Analysis of Models to Predict Mechanical Properties of High-Performance and Ultra-High-Performance Concrete Using Machine Learning

Abstract

1. Introduction

2. Materials and Methods

2.1. Prediction of Mechanical Properties

2.2. Regression Types

2.3. Accuracy Finding

3. Results and Discussion

3.1. HPC Concrete

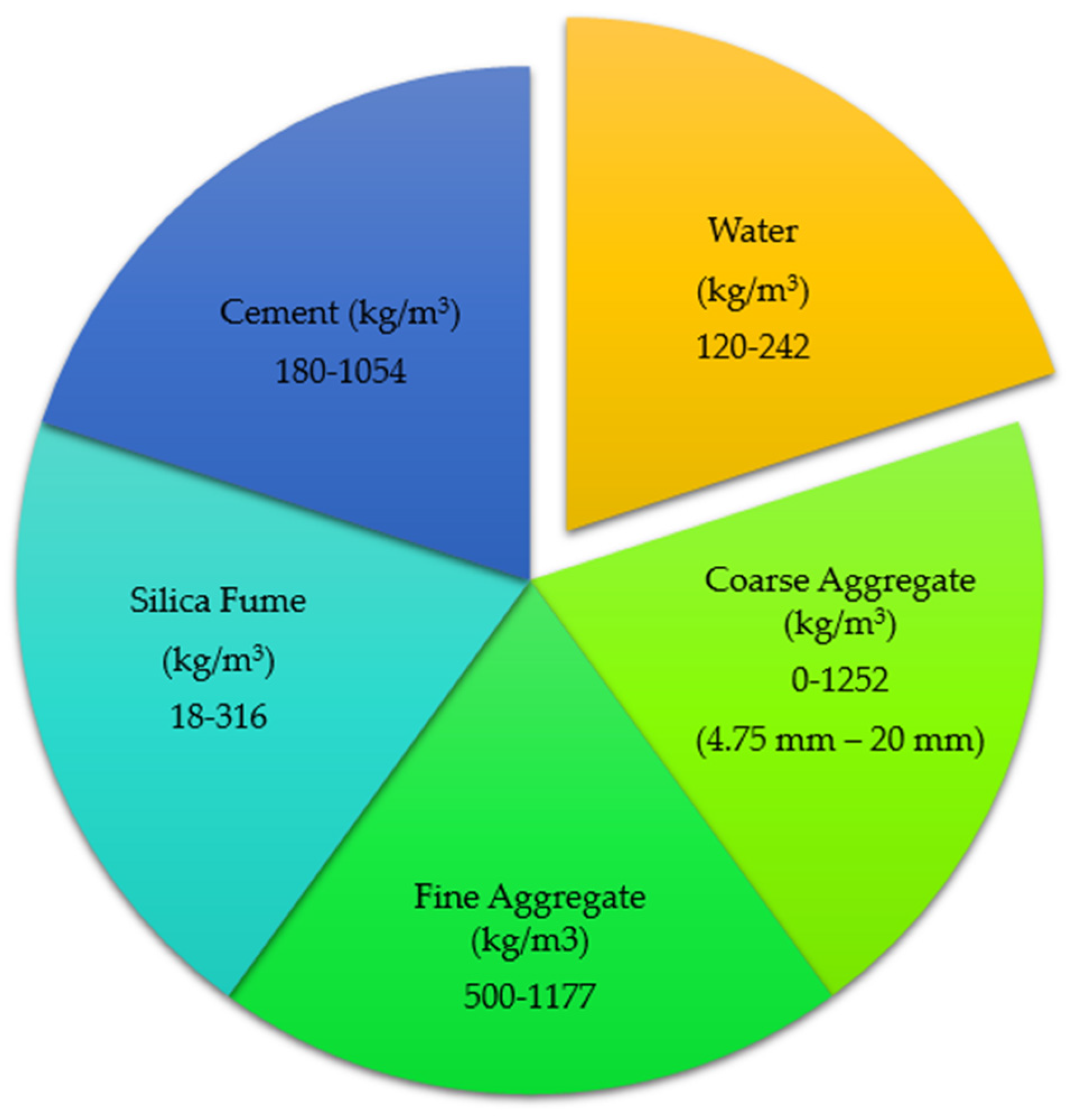

3.1.1. HPC Mixture Design

| Studies | Specimens | Cement (kg/m3) | Water (kg/m3) | Mineral Admixture (kg/m3) | Filler (kg/m3) | Superplasticizer | Fiber (%) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| Ayub et al. [9] | P-0 | 450 | 180 | - | - | - | 0 (Basalt Fiber) | 670 | 1100 |

| PB-1 | 450 | 180 | - | - | - | 1 (Basalt Fiber) | 670 | 1100 | |

| PB-2 | 450 | 180 | - | - | - | 2 (Basalt Fiber) | 670 | 1100 | |

| PB-3 | 450 | 180 | - | - | - | 3 (Basalt Fiber) | 670 | 1100 | |

| S-0 | 450 | 180 | 45 (Silica Fume) | - | - | 0 (Basalt Fiber) | 670 | 1100 | |

| SB-1 | 450 | 180 | 45 (Silica Fume) | - | - | 1 (Basalt Fiber) | 670 | 1100 | |

| SB-2 | 450 | 180 | 45 (Silica Fume) | - | - | 2 (Basalt Fiber) | 670 | 1100 | |

| SB-3 | 450 | 180 | 45 (Silica Fume) | - | - | 3 (Basalt Fiber) | 670 | 1100 | |

| MB-1 | 450 | 180 | 45 (Metakaolin) | - | - | 1 (Basalt Fiber) | 670 | 1100 | |

| MB-2 | 450 | 180 | 45 (Metakaolin) | - | - | 2 (Basalt Fiber) | 670 | 1100 | |

| MB-3 | 450 | 180 | 45 (Metakaolin) | - | - | 3 (Basalt Fiber) | 670 | 1100 | |

| Mohaghegh et al. [83] | S-I-0 | 495.6 | 184.4 | 63.2 (Silica Fume) | 161.1 | 12 | 0 (Basalt Fiber) | 1066.6 | 419.3 |

| S-II-0 | 495.6 | 184.4 | 63.2 (Silica Fume) | 161.1 | 12 | 0 (Basalt Fiber) | 1066.6 | 419.3 | |

| S-III-0.5 | 495.6 | 184.4 | 63.2 (Silica Fume) | 159.7 | 12 | 0.5 (Basalt Fiber) | 1057.7 | 415.8 | |

| S-IV-1 | 495.6 | 184.4 | 63.2 (Silica Fume) | 158.4 | 12 | 1 (Basalt Fiber) | 1048.9 | 412.3 | |

| S-V-1.33 | 501.0 | 184.2 | 63.9 (Silica Fume) | 175.5 | 14 | 1.33 (Basalt Fiber) | 1043 | 410 | |

| S-VI-1.67 | 501.0 | 184.2 | 63.9 (Silica Fume) | 156.6 | 14 | 1.67 (Basalt Fiber) | 1037 | 407.7 | |

| S-VII-2 | 501.0 | 184.2 | 63.9 (Silica Fume) | 155.7 | 14 | 2 (Basalt Fiber) | 1031.1 | 405.4 | |

