Performance of GFRP-Confined Rubberized Engineered Cementitious Composite Columns

Abstract

:1. Introduction

2. Experimental Program

2.1. Specimen Details and Test Program

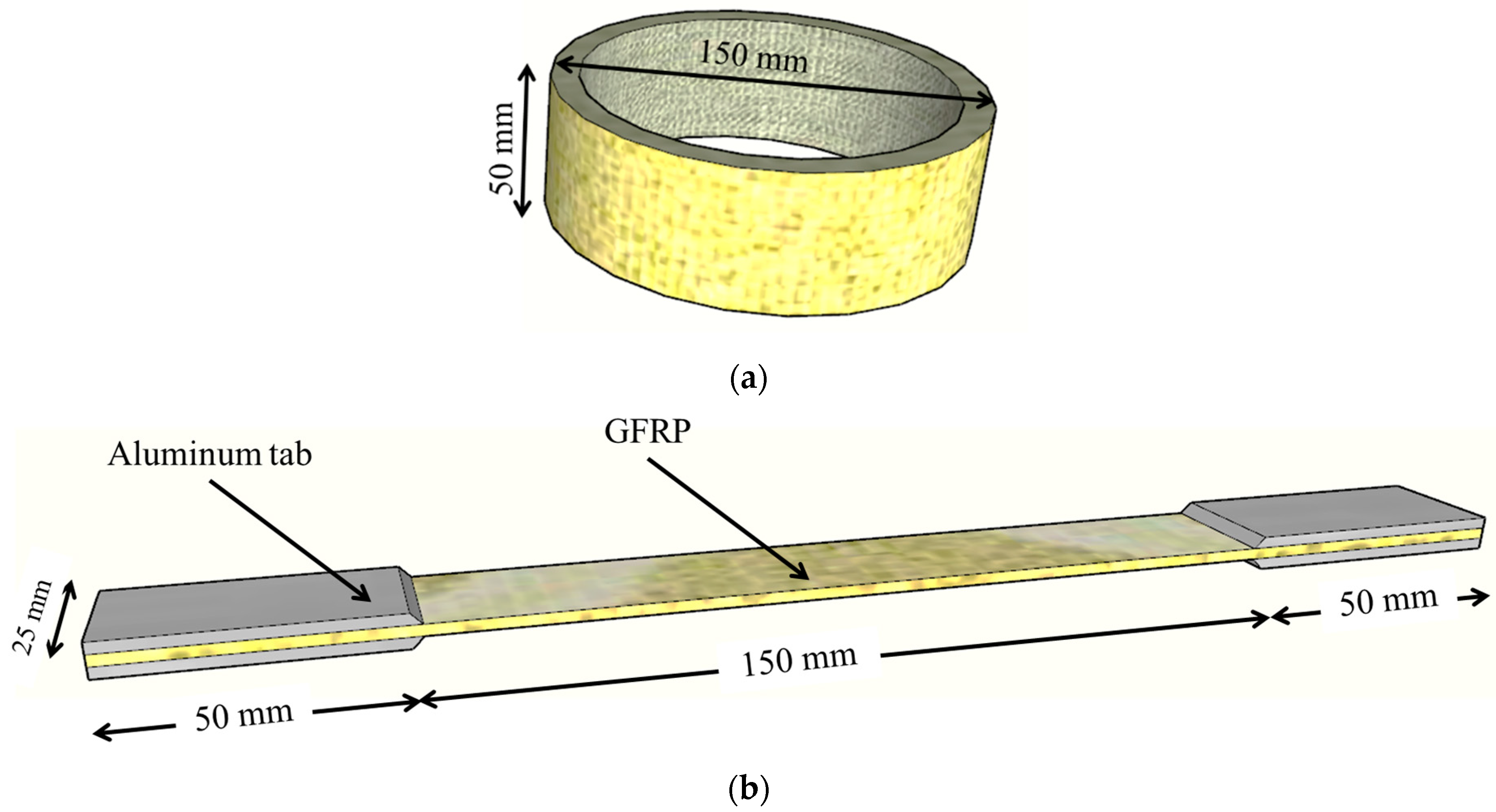

2.2. Material Properties and Mix Proportions

2.3. Test Setup and Instrumentations

3. Results and Discussion

3.1. Compression Test Results

3.2. Push-Out Test Results

4. Numerical Simulation

4.1. FE Model Built-Up, Interaction, and Boundary Conditions

4.2. Material Constitutive Modeling

4.3. FE Model Verification

5. Parametric Study

6. Conclusions

- As a result of confinement, GFRP tubes significantly enhanced column capacity, with ECC/RECC providing even greater improvements compared to standard NC in terms of fracture toughness.

