Comparative Analysis of Bending and Rolling Shear Performance of Poplar and Hybrid Maple–Poplar Cross-Laminated Timber (CLT)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Three-Layered CLT Panels

2.3. Experimental Testing

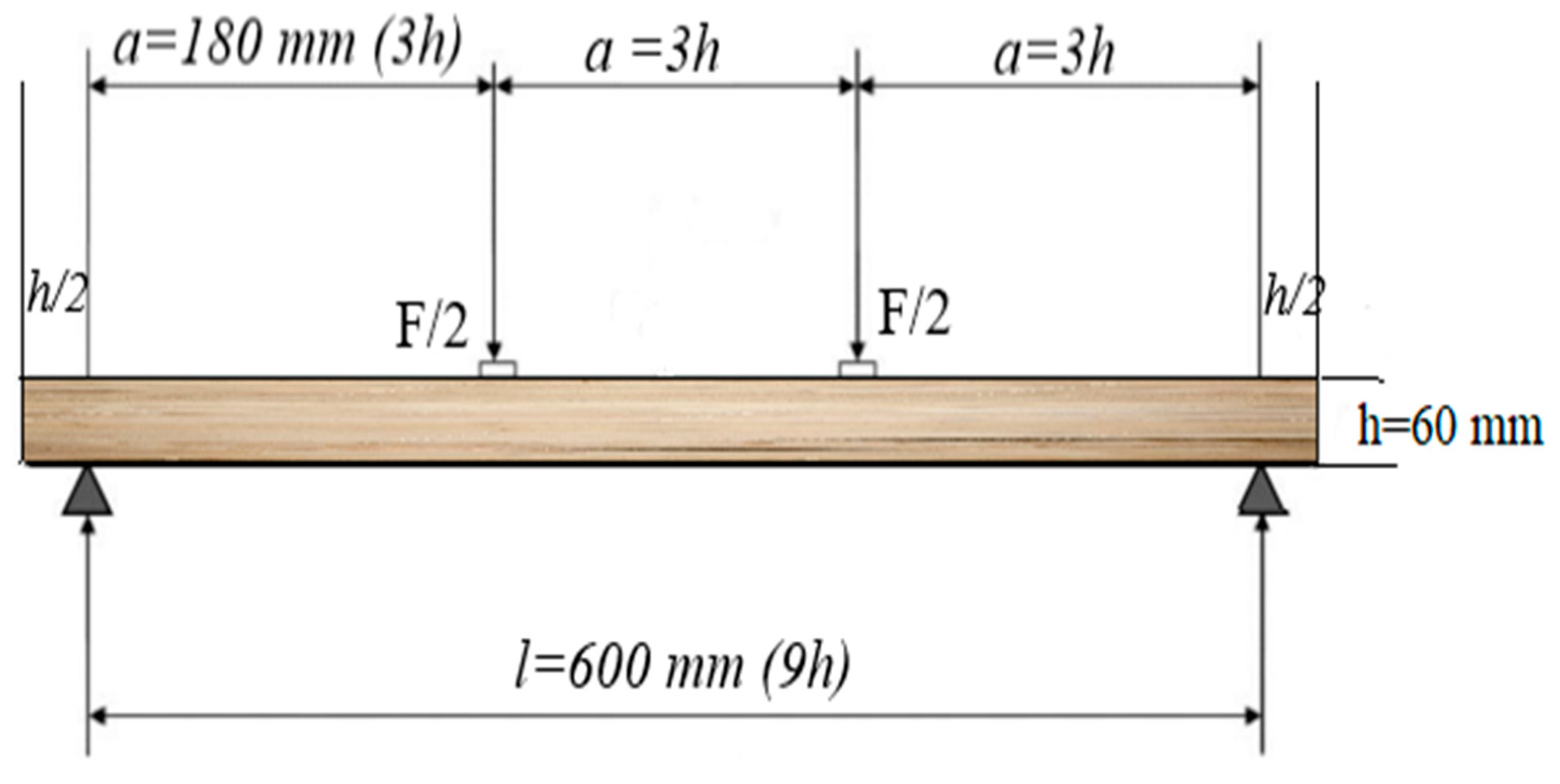

2.3.1. Bending Test

2.3.2. Rolling Shear (RS) Test

2.4. Statistical Analysis

2.5. Theoretical Calculation

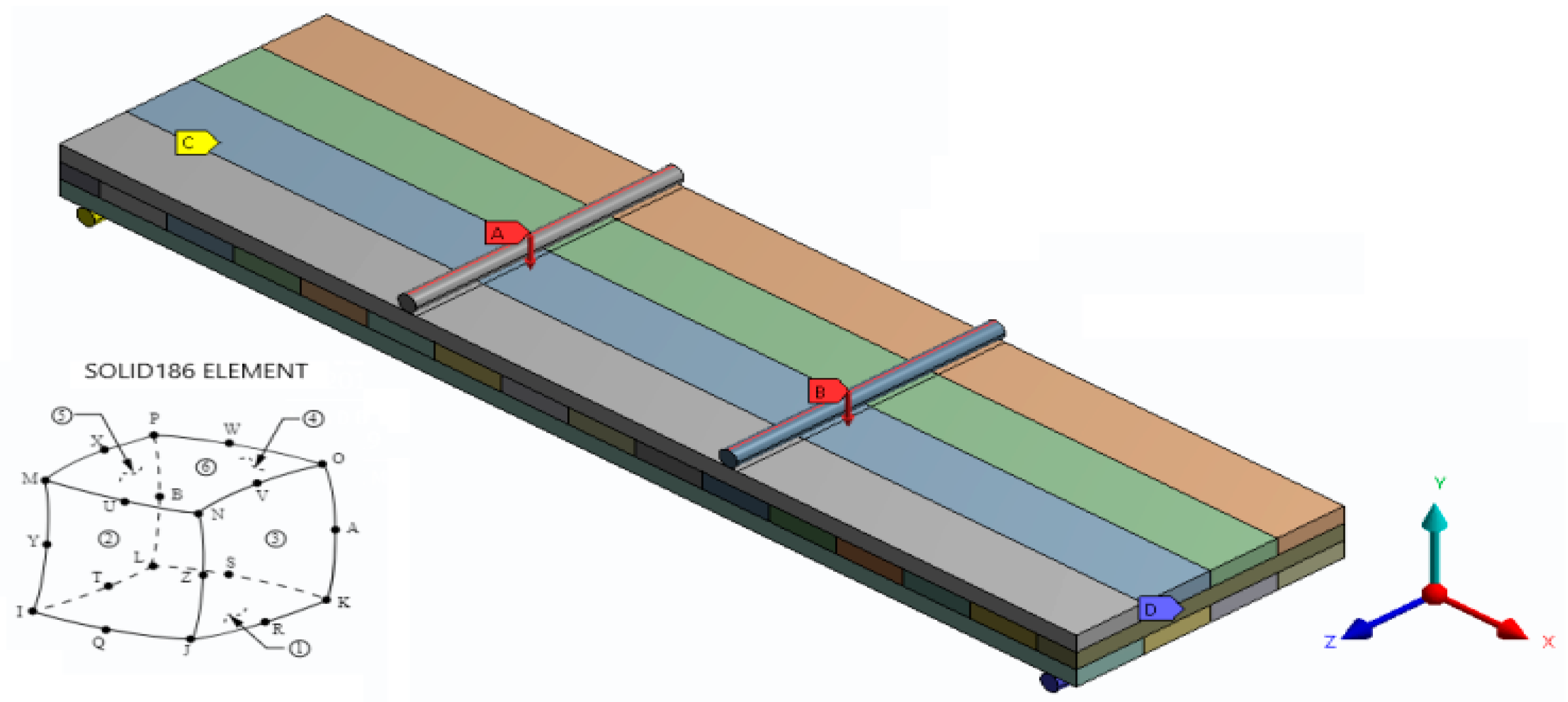

2.6. Finite Element Modelling

3. Results and Discussion

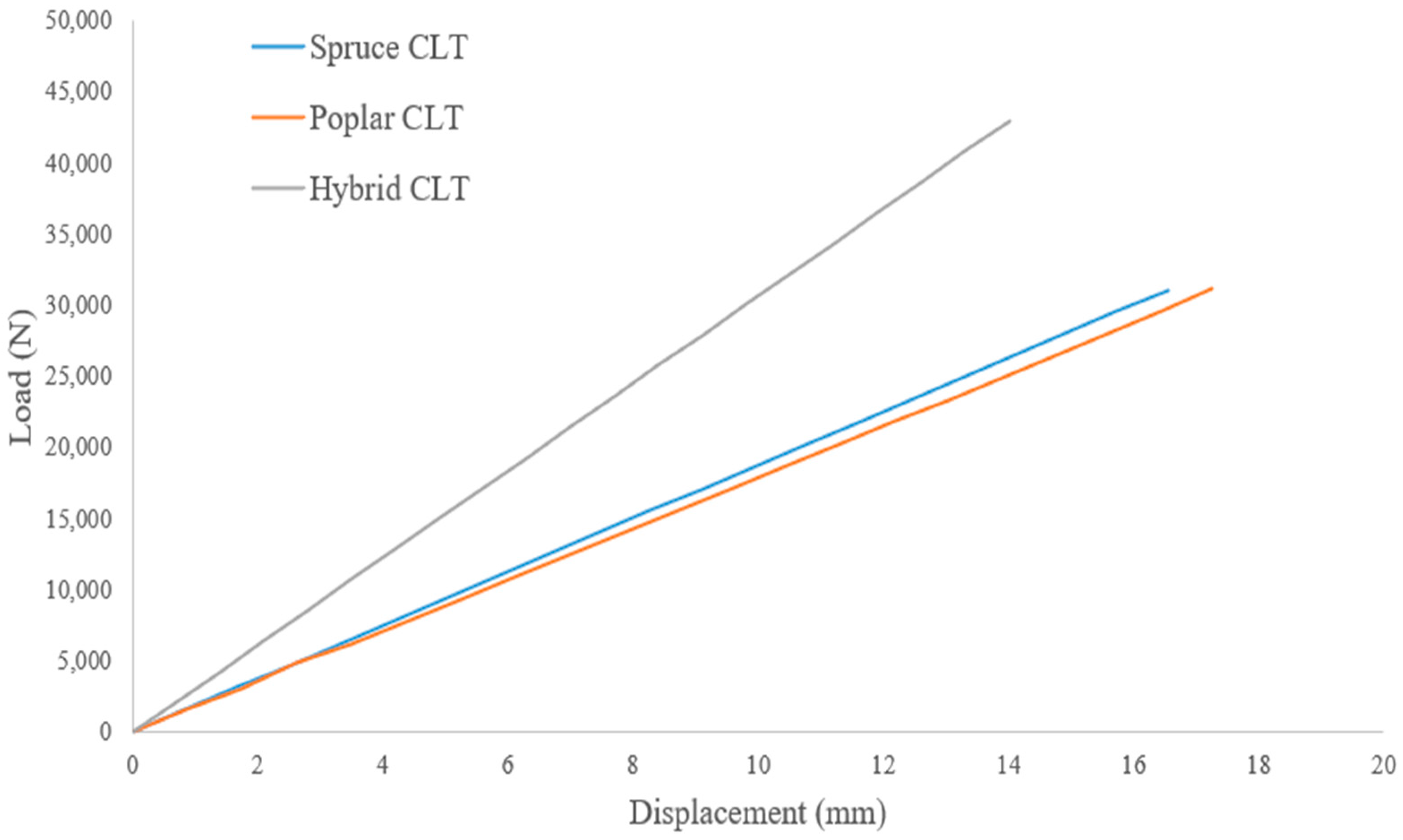

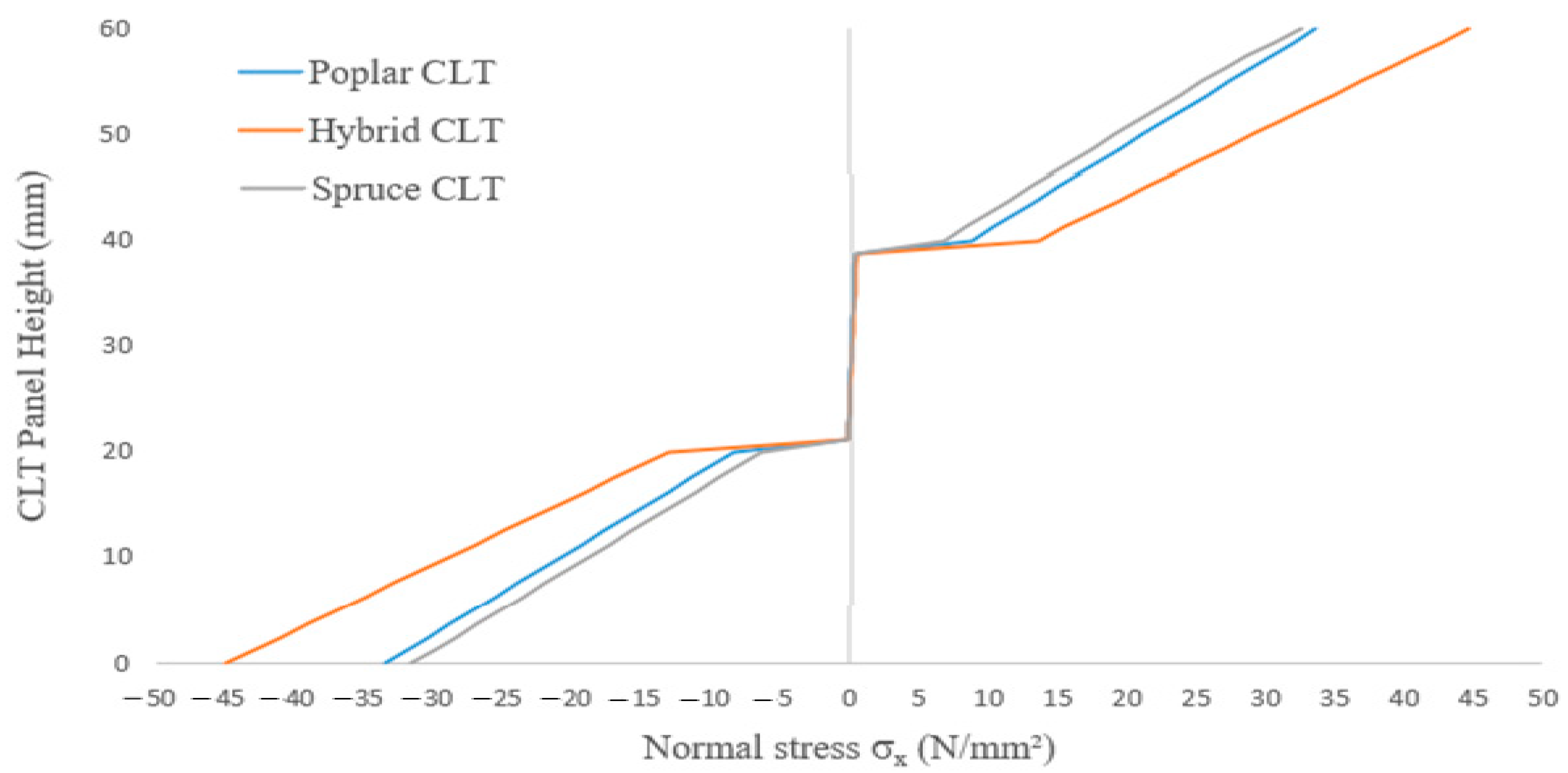

3.1. Bending Characteristics

3.2. Rolling Shear Test

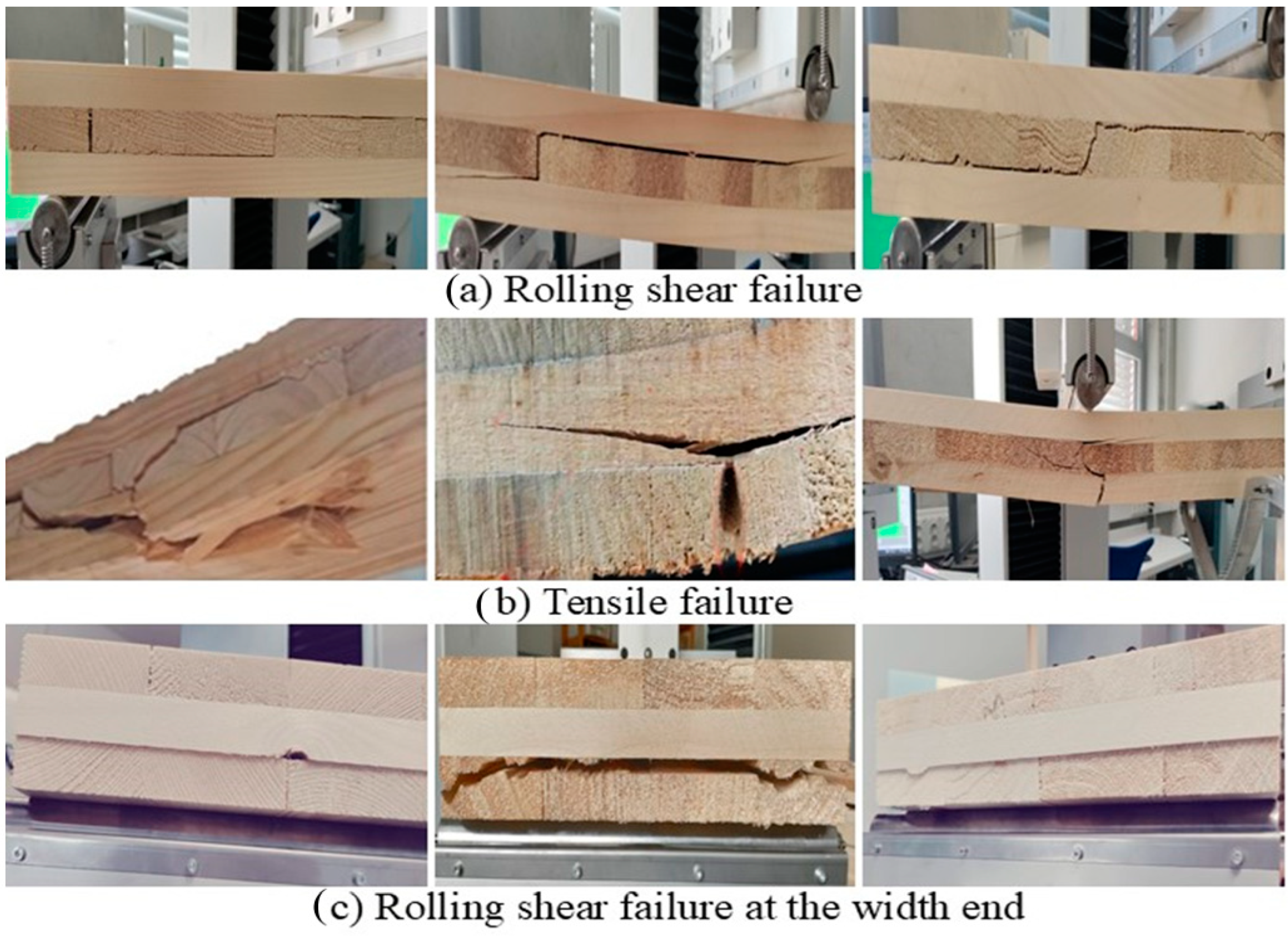

3.3. Failure Modes in Bending and Rolling Shear

3.4. Comparison of Experimental and Theoretical Data

