Experimental Assessment of the Strength and Microstructural Properties of Fly Ash-Containing Basalt Fiber-Reinforced Self-Compacting Sustainable Concrete

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.2. Mixture and Sample Preparation

- Grade 1: cylindrical compressive strength ranged from 40 to 55 MPa.

- Grade 2: cylindrical compressive strength ranged from 55 to 70 MPa.

- Grade 3: cylindrical compressive strength ranged from 70 to 85 MPa.

2.3. Fresh Concrete Properties

2.4. Mixing, Casting, Curing, and Transportation of Specimens

- The dry materials (cement, fly ash, and aggregates) were mixed for 5 min to ensure uniform distribution. Basalt fibers were gradually added to the mix to prevent agglomeration, followed by the addition of water and superplasticizer. The total mixing time was 15 min.

- No vibration or compaction was required for this type of concrete.

- The specimens cast were standard cylinders, in accordance with ASTM C470 [30] and ASTM C192 [31] specifications:

- ○

- Four cylinders, each measuring 150 × 300 mm, were cast from each mix and subjected to compression testing.

- ○

- Four additional cylinders, also measuring 150 × 300 mm, were cast from each mix and tested for split tensile strength.

- ○

- Furthermore, four beams, each measuring 100 × 100 × 500 mm3, were cast from each mix and tested for flexural strength.

- After 24 h of casting, the specimens were de-molded and placed in moist curing conditions within the ready-mix company’s curing chambers, maintained at 23 ± 2 °C, for a period of 28 days.

- Upon completion of the 28-day curing period, the specimens were transported to the material lab for testing, following the transportation guidelines outlined in ASTM C31 [32].

2.5. Hardened Concrete Properties

2.6. Microstructural Analysis

2.7. ANOVA Analysis

- Factors: the factors under investigation are basalt fiber concentration and SCC grade, each with multiple levels representing different concentrations and grades.

- Repetitions: the repeated measures aspect involves testing several specimens under identical conditions, thereby minimizing individual variability, reducing error variance, and enhancing the statistical power of the analysis.

- Main Effects: The analysis independently evaluates the main effects of each factor. The main effect of Factor A (basalt fiber concentration) represents its impact on the dependent variable (mechanical properties), averaged across the levels of Factor B (SCC grade), and vice versa.

- Interaction Effect: The two-factor ANOVA also examines the potential interaction effect between the two factors (basalt fiber concentration and SCC grade). An interaction effect occurs when the influence of one factor on the dependent variable (SCC mechanical properties) depends on the level of the other factor. Identifying interactions is crucial, as it reveals whether the factors interact synergistically or antagonistically in ways that cannot be predicted by examining each factor in isolation.

- Assumptions:

- ○

- Sphericity: This assumption requires that the variances of the differences between all combinations of related groups (i.e., the repeated measures) are equal. Violations of this assumption can lead to inaccurate conclusions; therefore, it is typically tested using Mauchly’s test of sphericity. If sphericity is violated, adjustments such as the Greenhouse–Geisser correction are applied.

- ○

- Normality: the data within each group should be approximately normally distributed.

- ○

- Independence: while measurements within each subject are repeated, the measurements between different subjects are assumed to be independent.

