Assessing the Eco-Efficiency of High Recycled Content Pavement Solutions: An Evaluation of the Mechanical, Durability, and Environmental Impacts

Abstract

1. Introduction

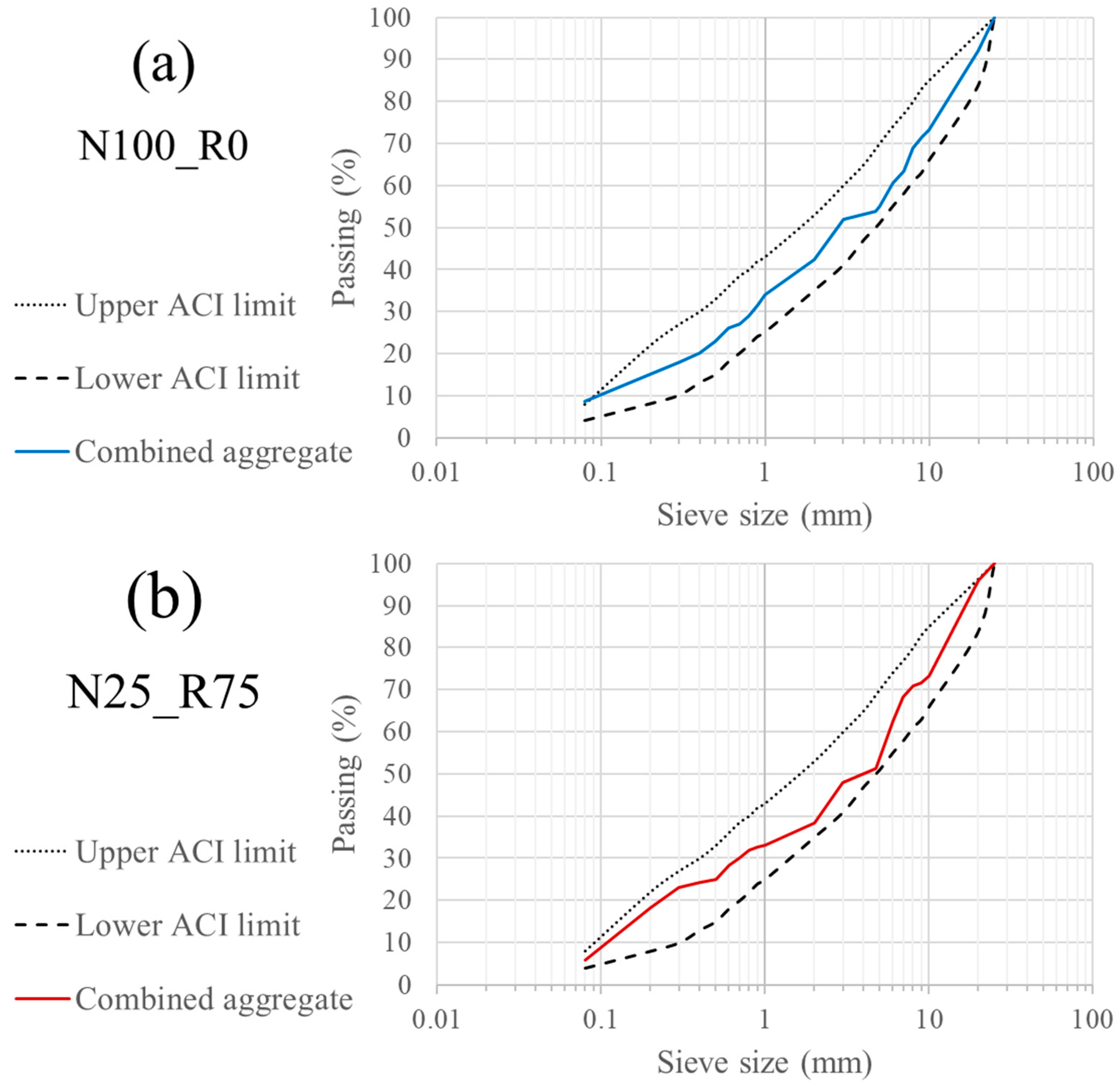

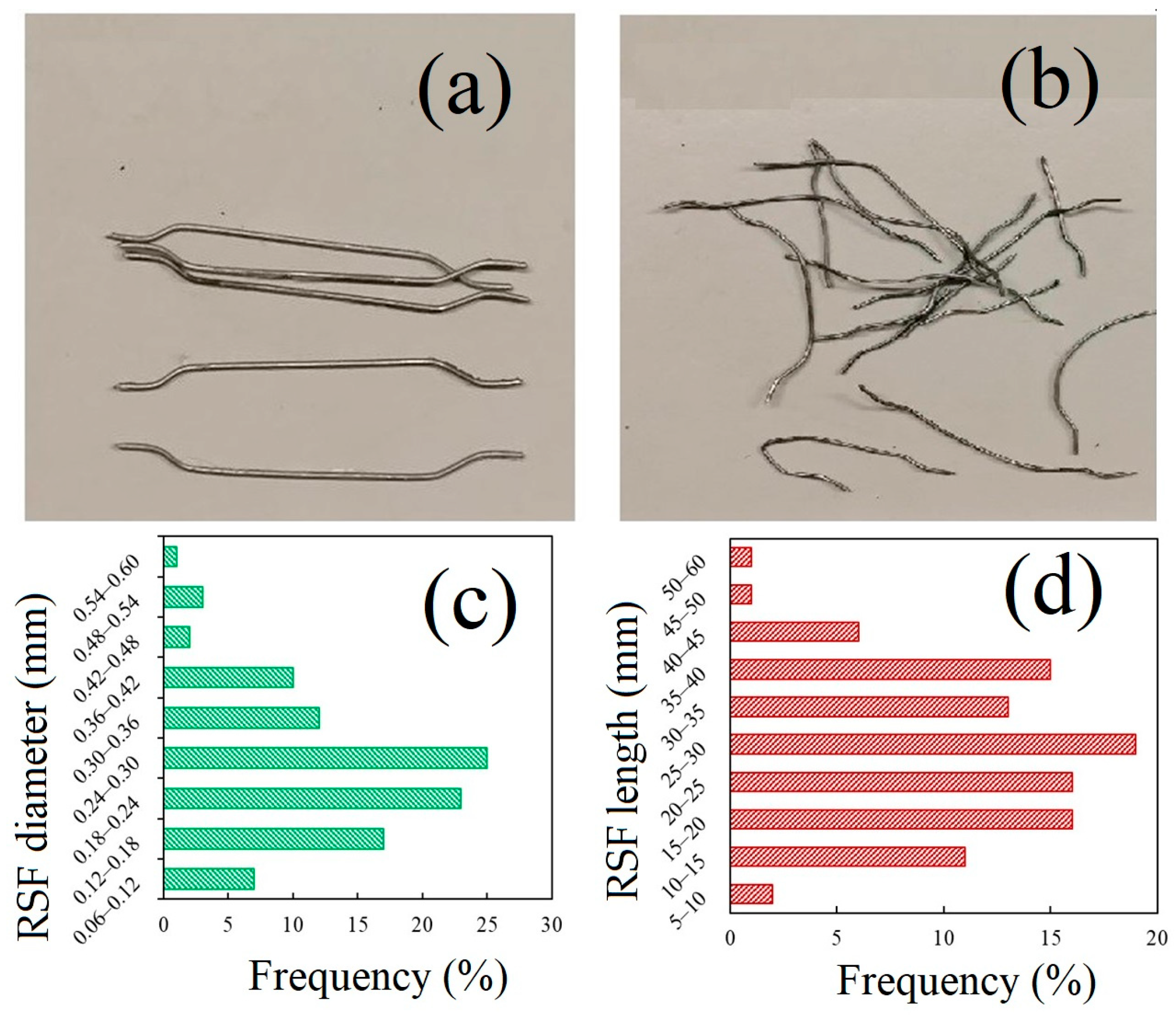

2. Materials

3. Methodology

4. Results and Discussion

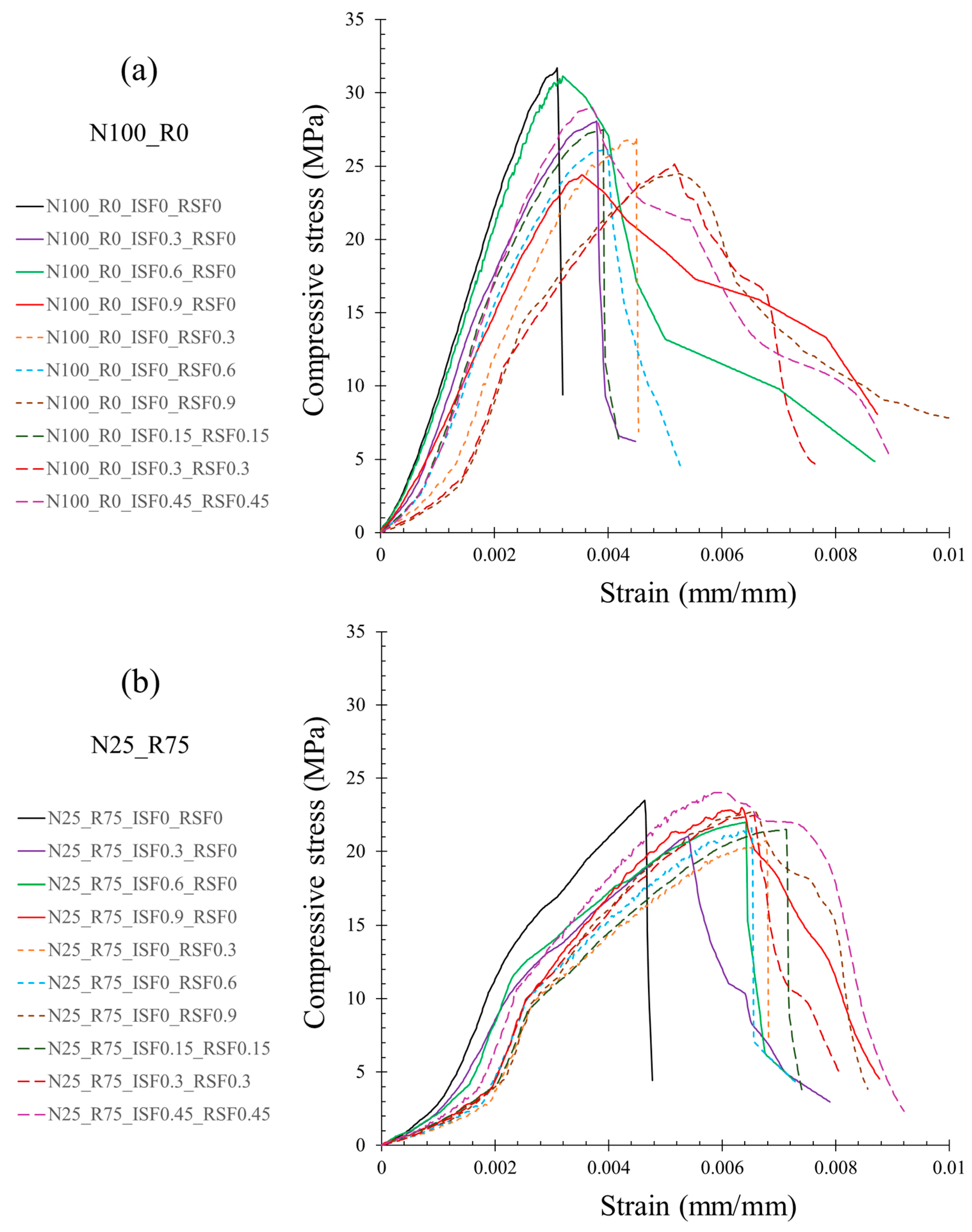

4.1. Mechanical Performance

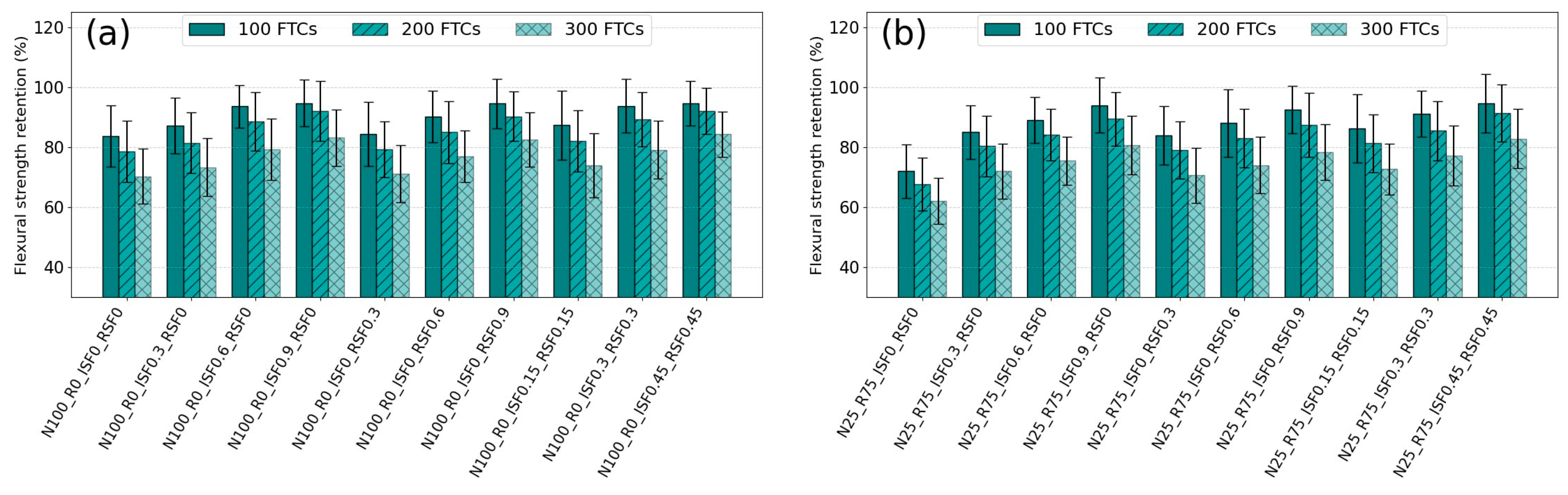

4.2. Durability

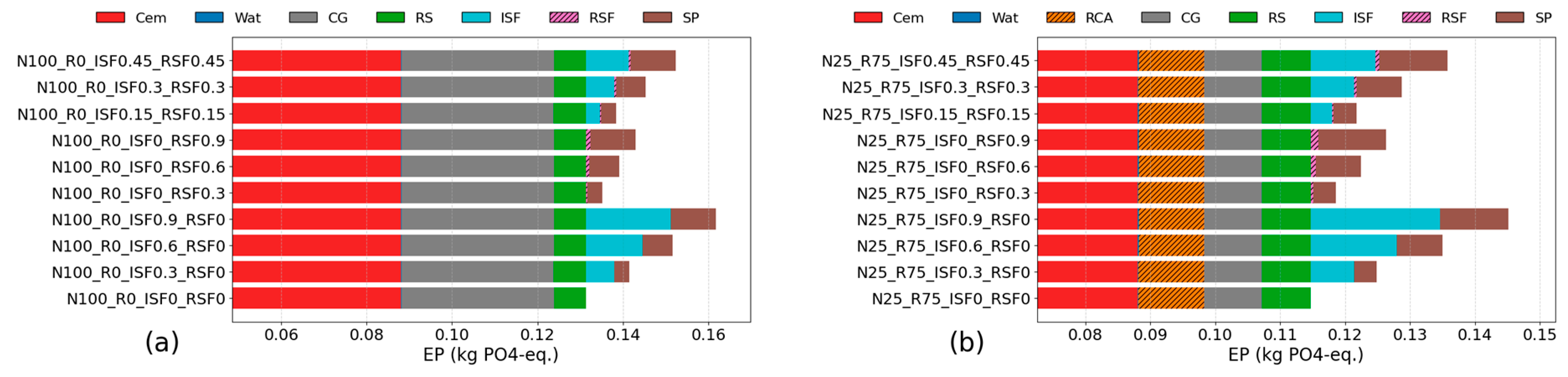

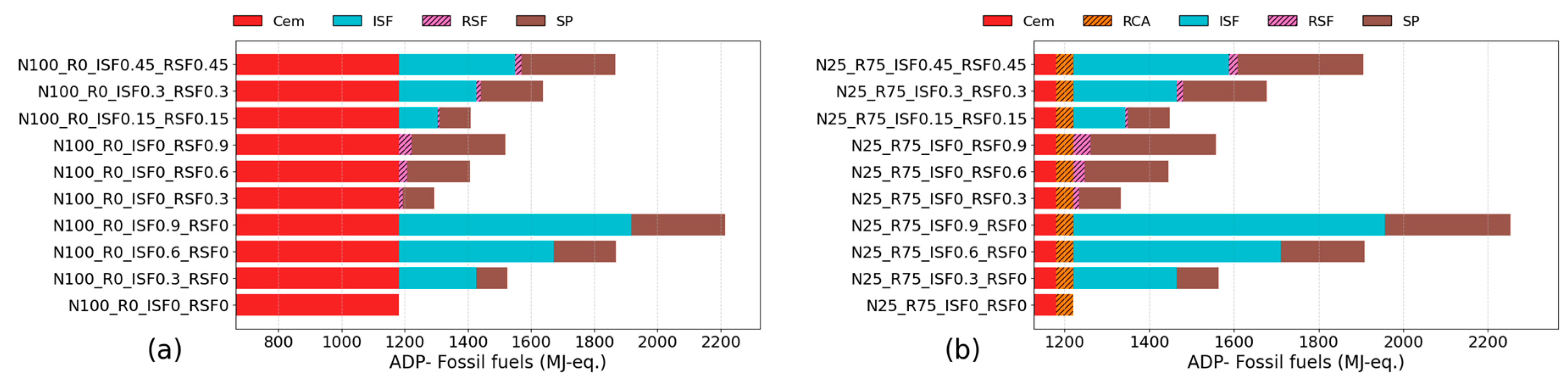

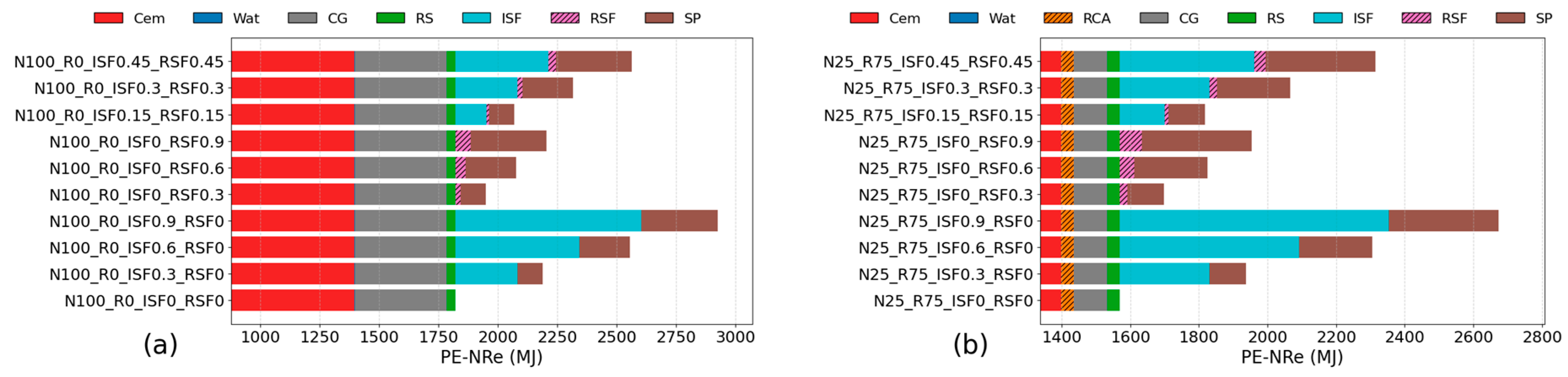

4.3. Environmental Impacts and Eco-Efficiency Ranking

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADP-Elem | Abiotic depletion of elements |

| ADP-fossil | Abiotic depletion of fossil fuels |

| AP | Acidification potential |

| Cem | Cement |

| CG | Crushed granite (coarse aggregate) |

| CMOD | Crack mouth opening displacement |

| CSR_300FTCs | Compressive strength retention after 300 freeze–thaw cycles |

| Ecm | Secant modulus of elasticity |

| EP | Eutrophication |

| fcm | Uniaxial compressive strength |

| fct,L | Initial flexural tensile strength |

| FRC | Fiber-reinforced concrete |

| FSR_300FTCs | Flexural strength retention after 300 freeze–thaw cycles |

| ft | Splitting tensile strength |

| FTCs | Freeze–thaw cycles |

| Gf | Fracture energy |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| HSF | Hybrid ISF/RSF |

