Multi-Material Fused Filament Fabrication of TPU Composite Honeycombs Featuring Out-of-Plane Gradient Stiffness

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Gradient Stiffness Honeycomb Structures

2.3. Manufacturing of the Samples

2.4. Tensile and Compressions Tests

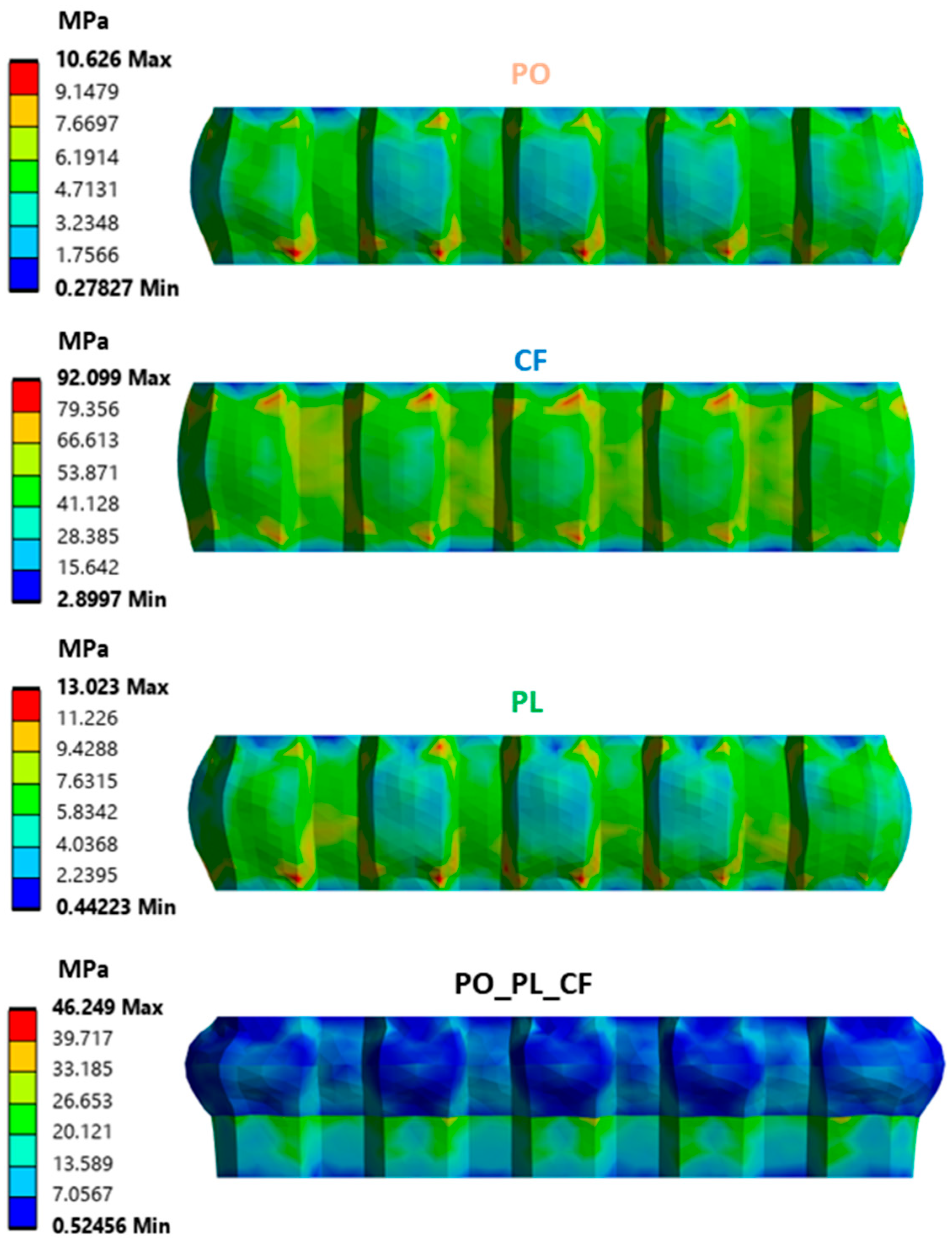

2.5. Finite Element Analysis

3. Results