3. Results and Discussion

3.1. Fresh Concrete Results

3.2. Mechanical Properties

3.2.1. Compressive Strength

3.2.2. Flexural Strength

3.2.3. Splitting Tensile Strength

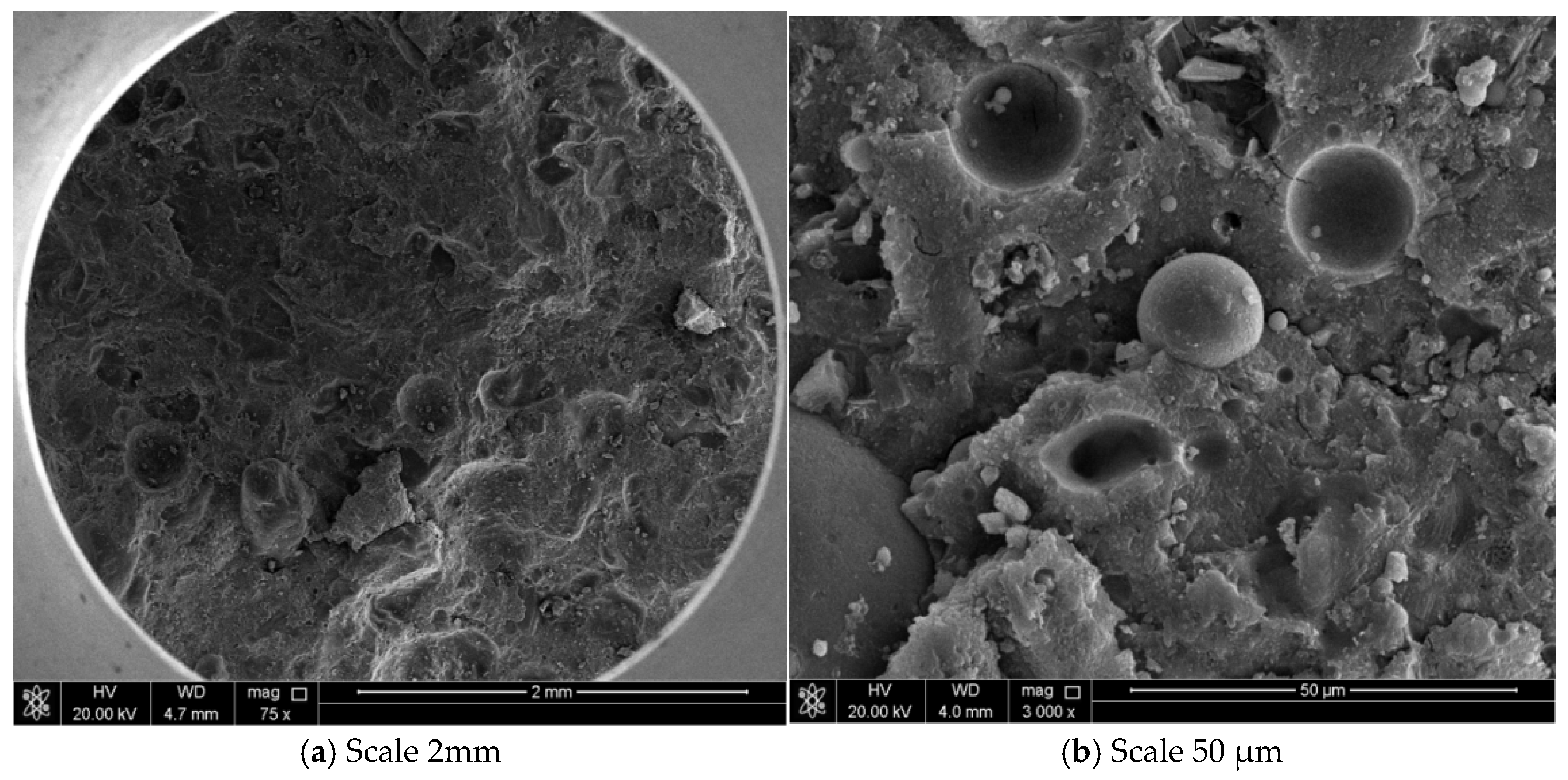

3.3. Microstructural Analysis Results

3.4. ANOVA Analysis Test

- The ANOVA results indicate a significant effect of the SCC grade factor. The F-value is 455.71, and the corresponding p-value is always 0, which is much lower than the significance level (usually 0.05). This suggests a statistically significant difference in the means between Grade 2 and Grade 3.

- There is also a significant effect of the basalt fiber quantity. The F-value is 12.39 with a p-value of 0.0004, indicating a significant difference between basalt fiber quantities (0, 1.4, and 2.8).

- The interaction between the grade and the basalt fiber factors is not statistically significant. The F-value is 1.043, and the p-value is 0.3727, which is greater than 0.05.

- In summary:

- There is a significant main effect for both grade and basalt fiber factors, indicating that both factors independently influence SCC compressive strength.

- No significant interaction effect is found, suggesting that the impact of one factor does not depend on the levels of the other factor.

- The two factors considered in the analysis are grades and basalt fiber values (0, 1.4, and 2.8).

- The results indicate a significant effect of the grade factor. The F-value is 67.78, and the p-value is almost zero, which is far below the standard significance level (0.05).

- There is also a significant effect of the basalt fiber factor. The F-value is 13.84 with a p-value of 0.0002, indicating significant differences between the column levels (0, 1.4, and 2.8).

- The interaction between the grade and column factors (interaction) is not statistically significant. The F-value is 2.24, and the p-value is 0.135, which is greater than 0.05. This indicates no significant interaction effect between the grade levels and basalt fiber levels on the SCC flexural strength variable.

