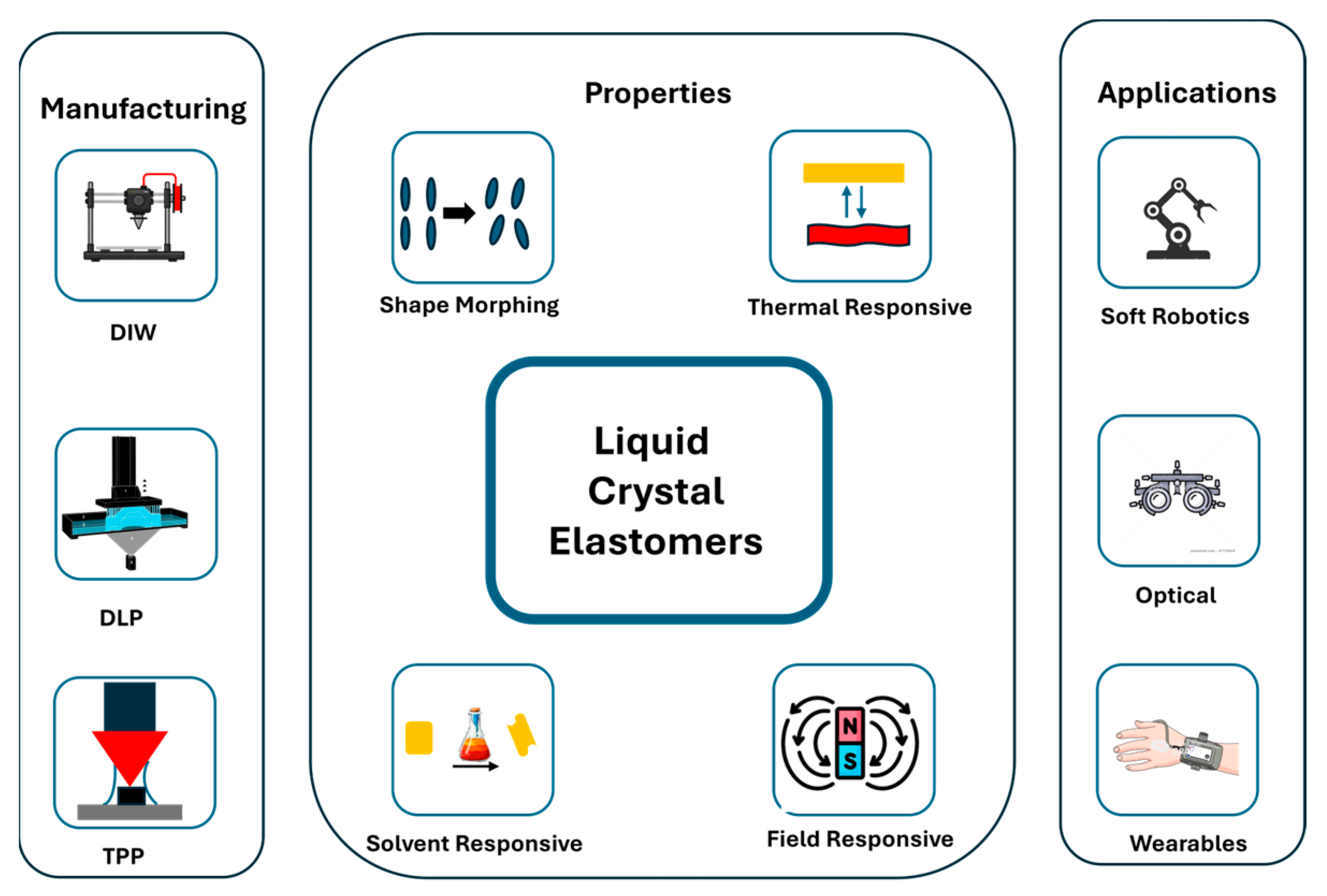

4D-Printed Liquid Crystal Elastomers: Printing Strategies, Actuation Mechanisms, and Emerging Applications

