The Effect of Lubricant and Nanofiller Additives on Drilling Temperature in GFRP Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Sample Preparation

- Samples 1–3 contained no wax, with graphene levels of 0%, 0.25%, and 2%, respectively.

- Samples 4–6 incorporated 1% wax, paired with the same increasing concentrations of graphene (0%, 0.25%, and 2%).

- Samples 7–9 featured 2% wax, again matched with 0%, 0.25%, and 2% graphene.

2.1.2. Laminate Fabrication

2.1.3. Drilling Procedure

2.2. Methods

3. Results

3.1. Experimental Drilling Temperature Analysis

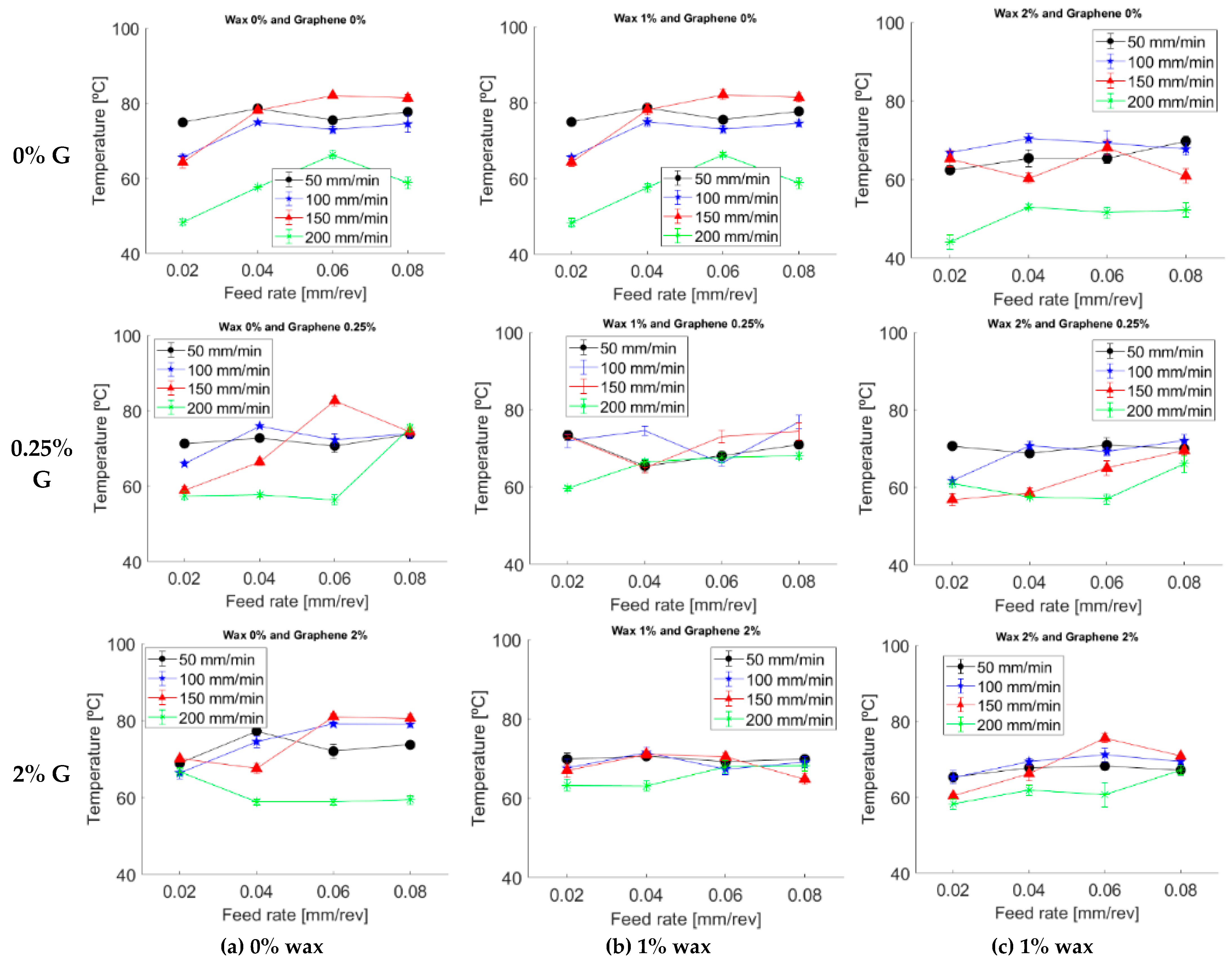

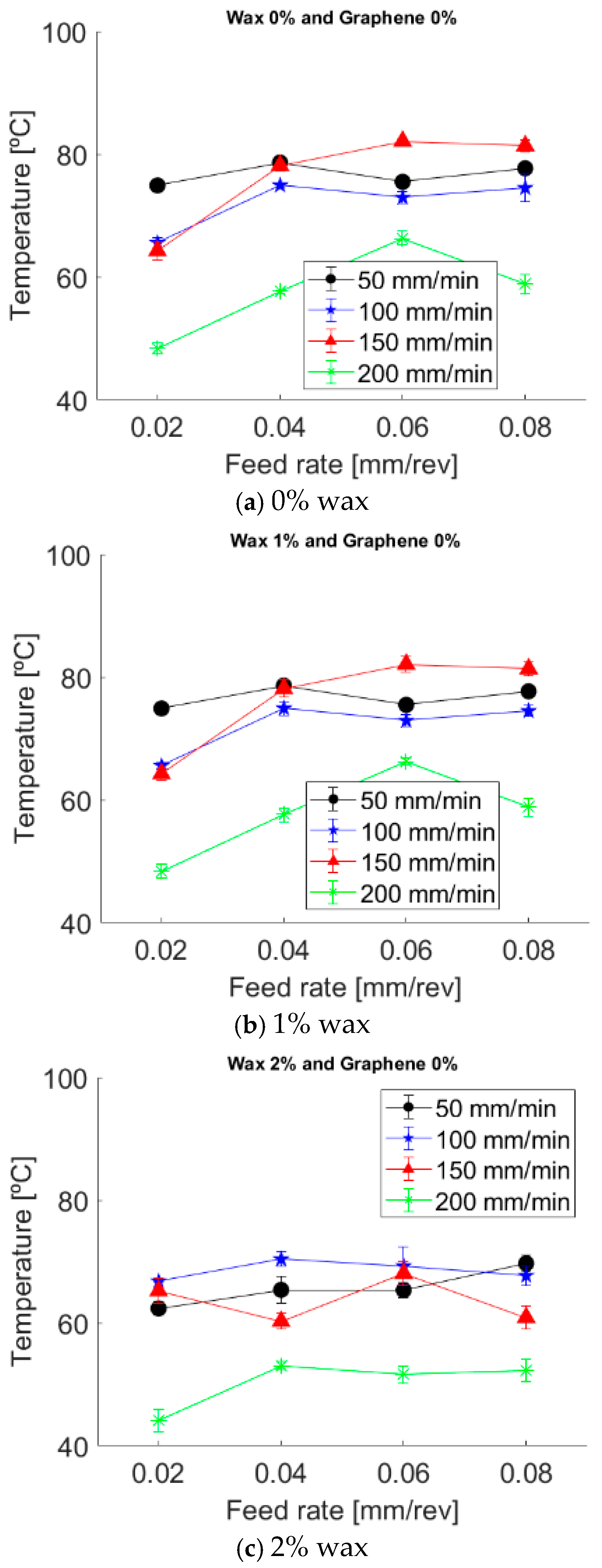