- ECC increased initial stiffness and peak load by about 90% and 55%, respectively, compared to N-C.

- RECC exhibited comparable behavior to NC.

- Concerning N-C, the observed peak load was 13% higher than that of RE-C and 10% lower than that of E-C.

- The existence of fibers in E-C-S and RE-C-S provided with shear connectors increased peak load by about 12% and 14%, respectively, compared to specimens without shear connectors.

- From the pushout test results, it can be concluded that changing the concrete type has an insignificant effect on contact/friction between concrete and GFRP tubes for specimens without shear connectors. On the other hand, providing the specimens with shear connectors significantly increases load-carrying capacity.

- Increasing GFRP tube thickness resulted in greater confinement; indicating that load-carrying capacity can be increased by increasing tube thickness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z.; Zhao, X.L.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saadi, S. Durability Study on Interlaminar Shear Behaviour of Basalt-, Glass- and Carbon-Fibre Reinforced Polymer (B/G/CFRP) Bars in Seawater Sea Sand Concrete Environment. Constr. Build. Mater. 2017, 156, 985–1004. [Google Scholar] [CrossRef]

- Ren, F.; Liu, T.; Chen, G.; Xie, P.; Xiong, M.X.; Yuan, T.; Chen, Y.; Guo, S. Flexural Behavior and Modelling of FRP-Bar Reinforced Seawater Sea Sand Concrete Beams Exposed to Subtropical Coastal Environment. Constr. Build. Mater. 2021, 309, 125071. [Google Scholar] [CrossRef]

- Jarek, A.; Dos Santos, A.T.; Bragança, M.O.G.P.; Pinkoski, I.M.; Neri, M.A.T.; Diniz, J.H.O.T.; Gomes, R.A.N. Experimental and Numerical Investigations to Evaluate the Structural Integrity of Concrete Beams Exposed to an Aggressive Coastal Environment. Structures 2022, 37, 795–806. [Google Scholar] [CrossRef]

- Van Den Einde, L.; Zhao, L.; Seible, F. Use of FRP Composites in Civil Structural Applications. Constr. Build. Mater. 2003, 17, 389–403. [Google Scholar] [CrossRef]

- Zhao, X.-L.; Bai, Y.; Al-Mahaidi, R.; Rizkalla, S. Effect of Dynamic Loading and Environmental Conditions on the Bond between CFRP and Steel: State-of-the-Art Review. J. Compos. Constr. 2013, 18, A4013005. [Google Scholar] [CrossRef]

- Emara, M.; Elkomy, N.; Hassan, H. Numerical Assessment of Reinforced Concrete Beams Strengthened with CFRP Sheets under Impact Loading. Frat. Integrità Strutt. 2021, 15, 48–64. [Google Scholar] [CrossRef]

- Emara, M.; El-Zohairy, A.; Fekry, M.; Husain, M. Effect of Using ECC Layer on the Flexural Performance of RC Beams Previously Strengthened with EB CFRP Laminates. Sustainability 2022, 14, 16990. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Teng, J.G. Near-Surface Mounted FRP Reinforcement: An Emerging Technique for Strengthening Structures. Compos. Part B Eng. 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Emara, M.; Torres, L.; Baena, M.; Barris, C.; Cahís, X. Bond Response of NSM CFRP Strips in Concrete under Sustained Loading and Different Temperature and Humidity Conditions. Compos. Struct. 2018, 192, 1–7. [Google Scholar] [CrossRef]

- Zaghi, A.E.; Saiidi, M.S.; Mirmiran, A. Shake Table Response and Analysis of a Concrete-Filled FRP Tube Bridge Column. Compos. Struct. 2012, 94, 1564–1574. [Google Scholar] [CrossRef]

- ElGawady, M.A.; Dawood, H.M. Analysis of Segmental Piers Consisted of Concrete Filled FRP Tubes. Eng. Struct. 2012, 38, 142–152. [Google Scholar] [CrossRef]

- Lin, S.; Zhang, B.; Zhang, S.; Cai, Z.; Lai, C.; Zhang, J. Behavior and Modeling of Large-Scale Concrete-Filled FRP Tubes with Longitudinal Steel Rebars under Lateral Impact Loading. Thin-Walled Struct. 2023, 186, 110691. [Google Scholar] [CrossRef]

- Bazli, M.; Dorothea Luck, J.; Rajabipour, A.; Arashpour, M. Bond-Slip Performance of Seawater Sea Sand Concrete Filled Filament Wound FRP Tubes under Cyclic and Static Loads. Structures 2023, 52, 889–903. [Google Scholar] [CrossRef]

