Investigation of the Possibility of Utilizing Man-Made Waste to Produce Composite Binders

Abstract

1. Introduction

- These costs are proportionate to 11.9% of the cost of building of a phosphoric acid plant.

- The cost of exploiting dumps with phosphogypsum is rather high, and is equal to approximately 20% of the expense of phosphogypsum processing.

- The areas of land occupied by dumps can successfully be used for agriculture.

- The negative impacts of these dumps on the environment cannot be evaluated.

- Binder production;

- Cement production;

- Calcium carbonate and acid production;

- Soil remediation.

- -

- Alpha and beta modifications of gypsum binders;

- -

- Construction material production;

- -

- Application as an additive or filler substance

2. Materials and Methods

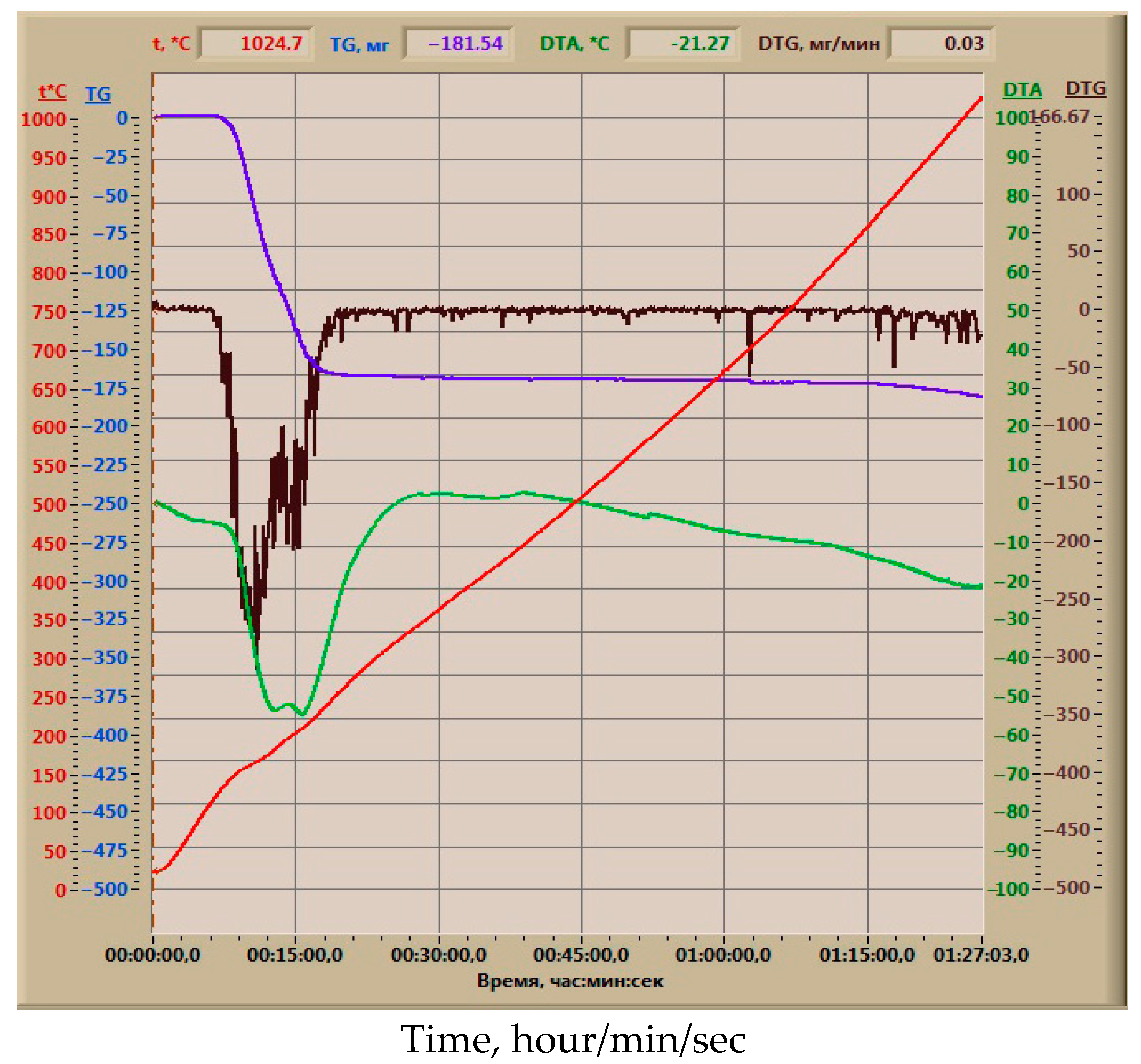

- Identifying the character of chemical substances with the aid of melting points, transitions among polymorphic features, and thermal decomposition;

- Carrying out qualitative and, in a few cases, quantitative evaluation of mechanical combinations of numerous materials;

- Measuring temperatures of segment transitions in character materials and systems, in addition to generating melting diagrams based on them;

- Determining the kinetic and thermodynamic traits of segment and chemical transitions;

- Determining the thermophysical traits of materials.

3. Results and Discussion

- Environmental and economic benefits. Phosphogypsum, phosphorous slags, and enrichment tailings, which would conventionally be disposed of as waste, can be used to replace natural raw materials (gypsum, cement). Energy consumption is reduced due to no need for high-temperature firing (unlike Portland cement, which requires 1450 °C).

- Technological advantages. Hydrothermal treatment accelerates hardening (steaming gives a strength of 30 MPa in 28 days). Alkaline components (MgO, CaO from tailings) neutralize the acidic impurities of phosphogypsum, increasing durability. Mechanical activation (grinding) enhances recrystallization, improving the structure of the material.