| ISF | Industrial steel fiber |

| ITZ | Interfacial transition zone |

| LCA | Life Cycle Assessment |

| LCI | Life cycle inventory |

| MCDA | Multi-Criteria Decision Analysis |

| MDD | Maximum dry density |

| NA | Natural aggregate |

| ODP | Ozone depletion |

| OMC | Optimum moisture content |

| OPC | Ordinary Portland Cement |

| PE_NRe | Non-renewable energy |

| PE_Re | Renewable energy |

| POCP | Photochemical ozone creation potential |

| RCA | Recycled concrete aggregate |

| RCCP | Roller-compacted concrete pavement |

| RS | River sand (fine aggregate) |

| RSF | Recycled steel fiber |

| SP | Superplasticizer |

| TOPSIS | Technique for Order of Preference by Similarity to Ideal Solution |

| Toug_Comp | Compressive toughness |

| Toug_Flex | Flexural toughness |

| TSR_300FTCs | Tensile strength retention after 300 freeze–thaw cycles |

| Wat | Water |

| WSM | Weighted Sum Method |

| 3PNBBT | Three-point notched beam-bending tests |

Appendix A

| Specimens | Compressive Strength Retention | |||||

|---|---|---|---|---|---|---|

| 100 FTCs | 200 FTCs | 300 FTCs | ||||

| Retention (%) | CoV (%) | Retention (%) | CoV (%) | Retention (%) | CoV (%) | |

| N100_R0_ISF0_RSF0 | 85.43 | 6.65 | 76.38 | 7.49 | 63.83 | 8.46 |

| N100_R0_ISF0.3_RSF0 | 86.2 | 7.89 | 79.05 | 4.58 | 66.41 | 9.61 |

| N100_R0_ISF0.6_RSF0 | 94.43 | 6.17 | 86.38 | 5.26 | 83.83 | 6.33 |

| N100_R0_ISF0.9_RSF0 | 95.53 | 7.51 | 90.18 | 5.48 | 85.2 | 3.54 |

| N100_R0_ISF0_RSF0.3 | 85.62 | 7.68 | 77.0 | 9.09 | 64.16 | 10.54 |

| N100_R0_ISF0_RSF0.6 | 88.97 | 6.72 | 82.3 | 7.38 | 73.05 | 8.27 |

| N100_R0_ISF0_RSF0.9 | 95.41 | 6.65 | 89.0 | 3.93 | 84.95 | 6.51 |

| N100_R0_ISF0.15_RSF0.15 | 85.83 | 7.6 | 77.98 | 8.12 | 65.21 | 8.44 |

| N100_R0_ISF0.3_RSF0.3 | 94.68 | 7.04 | 86.95 | 4.31 | 84.05 | 6.16 |

| N100_R0_ISF0.45_RSF0.45 | 95.59 | 6.57 | 89.86 | 5.66 | 85.6 | 4.06 |

| N25_R75_ISF0_RSF0 | 76.05 | 7.67 | 64.91 | 9.09 | 56.0 | 10.49 |

| N25_R75_ISF0.3_RSF0 | 85.69 | 8.02 | 76.55 | 8.92 | 64.56 | 7.25 |

| N25_R75_ISF0.6_RSF0 | 88.17 | 7.51 | 79.69 | 7.64 | 68.25 | 7.18 |

| N25_R75_ISF0.9_RSF0 | 94.63 | 6.42 | 87.53 | 3.81 | 84.42 | 5.96 |

| N25_R75_ISF0_RSF0.3 | 85.67 | 8.37 | 77.18 | 7.62 | 64.38 | 9.32 |

| N25_R75_ISF0_RSF0.6 | 86.13 | 8.21 | 78.78 | 8.16 | 66.58 | 7.72 |

| N25_R75_ISF0_RSF0.9 | 94.92 | 6.42 | 87.64 | 4.26 | 84.27 | 4.34 |

| N25_R75_ISF0.15_RSF0.15 | 86.0 | 7.93 | 78.71 | 6.82 | 65.92 | 10.32 |

| N25_R75_ISF0.3_RSF0.3 | 91.45 | 8.87 | 84.71 | 6.42 | 82.5 | 6.82 |

| N25_R75_ISF0.45_RSF0.45 | 95.44 | 6.43 | 89.42 | 6.64 | 85.56 | 5.84 |

| Specimens | Tensile Strength Retention | |||||

|---|---|---|---|---|---|---|

| 100 FTCs | 200 FTCs | 300 FTCs | ||||

| Retention (%) | CoV (%) | Retention (%) | CoV (%) | Retention (%) | CoV (%) | |

| N100_R0_ISF0_RSF0 | 85.62 | 14.11 | 74.92 | 10.76 | 67.62 | 13.2 |

| N100_R0_ISF0.3_RSF0 | 86.8 | 14.33 | 75.3 | 13.57 | 69.32 | 12.11 |

| N100_R0_ISF0.6_RSF0 | 97.62 | 14.85 | 91.92 | 9.4 | 87.62 | 11.89 |

| N100_R0_ISF0.9_RSF0 | 97.7 | 14.47 | 91.1 | 8.71 | 85.91 | 7.53 |

| N100_R0_ISF0_RSF0.3 | 85.91 | 15.46 | 75.02 | 12.97 | 68.0 | 11.45 |

| N100_R0_ISF0_RSF0.6 | 89.16 | 12.95 | 78.82 | 10.41 | 73.03 | 11.18 |

| N100_R0_ISF0_RSF0.9 | 94.52 | 11.75 | 85.37 | 10.12 | 80.12 | 11 |

| N100_R0_ISF0.15_RSF0.15 | 86.78 | 14.63 | 75.34 | 13.2 | 69.5 | 12.08 |

| N100_R0_ISF0.3_RSF0.3 | 92.14 | 11.39 | 82.0 | 12.38 | 77.61 | 9.67 |

| N100_R0_ISF0.45_RSF0.45 | 96.93 | 12.82 | 90.82 | 7.24 | 86.5 | 7.63 |

| N25_R75_ISF0_RSF0 | 75.72 | 17.52 | 66.82 | 12.1 | 60.46 | 14.36 |

| N25_R75_ISF0.3_RSF0 | 85.78 | 16.49 | 75.0 | 13.15 | 67.92 | 12.59 |

| N25_R75_ISF0.6_RSF0 | 87.51 | 14.22 | 75.97 | 12.98 | 69.86 | 13.29 |

| N25_R75_ISF0.9_RSF0 | 92.97 | 13.6 | 84.97 | 8.64 | 78.05 | 9.91 |

| N25_R75_ISF0_RSF0.3 | 86.0 | 14.39 | 75.06 | 12.3 | 68.15 | 14.46 |

| N25_R75_ISF0_RSF0.6 | 87.35 | 14.63 | 75.39 | 12.13 | 70.31 | 13.95 |

| N25_R75_ISF0_RSF0.9 | 91.65 | 12.71 | 82.11 | 8.53 | 79.75 | 9.72 |

| N25_R75_ISF0.15_RSF0.15 | 86.72 | 15.11 | 75.28 | 13.17 | 69.28 | 11.9 |

| N25_R75_ISF0.3_RSF0.3 | 89.75 | 14.79 | 79.63 | 10.05 | 73.98 | 9.6 |

| N25_R75_ISF0.45_RSF0.45 | 96.5 | 12.27 | 89.3 | 7.99 | 84.02 | 9.63 |

| Specimens | Flexural Strength Retention | |||||

|---|---|---|---|---|---|---|

| 100 FTCs | 200 FTCs | 300 FTCs | ||||

| Retention (%) | CoV (%) | Retention (%) | CoV (%) | Retention (%) | CoV (%) | |

| N100_R0_ISF0_RSF0 | 83.58 | 12.22 | 78.55 | 13.12 | 70.24 | 13.03 |

| N100_R0_ISF0.3_RSF0 | 87.22 | 10.64 | 81.39 | 12.43 | 73.3 | 13.24 |

| N100_R0_ISF0.6_RSF0 | 93.58 | 7.51 | 88.56 | 11.02 | 79.24 | 12.96 |

| N100_R0_ISF0.9_RSF0 | 94.64 | 8.21 | 91.99 | 10.95 | 83.1 | 11.43 |

| N100_R0_ISF0_RSF0.3 | 84.33 | 12.66 | 79.29 | 11.8 | 71.1 | 13.4 |

| N100_R0_ISF0_RSF0.6 | 90.19 | 9.62 | 84.97 | 12.17 | 76.87 | 11.19 |

| N100_R0_ISF0_RSF0.9 | 94.56 | 8.71 | 90.23 | 9.13 | 82.4 | 10.97 |

| N100_R0_ISF0.15_RSF0.15 | 87.36 | 13.17 | 82.1 | 12.4 | 73.91 | 14.41 |

| N100_R0_ISF0.3_RSF0.3 | 93.67 | 9.55 | 89.19 | 10.21 | 79.1 | 12.19 |

| N100_R0_ISF0.45_RSF0.45 | 94.5 | 7.89 | 92.11 | 8.31 | 84.31 | 8.97 |

| N25_R75_ISF0_RSF0 | 71.98 | 12.42 | 67.64 | 13.2 | 62.02 | 12.41 |

| N25_R75_ISF0.3_RSF0 | 85.0 | 10.51 | 80.33 | 12.58 | 71.93 | 12.67 |

| N25_R75_ISF0.6_RSF0 | 88.94 | 8.64 | 84.11 | 10.19 | 75.45 | 10.54 |

| N25_R75_ISF0.9_RSF0 | 93.9 | 9.78 | 89.44 | 9.98 | 80.63 | 12.01 |

| N25_R75_ISF0_RSF0.3 | 83.96 | 11.65 | 78.96 | 12.11 | 70.62 | 13.02 |

| N25_R75_ISF0_RSF0.6 | 87.96 | 12.93 | 83.0 | 11.75 | 74.0 | 12.62 |

| N25_R75_ISF0_RSF0.9 | 92.45 | 8.55 | 87.36 | 12.19 | 78.29 | 11.91 |

| N25_R75_ISF0.15_RSF0.15 | 86.23 | 13.13 | 81.24 | 11.92 | 72.63 | 11.66 |

| N25_R75_ISF0.3_RSF0.3 | 91.15 | 8.45 | 85.47 | 11.57 | 77.1 | 12.92 |

| N25_R75_ISF0.45_RSF0.45 | 94.54 | 10.4 | 91.39 | 10.42 | 82.76 | 11.92 |

| RCCP Mixtures | GWP (kg CO2-eq.) | ODP (kg CFC11-eq.) | AP (kg SO2-eq.) | EP (-eq.) | POCP (kg ethene-eq.) | ADP | |