4. Conclusions

- ◾

- The hybrid CLT, involving high-density outer maple layers and a poplar core layer, resulted in significant increases in Emg, fm, and fr by 74%, 37%, and 48%, respectively, compared to homogeneous poplar CLT. Additionally, the hybrid CLT also demonstrated superior performance compared to conventional spruce CLT, as well as red maple and birch CLT, in terms of rolling shear strength. The inclusion of maple lamellas in the outer layers of hybrid CLT enhanced its load-carrying capacity during bending tests.

- ◾

- The homogenous poplar CLT exhibited Emg, fm, and fr values nearly equivalent to or better than those of spruce CLT, thereby indicating its potential application in load-bearing structures and as a viable alternative for CLT production. The production of CLT presents a promising opportunity for the value-added utilization of poplar.

- ◾

- Both the adhesive type and wood species had a significant impact on the bending strength (fm), global bending modulus (Emg), and rolling shear strength (fr) independently; however, their interaction effect was not found to be significant.

- ◾

- 1C-PUR adhesive outperformed the ME in terms of global bending modulus, bending strength, and rolling shear strength.

- ◾

- For homogeneous poplar and spruce CLT, a 19% variation in bending stiffness was observed between the theoretical and experimental values, whereas a 12% variation was noted for hybrid CLT, with the modified gamma approach yielding the most accurate results. Furthermore, the theoretical