- In summary:

- Both the grade and basalt fiber factors show significant main effects, indicating that they independently influence the flexural strength variable.

- The lack of a significant interaction effect suggests that the impact of one factor does not depend on the levels of the other factor.

- The results indicate a significant effect of the grade factor. The F-value is 32.61, and the p-value is very close to zero, which is well below the standard significance level (0.05).

- There is also a significant effect of the column factor. The F-value is 37.03 with a p-value of a value very close to zero, indicating significant differences between the basalt fiber levels (0, 0.05, and 0.1).

- The interaction between the grade and basalt fiber factors (interaction) is statistically significant. The F-value is 17.54, and the p-value is very close to zero, which is lower than 0.05.

- In summary:

- There are significant main effects for both the grade and basalt fiber factors, indicating that both factors independently influence the tensile strength of SCC.

- The significant interaction effect suggests that the impact of one factor depends on the levels of the other factor, meaning the effect of grades on the dependent variable varies depending on the column levels.

4. Conclusions

- The incorporation of basalt fibers adversely affected the rheological properties of fresh SCC mixtures. Specifically, the slump flow values of concrete decreased as the volume fraction of basalt fibers increased.

- While the addition of basalt fibers had a minimal impact on the compressive strength of SCC specimens, it significantly enhanced both the tensile strength and the flexural strength.

- The optimal ratio of basalt fibers was identified in the SCC70-85/0.10 mix specimens, which exhibited a 69.90% increase in flexural strength and a 23.47% increase in splitting tensile strength compared with the control specimen.

- Increasing the dosage of basalt fibers in concrete mixes led to a reduction in efficiency. Higher fiber content resulted in the formation of additional voids within the concrete matrix, which introduced air and subsequently diminished the concrete’s effectiveness.

- Scanning electron microscope (SEM) analysis revealed an improvement in the microstructural density of the concrete matrix containing basalt fibers. This enhancement was attributed to the bridging effect of the fibers and their ability to fill pores.

- Basalt fibers enhanced the overall performance of concrete, offering a competitive alternative to traditional fibers due to their superior mechanical and chemical properties and their cost-effectiveness.

- A two-factor analysis of variance (ANOVA) with repetitions was conducted to evaluate the effects of varying basalt fiber concentrations on the compressive, flexural, and tensile strengths of SCC mixes. This method examined the impact of two independent variables—SCC grade and basalt fiber concentration—on SCC mechanical properties, accounting for repeated measurements to control individual variability. The ANOVA results indicated significant main effects for both SCC grade and basalt fiber concentration, demonstrating that each factor independently affected the compressive and flexural strengths of SCC. However, it was found that there was a significant interaction between the effect of SCC grade and basalt fiber concentration on the tensile strength results.

Future Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vavilla, V.; Siempu, R. Effect of Basalt fibers on the properties of high strength self-compacting concrete. Int. J. Innov. Technol. Explor. Eng. 2019, 9, 3995–3998. [Google Scholar] [CrossRef]

- Ramesh, G. Self-Compacting Concrete: A Review. Indian J. Struct. Eng. 2021, 1, 9–12. [Google Scholar] [CrossRef]

- Shi, C.; Lv, K.; Wu, L. A review on mixture design methods for self-compacting concrete. Constr. Build. Mater. 2015, 84, 387–398. [Google Scholar] [CrossRef]

- Azarhomayun, F.; Haji, M.; Shekarchi, M.; Kioumarsi, M. Investigating the Effectiveness of the Stable Measurement Tests of Self-Compacting Concrete. SSRN Electron. J. 2022, 383, 131262. [Google Scholar] [CrossRef]

- Tripathi, D.; Kumar, R.; Mehta, P.; Singh, A. A Comparative Study of Normal and Self-compacting Concrete. In Advances in Structural Technologies: Select Proceedings of CoAST 2019; Springer: Singapore, 2020; pp. 133–143. [Google Scholar] [CrossRef]

- Haido, J.; Tayeh, B.; Majeed, S.; Karpuzcu, M. Effect of high temperature on the mechanical properties of basalt fibre self-compacting concrete as an overlay material. Constr. Build. Mater. 2020, 268, 121725. [Google Scholar] [CrossRef]