- Improved physical and mechanical properties. Due to the high early strength (5–7 MPa for bending, 20–30 MPa for compression), strength increases over time through the hydration of slag and formation of hydrosilicates. Water resistance is increased due to the formation of insoluble compounds (calcium fluoride, hydroxylapatite).

4. Conclusions

- -

- the optimal composition (65% phosphorous slag, 20% phosphogypsum, 15% burnt tailings) provides compressive strength up to 31.1 MPa after steaming, which is comparable to cement grade M300;

- -

- when replacing natural gypsum with phosphogypsum, the strength increases by 5–10% (from 26.7 to 28.3 MPa after 6 months of hardening);

- -

- the technology eliminates the need for high-temperature firing (unlike Portland cement), reducing energy consumption by 40–50%;

- -

- the use of waste reduces the cost of raw materials by 30–35% compared to the production of traditional binders;

- -

- utilization of phosphogypsum and slags reduces the load on landfills and prevents environmental pollution;

- -

- neutralization of acidic impurities of phosphogypsum with oxides of MgO and CaO from tailings reduces leaching of toxins by 70–80%;

- -

- hydrothermal treatment (steaming) accelerates strength gain, up to 90% of the grade in 28 days against 60–70% for cement systems;

- -

- mechanical activation of the components increases the reactivity of the binder by 15–20% by increasing the degree of recrystallization of gypsum;

- -

- the technology is applicable in the production of building blocks, road foundations, and reclamation materials with a cost 20–25% lower than analogs.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kulikova, E.Y.; Balovtsev, S.V.; Skopintseva, O.V. Complex estimation of geotechnical risks in mine and underground construction. Sustain. Dev. Mt. Territ. 2023, 15, 7–16. [Google Scholar] [CrossRef]

- Yessenbayev, B.A.; Naukenova, A.S.; Shapalov, S.K.; Ramatullaeva, L.I.; Ivakhniyuk, G.K. Analysis of the impact of bauxite dumps on the environment and public health. MIAB. Min. Inf. Anal. Bull. 2024, 3, 55–69. [Google Scholar]