approaches indicated a 6.5% reduction in rolling shear strength and a 4.5% overestimation of bending strength, with the shear analogy yielding the most precise result.

- ◾

- The bending stiffness of hybrid CLT, as per FEM, was approximately 11% lower than the experimental values, whereas, for both poplar and spruce CLT, the difference was between 6–8%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, X.; Yang, S.; Fei, B.; Qin, D.; Yang, J.; Li, H.; Wang, X. Bending and shear performance of a cross-laminated composite consisting of flattened bamboo board and Chinese fir lumber. Constr. Build. Mater. 2023, 392, 131913. [Google Scholar] [CrossRef]

- Matsushita, A.K.; Gonzalez, D.; Wang, M.; Doan, J.; Qiao, Y.; McKittrick, J. Beyond density: Mesostructural features of impact resistant wood. Mater. Today Commun. 2020, 22, 100697. [Google Scholar] [CrossRef]

- Li, T.Y.; Deng, J.Y.; Chen, J.Q.; Xiao, Y.; Shan, B.; Xu, H.; Qin, S.J.; Yu, Q. Bending performance of nail-laminated bamboo-timber panels made with glubam and fast-grown plantation Chinese fir. Constr. Build. Mater. 2023, 384, 131425. [Google Scholar] [CrossRef]

- Muszynski, L.; Hansen, E.; Fernando, S.; Schwarzmann, G.; Rainer, J. Insights into the global cross-laminated timber industry. BioProd. Bus. 2017, 2, 77–92. [Google Scholar] [CrossRef]

- De Araujo, V.; Christoforo, A. The global cross-laminated timber (CLT) industry: A systematic review and a sectoral survey of its main developers. Sustainability 2023, 15, 7827. [Google Scholar] [CrossRef]

