Sensor Systems for Measuring Force and Temperature with Fiber-Optic Bragg Gratings Embedded in Composite Materials

Abstract

1. Introduction

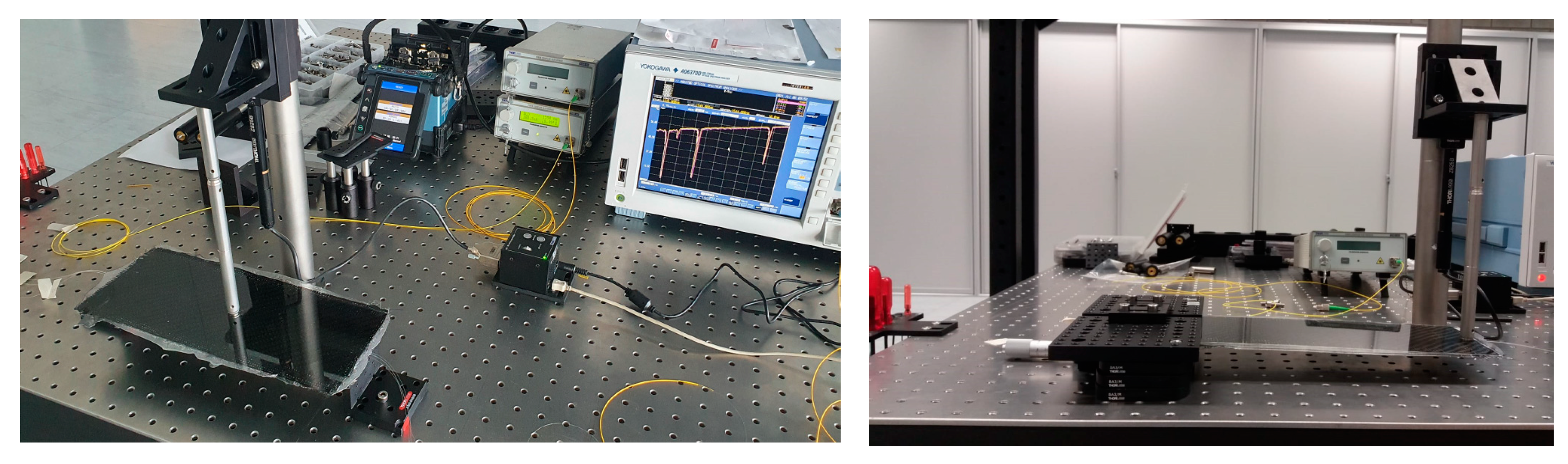

2. Materials and Methods

2.1. Sensor Diagram

2.2. Theory

- where is the coefficient of thermal expansion of the rack, is the coefficient of thermal expansion of the holder, and is the coefficient of thermal expansion of the stand on which the Bragg grating is installed, depending on the material of the stand.

3. Results

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Chung, D.D.L. Processing-structure-property relationships of continuous carbon fiber polymer-matrix composites. Mater. Sci. Eng. R Rep. 2017, 113, 1–29. [Google Scholar] [CrossRef]

- Akman, F.; Ogul, H.; Ozkan, I.; Kaçal, M.R.; Agar, O.; Polat, H.; Dilsiz, K. Study on gamma radiation attenuation and non-ionizing shielding effectiveness of niobium-reinforced novel polymer composite. Nucl. Eng. Technol. 2022, 54, 283–292. [Google Scholar] [CrossRef]

- Ramadan, W.; Sakr, K.; Sayed, M.; Maziad, N.; El-Faramawy, N. Investigation of acrylic/boric acid composite gel for neutron attenuation. Nucl. Eng. Technol. 2020, 52, 2607–2612. [Google Scholar] [CrossRef]

- Berthelot, J.M. Composite Materials: Mechanical Behavior and Structural Analysis; Springer: New York, NY, USA, 1999. [Google Scholar]

- Gay, D.; Hoa, S.V.; Tsai, S.W. Composite Materials: Design and Applications; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Othonos, A.; Kalli, K. Fiber Bragg Gratings: Fundamentals and Applications in Telecommunications and Sensing; Artech House: New York, NY, USA, 1999. [Google Scholar]

- Kersey, A.; Davis, M.A.; Patrick, H.J.; Leblanc, M. Fiber grating sensors. J. Light. Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain measurements of composite laminates with embedded fibre Bragg gratings: Criticism and opportunities for research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef] [PubMed]

- Luyckx, G.; Kinet, D.; Lammens, N.; Chah, K.; Caucheteur, C.; Mégret, P.; Degrieck, J. Temperature-insensitive cure cycle monitoring of cross-ply composite laminates using the polarization dependent loss property of FBG. In Proceedings of the 15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012. [Google Scholar]

