, M.; Sangermano, M. Cationic UV-curing of epoxidized biobased resins. Polymers 2020, 13, 89. [Google Scholar] [CrossRef]

- Strużyńska-Piron, I.; Loccufier, J.; Vanmaele, L.; Vankelecom, I.F.J. Synthesis of solvent stable polymeric membranes via UV depth-curing. Chem. Commun. 2013, 49, 11494–11496. [Google Scholar] [CrossRef]

- Strużyńska-Piron, I.; Bilad, M.R.; Loccufier, J.; Vanmaele, L.; Vankelecom, I.F.J. Influence of UV curing on morphology and performance of polysulfone membranes containing acrylates. J. Membr. Sci. 2014, 462, 17–27. [Google Scholar] [CrossRef]

- Kamochi, N.; Yamasaki, K. Technological Development for Diversification of High Precision Ceramics Products (1) Sintering Behaver and Pore Properties of High Precision Ceramics. Saga Ceram. Res. Lab. Annu. Rep. 2019, 40–44. [Google Scholar]

- Oftadeh, R.; Entezari, V.; Spörri, G.; Villa-Camacho, J.C.; Krigbaum, H.; Strawich, E.; Graham, L.; Rey, C.; Chiu, H.; Müller, R. Hierarchical analysis and multi-scale modelling of rat cortical and trabecular bone. J. R. Soc. Interface 2015, 12, 20150070. [Google Scholar] [CrossRef]

- Velnar, T.; Bunc, G.; Gradišnik, L. Fractures and Biomechanical Characteristics of the Bone. Surg. Sci. 2015, 6, 255–263. [Google Scholar] [CrossRef]

- Yada, M.; Tanaka, G.; Isono, K.; Kamochi, N.; Ichinose, H. Ultra-reduction of drying and firing shrinkage on pottery slip casting by adding mullite fiber. J. Eur. Ceram. Soc. 2024, 44, 2677–2684. [Google Scholar] [CrossRef]

- Gür, M.; Kocaokutgen, H.; Kandemirli, F.; Özkinali, S.; Yerlikaya, Z. Synthesis, Spectral and Thermal Characterization of Some Azo-Polymers Containing Acrylate Derivatives. Res. Rev. J. Chem. 2016, 5, 1–9. [Google Scholar]

- Obazee, E.O.; Okieimen, F.E.; Felix, P.S.; Ghosh, S.; Aigbodion, A.I.; Bakare, I.O. Synthesis and characterization of acrylated rubber seed oil. J. Chem. Soc. Niger. 2018, 43, 499–507. [Google Scholar]

- Zhang, L.; Wei, X.; Huang, B.; Wang, L.; Xiong, X. Ultraviolet Curing Kinetics of Epoxy Resin in UV-Curing Reaction Photopolymerization with Real-Time Fourier Transform Infrared Spectroscopy. In Applied Sciences in Graphic Communication and Packaging: Proceedings of 2017 49th Conference of the International Circle of Educational Institutes for Graphic Arts Technology and Management & 8th China Academic Conference on Printing and Packaging; Springer: Singapore, 2018; pp. 761–767. [Google Scholar]

- Hong, B.T.; Shin, K.S.; Kim, D.S. Ultraviolet-curing behavior of an epoxy acrylate resin system. J. Appl. Polym. Sci. 2005, 98, 1180–1185. [Google Scholar] [CrossRef]

- Lee, I.B.; Um, C.-M. Thermal Analysis on the Cure Speed of Dual Cured Resin Cements Under Porcelain Inlays. J. Oral Rehabil. 2001, 28, 186–197. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Zhang, Y.; Shen, Z.; Du, D.; Huang, S.; Liu, L.; Huang, L. Fiber Bragg Grating Detection of Gel Time and Residual Strain of Curing in Epoxy Resins. Polym. Eng. Sci. 2024, 64, 3101–3108. [Google Scholar] [CrossRef]

- Jiang, H.; Du, Y.; Wang, J.; Cao, Y.; Jin, C.; Yan, Y. Enhanced Bamboo Interfacial Bonding Performance on the Basis of Toughening Phenol Formaldehyde Resin by Flour. Polym. Compos. 2022, 44, 524–535. [Google Scholar] [CrossRef]

- Yu, Z.; Cui, A.; Zhao, P.; Wei, H.; Hu, F. Preparation and properties studies of UV-curable silicone modified epoxy resin composite system. J. Appl. Biomater. Funct. Mater. 2018, 16, 170–176. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Basu, S.; DeMeter, E.C. Coupling Monte Carlo Light Propagation Method and Curing Kinetic Equations to Model the Degree of Conversion Evolution of UV-Curable Composites. Ind. Eng. Chem. Res. 2021, 60, 10431–10444. [Google Scholar] [CrossRef]

- Zhang, W.; Shentu, B.; Weng, Z. Preparation and properties of heat and ultraviolet-induced bonding and debonding epoxy/epoxy acrylate adhesives. J. Appl. Polym. Sci. 2018, 135, 46435. [Google Scholar] [CrossRef]

- Sun, G.; Mao, X.; Luo, J.; Liu, R. Mitigating Shrinkage Stress in UV-Curable Resin: Shape Memory Microcapsules Enable Shrinkage Stress Reduction via Photopolymerization-Induced Shape Recovery. ACS Appl. Polym. Mater. 2024, 6, 977–985. [Google Scholar] [CrossRef]

- Rahman, M.M.; Maeda, T.; Osada, T.; Ozaki, S. Method of Determining Kinetic Parameters of Strength Recovery in Self-Healing Ceramic Composites. Materials 2023, 16, 4079. [Google Scholar] [CrossRef]

- Sloof, W.G.; Pei, R.; McDonald, S.; Fife, J.L.; Shen, L.; Boatemaa, L.; Farle, A.S.; Yan, K.; Zhang, X.; Zwaag, S.v.d.; et al. Repeated Crack Healing in MAX-phase Ceramics Revealed by 4D in Situ Synchrotron X-Ray Tomographic Microscopy. Sci. Rep. 2016, 6, 23040. [Google Scholar] [CrossRef]

- Souza, N.R.d.; Paiva, P.R.P. Evaluation of the Self-Healing Capacity of Ceramics Produced with Alumina and Silicon Carbide. Cerâmica 2022, 68, 229–235. [Google Scholar] [CrossRef]

- Lee, J.S.; Akutsu, Y.; Nakao, W. Mechanical Properties Due to Competition Behavior Between Damage and Recovery of Self-healing Fiber-reinforced Ceramics. Int. J. Appl. Ceram. Technol. 2024, 21, 2228–2234. [Google Scholar] [CrossRef]

- Cai, H.; Wei, Y.; Wang, B.; Jiang, K. Oxidation-induced Crack-healing Behavior of SiC-Al2O3-TiB2 Composites at 600 °C–800 °C. Int. J. Appl. Ceram. Technol. 2023, 20, 3635–3646. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).