A Model of a “Smart” Thermoresponsive Composite with Convertible Surface Geometry Controlled by the Magnetocaloric Effect

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

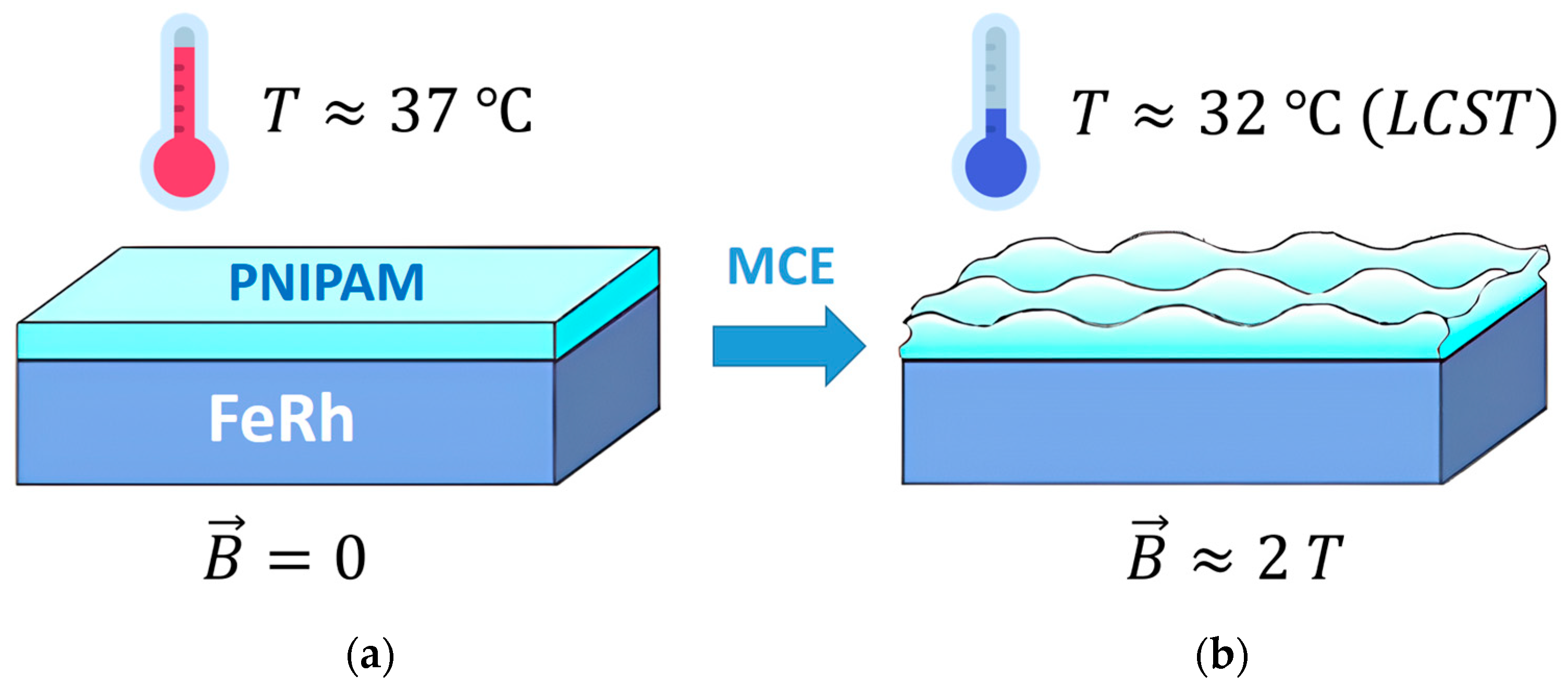

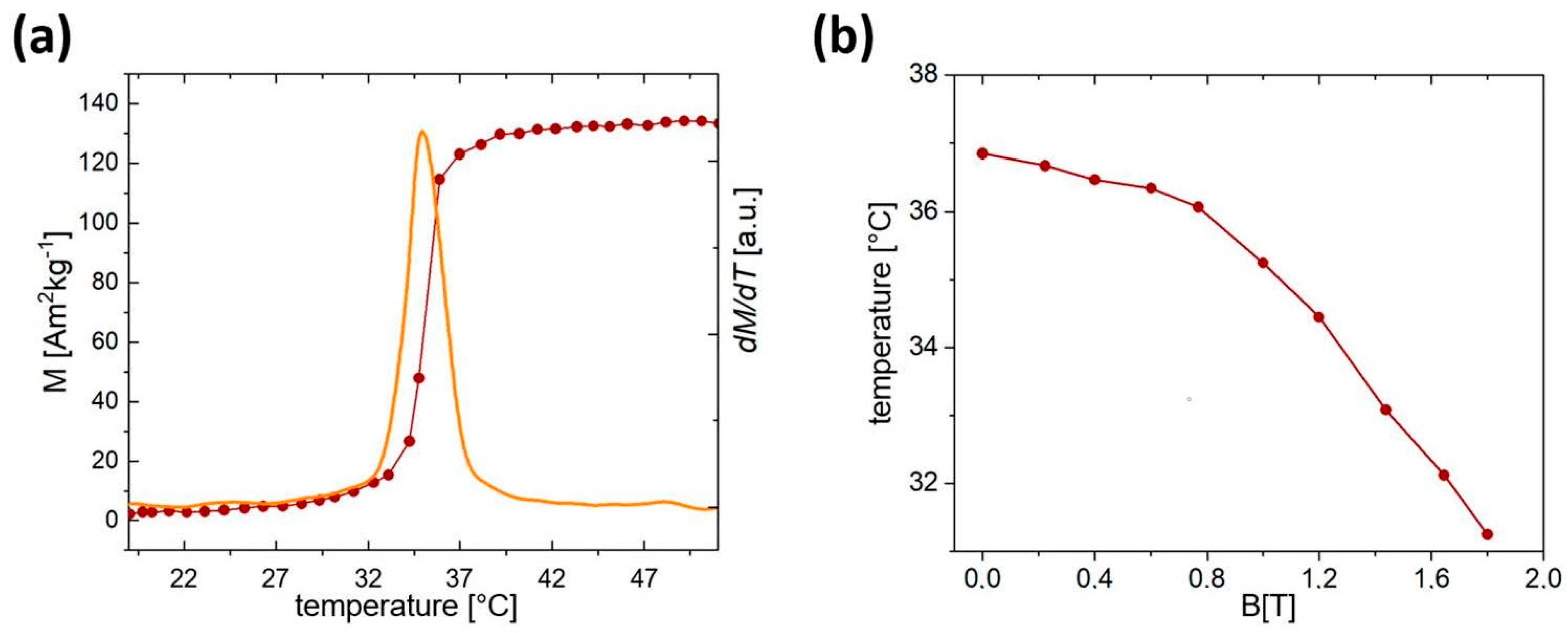

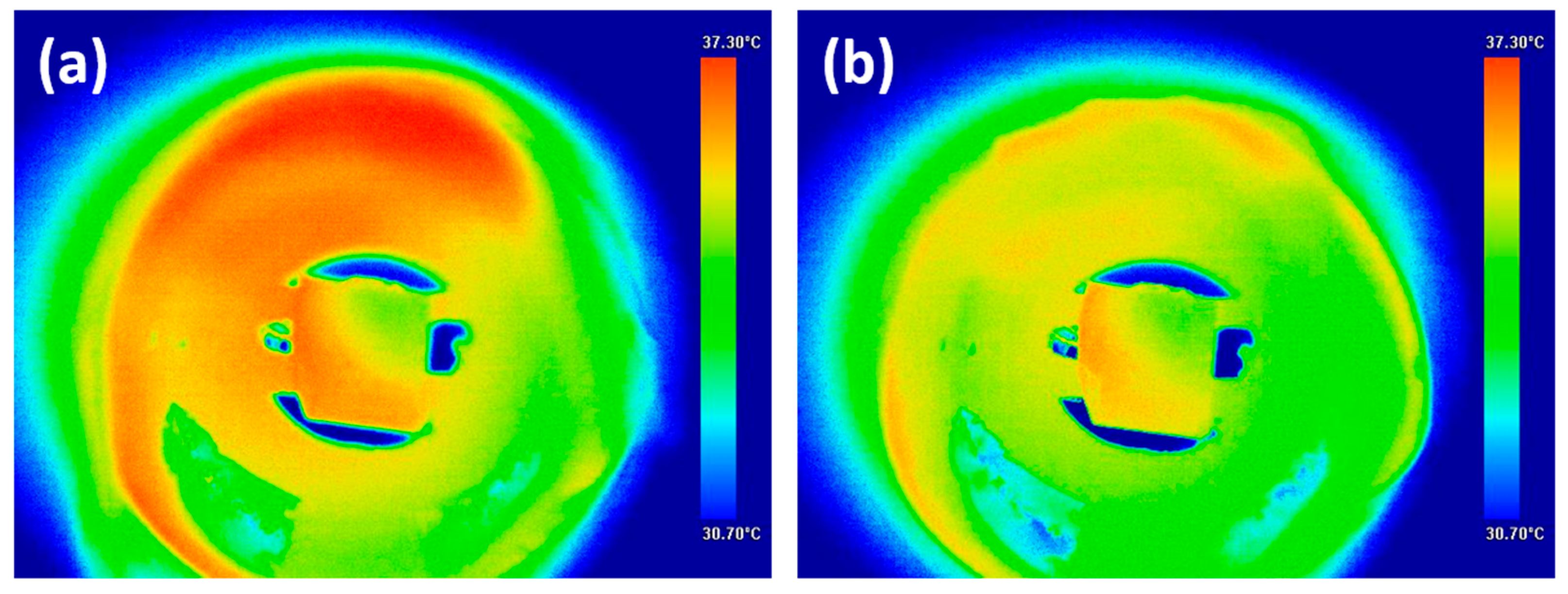

3.1. Experiment

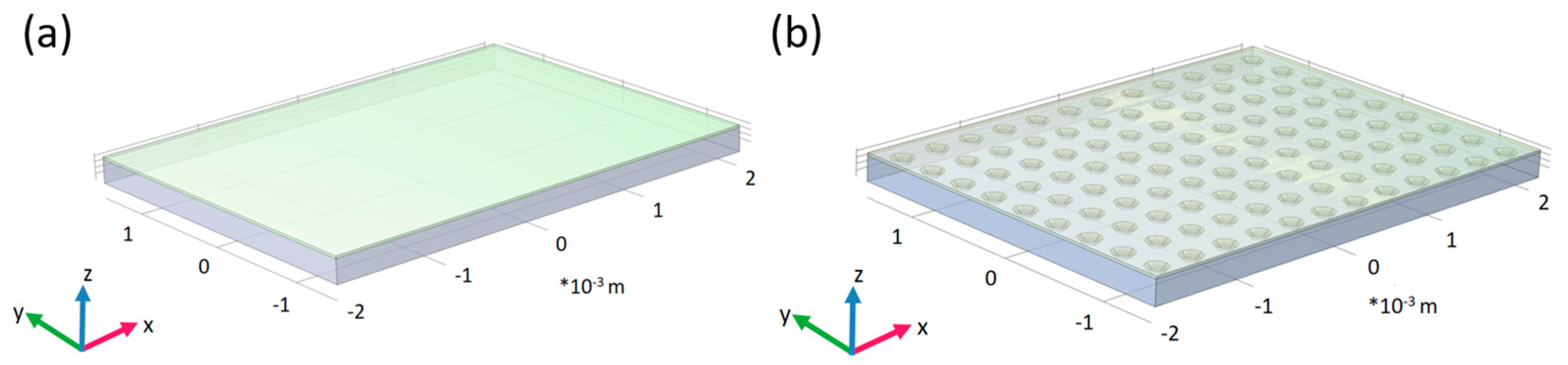

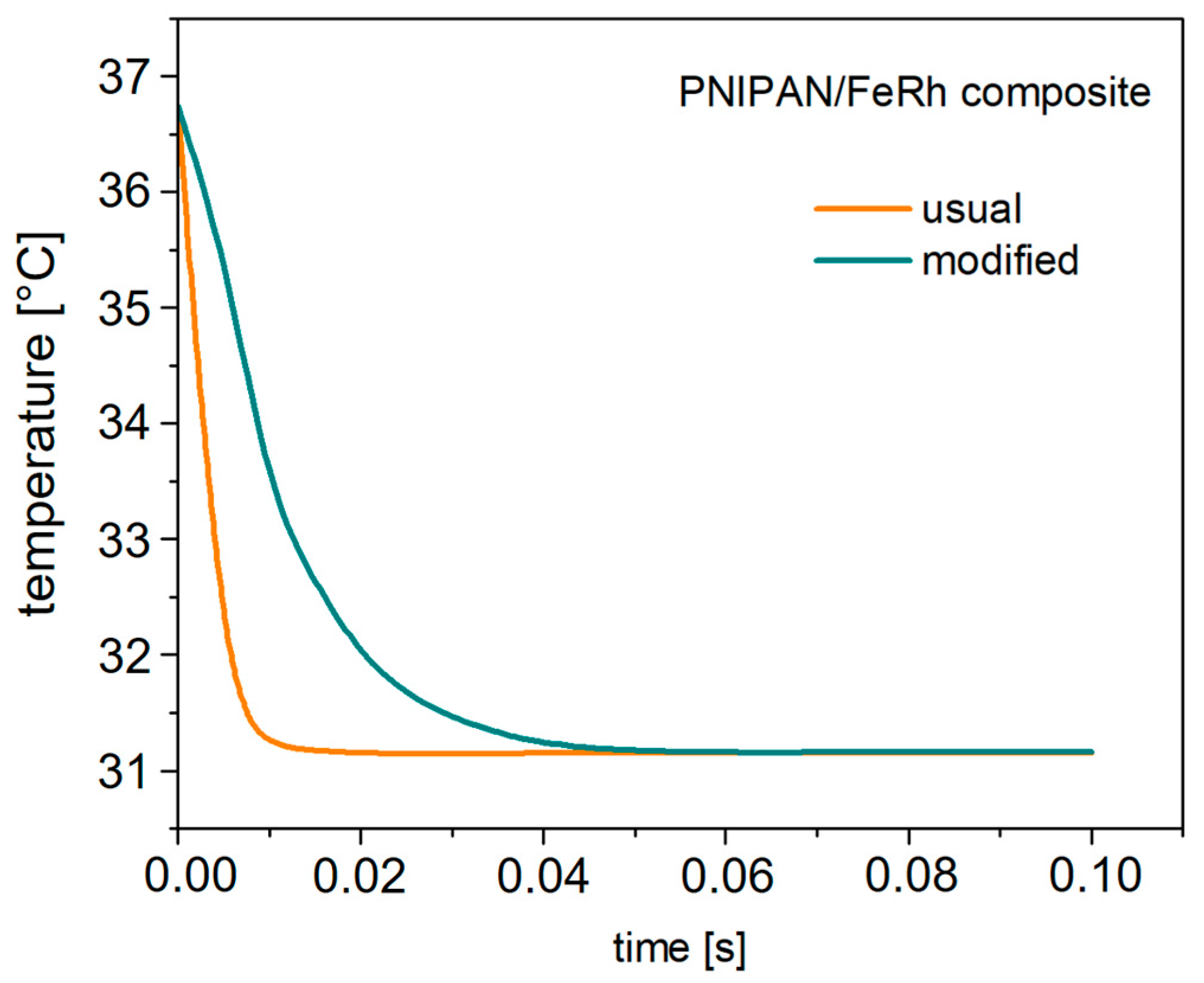

