Friction Stir Spot Welding of Aluminum Alloy to Carbon Fiber-Reinforced Thermosetting Resin Coated by Thermoplastic Resin Using Tools with Different Surface Shapes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

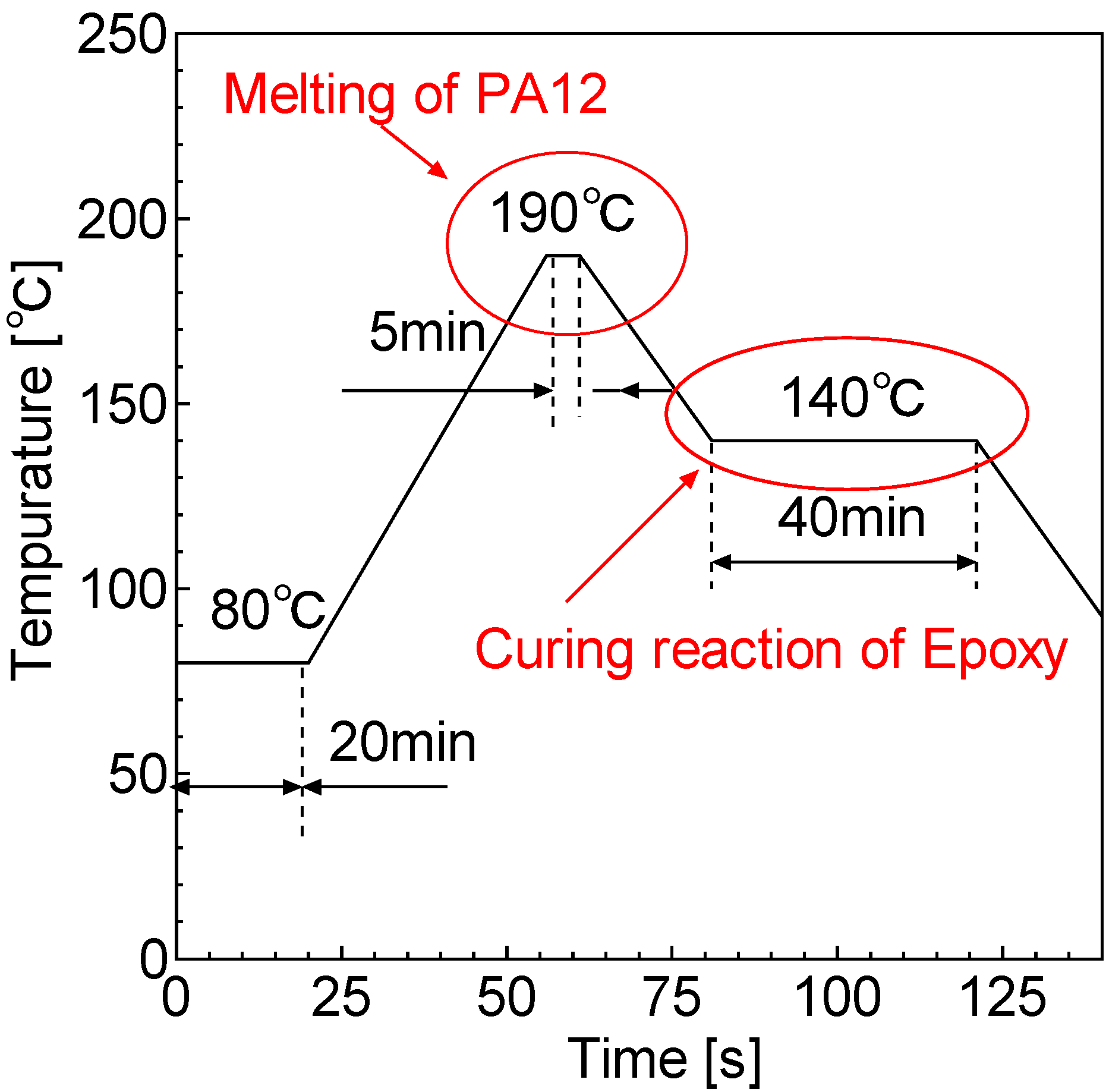

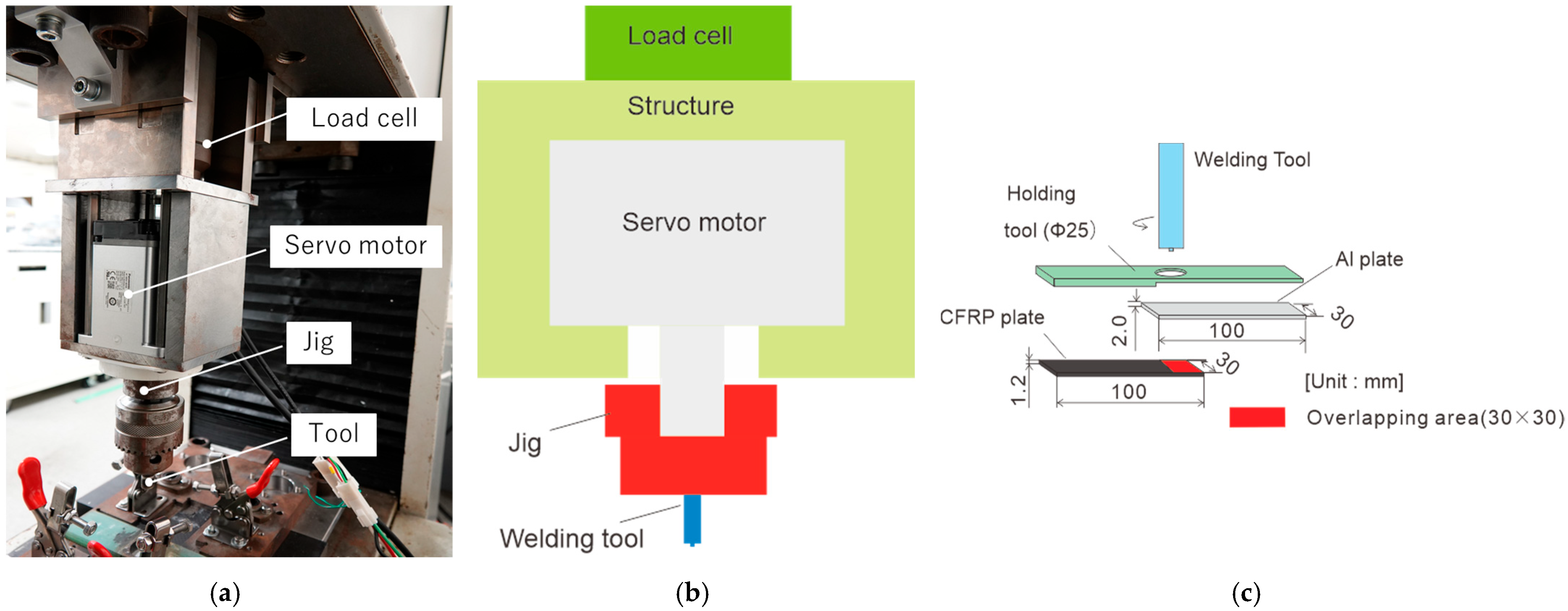

