A Review of the Current State of Research and Future Prospectives on Stimulus-Responsive Shape Memory Polymer Composite and Its Blends

Abstract

1. Introduction

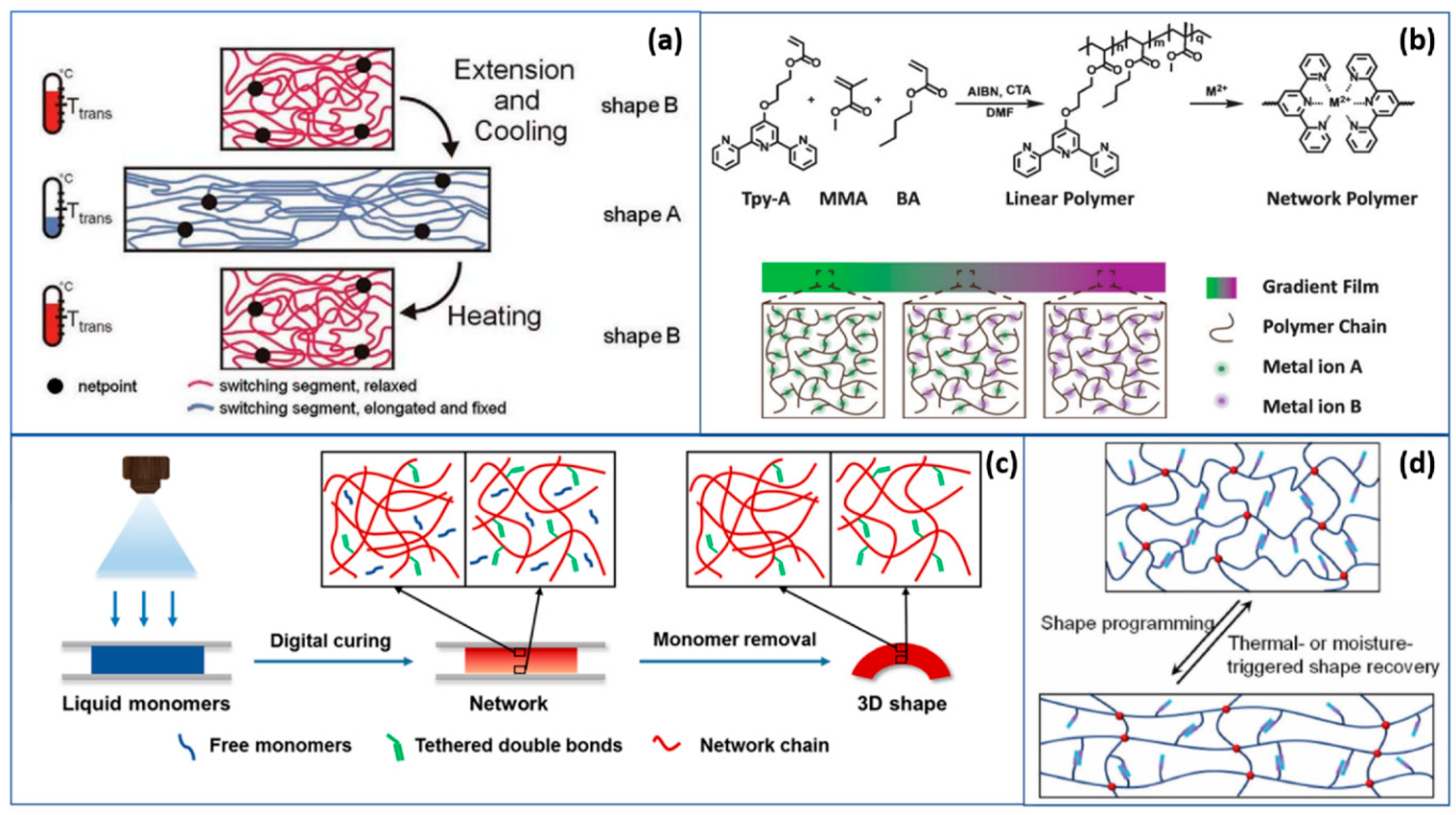

2. Classification of SMPs

2.1. Based on Net Points

2.1.1. Physically Crosslinked SMPs

2.1.2. Covalently Crosslinked/Chemically Crosslinked SMPs

2.2. Based on Composition and Structure

2.2.1. Segmented Block Copolymers

2.2.2. Crosslinked Homopolymers

2.2.3. Polymer IPN/Semi-iPN

2.2.4. Supramolecular Polymer Networks

2.2.5. Hydrogels

2.2.6. Polymer Composites

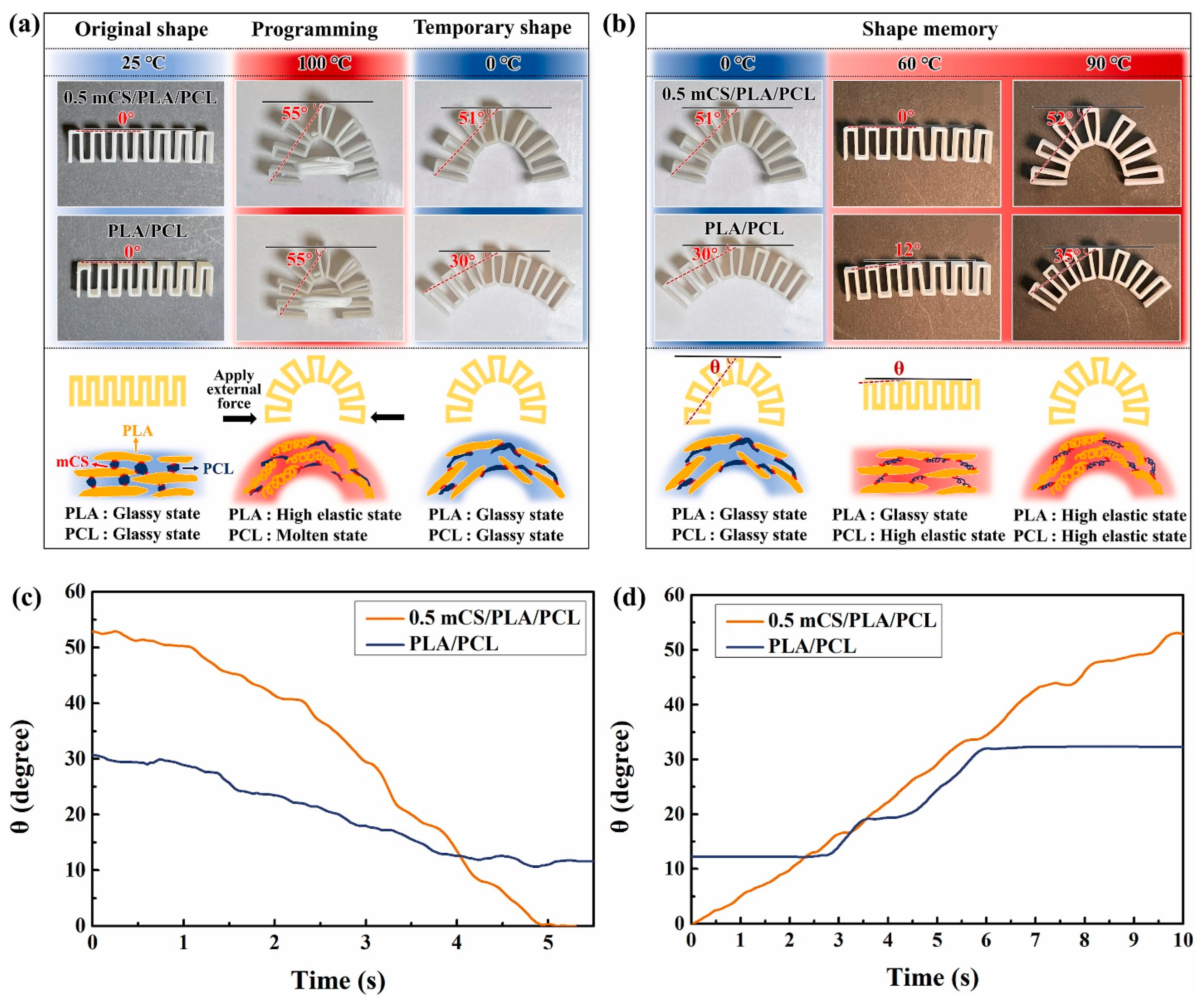

2.2.7. Polymer Blends

Miscible Blends

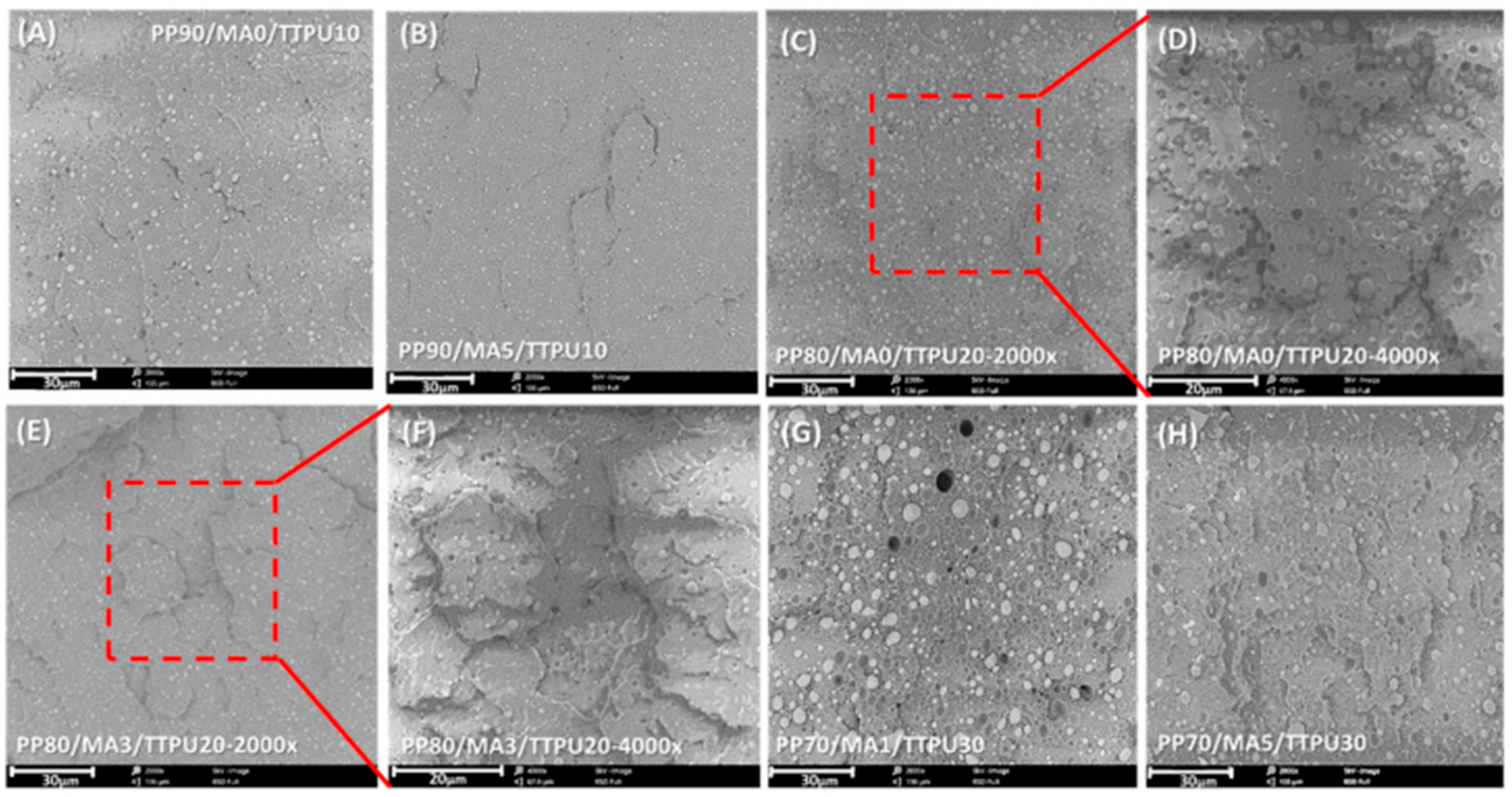

Immiscible Blends

2.3. Based on Shape Memory Effect (SME)

2.3.1. One-Way SME

2.3.2. Two-Way SME

2.3.3. Multi-Way SME

2.4. Based on Stimulus for Activation

3. Fabrication Methods

3.1. Melt Blending

3.2. Solution Mixing

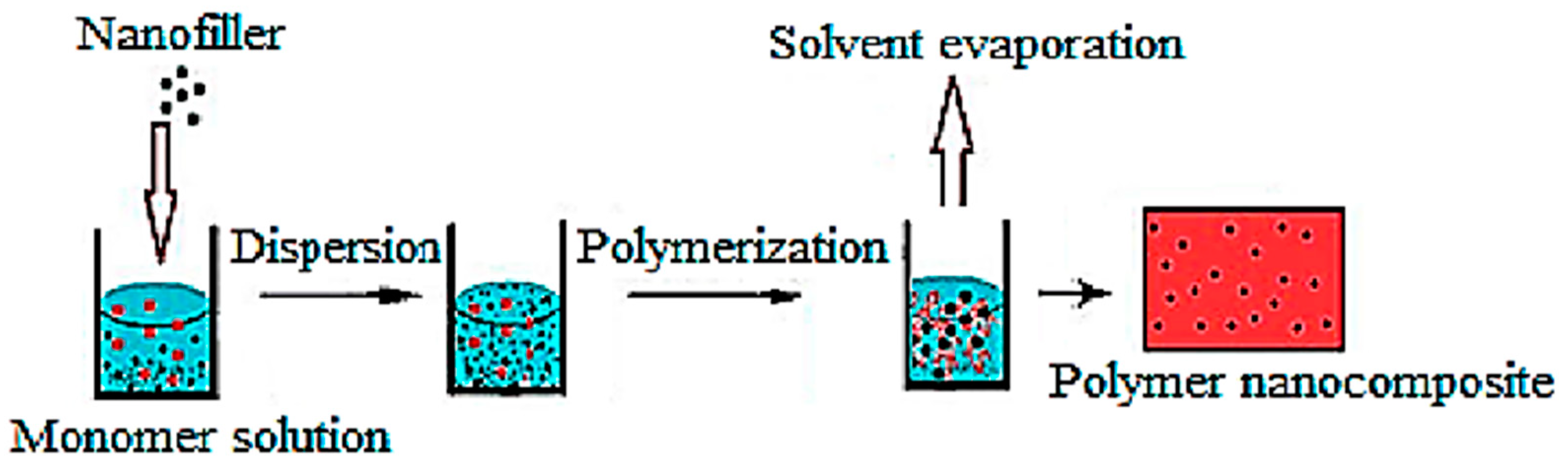

3.3. In Situ Polymerization

4. Characterization Techniques

4.1. Mechanical Characterization

4.2. Thermal Characterization

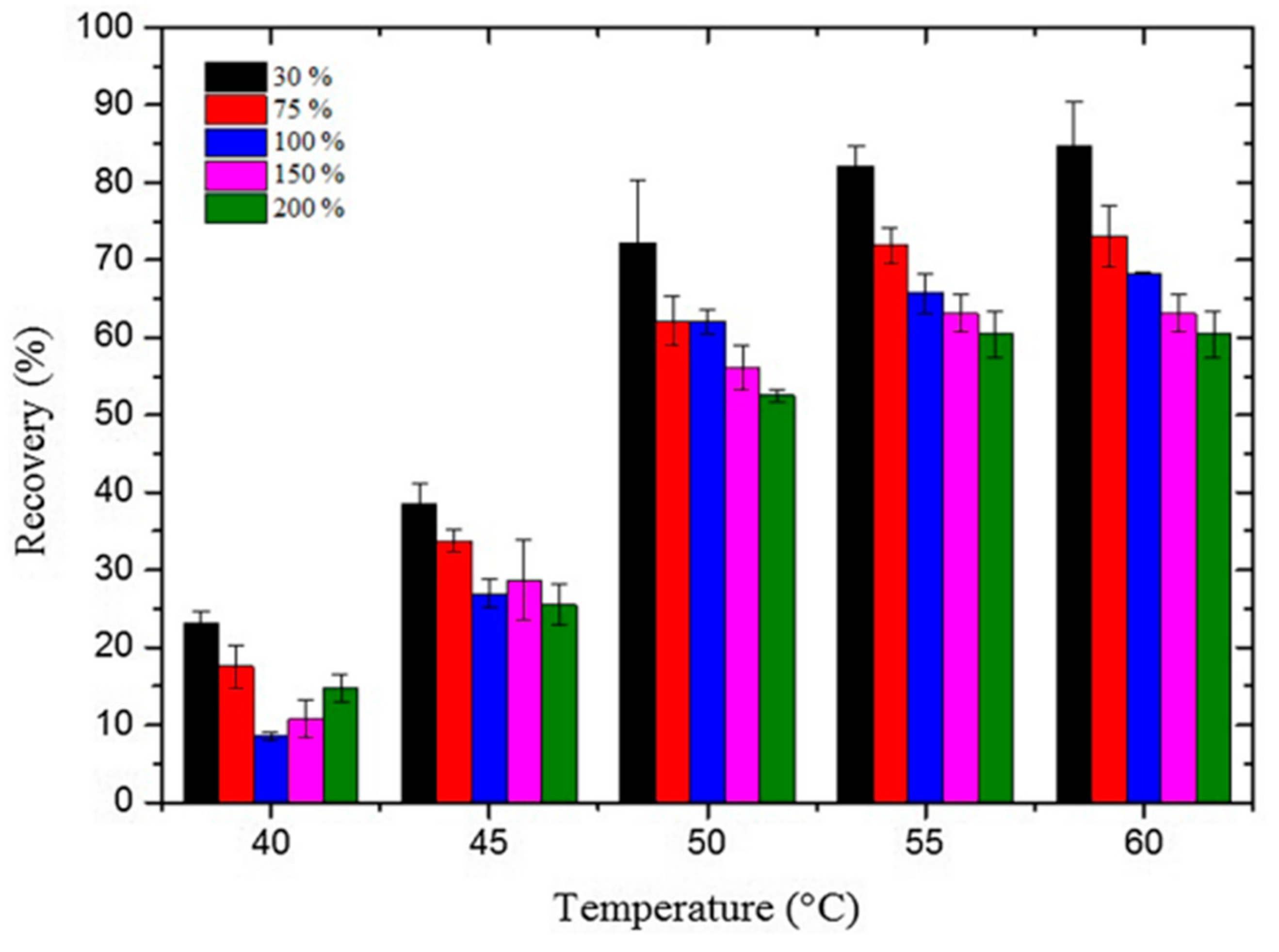

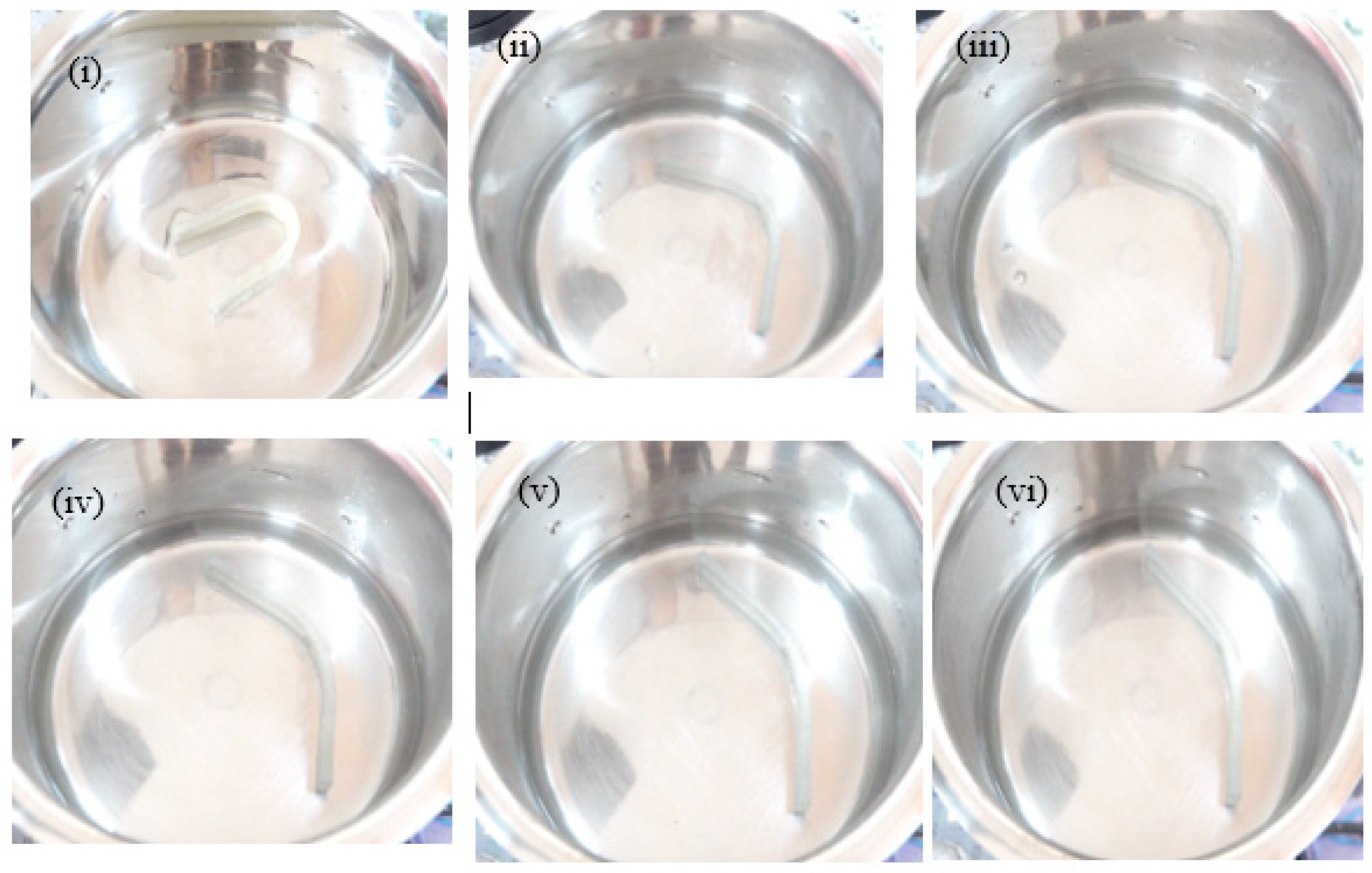

4.3. Shape Memory Behavior

5. Applications

6. Conclusions

- Shape memory polymers (SMPs) respond uniquely to external stimuli;

- SMP composites with fillers exhibit improved mechanical and thermal properties;

- Blends, especially those with polylactic acid (PLA), show superior shape recovery efficiency;

- SMP blends offer promising features for mechanical, thermal, and shape recovery applications.

7. Future Prospectives

7.1. Bioprinting

7.2. Self-Healing Material

7.3. Agricultural

7.4. Bio-Robots

7.5. Drug Delivery

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nayak, A.; Rama Sreekanth, P.S.; Sahu, S.K.; Sahu, D. Structural tuning of low band gap intermolecular push/pull side-chain polymers for organic photovoltaic applications. Chin. J. Polym. Sci. 2017, 35, 1073–1085. [Google Scholar] [CrossRef]

- Satchanska, G.; Davidova, S.; Petrov, P.D. Natural and Synthetic Polymers for Biomedical and Environmental Applications. Polymers 2024, 16, 1159. [Google Scholar] [CrossRef] [PubMed]

- Sahu, S.K.; Sreekanth, P.R. Experimental investigation of in-plane compressive and damping behavior anisotropic graded honeycomb structure. Arab. J. Sci. Eng. 2022, 47, 15741–15753. [Google Scholar] [CrossRef]