- Kinet, D.; Garray, D.; Wuilpart, M.; Dortu, F.; Dusermont, X.; Giannone, D.; Mégret, P. Behaviour of optical fibre Bragg grating sensors embedded into composite material under flexion. In Proceedings of the 14th European Conference on Composite Materials, Budapest, Hungary, 7–10 June 2010; pp. 289–292. [Google Scholar]

- Peairs, D.M.; Sterner, L.; Flanagan, K.; Kochergin, V. Fiber optic monitoring of structural composites using optical backscatter reflectometry. In Proceedings of the 41st International SAMPE Technical Conference, Wichita, KS, USA, 19–22 October 2009. [Google Scholar]

- Beukema, R.P. Embedding technologies of FBG sensors in composites: Technologies, applications and practical use. In Proceedings of the 6th European Workshop on Structural Health Monitoring, Dresden, Germany, 3 July 2012. [Google Scholar]

- Qiu, Y.; Wang, Q.-B.; Zhao, H.-T.; Chen, J.-A.; Wang, Y.-Y. Review on composite structural health monitoring based on fiber Bragg grating sensing principle. J. Shanghai Jiaotong Univ. Sci. 2013, 18, 129–139. [Google Scholar] [CrossRef]

- Lau, K.-T. Structural health monitoring for smart composites using embedded FBG sensor technology. Mater. Sci. Technol. 2014, 30, 1642–1654. [Google Scholar] [CrossRef]

- Takeda, N.; Okabe, Y. Fiber Bragg grating sensors: Recent advancements industrial applications and market exploitation. In Fiber Bragg Grating Sensors in Aeronautics and Astronautics; Bentham Science Publishers: Sharjah, United Arab Emirates, 2011; pp. 171–184. [Google Scholar]

- Tosi, D.; Olivero, M.; Perrone, G.; Vallan, A.; Arcudi, L. Simple fiber Bragg grating sensing systems for structural health monitoring. In Proceedings of the 2009 IEEE Workshop on Environmental, Energy, and Structural Monitoring Systems, Crema, Italy, 25 September 2009; pp. 80–86. [Google Scholar]

- Leal-Junior, A.G.; Marques, C. Diaphragm-embedded optical fiber sensors: A review and tutorial. IEEE Sens. J. 2021, 21, 12719–12733. [Google Scholar] [CrossRef]

- Marques, C.; Leal-Júnior, A.; Kumar, S. Multifunctional integration of optical fibers and nanomaterials for aircraft systems. Materials 2023, 16, 1433. [Google Scholar] [CrossRef] [PubMed]

- Jang, J.; Hong, S.; Kim, J.; Goo, N.; Yu, W. Accelerated testing method for predicting long-term properties of carbon fiber-reinforced shape memory polymer composites in a low earth orbit environment. Polymers 2021, 13, 1628. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, F.; Liu, Y. γ-rays radiation resistant shape memory cyanate ester resin and its composites with high transition temperature. Smart Mater. Struct. 2019, 28, 075039. [Google Scholar] [CrossRef]

- Nishida, M.; Hongo, A.; Hiraiwa, Y.; Higashide, M. Effects of gamma ray irradiation on penetration hole in and fragment size from carbon fiber reinforced composite plates in hypervelocity impacts. Compos. Part B Eng. 2019, 169, 229–238. [Google Scholar] [CrossRef]

- Pastore, R.; Delfini, A.; Albano, M.; Vricella, A.; Marchetti, M.; Santoni, F.; Piergentili, F. Outgassing effect in polymeric composites exposed to space environment thermal-vacuum conditions. Acta Astronaut. 2020, 170, 466–471. [Google Scholar] [CrossRef]

- Jang, J.H.; Hong, S.B.; Kim, J.; Goo, N.S.; Lee, H.; Yu, W. Long-term properties of carbon fiber-reinforced shape memory epoxy/polymer composites exposed to vacuum and ultraviolet radiation. Smart Mater. Struct. 2019, 28, 115013. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, L.; Wang, Z.; Wang, L. Effects of γ-ray irradiation on the fatigue strength, thermal conductivities and thermal stabilities of the glass fibres/ epoxy resins composites. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 105–112. [Google Scholar] [CrossRef]

- Sekulic, D.; Stevanovic, M.M. Effects of gamma irradiation and post-irradiation annealing on carbon/epoxy UDC properties deduced by methods of local loading. J. Nucl. Mater. 2011, 412, 190–194. [Google Scholar] [CrossRef]

- Wu, Z.X.; Li, J.W.; Huang, C.J.; Huang, R.J.; Li, L.F. Effect of gamma irradiation on the mechanical behavior, thermal properties and structure of epoxy/glassfiber composite. J. Nucl. Mater. 2013, 441, 67–72. [Google Scholar] [CrossRef]