Abstract

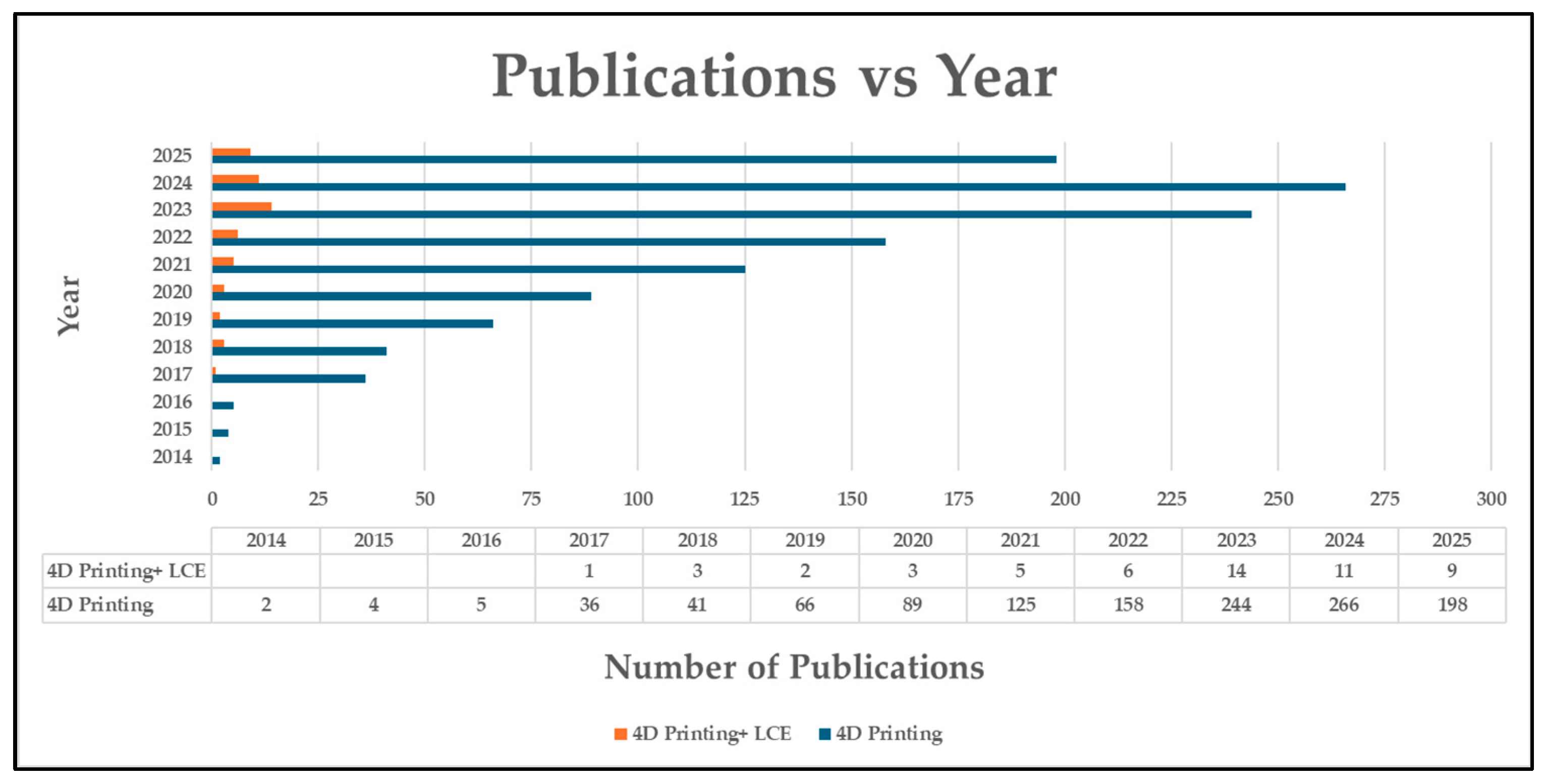

1. Introduction

2. Synthesis and Shape Programming of LCE

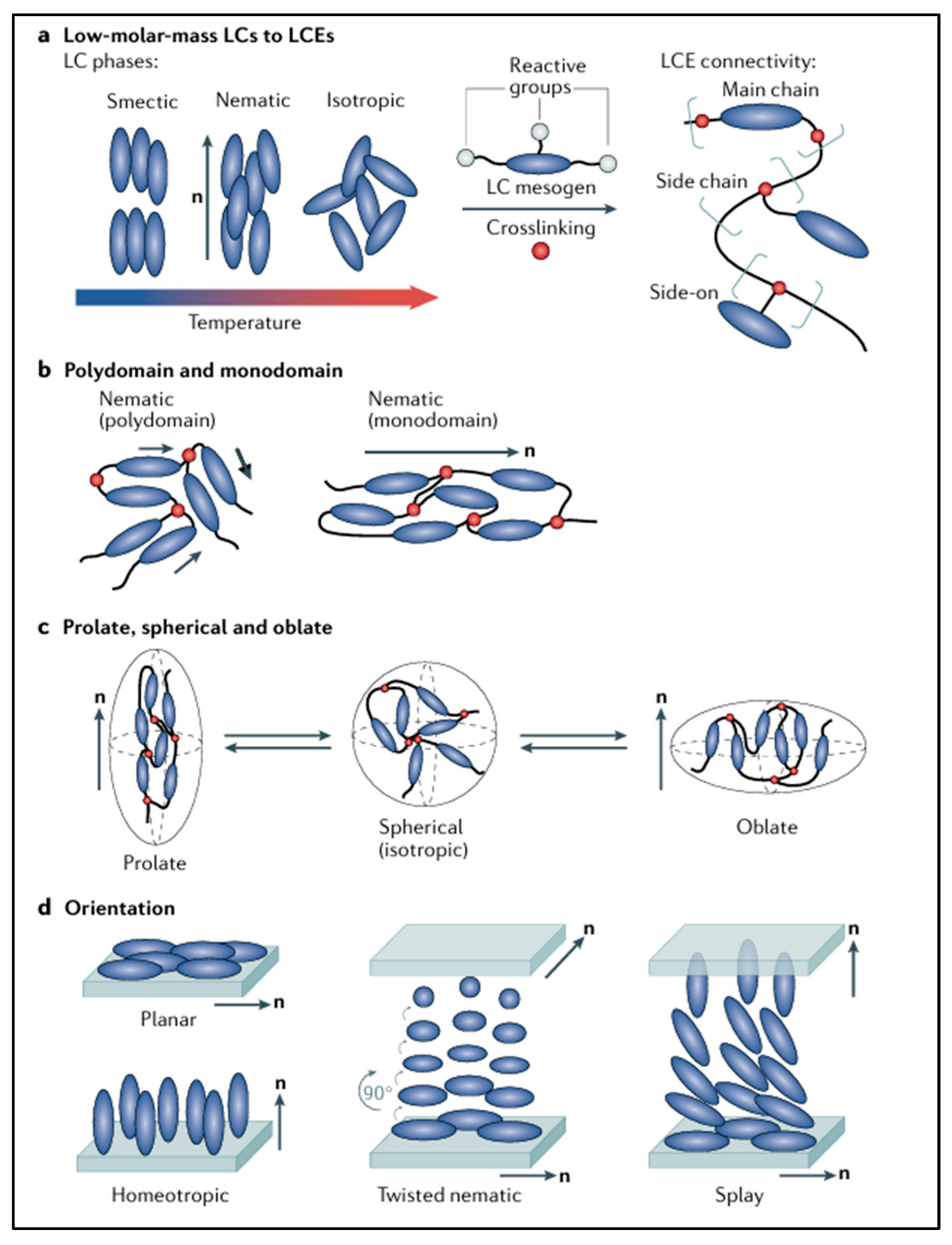

2.1. Fundamentals of Liquid Crystal Elastomers

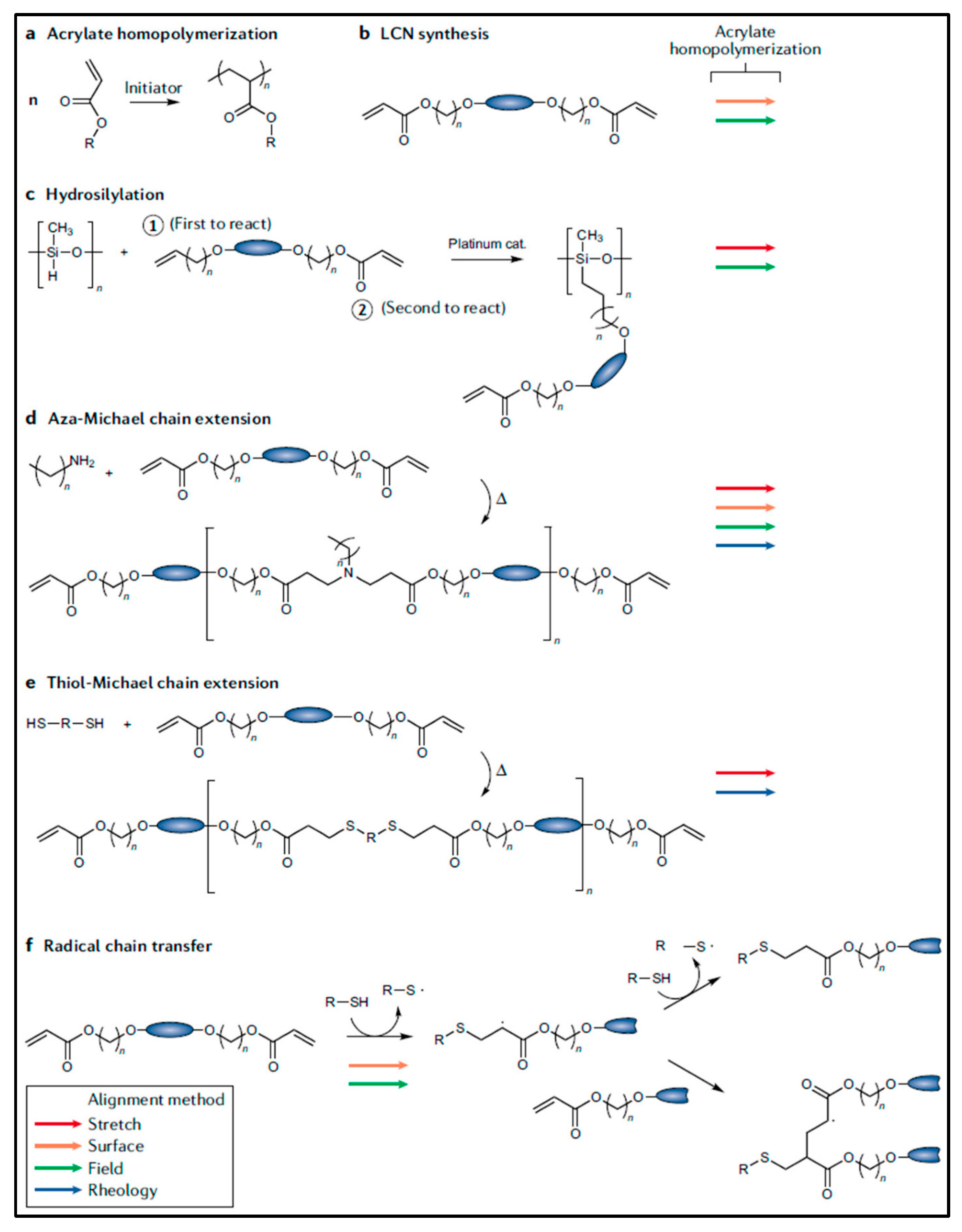

2.2. Synthesis of LCEs

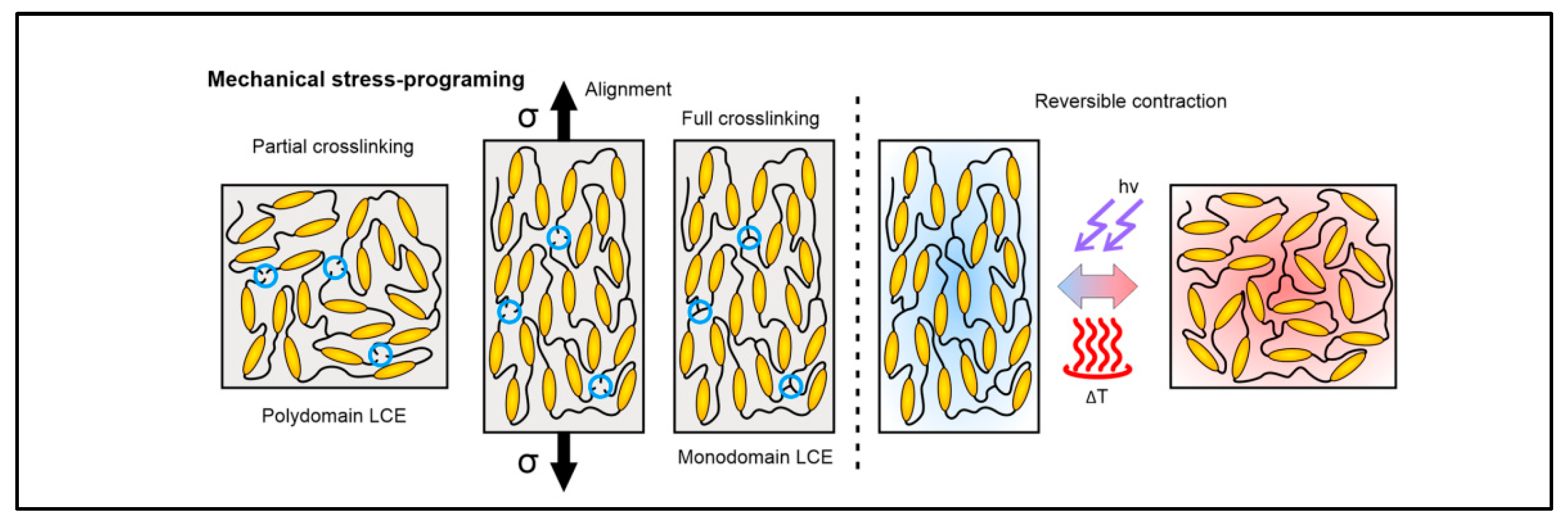

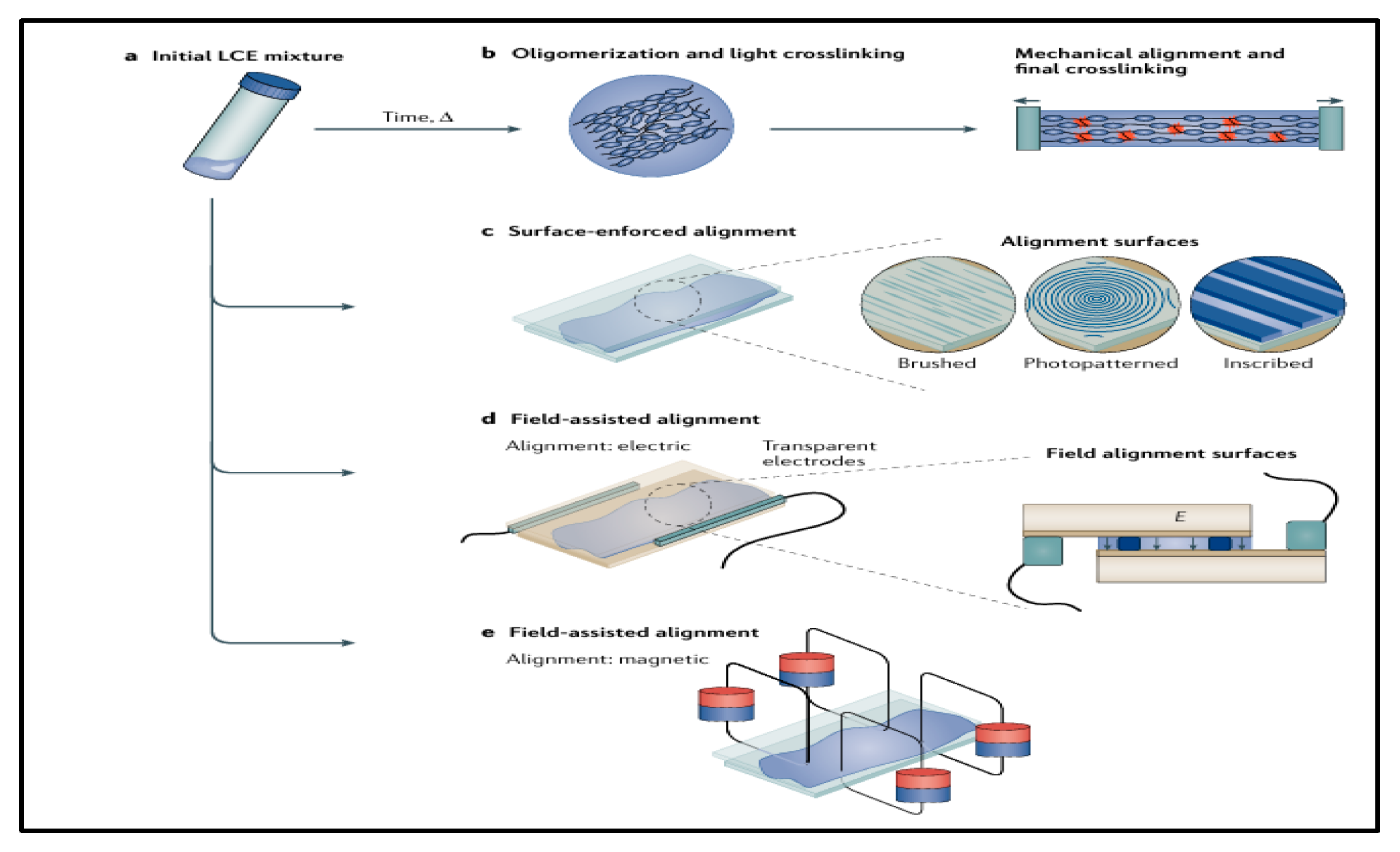

2.3. Orientation and Shape Programming Mechanism

3. Additive Manufacturing Mechanisms of LCE

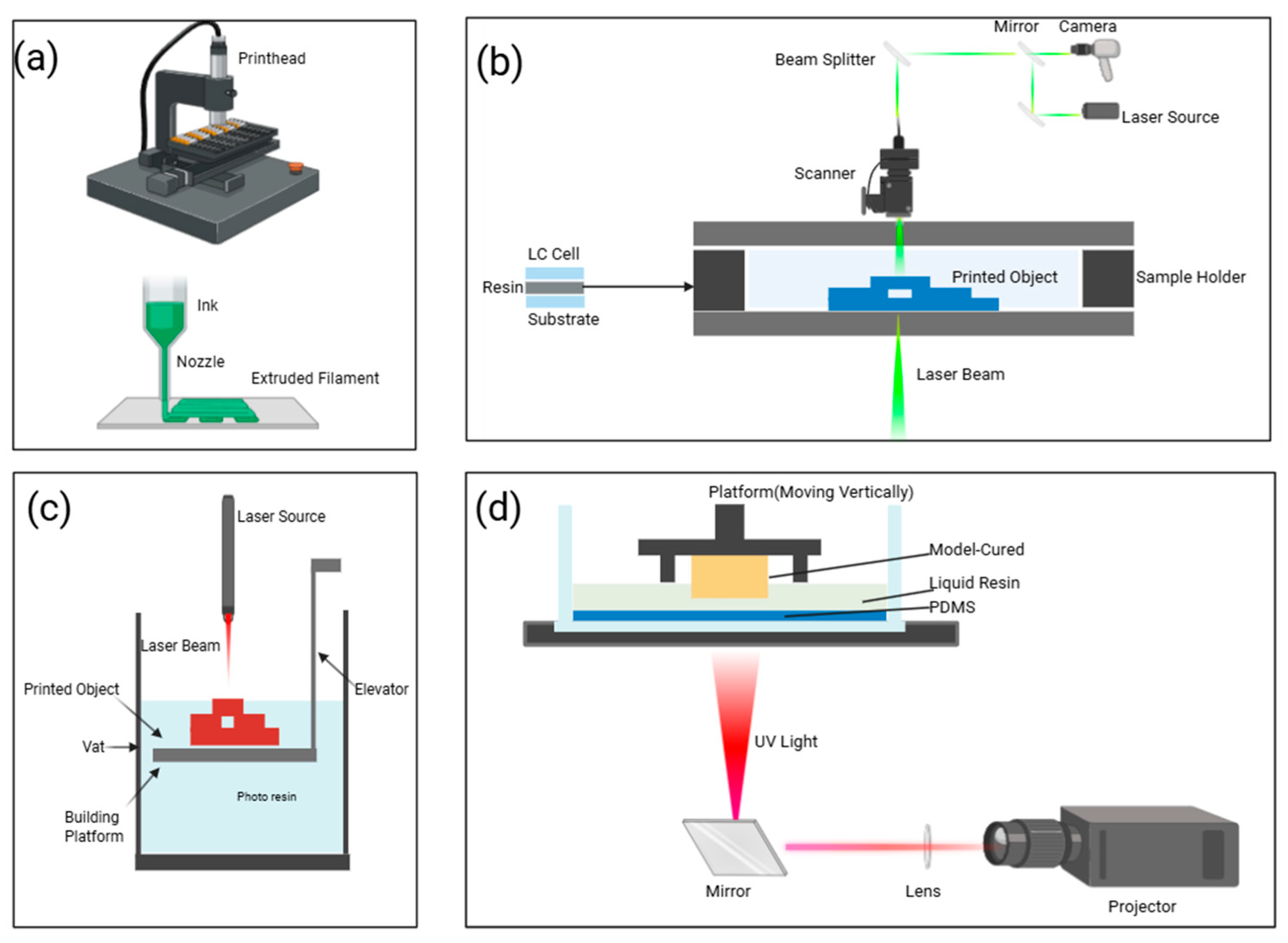

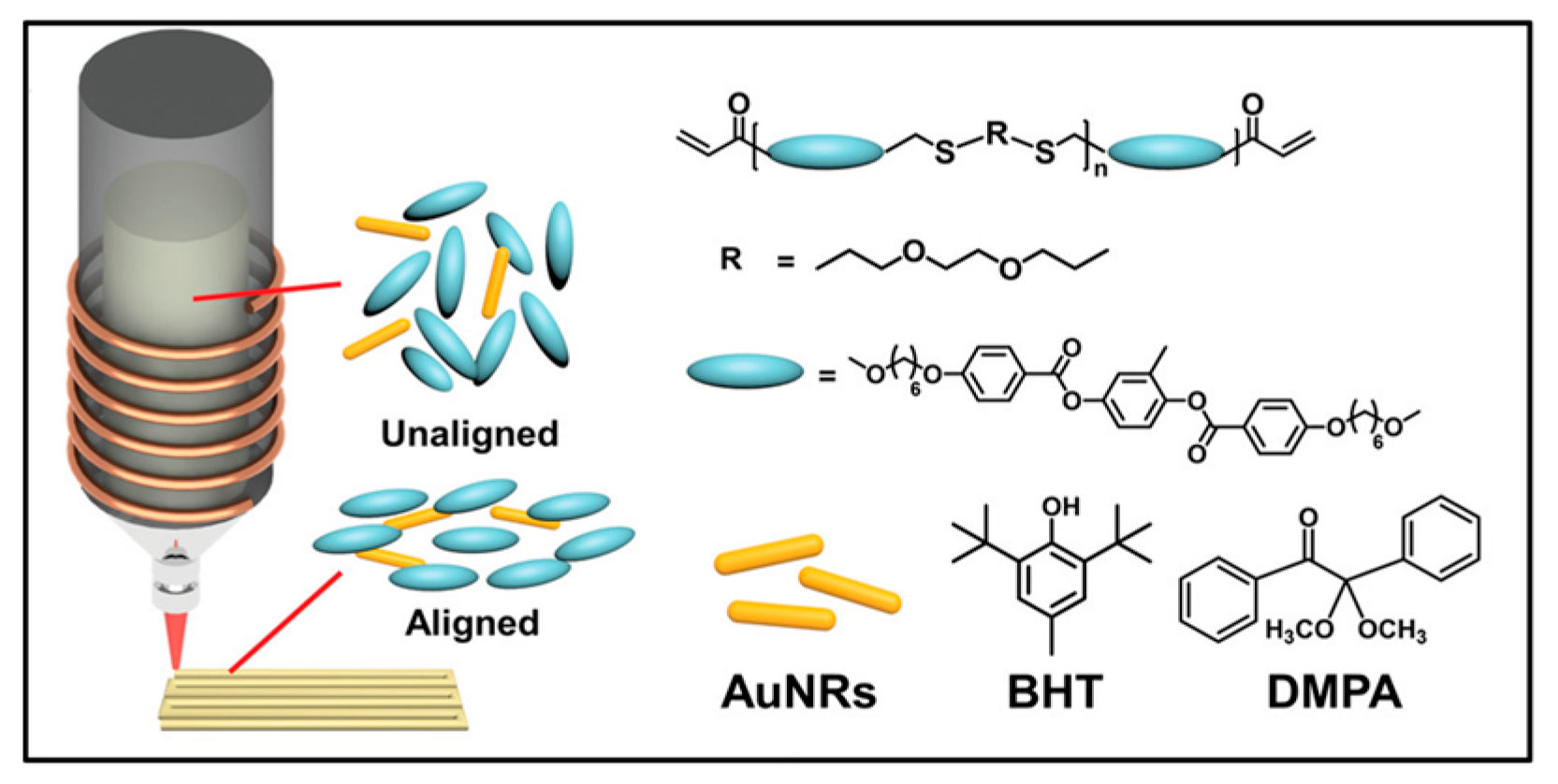

3.1. Direct Ink Writing (DIW)

3.2. Vat Photopolymerization (VP)

3.2.1. Two-Photon Polymerization (TPP)

3.2.2. Digital Light Processing (DLP)

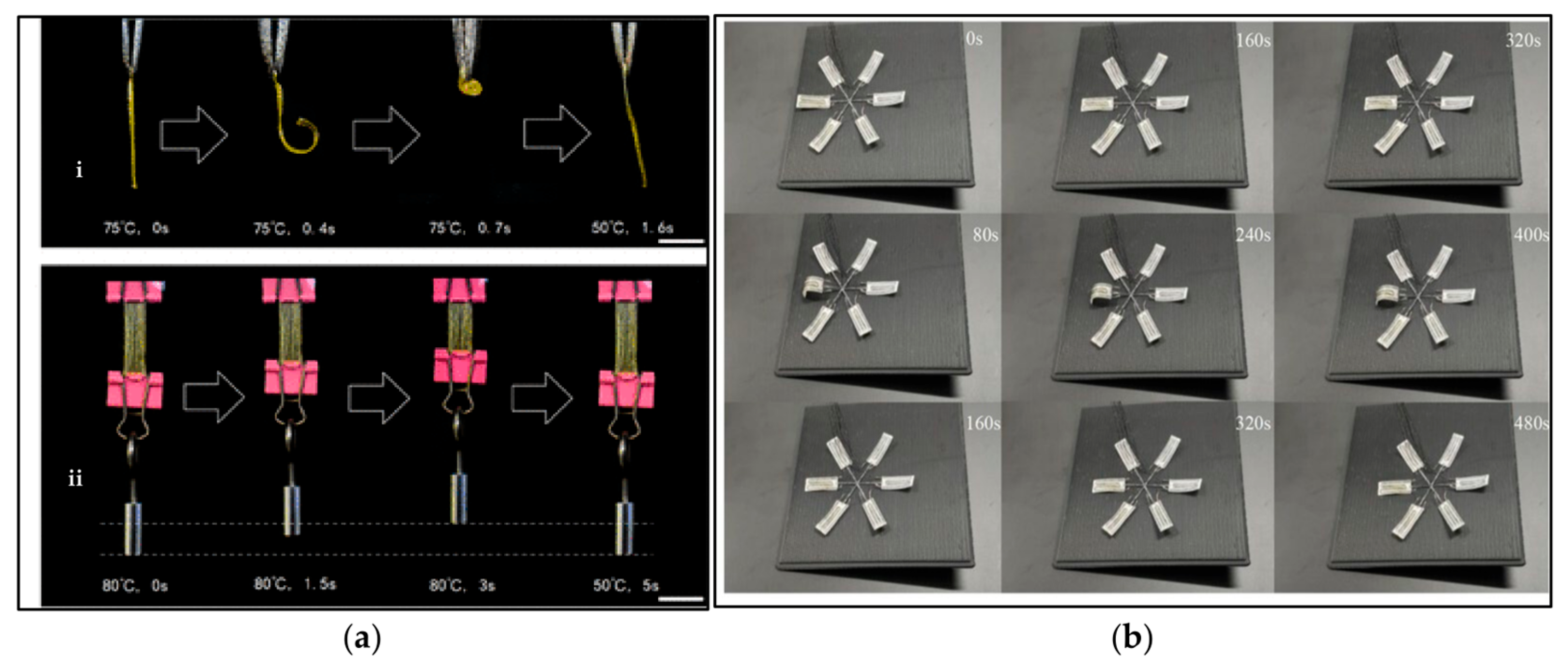

4. Application of LCE-Based Actuators in Soft Robotics

5. Applications in Biomedical Technology

5.1. Bioprinting

5.2. Implantable Devices

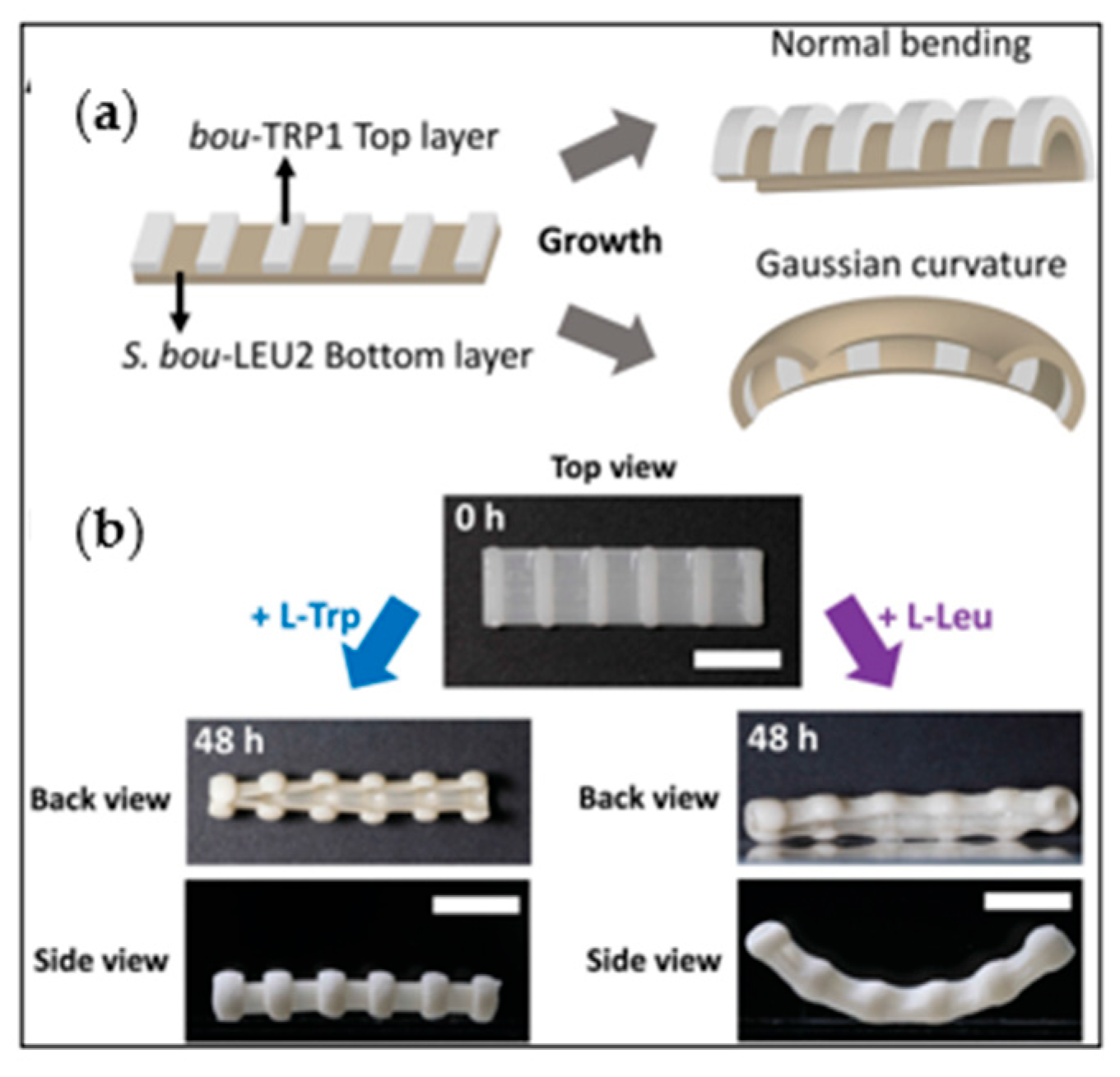

5.3. Bioresponsive and Living Systems

5.4. Wearables and Artificial Muscles

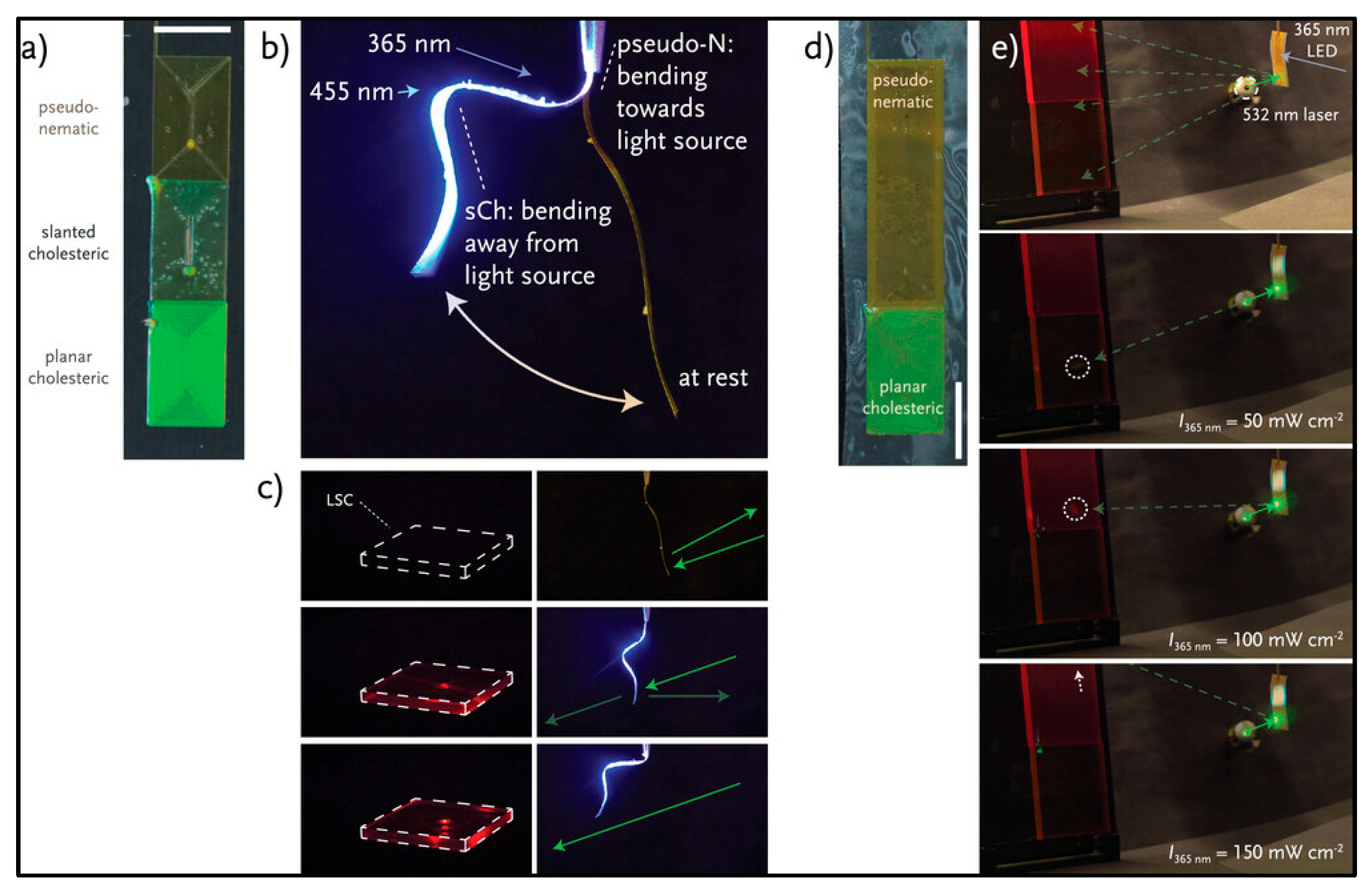

5.5. Programmable and Light-Responsive Actuators

6. Challenges and Future Perspectives

6.1. Challenges

6.1.1. Challenges for the Printing Process

6.1.2. Challenges for Soft Robotic Actuators

6.1.3. Challenges for Biomedical Applications

6.2. Future Perspectives

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| CNC | Cellulose Nanocrystals |

| Ch-LCE | Cholesteric Liquid Crystal Elastomer |

| ECM | Extracellular Matrix |

| ELM | Engineered Living Material |

| DFT | Density Functional Theory |

| DIW | Direct Ink Writing |

| DLP | Digital Light Processing |