- Yesaswi, C.S.; Sahu, S.K.; Sreekanth, P.R. Experimental investigation of electro-mechanical behavior of silver-coated teflon fabric-reinforced nafion ionic polymer metal composite with carbon nanotubes and graphene nanoparticles. Polymers 2022, 14, 5497. [Google Scholar] [CrossRef]

- Sahu, S.K.; Badgayan, N.D.; Sreekanth, P.R. Numerical investigation on the effect of wall thickness on quasistatic crushing properties of nylon honeycomb structure. Mater. Today Proc. 2020, 27, 798–804. [Google Scholar] [CrossRef]

- Kushwaha, Y.S.; Hemanth, N.S.; Badgayan, N.D.; Sahu, S.K. Free vibration analysis of PLA based auxetic metamaterial structural composite using finite element analysis. Mater. Today Proc. 2022, 56, 1063–1067. [Google Scholar] [CrossRef]

- Sahu, S.K.; Rama Sreekanth, P.S. Multiscale RVE modeling for assessing effective elastic modulus of HDPE based polymer matrix nanocomposite reinforced with nanodiamond. Int. J. Interact. Des. Manuf. (IJIDeM) 2022, 1–10. [Google Scholar] [CrossRef]

- Pradhan, S.; Sahu, S.K.; Pramanik, J.; Badgayan, N.D. An insight into mechanical & thermal properties of shape memory polymer reinforced with nanofillers; a critical review. Mater. Today Proc. 2022, 50, 1107–1112. [Google Scholar]

- Sanaka, R.; Sahu, S.K. Experimental investigation into mechanical, thermal, and shape memory behavior of thermoresponsive PU/MXene shape memory polymer nanocomposite. Heliyon 2024, 10, e24014. [Google Scholar] [CrossRef]

- Jingcheng, L.; Reddy, V.S.; Jayathilaka, W.A.; Chinnappan, A.; Ramakrishna, S.; Ghosh, R. Intelligent polymers, fibers and applications. Polymers 2021, 13, 1427. [Google Scholar] [CrossRef]

- Sanaka, R.; Sahu, S.K. Influence of nanofiller addition on the mechanical, thermal, and shape recovery behavior of shape memory polymer nanocomposite: A brief review. Mater. Today Proc. 2023, in press. [CrossRef]

- Backes, E.H.; Harb, S.V.; Pinto, L.A.; de Moura, N.K.; de Melo Morgado, G.F.; Marini, J.; Passador, F.R.; Pessan, L.A. Thermoplastic polyurethanes: Synthesis, fabrication techniques, blends, composites, and applications. J. Mater. Sci. 2024, 59, 1123–1152. [Google Scholar] [CrossRef]

- Da Silva, M.M.; Proença, M.P.; Covas, J.A.; Paiva, M.C. Shape-Memory Polymers Based on Carbon Nanotube Composites. Micromachines 2024, 15, 748. [Google Scholar] [CrossRef]