- Kizilkanat, A.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akca, A. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Shahidan, S.; Tayeh, B.; Jamaludin, A.; Saiful Bahari, M.; Mohd Zuki, S.S.; Ali, N.; Sheikh Khalid, F. Physical and mechanical properties of self-compacting concrete containing superplasticizer and metakaolin. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012004. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R.; Tayeh, B. Properties of Self-Compacting High-strength Concrete Containing Multiple Use of Recycled Aggregate. J. King Saud Univ.-Eng. Sci. 2018, 32, 108–114. [Google Scholar] [CrossRef]

- Tayeh, B.; Abu Maraq, M.; Ziara, M. Flexural performance of reinforced concrete beams strengthened with self-compacting concrete jacketing and steel welded wire mesh. Structures 2020, 28, 2146–2162. [Google Scholar] [CrossRef]

- Khatib, J.M. Performance of self-compacting concrete containing fly ash. Constr. Build. Mater. 2008, 22, 1963–1971. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly ash properties, characterization, and applications: A review. J. King Saud Univ.-Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Dinakar, P.; Kartik Reddy, M.; Sharma, M. Behaviour of self compacting concrete using Portland pozzolana cement with different levels of fly ash. Mater. Des. (1980–2015) 2013, 46, 609–616. [Google Scholar] [CrossRef]

- Zabihi Samani, M.; Mokhtari, S.; Raji, F. Effects of Fly Ash on Mechanical Properties of Concrete. J. Appl. Eng. Sci. 2018, 8, 35–40. [Google Scholar] [CrossRef]

- Mohsen, M.; Aburumman, M.; Al Diseet, M.; Taha, R.; Abdel-Jaber, M.t.; Senouci, A.; Abu Taqa, A. Fly Ash and Natural Pozzolana Impacts on Sustainable Concrete Permeability and Mechanical Properties. Buildings 2023, 13, 1927. [Google Scholar] [CrossRef]

- Aburumman, M.; Al Diseet, M.; Mohsen, M.; Abdel-Jaber, M.t.; Abu Taqa, A. A Comparison between Natural Pozzolana and Fly Ash Replacements on the Mechanical Properties of Concrete. In Proceedings of the International Conference on Civil Infrastructure and Construction (CIC), Doha, Qatar, 5–8 February 2023. [Google Scholar] [CrossRef]

- Bhagath Singh, G.V.P.; Durga Prasad, V. Environmental impact of concrete containing high volume fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2024, 448, 141729. [Google Scholar] [CrossRef]

- Ma, J.; Qiu, X.; Cheng, L.; Wang, Y. Experimental Research on the Fundamental Mechanical Properties of Presoaked Basalt Fiber Concrete. In Advances in FRP Composites in Civil Engineering: Proceedings of the 5th International Conference on FRP Composites in Civil Engineering (CICE 2010), Beijing, China, 27–29 September 2010; Springer: Berlin/Heidelberg, Germany, 2011; pp. 85–88. [Google Scholar]

- Pepe, M.; Mazaheripour, H.; Barros, J.; Sena-Cruz, J.; Martinelli, E. Numerical calibration of bond law for GFRP bars embedded in steel fibre-reinforced self-compacting concrete. Compos. Part B Eng. 2013, 50, 403–412. [Google Scholar] [CrossRef]

- Biradar, S.V.; Dileep, M.S.; Vijaya Gowri, D.T. Studies of Concrete Mechanical Properties with Basalt Fibers. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1006, 012031. [Google Scholar] [CrossRef]

- Al-Kharabsheh, B.N.; Arbili, M.M.; Majdi, A.; Alogla, S.M.; Hakamy, A.; Ahmad, J.; Deifalla, A.F. Basalt Fibers Reinforced Concrete: Strength and Failure Modes. Materials 2022, 15, 7350. [Google Scholar] [CrossRef]

- Uzun, M.; Arslan, M. Effect of basalt fiber aspect ratio on mechanical and workability properties of self-compacting concrete. Konya J. Eng. Sci. 2023, 12, 14–21. [Google Scholar] [CrossRef]

- Çelik, Z.; Bingöl, A.F. Mechanical properties and postcracking behavior of self-compacting fiber reinforced concrete. Struct. Concr. 2019, 21, 2124–2133. [Google Scholar] [CrossRef]

- Ozodabas, A. Investigation of the effect of basalt fiber on self-compacting concrete. Int. J. Res. GRANTHAALAYAH 2018, 6, 38–45. [Google Scholar] [CrossRef]

- Kamal, M.; Saafan, M.; Etman, Z.; Kasem, B. Mechanical properties of self-compacted fiber concrete mixes. HBRC J. 2013, 10, 25–34. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Durable fiber reinforced self-compacting concrete. Cem. Concr. Res. 2004, 34, 249–254. [Google Scholar] [CrossRef]

