Evaluation of the Reinforcing Effect of Intermetallic and Ceramic Phases in a WE54-15%(Vol.%)SiCw Composite Using In Situ Synchrotron Radiation Diffraction

Abstract

1. Introduction

2. Materials and Methods

3. Results

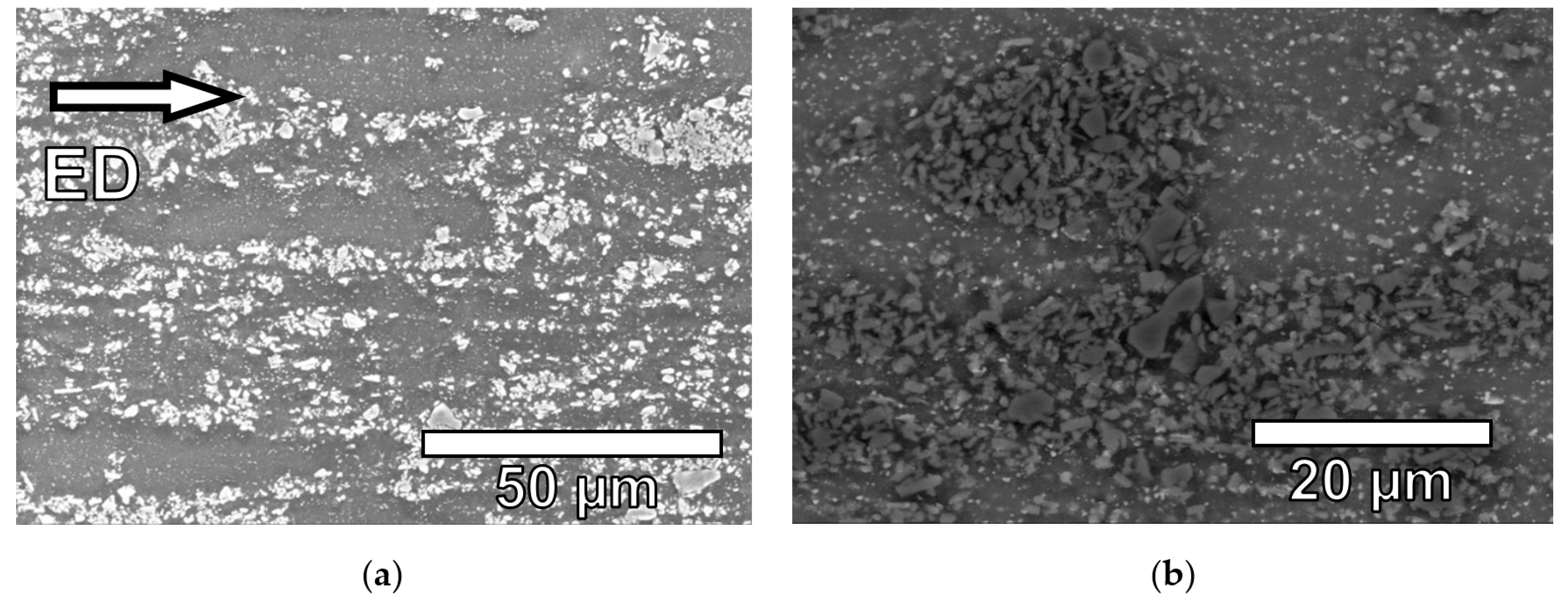

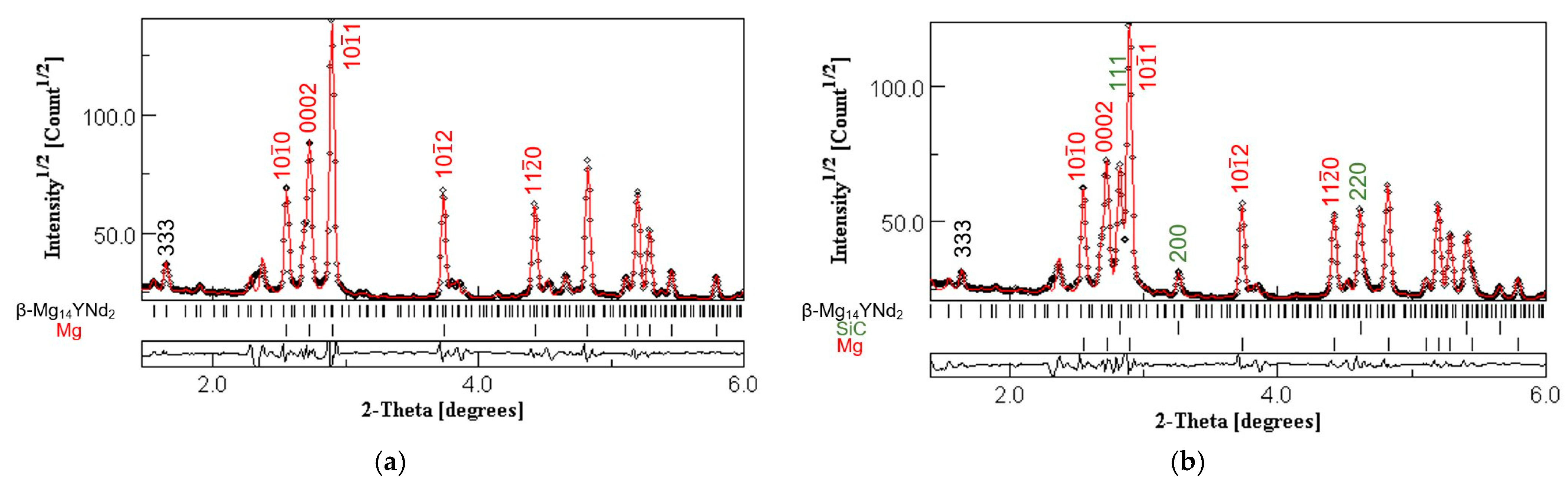

3.1. Microstructural Characterization of the WE54 Alloy and the WE54-15%SiCw Composite

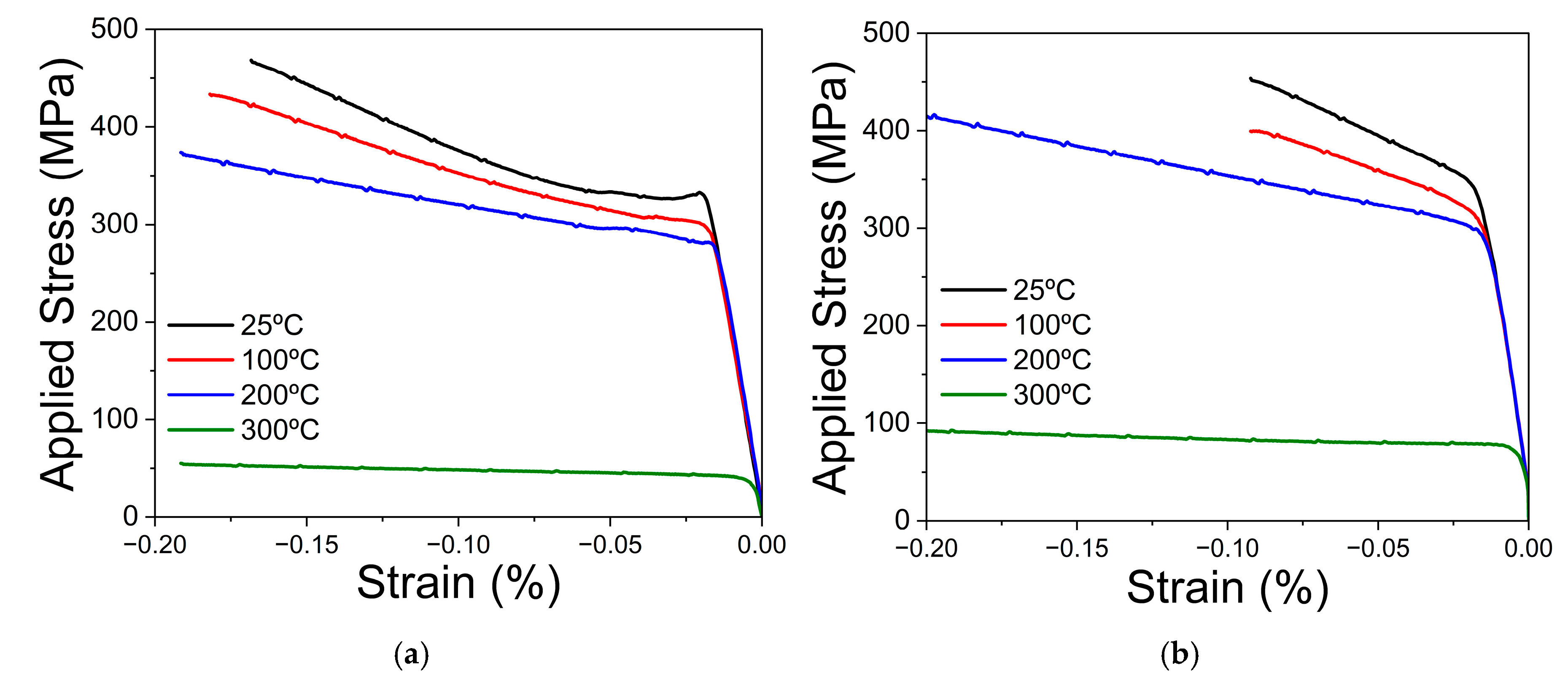

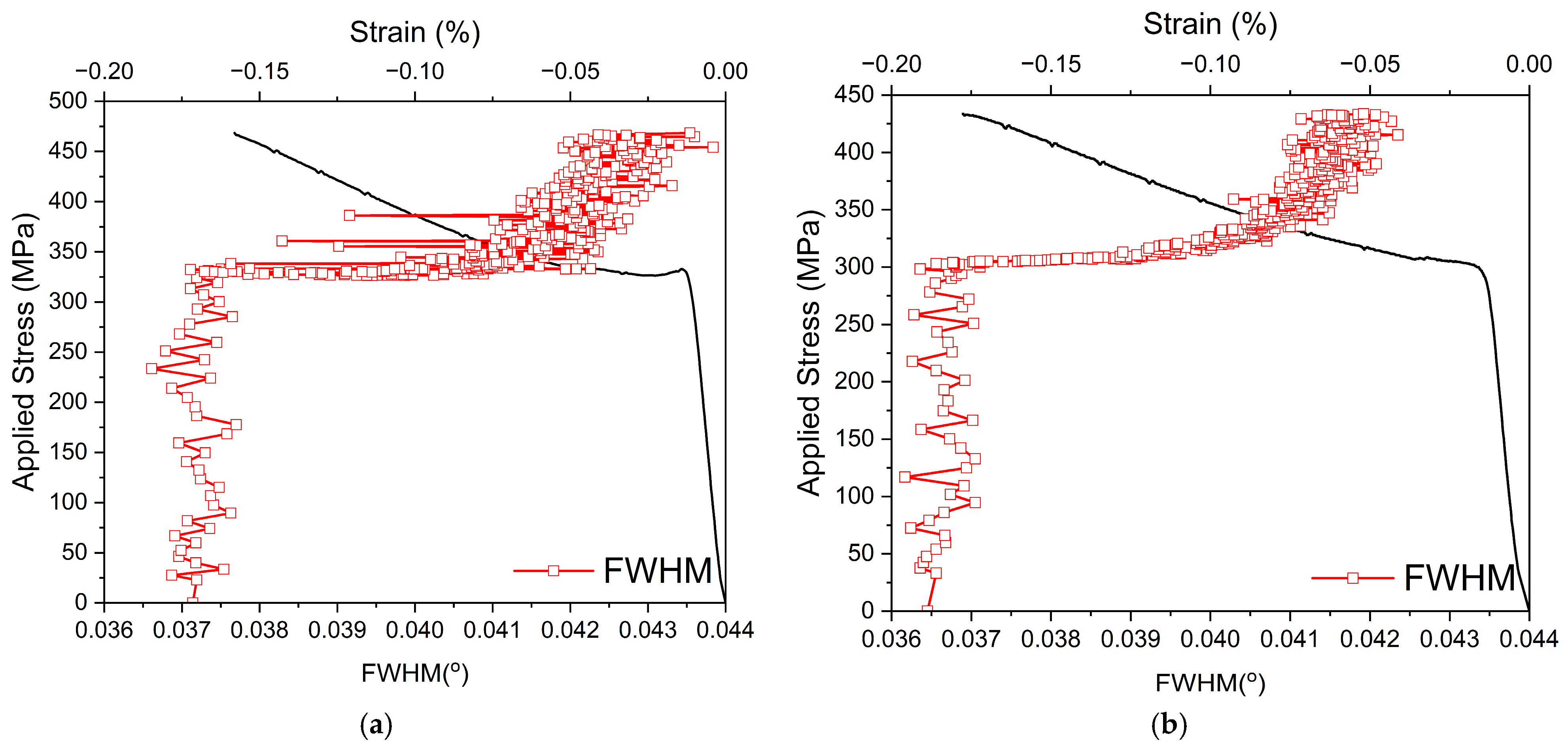

3.2. Compressive Behaviour of the WE54 Alloy and the WE54-15%SiCw Composite

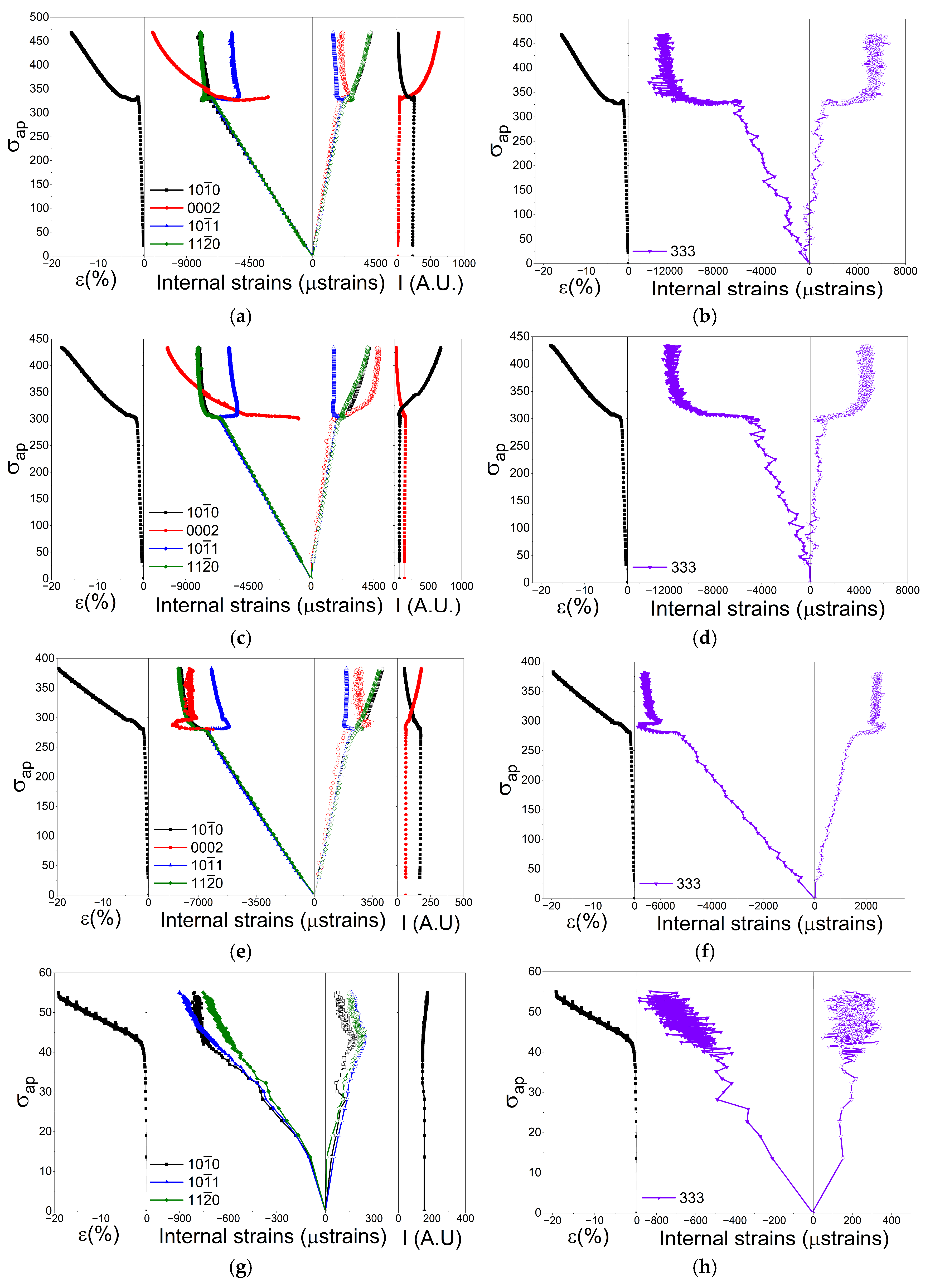

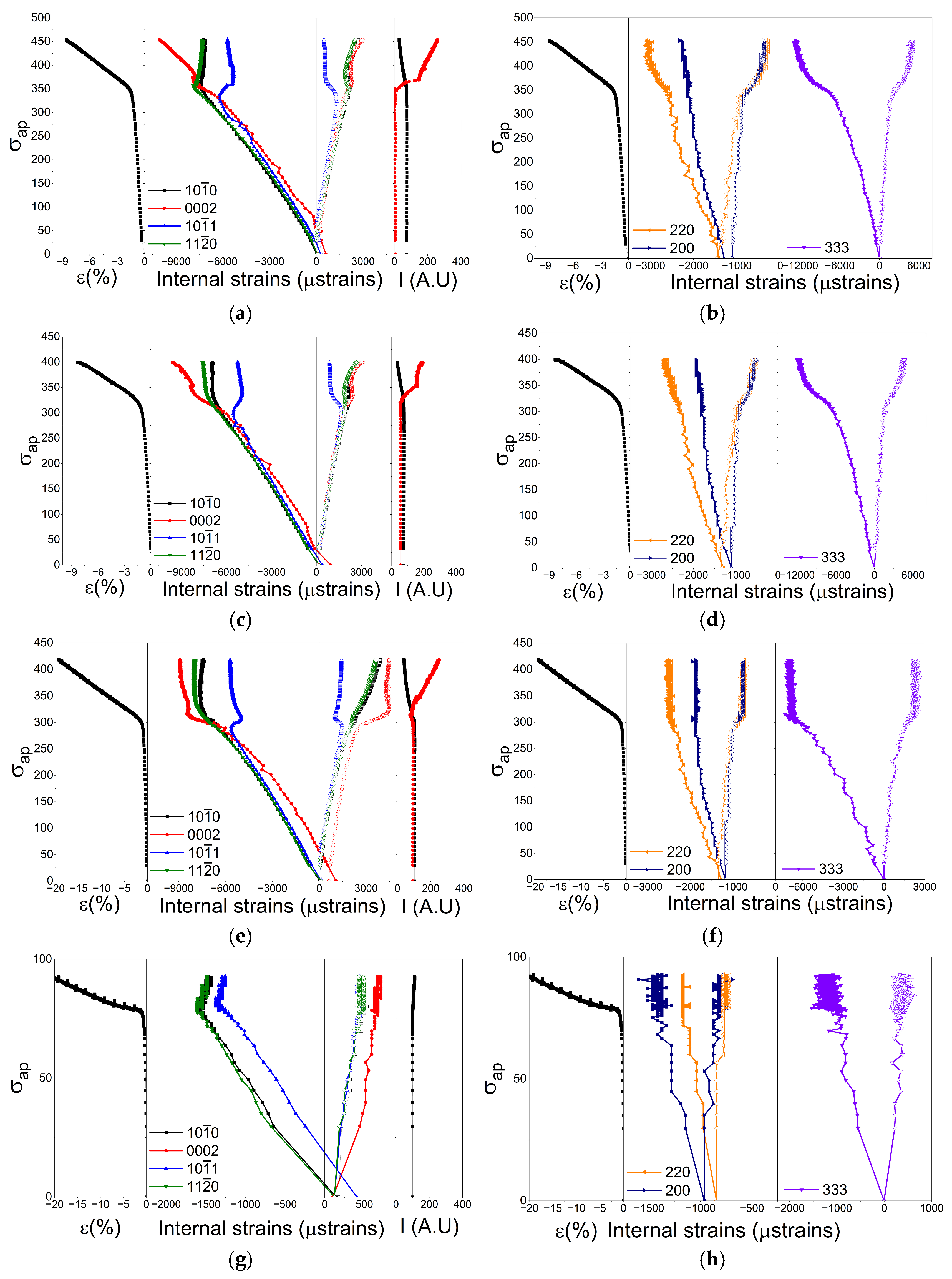

3.3. Evolution of Internal Strains in the WE54 Alloy

3.4. Evolution of Internal Strains in the WE54-15%SiCw Composite

4. Discussion

5. Conclusions

- (1)