| Nguyen et al. [94] | A | 954.1 | 215.9 | 73.8 (Silica Fume) | - | - | 0 | 1078.2 | - |

| B | 954.1 | 215.9 | 73.8 (Silica Fume) | - | - | 2 (Steel Fiber) | 1058.1 | - | |

| C | 954.1 | 215.9 | 73.8 (Silica Fume) | - | - | 4 (Steel Fiber) | 1038.1 | - | |

| Kharun et al. [32] | HPC0 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 0 | 585 | 1005 |

| HPC06 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 0.6 (Chopped Basalt Fiber) | 585 | 1005 | |

| HPC09 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 0.9 (Chopped Basalt Fiber) | 585 | 1005 | |

| HPC12 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 1.2 (Chopped Basalt Fiber) | 585 | 1005 | |

| HPC15 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 1.5 (Chopped Basalt Fiber) | 585 | 1005 | |

| HPC18 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 1.8 (Chopped Basalt Fiber) | 585 | 1005 | |

| Alaraza et al. [84] | HPC0 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 0 | 585 | 1005 |

| HPC06 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 0.6 (Minibar Basalt Fiber) | 585 | 1005 | |

| HPC09 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 0.9 (Minibar Basalt Fiber) | 585 | 1005 | |

| HPC12 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 1.2 (Minibar Basalt Fiber) | 585 | 1005 | |

| HPC15 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 1.5 (Minibar Basalt Fiber) | 585 | 1005 | |

| HPC18 | 500 | 125 | 125 (Micro Silica) | 100 | 12.5 | 1.8 (Minibar Basalt Fiber) | 585 | 1005 |

3.1.2. HPC Mechanical Properties

3.2. UHPC Concrete

3.2.1. UHPC Mixture Design

| Studies | Sample | Cement (kg/m3) | Water (kg/m3) | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Metacaoline (kg/m3) | Dolomite (kg/m3) | Super-Plasticizer (%) | Silica Fume (kg/m3) | Quartz Fluor (kg/m3) | Fly Ash (kg/m3) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Saji and Unnikrishnan [81] | MC | 0.26 | 523 | 141 | 1252 | 604 | - | - | 2.61 | - | - | - |

| MK10 | 0.3 | 470.7 | 141 | 1252 | 604 | 52 | - | 2.61 | - | - | - | |

| MK20 | 0.3 | 418 | 141 | 1252 | 604 | 104 | - | 2.61 | - | - | - | |

| MK30 | 0.38 | 366 | 141 | 1252 | 604 | 156 | - | 2.61 | - | - | - | |

| MK10D5 | 0.315 | 447 | 141 | 1252 | 604 | 52 | 23 | 2.61 | - | - | - | |

| MK10D7.5 | 0.32 | 435 | 141 | 1252 | 604 | 52 | 35 | 2.61 | - | - | - | |

| MK10D10 | 423 | 141 | 1252 | 604 | 52 | 47 | 2.61 | - | - | - | ||

| MK10D12.5 | 414 | 141 | 1252 | 604 | 52 | 56 | 2.61 | - | - | - | ||

| Patel et al. [106] | C0 | 0.99 | 450 | 141 | 1134 | 731 | - | - | 2.61 | - | - | - |

| C1 | 450 | 141 | 1134 | 731 | 18.5 | - | 2.61 | - | - | - | ||

| C2 | 450 | 141 | 1134 | 731 | 23 | - | 2.61 | - | - | - | ||

| C3 | 450 | 141 | 1134 | 731 | 35 | - | 2.61 | - | - | - | ||

| C4 | 450 | 141 | 1134 | 731 | - | - | 2.61 | 18.5 | - | - | ||

| C5 | 450 | 141 | 1134 | 731 | - | - | 2.61 | 23 | - | - | ||

| C7 | 450 | 141 | 1134 | 731 | - | - | 2.61 | 28 | - | - | ||

| Ghazy et al. [109] | UHPC | 0.17 | 950 | 170 | - | 750 | - | - | 3 | 200 | 450 | - |

| UHPC 1-C | 950 | 170 | - | 725 | - | - | 3 | 200 | 400 | - | ||

| UHPC 1-HE | 950 | 170 | - | 725 | - | - | 3 | 200 | 400 | - | ||

| UHPC 2-C | 950 | 170 | - | 700 | - | - | 3 | 200 | 350 | - | ||

| UHPC 2-HE | 950 | 170 | - | 700 | - | - | 3 | 200 | 350 | - | ||

| UHPC 3-C | 950 | 170 | - | 650 | - | - | 3 | 200 | 750 | - | ||

| UHPC 3-HE | 950 | 170 | - | 650 | - | - | 3 | 200 | 300 | - | ||

| Tahwia et al. [107] | Co | 0.27 | 450 | 125 | 1110 | 740 | - | - | 12.5 | 50 | - | - |

| CO-SF | 450 | 125 | 1110 | 740 | 0.75 | - | 12.5 | 50 | - | - | ||

| CO-MF | 450 | 125 | 1110 | 740 | - | - | 12.5 | 50 | - | - | ||

| M1 | 450 | 125 | 1110 | 740 | 0.75 | - | 12.5 | 50 | - | - | ||

| M2 | 450 | 125 | 1110 | 740 | 1 | - | 12.5 | 50 | - | - | ||

| M3 | 450 | 125 | 1110 | 740 | 0.75 | - | 12.5 | 50 | - | - | ||

| M4 | 450 | 125 | 1110 | 740 | 0.53 | - | 12.5 | 50 | - | - | ||

| M5 | 450 | 125 | 1110 | 740 | 0.92 | - | 12.5 | 50 | - | - | ||

| M6 | 450 | 125 | 1110 | 740 | 0.75 | - | 12.5 | 50 | - | - | ||

| M7 | 450 | 125 | 1110 | 740 | 0.57 | - | 12.5 | 50 | - | - | ||

| M8 | 450 | 125 | 1110 | 740 | 0.97 | - | 12.5 | 50 | - | - | ||

| M9 | 450 | 125 | 1110 | 740 | 0.75 | - | 12.5 | 50 | - | - | ||

| M10 | 450 | 125 | 1110 | 740 | 0.75 | - | 12.5 | 50 | - | - | ||

| M11 | 450 | 125 | 1110 | 740 | 0.75 | - | 12.5 | 50 | - | - | ||

| M12 | 450 | 125 | 1110 | 740 | 0.5 | - | 12.5 | 50 | - | - | ||

| M13 | 450 | 125 | 1110 | 740 | 0.75 | - | 12.5 | 50 | - | - | ||

| Han and Zhou [110] | A | 470 | 165 | 1000 | 500 | - | - | 4.8 | - | - | - | |

| B | 0.402 | 410 | 165 | 1000 | 500 | - | - | 4.8 | - | - | 25 | |

| C | 0.54 | 350 | 165 | 1000 | 500 | - | - | 4.8 | - | - | 50 | |

| D | 260 | 165 | 1000 | 500 | - | - | 4.8 | - | - | 90 | ||

| E | 180 | 165 | 1000 | 500 | - | - | 4.8 | - | - | 120 | ||

| Zhou et al. [108] | PC-80 | 0.212 | 856 | 182 | - | 1177 | - | - | 4 | 214 | - | - |