- Liu, L.; Feng, L.; Ma, T.; Xu, Z.; Pei, X.; Liu, Y.; Shi, H.; Tang, Y.; Liu, L.; Deng, H.; et al. Mechanical properties, thermal stability and microstructure evolution of carbon fiber-reinforced epoxy composites exposed to high-dose grays. Radiat. Phys. Chem. 2022, 194, 110056. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Yang, Z.; Li, M.; Wang, S.; Zhang, Z. Effect of g irradiation on the properties of basalt fiber reinforced epoxy resin matrix composite. J. Nucl. Mater. 2015, 466, 100–107. [Google Scholar] [CrossRef]

- Hoffman, E.N.; Skidmore, T.E. Radiation effects on epoxy/carbon-fiber composite. J. Nucl. Mater. 2009, 392, 371–378. [Google Scholar] [CrossRef]

- Hassani, S.; Mousavi, M.; Gandomi, A.H. Structural health monitoring in composite structures: A comprehensive review. Sensors 2022, 22, 153. [Google Scholar] [CrossRef] [PubMed]

- Goossens, S.; Berghmans, F.; Sharif Khodaei, Z.; Lambinet, F.; Karachalios, E.; Saenz-Castillo, D.; Geernaert, T. Practicalities of BVID detection on aerospacegrade CFRP materials with optical fibre sensors. Compos. Struct. 2021, 259, 113243. [Google Scholar] [CrossRef]

- Tuloup, C.; Harizi, W.; Aboura, Z.; Meyer, Y.; Khellil, K.; Lachat, R. On the use of insitu piezoelectric sensors for the manufacturing and structural health monitoring of polymer-matrix composites: A literature review. Compos. Struct. 2019, 215, 127–149. [Google Scholar] [CrossRef]

- Wronkowicz, A.; Dragan, K.; Lis, K. Assessment of uncertainty in damage evaluation by ultrasonic testing of composite structures. Compos. Struct. 2018, 203, 71–84. [Google Scholar] [CrossRef]

- Sikdar, S.; Liu, D.; Kundu, A. Acoustic emission data based deep learning approach for classification and detection of damage-sources in a composite panel. Compos. Part B Eng. 2022, 228, 109450. [Google Scholar] [CrossRef]

- Grassia, L.; Iannone, M.; Califano, A.; D’Amore, A. Strain based method for monitoring the health state of composite structures. Compos. Part B Eng. 2019, 176, 107253. [Google Scholar] [CrossRef]

- Ahmed, O.; Wang, X.; Tran, M.; Ismadi, M. Advancements in fiber-reinforced polymer composite materials damage detection methods: Towards achieving energy-efficient SHM systems. Compos. Part B Eng. 2021, 223, 109136. [Google Scholar] [CrossRef]

- Rifaie-Graham, O.; Apebende, E.A.; Bast, L.K.; Bruns, N. Self-reporting fiberreinforced composites that mimic the ability of biological materials to sense and report damage. Adv. Mater. 2018, 30, 1705483. [Google Scholar] [CrossRef]

- Di Sante, R. Fibre optic sensors for structural health monitoring of aircraft composite structures: Recent advances and applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

- Frieden, J.; Cugnoni, J.; Botsis, J.; Gmür, T.; Coric, D. High-speed internal strain measurements in composite structures under dynamic load using embedded FBG sensors. Compos. Struct. 2010, 92, 1905–1912. [Google Scholar] [CrossRef]

- Hao, J.Z.; Ong, L.C.; Gong, Y.D.; Cai, Z.H.; Ng, J.H.; Varghese, P. A Temperature-independent Lateral Force Sensor using a Pair of FBGs. In Proceedings of the 2007 Asia-Pacific Microwave Conference, Bangkok, Thailand, 11–14 December 2007. [Google Scholar] [CrossRef]

- Pant, J.; Mitra, A.; Tiwari, U.; Mondal, S.; Singh, N.; Jain, S.; Kapur, P. Temperature Compensated Transverse Load Sensor Based on Dual FBG Sensor. In Proceedings of the 2008 International Conference on Recent Advances in Microwave Theory and Applications, Jaipur, India, 21–24 November 2008; pp. 395–397. [Google Scholar] [CrossRef]

- Dong, B.; Zhao, Q.; Zhao, L.; Jin, L.; Miao, Y.; Liao, T.; Zeng, X. Simultaneous measurement of temperature and force based on a special- strain-function-chirped FBG. Sens. Actuators A Phys. 2008, 147, 169–172. [Google Scholar] [CrossRef]

- Sorensen, L.; Botsis, J.; Gmur, T.; Cugnoni, J. Delamination detection and characterisation of bridging tractions using long FBG optical sensors. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2087–2096. [Google Scholar] [CrossRef]

