Abstract

The application of rubber in geotechnical engineering has gained widespread popularity due to its potential to enhance the engineering properties of foundation fills while reducing environmental pollution. This study focuses on investigating the influence of the rubber fiber content on the performance of calcareous sand by conducting a series of triaxial tests. The effects of the rubber fiber content and axial pressure on the strength, deformation, permeability, and particle breakage of rubber–calcareous sand were systematically studied. The experimental results reveal that increasing the rubber fiber content reduces the strength of rubber–calcareous sand, but it also inhibits the shear dilation and mitigates the occurrence of rupture surfaces: the sample with a rubber content of more than 10% only has shear-contraction. Both the rubber fiber content and axial stress contribute to the increased impermeability of rubber-modified calcareous sand, although they exhibit different characteristics. The relationship between the rubber fiber content and permeability coefficient is linear, while, under increasing axial stress, the permeability coefficient initially decreases rapidly; when the deviatoric stresses exceeds 1000 kPa, the decreasing rate slows down. Furthermore, rubber fiber significantly reduces particle breakage in calcareous sand. The relationship between the input energy applied to rubber-modified calcareous sand and the relative breakage rate of calcareous sand can be well-fitted with a power function. Samples with a higher rubber fiber content exhibit a lower relative breakage rate of calcareous sand under the same absorbed input energy. Through the research results of this paper, the best rubber ratio can be selected as the road filler in engineering practice to ensure both cost-effectiveness and environmental protection.

1. Introduction

Calcareous sand is a sediment formed through a series of intricate physical, biological, and chemical reactions involving the remains of marine organisms; Its primary component is calcium carbonate [1]. In contemporary marine engineering construction, calcareous sand plays a crucial role as a vital material in the development of civil engineering infrastructure, particularly in the construction of reefs and islands [2,3,4,5,6] (Figure 1).

Figure 1.

Hydraulic reclamation.

Due to the inherent characteristics of calcareous sand, such as its high porosity, pronounced permeability, susceptibility to breakage, and irregular particle shape [7,8], the engineering mechanical properties of calcareous sand exhibit notable distinctions compared to those of conventional natural sands. In recent years, a multitude of researchers have conducted comprehensive experimental investigations encompassing diverse facets of calcareous sand. In terms of the permeability of calcareous sand, pore characteristics are one of the significant factors influencing its permeability. Based on the constant head permeability experiments, Wang et al. [9] discovered that the permeability coefficient of calcareous sand exhibited a linear relationship with 10e (where e is the void ratio). Using a three-dimensional X-ray microanalysis device, Fan et al. [10] observed the three-dimensional pore characteristics of calcareous sand with different particle sizes, revealing that the quantity and volume of pores in calcareous sand significantly impact its permeability. Moreover, due to the irregular nature of calcareous sand particles, the particle size and shape also exert an influence on permeability [11]. By using the homemade Velocity-controlled Pressure-differential Acquisition Flow Apparatus, Wang et al. [12] indicated that irregular particle shapes reduced the permeability coefficient of calcareous sand. In practical engineering applications, calcareous sand is commonly used as a filling material for subsoil, and is thus inevitably subjected to the loads from the overlying structure. Under the action of the load, the pores between calcareous sand particles are compressed, and the particles themselves undergo stress-induced breakage, leading to changes in the particle shape and size. Therefore, the influence of the load on the permeability of calcareous sand cannot be ignored. By utilizing a piece of homemade permeability equipment, Wang et al. [13] analyzed the effect of the load on the permeability coefficient of calcareous sand. The results demonstrated that, with the gradual increase in load, the permeability coefficient of calcareous sand initially decreased rapidly and then decreased slowly. On the other hand, Li et al. [14] found that impact loads can also significantly reduce the permeability of calcareous sand, and many studies have shown that particle breakage has an impact on permeability [13], indicating a correlation between these two factors. Compared to quartz sands, calcareous sand is more prone to particle breakage [15]. The breakage of larger particles will lead to a decline in the foundation settlement and bearing capacity, posing instability factors and risks to engineering projects [16,17]. Moreover, the increase in the density and confining pressure will also lead to a higher degree of breakage in calcareous sand [18], while the non-uniform calcareous sand particles exhibit significantly stronger deformation resistance and compressive strength [19,20]. At present, most of the studies on the breakage characteristics of calcareous sand focus on particle breakage patterns and the inducing factors such as stress and strain. When it comes to the breakage mechanism of individual calcareous sand particles, the individual calcareous sand particle breakage can be classified into three modes: the primary splitting, the successive breaking, and the severe disintegration [21]. Through the triaxial shear tests of calcareous sand, it has been explained that the shear is the triggering factor for the particle breakage of calcareous sand, and it continues to occur with increasing shear strain under fully plastic conditions after reaching the peak deviator stress [22,23]. From the ring shear tests of calcareous sand, it can be found that the breakage rate of calcareous sand far exceeds the triaxial test; as long as the shear strain is present, the fracture will occur [24,25]. Therefore, both stress and strain can induce particle breakage in calcareous sand. In order to better analyze the particle breakage of calcareous sand and achieve a comprehensive understanding of calcareous sand breakage, some researchers have considered introducing the concept of input energy. Studies have found that the relationship between the breakage rate of the calcareous sand and input energy is independent of the loading conditions, confining pressure, and density [26,27]. Thus, the breakage trend in calcareous sand can be accurately predicted by studying the relationship between the input energy and the breakage rate.

When pure calcareous sand is used as a fill material for island reef construction, it is easily susceptible to groundwater and microbial erosion. Due to its porous nature and significant water absorption capacity, its mechanical properties undergo significant changes, thereby posing potential risks to engineering projects. However, rubber, being a hydrophobic material, exhibits long-term stability in its mechanical properties, as it has minimal reactivity with groundwater. And rubber has advantages in engineering applications because it can reinforce the sand while maintaining its lightweight capabilities, and the waste tire rubber particles, with their low density, lightweight nature, good compressibility, durability, and slow aging in the absence of light [28,29], make it suitable as a new lightweight composite fill material, widely used in the field of geotechnical engineering, including roadbeds [30,31], slopes, concrete [32,33], and retaining walls [34,35,36]. As the number of private vehicles grows exponentially, countless tires are discarded worldwide each year (Figure 2). The inadequate disposal of these waste tires can cause significant environmental pollution, and direct disposal will also lead to the waste of resources. Therefore, its comprehensive utilization would be beneficial for the development of social economy and ecological preservation [37]. Through consolidation tests, direct shear tests, and triaxial tests, many researchers have investigated the mixing performance of rubber and sand, and concluded that the presence of rubber effectively inhibits the particle breakage behavior in the sand [38,39], suppresses particle reorganization and rearrangement, and delays the shear dilation behavior of the soil [40,41,42]. In addition, it is of great significance that we incorporate rubber with calcareous sand as a blended foundation fill material in marine engineering construction for the development of marine engineering and environmental conservation. Research on the incorporation of rubber in calcareous sand can provide valuable insights into future reclamation projects of reefs and ground reinforcement projects.