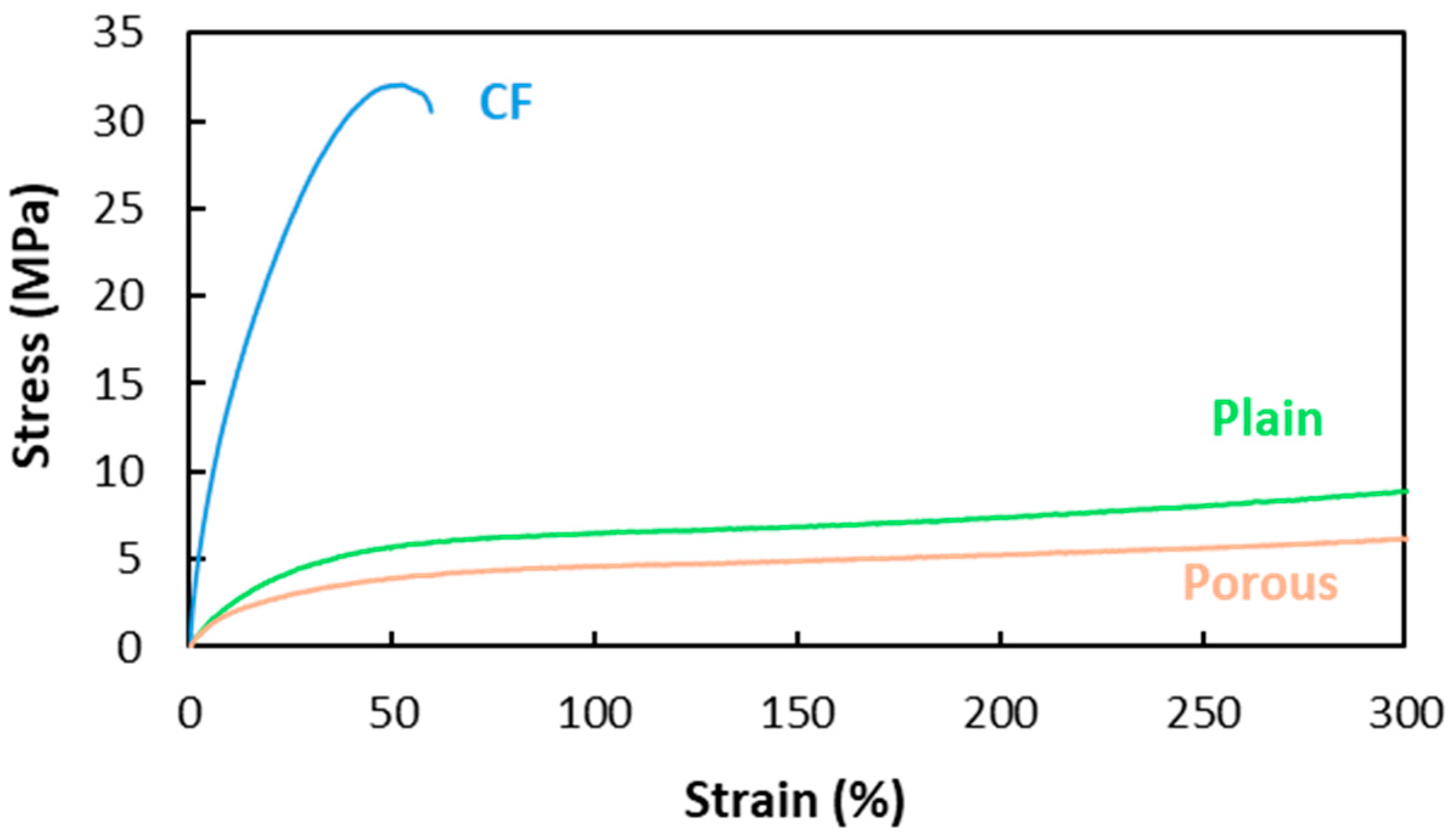

3.1. Materials Investigation

3.2. Single-Zone Honeycomb Investigation

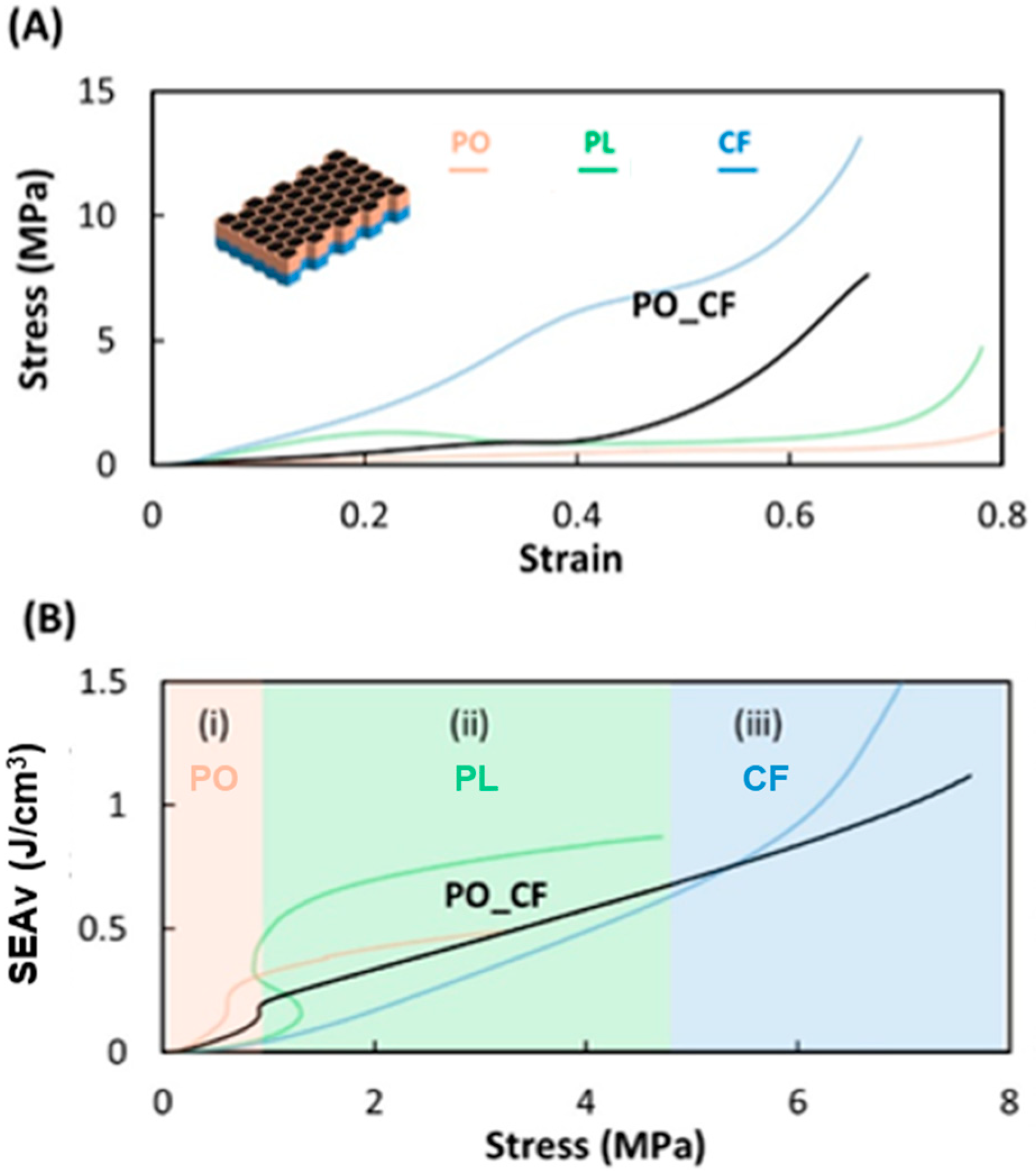

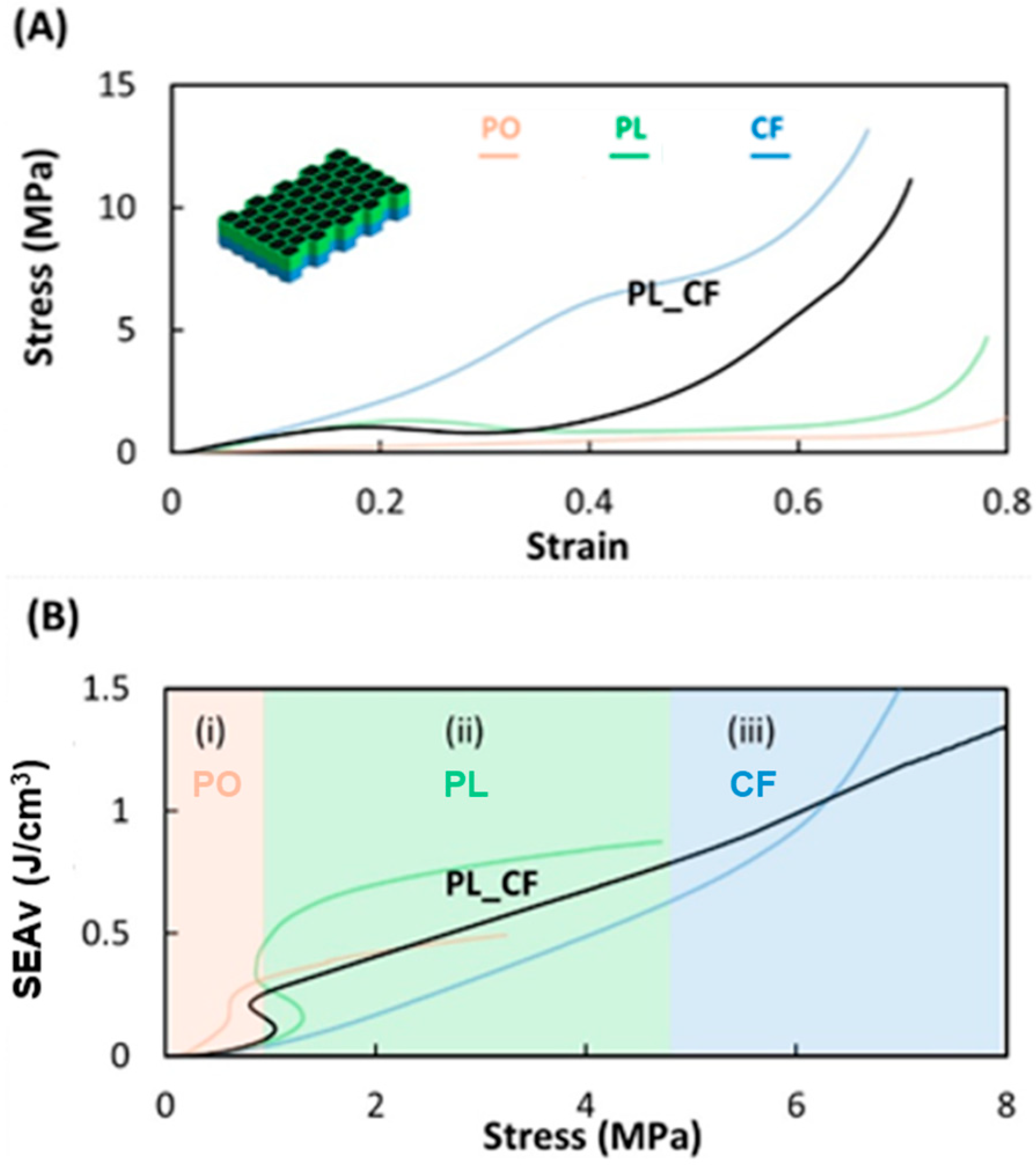

3.3. Dual-Zone Honeycomb Investigation

3.4. Three-Zone Honeycomb Investigation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, G.; Chen, D.; Zhu, G.; Li, Q. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook. Thin-Walled Struct. 2022, 172, 108760. [Google Scholar] [CrossRef]

- El-Baky, M.A.A.; Allah, M.M.A.; Kamel, M.; Abd-Elaziem, W. Lightweight cost-effective hybrid materials for energy absorption applications. Sci. Rep. 2022, 12, 21101. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Srivastawa, K.; Jana, S.; Dixit, C.; Ravichandran, S. Advancements in lightweight materials for aerospace structures: A comprehensive review. Acceleron Aerosp. J. 2024, 2, 173–183. [Google Scholar] [CrossRef]

- Guo, H.; Zhou, X.; Liu, Z. Advanced lightweight structural materials for automobiles: Properties, manipulation, and perspective. Sci. Adv. Mater. 2024, 16, 563–580. [Google Scholar] [CrossRef]