- Kulikova, E.Y.; Balovtsev, S.V. Risk control system for the construction of urban underground structures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 962, 042020. [Google Scholar] [CrossRef]

- Yesenbayev, B.; Kolesnikov, A.; Eremenko, O.; Issengaliyeva, G. Environmental assessment of the consequences of bauxite mining in Kazakhstan. MIAB. Min. Inf. Anal. Bull. 2025, 6, 82–93. [Google Scholar] [CrossRef]

- Skopintseva, O.V.; Ganova, S.D.; Buzin, A.A.; Fedotova, V.P. Measures to reduce dusting during loading and transportation of solid mineral resources. Gorn. Zhurnal 2019, 12, 76–79. [Google Scholar] [CrossRef]

- Filin, A.; Kolbina, I.; Seidaliyev, A.; Koibakova, S.; Mankesheva, O. Comparison of the Quality of Gas Equipment at Metallurgical and Coke-Chemical Enterprises and Production Plants. Pol. J. Environ. Stud. 2024, 33, 2999–3008. [Google Scholar] [CrossRef] [PubMed]

- Sapargaliyeva, B.O.; Bychkov, A.Y.; Alferyeva, Y.O.; Syrlybekkyzy, S.; Altybaeva, Z.K.; Nurshakhanova, L.K.; Seidaliyeva, L.K.; Suleimenova, B.S.; Zhidebayeva, A.E.; Zhanikulov, N.N.; et al. Thermodynamic modeling of the formation of the main minerals of cement clinker and zinc fumes in the processing of toxic technogenic waste of the metallurgical industry. Rasayan J. Chem. 2022, 15, 2181–2187. [Google Scholar] [CrossRef]

- Muratov, B.; Shapalov, S.; Syrlybekkyzy, S.; Volokitina, I.; Zhunisbekova, D.; Takibayeva, G.; Nurbaeva, F.; Aubakirova, T.; Nurshakhanova, L.; Koishina, A.; et al. Physico-Chemical Study of the Possibility of Utilization of Coal Ash by Processing as Secondary Raw Materials to Obtain a Composite Cement Clinker. J. Compos. Sci. 2023, 7, 234. [Google Scholar] [CrossRef]

- Bumanis, G.; Zorica, J.; Bajare, D. Properties of Foamed Lightweight High-Performance Phosphogypsum-Based Ternary System Binder. Appl. Sci. 2020, 10, 6222. [Google Scholar] [CrossRef]

- Kocherov, Y.; Makulbekova, G.; Mamitova, A.; Ramatullaeva, L.; Medeshev, B.; Kolesnikova, O. Investigation of the Physico-Chemical and Mechanical Properties of Expanded Ceramsite Granules Made on the Basis of Coal Mining Waste. J. Compos. Sci. 2024, 8, 306. [Google Scholar] [CrossRef]

- Donayev, A.; Shapalov, S.; Sapargaliyeva, B.; Ivakhniyuk, G. Studies of waste from the mining and metallurgical industry, with the determination of its impact on the life of the population. Ser. Geol. Tech. Sci. 2022, 4, 55–68. [Google Scholar] [CrossRef]

- Naraev, V.N.; Natorkhin, M.I.; Saipov, A.A.; Kolesnikova, O.G. Review of the processing of minerals and technogenic sulfide raw material with the extraction of metals and recovering elemental sulfur by electrochemical methods. Rasayan J. Chem. 2020, 13, 2420–2428. [Google Scholar] [CrossRef]

- Volokitina, I.E.; Volokitin, A.V.; Kolesnikov, A.S.; Kolesnikova, O.G. Effect of Deformation by High-Pressure Torsion in a Combined Matrix on the Properties of Brass. Metallurgist 2023, 66, 1601–1606. [Google Scholar] [CrossRef]