| FEM | Finite Element Method |

| LC | Liquid Crystal |

| LCE | Liquid Crystal Elastomer |

| LCN | Liquid Crystal Network |

| NAT-LCE | Near-Ambient Temperature-Responsive Liquid Crystal Elastomer |

| PDMS | Polydimethylsiloxane |

| PEI | Polyethyleneimine |

| RM | Reactive Mesogen |

| SLA | Stereolithography |

| TPP | Two-Photon Polymerization |

| VP | Vat Photopolymerization |

References

- Thomsen, D.L.; Keller, P.; Naciri, J.; Pink, R.; Jeon, H.; Shenoy, D.; Ratna, B.R. Liquid Crystal Elastomers with Mechanical Properties of a Muscle. Macromolecules 2001, 34, 5868–5875. [Google Scholar] [CrossRef]

- Camacho-Lopez, M.; Finkelmann, H.; Palffy-Muhoray, P.; Shelley, M. Fast Liquid-Crystal Elastomer Swims into the Dark. Nat. Mater. 2004, 3, 307–310. [Google Scholar] [CrossRef]

- Warner, M.; Modes, C.D.; Corbett, D. Curvature in Nematic Elastica Responding to Light and Heat. Proc. R. Soc. Math. Phys. Eng. Sci. 2010, 466, 2975–2989. [Google Scholar] [CrossRef]

- Zang, T.; Fu, S.; Cheng, J.; Zhang, C.; Lu, X.; Hu, J.; Xia, H.; Zhao, Y. 4D Printing of Shape-Morphing Liquid Crystal Elastomers. Chem Bio Eng. 2024, 1, 488–515. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, X.; Fei, G.; Wang, Z.; Xia, H.; Zhao, Y. 4D Printing of a Liquid Crystal Elastomer with a Controllable Orientation Gradient. ACS Appl. Mater. Interfaces 2019, 11, 44774–44782. [Google Scholar] [CrossRef]

- Küpfer, J.; Finkelmann, H. Nematic Liquid Single Crystal Elastomers. Makromol. Chem. Rapid Commun. 1991, 12, 717–726. [Google Scholar] [CrossRef]