|---|---|---|---|---|---|---|---|

| Elements (kg Sb-eq.) | Fossil Fuels (MJ) | ||||||

| N100_R0_ISF0_RSF0 | 337.39 | 1.52 × 10−5 | 0.946 | 0.131 | 0.0659 | 6.18 × 10−6 | 1180.5 |

| N100_R0_ISF0.3_RSF0 | 367.45 | 1.7 × 10−5 | 1.021 | 0.141 | 0.0774 | 9.92 × 10−6 | 1525.05 |

| N100_R0_ISF0.6_RSF0 | 397.52 | 1.87 × 10−5 | 1.095 | 0.152 | 0.0889 | 1.37 × 10−5 | 1869.6 |

| N100_R0_ISF0.9_RSF0 | 427.58 | 2.04 × 10−5 | 1.169 | 0.162 | 0.1005 | 1.74 × 10−5 | 2214.16 |

| N100_R0_ISF0_RSF0.3 | 344.97 | 1.54 × 10−5 | 0.963 | 0.135 | 0.067 | 9.95 × 10−6 | 1293.3 |

| N100_R0_ISF0_RSF0.6 | 352.54 | 1.56 × 10−5 | 0.98 | 0.139 | 0.068 | 1.37 × 10−5 | 1406.11 |

| N100_R0_ISF0_RSF0.9 | 360.12 | 1.58 × 10−5 | 0.997 | 0.143 | 0.0691 | 1.75 × 10−5 | 1518.92 |

| N100_R0_ISF0.15_RSF0.15 | 356.21 | 1.62 × 10−5 | 0.992 | 0.138 | 0.0722 | 9.93 × 10−6 | 1409.18 |

| N100_R0_ISF0.3_RSF0.3 | 375.03 | 1.72 × 10−5 | 1.038 | 0.145 | 0.0785 | 1.37 × 10−5 | 1637.86 |

| N100_R0_ISF0.45_RSF0.45 | 393.85 | 1.81 × 10−5 | 1.083 | 0.152 | 0.0848 | 1.74 × 10−5 | 1866.54 |

| N25_R75_ISF0_RSF0 | 319.82 | 1.51 × 10−5 | 0.847 | 0.115 | 0.0598 | 5.69 × 10−6 | 1219.76 |

| N25_R75_ISF0.3_RSF0 | 349.89 | 1.68 × 10−5 | 0.922 | 0.125 | 0.0713 | 9.43 × 10−6 | 1564.31 |

| N25_R75_ISF0.6_RSF0 | 379.95 | 1.85 × 10−5 | 0.996 | 0.135 | 0.0828 | 1.32 × 10−5 | 1908.86 |

| N25_R75_ISF0.9_RSF0 | 410.02 | 2.03 × 10−5 | 1.07 | 0.145 | 0.0944 | 1.69 × 10−5 | 2253.42 |

| N25_R75_ISF0_RSF0.3 | 327.4 | 1.53 × 10−5 | 0.864 | 0.119 | 0.0609 | 9.46 × 10−6 | 1332.56 |

| N25_R75_ISF0_RSF0.6 | 334.98 | 1.55 × 10−5 | 0.881 | 0.122 | 0.0619 | 1.32 × 10−5 | 1445.37 |

| N25_R75_ISF0_RSF0.9 | 342.55 | 1.57 × 10−5 | 0.898 | 0.126 | 0.063 | 1.7 × 10−5 | 1558.18 |

| N25_R75_ISF0.15_RSF0.15 | 338.65 | 1.6 × 10−5 | 0.893 | 0.122 | 0.0661 | 9.45 × 10−6 | 1448.44 |

| N25_R75_ISF0.3_RSF0.3 | 357.46 | 1.7 × 10−5 | 0.939 | 0.129 | 0.0724 | 1.32 × 10−5 | 1677.12 |

| N25_R75_ISF0.45_RSF0.45 | 376.28 | 1.8 × 10−5 | 0.984 | 0.136 | 0.0787 | 1.7 × 10−5 | 1905.8 |

| RCCP Mixtures | PE-NRe (MJ) | PE-Re (MJ) |

|---|---|---|

| N100_R0_ISF0_RSF0 | 1821.37 | 45.48 |

| N100_R0_ISF0.3_RSF0 | 2189.47 | 55.35 |

| N100_R0_ISF0.6_RSF0 | 2557.61 | 65.22 |

| N100_R0_ISF0.9_RSF0 | 2925.72 | 75.09 |

| N100_R0_ISF0_RSF0.3 | 1949.52 | 50.95 |

| N100_R0_ISF0_RSF0.6 | 2077.69 | 56.41 |

| N100_R0_ISF0_RSF0.9 | 2205.87 | 61.88 |

| N100_R0_ISF0.15_RSF0.15 | 2069.49 | 53.15 |

| N100_R0_ISF0.3_RSF0.3 | 2317.66 | 60.82 |

| N100_R0_ISF0.45_RSF0.45 | 2565.79 | 68.48 |

| N25_R75_ISF0_RSF0 | 1569.46 | 45.27 |

| N25_R75_ISF0.3_RSF0 | 1937.59 | 55.14 |

| N25_R75_ISF0.6_RSF0 | 2305.73 | 65.01 |

| N25_R75_ISF0.9_RSF0 | 2673.87 | 74.88 |

| N25_R75_ISF0_RSF0.3 | 1697.65 | 50.73 |

| N25_R75_ISF0_RSF0.6 | 1825.84 | 56.2 |

| N25_R75_ISF0_RSF0.9 | 1954.02 | 61.67 |

| N25_R75_ISF0.15_RSF0.15 | 1817.66 | 52.94 |

| N25_R75_ISF0.3_RSF0.3 | 2065.77 | 60.6 |

| N25_R75_ISF0.45_RSF0.45 | 2313.92 | 68.27 |

References

- Razi, N.; Ansari, R. A prediction-based model to optimize construction programs: Considering time, cost, energy consumption, and CO2 emissions trade-off. J. Clean. Prod. 2024, 445, 141164. [Google Scholar] [CrossRef]

- Min, J.; Yan, G.; Abed, A.M.; Elattar, S.; Khadimallah, M.A.; Jan, A.; Ali, H.E. The effect of carbon dioxide emissions on the building energy efficiency. Fuel 2022, 326, 124842. [Google Scholar] [CrossRef]

- Salles, A.; Salati, M.; Bragança, L. Using City Information Modelling to Evaluate Urban Circularity Through Sustainability Indicators. In Creating a Roadmap Towards Circularity in the Built Environment; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 385–394. [Google Scholar]

- Hasheminezhad, A.; King, D.; Ceylan, H.; Kim, S. Comparative life cycle assessment of natural and recycled aggregate concrete: A review. Sci. Total Environ. 2024, 950, 175310. [Google Scholar] [CrossRef]

- Shmlls, M.; Abed, M.; Fořt, J.; Horvath, T.; Bozsaky, D. Towards closed-loop concrete recycling: Life cycle assessment and multi-criteria analysis. J. Clean. Prod. 2023, 410, 137179. [Google Scholar] [CrossRef]

- Azimi, N.; Schollbach, K.; Oliveira, D.V.; Lourenço, P.B. Effect of exposure to alkaline environment on the mechanical properties of TRM composites. J. Build. Eng. 2025, 105, 112468. [Google Scholar] [CrossRef]

- Tang, Y.; Xiao, J.; Liu, Q.; Xia, B.; Singh, A.; Lv, Z.; Song, W. Natural gravel-recycled aggregate concrete applied in rural highway pavement: Material properties and life cycle assessment. J. Clean. Prod. 2022, 334, 130219. [Google Scholar] [CrossRef]

- Abedi, M.; Hassanshahi, O.; Rashiddel, A.; Ashtari, H.; Meddah, M.S.; Dias, D.; Arjomand, M.A.; Choong, K.K. A sustainable cementitious composite reinforced with natural fibers: An experimental and numerical study. Constr. Build. Mater. 2023, 378, 131093. [Google Scholar] [CrossRef]

- Keleş, Ö.F.; Bayrak, O.Ü.; Bayata, H.F. Experimental investigation on mechanical properties of sustainable roller compacted concrete pavement (RCCP) containing waste rubbers as alternative aggregates. Constr. Build. Mater. 2024, 424, 135930. [Google Scholar] [CrossRef]

- Debbarma, S.; Ransinchung, G.D. Achieving sustainability in roller compacted concrete pavement mixes using reclaimed asphalt pavement aggregates–state of the art review. J. Clean. Prod. 2021, 287, 125078. [Google Scholar] [CrossRef]

- de Bortoli, A. Understanding the environmental impacts of virgin aggregates: Critical literature review and primary comprehensive life cycle assessments. J. Clean. Prod. 2023, 415, 137629. [Google Scholar] [CrossRef]

- Sheikh, E.; Mousavi, S.R.; Afshoon, I. Producing green Roller Compacted Concrete (RCC) using fine copper slag aggregates. J. Clean. Prod. 2022, 368, 133005. [Google Scholar] [CrossRef]

- Aghayan, I.; Khafajeh, R.; Shamsaei, M. Life cycle assessment, mechanical properties, and durability of roller compacted concrete pavement containing recycled waste materials. Int. J. Pavement Res. Technol. 2021, 14, 595–606. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life cycle assessment of sustainable concrete with recycled aggregate and supplementary cementitious materials. Resour. Conserv. Recycl. 2023, 193, 106947. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Özçelikci, E.; Oskay, A.; Bayer, İ.R.; Şahmaran, M. Eco-hybrid cement-based building insulation materials as a circular economy solution to construction and demolition waste. Cem. Concr. Compos. 2023, 141, 105149. [Google Scholar] [CrossRef]

- Bai, W.; Song, Z.; Yuan, C.; Guan, J.; Xie, C.; Huang, H.; Ma, Y. Study on mechanical properties and damage mechanism of recycled concrete containing silica fume in freeze–thaw environment. Constr. Build. Mater. 2023, 375, 130872. [Google Scholar] [CrossRef]