- Gencel, O.; Brostow, W.; Datashvili, T.; Thedford, M. Workability and Mechanical Performance of Steel Fiber-Reinforced Self-Compacting Concrete with Fly Ash. Compos. Interfaces 2011, 18, 169–184. [Google Scholar] [CrossRef]

- ASTM C311/C311M-24; Standard Test Methods for Sampling and Testing Coal Ash or Natural Pozzolans for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C470/C470M-23; Standard Specification for Molds for Forming Concrete Test Cylinders Vertically. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C192/C192M-24; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C31/C31M-24; Standard Practice for Making and Curing Concrete Test Specimens in the Field. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C39/C39M-24; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C78/C78M-22; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2022.

- C1064/C1064M-23; Standard Test Method for Temperature of Freshly Mixed Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2023.

- C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- Balea, A.; Fuente, E.; Monte, M.C.; Blanco, Á.; Negro, C. 20—Fiber reinforced cement based composites. In Fiber Reinforced Composites; Joseph, K., Oksman, K., George, G., Wilson, R., Appukuttan, S., Eds.; Woodhead Publishing: Sawston, UK, 2021; pp. 597–648. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Zhang, X.; Ding, Y.; Xu, P. Mechanical properties and microstructure of basalt fiber-reinforced recycled concrete. J. Clean. Prod. 2021, 278, 123252. [Google Scholar] [CrossRef]

- Dayalan, P.; Mahanwar, P. Basalt Fibre as Potential Reinforcement for Polymer Matrix Composites: A Review. Emergent Mater. 2023, 5, 205–227. [Google Scholar] [CrossRef]

- Meddah, A.; Goufi, A.E.; Pantelidis, L. Improving Very High Plastic Clays with the Combined Effect of Sand, Lime, and Polypropylene Fibers. Appl. Sci. 2022, 12, 9924. [Google Scholar] [CrossRef]

- Adesina, A. Performance of cementitious composites reinforced with chopped basalt fibres—An overview. Constr. Build. Mater. 2021, 266, 120970. [Google Scholar] [CrossRef]

- Danish, A.; Ozbakkaloglu, T. Fiber classifications and physical and mechanical properties of different fibers used in alkali-activated composites. In Advanced Fiber-Reinforced Alkali-Activated Composites; Elsevier: Amsterdam, The Netherlands, 2023; pp. 23–58. [Google Scholar] [CrossRef]

- Wu, H.; Qin, X.; Huang, X.; Kaewunruen, S. Engineering, mechanical and dynamic properties of basalt fiber reinforced concrete. Materials 2023, 16, 623. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical Properties of High-performance Concrete Reinforced with Basalt Fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef]

- Taqa, A.A.; Mohsen, M.O.; Aburumman, M.O.; Naji, K.; Taha, R.; Senouci, A. Nano-fly ash and clay for 3D-Printing concrete buildings: A fundamental study of rheological, mechanical and microstructural properties. J. Build. Eng. 2024, 92, 109718. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Xie, A.; Qi, Y. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete. Constr. Build. Mater. 2017, 152, 154–167. [Google Scholar] [CrossRef]

- Chen, X.-F.; Kou, S.-C.; Xing, F. Mechanical and durable properties of chopped basalt fiber reinforced recycled aggregate concrete and the mathematical modeling. Constr. Build. Mater. 2021, 298, 123901. [Google Scholar] [CrossRef]

- Chen, X.-F.; Quan, C.-Q.; Jiao, C.-J. Experimental Study of Chloride Resistance of Polypropylene Fiber Reinforced Concrete with Fly Ash and Modeling. Materials 2021, 14, 4417. [Google Scholar] [CrossRef] [PubMed]

| Compound | Class F Fly Ash | Microsilica |

|---|---|---|

| Composition (wt%) | ||

| CaO | 1.34 | 3.5 |

| Al2O3 | 18.21 | 0.7 |

| SiO2 | 70.31 | 85 |

| Fe2O3 | 5.26 | 1.1 |

| MgO | 1.00 | 2.7 |

| K2O | 1.08 | 0.001 |

| Physical Properties | ||

| Moisture Content Max % | 3 | 3–4 |

| Loss on Ignition, Max % | 6 | 2–4 |

| Material | Source | Supplier | Type/Conformity |

|---|---|---|---|

| Cement | Qatar | Qatar National Cement Company (QNCC), Doha-Qatar | OPC Class 42.5N, conformance to EN 197-1 |