- Uyan, M.; Celiktas, M.S. Application areas, novel constitutive models, challenges and opportunities of shape memory polymer composites: A review. Emerg. Mater. Res. 2024, 13, 1–19. [Google Scholar]

- Sahu, S.K.; Rama Sreekanth, P.S. Mechanical, thermal and rheological properties of thermoplastic polymer nanocomposite reinforced with nanodiamond, carbon nanotube and graphite nanoplatelets. Adv. Mater. Process. Technol. 2022, 8 (Suppl. S4), 2086–2096. [Google Scholar] [CrossRef]

- Hooshyari, K.; Karimi, M.B.; Kakavand, P.; Mohammadifar, M.; Rahmani, S.; Tohidian, M.; Jamalpour, S. Thermal, Mechanical, and Viscoelastic Properties of Two-Dimensional Nanomaterial-Based Polymer Nanocomposites: Processing, Properties and Applications; Scrivener Publishing LLC: Beverly, MA, USA, 2024; pp. 311–341. [Google Scholar]

- Sahu, S.K.; Sreekanth, P.R.; Deepthi, Y.P.; Ma, Q.; Erinle, T.J. Tensile, flexural and free vibration characteristics of sustainable recycled polypropylene filled with spherical SiC through experimental and RVE analysis. Int. J. Struct. Integr. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Fang, C.; Chang, Y.; Nie, J. Influence of basalt fiber and polypropylene fiber on the mechanical and durability properties of cement-based composite materials. J. Build. Eng. 2024, 90, 109335. [Google Scholar] [CrossRef]

- Alekseeva, O.V.; Noskov, A.V.; Guseynov, S.S. A Study on the Thermal Behavior of Polymer Composites Based on Polystyrene for Environmental Protection. In Environmental Technology and Sustainability; Apple Academic Press: Goldenrod Circle NEPalm Bay, FL, USA, 2024; pp. 3–36. [Google Scholar]

- Boraei, S.B.A.; Bakhshandeh, B.; Mohammadzadeh, F.; Haghighi, D.M.; Mohammadpour, Z. Clay-reinforced PVC composites and nanocomposites. Heliyon 2024, 10, e29196. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, S.M.; Shafiq, M.; Abbas, N. A review on PLA-based biodegradable materials for biomedical applications. Giant 2024, 18, 100261. [Google Scholar] [CrossRef]

- Bedi, S.S.; Mallesha, V.; Mahesh, V.; Mahesh, V.; Ponnusami, S.A. Investigation of low-percentage graphene reinforcement on the mechanical behaviour of additively manufactured polyethylene terephthalate glycol composites. J. Thermoplast. Compos. Mater. 2024, 37, 910–930. [Google Scholar] [CrossRef]

- Scopus Data Base. Available online: https://www.scopus.com/search/form.uri?display=basic&zone=header&origin=sbrowse#basic (accessed on 10 June 2024).