- The addition of SiC whiskers increases the mechanical strength across the entire temperature range studied. However, this ceramic phase is not effective in increasing the strength of the composite compared to the unreinforced. The mechanical strength decays above 200 °C, regardless of the presence of SiC whiskers.

- (2)

- The plastic deformation process is dominated by tensile twinning and dislocation slip both in the basal system in “soft” grains and in the non-basal system in grains oriented with prismatic planes normal to the compression axis. Twins, which are mainly oriented with the (0002) plane normal to the compression axis, significantly increase their internal elastic deformation as the applied stress raises and as the deformation proceeds in the plastic regime up to 200 °C. At 300 °C, twinning is not activated, and deformation is dominated by dislocation slip and grain boundary sliding.

- (3)

- β-Mg14YNd2 precipitates assume a significant load after the yield point from the magnesium matrix, which tends to relax as the temperature increases. Above 200 °C, their effectiveness disappears. Precipitates within the grains generate an opposing stress that counteracts the applied compressive stress when they are “engulfed” by the twins during their growth.

- (4)

- The addition of SiC whiskers generates residual stresses in the composite material, which are tensile in the magnesium matrix and compressive in the ceramic reinforcement. The reinforcing effect of ceramic whiskers is greater than that of precipitates, although it also tends to disappear at temperatures equal to or higher than 200 °C. In the initial stages of twin formation, up to 200 °C, there is a sudden change