- Hassan, H.Z.; Saeed, N.M. Advancements and applications of lightweight structures: A comprehensive review. Discov. Civ. Eng. 2024, 1, 47. [Google Scholar] [CrossRef]

- Braga, D.F.; Tavares, S.M.O.; da Silva, L.F.; Moreira, P.M.G.P.; de Castro, P.M. Advanced design for lightweight structures: Review and prospects. Prog. Aerosp. Sci. 2014, 69, 29–39. [Google Scholar] [CrossRef]

- Thomas, T.; Tiwari, G. Crushing behavior of honeycomb structure: A review. Int. J. Crashworthiness 2019, 24, 555–579. [Google Scholar] [CrossRef]

- Chandrasekaran, N.K.; Arunachalam, V. State-of-the-art review on honeycomb sandwich composite structures with an emphasis on filler materials. Polym. Compos. 2021, 42, 5011–5020. [Google Scholar] [CrossRef]

- Anni, I.A.; Uddin, K.Z.; Pagliocca, N.; Singh, N.; Rahman, O.; Youssef, G.; Koohbor, B. Out-of-plane load-bearing and mechanical energy absorption properties of flexible density-graded TPU honeycombs. Compos. Part C Open Access 2022, 8, 100284. [Google Scholar] [CrossRef]

- Townsend, S.; Adams, R.; Robinson, M.; Hanna, B.; Theobald, P. 3D printed origami honeycombs with tailored out-of-plane energy absorption behavior. Mater. Des. 2020, 195, 108930. [Google Scholar] [CrossRef]

- Mohammadi, H.; Ahmad, Z.; Petrů, M.; Mazlan, S.A.; Johari, M.A.F.; Hatami, H.; Koloor, S.S.R. An insight from nature: Honeycomb pattern in advanced structural design for impact energy absorption. J. Mater. Res. Technol. 2023, 22, 2862–2887. [Google Scholar] [CrossRef]

- Dong, Y.; He, J.; Wang, D.; Luo, D.; Zeng, Y.; Feng, H.; You, X.; Shen, L. Advanced Modular Honeycombs with Biomimetic Density Gradients for Superior Energy Dissipation. Biomimetics 2025, 10, 221. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Ubaid, J.; Abishera, R.; Schiffer, A.; Deshpande, V.S. Tunable energy absorption characteristics of architected honeycombs enabled via additive manufacturing. ACS Appl. Mater. Interfaces 2019, 11, 42549–42560. [Google Scholar] [CrossRef] [PubMed]

- Jefferson Andrew, J.; Schneider, J.; Schiffer, A.; Hafeez, F.; Kumar, S. Dynamic crushing of tailored honeycombs realized via additive manufacturing. Int. J. Mech. Sci. 2022, 219, 107126. [Google Scholar] [CrossRef]

- Uddin, K.Z.; Anni, I.A.; Youssef, G.; Koohbor, B. Tuning Load Bearing Capacities of Flexible Honeycomb with Poisson’s Ratio Modulation. In Proceedings of the American Society for Composites-Thirty-Eighth Technical Conference, Woburn, MA, USA, 18–20 September 2023. [Google Scholar]

- You, J.F.; Zhang, H.C.; Zhu, H.X.; Kennedy, D. The high strain compression of micro-and nano-sized random irregular honeycombs. Mater. Res. Express 2016, 3, 095023. [Google Scholar] [CrossRef][Green Version]

- Nazir, A.; Arshad, A.B.; Lin, S.C.; Jeng, J.Y. Mechanical performance of lightweight-designed honeycomb structures fabricated using multijet fusion additive manufacturing technology. 3D Print. Addit. Manuf. 2022, 9, 311–325. [Google Scholar] [CrossRef] [PubMed]

- Afkhami, S.; Amraei, M.; Gardner, L.; Piili, H.; Wadee, M.A.; Salminen, A.; Björk, T. Mechanical performance and design optimisation of metal honeycombs fabricated by laser powder bed fusion. Thin-Walled Struct. 2022, 180, 109864. [Google Scholar] [CrossRef]

- Nazmul Ahsan, A.M.M.; Khoda, B. Characterizing novel honeycomb infill pattern for additive manufacturing. Manuf. Sci. Eng. 2021, 143, 021002. [Google Scholar] [CrossRef]