- Yang, L.; Lou, J.; Yuan, J.; Deng, J. A review of shape memory polymers based on the intrinsic structures of their responsive switches. RSC Adv. 2021, 11, 28838–28850. [Google Scholar] [CrossRef]

- Rokaya, D.; Skallevold, H.E.; Srimaneepong, V.; Marya, A.; Shah, P.K.; Khurshid, Z.; Zafar, M.S.; Sapkota, J. Shape Memory Polymeric Materials for Biomedical Applications: An Update. J. Compos. Sci. 2023, 7, 24. [Google Scholar] [CrossRef]

- Ebara, M. Shape-memory surfaces for cell mechanobiology. Sci. Technol. Adv. Mater. 2015, 16, 014804. [Google Scholar] [CrossRef]

- Madbouly, S.A.; Lendlein, A. Shape-memory polymer composites. In Shape-Memory Polymers; Springer: Berlin/Heidelberg, Germany, 2010; pp. 41–95. [Google Scholar]

- Hu, J.; Zhu, Y.; Huang, H.; Lu, J. Recent advances in shape–memory polymers: Structure, mechanism, functionality, modeling and applications. Prog. Polym. Sci. 2012, 37, 1720–1763. [Google Scholar] [CrossRef]

- Jose, S.; George, J.J.; Siengchin, S.; Parameswaranpillai, J. Introduction to shape-memory polymers, polymer blends and composites: State of the art, opportunities, new challenges and future outlook. In Shape Memory Polymers, Blends and Composites: Advances and Applications; Springer: Singapore, 2020; pp. 1–19. [Google Scholar]

- Wang, Y.; Ye, J.; Tian, W. Shape memory polymer composites of poly (styrene-b-butadiene-b-styrene) copolymer/liner low density polyethylene/Fe3O4 nanoparticles for remote activation. Appl. Sci. 2016, 6, 333. [Google Scholar] [CrossRef]

- Chen, W.; Zhu, C.; Gu, X. Thermosetting polyurethanes with water-swollen and shape memory properties. J. Appl. Polym. Sci. 2002, 84, 1504–1512. [Google Scholar] [CrossRef]

- Alteheld, A.; Feng, Y.; Kelch, S.; Lendlein, A. Biodegradable, amorphous copolyester urethane networks having shape-memory properties. Angew. Chem. Int. Ed. 2005, 44, 1188–1192. [Google Scholar] [CrossRef]

- Lendlein, A.; Zotzmann, J.; Feng, Y.; Alteheld, A.; Kelch, S. Controlling the switching temperature of biodegradable, amorphous, shape-memory poly(rac-lactide)urethane networks by incorporation of different comonomers. Biomacromolecules 2009, 10, 975–982. [Google Scholar] [CrossRef]

- Zotzmann, J.; Alteheld, A.; Behl, M.; Lendlein, A. Amorphous phase–segregated copoly(ether) esterurethane thermoset networks with oligo(propylene glycol) and oligo[(raclactide)-co-glycolide] segments: Synthesis and characterization. J. Mater. Sci. Mater. Med. 2009, 20, 1815–1824. [Google Scholar] [CrossRef]

- Wu, Y.; Fei, M.; Qiu, R.; Liu, W.; Qiu, J. A review on styrene substitutes in thermosets and their composites. Polymers 2019, 11, 1815. [Google Scholar] [CrossRef]

- Gall, K.; Dunn, M.L.; Liu, Y.; Finch, D.; Lake, M.; Munshi, N.A. Shape memory polymer nanocomposites. Acta Mater. 2002, 50, 5115–5126. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Beygelzimer, Y.E.; Borzenko, A.P.; Varyukhin, V.N. Shape memory effect in the epoxy polymer–thermo expanded graphite system. Compos. Part. A Appl. Sci. Manuf. 2002, 33, 1001–1006. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Beigelzimer, Y.E.; Borzenko, A.P.; Varyukhin, V.N. Shape-memory effect in polymer composites with a compactible filler. Mech. Compos. Mater. 2003, 39, 255–264.49. [Google Scholar] [CrossRef]

- Zhu, J.; Fang, G.; Cao, Z.; Meng, X.; Ren, H. A self-folding dynamic covalent shape memory epoxy and its continuous glass fiber composite. Ind. Eng. Chem. Res. 2018, 57, 5276–5281. [Google Scholar] [CrossRef]

- Shim, Y.S.; Chun, B.C.; Chung, Y.-C. Thermomechanical properties and shape memory effect of PET-PEG copolymers cross-linked with pentaerythritol. Fiber Polym. 2006, 7, 328–332. [Google Scholar] [CrossRef]

- Bertmer, M.; Buda, A.; Hofges, I.B.; Kelch, S.; Lendlein, A. Biodegradable shape-memory polymer networks: Characterization with solid-state NMR. Macromolecules 2005, 38, 3793–3799. [Google Scholar] [CrossRef]

- Mather, P.T.; Liu, C. Castable Shape Memory Polymers. World Patent WO2003093341, 30 April 2003. [Google Scholar]

- Nagata, N. Development of polynorbornene-based shape-memory resins. Kagaku 1990, 45, 554–557. [Google Scholar]

- Jeon, H.G.; Mather, P.T.; Haddad, T.S. Shape memory and nanostructure in poly(norbornyl POSS) copolymers. Polym. Int. 2000, 49, 453–457. [Google Scholar] [CrossRef]

- Kelch, S.; Steuer, S.; Schmidt, A.M.; Lendlein, A. Shape–memory polymer networks from oligo[(ε-hydroxycaproate)-co-glycolate] dimethacrylates and butyl acrylate with adjustable hydrolytic degradation rate. Biomacromol 2007, 8, 1018–1027. [Google Scholar] [CrossRef]

- Lendlein, A.; Schmidt, A.M.; Langer, R. AB-polymer networks based on oligo(2-caprolactone) segments showing shape-memory properties. Proc. Natl. Acad. Sci. USA 2001, 98, 842–847. [Google Scholar]

- Rezanejad, S.; Kokabi, M. Shape memory and mechanical properties of cross-linked polyethylene/clay nanocomposites. Eur. Polym. J. 2007, 43, 2856–2865. [Google Scholar] [CrossRef]

- Guo, B.; Chen, Y.; Lei, Y.; Zhang, L.; Zhou, W.Y.; Rabie, A.B.M.; Zhao, J. Biobased poly(propylene sebacate) as shape memory polymer with tunable switching temperature for potential biomedical applications. Biomacromol 2011, 12, 1312–1321. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Chen, M.; Wang, X.; Zhao, X.; Wang, Z.; Dang, Z.; Ma, L.; Hu, G.; Chen, F. Triple shape memory effects of cross-linked polyethylene/polypropylene blends with cocontinuous architecture. ACS Appl. Mater. Interfaces 2013, 5, 5550–5556. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Liang, G.; Xu, Q.; Yu, Q. Shape-memory effects of radiation crosslinked poly(-caprolactone). J. Appl. Polym. Sci. 2003, 90, 1589–1595. [Google Scholar] [CrossRef]

- Lendlein, A.; Schmidt, A.M.; Schroeter, M.; Langer, R. Shape-memory polymer networks from oligo(epsilon-caprolactone)dimethacrylates. J. Polym. Sci. 2005, 43, 1369–1381. [Google Scholar] [CrossRef]

- Lee, K.M.; Knight, P.T.; Chung, T.; Mather, P.T. Polycaprolactone-POSS chemical/physical double networks. Macromolecules 2008, 41, 4730–4738. [Google Scholar] [CrossRef]

- Zotzmann, J.; Behl, M.; Hofmann, D.; Lendlein, A. Reversible triple-shape effect of polymer networks containing polypentadecalactone- and poly(-caprolactone)-segments. Adv. Mater. 2010, 22, 3424–3429. [Google Scholar] [CrossRef] [PubMed]

- Mya, K.Y.; Gose, H.B.; Pretsch, T.; Bothe, M.; He, C. Star-shaped POSS-polycaprolactone polyurethanes and their shape memory performance. J. Mater. Chem. 2011, 21, 4827–4836. [Google Scholar] [CrossRef]