3.1.1. Feed Rate Effects

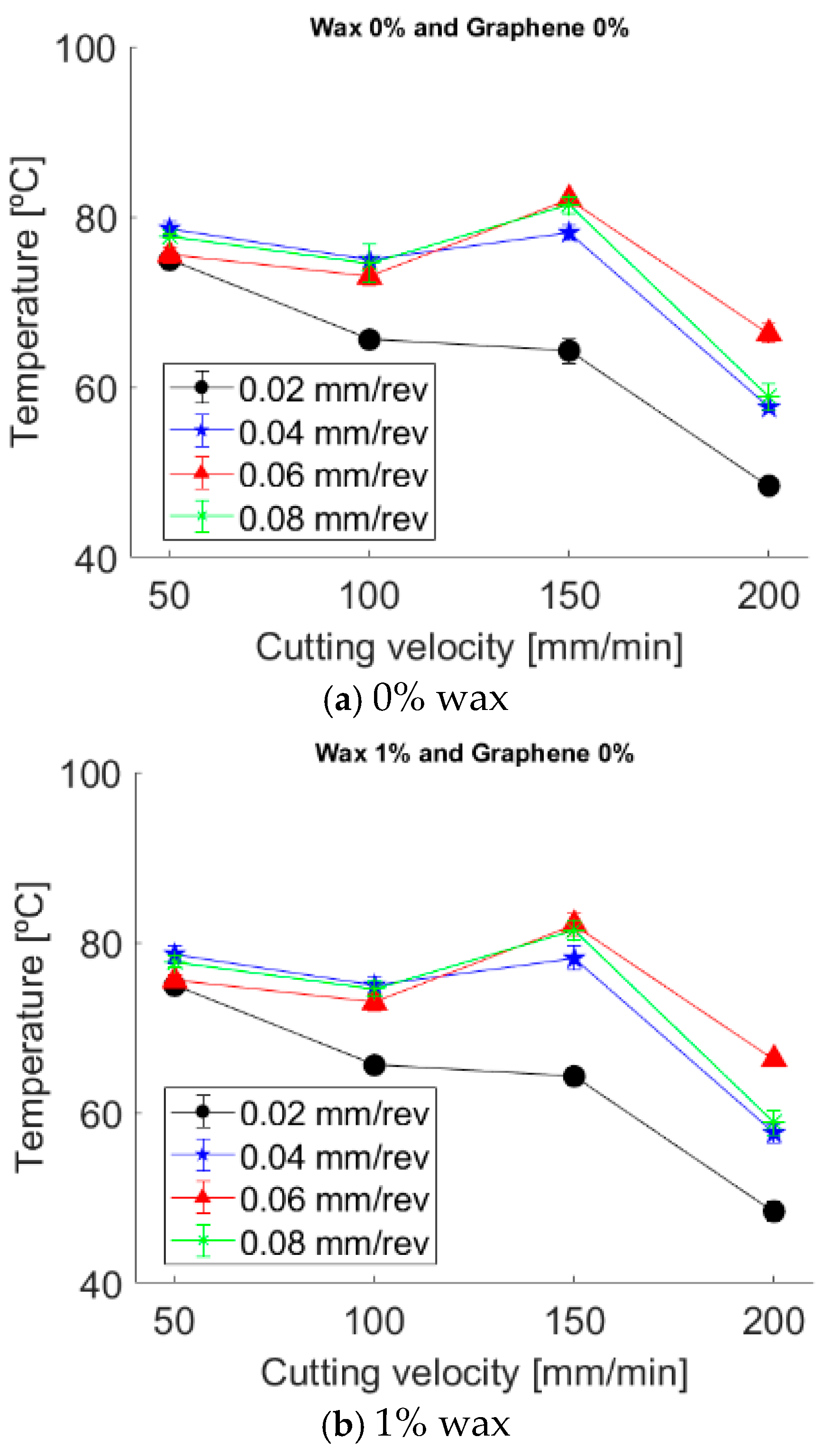

3.1.2. Cutting Speed Effects

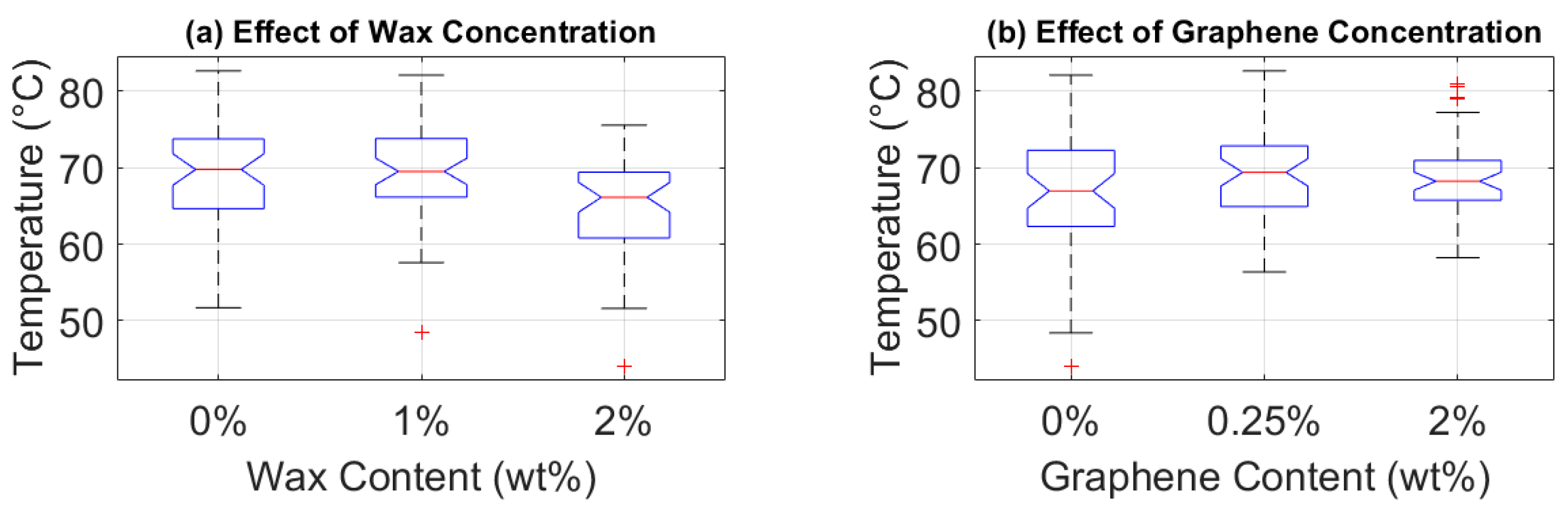

3.2. Boxplot Analysis of Temperature Variation

- (a)

- Effect of wax concentration

- (b)

- Effect of graphene concentration

- (c)

- Effect of feed rate

- (d)