Figure 2.

Stacking of waste tires.

Most of the previous studies focused on the combination of siliceous sand and rubber, and there were few studies on the deformation, permeability, and particle breakage characteristics of the rubber fiber and calcareous sand mixture. To further investigate the influence of rubber fiber on the engineering mechanical properties of calcareous sand, an SLB-1-type stress–strain-controlled triaxial shear permeability test apparatus was employed in this study. The rubber-modified calcareous sand samples with different rubber fiber contents were subjected to triaxial consolidated–drained shear tests (CD), triaxial permeability experiments, and particle analysis tests before and after triaxial compression. The effects of the rubber fiber content on the rubber-calcareous sand’s strength, permeability, and breakage characteristics were analyzed. The goal of this study is to provide a reference for future projects to reclaim reefs and subsequent theoretical research.

2. Materials and Methods

2.1. Test Materials

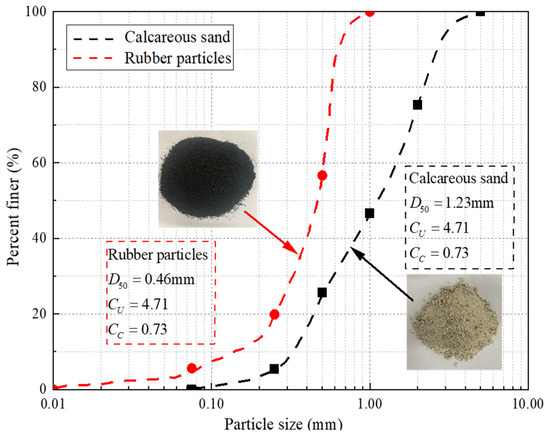

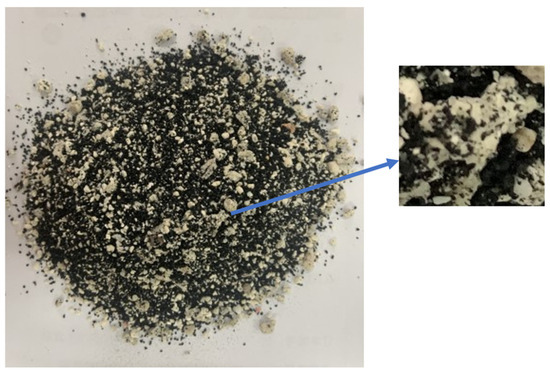

The test calcareous sand was taken from the South China Sea. It was an uncemented loose body of particles with extremely irregular surfaces, different sizes, white color, rich internal pores, and different particle shapes such as sheets, spindles, and branches. The rubber fiber was black granular debris obtained by mechanical crushing. The test parameters of the two materials are shown in Table 1, and the particle grading curves obtained after the particle analysis test are shown in Figure 3.

Table 1.

Physical parameters of calcareous sand and rubber particles for testing.

Figure 3.

Particle grading curves of rubber fiber and calcareous sand.

The percentage of rubber fiber content in rubber-modified calcareous sand was expressed by the rubber mass ratio (RM= mrubber/mtotal), where mrubber is the mass of rubber and mtotal is the total mass of rubber-modified calcareous sand. Since the relative density (Dr) has a great influence on the mechanical properties of the calcareous sand, to ensure the comparability of the test results, Dr was set to 70% to control the loading density of the test, and the calculation formula was as follows:

where Dr is the relative density of the sample; ρdmax is the maximum dry density of the sample; and ρdmin is the minimum dry density of the sample. ρc is the control density of the sample; V is the sample volume; m is the total mass; RM is the proportion of rubber content in the sample; mr is the mass of rubber; and ms is the mass of calcareous sand.

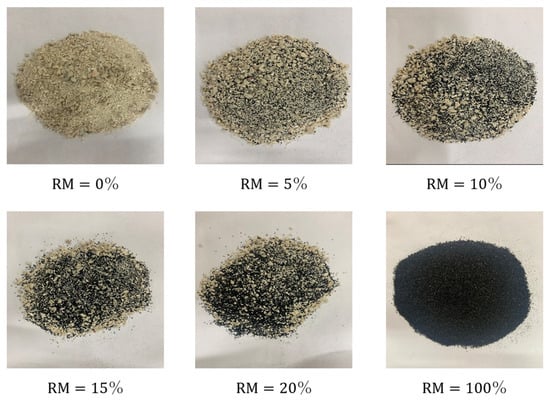

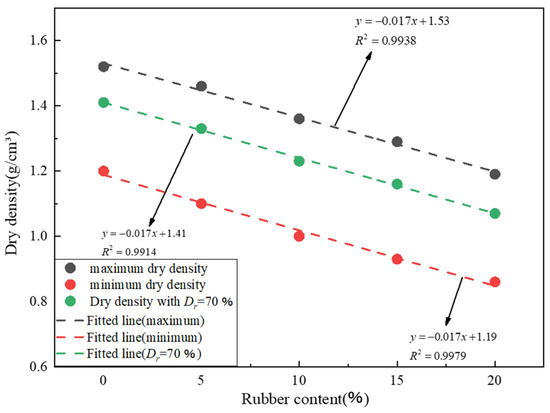

The rubber-modified calcareous sand samples for different RMs are shown in Figure 4. The maximum, minimum, and Dr = 70% dry densities of the samples for different RM values are provided in Table 2. The variation in the dry density of the sample with increasing RM is shown in Figure 5. The dry densities of the samples in different states gradually decreased with increasing RM, which showed a nearly linear trend. To prevent uncertainty in the experimental results caused by the salt and binders on the surface of the calcareous sand, the samples were cleaned until the filtrate was transparent and the suspended matter is not obvious and then dried before testing began.