| PC-55 | 0.31 | 577 | 178 | - | 1154 | - | - | 4 | 210 | - | - | |

| PC-35 | 364 | 177 | - | 1145 | - | - | 4 | 208 | - | - | ||

| PC-35-NS | 359 | 177 | - | 1145 | - | - | 4 | 205 | - | - | ||

| PC-35-NA | 359 | 177 | - | 1145 | - | - | 4 | 205 | - | - | ||

| PC-35-AA | 369 | 177 | 155 | 1145 | - | - | 4 | 207 | - | 311 | ||

| Liu et al. [111] | A 0.24 | 0.23 | 1054.6 | 242.6 | 210.9 | 1054.5 | - | - | 3 | 316.4 | - | - |

| Fan et al. [112] | ST-0 | 700 | 180 | - | 1104 | - | - | 2 | 125 | - | 175 | |

| ST-0.5 | 700 | 190 | - | 1104 | - | - | 2 | 125 | - | 175 | ||

| ST-2 | 700 | 200 | - | 1104 | - | - | 2 | 125 | - | 175 |

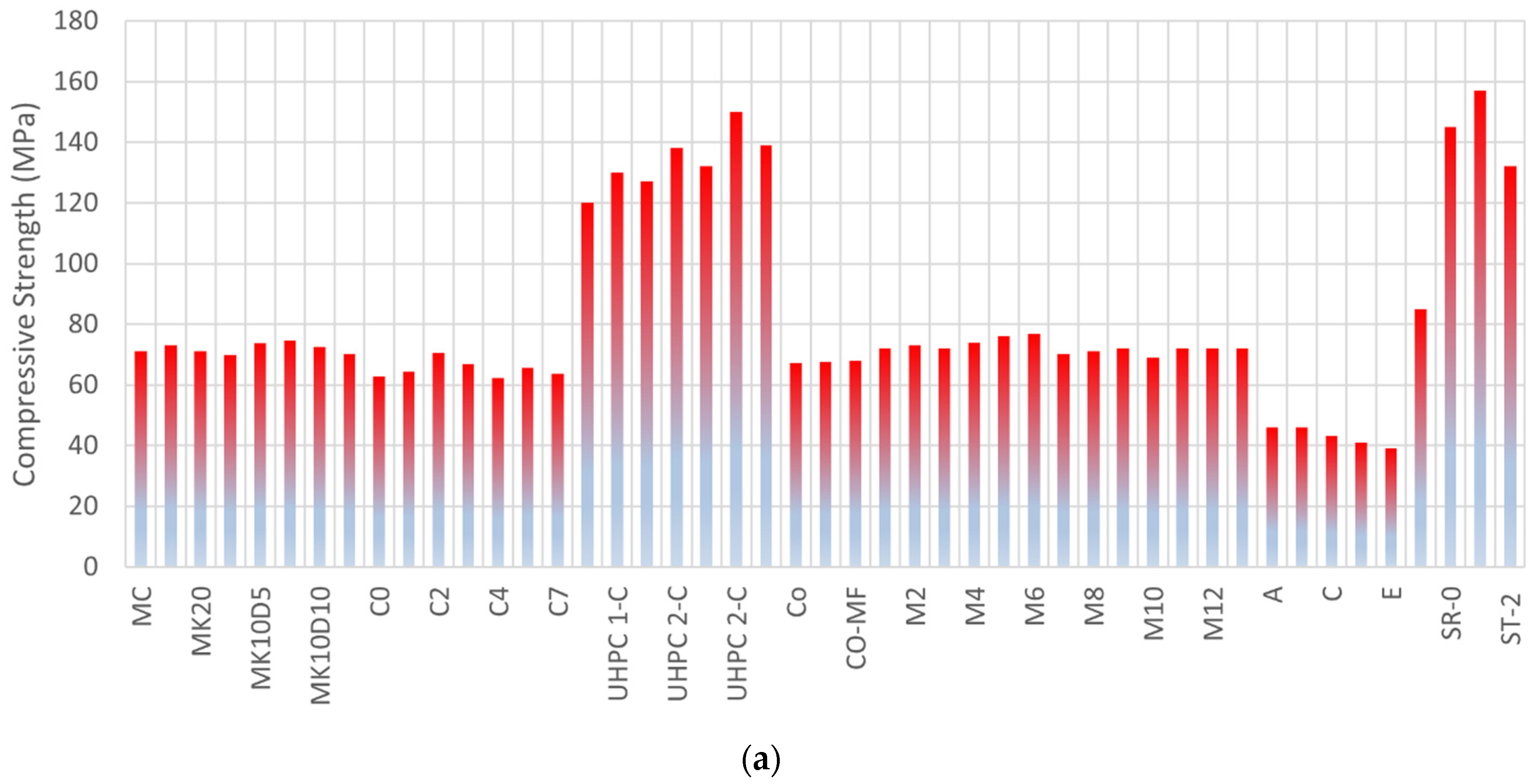

3.2.2. UHPC Mechanical Properties

3.3. Differences between HPC and UHPC

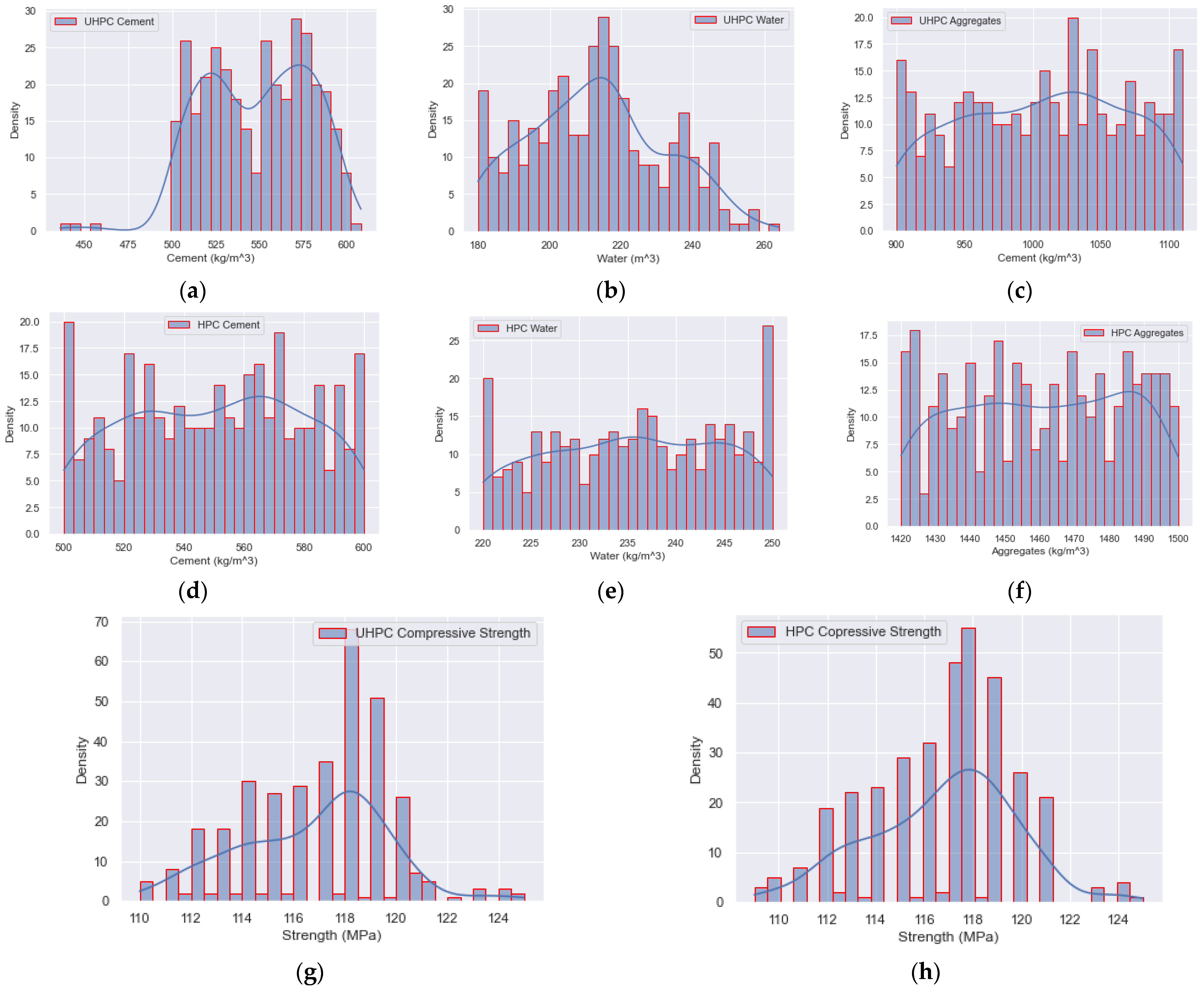

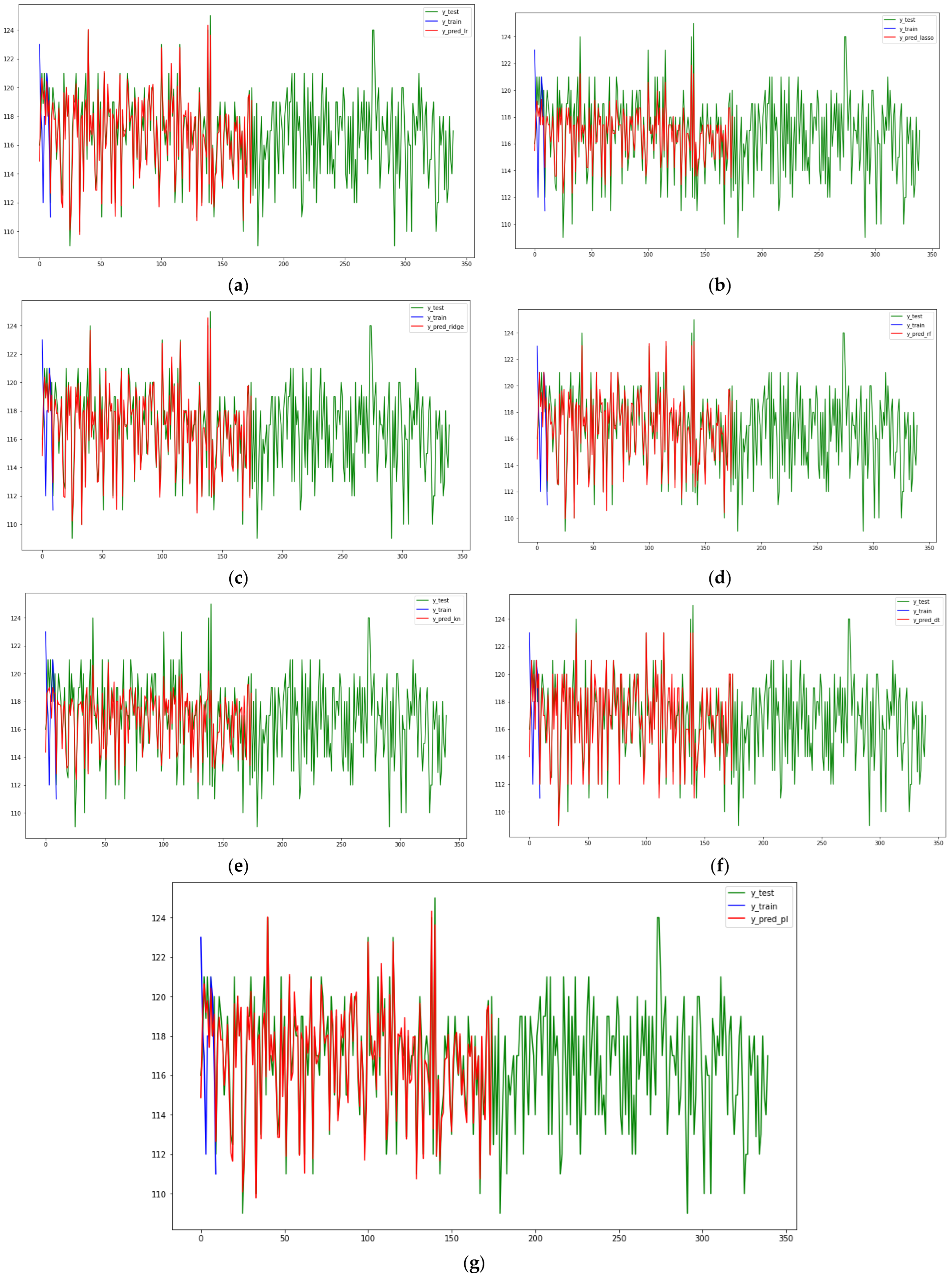

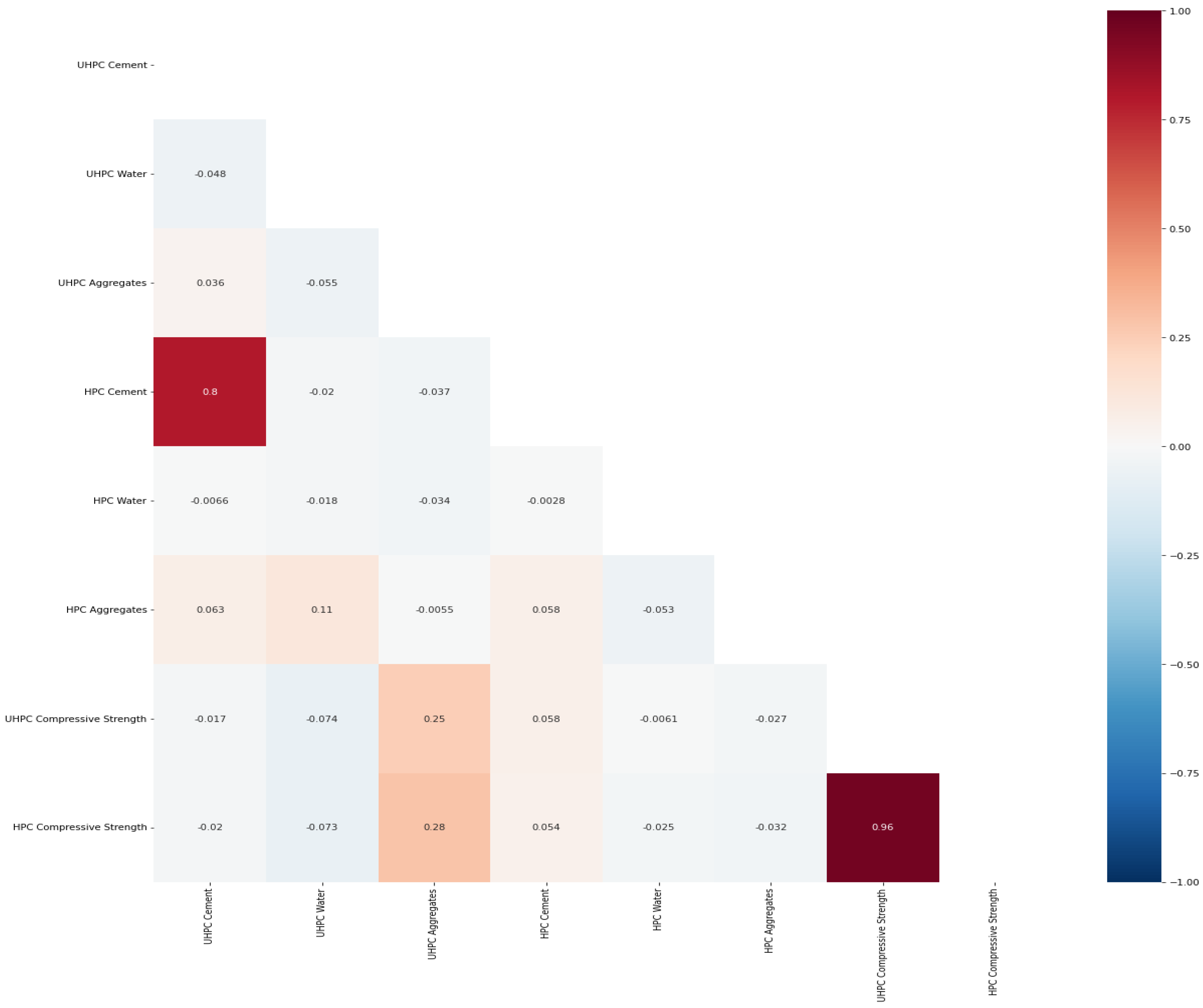

3.4. Machine Learning Results

- HPC Cement element lacks correlation with all characters except UHPC. This positive correlation was due to the near closeness of cement values of both mixture types.

- UHPC and HPC water did not correlate with characters. It noted that the UHPC and HPC water had no positive or negative effect on other elements.

- UHPC aggregates had a little positive effect on UHPC compressive strength. UHPC and HPC compressive strengths had a strong positive effect together.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghafari, E.; Costa, H.; Júlio, E. Statistical Mixture Design Approach for Eco-Efficient UHPC. Cem. Concr. Compos. 2015, 22, 17–25. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H.; Xie, L. Effect of SCM and Nano-Particles on Static and Dynamic Mechanical Properties of UHPC. Constr. Build. Mater. 2018, 182, 118–125. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Hussein, H.H.; Liu, J.; Chen, G. Experimental Study and Theoretical Prediction on Shrinkage-Induced Restrained Stresses in UHPC-RC Composites under Normal Curing and Steam Curing. Cem. Concr. Compos. 2020, 110, 103602. [Google Scholar] [CrossRef]

- Teng, L.; Huang, H.; Khayat, K.H.; Gao, X. Simplified Analytical Model to Assess Key Factors Influenced by Fiber Alignment and Their Effect on Tensile Performance of UHPC. Cem. Concr. Compos. 2022, 127, 104395. [Google Scholar] [CrossRef]

- Hematibahar, M.; Hasanzadeh, A.; Ivanovich Vatin, N.; Kharun, M.; Shooshpasha, I. Influence of 3D-Printed Reinforcement on the Mechanical and Fracture Characteristics of Ultra High Performance Concrete. Results Eng. 2023, 19, 101365. [Google Scholar] [CrossRef]

- Hematibahar, M.; Vatin, N.I.; Hamid, T.J.; Gebre, T.H. Effect of Using 3D-Printed Shell Structure for Reinforcement of Ultra-High-Performance Concrete. Struct. Mech. Eng. Constr. Build. 2023, 19, 534–547. [Google Scholar] [CrossRef]

- Russell, H.G.; Graybeal, B.A.; Russell, B.A. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community; Federal Highway Administration Office of Infrastructure Research and Development: McLean, VA, USA, 2013.

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Effect of Chopped Basalt Fibers on the Mechanical Properties and Microstructure of High Performance Fiber Reinforced Concrete. Adv. Mater. Sci. Eng. 2014, 14, 587686. [Google Scholar] [CrossRef]

- Meng, W.; Valipour, M.; Khayat, K.H. Optimization and Performance of Cost-Effective Ultra-High Performance Concrete. Mater. Struct. 2017, 50, 29. [Google Scholar] [CrossRef]

- Kusumawardaningsih, Y.; Fehling, E.; Ismail, M.; Aboubakr, A.A.M. Tensile Strength Behavior of UHPC and UHPFRC. Procedia Eng. 2015, 125, 1081–1086. [Google Scholar] [CrossRef]