- Defize, T.; Riva, R.; Raquez, J.M.; Dubois, P.; Jerome, C.; Alexandre, M. Thermoreversibly crosslinked poly(ε-caprolactone) as recyclable shape-memory polymer network. Macromol. Rapid Commun. 2011, 32, 1264–1269. [Google Scholar] [CrossRef] [PubMed]

- Garle, A.; Kong, S.; Ojha, U.; Budhlall, B.M. Thermoresponsive semicrystalline poly(εcaprolactone) networks: Exploiting cross-linking with cinnamoyl moieties to design polymers with tunable shape memory. Appl. Mater. Interfaces 2012, 4, 645–657. [Google Scholar] [CrossRef]

- Pandini, S.; Passera, S.; Messori, M.; Paderni, K.; Toselli, M.; Gianoncelli, A.; Bontempi, E.; Riccò, T. Two-way reversible shape memory behaviour of crosslinked poly(ε-caprolactone). Polymer 2012, 53, 1915–1924. [Google Scholar] [CrossRef]

- Pandini, S.; Baldi, F.; Paderni, K.; Messori, M.; Toselli, M.; Pilati, F.; Gianoncelli, A.; Brisotto, M.; Bon Tempi, E.; Riccò, T. One-way and two-way shape memory behaviour of semi-crystalline networks based on sol-gel cross-linked poly(ε-caprolactone). Polymer 2015, 54, 4253–4265. [Google Scholar] [CrossRef]

- Dureamae, I.; Nishida, M.; Hirabayashi, T.N.; Matsumura, K.; Kitano, H. Biodegradable shape memory polymers functionalized with anti-biofouling interpenetrating polymer networks. J. Mater. Chem. B 2016, 4, 5394–5404. [Google Scholar] [CrossRef]

- Tian, G.; Zhu, G.; Ren, T.; Liu, Y.; Wei, K.; Liu, Y.X. The effects of PCL diol molecular weight on properties of shape memory poly(ε-caprolactone) networks. J. Appl. Polym. Sci. 2019, 136, 47055. [Google Scholar] [CrossRef]

- Liu, C.; Chun, S.B.; Mather, P.T.; Zheng, L.; Haley, E.H.; Coughlin, E.B. Chemically cross-linked polycyclooctene: Synthesis, characterization, and shape memory behavior. Macromolecules 2002, 35, 9868–9874. [Google Scholar] [CrossRef]

- Mather, P.T.; Liu, C.; Coughlin, E.B.; Chun, S.B. Crosslinked Polycyclooctene. U.S. Patent US7173096B2, 6 February 2004. [Google Scholar]

- Campo, C.J.; Mather, P.T. PVDF: PMMA shape memory blends: Effect of short carbon fiber addition. Polym. Mater. Sci. Eng. 2005, 93, 933–934. [Google Scholar]

- Li, F.; Chen, Y.; Zhu, W.; Zhang, X.; Xu, M. Shape memory effect of polyethylene/nylon 6 graft copolymers. Polymer 1998, 39, 6929–6934. [Google Scholar] [CrossRef]

- Langer, R.S.; Lendlein, A. Biodegradable Shape Memory Polymeric Sutures. World Patent WO 2003088818 A2, 6 November 2003. [Google Scholar]

- Nagahama, K.; Ueda, Y.; Ouchi, T.; Ohya, Y. Biodegradable shape-memory polymers exhibiting sharp thermal transitions and controlled drug release. Biomacromol 2009, 10, 1789–1794. [Google Scholar] [CrossRef] [PubMed]

- Mather, P.T.; Kim, B.S.; Ge, Q.; Liu, C. Nonionic Telechelic Polymers Incorporating Polyhedral Oligosilsesquioxane (POSS) and Uses Thereof. U.S. Patent 20040024098A1, 5 February 2004. [Google Scholar]

- Mather, P.T.; Kim, B.S.; Ge, Q.; Liu, C. Preparation and Uses of Nonionic Telechelic Polymers Incorporating Polyhedral Oligosilsesquioxane (POSS). World Patent 2004011525, 27 June 2004. [Google Scholar]

- Luo, X.; Zhang, X.; Wang, M.; Ma, D.; Xu, M.; Li, F. Thermally stimulated shape-memory behavior of ethylene oxide-ethylene terephthalate segmented copolymer. J. Appl. Polym. Sci. 1997, 64, 2433–2440. [Google Scholar] [CrossRef]

- Wang, M.; Luo, X.; Ma, D. Dynamic mechanical behavior in the ethylene terephthalate ethylene oxide copolymer with long soft segment as a shape memory material. Eur. Polym. J. 1998, 34, 1–5. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, L. Recovery as a measure of oriented crystalline structure in poly(ether ester)s based on poly(ethylene oxide) and poly(ethylene terephthalate) used as shape memory polymers. J. Polym. Sci. Part. B Polym. Phys. 1999, 37, 101–112. [Google Scholar] [CrossRef]

- Jeong, H.M.; Song, J.H.; Chi, K.W.; Kim, I.; Kim, K.T. Shape memory effect of poly(methylene 1,3-cyclopentane) and its copolymer with polyethylene. Polym. Int. 2002, 51, 275–280. [Google Scholar] [CrossRef]

- Zheng, X.T.; Zhou, S.B.; Li, X.H.; Weng, H. Shape memory properties of poly(D, L-lactide)/hydroxyapatite composites. Biomaterials 2006, 27, 4288–4295. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Zhou, S.; Yu, X.; Li, X.; Feng, B.; Qu, S.; Wenig, J. Effect of in vitro degradation of poly(D, L–lactide)/β–tricalcium composite on its shape memory properties. J. Biomed. Mater. Res. B 2008, 86B, 170–180. [Google Scholar] [CrossRef]

- Radjabian, M.; Kish, M.H.; Mohammadi, N. Structure–property relationship for poly(lactic acid) (PLA) filaments: Physical, thermomechanical and shape memory characterization. J. Polym. Res. 2012, 19, 9870. [Google Scholar] [CrossRef]

- Ferreroa, S.P.; Fernandez, J.; Martın, M.M.F.S.; Barburu, P.A.S.; Oiz, J.R.S. The relevance of molecular weight in the design of amorphous biodegradable polymers with optimized shape memory effect. J. Mech. Behav. Biomed. Mater. 2016, 61, 541–553. [Google Scholar] [CrossRef]

- Ikematsu, T.K.; Kishimoto, Y.; Miyamoto, K. Shape Memory Polymer Resin, Resin Composition and Shape-Memorizing Molded Product Therefrom. Europe Patent EP374961A2, 27 June 1990. [Google Scholar]

- Kitahara, S.N.; Nigata, N. Novel Crosslinked Polymer Having Shape Memorizing Property, Method of Its Use, and Molded Article Having Shape Memory. U.S. Patent 5043396A, 27 August 1991. [Google Scholar]

- Lin, J.R.; Chen, L.W. Shape-memorized crosslinked ester-type polyurethane and its mechanical viscoelastic model. J. Appl. Polym. Sci. 1999, 73, 1305–1319. [Google Scholar] [CrossRef]

- Kim, B.K.; Lee, S.Y.; Lee, J.S.; Baek, S.H.; Choi, Y.J.; Lee, J.O.; Xu, M. Polyurethane ionomers having shape memory effects. Polymer 1998, 39, 2803–2808. [Google Scholar] [CrossRef]

- Jeong, H.M.; Kim, B.K.; Choi, Y.J. Synthesis and properties of thermotropic liquid crystalline polyurethane elastomers. Polymer 1999, 41, 1849–1855. [Google Scholar] [CrossRef]

- Li, F.; Qi, L.; Yang, J.; Xu, M.; Luo, X.; Ma, D. Polyurethane/conducting carbon black composites: Structure, electric conductivity, strain recovery behavior, and their relationships. J. Appl. Polym. Sci. 2000, 75, 68–77. [Google Scholar] [CrossRef]

- Kim, B.K.S.; Shin, Y.J.; Cho, S.M.; Jeong, H.M. Shape-memory behavior of segmented polyurethanes with an amorphous reversible phase: The effect of block length and content. J. Polym. Sci. Part. B Polym. Phys. 2000, 38, 2652–2657. [Google Scholar] [CrossRef]

- Lee, B.S.; Chun, B.C.; Chung, Y.C.; Sul, K.I.; Cho, J.W. Structure and thermomechanical properties of polyurethane block copolymers with shape memory effect. Macromolecules 2001, 34, 6431–6437. [Google Scholar] [CrossRef]

- Ping, P.; Wang, W.S.; Chen, X.S.; Jing, X.B. Poly(epsilon-caprolactone) polyurethane and its shape-memory property. Biomacromol 2005, 6, 587–592. [Google Scholar] [CrossRef] [PubMed]

- Knight, P.T.; Lee, K.M.; Qin, H.; Mather, P.T. Biodegradable thermoplastic polyurethanes incorporating polyhedral oligosilsesquioxane. Biomacromol 2008, 9, 2458–2467. [Google Scholar] [CrossRef]

- Pretsch, T.; Jakob, I.; Müller, W. Hydrolytic degradation and functional stability of a segmented shape memory poly(ester urethane). Polym. Degrad. Stab. 2009, 94, 61–73. [Google Scholar] [CrossRef]

- Bothe, M.; Pretsch, T. Two-way shape changes of a shape-memory poly(ester urethane). Macromol. Chem. Phys. 2012, 213, 2378–2385. [Google Scholar] [CrossRef]

- Bothe, M.; Emmerling, F.; Pretsch, T. Poly(ester urethane) with varying polyester chain length: Polymorphism and shape-memory behavior. Macromol. Chem. Phys. 2013, 214, 2683–2693. [Google Scholar] [CrossRef]