- Herbert, K.M.; Fowler, H.E.; McCracken, J.M.; Schlafmann, K.R.; Koch, J.A.; White, T.J. Synthesis and Alignment of Liquid Crystalline Elastomers. Nat. Rev. Mater. 2022, 7, 23–38. [Google Scholar] [CrossRef]

- Bodaghi, M.; Wang, L.; Zhang, F.; Liu, Y.; Leng, J.; Xing, R.; Dickey, M.D.; Vanaei, S.; Elahinia, M.; Hoa, S.V.; et al. 4D Printing Roadmap. Smart Mater. Struct. 2024, 33, 113501. [Google Scholar] [CrossRef]

- Zhao, C.; Lv, Q.; Wu, W. Application and Prospects of Hydrogel Additive Manufacturing. Gels 2022, 8, 297. [Google Scholar] [CrossRef] [PubMed]

- McDougall, L.; Herman, J.; Huntley, E.; Leguizamon, S.; Cook, A.; White, T.; Kaehr, B.; Roach, D.J. Free-Form Liquid Crystal Elastomers via Embedded 4D Printing. ACS Appl. Mater. Interfaces 2023, 15, 58897–58904. [Google Scholar] [CrossRef]

- Huang, T.-Y.; Huang, H.-W.; Jin, D.D.; Chen, Q.Y.; Huang, J.Y.; Zhang, L.; Duan, H.L. Four-Dimensional Micro-Building Blocks. Sci. Adv. 2020, 6, eaav8219. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Lu, Y.; Jiang, L.; Yu, Y. Liquid Crystal Soft Actuators and Robots toward Mixed Reality. Adv. Funct. Mater. 2021, 31, 2009835. [Google Scholar] [CrossRef]

- He, Z.; Tan, G.; Chanda, D.; Wu, S.-T. Novel Liquid Crystal Photonic Devices Enabled by Two-Photon Polymerization [Invited]. Opt. Express 2019, 27, 11472–11491. [Google Scholar] [CrossRef]

- Hasan, M.; Sakib, M.N.; Sabroj, R.B.; Rahman, M.Z. 7.03—Advanced Nanomaterial-Based Biosensors for Clinical Diagnosis, Environmental Protection and Industrial Fermentation. In Comprehensive Materials Processing, 2nd ed.; Hashmi, S., Ed.; Elsevier: Oxford, UK, 2024; pp. 30–47. ISBN 978-0-323-96021-2. [Google Scholar]