- de Larrard, F.; Sedran, F. Optimization of Ultra-High-Performance Concrete by the Use of a Packing Model. Cem. Concr. Res. 1194, 24, 997–1009. [Google Scholar] [CrossRef]

- Graybeal, B. Ultra-High Performance Concrete (FHWA-HRT-11-038); Federal Highway Administration: Washington, DC, USA, 2011.

- Wetzel, A.; Middendorf, B. Influence of Silica Fume on Properties of Fresh and Hardened Ultra-High Performance Concrete Based on Alkali-Activated Slag. Cem. Concr. Compos. 2019, 100, 53–59. [Google Scholar] [CrossRef]

- Abdelmelek, E.; Lubloy, E. Evaluation of the Mechanical Properties of High Strength Cement Paste at Elevated Temperatures Using Metakaolin. J. Therm. Anal. Calorim. 2021, 145, 2891–2905. [Google Scholar] [CrossRef]

- Swaminathen, A.N.; Vivek Kumar, C.; Robert Ravi, S.; Debnath, S. Evaluation of Strength and Durability Assessment for the Impact of Rice Husk Ash and Metakaolin at High Performance Concrete Mixes. Mater. Today Proc. 2021, 47, 4584–4591. [Google Scholar] [CrossRef]

- Hongjian, D.; Sze Dai, P. High Performance Concrete Incorporating Calcined Kaolin Clay and Lime Stone as Cement Substitute. Constr. Build. Mater. 2020, 264, 120152. [Google Scholar]

- Adanagouda, H.M.; Somasekharaiah, M.S.; Shobha, H.; Mallikarjuna, M. Combined Effect of Metakaolin and Hybrid Fibres on the Strength Properties of High-Performance Concrete. Mater. Today Proc. 2021, 49, 1527–1536. [Google Scholar] [CrossRef]

- Chiadighikaobi, P.C.; Hasanzadeh, A.; Hematibahar, M.; Kharun, M.; Mousavi, M.S.; Stashevskaya, N.A.; Adedapo Adegoke, M. Evaluation of the Mechanical Behavior of High-Performance Concrete (HPC) Reinforced with 3D-Printed Trusses. Results Eng. 2024, 22, 102058. [Google Scholar] [CrossRef]