- Volokitina, I.; Bychkov, A.; Volokitin, A.; Kolesnikov, A. Natural Aging of Aluminum Alloy 2024 After Severe Plastic Deformation. Metallogr. Microstruct. Anal. 2023, 12, 564–566. [Google Scholar] [CrossRef]

- Gapparov, J.; Syrlybekkyzy, S.; Filin, A.; Zhatkanbayev, Y. Overview of techniques and methods of processing the waste of stale clinkers of zinc production. MIAB Min. Informational Anal. Bull. 2024, 4, 44–55. [Google Scholar]

- Zhangabay, N.; Suleimenov, U.; Utelbayeva, A.; Baibolov, K.; Imanaliyev, K.; Moldagaliyev, A.; Karshyga, G.; Duissenbekov, B.; Fediuk, R.; Amran, M. Analysis of a Stress-Strain State of a Cylindrical Tank Wall Vertical Field Joint Zone. Buildings 2022, 12, 1445. [Google Scholar] [CrossRef]

- Bedov, A.I.; Gabitov, A.I.; Domarova, E.V.; Kolesnikov, A.S. Investigation of the stress-strain state of domical masonry vaults. Constr. Mater. Prod. 2023, 6, 6. [Google Scholar]

- Khudyakova, T.M.; Kolesnikova, O.G.; Zhanikulov, N.N.; Ashirbaev, H.A.; Kolesnikova, V.A. Low-Basicity Cement, Problems and Advantages of its Utilization. Refract. Ind. Ceram. 2021, 62, 369–374. [Google Scholar] [CrossRef]

- Klyuev, A.V.; Kashapov, N.F.; Klyuev, S.V.; Zolotareva, S.V.; Shchekina, N.A.; Shorstova, E.S.; Lesovik, R.V.; Ayubov, N.A. Experimental studies of the processes of structure formation of composite mixtures with technogenic mechanoactivated silica component. Constr. Mater. Prod. 2023, 6, 2. [Google Scholar]

- Nadirov, K.S.; Zhantasov, M.K.; Bimbetova, G.Z.; Sadyrbayeva, A.S.; Orynbasarov, A.K.; Sakybayev, B.A. The study of the gossypol resin impact on adhesive properties of the intermediate layer of the pipeline three-layer rust protection coating. Int. J. Adhes. Adhes. 2017, 78, 195–199. [Google Scholar] [CrossRef]

- Nurlankyzy, C.A.; Niyazbekova, R.K.; Al Azzam, M.K.; Mukhambetov, G.M.; Aimagambetova, R.Z.; El-Sayed, N.; Serekpayeva, M. An Overview of the Current State and Prospects for Oil Recovery from Oily Sludge. Indones. J. Chem. 2023, 23, 268–277. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, G.; Shi, C.; Dong, Q.; Ji, T. Achieving Practical Venue Recycle of Waste Oil-Based Drilling Fluids with Vacuum Distillation Technology. ACS Omega 2023, 8, 16306–16314. [Google Scholar] [CrossRef]

- Zhantasov, M.K.; Bimbetova, G.Z.; Sadyrbayeva, A.S.; Orynbasarov, A.K.; Kutzhanova, A.N.; Turemuratov, R.S.; Botabaev, N.E.; Zhantasova, D. Examination of optimal parameters of oxy-ethylation of fatty acids with a view to obtaining demulsifiers for deliquefaction in the system of skimming and treatment of oil: A method to obtain demulsifier from fatty acids. Chem. Today 2016, 34, 72–77. [Google Scholar]

- Levickaya, K.; Alfimova, N.; Nikulin, I.; Kozhukhova, N.; Buryanov, A. The Use of Phosphogypsum as a Source of Raw Materials for Gypsum-Based Materials. Resources 2024, 13, 69. [Google Scholar] [CrossRef]

- Garg, M.; Jain, N.; Singh, M. Development of alpha plaster from phosphogypsum for cementitious binders. Constr. Build. Mater. 2009, 23, 3138–3143. [Google Scholar] [CrossRef]