- Shiralipour, F.; Nik Akhtar, Y.; Gilmor, A.; Pegorin, G.; Valerio-Aguilar, A.; Hegmann, E. The Role of Liquid Crystal Elastomers in Pioneering Biological Applications. Crystals 2024, 14, 859. [Google Scholar] [CrossRef]

- Warner, M.; Terentjev, E.M. Liquid Crystal Elastomers; International Series of Monographs on Physics; Oxford University Press: Oxford, UK, 2003; ISBN 978-0-19-852767-1. [Google Scholar]

- de Gennes, P.-G. Un Muscle Artificiel Semi-Rapide. Comptes Rendus Académie Sci. Ser. IIB Mech. Phys. Chem. Astron. 1997, 324, 343–348. [Google Scholar] [CrossRef]

- Brannum, M.T.; Steele, A.M.; Venetos, M.C.; Korley, L.T.J.; Wnek, G.E.; White, T.J. Light Control with Liquid Crystalline Elastomers. Adv. Opt. Mater. 2019, 7, 1801683. [Google Scholar] [CrossRef]

- Ferrantini, C.; Pioner, J.M.; Martella, D.; Coppini, R.; Piroddi, N.; Paoli, P.; Calamai, M.; Pavone, F.S.; Wiersma, D.S.; Tesi, C.; et al. Development of Light-Responsive Liquid Crystalline Elastomers to Assist Cardiac Contraction. Circ. Res. 2019, 124, e44–e54. [Google Scholar] [CrossRef]

- Iseki, S. U.S. Patent Application No. 16/070555; Liquid Crystalline Elastomer Precursor and Liquid Crystalline Elastomer; The United States Patent and Trademark Office (USPTO): Alexandria, VA, USA, 2019. [Google Scholar]

- Hussain, M.; Jull, E.I.L.; Mandle, R.J.; Raistrick, T.; Hine, P.J.; Gleeson, H.F. Liquid Crystal Elastomers for Biological Applications. Nanomaterials 2021, 11, 813. [Google Scholar] [CrossRef]

- Rešetič, A. Shape Programming of Liquid Crystal Elastomers. Commun. Chem. 2024, 7, 56. [Google Scholar] [CrossRef]