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-Obeidah, A.; Nassif, H.; Wang, H. New Development of Ultra-High Performance Concrete (UHPC). Compos. Part B Eng. 2021, 224, 109220. [Google Scholar] [CrossRef]

- Mahjoubi, S.; Barhemat, R.; Meng, W.; Bao, Y. AI-Guided Auto-Discovery of Low-Carbon Cost-Effective Ultra-High Performance Concrete (UHPC). Resour. Conserv. Recycl. 2023, 189, 106741. [Google Scholar] [CrossRef]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and Numerical Study on Mechanical Properties of Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 156, 402–411. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D. Microstructure of Ultra-High-Performance Concrete (UHPC)—A Review Study. J. Build. Eng. 2022, 50, 104118. [Google Scholar] [CrossRef]

- Ju, Z.; Zhu, M.; Zhang, X.; Wang, D. Influence of Steel Fiber and Polyvinyl Alcohol Fiber on Properties of High Performance Concrete. Struct. Concr. 2022, 23, 1687–1703. [Google Scholar] [CrossRef]

- Mishra, O.; Singh, S.P. An Overview of Microstructural and Material Properties of Ultra-High-Performance Concrete. J. Sustain. Cem. Based Mater. 2019, 8, 97–143. [Google Scholar] [CrossRef]

- Lu, K.; Xu, Q.; Du, L.; Wang, J.; Yao, Y. Fatigue Performance of Prefabricated Coarse Aggregate Ultrahigh-Performance Concrete Deck Subjected to Negative Bending Moment. Eng. Struct. 2023, 274, 115098. [Google Scholar] [CrossRef]

- Christ, R.; Pacheco, F.; Ehrenbring, H.; Quinino, U.; Mancio, M.; Muñoz, Y.; Tutikian, B. Study of Mechanical Behavior of Ultra-High Performance Concrete (UHPC) Reinforced with Hybrid Fibers and with Reduced Cement Consumption. Rev. Ing. Construcción 2019, 34, 159–168. [Google Scholar] [CrossRef]

- Abubakar, A.U. Statistical Evaluation of Compressive Strength in High Performance Concrete (HPC) with Steel Fiber Addition. Sustain. Struct. Mater. 2019, 2, 14–31. [Google Scholar]

- Noumowe, A. Mechanical Properties and Microstructure of High Strength Concrete Containing Polypropylene Fbres Exposed to Temperatures up to 200 °C. Cem. Concr. Res. 2005, 11, 2192–2198. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Faraj, R.H.; Hilal, N.; Mohammed, A.A.; Sherwani, A.F.H. Use of Recycled Fbers n Concrete Composites: A Systematic Comprehensive Review. Compos. B Eng. 2021, 215, 108769. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Helal, K.A.; Youssf, O. Chopped Basalt Fber Reinforced High-Performance Concrete: An Experimental and Analytical Study. J. Compos. Sci. 2023, 7, 250. [Google Scholar] [CrossRef]

- Kharun, M.; Alaraza, H.A.; Hematibahar, M.; Al Daini, R.; Manoshin, A.A. Experimental Study on the Effect of Chopped Basalt Fiber on the Mechanical Properties of High-Performance Concrete. AIP Conf. Proc. 2022, 2559, 050017. [Google Scholar] [CrossRef]

- Vatin, N.I.; Hematibahar, M.; Gebre, T. Impact of Basalt Fiber Reinforced Concrete in Protected Buildings: A Review. Front. Built Environ. 2024, 10, 1407327. [Google Scholar] [CrossRef]

- Guan, S. Infuence of Polypropylene Fber on Concrete Performance. Jianzhu Jiegou Xuebao/J. Build. Struct 2006, 27, 44–49. [Google Scholar]

- Wang, R.; Gao, X.; Zhang, J.; Han, J. Spatial Distribution of Steel Fibers and Air Bubbles in UHPC Cylinder Determined by X-ray CT Method. Constr. Build. Mater. 2018, 160, 39–47. [Google Scholar] [CrossRef]

- Someh, A.K.; Saeki, N. The Role of Galvanic Steel Fibers in Corrosion-Protection of Reinforced Concrete. Proc. Jpn. Concr. Inst. 1997, 19, 889–894. [Google Scholar]

- Marcos-Meson, V.; Michel, A.; Solgaard, A.; Fischer, G.; Edvardsen, C.; Skovhus, T.L. Corrosion Resistance of Steel Fiber Reinforced Concrete—A Literature Review. Cem. Concr. Res. 2018, 103, 1–20. [Google Scholar] [CrossRef]

- Dong, S.; Han, B.; Ou, J.; Li, Z.; Han, L.; Yu, X. Electrically Conductive Behaviors and Mechanisms of Short-Cut Super-Fine Stainless Wire Reinforced Reactive Powder Concrete. Cem. Concr. Compos. 2016, 72, 48–65. [Google Scholar] [CrossRef]

- Chiadighikaobi, P.C.; Kharun, M.; Hematibahar, M. Historical Structure Design Method through Data Analysis and Soft Programming. Cogent Eng. 2023, 10, 2220499. [Google Scholar] [CrossRef]

- Chiadighikaobi, P.C.; Hematibahar, M.; Kharun, M.; Stashevskaya, N.A.; Camara, K. Predicting Mechanical Properties of Self-Healing Concrete with Trichoderma Reesei Fungus Using Machine Learning. Cogent Eng. 2024, 11, 2307193. [Google Scholar] [CrossRef]

- Hematibahar, M.; Kharun, M. Prediction of Concrete Mixture Design and Compressive Strength through Data Analysis and Machine Learning. J. Mech. Contin. Math. Sci. 2024, 19, 1–21. [Google Scholar] [CrossRef]

- Hematibahar, M.; Ivanovich Vatin, N.; Alaraza, H.A.; Khalilavi, H.; Kharun, M. The Prediction of Compressive Strength and Compressive Stress-Strain of Basalt Fiber Reinforced High-Performance Concrete Using Classical Programming and Logistic Map Algorithm. Materials 2022, 15, 6975. [Google Scholar] [CrossRef]

- Hasanzadeh, A.; Ivanovich Vatin, N.; Hematibahar, M.; Kharun, M.; Shooshpasha, I. Prediction of the Mechanical Properties of Basalt Fiber Reinforced High-Performance Concrete Using Machine Learning Techniques. Materials 2022, 15, 7165. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Vabbersgaard Andersen, L.; Wu, M. Prediction of Concrete Abrasion Depth and Computational Design Optimization of Concrete Mixtures. Cem. Concr. Compos. 2024, 148, 105431. [Google Scholar] [CrossRef]

- Ma, Q.; Xiao, J.; Ding, T.; Duan, Z.; Song, M.; Cao, X. The Prediction of Compressive Strength for Recycled Coarse Aggregate Concrete in Cold Region. Case Stud. Constr. Mater. 2023, 19, e02546. [Google Scholar] [CrossRef]

- Parhi, S.K.; Panigrahi, S.K. Alkali–Silica Reaction Expansion Prediction in Concrete Using Hybrid Metaheuristic Optimized Machine Learning Algorithms. Asian J. Civ. Eng. 2024, 25, 1091–1113. [Google Scholar] [CrossRef]