in elastic deformations. While grains oriented with {101} planes normal to the compression axis decrease their elastic deformations (in absolute value), grains oriented with {100} and {110} planes normal to the compression axis increase their elastic deformations. In the composite material, this effect is minimized by the presence of the ceramic phase.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luo, A. Recent magnesium alloy development for elevated temperature applications. Int. Mater. Rev. 2004, 49, 13–30. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, A.; Li, C.; Xie, H.; Jiang, B.; Dong, Z.; Jin, P.; Pan, F. Recent advances of high strength Mg-RE alloys: Alloy development, forming and application. J. Mater. Res. Technol. 2023, 26, 2919–2940. [Google Scholar] [CrossRef]

- Wu, G.; Wang, C.; Sun, M.; Ding, W. Recent developments and applications on high-performance cast magnesium rare-earth alloys. J. Magnes. Alloy. 2021, 9, 1–20. [Google Scholar] [CrossRef]

- Moreno, I.P.; Nandy, T.K.; Jones, J.W.; Allison, J.E.; Pollock, T.M. Microstructural stability and creep of rare-earth containing magnesium alloys. Scr. Mater. 2003, 48, 1029–1034. [Google Scholar] [CrossRef]

- Choudhuri, D.; Srinivasan, S.G.; Gibson, M.A.; Zheng, Y.; Jaeger, D.L.; Fraser, H.L.; Hamish, L.; Banerjee, R. Exceptional increase in the creep life of magnesium rare-earth alloys due to localized bond stiffening. Nat. Commun. 2017, 8, 2000. [Google Scholar] [CrossRef]

- Zhu, S.; Gibson, M.; Nie, J.F.; Easton, M.A.; Dunlop, G.L. Primary creep of die-cast magnesium–rare earth based alloys. Metall. Mater. Trans. A 2009, 40, 2036–2041. [Google Scholar] [CrossRef]