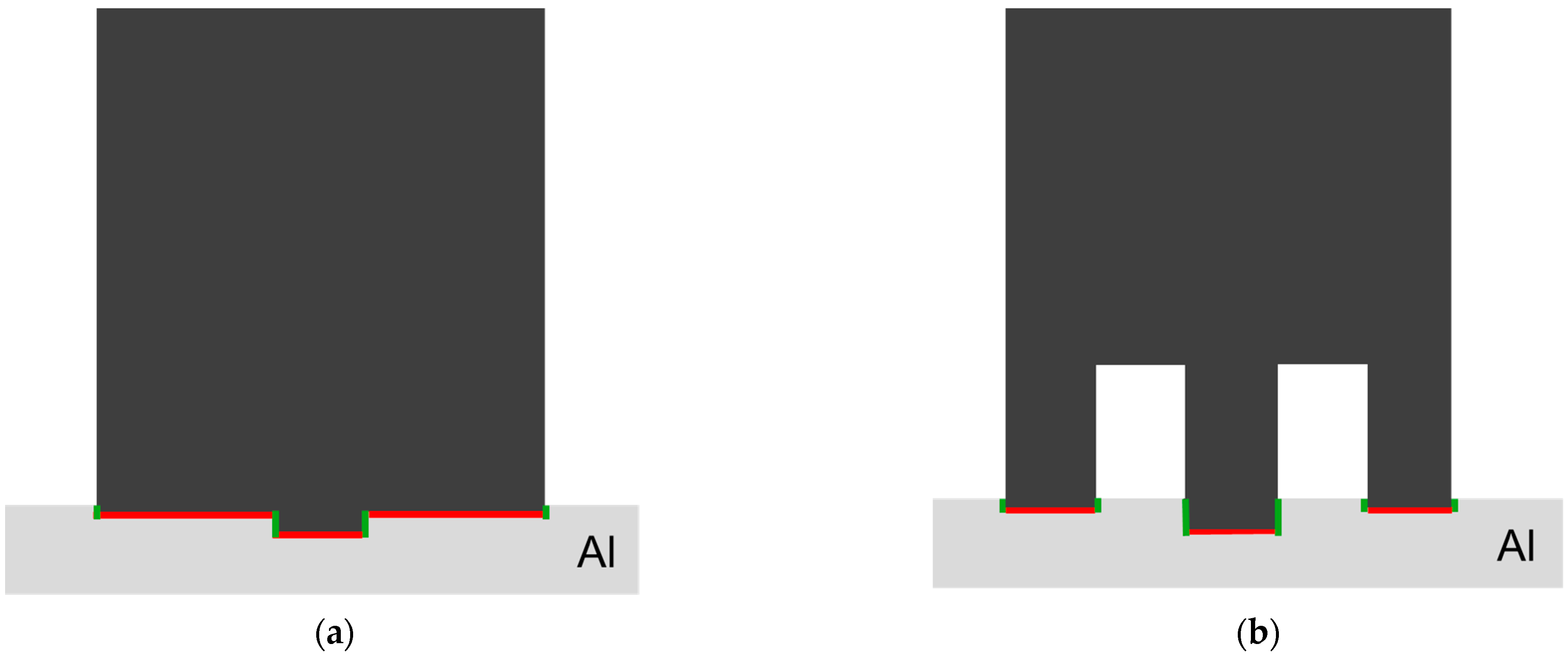

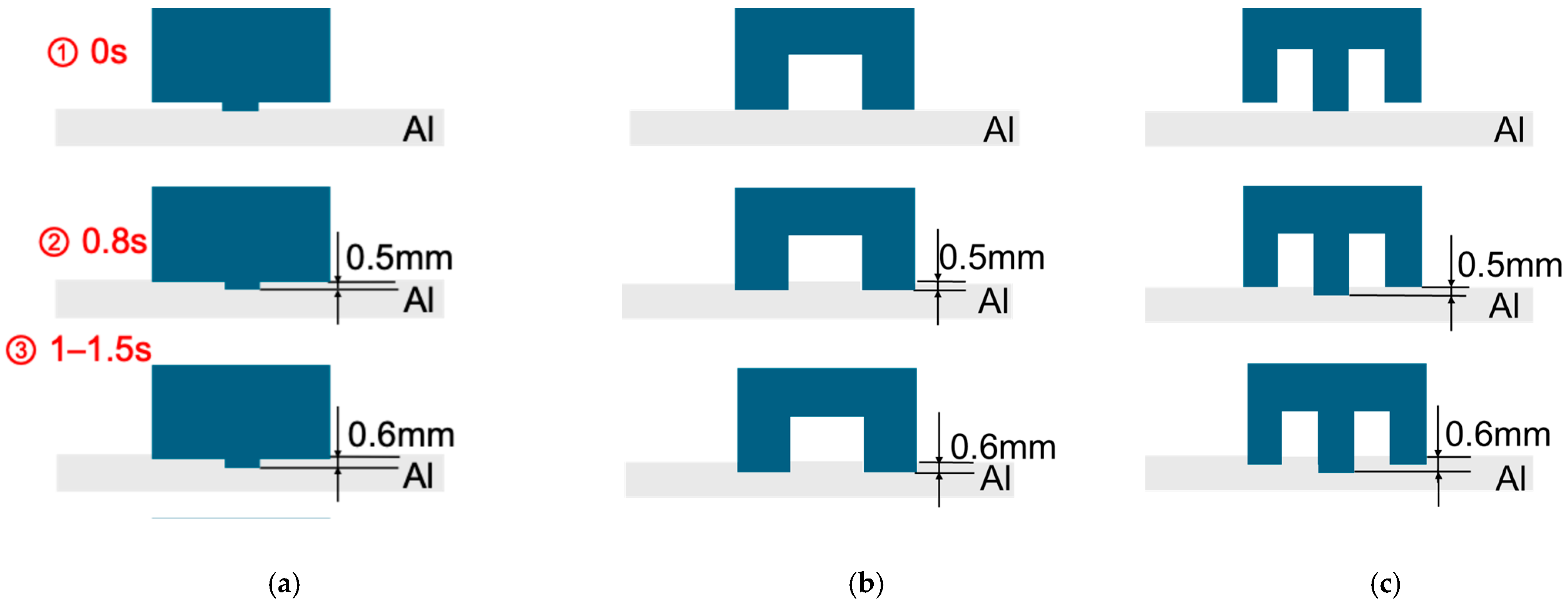

2.2. Welding Procedure

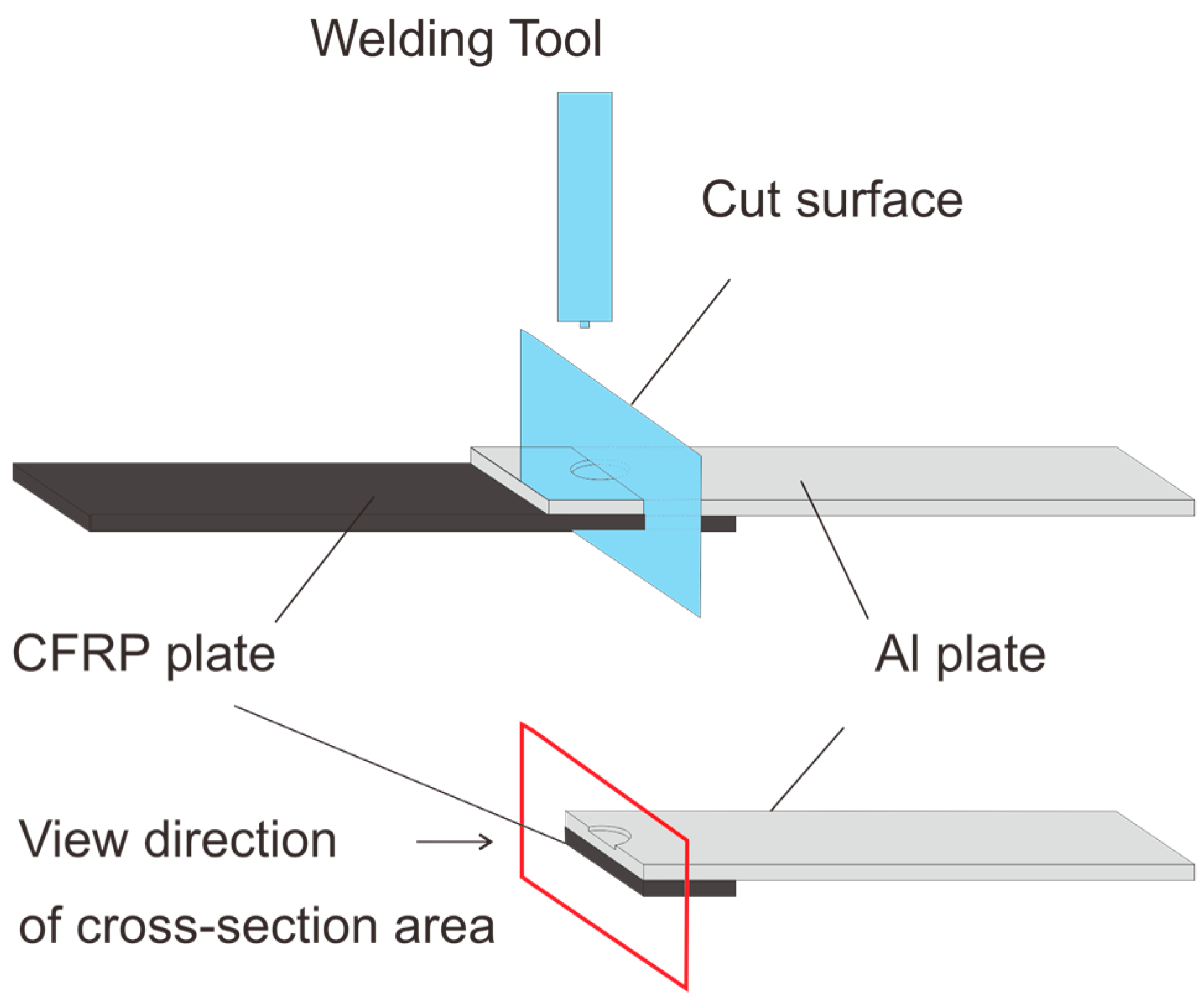

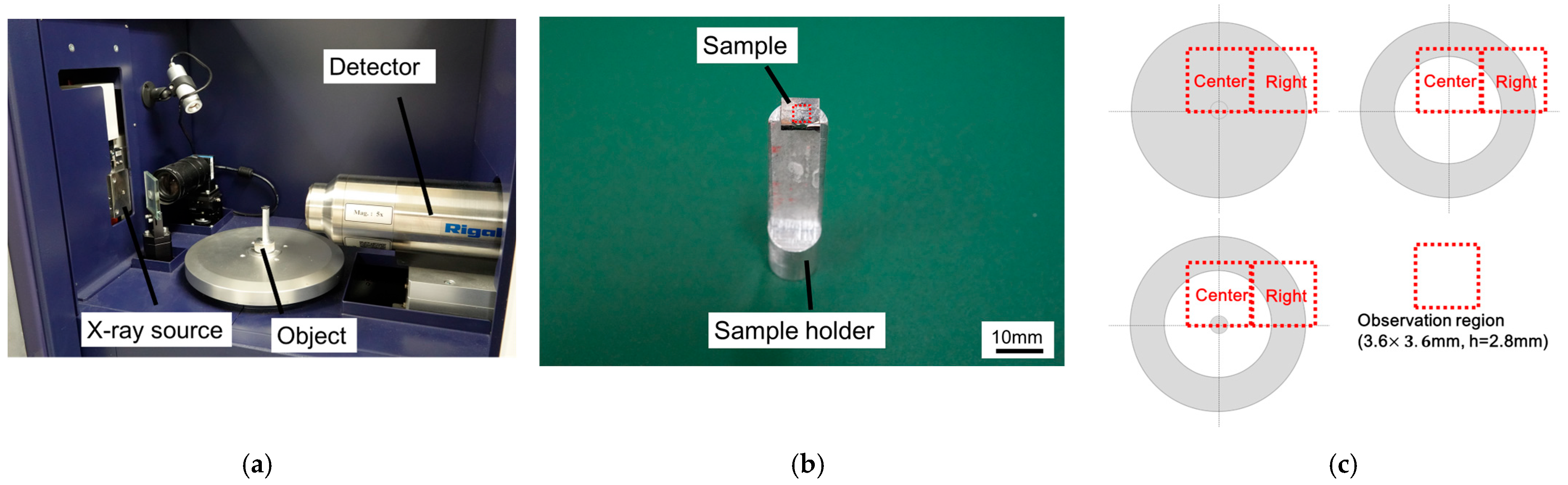

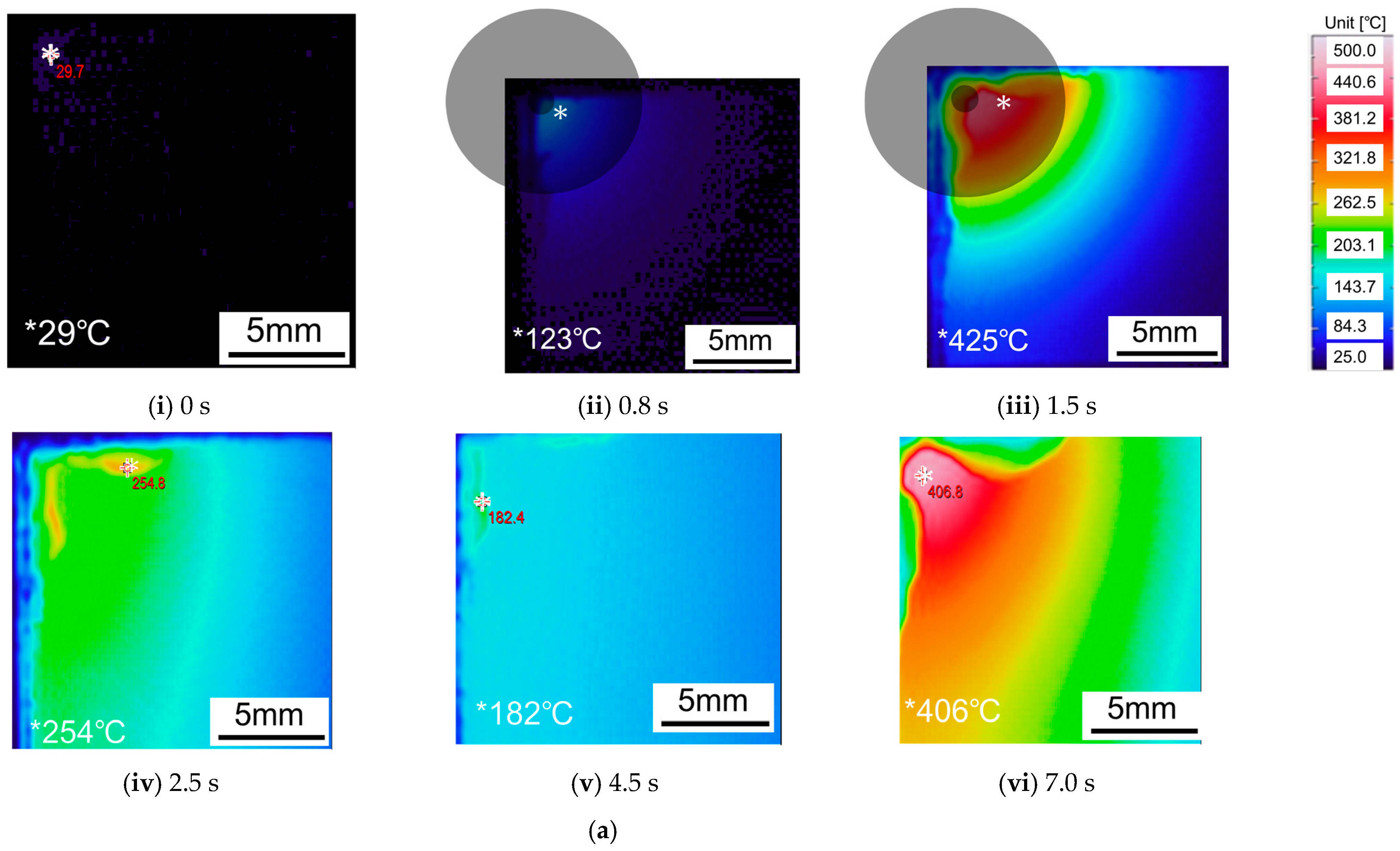

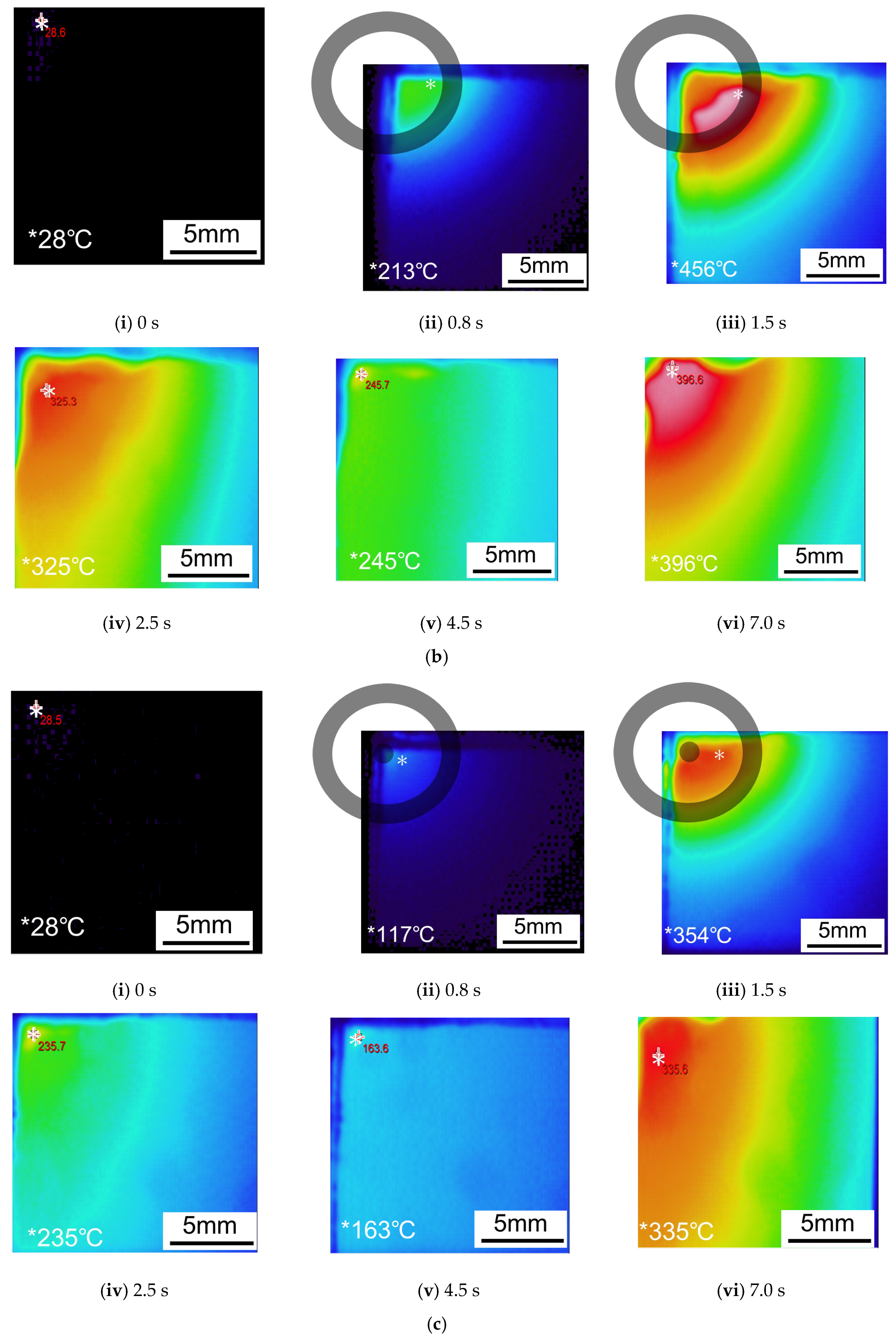