- Pramreiter, M.; Nenning, T.; Huber, C.; Müller, U.; Kromoser, B.; Mayencourt, P.; Konnerth, J. A review of the resource efficiency and mechanical performance of commercial wood-based building materials. Sustain. Mater. Technol. 2023, 38, e00728. [Google Scholar] [CrossRef]

- Huang, Z.; Jiang, L.; Ni, C.; Chen, Z. The appropriacy of the analytical models for calculating the shear capacity of cross-laminated timber (CLT) under out-of-plane bending. J. Wood Sci. 2023, 69, 14. [Google Scholar] [CrossRef]

- Zhou, J.; Chui, Y.H.; Niederwestberg, J.; Gong, M. Effective bending and shear stiffness of cross-laminated timber by modal testing: Method development and application. Compos. Part B Eng. 2020, 198, 108225. [Google Scholar] [CrossRef]

- Wang, Z.; Fu, H.; Gong, M.; Luo, J.; Dong, W.; Wang, T.; Chui, Y.H. Planar shear and bending properties of hybrid CLT fabricated with lumber and LVL. Constr. Build. Mater. 2017, 151, 172–177. [Google Scholar] [CrossRef]

- Aicher, S.; Hirsch, M.; Christian, Z. Hybrid cross-laminated timber plates with beech wood cross-layers. Constr. Build. Mater. 2016, 124, 1007–1018. [Google Scholar] [CrossRef]

- Muñoz, F.; Tenorio, C.; Moya, R.; Navarro-Mora, A. CLT fabricated with Gmelina arborea and Tectona grandis wood from fast-growth forest plantations: Physical and mechanical properties. J. Renew. Mater. 2022, 10, 1–17. [Google Scholar] [CrossRef]

- Hematabadi, H.; Madhoushi, M.; Khazaeian, A.; Ebrahimi, G. Structural performance of hybrid poplar-beech cross-laminated-timber (CLT). J. Build. Eng. 2021, 44, 102959. [Google Scholar] [CrossRef]

- Sciomenta, M.; Spera, L.; Bedon, C.; Rinaldi, V.; Fragiacomo, M.; Romagnoli, M. Mechanical characterization of novel homogeneous beech and hybrid beech-corsican pine thin cross-laminated timber panels. Constr. Build. Mater. 2021, 271, 121589. [Google Scholar] [CrossRef]

- Ma, Y.; Si, R.; Musah, M.; Dai, Q.; Xie, X.; Wang, X.; Ross, R.J. Mechanical property evaluation of hybrid mixed-species CLT panels with sugar maple and white spruce. J. Mater. Civ. Eng. 2021, 33, 04021171. [Google Scholar] [CrossRef]

- Gong, M.; Tu, D.; Li, L.; Chui, Y.H. Planar shear properties of hardwood cross layer in hybrid cross laminated timber. In Proceedings of the International Scientific Conference on Hardwood Processing, Quebec City, QC, Canada, 15–17 September 2015. [Google Scholar]

- Nero, R.; Christopher, P.; Ngo, T. Investigation of rolling shear properties of cross-laminated timber (CLT) and comparison of experimental approaches. Constr. Build. Mater. 2022, 316, 125897. [Google Scholar] [CrossRef]

- Ettelaei, A.; Taoum, A.; Shanks, J.; Lee, M.; Nolan, G. Evaluation of the bending properties of novel cross-laminated timber with different configurations made of Australian plantation Eucalyptus nitens using experimental and theoretical methods. Structures 2022, 42, 80–90. [Google Scholar] [CrossRef]

- Jeitler, G.; Augustin, M.; Schickhofer, G. Birch|GLT + CLT mechanical properties of glued laminated timber and cross laminated timber produced with the wood species birch. In Proceedings of the World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Das, S.; Gašparík, M.; Sethy, A.K.; Kytka, T.; Kamboj, G.; Rezaei, F. Bonding performance of mixed species cross laminated timber from poplar (Populus nigra L.) and maple (Acer platanoides L.) glued with melamine and PUR adhesive. J. Build. Eng. 2023, 68, 106159. [Google Scholar] [CrossRef]

- Davids, W.G.; Willey, N.; Lopez-Anido, R.; Shaler, S.; Gardner, D.; Edgar, R.; Tajvidi, M. Structural performance of hybrid SPFS-LSL cross-laminated timber panels. Constr. Build. Mater. 2017, 149, 156–163. [Google Scholar] [CrossRef]