| Fly ash | India | MSTC, Kolkata-India | CLASS F, conformance to ASTM C 618 |

| Microsilica | Qatar | Al Jabor, Doha-Qatar | Conformance to ASTM C 1240 |

| Coarse aggregate 20 mm and 10 mm | UAE | Village Trading Group, Doha-Qatar | Crushed gabbro, conformance to BS EN 12620 |

| Fine aggregate (washed sand) | Qatar | Qatar Primary Materials Company (QPMC), Doha-Qatar | Natural conformance to BS EN 12620 |

| Epsilon HP 540 | Qatar | Sodamco, Doha-Qatar | Polycarboxylate ether super-plasticizer, conformance to BS EN 934-2 and ASTM C 494 Type D and G |

| Basalt fibers | Techno basalt—Invest LLC Company, Slavuta Ukraine | Arabian Specialized Materials Co. (ASMA), Doha-Qatar | Diameter of 13-20 microns and length of 24 mm |

| Ingredients (kg/m3) | Grade 1 | Grade 2 | Grade 3 | |||||

|---|---|---|---|---|---|---|---|---|

| SCC 40–55/(0.00%) | SCC 40–55/(0.10%) | SCC 55–70/(0.00%) | SCC 55–70/(0.05%) | SCC 55–70/(0.10%) | SCC 70–85/(0.00%) | SCC 70–85/(0.05%) | SCC 70–85/(0.10%) | |

| Cement | 308 | 308 | 328 | 328 | 328 | 437 | 437 | 437 |

| Fly ash | 110 | 110 | 118 | 118 | 118 | 0 | 0 | 0 |

| Microsilica | 22 | 22 | 24 | 24 | 24 | 48 | 48 | 48 |

| Coarse aggregate 20 mm | 373 | 373 | 373 | 373 | 373 | 376 | 376 | 376 |

| Coarse aggregate 10 mm | 466 | 466 | 467 | 467 | 467 | 470 | 470 | 470 |

| Fine aggregate (washed sand) | 919 | 919 | 920 | 920 | 920 | 927 | 927 | 927 |

| Water | 174 | 174 | 163 | 163 | 163 | 161 | 161 | 161 |

| Epsilone HP 540 (% by weight of cementitious materials) | 4.0 (0.91%) | 4.3 (0.98%) | 4.0 (0.85%) | 4.5 (0.96%) | 4.5 (0.96%) | 6.40 (1.32%) | 7.50 (1.55%) | 8.00 (1.65%) |

| Basalt fibers | 0.0 | 2.8 | 0.00 | 1.4 | 2.8 | 0.0 | 1.4 | 2.8 |

| Calculated Using the Formula | Test Setup | Tested Specimens | |

|---|---|---|---|

| Compressive Strength | compressive strength, MPa failure load in compression, N diameter of the cylindrical specimen, mm |  |  |

| Split-Tension Strength | split-tension strength, MPa failure load in split tension, N. specimen diameter, mm. specimen length, mm. |  |  |

| Modulus of Rupture |  |  |

| Test | Grade 1 | Grade 2 | Grade 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SCC 40–55/0.00 | SCC 40–55/0.10 | SCC 55–70/0.00 | SCC 55–70/0.05 | SCC 55–70/0.10 | SCC 70–85/0.00 | SCC 70–85/0.05 | SCC 70–85/0.10 | ||

| Temperature (°C) ASTM C 1064 [36] | Immediate | 24.0 | 25.0 | 24.0 | 24.2 | 23.7 | 24.8 | 25.1 | 22.5 |

| 1 h | 23.4 | 24.6 | 23.4 | 23.9 | 23.2 | 24.05 | 24.3 | 21.1 | |

| Slump flow (mm) ASTM C 143 [37] | Immediate | 725 | 650 | 740 | 740 | 650 | 665 | 645 | 630 |

| 1 h | 690 | 600 | 695 | 685 | 610 | 620 | 595 | 580 | |

| V-funnel (sec.) | Immediate | 4.11 | 4.80 | 4.83 | 4.88 | 5.70 | 5.00 | 6.41 | 5.00 |

| 1 h | 3.77 | 5.20 | 5.78 | 5.69 | 6.90 | 5.41 | 6.48 | 6.30 | |

| Mix ID. | Compressive Strength (MPa) | Split-Tension Strength (MPa) | Flexural Strength (MPa) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | S1 | S2 | S3 | S4 | S1 | S2 | S3 | S4 | |