- Zhou, Z.; Graver, T.W.; Hsu, L.; Ou, J.P. Techniques of Advanced FBG sensors: Fabrication, demodulation, encapsulation and their application in the structural health monitoring of bridges. Pac. Sci. Rev. 2003, 5, 116–121. [Google Scholar]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg grating sensors for monitoring of physical parametrs: A comprehensive review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- Ramakrishnan, M. Hybrid Optical Fiber Sensors for Smart Materials and Structures. Ph.D Thesis, Technological University Dublin, Dublin, Ireland, 2016. [Google Scholar]

- Shen, C.; Zhong, C. Novel temperature-insensitive fiber Bragg grating sensor for displacement measurement. Sens. Actuators A Phys. 2011, 170, 51–54. [Google Scholar] [CrossRef]

- Zhang, W.; Dong, X.; Zhao, Q.; Kai, G.; Yuan, S. FBG-Type Sensor for Simultaneous Measurement of Force (or Displacement) and Temperature Based on Bilateral Cantilever Beam. IEEE Photonics Technol. Lett. 2001, 13, 1340–1342. [Google Scholar] [CrossRef]

- Dong, B.; Zhao, Q.; Liu, L.; Huang, G.; Jin, L.; Zhou, J.; Liao, T. Tunable Chirped Fiber Bragg Grating Filter Based on Special Strain Function Modulation and Its Application in Fiber Sensor. J. Light. Technol. 2008, 26, 2286–2290. [Google Scholar] [CrossRef]

| Bracket | Steel (Unit) | PMMA (Unit) | Glass (Unit) | |

|---|---|---|---|---|

| Parameters | ||||

| 1.2 nm/mε | 0.554 mn/mε | 0.987 mn/mε | ||

| E Young’s modulus | 200 GPa | 3 GPa | 73.5 GPa | |

| s the width of the composite | 10 mm | 10 mm | 10 mm | |

| g is its thickness | 1 mm | 1 mm | 1 mm | |

| 9.45 pm/°C | 7.6745 pm/°C | 14.3445 pm/°C | ||

| 2.6 × 10−3 nm/N | 1.2 × 10−3 nm/N | 3.5 × 10−3 nm/N | ||

| 8.35 pm/°C | 5.57 pm/°C | 6.24 pm/°C | ||

| 1.2 × 10−3 km/N | 2.78 × 10−3 km/N | 3.89 × 10−3 km/N | ||

| photo-elastic constant | 210 GPa | 45 GPa | 71.4 GPa | |

| the wavelength used for the Bragg grating | 1555 nm | 1555 nm | 1555 nm | |

| coefficient of thermal expansion of the rack | 1.2 × 10−5 1/K | 5 × 10−5 1/K | 5.8 × 10−7 1/K | |

| coefficient of thermal expansion of the holder | 1.3 × 10−6 1/K | 4.6 × 10−6 1/K | 8.6 × 10−6 1/K | |

| the coefficient of thermal expansion of the stand | 0.55 × 10−6 1/K | 3.5 × 10−6 1/K | 4 × 10−6 1/K | |

| the length of the Bragg grating | 530 nm | 530 nm | 530 nm | |

| the effective refractive index of the fiber | 100 | 100 | 150 | |

| Λ period | 100 mkm | 100 mkm | 100 mkm | |

| 55 nm | 55 nm | 55 nm | ||

| 60 nm | 60 nm | 60 nm | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalizhanova, A.; Kozbakova, A.; Kunelbayev, M.; Aitkulov, Z.; Utegenova, A.; Imanbekova, U. Sensor Systems for Measuring Force and Temperature with Fiber-Optic Bragg Gratings Embedded in Composite Materials. J. Compos. Sci. 2024, 8, 321. https://doi.org/10.3390/jcs8080321

Kalizhanova A, Kozbakova A, Kunelbayev M, Aitkulov Z, Utegenova A, Imanbekova U. Sensor Systems for Measuring Force and Temperature with Fiber-Optic Bragg Gratings Embedded in Composite Materials. Journal of Composites Science. 2024; 8(8):321. https://doi.org/10.3390/jcs8080321

Chicago/Turabian StyleKalizhanova, Aliya, Ainur Kozbakova, Murat Kunelbayev, Zhalau Aitkulov, Anar Utegenova, and Ulzhan Imanbekova. 2024. "Sensor Systems for Measuring Force and Temperature with Fiber-Optic Bragg Gratings Embedded in Composite Materials" Journal of Composites Science 8, no. 8: 321. https://doi.org/10.3390/jcs8080321

APA StyleKalizhanova, A., Kozbakova, A., Kunelbayev, M., Aitkulov, Z., Utegenova, A., & Imanbekova, U. (2024). Sensor Systems for Measuring Force and Temperature with Fiber-Optic Bragg Gratings Embedded in Composite Materials. Journal of Composites Science, 8(8), 321. https://doi.org/10.3390/jcs8080321