- Effect of Cutting Speed

3.3. Effect of Wax and Graphene Combinations on Average Machining Temperature

3.4. Relative Contribution of Machining Parameters to Temperature Generation

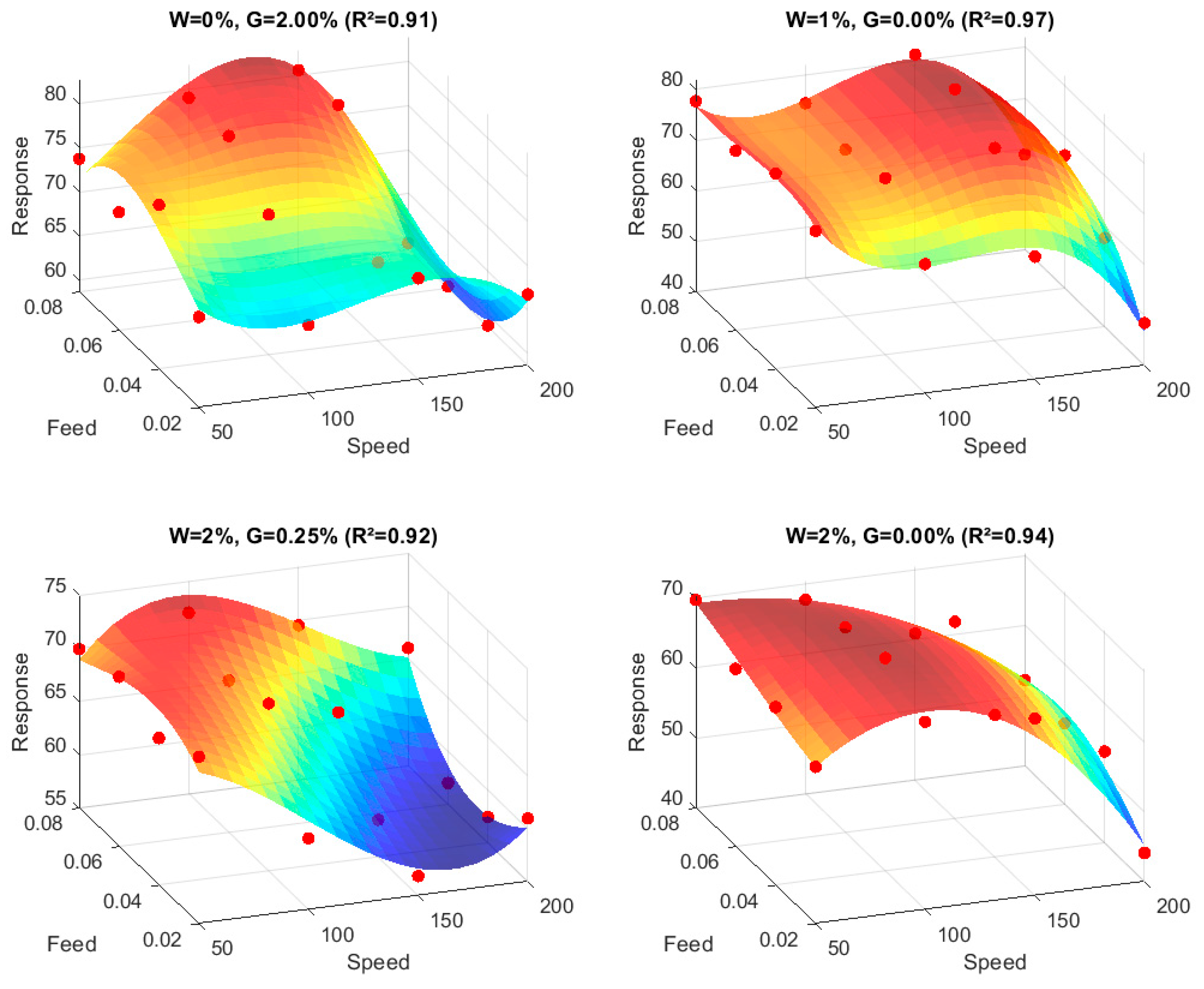

3.5. Prediction Results

4. Discussion

4.1. Interpretation of Drilling Temperature Trends

4.2. Boxplot Analysis

4.3. Implications of Parameter Influence for Thermal Control and Process Optimization

4.4. Thermal Behavior and Uncertainty Associated with Wax Concentration

4.5. Thermal Effects and Uncertainty Linked to Graphene Concentration

4.6. Combined Effects of Wax and Graphene on Thermal Management

4.7. Feed Rate Influence and Associated Variability

4.8. Cutting Speed as a Key Thermal Management Parameter

4.9. Model Performance Analysis

5. Conclusions

- The thermal response of GFRP composites is strongly governed by additive concentration and its interaction with drilling parameters.

- A 2% wax formulation without graphene proved most effective in reducing average drilling temperature, confirming wax’s role as a boundary lubricant and thermal buffer.

- Graphene alone slightly increased average drilling temperatures but significantly reduced thermal variability, contributing to a more stable machining process.

- Cutting speed was identified as the dominant factor, with higher speeds (200 mm/min) lowering temperatures due to reduced tool–workpiece contact time.

- The developed cubic response surface models (R2 = 0.89–0.97) demonstrated high predictive capability, offering a reliable tool for forecasting thermal behavior and optimizing machining strategies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RSM | Response Surface Methodology |

| PCM | Phase Change Material |

| SD | Standard Deviation |

| IQR | Interquartile Range |

| ANOVA | Analysis of Variance |

| GFRP | Glass Fiber Reinforced Polymer |

| CNC | Computer Numerical Control |

Appendix A

References

- Malik, K.; Ahmad, F.; Keong, W.T.; Gunister, E. The effects of drilling parameters on thrust force, temperature and hole quality of glass fiber reinforced polymer composites. Polym. Polym. Compos. 2022, 30, 09673911221131113. [Google Scholar] [CrossRef]