| SCC 40–55/0.00 | 51.22 | 52.54 | 49.16 | 48.96 | 4.44 | 4.07 | 4.33 | 3.73 | 4.36 | 4.93 | 6.05 | 4.24 |

| Average | Average | Average | ||||||||||

| 50.47 | 4.14 | 4.895 | ||||||||||

| SCC 40–55/0.10 | 51.99 | 52.62 | 53.66 | 53.14 | 4.79 | 4.19 | 4.67 | 3.74 | 5.47 | 5.91 | 6.56 | 6.18 |

| Average | Average | Average | ||||||||||

| 52.85 | 4.35 | 6.03 | ||||||||||

| Change (%) | Change (%) | Change (%) | ||||||||||

| +4.71 | +5.07 | +23.30 | ||||||||||

| SCC 55–70/0.00 | 66.56 | 67.89 | 62.76 | 61.8 | 3.87 | 4.32 | 4.10 | 3.36 | 5.21 | 5.74 | 5.56 | 6.12 |

| Average | Average | Average | ||||||||||

| 64.75 | 3.91 | 5.66 | ||||||||||

| SCC 55–70/0.05 | 66.88 | 69.51 | 68.02 | 67.67 | 3.87 | 4.32 | 4.35 | 3.81 | 6.12 | 5.8 | 5.65 | 6.44 |

| Average | Average | Average | ||||||||||

| 68.02 | 4.09 | 6.00 | ||||||||||

| Change (%) | Change (%) | Change (%) | ||||||||||

| +5.05 | +4.60 | +6.18 | ||||||||||

| SCC 55–70/0.10 | 69.39 | 68.49 | 69.58 | 70.58 | 3.89 | 4.49 | 4.59 | 4.65 | 6.38 | 6.21 | 5.92 | 6.95 |

| Average | Average | Average | ||||||||||

| 69.51 | 4.41 | 6.37 | ||||||||||

| Change (%) | Change (%) | Change (%) | ||||||||||

| +7.35 | +12.79 | +12.46 | ||||||||||

| SCC 70–85/0.0 | 78.07 | 79.96 | 82.85 | 83.64 | 4.56 | 5.00 | 4.91 | 4.47 | 5.00 | 5.40 | 4.73 | 5.46 |

| Average | Average | Average | ||||||||||

| 81.13 | 4.73 | 5.15 | ||||||||||

| SCC 70–85/0.05 | 81.9 | 82.19 | 81.63 | 81.95 | 5.05 | 5.09 | 5.33 | 4.52 | 8.33 | 7.4 | 7.59 | 7.48 |

| Average | Average | Average | ||||||||||

| 81.92 | 4.99 | 7.70 | ||||||||||

| Change (%) | Change (%) | Change (%) | ||||||||||

| +0.97 | +5.50 | +49.51 | ||||||||||

| SCC 70–85/0.10 | 84.68 | 86.62 | 84.05 | 85.04 | 5.95 | 5.84 | 5.58 | 6.00 | 9.71 | 8.89 | 8.84 | 7.54 |

| Average | Average | Average | ||||||||||

| 85.10 | 5.84 | 8.75 | ||||||||||

| Change (%) | Change (%) | Change (%) | ||||||||||

| +4.89 | +23.47 | +69.90 | ||||||||||

| SCC Grade | Basalt Fiber Percentage (%) | ||

| 0.0 | 1.4 | 2.8 | |

| Grade 2 | 66.56 | 66.88 | 69.39 |

| 67.89 | 69.51 | 68.49 | |

| 62.76 | 68.02 | 69.58 | |

| 61.80 | 67.67 | 70.58 | |

| Grade 3 | 78.07 | 81.90 | 84.68 |

| 79.96 | 82.19 | 86.62 | |

| 82.85 | 81.63 | 84.05 | |

| 83.64 | 81.95 | 85.04 | |

| SCC Grade | Basalt Fiber Percentage (%) | ||

| 0.0 | 1.4 | 2.8 | |

| Grade 2 | 3.87 | 3.87 | 3.89 |

| 4.32 | 4.32 | 4.49 | |

| 4.10 | 4.35 | 4.59 | |

| 3.36 | 3.81 | 4.65 | |

| Grade 3 | 4.56 | 5.05 | 5.95 |

| 5.00 | 5.09 | 5.84 | |

| 4.91 | 5.33 | 5.58 | |

| 4.47 | 4.52 | 6.00 | |

| SCC Grade | Basalt Fiber Percentage (%) | ||

| 0.0 | 1.4 | 2.8 | |

| Grade 2 | 5.21 | 6.12 | 6.38 |

| 5.74 | 5.80 | 6.21 | |

| 5.56 | 5.65 | 5.92 | |

| 6.12 | 6.44 | 6.95 | |

| Grade 3 | 5.00 | 8.33 | 9.71 |