3.2. Calculations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Greco, F.; Mattoli, V. Introduction to Active Smart Materials for Biomedical Applications. In Nanomedicine and Nanotoxicology; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–27. [Google Scholar] [CrossRef]

- Kotsuchibashi, Y.; Ebara, M.; Aoyagi, T.; Narain, R. Recent advances in dual temperature responsive block copolymers and their potential as biomedical applications. Polymers 2016, 8, 380. [Google Scholar] [CrossRef] [PubMed]

- Qiao, S.; Wang, H. Temperature-responsive polymers: Synthesis, properties, and biomedical applications. Nano Res. 2018, 11, 5400–5423. [Google Scholar] [CrossRef]

- Doberenz, F.; Zeng, K.; Willems, C.; Zhang, K.; Groth, T. Thermoresponsive polymers and their biomedical application in tissue engineering—A review. J. Mater. Chem. B 2020, 8, 607–628. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Tsujii, K. Potential application of poly(N-isopropylacrylamide) gel containing polymeric micelles to drug delivery systems. Colloids Surf. B Biointerfaces 2005, 46, 142–146. [Google Scholar] [CrossRef]

- Schild, H.G. Poly(N-isopropylacrylamide): Experiment, theory and application. Prog. Polym. Sci. 1992, 17, 163–249. [Google Scholar] [CrossRef]