Figure 4.

Samples of rubber–sand particle mixtures with different RM.

Table 2.

Dry densities of rubber-modified calcareous sand with different mix proportions.

Figure 5.

The dry density of the sample changed with increasing content of rubber fiber.

2.2. Experimental Apparatus and Methods

2.2.1. Experimental Apparatus

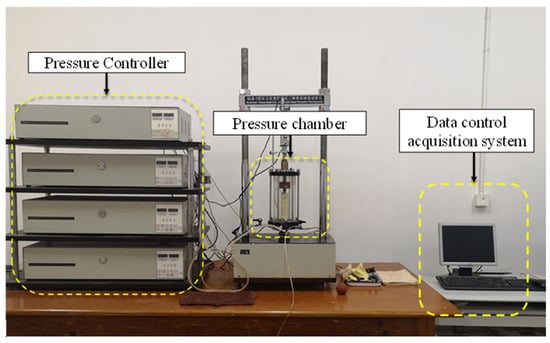

An SLB-1 stress–strain-controlled shear penetration tester (Figure 6), which was composed of a pressure controller, pressure chamber, and data acquisition system, was utilized to measure the shear strength and deformation characteristics of the calcareous sand. The maximum axial pressure was 20 kN, the maximum circumference range was 2 MPa, and the maximum osmotic pressure was 1 MPa.

Figure 6.

SLB-1-type stress–strain-controlled triaxial shear permeability apparatus.

2.2.2. Test Methods and Procedures

To explore the influence of different RM values on the mechanical properties of rubber-modified calcareous sand, samples with RM values of 0%, 5%, 10%, 15%, and 20% were used to carry out the triaxial consolidation drained shear test, triaxial constant head permeability test, and triaxial compression breakage test. According to the formula for relative density, the quality of each group of samples was calculated and weighed. To ensure the uniformity of each sample, the sample was divided into three equal parts, the stratification method was used to make the sample, and a small hammer was used to prevent particle breakage. After a sample was prepared, back pressure was used to saturate it to 95%.

- CD test: Rubber-modified calcareous sand with different RM values was subjected to triaxial consolidation drainage shear tests at three different confining pressures (100 kPa, 200 kPa, and 300 kPa). The shear rate was set to 1 mm/min and the test was terminated when the axial strain of the sample reached 20%.

- Triaxial constant head permeability test: Rubber-modified calcareous sand with different RM was subjected to the triaxial constant head permeability test at six different deviatoric stresses (0 kPa, 500 kPa, 1000 kPa, 1500 kPa, 2000 kPa, and 2500 kPa). The confining pressure of the test was set to 1200 kPa, and the osmotic pressure was set to 10 kPa. During the test, when the axial pressure reached the target, the drainage change of the sample was observed until the drainage volume is stable, and the permeability test was started. When the seepage velocity was stable, the test was stopped. Due to the effect of the osmotic pressure, the internal particles of the sample were transported, thus affecting the structure of the sample, which caused a certain degree of error in the test results. Therefore, every time that a set of tests was completed, the next set of tests was conducted using a new sample.

- Triaxial compression breakage test: Rubber-modified calcareous sand with different RM was subjected to the triaxial compression breakage test at six different deviatoric stresses (0 kPa, 500 kPa, 1000 kPa, 1500 kPa, 2000 kPa, and 2500 kPa), and the confining pressure and axial pressure were set the same as those in the penetration test. After the compression test, the samples were dried, weighed, and then subjected to particle sieve analysis.

The specific test types, loading conditions, and boundary conditions are shown in Table 3.

Table 3.

Test procedure.

3. Results and Discussion

3.1. Analysis of the CD Test Results

3.1.1. Stress–Axial Strain Curves

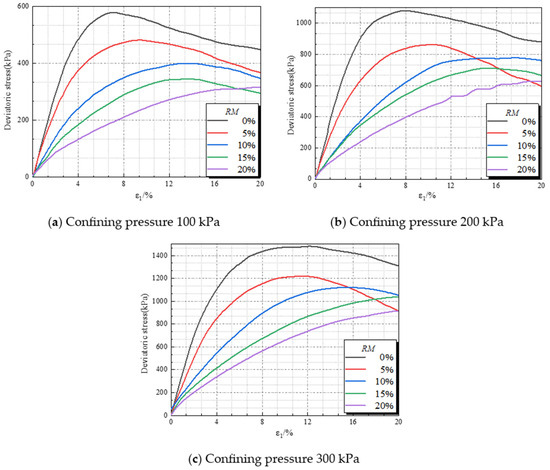

After processing the CD test data of the rubber-modified calcareous sand with different RMs, the deviatoric stress–axial strain curves for different confining pressures were obtained as shown in Figure 7. At the same confining pressure, the initial modulus of the stress–strain curve of each sample decreased with increasing RM, and the curve showed the more obvious characteristics of hardening. The peak stress achieved by the sample decreased with increasing RM, and the axial strain corresponding to the peak stress increased with increasing RM. After the toughness of the low RM sample is weak and reaches the maximum strength, the deviatoric stress decreases rapidly with the increase in strain. For the sample with more than 10% RM, the toughness is obviously enhanced, and the decrease rate of the deviatoric stress becomes slower. The trends were similar to those obtained by Anvari et al. [43] in CD tests of mixtures of rubber particles with quartz sand at different mix ratios.

Figure 7.

The stress–strain curves of rubber-modified calcareous sand at different mix ratios for different confining pressures.

For samples with the same RM value, stress–strain curves were compared at different confining pressures. As the confining pressure increased, the peak stress and initial modulus of the samples also increased. The main reason for this was that the higher confining pressure inhibited the movement and breakage of particles and reduced the expansion of the sample volume, thus increasing the shear strength of the sample.