- Yang, T.; Gong, L.; Jin, C.; Qin, J.; Dang, D.; Cui, X. Study on the pore characteristics and ITZ properties of recycled aggregate concrete by desert sand subjecting to salt freeze-thaw environments. J. Build. Eng. 2025, 108, 112918. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, H.; Liu, C. Impact of rice husk ash on the mechanical characteristics and freeze–thaw resistance of recycled aggregate concrete. Appl. Sci. 2022, 12, 12238. [Google Scholar] [CrossRef]

- Gao, D.; Luo, F.; Yan, Y.; Tang, J.; Yang, L. Experimental investigation on the flexural performance and damage process of steel fiber reinforced recycled coarse aggregate concrete. Structures 2023, 51, 1205–1218. [Google Scholar] [CrossRef]

- Guo, S.; Ding, Y.; Zhang, X.; Xu, P.; Bao, J.; Zou, C. Tensile properties of steel fiber reinforced recycled concrete under bending and uniaxial tensile tests. J. Build. Eng. 2024, 96, 110467. [Google Scholar] [CrossRef]

- Barros, J.; Costelha, H.; Bento, D.; Brites, N.; Luís, R.; Patrício, H.; Cunha, V.; Bento, L.; Miranda, T.; Coelho, P.; et al. A multidisciplinary engineering-based approach for tunnelling strengthening with a new fibre reinforced shotcrete technology. Tunn. Undergr. Space Technol. 2024, 147, 105707. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Effect of fibre length on the mechanical properties of SFRC using recycled Steel fibres. Constr. Build. Mater. 2024, 415, 134890. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Guo, J.; Wu, J.; Zhang, C. Production of sustainable steel fiber-reinforced rubberized concrete with enhanced mechanical properties: A state-of-the-art review. J. Build. Eng. 2024, 91, 109735. [Google Scholar] [CrossRef]

- Mahboob, A.; Hassanshahi, O.; Safi, M.; Majid, T.A. Experimental investigation of eco-friendly fiber-reinforced concrete using recycled and natural fibers, integrated with recycled aggregates. Adv. Compos. Mater. 2024, 33, 1101–1130. [Google Scholar] [CrossRef]

- Abdolpour, H.; Niewiadomski, P.; Kwiecień, A.; Tekieli, M.; Sadowski, Ł. Fundamental understanding of the mechanical and post-cracking behaviour of ultra-high performance mortar with recycled steel fibers. Constr. Build. Mater. 2023, 374, 130918. [Google Scholar] [CrossRef]

- Roshan, N.; Ghalehnovi, M.; Pakzad, S.S. Recycled steel fiber for fiber reinforced concrete production: Fresh and hardened properties, cost, and ecological assessments. J. Build. Pathol. Rehabil. 2023, 8, 24. [Google Scholar] [CrossRef]

- Gu, L.; Liu, Y.; Zeng, J.; Zhang, Z.; Pham, P.N.; Liu, C.; Zhuge, Y. The synergistic effects of fibres on mechanical properties of recycled aggregate concrete: A comprehensive review. Constr. Build. Mater. 2024, 436, 137011. [Google Scholar] [CrossRef]

- Zhong, H.; Chen, M.; Zhang, M. Effect of hybrid industrial and recycled steel fibres on static and dynamic mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 2023, 370, 130691. [Google Scholar] [CrossRef]

- Mehmandari; Asheghi, T.; Shokouhian, M.; Josheghan, M.Z.; Mirjafari, S.A.; Fahimifar, A.; Armaghani, D.J.; Tee, K.F. Flexural properties of fiber-reinforced concrete using hybrid recycled steel fibers and manufactured steel fibers. J. Build. Eng. 2024, 98, 111069. [Google Scholar] [CrossRef]

- Dharek, M.S.; Manjunatha, M.; Brijbhushan, S.; Vengala, J.; Tangadagi, R.B. Performance evaluation of hybrid fiber reinforced concrete on engineering properties and life cycle assessment: A sustainable approach. J. Clean. Prod. 2024, 458, 142498. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, X.; Liu, H.; Wang, Z.; Chen, C.; Li, H. Recycling of waste recycled aggregate concrete in freeze-thaw environment and emergy analysis of concrete recycling system. J. Build. Eng. 2024, 96, 110377. [Google Scholar] [CrossRef]

- Taheri, A.; Azimi, N.; Oliveira, D.V.; Tinoco, J.; Lourenço, P.B. Integrating Experimental Analysis and Gradient Boosting for the Durability Assessment of Lime-Based Mortar in Acidic Environment. Buildings 2025, 15, 408. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, X.; Zhu, X.; Xiao, J. Multi-criteria optimization of concrete mixes incorporating cenosphere waste and multi-minerals. J. Clean. Prod. 2022, 367, 133102. [Google Scholar] [CrossRef]

- Oh, C.L.; Choong, K.K.; Nishimura, T.; Kim, J.Y. Shape change analysis of tensegrity models. Lat. Am. J. Solids Struct. 2019, 16, e221. [Google Scholar] [CrossRef]

- Negrin, I.; Kripka, M.; Yepes, V. Multi-criteria optimization for sustainability-based design of reinforced concrete frame buildings. J. Clean. Prod. 2023, 425, 139115. [Google Scholar] [CrossRef]

- Khan, M.S.; Khan, M.S.; Khan, M.I.; Al-Nawasir, R.; Maureira-Carsalade, N.; Avudaiappan, S.; Choudhry, R.M. Enhancing rigid pavement performance: Experimental study and design optimization of bentonite clay-blended concrete with a focus on durability. Case Stud. Constr. Mater. 2025, 22, e04641. [Google Scholar] [CrossRef]

- Shahidan, S.; Azmi, M.A.M.; Kupusamy, K.; Zuki, S.S.M.; Ali, N. Utilizing construction and demolition (C&D) waste as recycled aggregates (RA) in concrete. Procedia Eng. 2017, 174, 1028–1035. [Google Scholar] [CrossRef]

- Silva, F.A.N.; Silva, M.T.A.; Delgado, J.M.P.Q.; Azevedo, A.C.; Pereira, G.F.C. Construction and demolition waste as raw material in pavements layers. Rev. Constr. 2022, 21, 184–192. [Google Scholar] [CrossRef]

- Kabir, S.; Al-Shayeb, A.; Khan, I.M. Recycled construction debris as concrete aggregate for sustainable construction materials. Procedia Eng. 2016, 145, 1518–1525. [Google Scholar] [CrossRef][Green Version]

- Khan, M.S.; Khan, M.I.; Choudhry, R.M.; Khahro, S.H.; Memon, Z.A. Performance analysis of fiber reinforced recycled aggregate concrete at elevated temperatures using response surface methodology. Sci. Rep. 2025, 15, 12916. [Google Scholar] [CrossRef]

- Almutairi, O.; Khan, M.I. Modeling Compressive and Flexural Strength of Cement Grouts with Fly Ash, Silica Fume, and Polyethylene Terephthalate: A Correlated Multivariate Regression Approach in Compositional Data Analysis. Buildings 2025, 15, 3976. [Google Scholar] [CrossRef]

- Khan, M.I. Robust prediction models for flow compressive strength of sustainable cement grouts for grouted macadam pavement using RSM. Constr. Build. Mater. 2024, 448, 138205. [Google Scholar] [CrossRef]

- Mehmood, S.A.; Khan, M.I.; Ahmed, S.; Al-Nawasir, R.; Choudhry, R.M. From Waste to Roads: Improving Pavement Performance and Achieving Sustainability with Recycled Steel Slag and Low-Density Polyethylene. Buildings 2025, 15, 476. [Google Scholar] [CrossRef]

- Yang, L.; Hu, X.; Liu, Y.; Zhou, D.; Yuan, B.; Liu, S.; Luo, Z.; Li, X.; Jin, D.; Xu, F. Multiscale characterization of geopolymers modified with alkali-catalyzed nano-silica: Effects on dispersion and mechanical properties. Cem. Concr. Compos. 2025, 165, 106324. [Google Scholar] [CrossRef]

- Hassanshahi, O.; Salati, M.; Azimi, N.; Bakhshi, M. Hybrid Steel Fibers and RCA in RCC Pavements: Mechanical Recovery, Freeze–Thaw Durability, and Eco-Efficiency. Infrastructures 2025, 10, 321. [Google Scholar] [CrossRef]

- Hassanshahi, O.; Karimzadeh, S.; Bakhshi, M.; Azimi, N. Synergistic Role of Recycled Concrete Aggregates and Hybrid Steel Fibers in Roller-Compacted Concrete Pavements: A Multi-Criteria Assessment for Eco-Efficiency Optimization. Buildings 2025, 15, 4279. [Google Scholar] [CrossRef]

- ACI 211.3R-02 (R09); Guide for Selecting Proportions for No-Slump Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2009.

- ACI 325.10R-95; Report on Roller-Compacted Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1995.

- ASTM C127-15/16; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C128-22; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C29/C29M-17a; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2017.

- ASTM C136-14; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C117-17; Standard Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing. ASTM International: West Conshohocken, PA, USA, 2020.

- Lu, L. Optimal replacement ratio of recycled concrete aggregate balancing mechanical performance with sustainability: A review. Buildings 2024, 14, 2204. [Google Scholar] [CrossRef]

- Alibeigibeni, A.; Stochino, F.; Zucca, M.; Gayarre, F.L. Enhancing concrete sustainability: A critical review of the performance of recycled concrete aggregates (RCAs) in structural concrete. Buildings 2025, 15, 1361. [Google Scholar] [CrossRef]

- ACI PRC-211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2009.

- ASTM D1557-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C1435/C1435M-20; Standard Practice for Molding Roller-Compacted Concrete in Cylinder Molds Using a Vibrating Hammer. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C192/C192M-22; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2022.

- NP EN 12390; Testing Hardened Concrete (Series). Portuguese Quality Institute: Lisbon, Portugal, 2009.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- International Federation for Structural Concrete (fib). fib Model Code 2010. FIB Model Code for Concrete Structures 2010; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2013. [Google Scholar]

- ASTM C666/C666M-15; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM International: West Conshohocken, PA, USA, 2015.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- EN 15804:2012+A1:2013; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- NP EN 12390-3:2011; Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens. Instituto Português da Qualidade (IPQ): Lisbon, Portugal, 2011.