- Rzaev, Z.M.O.; Dinçer, S.; Pişkin, E. Functional copolymers of N-isopropylacrylamide for bioengineering applications. Prog. Polym. Sci. 2007, 32, 534–595. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Y.; Fu, W.; Yao, M.; Ding, Z.; Xuan, J.; Li, D.; Wang, S.; Xia, Y.; Cao, M. Poly(N-isopropylacrylamide)-based thermoresponsive composite hydrogels for biomedical applications. Polymers 2020, 12, 580. [Google Scholar] [CrossRef]

- Frolova, A.; Ksendzov, E.; Kostjuk, S.; Efremov, Y.; Solovieva, A.; Rochev, Y.; Timashev, P.; Kotova, S. Thin Thermoresponsive Polymer Films for Cell Culture: Elucidating an Unexpected Thermal Phase Behavior by Atomic Force Microscopy. Langmuir 2021, 37, 11386–11396. [Google Scholar] [CrossRef]

- Throat, S.; Bhattacharya, S. Macromolecular Poly(N-isopropylacrylamide) (PNIPAM) in Cancer Treatment and Beyond. Adv. Polym. Technol. 2024, 2024, 1444990. [Google Scholar] [CrossRef]

- Nigro, V.; Angelini, R.; Buratti, E.; Colantonio, C.; D’Amato, R.; Dinelli, F.; Franco, S.; Limosani, F.; Montereali, R.M.; Nichelatti, E.; et al. Influence of a Solid Surface on PNIPAM Microgel Films. Gels 2024, 10, 473. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Z.; Serna, J.A.; Debastiani, R.; Gomez, J.E.U.; Lu, L.; Yang, W.; Dong, Z.; Levkin, P.A. Enhancing Temperature Responsiveness of PNIPAM Through 3D-Printed Hierarchical Porosity. Adv. Funct. Mater. 2024, 34, 2403794. [Google Scholar] [CrossRef]

- Vo, T.T.N.; Yang, R.; Aldabbagh, F.; Carroll, W.; Meere, M.; Rochev, Y. A Thermally Activated Drug Delivery System Based on a Thermoresponsive Polymer and a Cooling Device: A Theoretical Assessment. J. Therm. Sci. Eng. Appl. 2014, 6, 021012. [Google Scholar] [CrossRef]

- Yang, R.; Gorelov, A.V.; Aldabbagh, F.; Carroll, W.M.; Rochev, Y. An implantable thermoresponsive drug delivery system based on Peltier device. Int. J. Pharm. 2013, 447, 109–114. [Google Scholar] [CrossRef] [PubMed]

- Tishin, A.; Rochev, J.; Gorelov, A. Magnetic Carrier and Medical Preparation for Controllable Delivery and Release of Active Substances, a Method of Production and Method of Treatment Using Thereof. U.S. Patent 9,017,713, 28 April 2015. [Google Scholar]

- Amirov, A. Multiferroic, magnetic, and magnetoelectric nanomaterials for medical applications. Magn. Mater. Technol. Med. Appl. 2021, 469–484. [Google Scholar] [CrossRef]

- Tishin, A.M.; Spichkin, Y.I.; Zverev, V.I.; Egolf, P.W. A review and new perspectives for the magnetocaloric effect: New materials and local heating and cooling inside the human body. Int. J. Refrig. 2016, 68, 177–186. [Google Scholar] [CrossRef]

- Shen, B.; Ma, Y.; Yu, S.; Ji, C. Smart Multifunctional Magnetic Nanoparticle-Based Drug Delivery System for Cancer Thermo-Chemotherapy and Intracellular Imaging. ACS Appl. Mater. Interfaces 2016, 8, 24502–24508. [Google Scholar] [CrossRef]

- Amirov, A.A.; Yusupov, D.M.; Murliev, E.K.; Gritsenko, C.A.; Aliev, A.M.; Tishin, A.M. Smart thermoresponsive composite activated by magnetocaloric effect. Mater. Lett. 2021, 304, 130626. [Google Scholar] [CrossRef]

- Komlev, A.S.; Gimaev, R.R.; Zverev, V.I. Smart magnetocaloric coatings for implants: Controlled drug release for targeted delivery. Phys. Open 2021, 7, 100063. [Google Scholar] [CrossRef]