3.1.2. Volumetric Strain–Axial Strain Curves

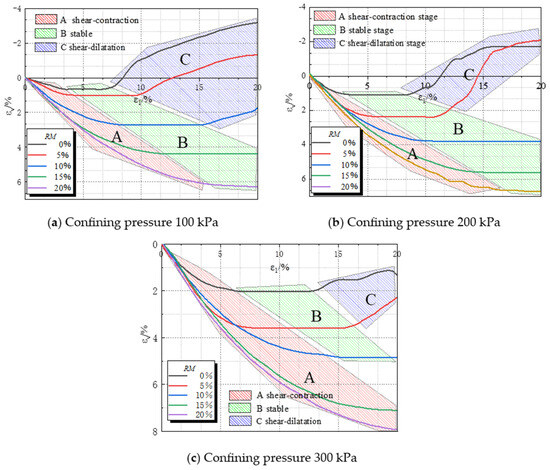

The characteristics of the volume strain–axial strain of rubber-modified calcareous sand samples with different RMs at different confining pressures are shown in Figure 8, where A represents the shear-contraction stage, B is the stable stage (with the increase in axial strain, the volume of the sample almost does not change), and C is the shear-dilatation stage.

Figure 8.

Volumetric strain-axial strain curves of rubber-modified calcareous sand at different mix ratios for different confining pressures.

At different confining pressures, the shear-contraction features of the rubber calcium sand were enhanced with increasing RM, and the shear-dilatation features weakened. An RM value of 10% could be used as a critical point. When the sample RM was less than 10%, the sample mainly underwent shear dilatation, and, when the sample RM was more than 10%, the sample was dominated by shear contraction.

The changes in the areas of different regions under different confining pressures in Figure 8 showed that the area of region C decreased obviously, and the area of region A increased, with increasing confining pressure. These results showed that, with increasing confining pressure, samples with different RM values showed the characteristics of weakened shear-dilatation and strengthening shear-contraction effects.

3.1.3. Analysis of the Shear Mechanism of Rubber-Modified Calcareous Sand

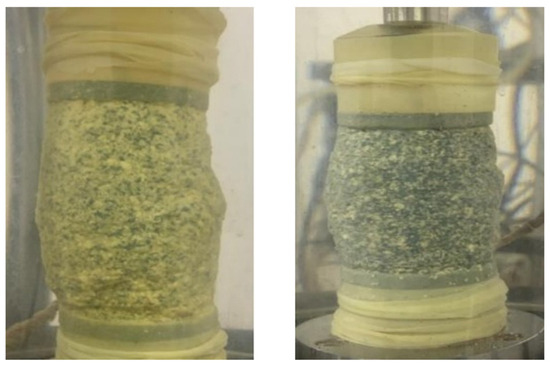

Calcareous sand was incompressible and undeformed, but, under high pressure, the extrusion between the particles caused the initially angular particles to be broken into multiple fragments; the particles to become rounder, and the rubber particles had small moduli and a strong ability to undergo deformation (mainly elastic deformation) [44]. Therefore, the shear characteristics of the rubber-modified calcareous sand were closely related to its RM. When the sample had a small RM, the force transmission mechanism under the action of external force was mainly the rigid contact between the particles of calcareous sand, and the shear compression characteristics of the sample were similar to those of unmodified calcareous sand. Before compression, the rubber-modified calcareous sand was very porous and in a loose state. When the axial stress was applied, the pores between the particles decreased rapidly, and the fine particles produced by particle grinding filled the pores of the large particles, making the sample more compact. The stress–strain curve of the sample showed a trend of approximate linear change with continuously increasing stress, and the volume of the sample decreased, which was characteristic of shear contraction. As the stress increased further, some large particles appeared to have become more spherical, which led to a dislocation movement between particles, and the interlocking friction between particles decreased. The rising slope of the stress–strain curve decreased rapidly, the axial strain of the sample continued to increase, the volume of the sample was no longer reduced, and the stress–strain curve of the sample showed characteristics of softening. When the axial stress increased to a certain value, the sample was completely destroyed, and the sample underwent shear dilatation and produced an inclined shear band, and the stress–strain curve showed a downward trend. When the sample had a high RM value, the force transmission mechanism of rubber-modified calcareous sand under the action of external force included rigid contacts between calcareous sand particles, nonrigid contacts between calcareous sand, and rubber and nonrigid contacts between rubber particles; As the sample RM increases, the proportion of the latter two non-rigid contact modes gradually increased. Due to the elastic deformation of the rubber fibers, the smoothing and breakage of calcareous sand particles caused by the stress concentration were inhibited. Additionally, the dislocations between particles were buffered. As a result, the deformability of the specimen was enhanced, and the stiffness of the specimen was reduced. As shown in Figure 9, it was difficult for a shear band to form, and the hardening features of the stress and strain curves of the sample were more obvious. At the same time, during the shear compression process, due to the increase in stress, the rubber fibers were tightly compressed, and they deformed and fully filled the pores of the calcareous sand particles, resulting in a reduction in the pore ratio of the sample. Thus, samples with large RM values exhibited monotonic shear contraction characteristics.

Figure 9.

Comparison diagram of sample failure under different RM.

3.2. Triaxial Permeability Test Results and Analysis

In the conventional triaxial shear permeability test, the permeability coefficient is calculated from the variation in Darcy’s law:

where is the total permeation within the time interval ; is the penetration path, which is the height of the sample during penetration; is the osmotic pressure (1 kPa osmotic pressure equivalent to a 102 mm head); is the cross-sectional area of the sample during penetration; is the time interval of penetration; and is the permeability coefficient.