- NP EN 12390-13:2014; Testing Hardened Concrete. Part 13: Determination of Secant Modulus of Elasticity in Compression. Instituto Português da Qualidade (IPQ): Caparica, Portugal, 2014.

- Hoseini, S.O.; Sohrabi, M.R.; Mousavi, S.R.; Ghasemi, M. Studying the rheological features, mechanical properties and flexural toughness of the WSFRSCC by varying the coarse aggregate volume. Structures 2023, 57, 105115. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- EFCA. Environmental Product Declaration (EPD) Report. Concrete Admixtures—Plasticisers and Superplasticisers; European Federation of Concrete Admixtures Associations Ltd. (EFCA): Brussels, Belgium, 2015. [Google Scholar]

- EN 197-1; European Reference Life Cycle Database of the Joint Research Center, Version 3.2: Portland Cement (CEM I). CEMBUREAU Production Mix, at Plant, CEMBUREAU Technology Mix. European Committee for Standardization: Brussels, Belgium, 2015.

- Park, W.J.; Kim, T.; Roh, S.; Kim, R. Analysis of life cycle environmental impact of recycled aggregate. Appl. Sci. 2019, 9, 1021. [Google Scholar] [CrossRef]

- Salati, M.; Bragança, L.; Mateus, R. Sustainability assessment on an urban scale: Context, challenges, and most relevant indicators. Appl. Syst. Innov. 2022, 5, 41. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Salles, A.; Salati, M.; Bragança, L. Analyzing the feasibility of integrating urban sustainability assessment indicators with city information modelling (CIM). Appl. Syst. Innov. 2023, 6, 45. [Google Scholar] [CrossRef]

- Abed, M.; Shmlls, M. Analysis of three generations of recycled concrete: An approach using LCA and weighted sum model. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Hassanshahi, O.; Kameli, S.; Mohammadpour, R.; Bakhshi, M.; Mahboob, A. Experimental Investigation of Sustainable Roller-Compacted Concrete Pavement (RCCP) Reinforced with Natural Fibers: Mechanical Performance, Durability, and Environmental Impacts. Int. J. Pavement Res. Technol. 2025, 1–24. [Google Scholar] [CrossRef]

- Kareem, M.A.; Ajadi, E.O.; Fadipe, O.O.; Ishola, K.; Olawuyi, O.A.; Ayanlere, S.A.; Olatoyan, O.J.; Adeosun, J.O.; Adefajo, A.A.; Oyewo, A.T.; et al. Sustainability-driven application of waste steel and tyre rubber fibres as reinforcement in concrete: An optimization study using response surface methodology. Next Mater. 2025, 7, 100345. [Google Scholar] [CrossRef]

- Hasanshahi, O.; Majid, T.A.; Lau, T.L.; Yousefi, A.; Tahara, R.M.K. Seismic performance of the typical RC beam–column joint subjected to repeated earthquakes. In Proceedings of the International Conference of Global Network for Innovative Technology and Awam International Conference in Civil Engineering (IGNITE-AICCE’17), Penang, Malaysia, 8–9 August 2017; AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017; Volume 1892, p. 120014. [Google Scholar] [CrossRef]

- Peen, W.Y.; Keong, C.K. Behaviour of hollow circular section with multiple perforations under compression, flexure and torsion. Lat. Am. J. Solids Struct. 2019, 16, e169. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Ni, S.; Liu, L.; Walubita, L.F. Mechanical performance and environmental impacts of self-compacting concrete with recycled demolished concrete blocks. J. Clean. Prod. 2021, 293, 126129. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Q.; Deng, Y.; Lin, J. Reinforcement effects of multi-scale hybrid fiber on flexural and fracture behaviors of ultra-low-weight foamed cement-based composites. Cem. Concr. Compos. 2022, 128, 104422. [Google Scholar] [CrossRef]

- Ramkumar, K.B.; Kannan Rajkumar, P.R. Impact of hybrid steel fibres on fresh and mechanical properties of Self-compacting concrete. Case Stud. Constr. Mater. 2022, 17, e01274. [Google Scholar] [CrossRef]

- Mahboob, A.; Hasanshahi, O.; Hakimi, A.; Safi, M. Evaluating the performance of hollow core slabs (HCS)-concrete and simplifying their implementation. Recent Prog. Mater. 2023, 5, 16. [Google Scholar] [CrossRef]

- Yin, D.; Zhang, M.; Xiong, B.; Zhang, S. Study on the physical and mechanical properties of concrete interfacial transition zones (ITZ) with consideration of positional effects. Constr. Build. Mater. 2025, 486, 141985. [Google Scholar] [CrossRef]

- Htet, P.; Chen, W.; Hao, H.; Shaikh, F. Influence of micro basalt and recycled macro polypropylene hybrid fibre on physical and mechanical properties of recycled aggregate concrete. J. Build. Eng. 2023, 76, 107083. [Google Scholar] [CrossRef]

- Cui, K.; Xu, L.; Tao, T.; Huang, L.; Li, J.; Hong, J.; Li, H.; Chi, Y. Mechanical behavior of multiscale hybrid fiber reinforced recycled aggregate concrete subject to uniaxial compression. J. Build. Eng. 2023, 71, 106504. [Google Scholar] [CrossRef]

- Abedi, M.; Sanivada, U.K.; Mirian, S.A.; Fangueiro, R. A self-sensing and self-heating planar braided composite for smart civil infrastructures reinforcement. Constr. Build. Mater. 2023, 387, 131617. [Google Scholar] [CrossRef]

- Zia, A.; Zhang, P.; Holly, I. Effectiveness of hybrid discarded tire/Industrial steel fibers for improving the sustainability of concrete structures. Constr. Build. Mater. 2023, 378, 131226. [Google Scholar] [CrossRef]

- Yousefi, A.; Bunnori, N.M.; Khavarian, M. Experimental investigation on effect of multi-walled carbon nanotubes concentration on flexural properties and microstructure of cement mortar composite. In Proceedings of the International Conference of Global Network for Innovative Technology and Awam International Conference in Civil Engineering (IGNITE-AICCE’17), Penang, Malaysia, 8–9 August 2017; AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017; Volume 1892. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, X.; Wan, S.; Cao, Z.; Weng, S.; Wu, K. Experimental and theoretical investigation on axial tensile behavior of ultra-high performance concrete (UHPC) with recycled steel fibers from waste tires. Constr. Build. Mater. 2024, 456, 139300. [Google Scholar] [CrossRef]

- Abedi, M.; Hasanshahi, O.; Barros, J.A.; Correia, A.G.; Fangueiro, R. Three-dimensional braided composites as innovative smart structural reinforcements. Compos. Struct. 2022, 297, 115912. [Google Scholar] [CrossRef]

- Yuan, C.; Qu, S.; Bai, W.; Guan, J.; Xie, Y. Study on the mechanical properties and mesoscopic damage mechanism of recycled aggregate concrete under different dynamic strain rates after freeze-thaw cycles. Case Stud. Constr. Mater. 2025, 22, e04182. [Google Scholar] [CrossRef]

- Liu, K.; Fu, K.; Sang, Y.; Yang, Y.; Zou, C.; Xie, T.; Zhao, X. Frost resistance of recycled aggregate concrete: A critical review. J. Build. Eng. 2024, 90, 109450. [Google Scholar] [CrossRef]

- Li, Y.; Qi, M.; Ji, S. Study on chloride penetration resistance of hybrid fiber-reinforced concrete in winter construction. Mater. Struct. 2025, 58, 27. [Google Scholar] [CrossRef]

- Shao, R.; Wu, C.; Li, J.; Liu, Z. Development of sustainable steel fibre-reinforced dry ultra-high performance concrete (DUHPC). J. Clean. Prod. 2022, 337, 130507. [Google Scholar] [CrossRef]

- Zhong, R.; Ai, X.; Pan, M.; Yao, Y.; Cheng, Z.; Peng, X.; Wang, J.; Zhou, W. Durability of micro-cracked UHPC subjected to coupled freeze-thaw and chloride salt attacks. Cem. Concr. Compos. 2024, 148, 105471. [Google Scholar] [CrossRef]

- Han, X.; Ding, N.; Chen, A.; Wang, Z.; Xu, Y.; Feng, L.; Ji, Y.; Li, K.; Jing, J.; Sun, S.; et al. Experimental study on freeze-thaw failure of concrete incorporating waste tire crumb rubber and analytical evaluation of frost resistance. Constr. Build. Mater. 2024, 439, 137356. [Google Scholar] [CrossRef]

- El Ouni, M.H.; Shah, S.H.A.; Ali, A.; Muhammad, S.; Mahmood, M.S.; Ali, B.; Marzouki, R.; Raza, A. Mechanical performance, water and chloride permeability of hybrid steel-polypropylene fiber-reinforced recycled aggregate concrete. Case Stud. Constr. Mater. 2022, 16, e00831. [Google Scholar] [CrossRef]

- Hasanshahi, O.; Jorge, M.; Sena-Cruz, J.; Correia, L.; Leite, C.; Hasan, T.; Correia, J.R.; Garrido, M.; Cabral-Fonseca, S. Durability of GFRP composites produced by pultrusion under thermal environments. Procedia Struct. Integr. 2024, 64, 81–88. [Google Scholar] [CrossRef]

- Lu, D.; Wang, D.; Wang, Y.; Zhong, J. Nano-engineering the interfacial transition zone between recycled concrete aggregates and fresh paste with graphene oxide. Constr. Build. Mater. 2023, 384, 131244. [Google Scholar] [CrossRef]

- Bao, X.; Li, Y.; Chen, X.; Yang, H.; Cui, H. Investigation on the flexural behaviour and crack propagation of hybrid steel fibre reinforced concrete with a low fibre content for tunnel structures. Constr. Build. Mater. 2024, 417, 135253. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Yoo, D.Y. Combined corrosion and inclination effects on pullout behavior of various steel fibers under wet-dry cycle deterioration. Cem. Concr. Compos. 2023, 142, 105229. [Google Scholar] [CrossRef]

- Salati, M.; Costa, A.A.; Silvestre, J.D. A Comprehensive Review of Dynamic Life Cycle Assessment for Buildings: Exploring Key Processes and Methodologies. Sustainability 2024, 17, 159. [Google Scholar] [CrossRef]