- Polmear, I.J. Light Alloys: Metallurgy of the Light Metals, 3rd ed.; Edward Arnold: London, UK, 1995. [Google Scholar]

- Nie, J.F. Precipitation and Strengthening in Selected Magnesium Alloys; Magnesium Technology 2002; The Institute of Metals: London, UK, 2002; pp. 103–110. [Google Scholar]

- Nie, J.F.; Muddle, B.C. Characterization of strengthening precipitate phases in a Mg–Y–Nd alloy. Acta Mater. 2000, 48, 1691–1703. [Google Scholar] [CrossRef]

- Wang, J.G.; Hsiung, L.M.; Nieh, T.G.; Mabuchi, M. Creep of a heat treated Mg–4Y–3RE alloy. Mater. Sci. Eng. A 2001, 315, 81–88. [Google Scholar] [CrossRef]

- Karimzadeh, H.; Worall, J.M.; Pilkington, R.; Lorimer, G.W. Tensile and creep fracture of a Mg-Y-RE alloy. In Proceedings of the London Conference on Magnesium Technology, London, UK, 3–4 November 1986; The Institute of Metals: London, UK, 1986; pp. 47–56. [Google Scholar]

- Nie, J.F.; Muddle, B.C. Precipitation in magnesium alloy WE54 during isothermal ageing at 250 °C. Scr. Mater. 1999, 40, 1089–1094. [Google Scholar] [CrossRef]

- Antion, C.; Donnadieu, P.; Perrard, F.; Deschamps, A.; Tassin, C.; Pisch, A. Hardening precipitation in a Mg–4Y–3RE alloy. Acta Mater. 2003, 51, 5335–5348. [Google Scholar] [CrossRef]

- Lukyanova, E.A.; Martynenko, N.S.; Shakhova, I.; Belyakov, A.N.; Rokhlin, L.L.; Dobatkin, S.V.; Estrin, Y. Strengthening of age-hardenable WE43 magnesium alloy processed by high pressure torsion. Mater. Lett. 2016, 170, 5–9. [Google Scholar] [CrossRef]

- Minárik, P.; Veselý, J.; Král, R.; Bohlen, J.; Kubásek, J.; Janeček, M.; Stráská, J. Exceptional mechanical properties of ultra-fine grain Mg-4Y-3RE alloy processed by ECAP. Mater. Sci. Eng. A 2017, 708, 193–198. [Google Scholar] [CrossRef]

- Martynenko, N.S.; Lukyanova, E.A.; Serebryany, V.N.; Gorshenkov, M.V.; Shchetinin, I.V.; Raab, G.I.; Dobatkin, S.V.; Estrin, Y. Increasing strength and ductility of magnesium alloy WE43 by equal-channel angular pressing. Mater. Sci. Eng. A 2018, 712, 625–629. [Google Scholar] [CrossRef]

- Daghigh, M.; Mohri, M.; Ghanbari, H.; Nili-ahmadabadi, M. The effect of thermal and strain-induced aging on the mechanical behavior of room temperature ECAP processing of WE43 magnesium alloy. J. Mater. Res. Technol. 2023, 24, 8508–8521. [Google Scholar] [CrossRef]

- Sanchez, C.; Nussbaum, G.; Azavant, P.; Octor, H. Elevated temperature behaviour of rapidly solidified magnesium alloys containing rare earths. Mater. Sci. Eng. A 1996, 221, 48–57. [Google Scholar] [CrossRef]

- Garces, G.; Maeso, M.; Perez, P.; Adeva, P. Effect of extrusion temperature on superplasticity of PM-WE54. Mater. Sci. Eng. A 2007, 462, 127–131. [Google Scholar] [CrossRef]

- Knapek, M.; Minárik, P.; Greš, A.; Zemková, M.; Lukáč, F.; Bohlen, J.; Chmelík, F.; Král, R. Spark plasma sintered Mg-4Y-3Nd with exceptional tensile performance. Mater. Sci. Eng. A 2022, 849, 143481. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Benson, G.; McWilliams, B.; Cho, K.; Sohn, Y. Additive manufacturing of dense WE43 Mg alloy by laser powder bed fusion. Addit. Manuf. 2020, 33, 101123. [Google Scholar] [CrossRef]

- Smola, B.; Joska, L.; Březina, V.; Stulíková, I.; Hnilica, F. Microstructure, corrosion resistance and cytocompatibility of Mg–5Y–4Rare Earth–0.5Zr (WE54) alloy. Mater. Sci. Eng. C 2012, 32, 659–664. [Google Scholar] [CrossRef]

- Xu, W.; Li, J.; Zhang, Z.; Yuan, H.; An, G.; Shi, H.; Cai, C.; Jiang, W.; Li, W.; Wei, Q. Laser powder bed fusion of WE43 magnesium alloy with superior balance of strength and ductility. J. Magnes. Alloys 2024, in press. [CrossRef]

- Garces, G.; Rodríguez, M.; Pérez, P.; Adeva, P. Microstructural and mechanical characterisation of WE54–SiC composites. Mater. Sci. Eng. A 2010, 527, 6511–6517. [Google Scholar] [CrossRef]