- Reyhan, R.R.; Andoko, A.; Prasetya, R. The Effect of Feed Rate Variation and Cooling on the Drilling Process of Carbon Fiber and Glass Fiber Composites. J. Appl. Sci. Eng. Technol. Educ. 2024, 6, 118–126. [Google Scholar] [CrossRef]

- Slamani, M.; Chatelain, J.-F. Kriging versus Bezier and regression methods for modeling and prediction of cutting force and surface roughness during high speed edge trimming of carbon fiber reinforced polymers. Measurement 2020, 152, 107370. [Google Scholar] [CrossRef]

- Slamani, M.; Chafai, H.; Chatelain, J. Effect of milling parameters on the surface quality of a flax fiber-reinforced polymer composite. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 238, 1537–1544. [Google Scholar] [CrossRef]

- Mudegowdar, M. Influence of cutting parameters during drilling of filled glass fabric-reinforced epoxy composites. Sci. Eng. Compos. Mater. 2015, 22, 81–88. [Google Scholar] [CrossRef]

- Jessy, K.; Satish Kumar, S.; Dinakaran, D.; Seshagiri Rao, V. Influence of different cooling methods on drill temperature in drilling GFRP. Int. J. Adv. Manuf. Technol. 2015, 76, 609–621. [Google Scholar] [CrossRef]

- Biruk-Urban, K.; Bere, P.; Udroiu, R.; Józwik, J.; Beer-Lech, K. Understanding the Effect of Drilling Parameters on Hole Quality of Fiber-Reinforced Polymer Structures. Polymers 2024, 16, 2370. [Google Scholar] [CrossRef]

- Tian, J.; Wu, F.; Zhang, P.; Lin, B.; Liu, T.; Liu, L. The coupling effect and damage analysis when drilling GFRP laminates using candlestick drills. Int. J. Adv. Manuf. Technol. 2019, 102, 519–531. [Google Scholar] [CrossRef]

- Thangavel, A.; Kuppusamy, R.; Lakshmanan, R. Optimization of drilling parameters using GRA for polyamide 6 nanocomposites. Matéria 2023, 28, e20220337. [Google Scholar] [CrossRef]

- Zhu, Z.; Sun, X.; Guo, K.; Sun, J.; Li, J. Recent advances in drilling tool temperature: A state-of-the-art review. Chin. J. Mech. Eng. 2022, 35, 148. [Google Scholar] [CrossRef]