- Han, S.; Gu, B.H.; Nam, K.H.; Im, S.J.; Kim, S.C.; Im, S.S. Novel copolyester-based ionomer for a shape-memory biodegradable material. Polymer 2007, 48, 1830–1834. [Google Scholar] [CrossRef]

- Ikematsu, T.; Kishimoto, Y.; Karaushi, M. Block Copolymer Bumpers with Good Shape Memory. Japan Patent 02022355, 1990. [Google Scholar]

- Luo, H.; Liu, Y.; Yu, Z.; Zhang, S.; Li, B. Novel biodegradable shape memory material based on partial inclusion complex formation between r-Cyclodextrin and poly(E-caprolactone). Biomacromolecules 2008, 9, 2573–2577. [Google Scholar] [CrossRef]

- Feng, Y.; Behl, M.; Kelch, S.; Lendlein, A. Biodegradable multiblock copolymers based on oligodepsipeptides with shape-memory properties. Macromol. Biosci. 2009, 9, 45–54. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, L.; Zhang, Y. Surprising shape-memory effect of polylactide resulted from toughening by polyamide elastomer. Polymer 2009, 50, 1311–1315. [Google Scholar] [CrossRef]

- Xue, L.; Dai, S.; Li, Z. Biodegradable shape-memory block co-polymers for fast self expandable stents. Biomaterials 2010, 31, 8132–8140. [Google Scholar] [CrossRef] [PubMed]

- Momtaz, M.; Nouri, M.R.; Barikani, M. Effect of block ratio and strain amplitude on thermal, structural, and shape memory properties of segmented polycaprolactone based polyurethanes. J. Mater. Sci. 2014, 49, 7575–7584. [Google Scholar] [CrossRef]

- Strzelec, K.; Sienkiewicz, N.; Szmechtyk, T. Classification of Shape-Memory Polymers, Polymer Blends, and Composites. In Shape Memory Polymers, Blends and Composites; Springer: Singapore, 2020. [Google Scholar]

- Feng, H.; Lu, X.; Wang, W.; Kang, N.-G.; Mays, J.W. Block Copolymers: Synthesis, Self-Assembly, and Applications. Polymers 2017, 9, 494. [Google Scholar] [CrossRef] [PubMed]

- Zafar, S.; Hanif, M.; Azeem, M.; Mahmood, K.; Gondal, S.A. Role of crosslinkers for synthesizing biocompatible, biodegradable and mechanically strong hydrogels with desired release profile. Polym. Bull. 2022, 79, 9199–9219. [Google Scholar] [CrossRef]

- Farooq, U.; Teuwen, J.; Dransfeld, C. Toughening of Epoxy Systems with Interpenetrating Polymer Network (IPN): A Review. Polymers 2020, 12, 1908. [Google Scholar] [CrossRef] [PubMed]

- Rossow, T.; Seiffert, S. Supramolecular polymer networks: Preparation, properties, and potential. Supramol. Polym. Netw. Gels 2015, 268, 1–46. [Google Scholar]

- Bahram, M.; Mohseni, N.; Moghtader, M. An introduction to hydrogels and some recent applications. In Emerging Concepts in Analysis and Applications of Hydrogels; IntechOpen: London, UK, 2016. [Google Scholar]

- Ajitha, A.R.; Thomas, S. Chapter 1-Introduction: Polymer Blends, Thermodynamics, Miscibility, Phase Separation, and Compatibilization; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–29. ISBN 9780128160060. [Google Scholar] [CrossRef]

- Arribada, R.G.; Behar-Cohen, F.; de Barros, A.L.B.; Silva-Cunha, A. The use of polymer blends in the treatment of ocular diseases. Pharmaceutics 2022, 14, 1431. [Google Scholar] [CrossRef]

- Mathur, V.; Agarwal, P.; Srinivasan, V.; Panwar, A.; Vasanthan, K.S. Facet of 4D printing in biomedicine. J. Mater. Res. 2023, 38, 2–18. [Google Scholar] [CrossRef]

- Namathoti, S.; Ravindra Kumar, V.M.; Rama Sreekanth, P.S. A review on progress in magnetic, microwave, ultrasonic responsive Shape-memory polymer composites. Mater. Today Proc. 2022, 56, 1182–1191. [Google Scholar] [CrossRef]

- Bhanushali, H.; Amrutkar, S.; Mestry, S.; Mhaske, S.T. Shape memory polymer nanocomposite: A review on structure–property relationship. Polym. Bull. 2021, 79, 3437–3493. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive manufacturing of polymer materials: Progress, promise and challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

- Zende, R.; Ghase, V.; Jamdar, V. A review on shape memory polymers. Polym.-Plast. Technol. Mater. 2022, 62, 1–19. [Google Scholar] [CrossRef]

- Peng, S.; Sun, Y.; Ma, C.; Duan, G.; Liu, Z.; Ma, C. Recent advances in dynamic covalent bond-based shape memory polymers. E-Polymers 2022, 22, 285–300. [Google Scholar] [CrossRef]

- Reghunadhan, A.; Jibin, K.P.; Kaliyathan, A.V.; Velayudhan, P.; Strankowski, M.; Thomas, S. Shape Memory Materials from Rubbers. Materials 2021, 14, 7216. [Google Scholar] [CrossRef] [PubMed]

- Maksimkin, A.V.; Dayyoub, T.; Telyshev, D.V.; Gerasimenko, A.Y. Electroactive Polymer-Based Composites for Artificial Musclelike Actuators: A Review. Nanomaterials 2022, 12, 2272. [Google Scholar] [CrossRef] [PubMed]

- Ornaghi, H.L., Jr.; Bianchi, O. Temperature-dependent shape-memory textiles: Physical principles and applications. Textiles 2023, 3, 257–274. [Google Scholar] [CrossRef]

- Farrukh, A.; Nayab, S. Shape Memory Hydrogels for Biomedical Applications. Gels 2024, 10, 270. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, Y.; Wei, Q.; Zhang, J. Light-responsive shape memory polymer composites. Eur. Polym. J. 2022, 173, 111314. [Google Scholar] [CrossRef]

- Yan, N.; Zheng, Z.; Liu, Y.; Jiang, X.; Wu, J.; Feng, M.; Xu, L.; Guan, Q.; Li, H. Photo-responsive shape memory polymer composites enabled by doping with biomass-derived carbon nanomaterials. Nano Res. 2022, 15, 1383–1392. [Google Scholar] [CrossRef]

- Zare, M.; Davoodi, P.; Ramakrishna, S. Electrospun shape memory polymer micro/nanofibers and tailoring their roles for biomedical applications. Nanomaterials 2021, 11, 933. [Google Scholar] [CrossRef]

- Yang, Z.X.; Liu, X.; Shao, Y.; Yin, B.; Yang, M.B. A facile fabrication of PCL/OBC/MWCNTs nanocomposite with selective dispersion of MWCNTs to access electrically responsive shape memory effect. Polym. Compos. 2019, 40, E1353–E1363. [Google Scholar] [CrossRef]

- Tan, R.Y.H.; Lee, C.S.; Pichika, M.R.; Cheng, S.F.; Lam, K.Y. PH Responsive Polyurethane for the Advancement of Biomedical and Drug Delivery. Polymers 2022, 14, 1672. [Google Scholar] [CrossRef] [PubMed]

- Xiao, R.; Huang, W.M. Heating/solvent responsive shapememory polymers for implant biomedical devices in minimally invasive surgery: Current status and challenge. Macromol. Biosci. 2020, 20, 2000108. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Sukyai, P.; Lv, D.; Zhang, F.; Wang, P.; Liu, C.; Li, B. Water and humidity-induced shape memory cellulose nanopaper with quick response, excellent wet strength and folding resistance. Chem. Eng. J. 2020, 392, 123673. [Google Scholar] [CrossRef]

- Xue, J.; Ge, Y.; Liu, Z.; Liu, Z.; Jiang, J.; Li, G. Photoprogrammable moisture-responsive actuation of a shape memory polymer film. ACS Appl. Mater. Interfaces 2022, 14, 10836–10843. [Google Scholar] [CrossRef] [PubMed]

- Fauser, D.; Steeb, H. Influence of humidity on the rheology of thermoresponsive shape memory polymers. J. Mater. Sci. 2022, 57, 1–17. [Google Scholar] [CrossRef]

- Gopinath, S.; Adarsh, N.N.; Radhakrishnan Nair, P.; Mathew, S. Recent trends in thermo-responsive elastomeric shape memory polymer nanocomposites. Polym. Compos. 2023, 44, 4433–4458. [Google Scholar] [CrossRef]

- Kalkornsurapranee, E.; Keereerak, A.; Lehman, N.; Tuljittraporn, A.; Johns, J.; Uthaipan, N. Thermo-Responsive Shape Memory Thermoplastic Elastomer Based on Natural Rubber and Ethylene Octene Copolymer Blends. Adv. Polym. Technol. 2023, 32, 7276854. [Google Scholar] [CrossRef]

- Piah, M.B.M.; Ahmad, M.N.; Abdullah, E.N.; Muzakkar, M.Z. Modifications of Poly (lactic Acid) with Blends and Plasticization for Tenacity and Toughness Improvement. Indones. J. Chem. 2023, 23, 1161–1180. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A. Clay-based polymer nanocomposites: Essential work of fracture. Polymers 2021, 13, 2399. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, A.D.; Beatrice, C.A.G. Polymer nanocomposites with different types of nanofiller. In Nanocomposites-Recent Evolutions; Intech Open: London, UK, 2018; pp. 103–104. [Google Scholar]