- Zhang, L.; Song, B.; Zhao, A.; Liu, R.; Yang, L.; Shi, Y. Study on mechanical properties of honeycomb pentamode structures fabricated by laser additive manufacturing: Numerical simulation and experimental verification. Compos. Struct. 2019, 226, 111199. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Kanatani, T.; Todoroki, A. Multi-material additive manufacturing of polymers and metals using fused filament fabrication and electroforming. Addit. Manuf. 2019, 29, 100812. [Google Scholar] [CrossRef]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on additive manufacturing of multi-material parts: Progress and challenges. J. Manuf. Mater. Process. 2021, 6, 4. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Tang, F.; Chen, J. Multi-material additive manufacturing via fused deposition modeling 3D printing: A systematic review on the material feeding mechanism. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089231223316. [Google Scholar] [CrossRef]

- Cunha, P.; Teixeira, R.; Carneiro, O.S.; Silva, A.F. Multi-material fused filament fabrication: An expedited methodology to assess the affinity between different materials. Prog. Addit. Manuf. 2023, 8, 195–204. [Google Scholar] [CrossRef]

- Dairabayeva, D.; Perveen, A.; Talamona, D. Flexural Performance of Mono-material and Multimaterial Fused Filament Fabrication Honeycomb Structures. In Proceedings of the 2023 14th International Conference on Mechanical and Aerospace Engineering (ICMAE), Porto, Portugal, 18–21 July 2023; IEEE: New York, NY, USA, 2023; pp. 54–59. [Google Scholar]

- Rajendra Boopathy, V.; Sriraman, A.; Arumaikkannu, G. Energy absorbing capability of additive manufactured multi-material honeycomb structure. Rapid Prototyp. J. 2019, 25, 623–629. [Google Scholar] [CrossRef]

- Mustafa, I.; Kwok, T.H. Interlacing infills for multi-material fused filament fabrication using layered depth material images. Micromachines 2022, 13, 773. [Google Scholar] [CrossRef] [PubMed]

- Yavas, D.; Liu, Q.; Zhang, Z.; Wu, D. Design and fabrication of architected multi-material lattices with tunable stiffness, strength, and energy absorption. Mater. Des. 2022, 217, 110613. [Google Scholar] [CrossRef]

- Desai, S.M.; Sonawane, R.Y.; More, A.P. Thermoplastic polyurethane for three-dimensional printing applications: A review. Polym. Adv. Technol. 2023, 34, 2061–2082. [Google Scholar] [CrossRef]

- Nihal, R.A.; Broti, N.M.; Deowan, S.A.; Rahman, S. Design and development of an anthropomorphic robotic hand using TPU material. In Proceedings of the 2019 2nd International Conference on Innovation in Engineering and Technology (ICIET), Dhaka, Bangladesh, 23–24 December 2019; IEEE: New York, NY, USA, 2019; pp. 1–6. [Google Scholar]

- Backes, E.H.; Harb, S.V.; Pinto, L.A.; de Moura, N.K.; de Melo Morgado, G.F.; Marini, J.; Passador, F.R.; Pessan, L.A. Thermoplastic polyurethanes: Synthesis, fabrication techniques, blends, composites, and applications. J. Mater. Sci. 2024, 59, 1123–1152. [Google Scholar] [CrossRef]

- Arifvianto, B.; Iman, T.N.; Prayoga, B.T.; Dharmastiti, R.; Salim, U.A.; Mahardika, M.; Suyitno. Tensile properties of the FFF-processed thermoplastic polyurethane (TPU) elastomer. Int. J. Adv. Manuf. Technol. 2021, 117, 1709–1719. [Google Scholar] [CrossRef]

- Kharbas, H.A.; McNulty, J.D.; Ellingham, T.; Thompson, C.; Manitiu, M.; Scholz, G.; Turng, L.S. Comparative study of chemical and physical foaming methods for injection-molded thermoplastic polyurethane. J. Cell. Plast. 2017, 53, 373–388. [Google Scholar] [CrossRef]

- Polat, Y.; Pampal, E.S.; Stojanovska, E.; Simsek, R.; Hassanin, A.; Kilic, A.; Demir, A.; Yilmaz, S. Solution blowing of thermoplastic polyurethane nanofibers: A facile method to produce flexible porous materials. J. Appl. Polym. Sci. 2016, 133, 43025. [Google Scholar] [CrossRef]