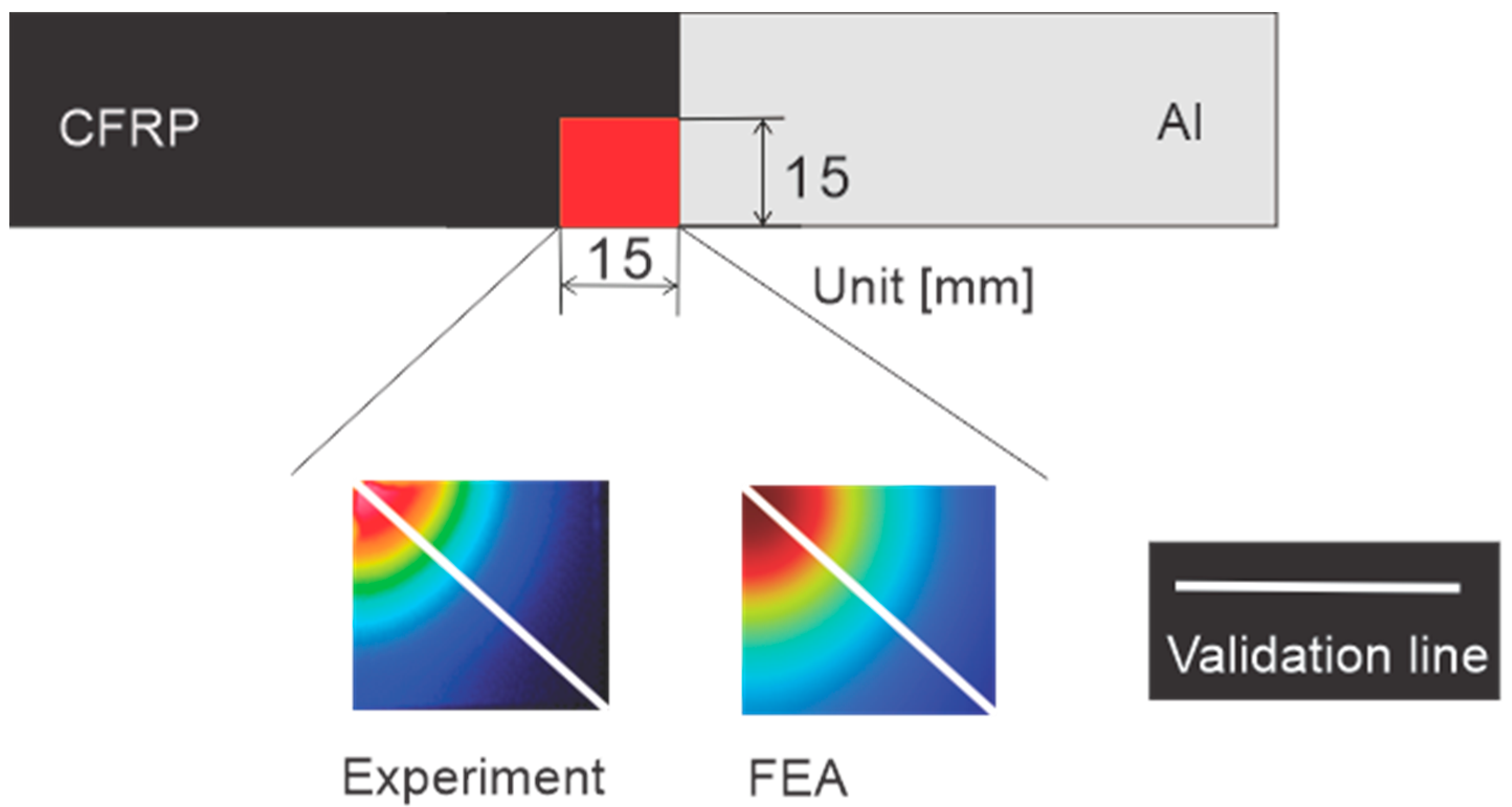

2.3. Observation of the Temperature Distribution During FSSW

2.4. Evaluation of Mechanical Properties of Joints

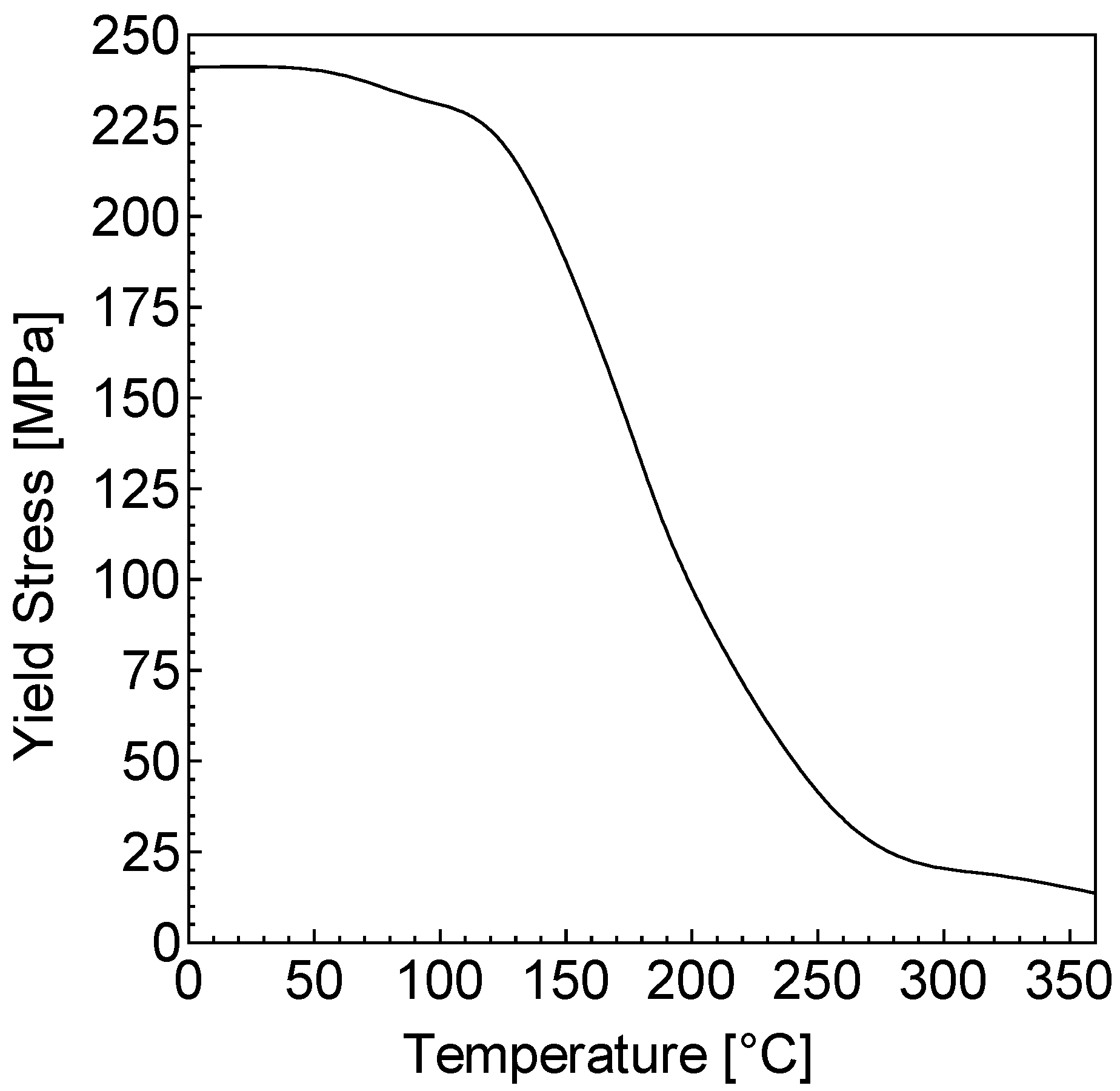

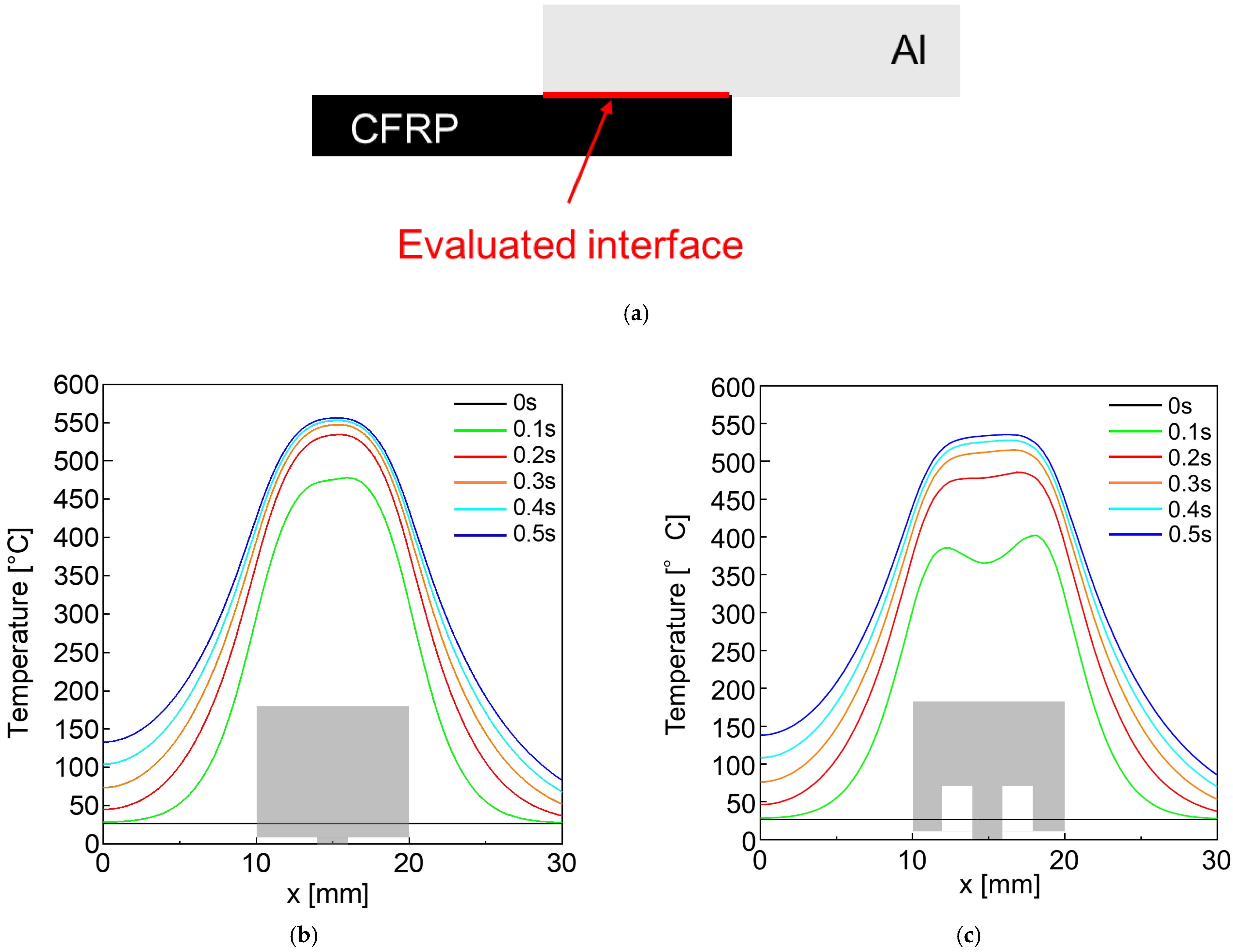