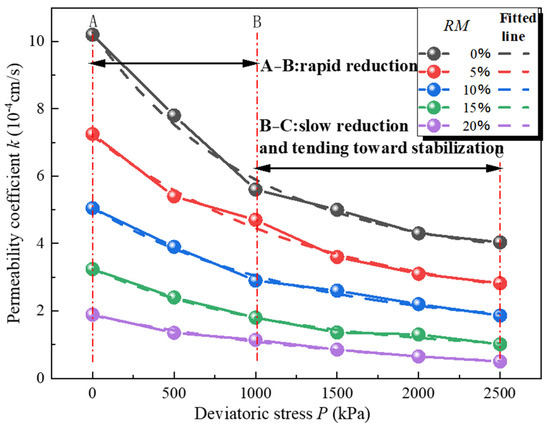

3.2.1. Analysis of the Influence of Load on the Permeability Coefficient of Calcareous Sand

The permeability coefficient–deviatoric stress curves of rubber-modified calcareous sand with different RMs are shown in Figure 10. Figure 10 shows that, with increasing deviatoric stress, the permeability coefficients of the samples with different RMs decreased, and the rate of decrease gradually decreased with increasing deviatoric stress. Each curve could be divided into two stages: rapid reduction (A–B), and the slow decrease and tendency toward stabilization (B–C); 1000 kPa was the boundary between the two stages. In stage A–B, there were multiple pores, calcareous sand particles with irregular shapes, and pores that were extremely sensitive to the change in load. Thus, the pores of rubber-modified calcareous sand were rapidly compressed and reduced by loading, and the water flow was blocked, resulting in a significant decrease in the permeability coefficient in this stage. In the B–C stage, with the increase in deviatoric stress, close contact developed between the particles of the rubber-modified calcareous sand. The particles of calcareous sand did not easily deform. When the original pore structure decreased under deviatoric stress, further compression was difficult. The sample pores were reduced by particle fracture, but the breakage amplitude of the particles was limited. Thus, the slope of the B–C stage of the curve slowly decreased.

Figure 10.

The permeability coefficient–deviatoric stress curves of rubber-modified calcareous sand with different RM values.

Figure 10 showed that, during the whole process of deviatoric stress application, the permeability coefficient variation of samples with a low RM was much larger than that of samples with a high RM. For example, the permeability coefficient of pure calcareous sand samples changed 4.45 times more than that of samples with an RM of 20% and even more significantly in stage A–B, which changed 6.13 times more.

In addition, the permeability coefficient and the deviatoric stress of samples with different RMs could be well-fitted by exponential functions, which were similar to the trends of the experimental curves obtained by Wang Shuai et al. [13] when exploring the influence of the load on the permeability coefficient of calcareous sand. The test data were fitted by Equation (6), and the fitting equations for the samples with different RMs are shown in Table 4.

where is the permeability coefficient; is the deviatoric stress; and are the curve fitting parameters related to the characteristics of rubber-modified calcareous sand.

Table 4.

K-P fitted equations for rubber-modified calcareous sand.

The curve fitting results for each RM are shown in Table 4.

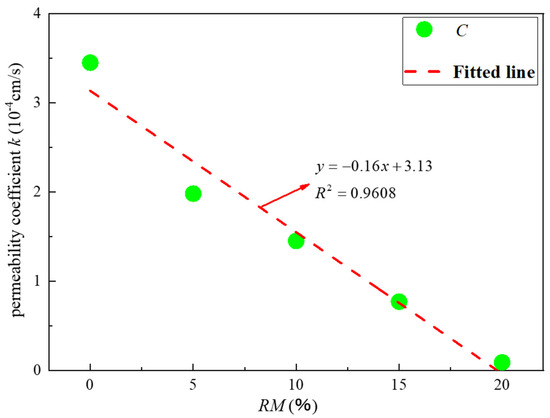

When p tended to infinity, the permeability coefficient k in Equation (6) was . There was a good linear relationship between C and RM, and the fitting formula was as follows:

The linear correlation between parameter C and complex W reached 0.96, as shown in Figure 11. Therefore, the limit minimum value of the permeability coefficient of rubber-modified calcareous sand with different RMs could be well-predicted according to this formula. The 3.13 in the formula represents the ultimate minimum permeability coefficient of pure calcareous sand, which is a theoretical prediction based on the test results.

Figure 11.

The variation trend of parameter c with RM.

3.2.2. Analysis of the Influence of the RM on the Permeability Coefficient of Rubber-Modified Calcareous Sand

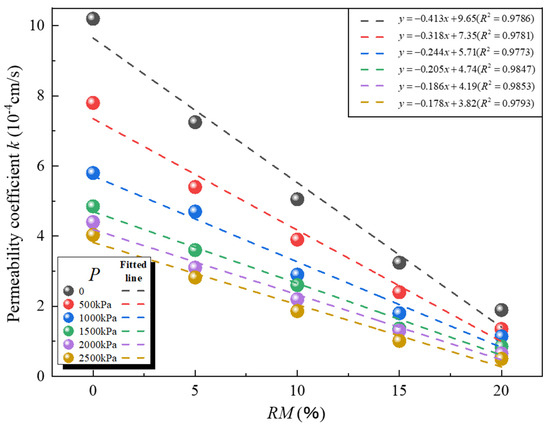

The relationship between the permeability coefficient and the RM of rubber-modified calcareous sand under different deviatoric stresses is shown in Figure 12. According to Figure 8, as the RM increased, the permeability coefficient of the rubber-modified calcareous sand gradually decreased under the same axial pressure. When the deviatoric stress was 0 kPa, the slope of the curve of the graph of the permeability coefficient vs. RM of the sample was 0.413, and when the deviatoric stress increased to 2500 kPa, the slope of the graph of the permeability coefficient vs. RM decreased to 0.178. This showed that, as the axial stress increased, the influence of the RM on the permeability of rubber-modified calcareous sand gradually weakened. This was because, when the deviatoric stress was between 0 kPa and 1000 kPa, the pores inside the sample were not completely compressed, and the rubber fiber was deformed under the stress and filled the pores of the calcareous sand particles. With the increase in the RM, the pores of the calcareous sand particles were more fully filled by the rubber particles, and the permeability of the sample was effectively reduced. When the deviatoric stress was between 1500 and 2500 kPa, the pores between the calcareous sand particles were completely compressed, and the fine particles produced by the friction between the calcareous sand particles filled the original pores to a certain extent. At this time, the decreased permeability coefficient of the sample was limited, and the influence of the RM on the permeability of the sample gradually weakened.

Figure 12.

Graphs of permeability coefficient vs. mix ratio for rubber-modified calcareous sand under different deviatoric stresses.