- Koltsakidis, S.; Tsongas, K.; Tzetzis, D. Combining Micro and Macro Relative Density: An Experimental and Computational Study on Hierarchical Porous 3D-Printed Polylactic Acid Structures. Adv. Eng. Mater. 2024, 26, 2402012. [Google Scholar] [CrossRef]

- Hao, M.; Wang, J.; Wang, R.; Gong, M.; Zhang, L.; Wang, D.; Lu, Y.; Zhang, L.; Lin, X. Mechanical dependence of 3D-printed thermoplastic polyurethane reinforced with minor continuous carbon fibres. Virtual Phys. Prototyp. 2023, 18, e2224304. [Google Scholar] [CrossRef]

- Sánchez-Adsuar, M.S.; Linares-Solano, A.; Cazorla-Amorós, D.; Ibarra-Rueda, L. Influence of the nature and the content of carbon fiber on properties of thermoplastic polyurethane-carbon fiber composites. J. Appl. Polym. Sci. 2003, 90, 2676–2683. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Liu, Y.; Wang, X.; Yang, B. A novel surface modification of carbon fiber for high-performance thermoplastic polyurethane composites. Appl. Surf. Sci. 2016, 382, 144–154. [Google Scholar] [CrossRef]

- Lin, M.-C.; Lin, J.-H.; Bao, L. Thermoplastic polyurethane reinforced with continuous carbon fiber tows: Manufacturing technique and fabric property evaluation. Appl. Compos. Mater. 2021, 28, 1531–1546. [Google Scholar] [CrossRef]

- Niknam, H.; Akbarzadeh, A.H. Graded lattice structures: Simultaneous enhancement in stiffness and energy absorption. Mater. Des. 2020, 196, 109129. [Google Scholar] [CrossRef]

- Rahman, H.; Yarali, E.; Zolfagharian, A.; Serjouei, A.; Bodaghi, M. Energy absorption and mechanical performance of functionally graded soft–hard lattice structures. Materials 2021, 14, 1366. [Google Scholar] [CrossRef] [PubMed]

- Meyers, M.A.; Chen, P.-Y.; Lin, A.Y.-M.; Seki, Y. Biological materials: Structure and mechanical properties. Prog. Mater. Sci. 2008, 53, 1–206. [Google Scholar] [CrossRef]

- ISO 37:2024; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2024.

| Honeycomb | Experimental (MPa) | Simulation (MPa) | Percentage Error (%) |

|---|---|---|---|

| PO | 0.61 | 0.66 | 8.20 |

| PL | 1.29 | 1.37 | 6.20 |

| CF | 6.31 | 6.09 | 3.33 |

| PO_PL_CF | 1.08 | 1.15 | 6.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koltsakidis, S.; Tsongas, K.; Papas, N.; Pechlivani, E.M.; Tzetzis, D. Multi-Material Fused Filament Fabrication of TPU Composite Honeycombs Featuring Out-of-Plane Gradient Stiffness. J. Compos. Sci. 2025, 9, 588. https://doi.org/10.3390/jcs9110588

Koltsakidis S, Tsongas K, Papas N, Pechlivani EM, Tzetzis D. Multi-Material Fused Filament Fabrication of TPU Composite Honeycombs Featuring Out-of-Plane Gradient Stiffness. Journal of Composites Science. 2025; 9(11):588. https://doi.org/10.3390/jcs9110588

Chicago/Turabian StyleKoltsakidis, Savvas, Konstantinos Tsongas, Nikolaos Papas, Eleftheria Maria Pechlivani, and Dimitrios Tzetzis. 2025. "Multi-Material Fused Filament Fabrication of TPU Composite Honeycombs Featuring Out-of-Plane Gradient Stiffness" Journal of Composites Science 9, no. 11: 588. https://doi.org/10.3390/jcs9110588

APA StyleKoltsakidis, S., Tsongas, K., Papas, N., Pechlivani, E. M., & Tzetzis, D. (2025). Multi-Material Fused Filament Fabrication of TPU Composite Honeycombs Featuring Out-of-Plane Gradient Stiffness. Journal of Composites Science, 9(11), 588. https://doi.org/10.3390/jcs9110588