- Pliaka, M.; Gaidajis, G. Examination of the environmental behavior of phosphogypsum with the application of lab-scale experiment. J. Environ. Sci. Health 2023, 58, 706–714. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Mo, K.H.; Yap, S.P.; Gencel, O.; Ling, T.C. Mechanical strength, water resistance and drying shrinkage of lightweight hemihydrate phosphogypsum-cement composite with ground granulated blast furnace slag and recycled waste glass. Constr. Build. Mater. 2022, 345, 128232. [Google Scholar] [CrossRef]

- Wang, Y.; Huo, H.; Chen, B.; Cui, Q. Development and optimization of phosphogypsum-based geopolymer cement. Constr. Build. Mater. 2023, 369, 130577. [Google Scholar] [CrossRef]

- Sun, T.; Li, W.; Xu, F.; Yu, Z.; Wang, Z.; Ouyang, G.; Xu, D. A new eco-friendly concrete made of high content phosphogypsum based aggregates and binder: Mechanical properties and environmental benefits. J. Clean. Prod. 2023, 400, 136555. [Google Scholar] [CrossRef]

- Fornes, I.V.; Vaičiukynienė, D.; Nizevičienė, D.; Doroševas, V.; Michalik, B. A comparative assessment of the suitability of phosphogypsum from different origins to be utilised as the binding material of construction products. J. Build. Eng. 2012, 44, 102995. [Google Scholar] [CrossRef]

- ASTM E300-03; Standard Practice for Sampling Industrial Chemicals. ASTM International: West Conshohocken, PA, USA, 2022.

- Andreev, E.E.; Tikhonov, O.N. Droblenie, izmel’chenie i podgotovka syr’ya: Uchebnik. In Crushing, Grinding and Raw Material Preparation: Textbook; Saint Petersburg State University of Mining and Geology Press: St. Petersburg, Russia, 2007; pp. 156–182. [Google Scholar]

- ASTM B214-22; Standard Test Method for Sieve Analysis of Metal Powders. ASTM International: West Conshohocken, PA, USA, 2022.

- Andreev, E.E.; Lvov, V.V.; Tikhonov, O.N. Analiz rezultatov opredeleniya krupnosti chastits razlichnymi metodami [Analysis of Results of Particle Size Determination by Various Methods]. Obogashchenie Rud 2011, 6, 30–33. [Google Scholar]

- ISO 679:2009; Methods of Testing Cements—Determination of Strength. International Organization for Standardization: Geneva, Switzerland, 2009.

- EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016.

- ASTM C109/C109M-21; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C187-16; Standard Test Method for Amount of Water Required for Normal Consistency of Hydraulic Cement Paste. ASTM International: West Conshohocken, PA, USA, 2016.

- ISO 1920-10:2010; Testing of Concrete—Part 10: Determination of Static Modulus of Elasticity in Compression. International Organization for Standardization: Geneva, Switzerland, 2010.

- ASTM C150/C150M-22; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- ISO 18589-3:2015; Measurement of Radioactivity in the Environment—Soil—Part 3: Test Method of Gamma-Emitting Radionuclides Using Gamma-Ray Spectrometry. International Organization for Standardization: Geneva, Switzerland, 2015.

- IAEA Safety Standards Series No. GSR Part 3; Radiation Protection and Safety of Radiation Sources: International Basic Safety Standards. International Atomic Energy Agency: Vienna, Austria, 2014.

- ISO 1893:2007; Refractory Products—Determination of Refractoriness Under Load—Differential Method with Rising Temperature. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 5017:2013; Dense Shaped Refractory Products—Determination of Bulk Density, Apparent Porosity and True Porosity. International Organization for Standardization: Geneva, Switzerland, 2013.

- ASTM C684-14; Standard Test Method for Making, Accelerated Curing, and Testing Concrete Compression Test Specimens. ASTM International: West Conshohocken, PA, USA, 2014.