2.5. Finite Element Analysis (FEA) of Temperature Distribution During FSSW

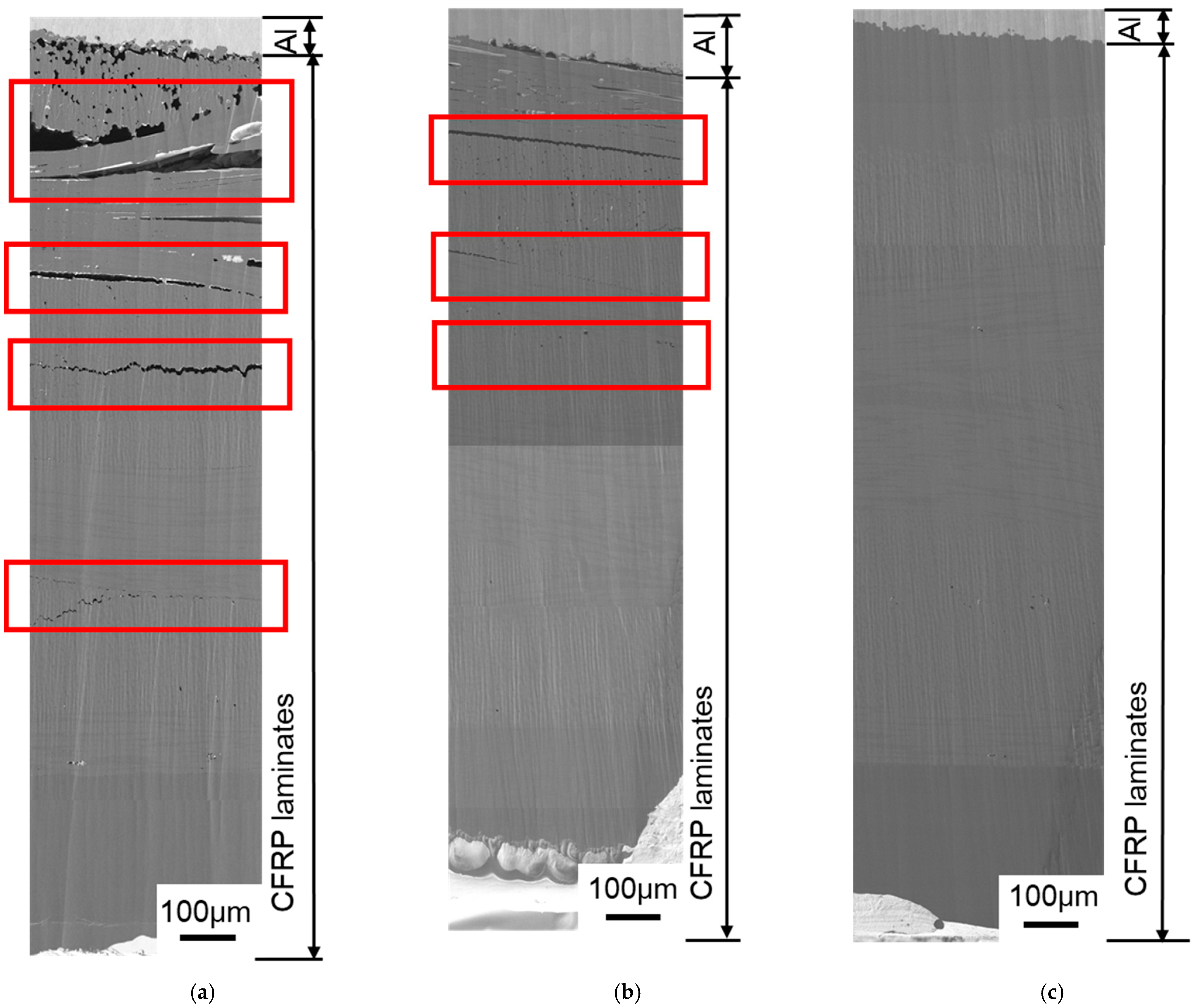

3. Results and Discussion

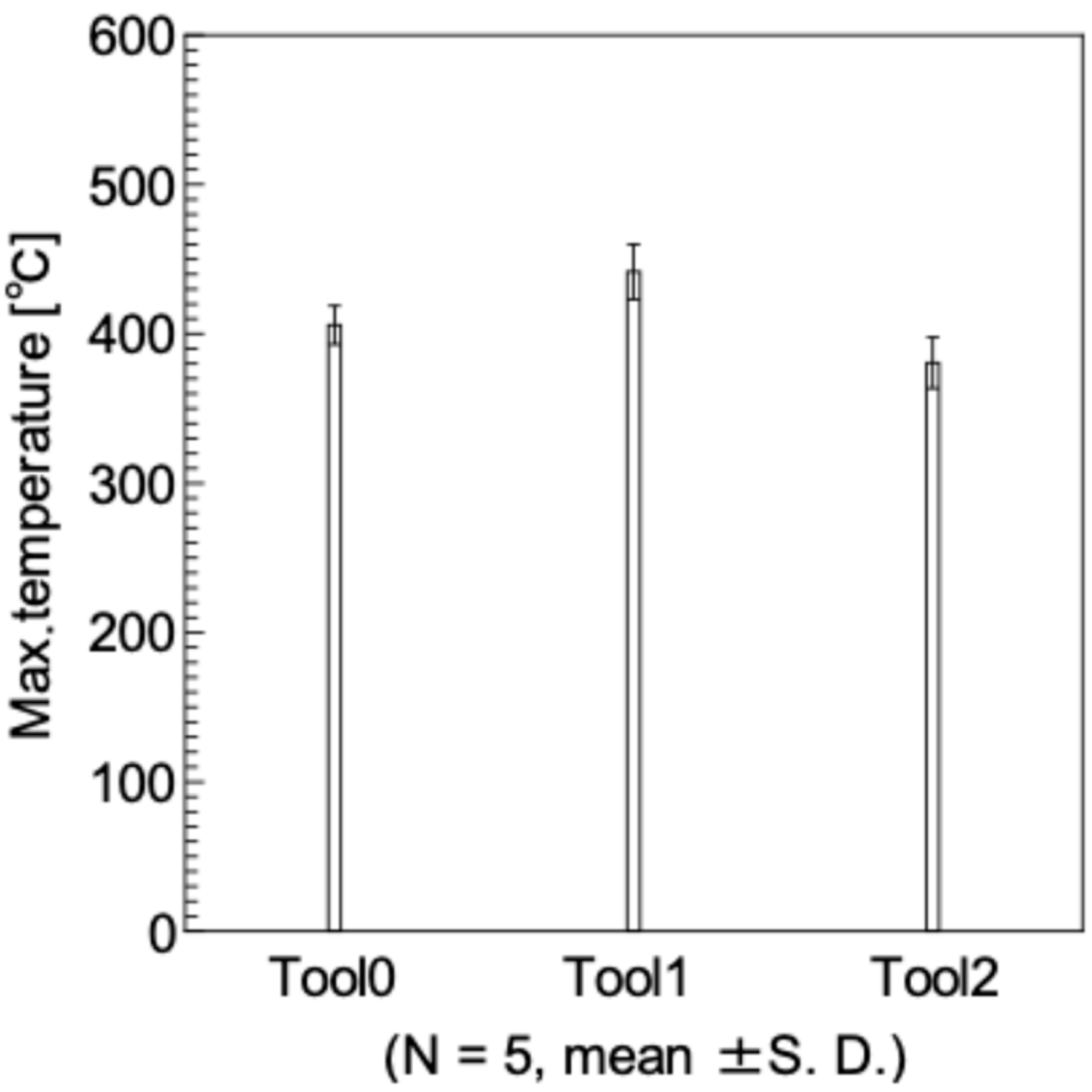

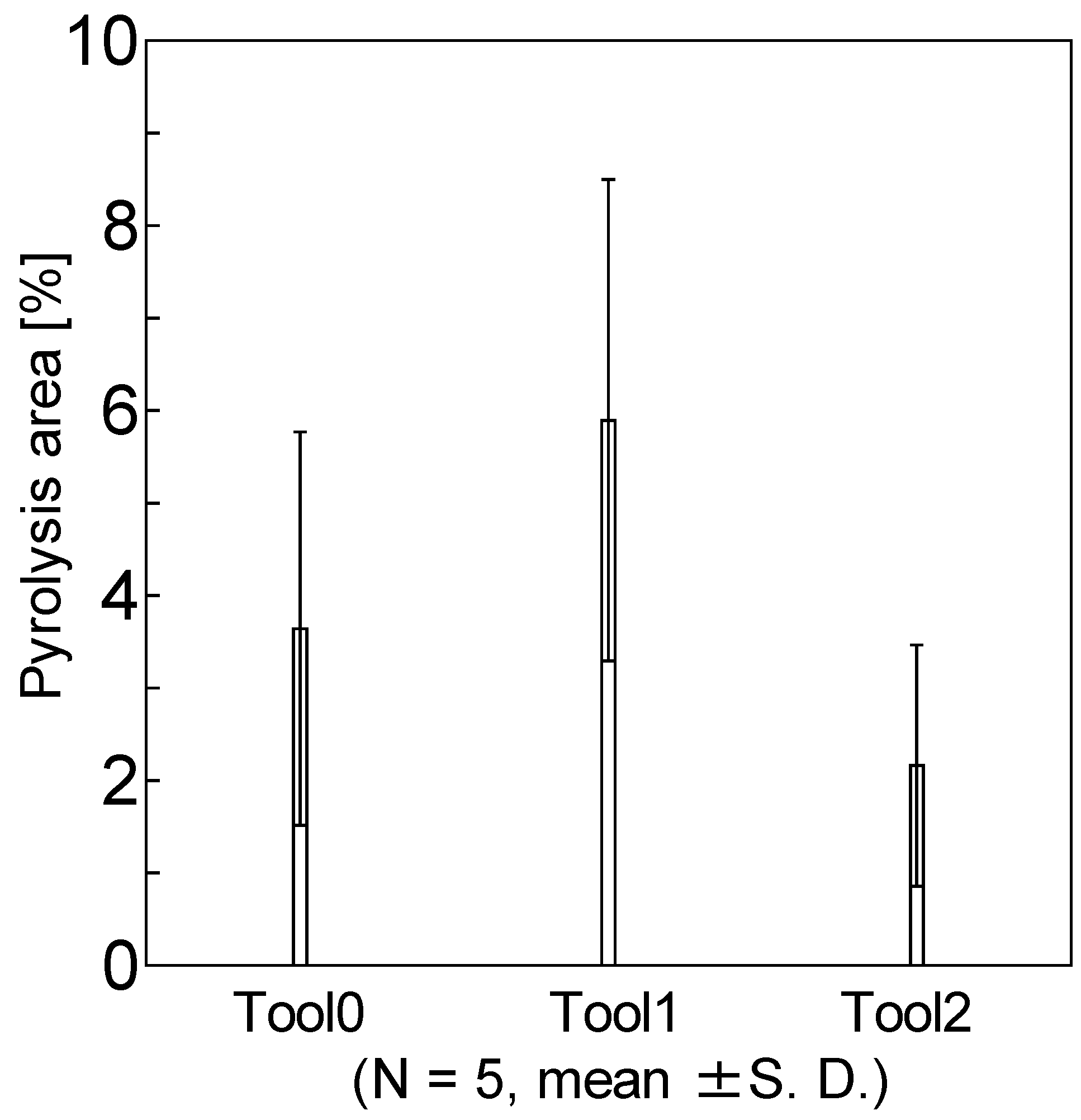

3.1. Results of the Temperature Distribution Observation

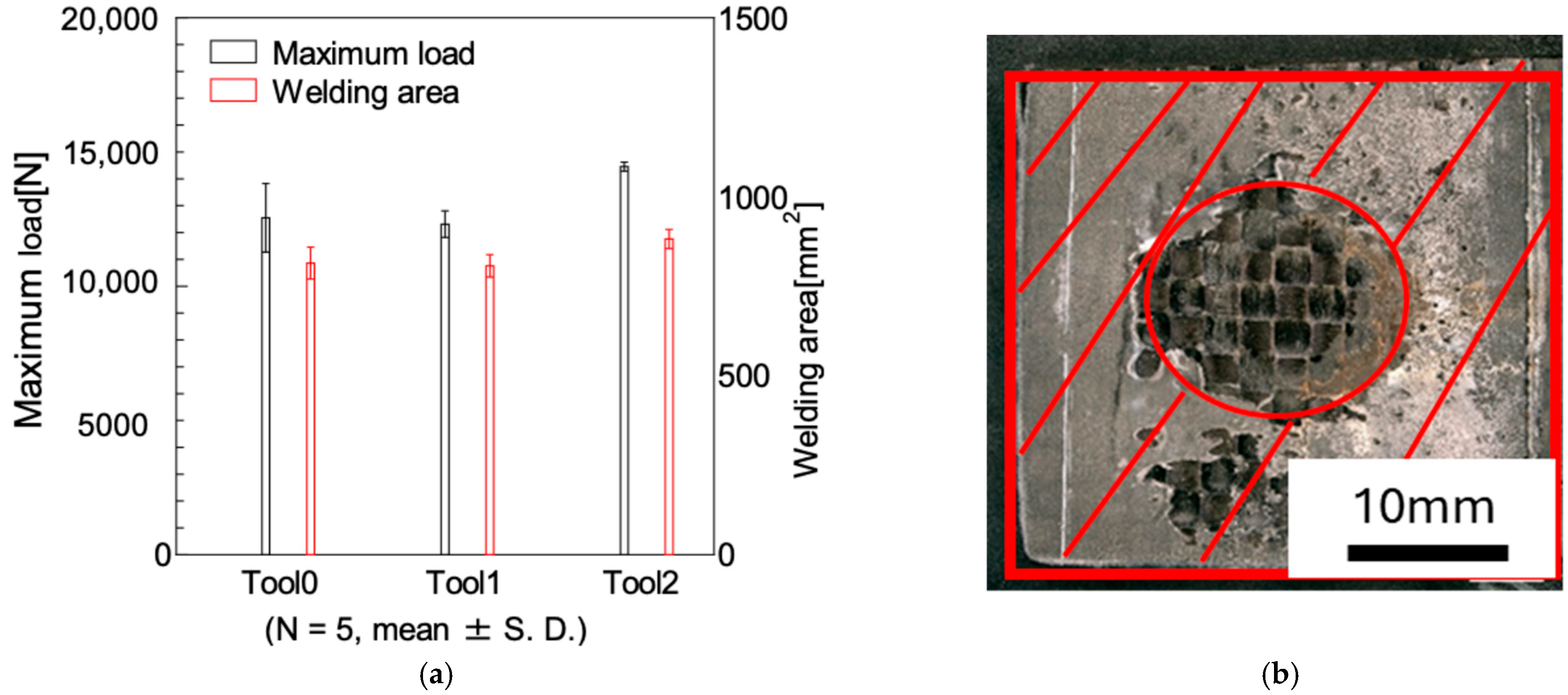