3.3. Triaxial Compression Breakage Test Results and Analysis

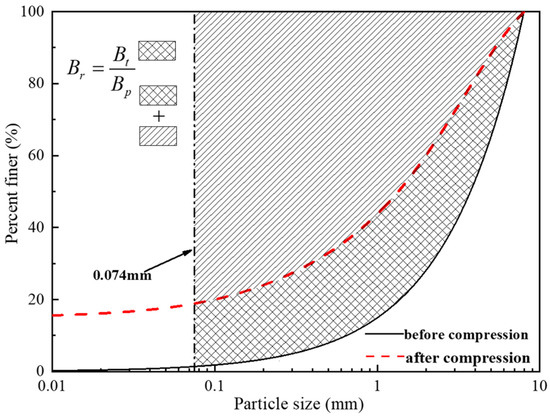

Particle breakage is a complex process related to the particle size, particle size distribution, particle shape, void ratio, and particle hardness. The most intuitive manifestation of particle breakage is the difference in the particle gradation curve before and after sample compression. Many scholars take the change at a certain point on the particle grading curve as an indicator of particle breakage. In this study, the breakage model proposed by Hardin [45] was adopted to evaluate the degree of breakage of particles, and the area enclosed by the particle grading curve before compression and the vertical line with particle size D equal to 0.074 mm was defined as the initial breakage potential BP0. It was considered that the particles less than the upper limit of 0.074 mm did not continue to break. The area of the particle gradation curve after compression and breakage and the initial gradation curve and the vertical line with particle size D equal to 0.074 mm were defined as the total breakage Bt (Figure 13). Then, the ratio of the total breakage Bt to the initial breakage potential BP0 was defined as the relative breakage rate Br, as shown below:

where Bt is the total breakage; BP0 is the initial breakage potential; and Br is the relative breakage rate.

Figure 13.

Diagram of the definition of Br.

Liu Huabei et al. [27] found that, for the same input energy, the samples with larger particle sizes were more broken than the samples with smaller particle sizes. To explore the effect of different RMs on the particle breakage of calcareous sand, the input energy was analyzed, and the input energy per unit volume of the sample from the beginning of the test to the end could be expressed as follows:

where WP is the input energy; is the effective major principal stress; is the effective minor principal stress; is the axial strain increment; and is the volumetric strain increment.

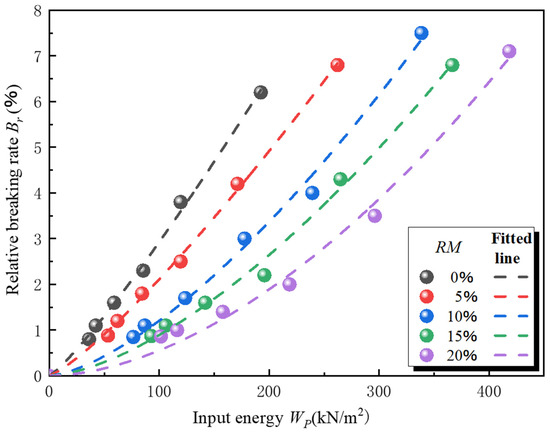

According to the test results, the relationship between the input energy WP and the relative breakage rate Br under different RMs is shown in Figure 14. The degree of breakage of the calcareous sand particles was closely related to the energy absorbed during the stress process and the RM value of the sample. For different RMs, the relationship between WP and Br could be fitted by a power function as shown in Equation (10). The curve-fitting formulae for different RMs are shown in Table 5.

where Br is the relative breakage rate; WP is the input energy; and a and b are the curve-fitting parameters related to the characteristics of the rubber-modified calcareous sand.

Figure 14.

Graphs of relative breakage rate–input energy for rubber-modified calcareous sand with different mix ratios.

Table 5.

K-P fitting equations for rubber-modified calcareous sand with different mix ratios.

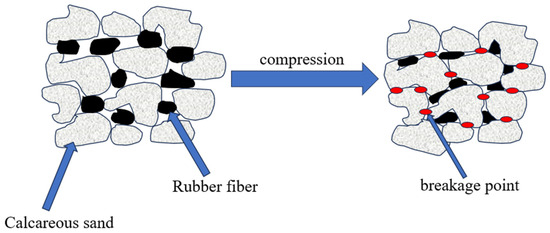

In the process of energy input, energy is absorbed by the calcareous sand and the rubber. As shown in Figure 14, with increasing RM, the sample Br-WP curve gradually became concave. For example, if the sample RM was 20%, then the slope of the curve was small during the initial stage of the energy input. When the input energy exceeded 220kN/m2, the slope of the curve gradually increased, which indicated that the proportion of energy absorbed by the rubber gradually decreased for a continuous energy input. This was because, during the process of compression, calcareous sand did not deform, and rubber underwent continuous deformation. When the rubber particles compressed and completely filled the pores of the calcareous sand, the contact mode between the particles changed from the rubber particle–calcareous sand particle back to the calcareous sand particle–calcareous sand particle. The change process is shown in Figure 15. As compression continued, the extent of this change continued to grow. When particles contact only calcareous sand particles–calcareous sand particles, the subsequent input energy was mainly absorbed by calcareous sand, which will lead to the breakage of the particles.

Figure 15.

Schematic diagram of particle compression.

In addition, with the same input energy, the relative breakage rates were much smaller for samples with larger RM values than for samples with smaller RM values. There were two main reasons for this behavior; (1) As shown in Figure 16, it can be found that the pores of calcareous sand contain a large number of rubber particles. The presence of rubber fibers reduced the stress concentrations between calcareous sand particles, thus reducing the breakage of particles. (2) The rubber fibers will serve as a skeleton to bear a portion of the load and undergo deformation under the action of the load, thereby absorbing some of the input energy [38,39].

Figure 16.

The sample diagram after compression.

4. Conclusions

The paper presents a comprehensive study on the strength, deformation, permeability, and particle breakage characteristics of rubber-modified calcareous sand, investigated through CD tests, triaxial permeability tests, and triaxial compression breakage tests under different rubber content (RM) values and axial stresses. Based on the analysis of the experimental results, the main conclusions are as follows:

- Increasing rubber content (RM) leads to a decrease in the strength of rubber-modified calcareous sand and an increase in the strain. The stress–strain curve exhibits hardening characteristics, as the modulus of the curve gradually decreases. This behavior is attributed to the presence of rubber, which inhibits shear dilation, enhances the shear compaction characteristics of calcareous sand, and delays the occurrence of rupture surfaces.

- Both the rubber content and axial stress have inhibitory effects on the permeability of rubber-modified calcareous sand. The permeability coefficient decreases linearly with increasing RM. On the other hand, with increasing axial stress, the permeability coefficient initially decreases rapidly, then slows down, and eventually converges. The final convergence value is significantly influenced by RM.