- Wermter, H.; Finkelmann, H. Liquid Crystalline Elastomers as Artificial Muscles. E-Polym. 2001, 1. [Google Scholar] [CrossRef]

- Terentjev, E.M. Liquid Crystal Elastomers: 30 Years After. Macromolecules 2025, 58, 2792–2806. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Qin, H.; Mather, P.T. Review of Progress in Shape-Memory Polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape Memory Polymers as Smart Materials: A Review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef]

- Jiang, Z.-C.; Liu, Q.; Xiao, Y.-Y.; Zhao, Y. Liquid Crystal Elastomers for Actuation: A Perspective on Structure-Property-Function Relation. Prog. Polym. Sci. 2024, 153, 101829. [Google Scholar] [CrossRef]

- Li, Y.; Liu, T.; Ambrogi, V.; Rios, O.; Xia, M.; He, W.; Yang, Z. Liquid Crystalline Elastomers Based on Click Chemistry. ACS Appl. Mater. Interfaces 2022, 14, 14842–14858. [Google Scholar] [CrossRef]

- Ware, T.H.; McConney, M.E.; Wie, J.J.; Tondiglia, V.P.; White, T.J. Voxelated Liquid Crystal Elastomers. Science 2015, 347, 982–984. [Google Scholar] [CrossRef]

- Yakacki, C.M.; Saed, M.; Nair, D.P.; Gong, T.; Reed, S.M.; Bowman, C.N. Tailorable and Programmable Liquid-Crystalline Elastomers Using a Two-Stage Thiol–Acrylate Reaction. RSC Adv. 2015, 5, 18997–19001. [Google Scholar] [CrossRef]

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D Printing of Liquid Crystal Elastomeric Actuators with Spatially Programed Nematic Order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef]

- Ambulo, C.P.; Burroughs, J.J.; Boothby, J.M.; Kim, H.; Shankar, M.R.; Ware, T.H. Four-Dimensional Printing of Liquid Crystal Elastomers. ACS Appl. Mater. Interfaces 2017, 9, 37332–37339. [Google Scholar] [CrossRef]

- López-Valdeolivas, M.; Liu, D.; Broer, D.J.; Sánchez-Somolinos, C. 4D Printed Actuators with Soft-Robotic Functions. Macromol. Rapid Commun. 2018, 39, 1700710. [Google Scholar] [CrossRef]

- Kloxin, C.J.; Bowman, C.N. Covalent Adaptable Networks: Smart, Reconfigurable and Responsive Network Systems. Chem. Soc. Rev. 2013, 42, 7161–7173. [Google Scholar] [CrossRef]

- Pei, Z.; Yang, Y.; Chen, Q.; Terentjev, E.M.; Wei, Y.; Ji, Y. Mouldable Liquid-Crystalline Elastomer Actuators with Exchangeable Covalent Bonds. Nat. Mater. 2014, 13, 36–41. [Google Scholar] [CrossRef] [PubMed]

- Saed, M.O.; Gablier, A.; Terentejv, E.M. Liquid Crystalline Vitrimers with Full or Partial Boronic-Ester Bond Exchange. Adv. Funct. Mater. 2020, 30, 1906458. [Google Scholar] [CrossRef]

- Saed, M.O.; Gablier, A.; Terentjev, E.M. Exchangeable Liquid Crystalline Elastomers and Their Applications. Chem. Rev. 2022, 122, 4927–4945. [Google Scholar] [CrossRef] [PubMed]

- Barnes, M.; Verduzco, R. Direct Shape Programming of Liquid Crystal Elastomers. Soft Matter 2019, 15, 870–879. [Google Scholar] [CrossRef] [PubMed]

- Harris, K.D.; Cuypers, R.; Scheibe, P.; van Oosten, C.L.; Bastiaansen, C.W.M.; Lub, J.; Broer, D.J. Large Amplitude Light-Induced Motion in High Elastic Modulus Polymer Actuators. J. Mater. Chem. 2005, 15, 5043–5048. [Google Scholar] [CrossRef]

- Ni, B.; Liu, G.; Zhang, M.; Tatoulian, M.; Keller, P.; Li, M.-H. Customizable Sophisticated Three-Dimensional Shape Changes of Large-Size Liquid Crystal Elastomer Actuators. ACS Appl. Mater. Interfaces 2021, 13, 54439–54446. [Google Scholar] [CrossRef]

- Tabrizi, M.; Ware, T.H.; Shankar, M.R. Voxelated Molecular Patterning in Three-Dimensional Freeforms. ACS Appl. Mater. Interfaces 2019, 11, 28236–28245. [Google Scholar] [CrossRef]

- Münchinger, A.; Hahn, V.; Beutel, D.; Woska, S.; Monti, J.; Rockstuhl, C.; Blasco, E.; Wegener, M. Multi-Photon 4D Printing of Complex Liquid Crystalline Microstructures by In Situ Alignment Using Electric Fields. Adv. Mater. Technol. 2022, 7, 2100944. [Google Scholar] [CrossRef]

- Yang, G.-Z.; Full, R.J.; Jacobstein, N.; Fischer, P.; Bellingham, J.; Choset, H.; Christensen, H.; Dario, P.; Nelson, B.J.; Taylor, R. Ten Robotics Technologies of the Year. Sci. Robot. 2019, 4, eaaw1826. [Google Scholar] [CrossRef]

- Tan, L.J.; Zhu, W.; Zhou, K. Recent Progress on Polymer Materials for Additive Manufacturing. Adv. Funct. Mater. 2020, 30, 2003062. [Google Scholar] [CrossRef]

- Chen, M.; Gao, M.; Bai, L.; Zheng, H.; Qi, H.J.; Zhou, K. Recent Advances in 4D Printing of Liquid Crystal Elastomers. Adv. Mater. 2023, 35, 2209566. [Google Scholar] [CrossRef] [PubMed]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef]

- Ohm, C.; Serra, C.; Zentel, R. A Continuous Flow Synthesis of Micrometer-Sized Actuators from Liquid Crystalline Elastomers. Adv. Mater. 2009, 21, 4859–4862. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Z.; Zheng, Y.; He, Q.; Wang, Y.; Cai, S. Three-Dimensional Printing of Functionally Graded Liquid Crystal Elastomer. Sci. Adv. 2020, 6, eabc0034. [Google Scholar] [CrossRef]

- Ren, L.; Li, B.; He, Y.; Song, Z.; Zhou, X.; Liu, Q.; Ren, L. Programming Shape-Morphing Behavior of Liquid Crystal Elastomers via Parameter-Encoded 4D Printing. ACS Appl. Mater. Interfaces 2020, 12, 15562–15572. [Google Scholar] [CrossRef] [PubMed]

- del Pozo Puig, M.; Sol, J.A.H.P.; van Uden, S.H.P.; Peeketi, A.R.; Lugger, S.J.D.; Annabattula, R.K.; Schenning, A.P.H.J.; Debije, M.G. Patterned Actuators via Direct Ink Writing of Liquid Crystals. ACS Appl. Mater. Interfaces 2021, 13, 59381–59391. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Gao, Y.; Wang, H.; Poling-Skutvik, R.; Osuji, C.O.; Yang, S. Shaping and Locomotion of Soft Robots Using Filament Actuators Made from Liquid Crystal Elastomer–Carbon Nanotube Composites. Adv. Intell. Syst. 2020, 2, 1900163. [Google Scholar] [CrossRef]

- del Pozo, M.; Sol, J.A.H.P.; Schenning, A.P.H.J.; Debije, M.G. 4D Printing of Liquid Crystals: What’s Right for Me? Adv. Mater. 2022, 34, 2104390. [Google Scholar] [CrossRef]

- Gantenbein, S.; Masania, K.; Woigk, W.; Sesseg, J.P.W.; Tervoort, T.A.; Studart, A.R. Three-Dimensional Printing of Hierarchical Liquid-Crystal-Polymer Structures. Nature 2018, 561, 226–230. [Google Scholar] [CrossRef]

- Naciri, J.; Srinivasan, A.; Jeon, H.; Nikolov, N.; Keller, P.; Ratna, B.R. Nematic Elastomer Fiber Actuator. Macromolecules 2003, 36, 8499–8505. [Google Scholar] [CrossRef]

- Controlled Microstructural Architectures Based on Smart Fabrication Strategies - Ding - 2020 - Advanced Functional Materials - Wiley Online Library. Available online: https://advanced-onlinelibrary-wiley-com.ezproxy.lib.ou.edu/doi/full/10.1002/adfm.201901760 (accessed on 4 September 2025).

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- The Recent Development of Vat Photopolymerization: A Review|Request PDF. Available online: https://www.researchgate.net/publication/355727288_The_recent_development_of_vat_photopolymerization_A_review (accessed on 4 September 2025).

- Multimaterial Vat Polymerization Additive Manufacturing. Available online: https://colab.ws/articles/10.1021%2Facsapm.1c00262 (accessed on 4 September 2025).