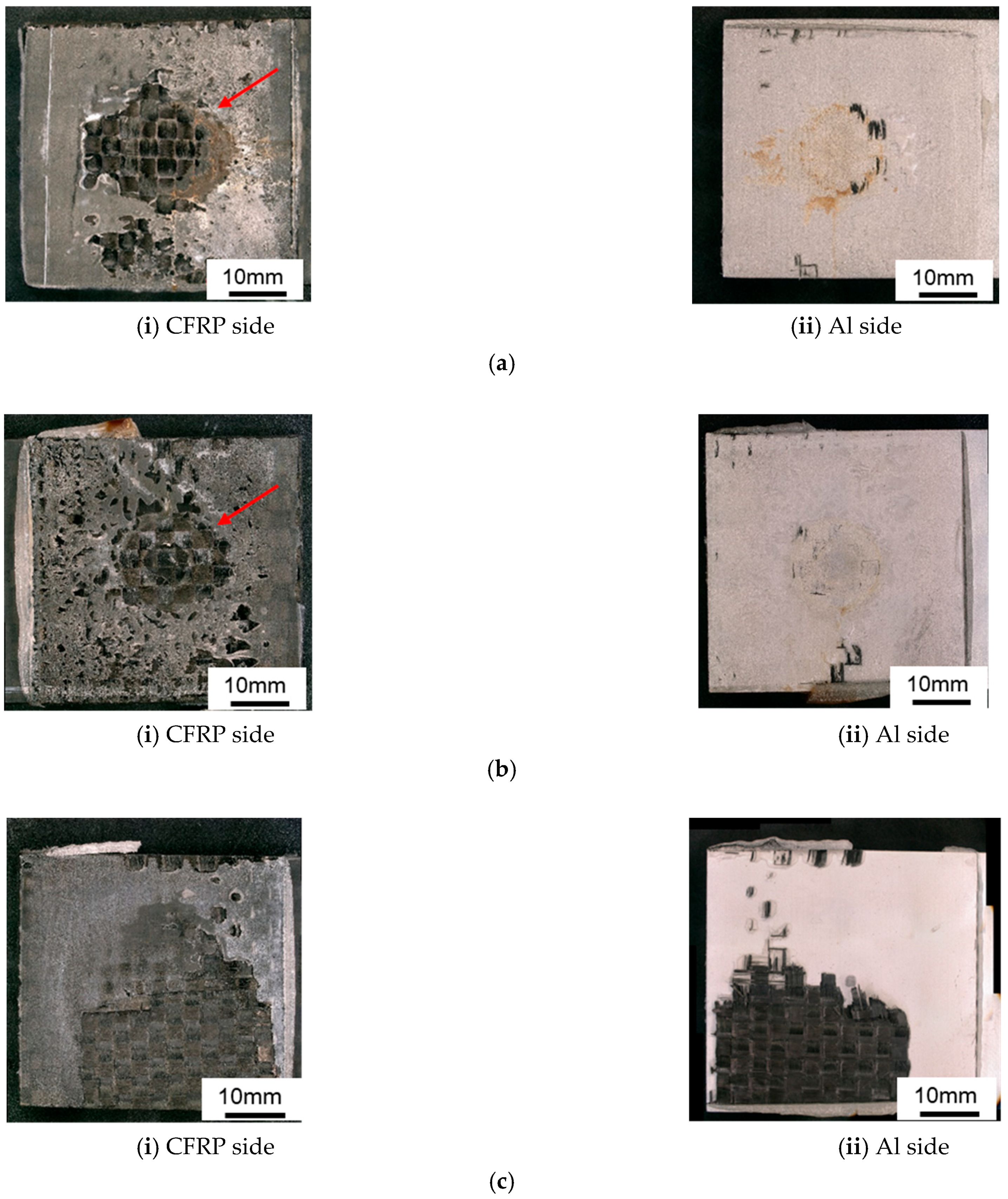

3.2. Tensile Shear Test

3.3. Finite Element Analysis (FEA) of Temperature Distribution

4. Conclusions

- Tool2, the newly developed concave-shaped tool with a probe effectively suppressed heat input compared to Tool0, the conventional tool with a probe, and Tool1, the newly developed concave-shaped tool without a probe. Tool2’s unique features of the probe induce a small initial heat input, and the ring surface spreads heat while suppressing it. Using Tool2, the maximum temperature input during FSSW and the pyrolysis area of resin can be reduced by 7% and 47%, respectively, compared to Tool0.

- The highest joint strength was achieved using Tool2, with a 4% improvement compared to Tool0. By reducing the pyrolysis area of resin, Tool2 led to a 12% increase in the welded area compared to Tool0.