- Qasrawi, Y.; Fam, A. Flexural Load Tests on New Spun-Cast Concrete-Filled Fiber-Reinforced Polymer Tubular Poles. Struct. J. 2008, 105, 750–759. [Google Scholar] [CrossRef]

- Mitchell, J.; Fam, A. Tests and Analysis of Cantilevered GFRP Tubular Poles with Partial Concrete Filling. J. Compos. Constr. 2009, 14, 115–124. [Google Scholar] [CrossRef]

- Masmoudi, R.; Mohamed, H.; Metiche, S. Finite Element Modeling for Deflection and Bending Responses of GFRP Poles. J. Reinf. Plast. Compos. 2008, 27, 639–658. [Google Scholar] [CrossRef]

- Nawar, M.T.; Kaka, M.E.; El-Zohairy, A.; Elhosseiny, O.; Arafa, I.T. Effect of Supporting Base System on the Flexural Behavior and Toughness of the Lighting GFRP Poles. Sustainability 2022, 14, 12614. [Google Scholar] [CrossRef]

- Desai, N.; Yuan, R. Investigation of Bending/Buckling Characteristics for FRP Composite Poles. In Proceedings of the Earth and Space 2006—Proceedings of the 10th Biennial International Conference on Engineering, Construction, and Operations in Challenging Environments, League City TX, USA, 5 March 2006; pp. 1–18. [Google Scholar] [CrossRef]

- Hamoda, A.; Abdelazeem, F.; Emara, M. Concentric Compressive Behavior of Hybrid Concrete–Stainless Steel Double-Skin Tubular Columns Incorporating High Performance Concretes. Thin-Walled Struct. 2020, 159, 107297. [Google Scholar] [CrossRef]

- Emara, M.; Mohamed, H.A.; Rizk, M.S.; Hu, J.W. Behavior of ECC Columns Confined Using Steel Wire Mesh under Axial Loading. J. Build. Eng. 2021, 43, 102809. [Google Scholar] [CrossRef]

- Hamoda, A.; Emara, M.; Abdelazeem, F.; Ahmed, M. Experimental and Numerical Analysis of RC Beams Strengthened with ECC and Stainless Steel Strips. Mag. Concr. Res. 2022, 75, 251–270. [Google Scholar] [CrossRef]

- Haruna, S.; Adamu, M.; Ibrahim, Y.E.; Haruna, S.I.; Seif Eldin, H.M.; Hamza, M.F.; Azab, M. Multifunctional Engineered Cementitious Composites Modified with Nanomaterials and Their Applications: An Overview. Rev. Adv. Mater. Sci. 2023, 62, 20220309. [Google Scholar] [CrossRef]

- Kelechi, S.E.; Adamu, M.; Mohammed, A.; Ibrahim, Y.E.; Obianyo, I.I. Durability Performance of Self-Compacting Concrete Containing Crumb Rubber, Fly Ash and Calcium Carbide Waste. Materials 2022, 15, 488. [Google Scholar] [CrossRef]

- Khusru, S.; Fawzia, S.; Thambiratnam, D.P.; Elchalakani, M. Confined Rubberised Concrete Tubular Column for High-Performance Structures—Review. Constr. Build. Mater. 2021, 276, 122216. [Google Scholar] [CrossRef]

- Siddika, A.; Mamun, M.A.A.; Alyousef, R.; Amran, Y.H.M.; Aslani, F.; Alabduljabbar, H. Properties and Utilizations of Waste Tire Rubber in Concrete: A Review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Musarat, M.A.; Tayeh, A.B.; Sivalingam, S.; Rosli, M.F.B.; Haruna, S.; Khan, M.I. Mechanical and Deformation Properties of Rubberized Engineered Cementitious Composite (ECC). Case Stud. Constr. Mater. 2020, 13, e00385. [Google Scholar] [CrossRef]

- Srikakulam, L.M.; Khed, V.C. Experimental Investigation on the Strength Parameters of Rubberized Engineered Cementitious Composite with M Sand. Mater. Today Proc. 2020, 27, 1230–1234. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM Specification: West Conshohocken, PA, USA, 2002.