- Rubber has a substantial impact on particle breakage in calcareous sand. It acts in two ways: firstly, it reduces the stress concentration between calcareous sand particles, preventing some particles from undergoing breakage; and, secondly, rubber serves as a skeleton, sharing the load with calcareous sand and undergoing deformation to absorb a portion of the input energy. The relationship between the input energy and the relative breakage rate of calcareous sand particles at different RM levels can be effectively fitted with a power function. Samples with a higher RM show a slow initial increase in the relative breakage rate with increasing input energy, followed by a faster growth rate in the later stage.

Author Contributions

Methodology, Y.C., L.W., and Y.X.; Validation, Y.W.; Formal analysis, H.G.; Investigation, Y.C.; Resources, H.G. and G.Y.; Data curation, Y.W.; Writing—original draft, Y.C.; Writing—review & editing, Y.C., L.W., G.Y., Y.X., L.M., and C.L.; Supervision, L.W. and G.Y.; Project administration, C.L.; Funding acquisition, H.G. and L.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China. The grant number were No. 52222110 and No. 52301353.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by authors on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Wang, X.Z.; Jiao, Y.Y.; Wang, R.; Hu, M.J.; Meng, Q.S.; Tan, F.Y. Engineering characteristics of the calcareous sand in Nansha Islands, South China Sea. Eng. Geol. 2011, 120, 40–47. [Google Scholar] [CrossRef]

- Shen, J.; Xu, D.; Liu, Z.; Wei, H. Effect of particle characteristics stress on the mechanical properties of cement mortar with coral sand. Constr. Build. Mater. 2020, 260, 119836. [Google Scholar] [CrossRef]

- Xu, D.; Chen, W.; Fan, X. Experimental investigation of particle size effect on the self-healing performance of microcapsule for cemented coral sand. Constr. Build. Mater. 2020, 256, 119343. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, C.Q.; Wang, X.Z.; Qin, Y. Study of dilatancy behaviors of calcareous soils in a triaxial test. Mar. Georesources Geotechnol. 2018, 37, 1057–1070. [Google Scholar] [CrossRef]

- Wang, X.; Cui, J.; Zhu, C.Q.; Wu, Y.; Wang, X. Experimental study of the mechanical behavior of calcareous sand under repeated loading-unloading. Bull. Eng. Geol. Environ. 2021, 80, 3097–3113. [Google Scholar] [CrossRef]

- Dai, J.Y.; Yin, S.P.; Hu, C.S. Analysis of key influencing factors of the bond performance between BFRP bars and coral reef and sand concrete. Constr. Build. Mater. 2020, 269, 121248. [Google Scholar] [CrossRef]

- Javdanian, H.; Jafarian, Y. Dynamic shear stiffness and damping ratio of marine calcareous and siliceous sands. Geo-Mar. Lett. 2018, 38, 315–322. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Y.; Cui, J.; Zhu, C.Q.; Wang, X.Z. Shape characteristics of coral sand from the South China Sea. J. Mar. Sci. Eng. 2020, 8, 803. [Google Scholar] [CrossRef]

- Wang, X.Z.; Wang, X.; Chen, J.W.; Wang, R.; Hu, M.J.; Meng, Q.S. Experimental study on permeability characteristics of calcareous soil. Bull. Eng. Geol. Environ. 2018, 77, 1753–1762. [Google Scholar] [CrossRef]

- Fan, Z.; Hu, C.; Zhu, Q.; Jia, Y.; Zuo, D.; Duan, Z. Three-dimensional pore characteristics and permeability properties of calcareous sand with different particle sizes. Bull. Eng. Geol. Environ. 2021, 80, 2659–2670. [Google Scholar] [CrossRef]

- Cui, X.; Zhu, C.; Hu, M.; Wang, R.; Liu, H. Permeability of porous media in coral reefs. Bull. Eng. Geol. Environ. 2021, 80, 5111–5126. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, Y.; Yang, Q. Experimental study on the hydraulic conductivity of calcareous sand in South China Sea. Mar. Georesources Geotechnol. 2017, 35, 1037–1047. [Google Scholar] [CrossRef]

- Wang, S.; Lei, X.W.; Meng, Q.S.; Xu, J.; Xu, Y.; Xie, L. Experimental study on the Influence of Load on Permeability Coefficient of Calcareous San. IOP Conf. Ser. Earth Environ. Sci. 2019, 304, 052066. [Google Scholar] [CrossRef]

- Li, X.; Qiu, Y.; Li, H.; Xu, G.; Xing, H.; Wang, M.; Shi, J. Influence of impact load on permeability of saturated calcareous sand. Mar. Georesources Geotechnol. 2024, 42, 223–232. [Google Scholar] [CrossRef]

- Chen, S.-S.; Zhang, J.-H.; Long, Z.-L.; Kuang, D.-M.; Cai, Y. Effects of particle size on the particle breakage of calcareous sand under impact loadings. Constr. Build. Mater. 2022, 341, 127809. [Google Scholar] [CrossRef]

- Rosa, A.F.; Aragão, F.T.S.; da Motta, L.M.G. Effects of particle size distribution and lithology on the resistance to breakage of ballast materials. Constr. Build. Mater. 2020, 267, 121015. [Google Scholar] [CrossRef]

- Shen, C.-M.; Yu, J.-D.; Liu, S.-H.; Mao, H.-Y. A unified fractional breakage model for granular materials inspired by the crushing tests of dyed gypsum particles. Constr. Build. Mater. 2021, 270, 121366. [Google Scholar] [CrossRef]

- Wu, Y.; Li, N.; Wang, X.; Cui, J.; Chen, Y.; Wu, Y.; Yamamoto, H. Experimental investigation on mechanical behavior and particle crushing of calcareous sand retrieved from South China Sea. Eng. Geol. 2020, 280, 105932. [Google Scholar] [CrossRef]

- Wang, C.; Ding, X.; Xiao, Y.; Peng, Y.; Liu, H. Effects of relative densities on particle breaking behaviour of non-uniform grading coral sand. Powder Technol. 2021, 382, 524–531. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, Z.; Qin, Y.; Yang, Y. Effect of particle size on the failure behavior of cemented coral sand under impact loading. Soil Dyn. Earthq. Eng. 2021, 149, 106884. [Google Scholar] [CrossRef]