- Finite element analysis (FEA) demonstrated the suppression of heat input using Tool2. While heat spreads from the probe and flat circular interface for Tool0, Tool2 distributes heat from the probe and concave-shaped interface. FEA also showed a reduced temperature rise at the interface between the Al alloy and CFRP laminates using Tool2 due to its concave shape.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rabbi, M.F.; Popp, J.; Máté, D.; Kovács, S. Energy Security and Energy Transition to Achieve Carbon Neutrality. Energies 2022, 15, 8126. [Google Scholar] [CrossRef]

- Serrenho, A.C.; Norman, J.B.; Julian, M.A. The impact of reducing car weight on global emissions: The future fleet in Great Britain. Philos. Trans. A Math. Phys. Eng. Sci. 2017, 375, 2095. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Tamanaka, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Wan, Y.; Takahashi, J. Development of Carbon Fiber-Reinforced Thermoplastics for Mass-Produced Automotive Applications in Japan. J. Compos. Sci. 2021, 5, 86. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Sustainable Processes in Aluminium, Magnesium, and Titanium Alloys Applied to the Transport Sector: A Review. Metals 2022, 12, 9. [Google Scholar] [CrossRef]

- Li, P.; Yan, Z.; Yang, Y. Progress in automobile body processing technology: Multi-material and lightweight strategies for saving energy and reducing emissions. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 324. [Google Scholar] [CrossRef]

- Barnes, T.A.; Pashby, I.R. Joining techniques for aluminium spaceframes used in automobiles: Part II—Adhesive bonding and mechanical fasteners. J. Mater. Process. Technol. 2000, 99, 72–79. [Google Scholar] [CrossRef]

- Maggiorfe, S.; Banea, M.D.; Stagnaro, P.; Luciano, G. A Review of Structural Adhesive Joints in Hybrid Joining Processes. Polymers 2021, 13, 3961. [Google Scholar] [CrossRef] [PubMed]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Pereira, M.A.R.; Galvão, I.; Costa, J.D.; Leal, R.M.; Amaro, A.M. Friction Stir Spot Welding of Thin Aluminium Sheets to Polyamide 6: A Study of the Welding Parameters and Strategies. J. Compos. Sci. 2024, 8, 21. [Google Scholar] [CrossRef]

- Pereira, M.A.R.; Galvão, I.; Costa, J.D.; Leal, R.M.; Amaro, A.M.; Leal, R.M. Production of Aluminium-Polymer Joints by Friction Stir Spot Welding. J. Manuf. Mater. Process. 2024, 8, 179. [Google Scholar] [CrossRef]

- Tanaka, K.; Kawakami, M.; Nishiguchi, K. Friction Stir Spot Welding for CFRP/Al Using Laminated Composites with an Outermost Layer of Thermoplastic Resin. J. Soc. Mater. Sci. 2022, 71, 453–460. [Google Scholar] [CrossRef]

- Cai, B.P.; Liu, Y.H.; Ren, C.K.; Liu, Z.K.; Tian, X.J.; Abulimiti, A.B.B. Experimental Study of Galvanic Corrosion Behaviour of Carbon Fibre Composite Coupled to Aluminium in Artificial Seawater. Corros. Eng. Sci. Technol. 2012, 47, 289–296. [Google Scholar] [CrossRef]

- Tanaka, K.; Aiba, Y. Evaluation of Joint Strength for CFRPs and Aluminum Alloys by Friction Stir Spot Welding Using Multi-Stage Heating. J. Compos. Sci. 2024, 8, 110. [Google Scholar] [CrossRef]

- Geng, P.; Ma, H.; Li, W.; Murakami, K.; Wang, Q.; Ma, N.; Aoki, Y.; Fujii, H.; Chen, C. Improving bonding strength of Al/CFRTP hybrid joint through modifying friction spot joining tools. Compos. B Eng. 2023, 254, 110588. [Google Scholar] [CrossRef]

- Colegrove, P.; Painter, M.; Graham, D.; Miller, T. 3-Dimensional Flow and Thermal Modelling of the Friction Stir Welding Process, In Proceedings of the 2nd International Symposium on Friction Stir Welding. Gothenburg, Sweden, 27–29 June 2000. [Google Scholar]

- Rasband, W.S. ImageJ, U.S. National Institutes of Health, Bethesda, Maryland, USA, 1997–2018. Available online: https://imagej.net/ij/ (accessed on 10 April 2024).

- Salloomi, K.N. Fully coupled thermomechanical simulation of friction stir welding of aluminum 6061-T6 alloy T-joint. J. Manuf. Process. 2019, 45, 746–754. [Google Scholar] [CrossRef]

- Zhang, X.X.; Xiao, B.L.; Ma, Z.Y. A Transient Thermal Model for Friction Stir Weld. Part 1: The Model. Metall. Mater. Trans. A 2011, 42, 3218–3228. [Google Scholar] [CrossRef]

- Song, M.; Kovacevic, R. Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int. J. Mach. Tools Manuf. 2003, 43, 605–615. [Google Scholar] [CrossRef]

- Bejan, A.; Kraus, A.D. Heat Transfer; John Wiley & Sons: Hoboken, NJ, USA, 1993. [Google Scholar]

- Geng, P.; Ma, N.; Ma, H.; Ma, Y.; Murakami, K.; Liu, H.; Aoki, Y.; Fujii, H. Flat Friction Spot Joining of Aluminum Alloy to Carbon Fiber Reinforced Polymer Sheets: Experiment and Simulation. J. Mater. Sci. Technol. 2022, 107, 266–289. [Google Scholar] [CrossRef]

- Tanaka, K.; Niwa, K.; Katayama, T.; Nishiguchi, K. Friction stir spot welding for CFRP/Al with polyamide resin. J. Soc. Mater. Sci. 2020, 69, 379–385. [Google Scholar] [CrossRef]

- Akbari, M.; Aliha, M.R.M.; Berto, F. Investigating the role of different components of friction stir welding tools on the generated heat and strain. Forces Mech. 2023, 10, 100166. [Google Scholar] [CrossRef]

- Ma, N.; Geng, P.; Ma, Y.; Shimakawa, K.; Choi, J.-W.; Aoki, Y.; Fujii, H. Thermo-mechanical modeling and analysis of friction spot joining of Al alloy and carbon fiber- reinforced polymer. J. Mater. Res. Technol. 2021, 12, 1777–1793. [Google Scholar] [CrossRef]

| Density | Heat Transfer Coefficient | Rotational Speed | Applied Force | Ambient Air Temperature | Surface Emissivity | ||

|---|---|---|---|---|---|---|---|

| Al Alloy | CFRP Laminates | Al Alloy | CFRP Laminates | ||||

| 2700 kg/m3 | 1225 kg/m3 | 70 W/(m2 K) | 20 W/(m2 K) | 3000 rpm | 3000 N | 293 K | 0.3 |

| Parameters | Materials | 20 °C | 100 °C | 200 °C | 300 °C | 400 °C | 500 °C | 600 °C |

|---|---|---|---|---|---|---|---|---|

| Thermal conductivity (W/(m K)) | Al alloy | 195 | 200 | 206 | 208 | 206 | 199 | 195 |

| CFRP laminates | 0.427 | 0.435 | 0.512 | - | - | - | - | |

| Specific heat (J/(kg K)) | Al alloy | 900 | 950 | 1000 | 1020 | 1050 | 1090 | 1200 |

| CFRP laminates | 1310 | 1950 | 2860 | - | - | - | - | |

| Expansion (10−6/K) | Al alloy | 22 | 24.6 | 26.6 | 27.8 | 3.01 | - | - |

| CFRP laminates | 5.0 | 4.9 | 3.1 | - | - | - | - |

| Tool Type | Tool0 | Tool1 | Tool2 | |||

|---|---|---|---|---|---|---|

| Calculated Region | Center | Right | Center | Right | Center | Right |

| Void ratio | 31.9% | 6.7% | 6.6% | 7.7% | 0.2% | 0.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanaka, K.; Nagae, Y. Friction Stir Spot Welding of Aluminum Alloy to Carbon Fiber-Reinforced Thermosetting Resin Coated by Thermoplastic Resin Using Tools with Different Surface Shapes. J. Compos. Sci. 2025, 9, 17. https://doi.org/10.3390/jcs9010017

Tanaka K, Nagae Y. Friction Stir Spot Welding of Aluminum Alloy to Carbon Fiber-Reinforced Thermosetting Resin Coated by Thermoplastic Resin Using Tools with Different Surface Shapes. Journal of Composites Science. 2025; 9(1):17. https://doi.org/10.3390/jcs9010017

Chicago/Turabian StyleTanaka, Kazuto, and Yuki Nagae. 2025. "Friction Stir Spot Welding of Aluminum Alloy to Carbon Fiber-Reinforced Thermosetting Resin Coated by Thermoplastic Resin Using Tools with Different Surface Shapes" Journal of Composites Science 9, no. 1: 17. https://doi.org/10.3390/jcs9010017

APA StyleTanaka, K., & Nagae, Y. (2025). Friction Stir Spot Welding of Aluminum Alloy to Carbon Fiber-Reinforced Thermosetting Resin Coated by Thermoplastic Resin Using Tools with Different Surface Shapes. Journal of Composites Science, 9(1), 17. https://doi.org/10.3390/jcs9010017