- Carreira, D.J.; Chu, K.-H. Stress-Strain Relationship for Plain Concrete in Compression. ACI Struct. J. 1985, 82, 797–804. [Google Scholar] [CrossRef]

- Zhou, J.; Pan, J.; Leung, C.K.Y. Mechanical Behavior of Fiber-Reinforced Engineered Cementitious Composites in Uniaxial Compression. J. Mater. Civ. Eng. 2015, 27, 04014111. [Google Scholar] [CrossRef]

- Aslani, F. Mechanical Properties of Waste Tire Rubber Concrete. J. Mater. Civ. Eng. 2016, 28, 04015152. [Google Scholar] [CrossRef]

- Tao, Z.; Wang, Z.B.; Yu, Q. Finite Element Modelling of Concrete-Filled Steel Stub Columns under Axial Compression. J. Constr. Steel Res. 2013, 89, 121–131. [Google Scholar] [CrossRef]

| Group | Specimen ID * | Concrete Type | Confinement | Shear Connectors | Loading |

|---|---|---|---|---|---|

| G1 | N-Control | NC | ---- | ---- | Compression |

| E-Control | ECC | ---- | ---- | Compression | |

| RE-Control | RECC | GFRP | ---- | Compression | |

| G2 | N-C | NC | GFRP | ---- | Compression |

| E-C | ECC | GFRP | ---- | Compression | |

| RE-C | RECC | GFRP | ---- | Compression | |

| G3 | N-C-S | NC | GFRP | Yes | Compression |

| E-C-S | ECC | GFRP | Yes | Compression | |

| RE-C-S | RECC | GFRP | Yes | Compression | |

| G4 | N-P | NC | GFRP | ---- | Push-out |

| E-P | ECC | GFRP | ---- | Push-out | |

| RE-P | RECC | GFRP | ---- | Push-out | |

| G5 | N-P-S | NC | GFRP | Yes | Push-out |

| E-P-S | ECC | GFRP | Yes | Push-out | |

| RE-P-S | RECC | GFRP | Yes | Push-out |

| Concrete | Cement (52.5) (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Fly Ash (kg/m3) | Crumb Rubber (kg/m3) | Water/Binder | PVA (% in Volume) | HRWR (kg/m3) | fc (MPa) | Elastic Modulus |

|---|---|---|---|---|---|---|---|---|---|---|

| (GPa) | ||||||||||

| NC | 350 | 700 | 1150 | --- | --- | 0.43 | --- | --- | 28 | 22,560 |

| ECC | 550 | 440 | --- | 660 | --- | 0.25 | 1 | 14.5 | 51 | 32,400 |

| RECC | 550 | 650 | --- | 660 | 50 | 0.25 | 1 | 14.5 | 34 | 24,315 |

| Group | Specimen ID | Concrete Type | GFRP Thickness (mm) | GFRP Diameter (mm) |

|---|---|---|---|---|

| G1 | E-T4-R150 | ECC | 4 | 150 |

| E-T6-R150 | ECC | 6 | 150 | |

| E-T8-R150 | ECC | 8 | 150 | |

| E-T10-R150 | ECC | 10 | 150 | |

| G2 | RE-T4-R150 | RECC | 4 | 150 |

| RE-T6-R150 | RECC | 6 | 150 | |

| RE-T8-R150 | RECC | 8 | 150 | |

| RE-T10-R150 | RECC | 10 | 150 | |

| G3 | E-T8-R100 | ECC | 8 | 100 |

| E-T8-R150 | ECC | 8 | 150 | |

| E-T8-R200 | ECC | 8 | 200 | |

| G4 | RE-T8-R100 | RECC | 8 | 100 |

| RE-T8-R150 | RECC | 8 | 150 | |

| RE-T8-R200 | RECC | 8 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nawar, M.T.; Selim, M.; Zaghlal, M.; El-Zohairy, A.; Emara, M. Performance of GFRP-Confined Rubberized Engineered Cementitious Composite Columns. J. Compos. Sci. 2024, 8, 330. https://doi.org/10.3390/jcs8080330

Nawar MT, Selim M, Zaghlal M, El-Zohairy A, Emara M. Performance of GFRP-Confined Rubberized Engineered Cementitious Composite Columns. Journal of Composites Science. 2024; 8(8):330. https://doi.org/10.3390/jcs8080330

Chicago/Turabian StyleNawar, Mahmoud T., Mohamed Selim, Mahmoud Zaghlal, Ayman El-Zohairy, and Mohamed Emara. 2024. "Performance of GFRP-Confined Rubberized Engineered Cementitious Composite Columns" Journal of Composites Science 8, no. 8: 330. https://doi.org/10.3390/jcs8080330

APA StyleNawar, M. T., Selim, M., Zaghlal, M., El-Zohairy, A., & Emara, M. (2024). Performance of GFRP-Confined Rubberized Engineered Cementitious Composite Columns. Journal of Composites Science, 8(8), 330. https://doi.org/10.3390/jcs8080330