- Száraz, Z.; Trojanová, Z.; Cabbibo, M.; Evangelista, E. Strengthening in a WE54 magnesium alloy containing SiC particles. Mater. Sci. Eng. A 2007, 462, 225–229. [Google Scholar] [CrossRef]

- Cabibbo, M. Compression Behavior of a Biocompatible We54 Alloy Reinforced by SiC. Biomed. J. Sci. Tech. Res. 2020, 26, 19565–19571. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Wang, Y.; Guan, B.; Luo, H.; Liu, B.; Deng, D.; Chen, X.; Zheng, K.; Pan, F. Effect of multi-directional compression on microstructure and mechanical properties of Tip/WE43 composite. J. Alloys Comp. 2024, 1007, 176497. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Tang, B.; Wang, Y.; Luo, H.; Guan, B.; Chen, X.; Zheng, K.; Pan, F. Heterogeneous deformation-induced strengthening of extruded Tip/WE43 composites. Mater. Charact. 2024, 207, 113526. [Google Scholar] [CrossRef]

- Nisar, L.; Maqbool, A.; Khan, N.Z.; Gull, A.; Siddiquee, A.N. Enhancing ductility, strength, and hardness of WE43 Mg alloy-based metal matrix composite fabricated via friction stir processing: Effect of hybrid reinforcement and Volume percentage. Mater. Chem. Phys. 2024, 323, 129620. [Google Scholar] [CrossRef]

- Wang, X.; Su, J.; Li, C.; Tang, J.; Jiang, F.; Fu, D.; Du, R.; Teng, J. Fabrication of high-performance biomedical rare-earth magnesium alloy-based WE43/hydroxyapatite composites through multi-pass friction stir processing. J. Mater. Res. Technol. 2024, 33, 5349–5363. [Google Scholar] [CrossRef]

- Maqbool, A.; Khan, N.Z. Fabrication and characterization of hybrid WE43 Mg alloy-based composite by friction stir processing with improved ductility. Vacuum 2023, 215, 112273. [Google Scholar] [CrossRef]

- Karthik, S.; Karunakaran, P.; Velmurugan, G. Experimental Investigation of WE43(T6) magnesium metal matrix composites to enhance mechanical properties and EDM process parameters. Int. J. Electrochem. Sci. 2024, 19, 100553G. [Google Scholar]

- Garces, G.; Oñorbe, E.; Pérez, P.; Klaus, M.; Genzel, C.; Adeva, P. Influence of SiC particles on compressive deformation of magnesium matrix composites. Mater. Sci. Eng. A 2012, 533, 119–123. [Google Scholar] [CrossRef]

- Garces, G.; Medina, J.; Perez, P.; Stark, A.; Schell, N.; Adeva, P. The effect of temperature on load partitioning evolution in magnesium metal matrix composite reinforced with Ti particles using in-situ synchrotron radiation diffraction experiments. J. Magnes. Alloy. 2023, 11, 706–719. [Google Scholar] [CrossRef]

- Elektron® WE54. Available online: https://www.luxfermeltechnologies.com/wp-content/uploads/2019/01/113897-Luxfer-MEL-Technologies-DS-466-Elektron-WE54-ST15.pdf (accessed on 1 January 2025).

- Lutterotti, L.; Bortolotti, M.; Ischia, G.; Lonardelli, I.; Wenk, H.R. Rietveld Texture Analysis from Diffraction Images. Z. Krist. Suppl. 2007, 1, 125–130. [Google Scholar] [CrossRef]

- Schindelin, J.; Rueden, C.T.; Hiner, M.C.; Eliceiri, K.W. The ImageJ ecosystem: An open platform for biomedical image analysis. Mol. Reprod. Dev. 2015, 82, 518–529. [Google Scholar] [CrossRef] [PubMed]

- Lutterotti, L.; Matthies, S.; Wenk, H.R.; Schultz, A.S.; Richardson, J.W. Combined texture and structure analysis of deformed limestone from time-of-flight neutron diffraction spectra. J. Appl. Phys. 1997, 81, 594–600. [Google Scholar] [CrossRef]

- Hammersley, A.P. FIT2D: A multi-purpose data reduction, analysis and visualization program. J. Appl. Crystallogr. 2016, 49, 646–652. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-Ray Diffraction Pearson Education Limited; Pearson Education Limited: Harlow, UK, 2014. [Google Scholar]

- Allen, A.J.; Bourke, M.A.M.; Dawes, S.; Hutchings, M.T.; Withers, P.J. The analysis of internal strains measured by neutron diffraction in Al/SiC metals matrix composites. Acta Metall. Mater. 1992, 40, 2361–2373. [Google Scholar] [CrossRef]

- Agnew, S.R.; Brown, D.W.; Tome, C.N. Validating a polycrystal model for the elastoplastic response of magnesium alloy AZ31 using in situ neutron diffraction. Acta Mater. 2006, 54, 4841–4852. [Google Scholar] [CrossRef]