- Li, X.; Ashraf, M.; Subhani, M.; Kremer, P.; Kafle, B.; Ghabraie, K. Experimental and numerical study on bending properties of heterogeneous lamella layups in cross laminated timber using Australian radiata pine. Constr. Build. Mater. 2020, 247, 118525. [Google Scholar] [CrossRef]

- Lu, W.; Gu, J.; Wang, B. Study on flexural behavior of cross-laminated timber based on different tree species. Adv. Mater. Sci. Eng. 2019, 2019, 1728258. [Google Scholar] [CrossRef]

- Yin, T.; He, L.; Huang, Q.; Gong, Y.; Wang, Z.; Gong, M. Effect of lamination grade on bending and shear properties of CLT made from fast-growing Chinese fir. Ind. Crop. Prod. 2024, 207, 117741. [Google Scholar] [CrossRef]

- Navaratnam, S.; Christopher, P.; Ngo, T.; Le, T. Bending and shear performance of Australian radiata pine cross-laminated timber. Constr. Build. Mater. 2020, 232, 117215. [Google Scholar] [CrossRef]

- Crovella, P.; Smith, W.; Bartczak, J. Experimental verification of shear analogy approach to predict bending stiffness for softwood and hardwood cross-laminated timber panels. Constr. Build. Mater. 2019, 229, 116895. [Google Scholar] [CrossRef]

- He, M.; Sun, X.; Li, Z. Bending and compressive properties of cross-laminated timber (CLT) panels made from Canadian hemlock. Constr. Build. Mater. 2018, 185, 175–183. [Google Scholar] [CrossRef]

- Dobeš, P.; Lokaj, A.; Vavrušová, K. Stiffness and deformation analysis of cross-laminated timber (clt) panels made of nordic spruce based on experimental testing, analytical calculation and numerical modeling. Buildings 2023, 13, 200. [Google Scholar] [CrossRef]

- Mácová, K.; Szórádová, A.; Kolařík, J. Are trees planted along the roads sustainable? A large-scale study in the Czech Republic. Sustainability 2022, 14, 5026. [Google Scholar] [CrossRef]

- EN 16351; Timber Structures—Cross Laminated Timber—Requirements. European Committee for Standardization: Brussels, Belgium, 2021.

- Jan Brundin, J.; Eriksson, P.; Godonou, P. Guide to Assessing CLT Surface Quality; Swedishwood, Swedish Forest Industries Federation: Stockholm, Sweden, 2022; ISBN 978-91-985213-3-7. [Google Scholar]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (clt): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Wang, J.; Ning, F.; Li, J.; Zhu, H. Experimental study and finite element simulation analysis of the bending properties of cross-laminated timber (clt) two-way plates. J. Eng. Sci. Technol. Rev. 2020, 13, 132–142. [Google Scholar] [CrossRef]

- Sikora, K.S.; McPolin, D.O.; Harte, A.M. Effects of the thickness of cross-laminated timber (CLT) panels made from Irish Sitka spruce on mechanical performance in bending and shear. Constr. Build. Mater. 2016, 116, 141–150. [Google Scholar] [CrossRef]

- Hariz, T.M.R.; Hadi, Y.S.; Lubis, M.A.R.; Maulana, M.I.; Sari, R.K.; Hidayat, W. Physical and mechanical properties of cross-laminated timber made of a combination of mangium-puspa wood and polyurethane adhesive. J. Sylva Lestari 2023, 11, 37–65. [Google Scholar] [CrossRef]

- Niederwestberg, J. Influence of Laminate Characteristics on Properties of Single-Layer and Cross Laminated Timber (CLT) Panels. Ph.D. Thesis, University of New Brunswick, Fredericton, NB, Canada, 2019. [Google Scholar]

- Fan, Z.; Ye, G.; Li, S.; Bai, Z.; Yong, Q.; Zhang, Y.; Hu, Y. Compression performance and failure mechanism of honeycomb structures fabricated with reinforced wood. Structures 2023, 48, 1868–1882. [Google Scholar] [CrossRef]

- Karakoç, A.; Tukiainen, P.; Freund, J.; Hughes, M. Experiments on the effective compliance in the radial–tangential plane of Norway spruce. Compos. Struct. 2013, 102, 287–293. [Google Scholar] [CrossRef]

- Niemz, P.; Teischinger, A.; Sandberg, D. (Eds.) Springer Handbook of Wood Science and Technology; Springer: Berlin/Heidelberg, Germany, 2023; p. 2069. ISBN 978-3-030-81315-4. [Google Scholar]

- Gardner, C.; Davids, W.G.; Lopez-Anido, R.; Herzog, B.; Edgar, R.; Nagy, E.; Berube, K.; Shaler, S. The effect of edge gaps on shear strength and rolling shear modulus of cross laminated timber panels. Constr. Build. Mater. 2020, 259, 119710. [Google Scholar] [CrossRef]