- Broer, D.J. On the History of Reactive Mesogens: Interview with Dirk J. Broer. Adv. Mater. 2020, 32, 1905144. [Google Scholar] [CrossRef]

- Saha, S.K.; Wang, D.; Nguyen, V.H.; Chang, Y.; Oakdale, J.S.; Chen, S.-C. Scalable Submicrometer Additive Manufacturing. Science 2019, 366, 105–109. [Google Scholar] [CrossRef]

- Ge, Q.; Chen, Z.; Cheng, J.; Zhang, B.; Zhang, Y.-F.; Li, H.; He, X.; Yuan, C.; Liu, J.; Magdassi, S.; et al. 3D Printing of Highly Stretchable Hydrogel with Diverse UV Curable Polymers. Sci. Adv. 2021, 7, eaba4261. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Schimelman, J.; Wang, P.; Miller, K.L.; Ma, X.; You, S.; Guan, J.; Sun, B.; Zhu, W.; Chen, S. Photopolymerizable Biomaterials and Light-Based 3D Printing Strategies for Biomedical Applications. Chem. Rev. 2020, 120, 10695–10743. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Ye, H.; Duan, G.; Duan, H.; Ge, Q.; Wang, Z. Color-Changeable Four-Dimensional Printing Enabled with Ultraviolet-Curable and Thermochromic Shape Memory Polymers. ACS Appl. Mater. Interfaces 2021, 13, 18120–18127. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Cerretti, G.; Martella, D.; Parmeggiani, C.; Wiersma, D.S. Alignment Engineering in Liquid Crystalline Elastomers: Free-Form Microstructures with Multiple Functionalities. Appl. Phys. Lett. 2015, 106, 111902. [Google Scholar] [CrossRef]

- Lin, J.-D.; Daniel Ho, Y.-L.; Chen, L.; Lopez-Garcia, M.; Jiang, S.-A.; Taverne, M.P.C.; Lee, C.-R.; Rarity, J.G. Microstructure-Stabilized Blue Phase Liquid Crystals. ACS Omega 2018, 3, 15435–15441. [Google Scholar] [CrossRef]

- He, Z.; Lee, Y.-H.; Chen, R.; Chanda, D.; Wu, S.-T. Switchable Pancharatnam–Berry Microlens Array with Nano-Imprinted Liquid Crystal Alignment. Opt. Lett. 2018, 43, 5062–5065. [Google Scholar] [CrossRef]

- Serra, F.; Eaton, S.M.; Cerbino, R.; Buscaglia, M.; Cerullo, G.; Osellame, R.; Bellini, T. Nematic Liquid Crystals Embedded in Cubic Microlattices: Memory Effects and Bistable Pixels. Adv. Funct. Mater. 2013, 23, 3990–3994. [Google Scholar] [CrossRef]

- Sungur, E.; Li, M.-H.; Taupier, G.; Boeglin, A.; Romeo, M.; Méry, S.; Keller, P.; Dorkenoo, K.D. External Stimulus Driven Variable-Step Grating in a Nematic Elastomer. Opt. Express 2007, 15, 6784–6789. [Google Scholar] [CrossRef] [PubMed]

- McCracken, J.M.; Tondiglia, V.P.; Auguste, A.D.; Godman, N.P.; Donovan, B.R.; Bagnall, B.N.; Fowler, H.E.; Baxter, C.M.; Matavulj, V.; Berrigan, J.D.; et al. Microstructured Photopolymerization of Liquid Crystalline Elastomers in Oxygen-Rich Environments. Adv. Funct. Mater. 2019, 29, 1903761. [Google Scholar] [CrossRef]

- Li, S.; Bai, H.; Liu, Z.; Zhang, X.; Huang, C.; Wiesner, L.W.; Silberstein, M.; Shepherd, R.F. Digital Light Processing of Liquid Crystal Elastomers for Self-Sensing Artificial Muscles. Sci. Adv. 2021, 7, eabg3677. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Jin, B.; Shi, Y.; Zhao, Q.; Shen, Y.; Xie, T. Rapidly and Repeatedly Reprogrammable Liquid Crystalline Elastomer via a Shape Memory Mechanism. Adv. Mater. 2022, 34, 2201679. [Google Scholar] [CrossRef]

- Yuan, C.; Roach, D.J.; Dunn, C.K.; Mu, Q.; Kuang, X.; Yakacki, C.M.; Wang, T.J.; Yu, K.; Qi, H.J. 3D Printed Reversible Shape Changing Soft Actuators Assisted by Liquid Crystal Elastomers. Soft Matter 2017, 13, 5558–5568. [Google Scholar] [CrossRef]

- Zhang, D.; Tian, X.; Zhou, Y.; Li, D. 4D-Printed Fiber-Reinforced Liquid Crystal Elastomer Composites for Multifunctional Soft Robots with Self-Heating Actuation. Virtual Phys. Prototyp. 2025, 20, e2499927. [Google Scholar] [CrossRef]

- Luo, C.; Chung, C.; Traugutt, N.A.; Yakacki, C.M.; Long, K.N.; Yu, K. 3D Printing of Liquid Crystal Elastomer Foams for Enhanced Energy Dissipation Under Mechanical Insult. ACS Appl. Mater. Interfaces 2020, 13. [Google Scholar] [CrossRef]

- Kotikian, A.; Morales, J.M.; Lu, A.; Mueller, J.; Davidson, Z.S.; Boley, J.W.; Lewis, J.A. Innervated, Self-Sensing Liquid Crystal Elastomer Actuators with Closed Loop Control. Adv. Mater. 2021, 33, 2101814. [Google Scholar] [CrossRef]

- Song, X.; Zhang, W.; Liu, H.; Zhao, L.; Chen, Q.; Tian, H. 3D Printing of Liquid Crystal Elastomers-Based Actuator for an Inchworm-Inspired Crawling Soft Robot. Front. Robot. AI 2022, 9. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yin, R.; Jin, L.; Liu, M.; Gao, Y.; Raney, J.; Yang, S. 3D-Printed Photoresponsive Liquid Crystal Elastomer Composites for Free-Form Actuation. Adv. Funct. Mater. 2023, 33, 2210614. [Google Scholar] [CrossRef]

- Pluralizing Actuation Behavior of 3D Printable Liquid Crystal Elastomers via Polymerization Sequence Control|Science Advances. Available online: https://www.science.org/doi/10.1126/sciadv.adp4814 (accessed on 9 September 2025).

- Vinciguerra, M.R.; Patel, D.K.; Zu, W.; Tavakoli, M.; Majidi, C.; Yao, L. Multimaterial Printing of Liquid Crystal Elastomers with Integrated Stretchable Electronics. ACS Appl. Mater. Interfaces 2023, 15, 24777–24787. [Google Scholar] [CrossRef]

- Sgotti Veiga, J.; Reis Carneiro, M.; Molter, R.; Vinciguerra, M.; Yao, L.; Majidi, C.; Tavakoli, M. Toward Fully Printed Soft Actuators: UV-Assisted Printing of Liquid Crystal Elastomers and Biphasic Liquid Metal Conductors. Adv. Mater. Technol. 2023, 8, 2300144. [Google Scholar] [CrossRef]

- Kotikian, A.; Watkins, A.A.; Bordiga, G.; Spielberg, A.; Davidson, Z.S.; Bertoldi, K.; Lewis, J.A. Liquid Crystal Elastomer Lattices with Thermally Programmable Deformation via Multi-Material 3D Printing. Adv. Mater. 2024, 36, 2310743. [Google Scholar] [CrossRef]

- Jiang, H.; Chung, C.; Dunn, M.L.; Yu, K. 4D Printing of Liquid Crystal Elastomer Composites with Continuous Fiber Reinforcement. Nat. Commun. 2024, 15, 8491. [Google Scholar] [CrossRef]

- Xia, Y.; Mu, T.; Guo, J.; Liu, Y.; Leng, J. Multifunctional Untethered Soft Machines Driven by 4D Printed Electrically Responsive Actuators. ACS Appl. Mater. Interfaces 2025, 17, 36059–36068. [Google Scholar] [CrossRef]

- Yuan, L.-X.; Liu, C.-Y.; Yang, J.-P.; Wang, Z.-J. Soft Crawling and Flipping Robots Based on Liquid Metal-Liquid Crystal Elastomer Composites. Chin. J. Polym. Sci. 2025, 43, 588–596. [Google Scholar] [CrossRef]

- Herman, J.A.; Telles, R.; Cook, C.C.; Leguizamon, S.C.; Lewis, J.A.; Kaehr, B.; White, T.J.; Roach, D.J. Digital Light Process 3D Printing of Magnetically Aligned Liquid Crystalline Elastomer Free–Forms. Adv. Mater. 2024, 36, 2414209. [Google Scholar] [CrossRef] [PubMed]

- Gungor-Ozkerim, P.S.; Inci, I.; Zhang, Y.S.; Khademhosseini, A.; Dokmeci, M.R. Bioinks for 3D Bioprinting: An Overview. Biomater. Sci. 2018, 6, 915–946. [Google Scholar] [CrossRef]

- Groll, J.; Boland, T.; Blunk, T.; Burdick, J.A.; Cho, D.-W.; Dalton, P.D.; Derby, B.; Forgacs, G.; Li, Q.; Mironov, V.A.; et al. Biofabrication: Reappraising the Definition of an Evolving Field. Biofabrication 2016, 8, 013001. [Google Scholar] [CrossRef]

- Murphy, S.V.; Atala, A. 3D Bioprinting of Tissues and Organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Yue, K.; Aleman, J.; Moghaddam, K.M.; Bakht, S.M.; Yang, J.; Jia, W.; Dell’Erba, V.; Assawes, P.; Shin, S.R.; et al. 3D Bioprinting for Tissue and Organ Fabrication. Ann. Biomed. Eng. 2017, 45, 148–163. [Google Scholar] [CrossRef] [PubMed]

- Ustunel, S.; Sternbach, S.; Prévôt, M.E.; Freeman, E.J.; McDonough, J.A.; Clements, R.J.; Hegmann, E. 3D Co-Culturing of Human Neuroblastoma and Human Oligodendrocytes, Emulating Native Tissue Using 3D Porous Biodegradable Liquid Crystal Elastomers. J. Appl. Polym. Sci. 2023, 140, e53883. [Google Scholar] [CrossRef]

- Saed, M.O.; Ambulo, C.P.; Kim, H.; De, R.; Raval, V.; Searles, K.; Siddiqui, D.A.; Cue, J.M.O.; Stefan, M.C.; Shankar, M.R.; et al. Molecularly-Engineered, 4D-Printed Liquid Crystal Elastomer Actuators. Adv. Funct. Mater. 2019, 29, 1806412. [Google Scholar] [CrossRef]