- Ma, X.; Hu, H.; Luo, Y.; Yao, W.; Wei, Y.; She, A. A carbon footprint assessment for usage of recycled aggregate and supplementary cementitious materials for sustainable concrete: A life-cycle perspective in China. J. Clean. Prod. 2025, 490, 144772. [Google Scholar] [CrossRef]

- Li, L.; Li, S.; Li, W.; Xiao, H.; Xu, K.; Yang, J. Mechanical properties of soil reinforced by fiber and alkaline-activated rice husk ash, and rainfall erosion model tests. Sci. Total Environ. 2025, 958, 178099. [Google Scholar] [CrossRef] [PubMed]

- Hafez, H.; Malchiodi, B.; Tošić, N.; Drewniok, M.; Purnell, P.; de la Fuente, A. Decarbonization potential of steel fibre-reinforced limestone calcined clay cement concrete one-way slabs. Constr. Build. Mater. 2024, 435, 136847. [Google Scholar] [CrossRef]

- Dezhampanah, S.; Nikbin, I.; Charkhtab, S.; Fakhimi, F.; Bazkiaei, S.M.; Mohebbi, R. Environmental performance and durability of concrete incorporating waste tire rubber and steel fiber subjected to acid attack. J. Clean. Prod. 2020, 268, 122216. [Google Scholar] [CrossRef]

- Kumari, S.; Walia, R. Life cycle assessment of sustainable concrete by utilizing groundnut husk ash in concrete. Mater. Today Proc. 2022, 49, 1910–1915. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Sen, S.; Gadkari, S. The mathematics of life cycle sustainability assessment. J. Clean. Prod. 2021, 309, 127457. [Google Scholar] [CrossRef]

- Huang, W.; Wang, H. Comprehensive assessment of engineering and environmental attributes of geopolymer pervious concrete with natural and recycled aggregate. J. Clean. Prod. 2024, 468, 143138. [Google Scholar] [CrossRef]

- Biswas, W.K.; Zhang, X.; Matters, C.; Maboud, M. Techno-Eco-Efficiency Assessment of Using Recycled Steel Fibre in Concrete. Sustainability 2024, 16, 3717. [Google Scholar] [CrossRef]

| Variables | RCA (kg/m3) | CG (kg/m3) | RS (kg/m3) |

|---|---|---|---|

| Bulk specific gravity (OD) | 2.35 | 2.68 | 2.56 |

| Bulk specific gravity (SSD) | 2.45 | 2.72 | 2.61 |

| Apparent specific gravity | 2.55 | 2.78 | 2.66 |

| Fineness modulus (FM) | - | - | 2.85 |

| Absorption capacity (%) | 6.5 | 0.8 | 0.5 |

| Voids (%) | |||

| Loose condition | 35 | 27 | 38 |

| Compact condition | 30 | 22 | 33 |

| Fibers | Density (kg/m3) | Tensile Strength (MPa) | Modulus of Elasticity (MPa) | Elongation (%) | Diameter (mm) | Length (mm) |

|---|---|---|---|---|---|---|

| ISF | 7400 | 1230 | 210,000 | 3.0 ± 1.0 | 0.55 | 33.0 |

| RSF | 7400 | 2648 ± 423 | 200,000 | 2.2 ± 1.5 | 0.25 ± 0.08 | 26 ± 10 |

| Components | Quantity (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cem | Wat | RCA | CG | RS | ISF | RSF | SP | Wat/Cem (-) | |

| N100_R0_ISF0_RSF0 | 340 | 159.5 | - | 1120 | 930 | - | - | - | 0.47 |

| N100_R0_ISF0.3_RSF0 | 340 | 154.04 | - | 1120 | 930 | 21.6 | - | 3.4 | 0.45 |

| N100_R0_ISF0.6_RSF0 | 340 | 158.6 | - | 1120 | 930 | 43.2 | - | 6.8 | 0.47 |

| N100_R0_ISF0.9_RSF0 | 340 | 157.3 | - | 1120 | 930 | 64.8 | - | 10.2 | 0.46 |

| N100_R0_ISF0_RSF0.3 | 340 | 156.04 | - | 1120 | 930 | - | 21.6 | 3.4 | 0.46 |

| N100_R0_ISF0_RSF0.6 | 340 | 156.2 | - | 1120 | 930 | - | 43.2 | 6.8 | 0.46 |

| N100_R0_ISF0_RSF0.9 | 340 | 159.7 | - | 1120 | 930 | - | 64.8 | 10.2 | 0.47 |

| N100_R0_ISF0.15_RSF0.15 | 340 | 155 | - | 1120 | 930 | 10.8 | 10.8 | 3.4 | 0.46 |

| N100_R0_ISF0.3_RSF0.3 | 340 | 159.71 | - | 1120 | 930 | 21.6 | 21.6 | 6.8 | 0.47 |

| N100_R0_ISF0.45_RSF0.45 | 340 | 157.54 | - | 1120 | 930 | 32.4 | 32.4 | 10.2 | 0.46 |

| N25_R75_ISF0_RSF0 | 340 | 201.4 | 736.6 | 280 | 930 | - | - | - | 0.59 |

| N25_R75_ISF0.3_RSF0 | 340 | 204.5 | 736.6 | 280 | 930 | 21.6 | - | 3.4 | 0.6 |

| N25_R75_ISF0.6_RSF0 | 340 | 208.07 | 736.6 | 280 | 930 | 43.2 | - | 6.8 | 0.61 |

| N25_R75_ISF0.9_RSF0 | 340 | 212.5 | 736.6 | 280 | 930 | 64.8 | - | 10.2 | 0.63 |

| N25_R75_ISF0_RSF0.3 | 340 | 206 | 736.6 | 280 | 930 | - | 21.6 | 3.4 | 0.61 |

| N25_R75_ISF0_RSF0.6 | 340 | 211.1 | 736.6 | 280 | 930 | - | 43.2 | 6.8 | 0.62 |

| N25_R75_ISF0_RSF0.9 | 340 | 214.4 | 736.6 | 280 | 930 | - | 64.8 | 10.2 | 0.63 |

| N25_R75_ISF0.15_RSF0.15 | 340 | 212.4 | 736.6 | 280 | 930 | 10.8 | 10.8 | 3.4 | 0.62 |

| N25_R75_ISF0.3_RSF0.3 | 340 | 206.9 | 736.6 | 280 | 930 | 21.6 | 21.6 | 6.8 | 0.61 |

| N25_R75_ISF0.45_RSF0.45 | 340 | 209 | 736.6 | 280 | 930 | 32.4 | 32.4 | 10.2 | 0.61 |

| Raw Materials | GWP (kg CO2-eq.) | ODP (kg CFC11-eq.) | AP (kg SO2-eq.) | EP -eq.) | POCP (kg Ethene-eq.) | ADP | |

|---|---|---|---|---|---|---|---|

| Elements (kg Sb-eq.) | Fossil Fuels (MJ) | ||||||

| Cem | 0.90323 | 4.37 × 10−8 | 0.00221 | 0.000259 | 0.000166 | 1.43 × 10−8 | 3.47205 |

| Wat | 0.00026 | 3.01 × 10−11 | 1.31 × 10−6 | 7.28 × 10−7 | 5.88 × 10−8 | 5.83 × 10−10 | 0.0 |

| RCA | 0.00396 | 6.82 × 10−11 | 2.97 × 10−5 | 1.37 × 10−5 | 6.33 × 10−7 | 5.5 × 10−10 | 0.0533 |

| CG | 0.0244 | 2.43 × 10−10 | 0.000144 | 3.18 × 10−5 | 7.83 × 10−6 | 1.09 × 10−9 | 0.0 |

| RS | 0.003145 | 1.17 × 10−10 | 3.59 × 10−5 | 8.1 × 10−6 | 7.28 × 10−7 | 3.28 × 10−12 | 0.0 |

| ISF | 1.09588 | 7.97 × 10−8 | 0.00298 | 0.000307 | 0.0005 | 0.0 | 11.371 |

| RSF | 0.05474 | 8.63 × 10−9 | 0.000327 | 1.72 × 10−5 | 1.62 × 10−5 | 1.36 × 10−9 | 0.642 |

| SP | 1.88 | 2.3 × 10−10 | 0.00292 | 0.00103 | 0.000212 | 0.0000011 | 29.1 |

| Raw Materials | PE-NRe (MJ) | PE-Re (MJ) |

|---|---|---|

| Cem | 4.112 | 0.1322 |

| Wat | 0.0051 | 0.000683 |

| RCA | 0.05 | 0.0001 |

| CG | 0.344 | 0.000381 |

| RS | 0.04 | 0.0 |

| ISF | 12.1 | 0.21928 |

| RSF | 0.991 | 0.01527 |

| SP | 31.4 | 1.51 |

| Cylinder Specimens | Compressive Strength | Secant Modulus of Elasticity | Compressive Toughness | |||