- Franz, G.; Vantomme, P.; Hassan, M.H. A review on drilling of multilayer fiber-reinforced polymer composites and aluminum stacks: Optimization of strategies for improving the drilling performance of aerospace assemblies. Fibers 2022, 10, 78. [Google Scholar] [CrossRef]

- Spanu, P.; Abaza, B.F.; Constantinescu, T.C. Analysis and Prediction of Temperature Using an Artificial Neural Network Model for Milling Glass Fiber Reinforced Polymer Composites. Polymers 2024, 16, 3283. [Google Scholar] [CrossRef]

- Biruk-Urban, K.; Bere, P.; Józwik, J. Machine learning models in drilling of different types of glass-fiber-reinforced polymer composites. Polymers 2023, 15, 4609. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Barreiro, J.; Fernández-Abia, A.I.; de Lacalle, L.N.L. Nozzle design for combined use of MQL and cryogenic gas in machining. Int. J. Precis. Eng. Manuf. -Green Technol. 2017, 4, 87–95. [Google Scholar] [CrossRef]

- Pereira, O.; Català, P.; Rodríguez, A.; Ostra, T.; Vivancos, J.; Rivero, A.; López-de-Lacalle, L.N. The use of hybrid CO2+ MQL in machining operations. Procedia Eng. 2015, 132, 492–499. [Google Scholar] [CrossRef]

- Pereira, O.; Celaya, A.; Urbikaín, G.; Rodríguez, A.; Fernández-Valdivielso, A.; de Lacalle, L.N.L. CO2 cryogenic milling of Inconel 718: Cutting forces and tool wear. J. Mater. Res. Technol. 2020, 9, 8459–8468. [Google Scholar] [CrossRef]

- Rao, Y.S.; Mohan, N.S.; Shetty, N.; Acharya, S. Drilling response of carbon fabric/solid lubricant filler/epoxy hybrid composites: An experimental investigation. J. Compos. Sci. 2023, 7, 46. [Google Scholar] [CrossRef]

- Kargar, F.; Barani, Z.; Salgado, R.; Debnath, B.; Lewis, J.S.; Aytan, E.; Lake, R.K.; Balandin, A.A. Thermal percolation threshold and thermal properties of composites with high loading of graphene and boron nitride fillers. ACS Appl. Mater. Interfaces 2018, 10, 37555–37565. [Google Scholar] [CrossRef]

- Danayat, S.; Nayal, A.S.; Tarannum, F.; Annam, R.; Muthaiah, R.; Arulanandam, M.K.; Garg, J. Superior enhancement in thermal conductivity of epoxy/graphene nanocomposites through use of dimethylformamide (DMF) relative to acetone as solvent. MethodsX 2023, 11, 102319. [Google Scholar] [CrossRef]

- Lewis, J.S.; Barani, Z.; Magana, A.S.; Kargar, F.; Balandin, A.A. Thermal and Electrical Properties of Hybrid Composites with Graphene and Boron Nitride Fillers. arXiv 2019, arXiv:1903.01025. [Google Scholar]

- Unal, E. Temperature and thrust force analysis on drilling of glass fiber reinforced plastics. Therm. Sci. 2019, 23, 347–352. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; El Mansori, M.; Liu, G.; Chen, M. Study on the frictional heat at tool-work interface when drilling CFRP composites. Procedia Manuf. 2018, 26, 415–423. [Google Scholar] [CrossRef]

- Zitoune, R.; Cadorin, N.; Collombet, F.; Šíma, M. Temperature and wear analysis in function of the cutting tool coating when drilling of composite structure: In situ measurement by optical fiber. Wear 2017, 376, 1849–1858. [Google Scholar] [CrossRef]

- Nightingale, C.; Day, R. Flexural and interlaminar shear strength properties of carbon fibre/epoxy composites cured thermally and with microwave radiation. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1021–1030. [Google Scholar] [CrossRef]

- Gao, C.; Xiao, J.; Xu, J.; Ke, Y. Factor analysis of machining parameters of fiber-reinforced polymer composites based on finite element simulation with experimental investigation. Int. J. Adv. Manuf. Technol. 2016, 83, 1113–1125. [Google Scholar] [CrossRef]

- Hocheng, H.; Tsao, C. Comprehensive analysis of delamination in drilling of composite materials with various drill bits. J. Mater. Process. Technol. 2003, 140, 335–339. [Google Scholar] [CrossRef]