- Kuang, D.-M.; Long, Z.-L.; Guo, R.-Q.; Zhao, T.; Wu, K. Experimental and numerical study on the fragmentation mechanism of a single calcareous sand particle under normal compression. Bull. Eng. Geol. Environ. 2021, 80, 2875–2888. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Z.; Ye, Q.; Zha, J. Particle breakage evolution of coral sand using triaxial compression tests. J. Rock Mech. Geotech. Eng. 2021, 13, 321–334. [Google Scholar] [CrossRef]

- Yu, F.W. Influence of particle breakage on behavior of coral sands in triaxial tests. Int. J. Geomech. 2019, 19, 04019131. [Google Scholar] [CrossRef]

- Wei, H.; Zhao, T.; He, J.; Meng, Q.; Wang, X. Evolution of particle breakage for calcareous sands during ring shear tests. Int. J. Geomech. 2018, 18, 04017153. [Google Scholar] [CrossRef]

- Coop, M.R.; Sorensen, K.K.; Freitas, T.B.; Georgoutsos, G. Particle breakage during shearing of a carbonate sand. Géotechnique 2004, 54, 157–163. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.-Q.; Cui, J.; Wang, X.-Z.; Shen, J.-H.; Zhu, C.-Q. Particle breakage characteristics of a foundation filling material on island-reefs in the South China Sea. Constr. Build. Mater. 2021, 306, 124690. [Google Scholar] [CrossRef]

- Liu, H.B.; Zeng, K.F.; Zou, Y. Particle breakage of calcareous sand and its correlation with input energy. Int. J. Geomech. 2020, 20, 04019151. [Google Scholar] [CrossRef]

- Mohajerani, A.; Kurmus, H.; Conti, D.; Cash, L.; Semcesen, A.; Abdurahman, M.; Rahman, T. Environmental impacts and leachate analysis of waste rubber incorporated in construction and road materials: A review. Sci. Total Environ. 2022, 2022, 835. [Google Scholar] [CrossRef]

- Mashiri, M.; Vinod, J.; Sheikh, M.N.; Tsang, H.-H. Shear strength and dilatancy behaviour of sand–tyre chip mixtures. Soils Found. 2015, 55, 517–528. [Google Scholar] [CrossRef]

- Chompoorat, T.; Jongpradist, P.; Dejdonbomand, C.; Harnnarongchai, W.; Jing, G.; Jamsawang, P. Utilization of Para Rubber Latex and Geopolymer-Stabilized Laterite as Bases and Subbases. J. Mater. Civ. Eng. 2025, 37, 04025410. [Google Scholar] [CrossRef]

- Chompoorat, T.; Sangsai, N.; Tanapalungkorn, W.; Chindasiriphan, P.; Nuaklong, P.; Jongvivatsakul, P.; Likitlersuang, S. Cement-based and alkali-activated controlled low-strength materials made from cup lump rubber for use as road materials. Road Mater. Pavement Des. 2025, 26, 1151–1171. [Google Scholar] [CrossRef]

- Ecemiş, A.S.; Madenci, E.; Karalar, M.; Fayed, S.; Althaqafi, E.; Özkılıç, Y.O. Bending Performance of Reinforced Concrete Beams with Rubber as Form of Fiber from Waste Tires. Materials 2024, 17, 4958. [Google Scholar] [CrossRef] [PubMed]

- Ecemis, A.S.; Madenci, E.; Karalar, M.; Fayed, S.; Althaqafi, E.; OzkillC, Y.O. Shear performance of reinforced concrete beams with rubber as form of fiber from waste tire. Steel Compos. Struct. 2024, 51, 337. [Google Scholar]

- Hazarika, H.; Kohama, E.; Sugano, T. Underwater shake table tests on waterfront structures protected with tire chips cushion. J. Geotech. Geoenviron. Eng. 2008, 134, 1706–1719. [Google Scholar] [CrossRef]

- Lee, J.H.; Salgado, R.; Bernal, A.; Lovell, C.W. Shredded tires and rubber-sand as lightweight backfill. J. Geotech. Geoenviron. Eng. 1999, 125, 132–141. [Google Scholar] [CrossRef]

- Anvari, S.M.; Shooshpasha, I. Influence of size of granulated rubber on bearing capacity of fine-grained sand. Arab. J. Geosci. 2016, 9, 707. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Liu, L.; Cai, G.; Liu, S. Compression properties and micro-mechanisms of rubber-sand particle mixtures considering grain breakage. Constr. Build. Mater. 2018, 187, 1061–1072. [Google Scholar] [CrossRef]

- Liu, X.; Tian, C.; Lan, H. Laboratory Investigation of the Mechanical Properties of a Rubber–Calcareous Sand Mixture: The Effect of Rubber Content. Appl. Sci. 2020, 10, 6583. [Google Scholar] [CrossRef]

- Dai, B.-B.; Liu, Q.; Mao, X.; Li, P.-Y.; Liang, Z.-Z. A reinterpretation of the mechanical behavior of rubber-sand mixtures in direct shear testing. Constr. Build. Mater. 2023, 363, 129771. [Google Scholar] [CrossRef]

- Cui, M.-J.; Zheng, J.-J.; Dahal, B.K.; Lai, H.-J.; Huang, Z.-F.; Wu, C.-C. Effect of waste rubber particles on the shear behaviour of bio-cemented calcareous sand. Acta Geotech. 2021, 16, 1429–1439. [Google Scholar] [CrossRef]

- Liu, Y.; Liao, X.; Li, L.; Mao, H. Discrete Element Modelling of the Mechanical Behavior of Sand–Rubber Mixtures under True Triaxial Tests. Materials 2020, 13, 5716. [Google Scholar] [CrossRef] [PubMed]

- Anvari, S.M.; Shooshpasha, I.; Kutanaei, S.S. Effect of granulated rubber on shear strength of fine-grained sand. J. Rock Mech. Geotech. Eng. 2017, 9, 936–944. [Google Scholar] [CrossRef]

- Holownia, B.P. Effect of Poisson’s ratio on bonded rubber blocks. J. Strain Anal. 1972, 7, 236–242. [Google Scholar] [CrossRef]

- Hardin, B.O. Crushing of soil particles. J. Geotech. Eng. 1985, 111, 1177–1192. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).