- Franzoni, L.; Lebée, A.; Lyon, F.; Forêt, G. Elastic behavior of Cross Laminated Timber and timber panels with regular gaps: Thick-plate modeling and experimental validation. Eng. Struct. 2017, 141, 402–416. [Google Scholar] [CrossRef]

- Cao, Y.; Street, J.; Li, M.; Lim, H. Evaluation of the effect of knots on rolling shear strength of cross laminated timber (CLT). Constr. Build. Mater. 2019, 222, 579–587. [Google Scholar] [CrossRef]

- Dong, W.; Wang, Z.; Zhou, J.; Gong, M. Experimental study on bending properties of cross-laminated timber-bamboo composites. Constr. Build. Mater. 2021, 300, 124313. [Google Scholar] [CrossRef]

| Wood Species | Mean Density | Mean Moisture Content | Mean MOE |

|---|---|---|---|

| Poplar | 398 ± 46 | 11.9 ± 0.6 | 8900 ± 849 |

| Spruce | 423 ± 36 | 11.7 ± 0.7 | 9800 ± 942 |

| Maple | 653 ± 76 | 12.3 ± 0.5 | 13,810 ± 1142 |

| Wood | EL (N/mm2) | ER | ET | vLR (-) | vLT (-) | vRT (-) | GLR (N/mm2) | GLT | GRT |

|---|---|---|---|---|---|---|---|---|---|

| Poplar | 8900 | 739 | 418 | 0.344 | 0.42 | 0.875 | 676 | 463 | 134 |

| Spruce | 9800 | 1080 | 578 | 0.422 | 0.462 | 0.530 | 950 | 900 | 98 |

| Maple | 13,810 | 1311 | 678 | 0.46 | 0.50 | 0.82 | 1013 | 753 | 255 |

| Effect | Value | F | df | Error | p-Value |

|---|---|---|---|---|---|

| Intercept | 0.000547 | 48,435.53 | 2 | 53 | 0.000000 |

| Species | 0.008594 | 259.36 | 4 | 106 | 0.000000 |

| Adhesive | 0.888103 | 3.34 | 2 | 53 | 0.043080 |

| Species×Adhesive | 0.991690 | 0.11 | 4 | 106 | 0.978501 |

| Species | Adhesive | Emg | fm | fr |

|---|---|---|---|---|

| Poplar | MF | 7802 a | 29.97 a | 2.17 a |

| 1C-PUR | 7950 ab | 31.10 ab | 2.12 a | |

| Spruce | MF | 8152 bc | 31.63 ab | 2.00 b |

| 1C-PUR | 8338 c | 32.00 b | 1.88 c | |

| Hybrid | MF | 13,276 d | 44.33 c | 3.17 d |

| 1C-PUR | 13,426 d | 44.77 c | 3.08 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, S.; Gašparík, M.; Sethy, A.K.; Niemz, P.; Mahapatra, M.; Lagaňa, R.; Langová, N.; Kytka, T. Comparative Analysis of Bending and Rolling Shear Performance of Poplar and Hybrid Maple–Poplar Cross-Laminated Timber (CLT). J. Compos. Sci. 2025, 9, 134. https://doi.org/10.3390/jcs9030134

Das S, Gašparík M, Sethy AK, Niemz P, Mahapatra M, Lagaňa R, Langová N, Kytka T. Comparative Analysis of Bending and Rolling Shear Performance of Poplar and Hybrid Maple–Poplar Cross-Laminated Timber (CLT). Journal of Composites Science. 2025; 9(3):134. https://doi.org/10.3390/jcs9030134

Chicago/Turabian StyleDas, Sumanta, Miroslav Gašparík, Anil Kumar Sethy, Peter Niemz, Manaswini Mahapatra, Rastislav Lagaňa, Nadežda Langová, and Tomáš Kytka. 2025. "Comparative Analysis of Bending and Rolling Shear Performance of Poplar and Hybrid Maple–Poplar Cross-Laminated Timber (CLT)" Journal of Composites Science 9, no. 3: 134. https://doi.org/10.3390/jcs9030134

APA StyleDas, S., Gašparík, M., Sethy, A. K., Niemz, P., Mahapatra, M., Lagaňa, R., Langová, N., & Kytka, T. (2025). Comparative Analysis of Bending and Rolling Shear Performance of Poplar and Hybrid Maple–Poplar Cross-Laminated Timber (CLT). Journal of Composites Science, 9(3), 134. https://doi.org/10.3390/jcs9030134