- Brandes, E.A.; Brooks, G.B. Smithells Metals Reference Book; Butterworth-Heinemann: Oxford, UK, 1992. [Google Scholar]

- Zhang, J.; Liu, S.; Wu, R.; Hou, L.; Zhang, M. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg-Gd and Mg-Y systems. J. Magnes. Alloy. 2018, 6, 277–291. [Google Scholar] [CrossRef]

- Garces, G.; Medina, J.; Chávez, B.; Pérez, P.; Barea, R.; Stark, A.; Schell, N.; Adeva, P. Load partitioning between Mg17Al12 precipitates and Mg phase in the AZ91 alloy using in-situ synchrotron radiation diffraction experiments. Metall. Mater. Trans. A 2021, 52, 2732–2745. [Google Scholar] [CrossRef]

- Garces, G.; Medina, J.; Pérez, P.; Máthis, K.; Horváth, K.; Stark, A.; Schell, N.; Adeva, P. Influence of quasicrystal I-phase on twinning of extruded Mg-Zn-Y alloys under compression. Acta Mater. 2018, 151, 271–281. [Google Scholar] [CrossRef]

- Garces, G.; Medina, J.; Pérez, P.; Barea, R.; Lim, H.; Kim, S.K.; Maawad, E.; Schell, N.; Adeva, P. Study of tensile and compressive behavior of ECO-Mg97Gd2Zn1 alloys containing long-period stacking ordered phase with lamellar structure. Metals 2024, 14, 530. [Google Scholar] [CrossRef]

- Garces, G.; Máthis, K.; Barea, R.; Medina, J.; Pérez, P.; Stark, A.; Schell, N.; Adeva, P. Effect of precipitation on the compressive behavior of high-strength Mg-Gd-Y-Zn extruded alloy. Mater. Sci. Eng. A 2019, 768, 138452. [Google Scholar] [CrossRef]

- Garces, G.; Pérez, P.; Adeva, P. Effect of the extrusion texture on the mechanical behaviour of Mg–SiCp composites. Scr. Mater. 2005, 52, 615–619. [Google Scholar] [CrossRef]

- Zhu, S.M.; Nie, J.F. Serrated flow and tensile properties of a Mg–Y–Nd alloy. Scr. Mater. 2004, 50, 51–55. [Google Scholar] [CrossRef]

- Brown, L.M.; Stobbs, W.M. The work-hardening of copper-silica I. A model based on internal stresses, with no plastic relaxation. Philos. Mag. 1971, 23, 1185–1199. [Google Scholar] [CrossRef]

- Robson, J.D.; Stanford, N.; Barnett, M.R. Effect of precipitates shape on slip and twinning in magnesium alloys. Acta Mater. 2011, 59, 1945–1956. [Google Scholar] [CrossRef]

| Yttrium | Neodymium | Heavy Rare Earths 1 | Zirconium | Magnesium |

|---|---|---|---|---|

| 4.75–5.5% | 1.5–2.0% | 1.0–2.0% | 0.4% min. | Balance |

| Setup Parameters | |

|---|---|

| Gauge volume | 0.8 × 0.8 × 5 mm3 |

| Exposure time | 0.5 s |

| Effective pixel size | 200 × 200 µm2 |

| Energy/Wavelength | 100 keV/0.01202 nm |

| Detector-to-sample distance | 1640 mm |

| Integration angle | ±7.5° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garces, G.; Pérez, P.; Medina, J.; Adeva, P. Evaluation of the Reinforcing Effect of Intermetallic and Ceramic Phases in a WE54-15%(Vol.%)SiCw Composite Using In Situ Synchrotron Radiation Diffraction. J. Compos. Sci. 2025, 9, 46. https://doi.org/10.3390/jcs9010046

Garces G, Pérez P, Medina J, Adeva P. Evaluation of the Reinforcing Effect of Intermetallic and Ceramic Phases in a WE54-15%(Vol.%)SiCw Composite Using In Situ Synchrotron Radiation Diffraction. Journal of Composites Science. 2025; 9(1):46. https://doi.org/10.3390/jcs9010046

Chicago/Turabian StyleGarces, Gerardo, Pablo Pérez, Judit Medina, and Paloma Adeva. 2025. "Evaluation of the Reinforcing Effect of Intermetallic and Ceramic Phases in a WE54-15%(Vol.%)SiCw Composite Using In Situ Synchrotron Radiation Diffraction" Journal of Composites Science 9, no. 1: 46. https://doi.org/10.3390/jcs9010046

APA StyleGarces, G., Pérez, P., Medina, J., & Adeva, P. (2025). Evaluation of the Reinforcing Effect of Intermetallic and Ceramic Phases in a WE54-15%(Vol.%)SiCw Composite Using In Situ Synchrotron Radiation Diffraction. Journal of Composites Science, 9(1), 46. https://doi.org/10.3390/jcs9010046