- Harith, I.K.; Nadir, W.; Salah, M.S.; Hussien, M.L. Prediction of High-Performance Concrete Strength Using Machine Learning with Hierarchical Regression. Multiscale Multidiscip. Model. Exp. Des. 2024. [Google Scholar] [CrossRef]

- Bernardo, D.S.O.; Bernardo, L.F.A.; Imran, H.; Ribeiro, T.P. Torsional Capacity Prediction of Reinforced Concrete Beams Using Machine Learning Techniques Based on Ensemble of Trees. Appl. Sci. 2023, 13, 1385. [Google Scholar] [CrossRef]

- Mahmood, M.S.; Elahi, A.; Zaid, O.; Alashker, Y.; Șerbanoiu, A.A.; Gradinaru, C.M.; Ullah, K.; Ali, T. Enhancing Compressive Strength Prediction in Self-Compacting Concrete Using Machine Learning and Deep Learning Techniques with Incorporation of Rice Husk Ash and Marble Powder. Case Stud. Constr. Mater. 2023, 19, e02557. [Google Scholar] [CrossRef]

- De Marchi, L.; Mitchell, L. Hands-On Neural Networks: Learn How to Build and Train Your First Neural Network Model Using Python; Packt Publishing: Birmingham, UK, 2019. [Google Scholar]

- Khademi, F.; Behfarnia, K. Evaluation of Concrete Compressive Strength Using Artificial Neural Network and Multiple Linearregression Models. Int. J. Optim. Civ. Eng 2016, 6, 423–432. [Google Scholar]

- Abhishek, T. Comparative Assessment of Regression Models Based on Model Evaluation Metrics. Int. Res. J. Eng. Technol. 2021, 9, 853–860. [Google Scholar]

- Enwere, K.; Nduka, E.; Ogoke, U. Comparative Analysis of Ridge, Bridge and Lasso Regression Models in the Presence of Multicollinearity. IPS Intelligentsia Multidiscip. J. 2023, 3, 1–8. [Google Scholar] [CrossRef]

- Melkumovaa, L.; Shatskikhb, S. Comparing Ridge and LASSO Estimators for Data Analysis. Procedia Eng. 2017, 201, 746–755. [Google Scholar] [CrossRef]

- Abrori, M.A.M.; Syukur, A.; Affandy, A.; Soeleman, M.A. Improving C4. 5 Algorithm Accuracy with Adaptive Boosting Method for Predicting Students in Obtaining Education Funding. J. Dev. Res. 2022, 6, 137–140. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Roke, D.A. Assessment of Artificial Neural Network and Genetic Programming as Predictive Tools. Adv. Eng. Softw. 2015, 88, 63–72. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Chernil’nik, A.; Beskopylny, N. Concrete Strength Prediction Using Machine Learning Methods CatBoost, k-Nearest Neighbors, Support Vector Regression. Appl. Sci. 2022, 12, 10864. [Google Scholar] [CrossRef]

- Song, Y.Y.; Ying, L. Decision Tree Methods: Applications for Classification and Prediction. Shanghai Arch. Psychiatry 2015, 27, 130. [Google Scholar] [PubMed]

- Myles, A.J.; Feudale, R.N.; Liu, Y.; Woody, N.A.; Brown, S.D.; Chemom, A.J. An Introduction to Decision Tree Modeling. J. Chemom. A J. Chemom. Soc. 2004, 18, 275–285. [Google Scholar] [CrossRef]

- Wang, Q.; Cheng, T.; Lu, Y.; Liu, H.; Zhang, R.; Huang, J. Underground Mine Safety and Health: A Hybrid MEREC–CoCoSo System for the Selection of Best Sensor. Sensors 2024, 24, 1285. [Google Scholar] [CrossRef]

- Qureshi, H.J.; Alyami, M.; Nawaz, R.; Hakeem, I.Y.; Aslam, F.; Iftikhar, B.; Gamil, Y. Prediction of Compressive Strength of Two-Stage (Preplaced Aggregate) Concrete Using Gene Expression Programming and Random Forest. Case Stud. Constr. Mater. 2023, 19, e02581. [Google Scholar] [CrossRef]

- Rong, L.; Wang, Y.; Wang, Y.; Jiang, D.; Bai, J.; Wu, Z.; Li, L.; Wang, T.; Tan, H. A Fresh-Cut Papaya Freshness Prediction Model Based on Partial Least Squares Regression and Support Vector Machine Regression. Heliyon 2024, 10, e30255. [Google Scholar] [CrossRef]

- Nguyen, H.; Vu, T.; Vo, T.P. Efficient Machine Learning Models for Prediction of Concrete Strengths. Constr. Build. Mater. 2022, 266, 120950. [Google Scholar] [CrossRef]

- Yang, I.-H.; Joh, C.; Lee, J.W.; Kim, B.-S. Torsional Behavior of Ultra-High Performance Concrete Squared Beams. Eng. Struct. 2013, 56, 372–383. [Google Scholar] [CrossRef]

- Fehling, E.; Schmidt, M.; Stürwald, S. Ultra High Performance Concrete (UHPC). In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008. [Google Scholar]

- Schmidt, M.; Fehling, E.; Geisenhanslüke, C. Ultra High Performance Concrete (UHPC). In Proceedings of the International Symposium on UHPC, Kassel, Germany, 24 September 2004. Volume 3 of Schriftenreihe Baustoffe und Massivbau–Structural Materials and Engineering Series. [Google Scholar]

- Lee, N.K.; An, G.H.; Koh, K.T.; Ryu, G.S. Improved Reactivity of Fly Ash-Slag Geopolymer by the Addition of Silica Fume. Adv. Mater. Sci. Eng. 2016, 2016, 2192053. [Google Scholar] [CrossRef]

- Adak, D.; Sarkar, M.; Mandal, S. Structural Performance of Nano-Silica Modified Fly-Ash Based Geopolymer Concrete. Constr. Build. Mater. 2017, 135, 430–439. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, C. Compressive Strength and Microstructure of Fly Ash Based Geopolymer Blended with Silica Fume under Thermal Cycle. Cem. Concr. Compos. 2017, 78, 108–119. [Google Scholar] [CrossRef]

- Saini, G.; Vattipalli, U. Assessing Properties of Alkali Activated GGBS Based Self-Compacting Geopolymer Concrete Using Nano-Silica. Case Stud. Constr. Mater. 2020, 12, e00352. [Google Scholar] [CrossRef]

- Liu, D.; Shi, C.; Zhang, Z.; Li, N.; Shi, D. Mechanical and Fracture Properties of Ultra-High Performance Geopolymer Concrete. Cem. Concr. Compos. 2020, 112, 103665. [Google Scholar] [CrossRef]

- Khater, H.M. Effect of Nano-Silica on Microstructure Formation of Low-Cost Geopolymer Binder. Nanocomposites 2016, 2, 84–97. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Potential of Siliceous Fly Ash and Silica Fume as a Substitute for Binder in Cementitious Concretes. E3S Web Conf. 2018, 49, 00030. [Google Scholar] [CrossRef]

- Golewski, G.L. Green Concrete Based on Quaternary Binders with Significant Reduced of CO2 Emissions. Energies 2021, 14, 4558. [Google Scholar] [CrossRef]