- EN 12390-9:2017; Testing Hardened Concrete—Part 9: Freeze-Thaw Resistance—Scaling. European Committee for Standardization: Brussels, Belgium, 2017.

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2019.

- Khudyakova, T.M.; Luginina, I.G.; Shaposhnikova, M.A. Binding Material. Author’s Certificate No. 767049, USSR. Publ. 23 August 1981, Bull. No. 31, 2p.

- Khudyakova, T.M.; Luginina, I.G.; Shaposhnikova, M.A.; Mikhailova, V.I. Binding Material. Author’s Certificate No. 1560502, USSR. Publ. 30 April 1990, Bull. No. 36, 2p.

- Murali, G.; Azab, M. Recent research in utilization of phosphogypsum as building materials: Review. J. Mater. Res. Technol. 2023, 25, 960–987. [Google Scholar] [CrossRef]

- Seraya, N.; Litvinov, V.; Daumova, G.; Zhusipov, N.; Idrisheva, Z.; Aubakirova, R. Production Waste Management: Qualitative and Quantitative Characteristics and the Calculation of the Hazard Class of Phosphogypsum. Processes 2023, 11, 3033. [Google Scholar] [CrossRef]

- Ibragimov, R.A.; Shakirzyanov, F.R.; Kayumov, R.A.; Korolev, E.V. Evaluation of the influence of an aggressive environment on the durability of the cement stone. Constr. Mater. Prod. 2024, 7, 4. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Slobodchikova, N.A.; Saidumov, M.S.; Abumuslimov, A.S.; Mezhidov, D.A.; Khezhev, T.A. Application of ash and slag waste from coal combustion in the construction of the earth bed of roads. Constr. Mater. Prod. 2024, 7, 3. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.; Li, H. Utilization of Phosphogypsum in Cementitious Materials: Mechanical Properties and Microstructure Analysis. Materials 2021, 14, 4567. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, G.; Zhou, Y. Comparative Study on the Performance of Phosphorus Slag-Based and Portland Cement-Based Binders. Sustainability 2022, 14, 10234. [Google Scholar] [CrossRef]

- Ivanova, T.; Kolesnekov, A.; Torlova, A. Barium-Containing Tailings as an Active Mineral Additive for Composite Binders. Appl. Sci. 2020, 10, 7825. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Hydration Mechanisms and Strength Development of Phosphogypsum-Slag Cementitious Systems. Materials 2019, 12, 3568. [Google Scholar] [CrossRef]

- Baruzdin, A.A.; Zakrevskaya, L.V.; Nikolaeva, K.A. COMPOSITE MATERIAL BASED ON INDUSTRIAL WASTES. Expert. Theory Pr. 2023, 17–23. [Google Scholar] [CrossRef] [PubMed]

| Compound | Components, wt.% | Binder Activity, MPa | |||||

|---|---|---|---|---|---|---|---|

| Phosphogypsum Dihydrate | Granular Phosphorus Slag | Burnt “Tails” tobzh = 900 °C | Steaming | Water Curing | |||

| Rcom | Rmeas | Rcom. | Rmeas | ||||

| 1 | 20 | 50 | 30 | 5.29 | 27.88 | 5.57 | 28.48 |

| 2 | 15 | 60 | 25 | 5.48 | 29.87 | 5.08 | 24.29 |

| 3 | 20 | 65 | 15 | 5.58 | 31.08 | 4.49 | 24.12 |

| Compound | Components, wt.% | Binder Activity, MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Phosphogypsum Dihydrate | Granular Phosphorus Slag | Burnt “Tails” tobzh = 900 °C | Rcom. | Rmeas | |||||