- Qi, X.D.; Wang, Y. Novel techniques for the preparation of shape-memory Polymers, polymer blends and composites at micro and nanoscales. In Shape Memory Polymers, Blends and Composites: Advances and Applications; Springer: Singapore, 2020; pp. 53–83. [Google Scholar]

- Zheng, Y.; Shen, J.; Guo, S. Optical, electrical, and magnetic properties of shape-memory polymers, polymer blends, and composites. In Shape Memory Polymers, Blends and Composites: Advances and Applications; Springer: Singapore, 2020; pp. 237–268. [Google Scholar]

- Lin, T.A.; Lin, J.H.; Bao, L. Polypropylene/thermoplastic polyurethane blends: Mechanical characterizations, recyclability and sustainable development of thermoplastic materials. J. Mater. Res. Technol. 2020, 9, 5304–5312. [Google Scholar] [CrossRef]

- Bianchi, M.; Dorigato, A.; Morreale, M.; Pegoretti, A. Evaluation of the physical and shape memory properties of fully biodegradable poly (lactic acid)(PLA)/poly (butylene adipate terephthalate)(PBAT) blends. Polymers 2023, 15, 881. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, M.; Rawat, R.S.; Tyagi, V.K.; Talwar, M.; Kumar, M.; Das, M.; Roy, P. Study on mechanical, thermal and shape memory properties of polycarbonate/thermoplastic polyurethane blends. J. Appl. Polym. Sci. 2024, 141, e55259. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, D.; Luo, X.; Zhou, J.; Zheng, J.; Lai, C. Preparation and characterization of thermo-responsive shape memory polycaprolactone/poly(ethylene-co-octene) blends for 4D printing. Polym. Eng. Sci. 2023, 63, 2828–2840. [Google Scholar] [CrossRef]

- Tekay, E.; Aybakan, B.; Aslan, V.U.; Orhun, T. 4D Printing of novel poly (ethylene-vinyl acetate)/poly (butyl methacrylate-co-isobutyl methacrylate) shape memory polymer blends. Appl. Mater. Today 2024, 38, 102199. [Google Scholar] [CrossRef]

- Shi, S.; Shen, D.; Xu, T.; Zhang, Y. Thermal, optical, interfacial and mechanical properties of titanium dioxide/shape memory polyurethane nanocomposites. Compos. Sci. Technol. 2018, 164, 17–23. [Google Scholar] [CrossRef]

- Gohar, G.A.; Akhtar, A.; Raza, H.; Mustafa, G.; Fatima, M.; Rehman, H.U.; Aslam, M.W.; ul Haq, A.; Manzoor, W. Achieving enhanced tensile properties of polyurethane-multiwall carbon nanotubes nanocomposites. Nano Express 2023, 4, 045013. [Google Scholar] [CrossRef]

- Namathoti, S.; Vakkalagadda, M.R.K. Mechanical and shape recovery characterization of MWCNTs/HNTs-reinforced thermal-responsive shape-memory polymer nanocomposites. Polymers 2023, 15, 710. [Google Scholar] [CrossRef]

- Tekay, E.; Şen, S.; Korkmaz, M.A.; Nugay, N. Preparation and characterization of thermo-responsive shape memory ester-based polymer blends. J. Mater. Sci. 2023, 58, 8241–8260. [Google Scholar] [CrossRef]

- Pinto, L.A.; Backes, E.H.; Harb, S.V.; Pinto, G.M.; da Cunha, D.A.L.V.; Andrade, R.J.E.; Fechine, G.J.M.; Selistre-de-Araújo, H.S.; Costa, L.C.; Pessan, L.A. Shape memory thermoplastic polyurethane/polycaprolactone blend and composite with hydroxyapatite for biomedical application. J. Mater. Res. 2024, 39, 90–106. [Google Scholar] [CrossRef]

- Fulati, A.; Uto, K.; Ebara, M. Influences of crystallinity and crosslinking density on the shape recovery force in poly (ε-caprolactone)-based shape-memory polymer blends. Polymers 2022, 14, 4740. [Google Scholar] [CrossRef] [PubMed]

- Gopinath, S.; Adarsh, N.N.; Nair, P.R.; Mathew, S. One-way thermo-responsive shape memory polymer nanocomposite derived from polycaprolactone and polystyrene-block-polybutadiene-block-polystyrene packed with carbon nanofiber. Mater. Today Commun. 2020, 22, 100802. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, Z.; Zhou, Q.; Ma, S.; Liang, Y.; Zhang, Z. PEEK modified PLA shape memory blends: Towards enhanced mechanical and deformation properties. Front. Mater. Sci. 2020, 14, 177–187. [Google Scholar] [CrossRef]

- Song, M.; Li, S.; Zhu, G.; Guo, J. Compatibilised and toughened of PLA/PCL blends via modified-chitosan linking amorphous regions: 4D printing and shape memory processes. Polym. Test. 2023, 125, 108105. [Google Scholar] [CrossRef]

- Pekdemir, M.E.; Aydin, D.; Selçuk Pekdemir, S.; Erecevit Sönmez, P.; Aksoy, E. Shape memory polymer-based nanocomposites magnetically enhanced with Fe3O4 nanoparticles. J. Inorg. Organomet. Polym. Mater. 2023, 33, 1147–1155. [Google Scholar] [CrossRef] [PubMed]

- Sofla, R.L.M.; Rezaei, M.; Babaie, A.; Nasiri, M. Preparation of electroactive shape memory polyurethane/graphene nanocomposites and investigation of relationship between rheology, morphology and electrical properties. Compos. Part B Eng. 2019, 175, 107090. [Google Scholar] [CrossRef]

- Liu, J.; Teng, J.; Yun, K.; Wang, Z.; Sun, X. Investigation of thermodynamic and shape memory properties of alumina nanoparticle-loaded graphene oxide (GO) reinforced nanocomposites. Mater. Des. 2019, 181, 107926. [Google Scholar] [CrossRef]

- Negaresh, M.; Javadi, A.; Garmabi, H. Poly (lactic acid)/poly (ε-caprolactone) blends: The effect of nanocalcium carbonate and glycidyl methacrylate on interfacial characteristics. Front. Mater. 2024, 11, 1377340. [Google Scholar] [CrossRef]

- Pekdemir, M.E.; Öner, E.; Kök, M.; Qader, I.N. Thermal behavior and shape memory properties of PCL blends film with PVC and PMMA polymers. Iran. Polym. J. 2021, 30, 633–641. [Google Scholar] [CrossRef]

- Shin, E.J.; Song, Y.J.; Jung, Y.S.; Jung, I.; Lee, S. Manufacturing of Filament for 4D Printing through Polyether-Type TPU/PLA Blend. Adv. Polym. Technol. 2023, 2023, 4875625. [Google Scholar] [CrossRef]

- Boyacioglu, S.; Kodal, M.; Ozkoc, G. A comprehensive study on shape memory behavior of PEG plasticized PLA/TPU bio-blends. Eur. Polym. J. 2020, 122, 109372. [Google Scholar] [CrossRef]

- Nonkrathok, W.; Trongsatitkul, T.; Suppakarn, N. Role of maleic anhydride-grafted poly (lactic acid) in improving shape memory properties of thermoresponsive poly (ethylene glycol) and poly (lactic acid) blends. Polymers 2022, 14, 3923. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.C.; Huang, J.; Zhao, P.F.; Lu, X. Bio-based ethylene-co-vinyl acetate/poly (lactic acid) thermoplastic vulcanizates with enhanced mechanical strength and shape memory behavior. Polym. Test. 2020, 87, 106537. [Google Scholar] [CrossRef]

- Razquin Martín, I.; Iregui Gómez, J.Á.; Orduña Velasco, L.; Martín Alberdi, M.D.; González Vives, A.; Irusta Maritxalar, M.L. Reprogrammable Permanent Shape Memory Materials Based on Reversibly Crosslinked Epoxy/PCL Blends. Molecules 2020, 25, 1568. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Panahi-Sarmad, M.; Dong, K.; Cui, Z.; Zhang, K.; Gonzalez, O.G.; Xiao, X. 4D printed TPU/PLA/CNT wave structural composite with intelligent thermal-induced shape memory effect and synergistically enhanced mechanical properties. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106946. [Google Scholar] [CrossRef]

- Sahu, S.K.; Badgayan, N.D.; Sreekanth, P.R. Rheological Properties of HDPE based thermoplastic polymeric nanocomposite reinforced with multidimensional carbon-based nanofillers. Biointerface Res. Appl. Chem. 2022, 12, 5709–5715. [Google Scholar]

- Luo, L.; Zhang, F.; Wang, L.; Liu, Y.; Leng, J. Recent Advances in Shape Memory Polymers: Multifunctional Materials, Multiscale Structures, and Applications. Adv. Funct. Mater. 2024, 34, 2312036. [Google Scholar] [CrossRef]

- Sahu, S.K.; Badgayan, N.D.; Samanta, S.; Sreekanth, P.S.R. Dynamic mechanical thermal analysis of high density polyethylene reinforced with nanodiamond, carbon nanotube and graphite nanoplatelet. Mater. Sci. Forum 2018, 917, 27–31. [Google Scholar] [CrossRef]

- Deepthi, Y.P.; Sahu, S.K.; Anitha, D.; Gupta, N.; Dude, N.; Setti, S.G.; Sandeep, C.D. Tribological investigation into nickel-coated graphite polytetrafluoroethylene composites. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089241255943. [Google Scholar] [CrossRef]