- Ribeiro, C.; Costa, C.M.; Correia, D.M.; Nunes-Pereira, J.; Oliveira, J.; Martins, P.; Gonçalves, R.; Cardoso, V.F.; Lanceros-Méndez, S. Electroactive poly(vinylidene fluoride)-based structures for advanced applications. Nat. Protoc. 2018, 13, 681–704. [Google Scholar] [CrossRef]

- Amirov, A.; Yusupov, D.; Sobolev, K. Polymer Fe-Rh / PVDF multicaloric composite. Lett. Mater. 2021, 11, 213–217. [Google Scholar] [CrossRef]

- Orudzhev, F.; Alikhanov, N.; Amirov, A.; Rabadanova, A.; Selimov, D.; Shuaibov, A.; Gulakhmedov, R.; Abdurakhmanov, M.; Magomedova, A.; Ramazanov, S.; et al. Porous Hybrid PVDF/BiFeO3 Smart Composite with Magnetic, Piezophotocatalytic, and Light-Emission Properties. Catalysts 2023, 13, 874. [Google Scholar] [CrossRef]

- Chirkova, A.; Skokov, K.P.; Schultz, L.; Baranov, N.V.; Gutfleisch, O.; Woodcock, T.G. Giant adiabatic temperature change in FeRh alloys evidenced by direct measurements under cyclic conditions. Acta Mater. 2016, 106, 15–21. [Google Scholar] [CrossRef]

- Kamantsev, A.P.; Amirov, A.A.; Yusupov, D.M.; Butvina, L.N.; Koshkid’ko, Y.S.; Golovchan, A.V.; Valkov, V.I.; Aliev, A.M.; Koledov, V.V.; Shavrov, V.G. Advanced Non-Contact Optical Methods for Measuring the Magnetocaloric Effect. Phys. Met. Metallogr. 2023, 124, 1075–1091. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, S.; Peng, J.; Tan, Y.; Li, C.; Boey, F.Y.C.; Long, Y. Liquid Thermo-Responsive Smart Window Derived from Hydrogel. Joule 2020, 4, 2458–2474. [Google Scholar] [CrossRef]

- Amirov, A.A.; Permyakova, E.S.; Yusupov, D.M.; Savintseva, I.V.; Murliev, E.K.; Rabadanov, K.S.; Popov, A.L.; Chirkova, A.M.; Aliev, A.M. Thermoresponsive PNIPAM/FeRh Smart Composite Activated by a Magnetic Field for Doxorubicin Release. ACS Appl. Eng. Mater. 2025. [Google Scholar] [CrossRef]

| Material | ρ (kg/m3) | K (W/m × K) | C (J/kg × °C) | t (µm) | TAD (°C) |

|---|---|---|---|---|---|

| FeRh | 10,000 | 150 | 6000 | 200 | 5.6 |

| PNIPAM | 1000 | 0.56 | 4200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amirov, A.A.; Koliushenkov, M.A.; Yusupov, D.M.; Murliev, E.K.; Chirkova, A.M.; Kamantsev, A.P. A Model of a “Smart” Thermoresponsive Composite with Convertible Surface Geometry Controlled by the Magnetocaloric Effect. J. Compos. Sci. 2025, 9, 97. https://doi.org/10.3390/jcs9030097

Amirov AA, Koliushenkov MA, Yusupov DM, Murliev EK, Chirkova AM, Kamantsev AP. A Model of a “Smart” Thermoresponsive Composite with Convertible Surface Geometry Controlled by the Magnetocaloric Effect. Journal of Composites Science. 2025; 9(3):97. https://doi.org/10.3390/jcs9030097

Chicago/Turabian StyleAmirov, Abdulkarim A., Maksim A. Koliushenkov, Dibir M. Yusupov, Eldar K. Murliev, Alisa M. Chirkova, and Alexander P. Kamantsev. 2025. "A Model of a “Smart” Thermoresponsive Composite with Convertible Surface Geometry Controlled by the Magnetocaloric Effect" Journal of Composites Science 9, no. 3: 97. https://doi.org/10.3390/jcs9030097

APA StyleAmirov, A. A., Koliushenkov, M. A., Yusupov, D. M., Murliev, E. K., Chirkova, A. M., & Kamantsev, A. P. (2025). A Model of a “Smart” Thermoresponsive Composite with Convertible Surface Geometry Controlled by the Magnetocaloric Effect. Journal of Composites Science, 9(3), 97. https://doi.org/10.3390/jcs9030097