- Davidson, E.C.; Kotikian, A.; Li, S.; Aizenberg, J.; Lewis, J.A. 3D Printable and Reconfigurable Liquid Crystal Elastomers with Light-Induced Shape Memory via Dynamic Bond Exchange. Adv. Mater. 2020, 32, 1905682. [Google Scholar] [CrossRef]

- Volpe, R.H.; Mistry, D.; Patel, V.V.; Patel, R.R.; Yakacki, C.M. Dynamically Crystalizing Liquid-Crystal Elastomers for an Expandable Endplate-Conforming Interbody Fusion Cage. Adv. Healthc. Mater. 2020, 9, 1901136. [Google Scholar] [CrossRef]

- Rivera-Tarazona, L.K.; Shukla, T.; Singh, K.A.; Gaharwar, A.K.; Campbell, Z.T.; Ware, T.H. 4D Printing of Engineered Living Materials. Adv. Funct. Mater. 2022, 32, 2106843. [Google Scholar] [CrossRef]

- Sydney Gladman, A.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D Printing. Nat. Mater. 2016, 15, 413–418. [Google Scholar] [CrossRef]

- Li, D.X.; Yan, Y.D.; Oh, D.H.; Yang, K.Y.; Seo, Y.G.; Kim, J.O.; Kim, Y.-I.; Yong, C.S.; Choi, H.-G. Development of Valsartan-Loaded Gelatin Microcapsule without Crystal Change Using Hydroxypropylmethylcellulose as a Stabilizer. Drug Deliv. 2010, 17, 322–329. [Google Scholar] [CrossRef]

- Dai, L.; Wang, L.; Chen, B.; Xu, Z.; Wang, Z.; Xiao, R. Shape Memory Behaviors of 3D Printed Liquid Crystal Elastomers. Soft Sci. 2023, 3, 5. [Google Scholar] [CrossRef]

- Li, D.; Sun, Y.; Li, X.; Li, X.; Zhu, Z.; Sun, B.; Nong, S.; Wu, J.; Pan, T.; Li, W.; et al. 3D Printing of Near-Ambient Responsive Liquid Crystal Elastomers with Enhanced Nematic Order and Pluralized Transformation. ACS Nano 2025, 19, 7075–7087. [Google Scholar] [CrossRef]

- He, Z.; Jiang, S.; Wang, J.; Attia, N.F.; Kang, D.; Zhou, G.; Xiao, S. Sweat Gland-Inspired Skin Soft Actuators of the Liquid Crystal Elastomer Enabled by 3D Printing. Chem. Eng. J. 2025, 506, 160261. [Google Scholar] [CrossRef]

- Hou, W.; Wang, J.; Lv, J. Bioinspired Liquid Crystalline Spinning Enables Scalable Fabrication of High-Performing Fibrous Artificial Muscles. Adv. Mater. 2023, 35, 2211800. [Google Scholar] [CrossRef]

- Roach, D.J.; Yuan, C.; Kuang, X.; Li, V.C.-F.; Blake, P.; Romero, M.L.; Hammel, I.; Yu, K.; Qi, H.J. Long Liquid Crystal Elastomer Fibers with Large Reversible Actuation Strains for Smart Textiles and Artificial Muscles. ACS Appl. Mater. Interfaces 2019, 11, 19514–19521. [Google Scholar] [CrossRef]

- Sol, J.A.H.P.; Douma, R.F.; Schenning, A.P.H.J.; Debije, M.G. 4D Printed Light-Responsive Patterned Liquid Crystal Elastomer Actuators Using a Single Structural Color Ink. Adv. Mater. Technol. 2023, 8, 2200970. [Google Scholar] [CrossRef]

- Prévôt, M.E.; Ustunel, S.; Freychet, G.; Webb, C.R.; Zhernenkov, M.; Pindak, R.; Clements, R.J.; Hegmann, E. Physical Models from Physical Templates Using Biocompatible Liquid Crystal Elastomers as Morphologically Programmable Inks For 3D Printing. Macromol. Biosci. 2023, 23, 2200343. [Google Scholar] [CrossRef]

- Lugger, S.J.D.; Verbroekken, R.M.C.; Mulder, D.J.; Schenning, A.P.H.J. Direct Ink Writing of Recyclable Supramolecular Soft Actuators. ACS Macro Letters 2022, 11, 935–940. [Google Scholar] [CrossRef]

- Sun, D.; Zhang, J.; Li, H.; Shi, Z.; Meng, Q.; Liu, S.; Chen, J.; Liu, X. Toward Application of Liquid Crystalline Elastomer for Smart Robotics: State of the Art and Challenges. Polymers 2021, 13, 1889. [Google Scholar] [CrossRef]

- Li, S.; Song, Z.; Fan, Y.; Wei, D.; Liu, Y. Four-Dimensional Printing of Temperature-Responsive Liquid Crystal Elastomers with Programmable Shape-Changing Behavior. Biomimetics 2023, 8, 196. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, Y.; Cai, S.; Yang, J. Liquid Crystal Elastomers for Soft Actuators. Mater. Lab 2022, 1, 220030–220034. [Google Scholar] [CrossRef]

- Warner, M. Topographic Mechanics and Applications of Liquid Crystalline Solids. Annu. Rev. Condens. Matter Phys. 2020, 11, 125–145. [Google Scholar] [CrossRef]

- Bischoff, A.; Bawcutt, C.; Sorkin, M.; Yazzie, J.; Cook, C.; Leguizamon, S.C.; Cook, A.W.; Roach, D.J. Monodomain Liquid-Crystal Elastomer Lattices for Broad Strain-Rate Mechanical Damping. Adv. Eng. Mater. 2025, 27, 2401796. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Zhao, Y.; Ye, F.; Shang, L. Liquid Crystal Materials for Biomedical Applications. Adv. Mater. 2023, 35, 2300220. [Google Scholar] [CrossRef] [PubMed]

- Barnes, M.; Cetinkaya, S.; Ajnsztajn, A.; Verduzco, R. Understanding the Effect of Liquid Crystal Content on the Phase Behavior and Mechanical Properties of Liquid Crystal Elastomers. Soft Matter 2022, 18, 5074–5081. [Google Scholar] [CrossRef]

- Ustunel, S.; Pandya, H.; Prévôt, M.E.; Pegorin, G.; Shiralipour, F.; Paul, R.; Clements, R.J.; Khabaz, F.; Hegmann, E. A Molecular Rheology Dynamics Study on 3D Printing of Liquid Crystal Elastomers. Macromol. Rapid Commun. 2024, 45, 2300717. [Google Scholar] [CrossRef]

- Ambulo, C.P.; Tasmim, S.; Wang, S.; Abdelrahman, M.K.; Zimmern, P.E.; Ware, T.H. Processing Advances in Liquid Crystal Elastomers Provide a Path to Biomedical Applications. J. Appl. Phys. 2020, 128, 140901. [Google Scholar] [CrossRef]

- Peng, X.; Wu, S.; Sun, X.; Yue, L.; Montgomery, S.M.; Demoly, F.; Zhou, K.; Zhao, R.R.; Qi, H.J. 4D Printing of Freestanding Liquid Crystal Elastomers via Hybrid Additive Manufacturing. Adv. Mater. 2022, 34. [Google Scholar] [CrossRef]

- Razib, R.; Hasan, M.; Bhuiyan, S.A.; Kader, M.S. Numerical analysis of steady laminar flow by finite volume method in connection with simple algorithm 2023. In Proceedings of the 13th International Conference on Marine Technology (MARTEC 2022), Skudai, Malazia, 21–22 December 2022. [Google Scholar]

- Guo, S.; Cui, H.; Agarwal, T.; Zhang, L.G. Nanomaterials in 4D Printing: Expanding the Frontiers of Advanced Manufacturing. Small 2024, 20, 2307750. [Google Scholar] [CrossRef] [PubMed]

| Country/Territory | Number of Publications | Most Contributing Affiliations | Number of Publications |

|---|---|---|---|

| China | 507 | Ministry of Education of the People’s Republic of China | 77 |

| United States | 211 | Georgia Institute of Technology | 40 |

| United Kingdom | 132 | Nottingham Trent University | 59 |

| India | 87 | National Institute of Technical Teachers Training & Research | 11 |

| Singapore | 67 | Nanyang Technological University | 39 |

| Germany | 61 | Universität Heidelberg | 11 |

| France | 60 | CNRS Centre National de la Recherche Scientifique | 28 |

| Iran | 59 | University of Tehran | 34 |

| South Korea | 57 | Seoul National University | 14 |

| Australia | 52 | Deakin University | 26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, M.; Liu, Y. 4D-Printed Liquid Crystal Elastomers: Printing Strategies, Actuation Mechanisms, and Emerging Applications. J. Compos. Sci. 2025, 9, 633. https://doi.org/10.3390/jcs9110633

Hasan M, Liu Y. 4D-Printed Liquid Crystal Elastomers: Printing Strategies, Actuation Mechanisms, and Emerging Applications. Journal of Composites Science. 2025; 9(11):633. https://doi.org/10.3390/jcs9110633

Chicago/Turabian StyleHasan, Mehrab, and Yingtao Liu. 2025. "4D-Printed Liquid Crystal Elastomers: Printing Strategies, Actuation Mechanisms, and Emerging Applications" Journal of Composites Science 9, no. 11: 633. https://doi.org/10.3390/jcs9110633

APA StyleHasan, M., & Liu, Y. (2025). 4D-Printed Liquid Crystal Elastomers: Printing Strategies, Actuation Mechanisms, and Emerging Applications. Journal of Composites Science, 9(11), 633. https://doi.org/10.3390/jcs9110633