| 28 Days | 3 Months | 6 Months | 28 Days | 3 Months | 6 Months | ||||

| 1 | 55 | 25 | 20 | 6.11 | 6.77 | 7.18 | 23.18 | 25.08 | 26.68 |

| 2 | 55 | 15 | 30 | 5.77 | 6.58 | 6.79 | 19.68 | 21.48 | 23.11 |

| 3 | 35 | 30 | 35 | 5.19 | 6.12 | 6.28 | 19.79 | 21.27 | 22.12 |

| 4 | 35 | 35 | 10 | 4.18 | 4.89 | 5.77 | 18.69 | 19.08 | 21.17 |

| Compound | Components, wt.% | Binder Activity, MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Phosphogypsum Dihydrate | Granular Phosphorus Slag | Burnt “Tails” tobzh = 900 °C | Rcom. | Rmeas | |||||

| 28 Days | 3 Months | 6 Months | 28 Days | 3 Months | 6 Months | ||||

| 1 | 55 | 25 | 20 | 6.58 | 7.29 | 7.49 | 24.08 | 25.87 | 28.28 |

| 2 | 55 | 15 | 30 | 6.12 | 6.78 | 7.02 | 21.48 | 23.88 | 25.58 |

| 3 | 35 | 30 | 35 | 5.69 | 6.18 | 6.58 | 21.87 | 22.49 | 23.19 |

| 4 | 35 | 35 | 10 | 5.11 | 5.58 | 6.18 | 19.48 | 21.29 | 22.37 |

| Parameter | Proposed Binder | Portland Cement | Classic Gypsum Cement |

|---|---|---|---|

| Raw material base | Waste products (phosphogypsum, slags) | Limestone, clay | Natural gypsum |

| Energy consumption | Low (grinding + firing at 900 °C) | High (firing at 1450 °C) | Moderate (grinding) |

| Strength (Rsl, MPa) | 24–31 (28 days) | 30–50 (28 days) | 10–20 (28 days) |

| Water resistance | Increased (by neutralizing impurities) | High | Low |

| Environmental friendliness | Waste recycling | High carbon footprint | Depends on the extraction of gypsum |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuldeyev, E.; Begentayev, M.; Sarsenbayev, B.; Kolesnikov, A.; Syrlybekkyzy, S.; Agabekova, A.; Bayamirova, R.; Togasheva, A.; Zholbassarova, A.; Koishina, A.; et al. Investigation of the Possibility of Utilizing Man-Made Waste to Produce Composite Binders. J. Compos. Sci. 2025, 9, 531. https://doi.org/10.3390/jcs9100531

Kuldeyev E, Begentayev M, Sarsenbayev B, Kolesnikov A, Syrlybekkyzy S, Agabekova A, Bayamirova R, Togasheva A, Zholbassarova A, Koishina A, et al. Investigation of the Possibility of Utilizing Man-Made Waste to Produce Composite Binders. Journal of Composites Science. 2025; 9(10):531. https://doi.org/10.3390/jcs9100531

Chicago/Turabian StyleKuldeyev, Erzhan, Meiram Begentayev, Bakhitzhan Sarsenbayev, Alexandr Kolesnikov, Samal Syrlybekkyzy, Aktolkyn Agabekova, Ryskol Bayamirova, Aliya Togasheva, Akshyryn Zholbassarova, Akmaral Koishina, and et al. 2025. "Investigation of the Possibility of Utilizing Man-Made Waste to Produce Composite Binders" Journal of Composites Science 9, no. 10: 531. https://doi.org/10.3390/jcs9100531

APA StyleKuldeyev, E., Begentayev, M., Sarsenbayev, B., Kolesnikov, A., Syrlybekkyzy, S., Agabekova, A., Bayamirova, R., Togasheva, A., Zholbassarova, A., Koishina, A., Kuldeyeva, E., Zhunisbekova, D., & Mutasheva, G. (2025). Investigation of the Possibility of Utilizing Man-Made Waste to Produce Composite Binders. Journal of Composites Science, 9(10), 531. https://doi.org/10.3390/jcs9100531