- Gaitonde, V.; Karnik, S.; Rubio, J.C.; Correia, A.E.; Abrão, A.; Davim, J.P. Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J. Mater. Process. Technol. 2008, 203, 431–438. [Google Scholar] [CrossRef]

- Sorrentino, L.; Turchetta, S.; Bellini, C. In process monitoring of cutting temperature during the drilling of FRP laminate. Compos. Struct. 2017, 168, 549–561. [Google Scholar] [CrossRef]

- Chen, W.-C. Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int. J. Mach. Tools Manuf. 1997, 37, 1097–1108. [Google Scholar] [CrossRef]

- Rawat, S.; Attia, H. Wear mechanisms and tool life management of WC–Co drills during dry high speed drilling of woven carbon fibre composites. Wear 2009, 267, 1022–1030. [Google Scholar] [CrossRef]

- Meshreki, M.; Damir, A.; Sadek, A.; Attia, M. Investigation of drilling of CFRP-aluminum stacks under different cooling modes. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. The effects of minimum quantity lubrication and cryogenic liquid nitrogen cooling on drilled hole quality in GLARE fibre metal laminates. Mater. Des. 2016, 89, 996–1006. [Google Scholar] [CrossRef]

- Renteria, J.; Legedza, S.; Salgado, R.; Balandin, M.; Ramirez, S.; Saadah, M.; Kargar, F.; Balandin, A. Magnetically-functionalized self-aligning graphene fillers for high-efficiency thermal management applications. Mater. Des. 2015, 88, 214–221. [Google Scholar] [CrossRef]

- Shahil, K.M.; Balandin, A.A. Graphene—Multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett. 2012, 12, 861–867. [Google Scholar] [CrossRef]

- Gulotty, R.; Castellino, M.; Jagdale, P.; Tagliaferro, A.; Balandin, A.A. Effects of functionalization on thermal properties of single-wall and multi-wall carbon nanotube–polymer nanocomposites. ACS Nano 2013, 7, 5114–5121. [Google Scholar] [CrossRef]

- Xian, G.; Qi, X.; Shi, J.; Tian, J.; Xiao, H. Toughened and self-healing carbon nanotube/epoxy resin composites modified with polycaprolactone filler for coatings, adhesives and FRP. J. Build. Eng. 2025, 111, 113207. [Google Scholar] [CrossRef]

- Barani, Z.; Mohammadzadeh, A.; Geremew, A.; Huang, C.Y.; Coleman, D.; Mangolini, L.; Kargar, F.; Balandin, A.A. Thermal properties of the binary-filler hybrid composites with graphene and copper nanoparticles. Adv. Funct. Mater. 2020, 30, 1904008. [Google Scholar] [CrossRef]

- El-Ghaoui, K.; Chatelain, J.-F.; Ouellet-Plamondon, C. Effect of graphene on machinability of glass fiber reinforced polymer (GFRP). J. Manuf. Mater. Process. 2019, 3, 78. [Google Scholar] [CrossRef]

- Palanikumar, K.; Latha, B.; Senthilkumar, V.; Davim, J.P. Analysis on drilling of glass fiber–reinforced polymer (GFRP) composites using grey relational analysis. Mater. Manuf. Process. 2012, 27, 297–305. [Google Scholar] [CrossRef]

- Li, A.; Zhang, C.; Zhang, Y.-F. Thermal conductivity of graphene-polymer composites: Mechanisms, properties, and applications. Polymers 2017, 9, 437. [Google Scholar] [CrossRef]

- Liu, L.; Xu, C.; Yang, Y.; Fu, C.; Ma, F.; Zeng, Z.; Wang, G. Graphene-based polymer composites in thermal management: Materials, structures and applications. Mater. Horiz. 2025, 12, 64–91. [Google Scholar] [CrossRef]

- Donaldson, K.; Stone, V.; Tran, C.; Kreyling, W.; Borm, P.J. Nanotoxicology. Occup. Environ. Med. 2004, 61, 727–728. [Google Scholar] [CrossRef]

- Shvedova, A.; Kisin, E.; Porter, D.; Schulte, P.; Kagan, V.; Fadeel, B.; Castranova, V. Mechanisms of pulmonary toxicity and medical applications of carbon nanotubes: Two faces of Janus? Pharmacol. Ther. 2009, 121, 192–204. [Google Scholar] [CrossRef]

- OECD. Strategies, Techniques and Sampling Protocols for Determining the Concentrations of Manufactured Nanomaterials in Air at the Workplace; OECD Publishing: Paris, France, 2017. [Google Scholar]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef]