|---|---|---|---|---|---|---|

| (MPa) | CoV (%) | (MPa) | CoV (%) | (N/mm) | CoV (%) | |

| N100_R0_ISF0_RSF0 | 31.72 | 6.72 | 34,431.4 | 5.91 | 15.77 | 17.01 |

| N100_R0_ISF0.3_RSF0 | 28.1 | 4.89 | 32,304.44 | 5.88 | 18.42 | 19.63 |

| N100_R0_ISF0.6_RSF0 | 31.15 | 4.2 | 33,245.58 | 4.6 | 34.77 | 11.20 |

| N100_R0_ISF0.9_RSF0 | 24.42 | 6.91 | 29,177.7 | 5.89 | 39.62 | 13.76 |

| N100_R0_ISF0_RSF0.3 | 27.04 | 5.72 | 31,342.9 | 5.53 | 18.53 | 18.07 |

| N100_R0_ISF0_RSF0.6 | 26.18 | 4.28 | 30,987.92 | 4.56 | 20.83 | 20.05 |

| N100_R0_ISF0_RSF0.9 | 24.5 | 6.82 | 29,473.8 | 5.72 | 38.66 | 14.92 |

| N100_R0_ISF0.15_RSF0.15 | 27.5 | 3.81 | 31,677.1 | 6.57 | 18.07 | 21.87 |

| N100_R0_ISF0.3_RSF0.3 | 25.13 | 5.55 | 29,973.07 | 7.59 | 30.69 | 13.85 |

| N100_R0_ISF0.45_RSF0.45 | 29.05 | 4.37 | 33,358.41 | 4.7 | 40.48 | 13.11 |

| N25_R75_ISF0_RSF0 | 23.53 | 6.11 | 28,594.31 | 5.32 | 17.03 | 23.84 |

| N25_R75_ISF0.3_RSF0 | 21.04 | 7.73 | 24,987.65 | 8.02 | 22.8 | 22.13 |

| N25_R75_ISF0.6_RSF0 | 22.0 | 6.88 | 26,724.0 | 6.78 | 25.65 | 19.86 |

| N25_R75_ISF0.9_RSF0 | 23.04 | 5.69 | 28,123.01 | 6.69 | 32.0 | 16.06 |

| N25_R75_ISF0_RSF0.3 | 20.75 | 8.09 | 25,225.34 | 7.82 | 22.15 | 22.61 |

| N25_R75_ISF0_RSF0.6 | 21.61 | 7.19 | 26,208.73 | 7.94 | 22.11 | 18.07 |

| N25_R75_ISF0_RSF0.9 | 22.76 | 7.37 | 27,987.48 | 5.17 | 32.1 | 15.37 |

| N25_R75_ISF0.15_RSF0.15 | 21.51 | 7.98 | 25,788.83 | 6.47 | 25.39 | 22.43 |

| N25_R75_ISF0.3_RSF0.3 | 22.47 | 6.88 | 26,939.79 | 5.89 | 27.63 | 19.08 |

| N25_R75_ISF0.45_RSF0.45 | 24.03 | 6.42 | 28,965.98 | 7.52 | 37.61 | 15.84 |

| Notched Beam Specimens | CMOD ≤ 0.05 mm | CMOD1 = 0.5 mm | CMOD2 = 1.5 mm | CMOD3 = 2.5 mm | CMOD4 = 3.5 mm | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| fct,L (MPa) | CoV (%) | fR,1 (MPa) | CoV (%) | fR,2 (MPa) | CoV (%) | fR,3 (MPa) | CoV (%) | fR,4 (MPa) | CoV (%) | |

| N100_R0_ISF0_RSF0 | 4.14 | 6.32 | 0.03 | 9.29 | - | - | - | - | - | - |

| N100_R0_ISF0.3_RSF0 | 4.4 | 7.8 | 2.25 | 10.84 | 1.53 | 17.34 | 1.17 | 28.44 | 0.54 | 33.27 |

| N100_R0_ISF0.6_RSF0 | 5.92 | 5.3 | 5.18 | 7.1 | 4.3 | 10.81 | 3.44 | 12.52 | 2.55 | 19.02 |

| N100_R0_ISF0.9_RSF0 | 5.87 | 5.7 | 5.86 | 6.56 | 5.04 | 8.13 | 3.27 | 9.43 | 2.43 | 11.22 |

| N100_R0_ISF0_RSF0.3 | 4.29 | 8.51 | 2.67 | 11.74 | 1.32 | 19.66 | 0.83 | 33.42 | 0.51 | 37.1 |

| N100_R0_ISF0_RSF0.6 | 4.72 | 7.09 | 4.6 | 8.86 | 3.62 | 13.11 | 3.01 | 18.88 | 2.58 | 22.84 |

| N100_R0_ISF0_RSF0.9 | 5.94 | 6.12 | 5.68 | 6.92 | 4.52 | 8.79 | 3.65 | 11.08 | 2.6 | 13.52 |

| N100_R0_ISF0.15_RSF0.15 | 4.38 | 8.55 | 2.62 | 12.31 | 1.42 | 19.51 | 0.93 | 31.61 | 0.62 | 38.88 |

| N100_R0_ISF0.3_RSF0.3 | 5.91 | 4.1 | 5.45 | 5.37 | 4.28 | 7.46 | 3.54 | 11.19 | 2.84 | 13.88 |

| N100_R0_ISF0.45_RSF0.45 | 6.25 | 5.56 | 6.1 | 6.51 | 5.0 | 7.88 | 3.27 | 9.77 | 2.6 | 11.53 |

| N25_R75_ISF0_RSF0 | 3.65 | 8.91 | 0.12 | 13.45 | - | - | - | - | - | - |

| N25_R75_ISF0.3_RSF0 | 4.28 | 8.96 | 2.43 | 12.99 | 1.38 | 21.95 | 0.89 | 38.63 | 0.53 | 46.79 |

| N25_R75_ISF0.6_RSF0 | 4.36 | 7.4 | 3.39 | 9.84 | 3.0 | 14.86 | 2.82 | 22.88 | 1.7 | 31.57 |

| N25_R75_ISF0.9_RSF0 | 5.71 | 6.46 | 5.68 | 7.88 | 4.41 | 10.6 | 3.61 | 15.48 | 2.66 | 19.66 |

| N25_R75_ISF0_RSF0.3 | 4.24 | 7.36 | 2.8 | 10.01 | 1.21 | 17.07 | 0.75 | 30.38 | 0.48 | 39.57 |

| N25_R75_ISF0_RSF0.6 | 4.43 | 8.43 | 2.24 | 9.44 | 1.57 | 14.82 | 1.27 | 23.71 | 0.61 | 33.67 |

| N25_R75_ISF0_RSF0.9 | 5.94 | 4.3 | 5.31 | 4.77 | 4.3 | 6.49 | 3.6 | 8.57 | 2.94 | 10.97 |

| N25_R75_ISF0.15_RSF0.15 | 4.34 | 8.21 | 2.68 | 11.66 | 1.36 | 19.18 | 1.07 | 33.37 | 0.52 | 42.05 |

| N25_R75_ISF0.3_RSF0.3 | 5.31 | 5.71 | 4.71 | 7.37 | 3.79 | 10.69 | 3.16 | 15.82 | 2.22 | 21.2 |

| N25_R75_ISF0.45_RSF0.45 | 5.97 | 4.94 | 5.56 | 5.93 | 4.23 | 7.8 | 3.81 | 9.36 | 2.82 | 11.7 |

| Eco-Efficiency Ranking | WSM Ranking | TOPSIS Ranking | ||

|---|---|---|---|---|

| RCCP Mixtures | Score | RCCP Mixtures | Score | |

| 1 | N100_R0_ISF0.45_RSF0.45 | 0.67 | N100_R0_ISF0.45_RSF0.45 | 0.64 |

| 2 | N100_R0_ISF0_RSF0.9 | 0.66 | N100_R0_ISF0_RSF0.9 | 0.62 |

| 3 | N100_R0_ISF0.6_RSF0 | 0.65 | N100_R0_ISF0.6_RSF0 | 0.61 |

| 4 | N25_R75_ISF0_RSF0.9 | 0.63 | N25_R75_ISF0_RSF0.9 | 0.6 |

| 5 | N25_R75_ISF0.45_RSF0.45 | 0.61 | N100_R0_ISF0.3_RSF0.3 | 0.59 |

| 6 | N100_R0_ISF0.3_RSF0.3 | 0.61 | N25_R75_ISF0.45_RSF0.45 | 0.58 |

| 7 | N100_R0_ISF0_RSF0.6 | 0.55 | N100_R0_ISF0_RSF0.6 | 0.54 |

| 8 | N100_R0_ISF0_RSF0 | 0.54 | N25_R75_ISF0.3_RSF0.3 | 0.54 |

| 9 | N25_R75_ISF0.3_RSF0.3 | 0.54 | N100_R0_ISF0_RSF0 | 0.52 |

| 10 | N100_R0_ISF0.9_RSF0 | 0.51 | N100_R0_ISF0.9_RSF0 | 0.5 |

| 11 | N100_R0_ISF0_RSF0.3 | 0.48 | N100_R0_ISF0_RSF0.3 | 0.48 |

| 12 | N100_R0_ISF0.15_RSF0.15 | 0.47 | N25_R75_ISF0.9_RSF0 | 0.48 |

| 13 | N25_R75_ISF0.9_RSF0 | 0.47 | N100_R0_ISF0.15_RSF0.15 | 0.47 |

| 14 | N100_R0_ISF0.3_RSF0 | 0.45 | N25_R75_ISF0_RSF0 | 0.46 |

| 15 | N25_R75_ISF0.15_RSF0.15 | 0.44 | N100_R0_ISF0.3_RSF0 | 0.46 |

| 16 | N25_R75_ISF0_RSF0.3 | 0.44 | N25_R75_ISF0_RSF0.3 | 0.46 |

| 17 | N25_R75_ISF0_RSF0 | 0.43 | N25_R75_ISF0.15_RSF0.15 | 0.46 |

| 18 | N25_R75_ISF0_RSF0.6 | 0.42 | N25_R75_ISF0_RSF0.6 | 0.44 |

| 19 | N25_R75_ISF0.3_RSF0 | 0.39 | N25_R75_ISF0.3_RSF0 | 0.41 |

| 20 | N25_R75_ISF0.6_RSF0 | 0.36 | N25_R75_ISF0.6_RSF0 | 0.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammad, A.A.S.; Mohammad, S.I.; Oraini, B.A.; Alenazi, S.A.; Vasudevan, A.; Hassanshahi, O. Assessing the Eco-Efficiency of High Recycled Content Pavement Solutions: An Evaluation of the Mechanical, Durability, and Environmental Impacts. J. Compos. Sci. 2025, 9, 692. https://doi.org/10.3390/jcs9120692

Mohammad AAS, Mohammad SI, Oraini BA, Alenazi SA, Vasudevan A, Hassanshahi O. Assessing the Eco-Efficiency of High Recycled Content Pavement Solutions: An Evaluation of the Mechanical, Durability, and Environmental Impacts. Journal of Composites Science. 2025; 9(12):692. https://doi.org/10.3390/jcs9120692

Chicago/Turabian StyleMohammad, Anber Abraheem Shlash, Suleiman Ibrahim Mohammad, Badrea Al Oraini, Sultan Alaswad Alenazi, Asokan Vasudevan, and Omid Hassanshahi. 2025. "Assessing the Eco-Efficiency of High Recycled Content Pavement Solutions: An Evaluation of the Mechanical, Durability, and Environmental Impacts" Journal of Composites Science 9, no. 12: 692. https://doi.org/10.3390/jcs9120692

APA StyleMohammad, A. A. S., Mohammad, S. I., Oraini, B. A., Alenazi, S. A., Vasudevan, A., & Hassanshahi, O. (2025). Assessing the Eco-Efficiency of High Recycled Content Pavement Solutions: An Evaluation of the Mechanical, Durability, and Environmental Impacts. Journal of Composites Science, 9(12), 692. https://doi.org/10.3390/jcs9120692