| 5.40 | 7.40 | 8.89 | |

| 4.73 | 7.59 | 8.84 | |

| 5.46 | 7.48 | 7.54 | |

| ANOVE Two-Factors with Replication | ||||||

|---|---|---|---|---|---|---|

| Source of Variation | SS | df | MS | F | p-Value | F-Crit |

| SCC Grade | 1402.2460 | 1 | 1402.2460 | 455.7085 | 3.12 × 10−14 | 4.4139 |

| Basalt Fiber | 76.2517 | 2 | 38.1259 | 12.3903 | 0.000413 | 3.5546 |

| Interaction | 6.4204 | 2 | 3.2102 | 1.0433 | 0.372656 | 3.5546 |

| Within | 55.3872 | 18 | 3.0771 | |||

| Total | 1540.3050 | 23 | ||||

| ANOVE Two-Factors with Replication | ||||||

|---|---|---|---|---|---|---|

| Source of Variation | SS | df | MS | F | p-Value | F-Crit |

| SCC Grade | 6.6993 | 1 | 6.6993 | 67.7797 | 1.62 × 10−7 | 4.4139 |

| Basalt Fiber | 2.7352 | 2 | 1.3676 | 13.8367 | 0.000229 | 3.5546 |

| Interaction | 0.4428 | 2 | 0.2214 | 2.2398 | 0.135318 | 3.5546 |

| Within | 1.7791 | 18 | 0.0988 | |||

| Total | 11.6563 | 23 | ||||

| ANOVE Two-Factors with Replication | ||||||

|---|---|---|---|---|---|---|

| Source of Variation | SS | df | MS | F | p-Value | F-Crit |

| SCC Grade | 8.4847 | 1 | 8.4847 | 32.6082 | 2.05 × 10−5 | 4.4139 |

| Basalt Fiber | 19.2731 | 2 | 9.6365 | 37.0349 | 4.17 × 10−7 | 3.5546 |

| Interaction | 9.1273 | 2 | 4.5637 | 17.5389 | 5.93 × 10−5 | 3.5546 |

| Within | 4.6836 | 18 | 0.2602 | |||

| Total | 41.5687 | 23 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abu Taqa, A.; Ebead, U.A.; Mohsen, M.O.; Aburumman, M.O.; Senouci, A.; Maherzi, W.; Qtiashat, D. Experimental Assessment of the Strength and Microstructural Properties of Fly Ash-Containing Basalt Fiber-Reinforced Self-Compacting Sustainable Concrete. J. Compos. Sci. 2025, 9, 79. https://doi.org/10.3390/jcs9020079

Abu Taqa A, Ebead UA, Mohsen MO, Aburumman MO, Senouci A, Maherzi W, Qtiashat D. Experimental Assessment of the Strength and Microstructural Properties of Fly Ash-Containing Basalt Fiber-Reinforced Self-Compacting Sustainable Concrete. Journal of Composites Science. 2025; 9(2):79. https://doi.org/10.3390/jcs9020079

Chicago/Turabian StyleAbu Taqa, Ala, Usama A. Ebead, Mohamed O. Mohsen, Mervat O. Aburumman, Ahmed Senouci, Walid Maherzi, and Deya Qtiashat. 2025. "Experimental Assessment of the Strength and Microstructural Properties of Fly Ash-Containing Basalt Fiber-Reinforced Self-Compacting Sustainable Concrete" Journal of Composites Science 9, no. 2: 79. https://doi.org/10.3390/jcs9020079

APA StyleAbu Taqa, A., Ebead, U. A., Mohsen, M. O., Aburumman, M. O., Senouci, A., Maherzi, W., & Qtiashat, D. (2025). Experimental Assessment of the Strength and Microstructural Properties of Fly Ash-Containing Basalt Fiber-Reinforced Self-Compacting Sustainable Concrete. Journal of Composites Science, 9(2), 79. https://doi.org/10.3390/jcs9020079