- Cui, Y.; Wang, G.; Wang, W.; Cui, X.; Dong, W.; Wang, C.; Jin, M.; He, T.; Zhang, Z.; Liu, L. Trade-off between interface stiffening and Young’s modulus weakening in graphene/PMMA nanocomposites. Compos. Sci. Technol. 2022, 225, 109483. [Google Scholar] [CrossRef]

- Baldin, V.; Rosa Ribeiro da Silva, L.; Houck, C.F.; Gelamo, R.V.; Machado, Á.R. Effect of graphene addition in cutting fluids applied by MQL in end milling of AISI 1045 steel. Lubricants 2021, 9, 70. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Ma, J.; Gali, O.A.; Riahi, R.A. An evaluation of the tribological behavior of cutting fluid additives on aluminum-manganese alloys. Lubricants 2021, 9, 84. [Google Scholar] [CrossRef]

- Ameli Kalkhoran, S.N.; Vahdati, M.; Zhang, Z.; Yan, J. Influence of wax lubrication on cutting performance of single-crystal silicon in ultraprecision microgrooving. Int. J. Precis. Eng. Manuf. -Green Technol. 2021, 8, 611–624. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, S.; Shi, Q.; Ge, X.; Wang, W. Graphene-family lubricant additives: Recent developments and future perspectives. Lubricants 2022, 10, 215. [Google Scholar] [CrossRef]

- Gheisari, R.; Vazquez, M.; Tsigkis, V.; Erdemir, A.; Wooley, K.L.; Polycarpou, A.A. Microencapsulated paraffin as a tribological additive for advanced polymeric coatings. Friction 2023, 11, 1939–1952. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene as a protective coating and superior lubricant for electrical contacts. Appl. Phys. Lett. 2014, 105, 231907. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Abd-Elwahed, M.S.; Eltaher, M.A.; Najjar, I.; Melaibari, A.; Ahmed, K.I. Thermo-mechanical and delamination properties in drilling GFRP composites by various drill angles. Polymers 2021, 13, 1884. [Google Scholar] [CrossRef] [PubMed]

- Erturk, A.T.; Vatansever, F.; Yarar, E.; Guven, E.A.; Sinmazcelik, T. Effects of cutting temperature and process optimization in drilling of GFRP composites. J. Compos. Mater. 2021, 55, 235–249. [Google Scholar] [CrossRef]

| W% | G% | R2 | Adj R2 | RMSE | MAE | MAPE% | Sample Size |

|---|---|---|---|---|---|---|---|

| 0 | 0 | 0.90 | 0.88 | 2.87 | 1.51 | 2.28 | 16 |

| 0 | 0.25 | 0.90 | 0.88 | 3.01 | 1.58 | 2.38 | 16 |

| 0 | 2 | 0.92 | 0.91 | 2.60 | 1.58 | 2.16 | 16 |

| 1 | 0 | 0.97 | 0.94 | 2.52 | 1.34 | 2.01 | 16 |

| 1 | 0.25 | 0.91 | 0.89 | 2.56 | 1.35 | 2.03 | 16 |

| 1 | 2 | 0.89 | 0.87 | 3.60 | 1.89 | 2.86 | 16 |

| 2 | 0 | 0.94 | 0.93 | 3.03 | 1.44 | 2.37 | 16 |

| 2 | 0.25 | 0.92 | 0.90 | 2.58 | 1.26 | 1.92 | 16 |

| 2 | 2 | 0.90 | 0.88 | 3.08 | 1.62 | 2.44 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slamani, M.; Chatelain, J.-F.; Jammel, S. The Effect of Lubricant and Nanofiller Additives on Drilling Temperature in GFRP Composites. J. Compos. Sci. 2025, 9, 558. https://doi.org/10.3390/jcs9100558

Slamani M, Chatelain J-F, Jammel S. The Effect of Lubricant and Nanofiller Additives on Drilling Temperature in GFRP Composites. Journal of Composites Science. 2025; 9(10):558. https://doi.org/10.3390/jcs9100558

Chicago/Turabian StyleSlamani, Mohamed, Jean-François Chatelain, and Siwar Jammel. 2025. "The Effect of Lubricant and Nanofiller Additives on Drilling Temperature in GFRP Composites" Journal of Composites Science 9, no. 10: 558. https://doi.org/10.3390/jcs9100558

APA StyleSlamani, M., Chatelain, J.-F., & Jammel, S. (2025). The Effect of Lubricant and Nanofiller Additives on Drilling Temperature in GFRP Composites. Journal of Composites Science, 9(10), 558. https://doi.org/10.3390/jcs9100558