- Hassan, H.; Hallez, H.; Thielemans, W.; Vandeginste, V. A review of electro-active shape memory polymer composites: Materials engineering strategies for shape memory enhancement. Eur. Polym. J. 2024, 208, 112861. [Google Scholar] [CrossRef]

- Sanaka, R.; Sahu, S.K. FEM based RVE modeling for estimating axial modulus of polyurethane composite reinforced with MXene. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 18, 3259–3269. [Google Scholar] [CrossRef]

- Sahu, S.K.; Sreekanth, P.R. Artificial neural network for prediction of mechanical properties of HDPE based nanodiamond nanocomposite. Polymer 2022, 46, 614–620. [Google Scholar]

- Jones-Salkey, O.; Windows-Yule, C.R.K.; Ingram, A.; Stahler, L.; Nicusan, A.L.; Clifford, S.; de Juan, L.M.; Reynolds, G.K. Using AI/ML to predict blending performance and process sensitivity for Continuous Direct Compression (CDC). Int. J. Pharm. 2024, 651, 123796. [Google Scholar] [CrossRef]

- Hussain, A.; Goljandin, D.; Podgursky, V.; Yörük, C.R.; Sergejev, F.; Kübarsepp, J.; Maurya, H.S.; Rahmani, R. Industrial sustainable Fabrication, SEM Characterization, mechanical Testing, ANOVA analysis of PP-PETF recycled Composites: Artificial intelligence and deep learning studies for nuclear shielding applications. Eur. Polym. J. 2024, 213, 113082. [Google Scholar] [CrossRef]

- Roppolo, I.; Caprioli, M.; Pirri, C.F.; Magdassi, S. 3D printing of self-healing materials. Adv. Mater. 2024, 36, 2305537. [Google Scholar] [CrossRef]

- Sarrafan, S.; Li, G. Conductive and Ferromagnetic Syntactic Foam with Shape Memory and Self-Healing/Recycling Capabilities. Adv. Funct. Mater. 2024, 34, 2308085. [Google Scholar] [CrossRef]

- Saberi Riseh, R.; Hassanisaadi, M.; Vatankhah, M.; Varma, R.S.; Thakur, V.K. Nano/micro-structural supramolecular biopolymers: Innovative networks with the boundless potential in sustainable agriculture. Nano-Micro Lett. 2024, 16, 147. [Google Scholar] [CrossRef] [PubMed]

- Ram Kishore, S.; Sridharan, A.P.; Chadha, U.; Narayanan, D.; Mishra, M.; Selvaraj, S.K.; Patterson, A.E. Natural fiber biocomposites via 4D printing technologies: A review of possibilities for agricultural bio-mulching and related sustainable applications. Prog. Addit. Manuf. 2024, 9, 37–67. [Google Scholar] [CrossRef]

- Firouzeh, A.; Salerno, M.; Paik, J. Stiffness control with shape memory polymer in underactuated robotic origamis. IEEE Trans. Robot. 2017, 33, 765–777. [Google Scholar] [CrossRef]

- Zheng, Y.; Du, Y.; Chen, L.; Mao, W.; Pu, Y.; Wang, S.; Wang, D. Recent advances on shape memory polymeric nanocomposites for biomedical applications and beyond. Biomater. Sci. 2024, 12, 2033–2040. [Google Scholar] [CrossRef] [PubMed]

| Type | Materials | Observation | Ref. |

|---|---|---|---|

| Class I | Thermosetting PU, Styrene copolymers, Epoxy, PET-PEG copolymer, Methacrylate, PMMA-PBMA copolymers, Polynorbornen | Tg is the temperature at which a shape transition occurs, whereas vitrification fixes the secondary form. | [28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44] |

| Class II | Acrylates, PCL-BA copolymer, PE, Poly (Propylene sebacate), PE/PP blends, Poly(ε-caprolactone), Polycyclooctene | The shape transition temperature is Tm. While the secondary shape is fixed by crystallization. The permanent shape is fixed by chemical crosslinking. Here, quick shape restoration is possible. | [45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62] |

| Class III | PCL-b-ODX, Styrene block copolymer, PVDF/PMMA blend, PE-co-nylon 6, Polylactide-based systems oligo(ε-caprolactone), PE-co-PMCP Copolymer, PET-co-PEO, POSS telechelic, POSS-PN block | The permanent form is fixed by rigid amorphous domains, crystals, hydrogen bonds, or ionic clusters acting as physical crosslinks, but the secondary shape is fixed by soft segments with lower Tg or Tm upon cooling. | [63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80] |

| Class IV | Polyurethane copolymers, Copolyesters, Styrene–trans-butadiene–styrene, TBCP, PCL-based systems | The temperature of the shape transition is Tg or Tm. The permanent form is fixed by physical crosslinks (polar contact, hydrogen bonding, or crystallization with such crosslinks), whereas the secondary shape is determined by the crystallization of soft segments. | [81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97] |

| SMP | Blend | Reinforcement | Observations | Ref. |

|---|---|---|---|---|

| Polyurethane | - | Titaniumdiox de(TiO2) (0–5 wt %) | The tensile test data revealed that at 3 wt % TiO2/SMPU composite exhibited the highest tensile strength and largest elongation at break. | [136] |

| Polyurethane | - | Multiwalled carbon nanotubes (MWCNTs) (0–1.0 wt %) | For 1.0 wt % of MWCNT modulus of elasticity: increased 25%, ultimate tensile strength: increased 21%, elongation at break: 11% | [137] |

| Polyurethane | - | MWCNT and HNT (0–1 wt %). | At 0.1 wt % PU/MWCNT had 23.5 MPa tensile strength and 7.23% elongation, while 0.1 wt % PU/HNTs had 22.7 MPa tensile strength and 362% elongation at 1 wt %. | [138] |

| Copolyester thermoplastic elastomer (COPE): 50, 60, 70, 80, and 90 wt % | polycaprolactone (PCL): 10, 20, 30, 40 and 50 wt % | - | Elastic modulus was highest for COPE60 blend (49.78 MPa) and COPE90 blend (13.04 MPa), while neat COPE elastomer had 15.51 MPa. | [139] |

| Thermoplastic polyurethane (TPU) | polycaprolactone (PCL) | hydroxyapatite (HA) (5, 10, and 20 wt %) | Pure TPU exhibited an average modulus of 48.4 ± 0.8 MPa, while the blend 75TPU/25PCL showed 57.4 ± 0.7 MPa, and pure PCL had a modulus of 92.1 ± 4.4 MPa. | [140] |

| Polycaprolactone (PCL) | Polystyrene-block-Polybutadiene block-Polystyrene (SBS) | Carbon nanofibers (CNF) | As, the PCL content increases, elongation decreases. | [141] |

| Polylactic acid (PLA) | poly(butyleneadipate terephthalate) (PBAT) | - | Stiffness and strength decreased with increasing PBAT content. | [142] |

| Polylactic acid (PLA) | poly(ether ether ketone) (PEEK) | - | Tensile strength: PEEK 10%: 20.6 MPa, PEEK15: 18.9 MPa, PEEK5: 18.6 MPa, PEEK20: 16.1 MPa, Pure PLA: 15.3 MPa. | [143] |

| Smp | Blend | Reinforcement | Observation | Ref. |

|---|---|---|---|---|

| Polyurethane | PCL | PU/Graphene (1–3 wt %) |

| [146] |

| Trans-1,4-polyisoprene (TPI) | Al2O3-GO |

| [147] | |

| PLA | PCL |

| [148] | |

| PCL | PVC and PMMA |

| [149] |

| Smp | Blend | Reinforcement | Shape Memory Behavior | Ref. |

|---|---|---|---|---|

| PLA, Ethylene-co-vinylacetate (EVA) | Thermoplastic vulcanizates (TPVs) | - |

| [153] |

| PCL | Epoxy | - |

| [154] |

| TPU | PLA | CNT |

| [155] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanaka, R.; Sahu, S.K.; Sreekanth, P.S.R.; Senthilkumar, K.; Badgayan, N.D.; Siva, B.V.; Ma, Q. A Review of the Current State of Research and Future Prospectives on Stimulus-Responsive Shape Memory Polymer Composite and Its Blends. J. Compos. Sci. 2024, 8, 324. https://doi.org/10.3390/jcs8080324

Sanaka R, Sahu SK, Sreekanth PSR, Senthilkumar K, Badgayan ND, Siva BV, Ma Q. A Review of the Current State of Research and Future Prospectives on Stimulus-Responsive Shape Memory Polymer Composite and Its Blends. Journal of Composites Science. 2024; 8(8):324. https://doi.org/10.3390/jcs8080324

Chicago/Turabian StyleSanaka, Rajita, Santosh Kumar Sahu, P. S. Rama Sreekanth, K. Senthilkumar, Nitesh Dhar Badgayan, Bathula Venkata Siva, and Quanjin Ma. 2024. "A Review of the Current State of Research and Future Prospectives on Stimulus-Responsive Shape Memory Polymer Composite and Its Blends" Journal of Composites Science 8, no. 8: 324. https://doi.org/10.3390/jcs8080324

APA StyleSanaka, R., Sahu, S. K., Sreekanth, P. S. R., Senthilkumar, K., Badgayan, N. D., Siva, B. V., & Ma, Q. (2024). A Review of the Current State of Research and Future Prospectives on Stimulus-Responsive Shape Memory Polymer Composite and Its Blends. Journal of Composites Science, 8(8), 324. https://doi.org/10.3390/jcs8080324