- Golewski, G.L. An Extensive Investigations on Fracture Parameters of Concretes Based on Quaternary Binders (QBC) by Means of the DIC Technique. Constr. Build. Mater. 2022, 351, 128823. [Google Scholar] [CrossRef]

- Golewski, G.L. Fracture Performance of Cementitious Composites Based on Quaternary Blended Cements. Materials 2022, 15, 6023. [Google Scholar] [CrossRef] [PubMed]

- Vogt, O.; Ballschmiede, C.; Ukrainczyk, N.; Koenders, E. Evaluation of Sulfuric Acid-Induced Degradation of Potassium Silicate Activated Metakaolin Geopolymers by Semi-Quantitative Sem-Edx Analysis. Materials 2020, 13, 4522. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative Performance of Geopolymers Made with Metakaolin and Fly Ash after Exposure to Elevated Temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Praveen Kumar, V.V.; Prasad, N.; Dey, S. Influence of Metakaolin on Strength and Durability Characteristics of Ground Granulated Blast Furnace Slag Based Geopolymer Concrete. Struct. Concr. 2020, 21, 1040–1050. [Google Scholar] [CrossRef]

- Rovnaník, P. Effect of Curing Temperature on the Development of Hard Structure of Metakaolin-Based Geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Saji, S.; Unnikrishnan, S. Effect of Dolomite and Metakaolin on the Properties of High-Performance Concrete. IOP Conf. Ser. Earth Environ. Sci. 2023, 1237, 012005. [Google Scholar] [CrossRef]

- Gusain, I.; Sharma, S.; Debarma, S.; Kumar Sharma, A.; Mishra, N.; Dahale, P.P. Study of Concrete Mix by Adding Dolomite in Conventional Concrete as Partial Replacement with Cement. Mater. Today Proc. 2023, 73, 163–166. [Google Scholar] [CrossRef]

- Mohaghegh, A.L.; Silfwerbrand, J.; Årskog, V. Shear Behavior of High-Performance Basalt Fiber Concrete—Part II: Laboratory Punching Shear Tests on Small Slabs with Macrofibers without Bars. Struct. Concr. 2018, 19, 331–339. [Google Scholar] [CrossRef]

- Alaraza, H.; Kharun, M.; Chiadighikaobi, P. The Effect of Minibars Basalt Fiber Fraction on Mechanical Properties of High-Performance Concrete. Cogent Eng. 2022, 9, 213660. [Google Scholar] [CrossRef]

- Kabay, N. Abrasion Resistance and Fracture Energy of Concretes with Basalt Fiber. Constr. Build. Mater. 2014, 50, 95–101. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Smolyanichenko, A.S.; Chernil’nik, A.; Elshaeva, D.; Beskopylny, N. Influence of Polymer Fibers on the Structure and Properties of Modified Variatropic Vibrocentrifuged Concrete. Polymers 2024, 16, 642. [Google Scholar] [CrossRef] [PubMed]

- Hematibahar, M. Crack Resistance in Basalt Fibred High-Performance Concrete. Master’s Thesis, Department Civil Engineering, People Friendship University of Russia (Rudn), Moscow, Russia, 2021. [Google Scholar]

- Brik, V.; Ramakrishnan, V.; Tolmare, N. Performance Evaluation of 3-D Basalt Fibre Reinforced Concrete & Basalt Rod Reinforced Concrete. Ph.D. Thesis, South Dakota School of Mines and Technology, Rapid City, SD, USA, 1998. [Google Scholar]

- Van de Velde, K.; Kiekens, P.; Van Langenhove, L. Basalt Fibres as Reinforcement for Composites. In Proceedings of the 10th International Conference on Composites/Nano Engineering, New Orleans, LA, USA, 20–26 July 2003; Volume 20–26. [Google Scholar]

- Artemenko, S. Polymer Composite Materials Made from Carbon, Basalt, and Glass Fibres. Structure and Properties. Fibre Chem. 2003, 35, 226–229. [Google Scholar] [CrossRef]

- Sondarva, D.; Bhogayata, A.C. Usage of Chopped Basalt Fibers in Concrete Composites: A Review. Int. J. Eng. Res. Technol. (IJERT) 2017, 6, 323–327. [Google Scholar] [CrossRef]

- Guo, Y.; Hu, X.; Lv, J. Experimental Study on the Resistance of Basalt Fibre Reinforced Concrete to Chloride Penetration. Constr. Build. Mater. 2019, 223, 142–155. [Google Scholar] [CrossRef]

- Zhang, J.; Bian, F.; Zhang, Y.; Fang, Z.; Fu, C.; Guo, J. Effect of Pore Structures on Gas Permeability and Chloride Diffusivity of Concrete. Constr. Build. Mater. 2018, 163, 402–413. [Google Scholar] [CrossRef]

- Nguyen, T.N.; Nguyen, T.T.; Pansuk, W. Experimental Study of the Punching Shear Behavior of High Performance Steel Fiber Reinforced Concrete Slabs Considering Casting Directions. Eng. Struct. 2017, 131, 564–573. [Google Scholar] [CrossRef]

- Rashid, M.A.; Hossain, T. Properties of Higher Strength Concrete with Crushed Brick as Coarse Aggregate. Indian Concr. J. 2009, 37, 43–52. [Google Scholar]

- Singh, B.G. Specific Surface of Aggregates Related to Compressive and Flexural Strength of Concrete. Am. Concr. Inst. 1958, 54, 897–907. [Google Scholar]

- Rao, B.; Sen, S. Effect of Water Cement Ratio on the Workability and Strength of Low Strength Quarry Dust Concrete. Int. J. Civ. Eng. Technol. 2017, 10, 1448–1455. [Google Scholar]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of Limestone on the Hydration of Portland Cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Kumar, V.; Bhusare, P.; Ghodake, P.B. Experimental Study of Effect on Concrete Properties with Partial Replacement of Cement with Dolomite Powder. Int. J. Res. Appl. Sci. Eng. Technol. (IJRASET) 2019, 7, 536–542. [Google Scholar]

- Fraser, J.; McBride, R.A. The Utility of Aggregate Processing Fines in the Rehabilitation of Dolomite Quarries. Land Degrad. Dev. 2000, 11, 1–17. [Google Scholar] [CrossRef]

- Korjakins, A.; Gaidukovs, S.; Sahmenko, G.; Bajare, D.; Pizele, D. Investigation of Alternative Dolomite Filler Properties and Their Application in Concrete Production. Telecommun. Electron. 2008, 24, 64–71. [Google Scholar]

- Kate, G.K.; Thakare, S.B. An Experimental Study of High Strength-High Volume Fly Ash Concrete for Sustainable Construction Industry. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 12247. [Google Scholar] [CrossRef]

- Wang, L. Fly Ash Cementitious Efficiency in Fly Ash Concrete Mix Ratio. Chin. Sci. Technol. J. Database (Full Text) Eng. Technol. 2023, 67–70. [Google Scholar]

- Siswanto, A.B.; Salim, M.A.; Mindiastiwi, T. The Effect of Fly Ash on the Flexible Strength Concrete and Concrete Temperature. J. Surv. Fish. Sci. 2023, 10, 3133–3141. [Google Scholar]

- Chougule, M.B.; Chougule, V. Experimental Investigations on the Concrete Mix Design with Fly Ash. Int. J. Innov. Res. Eng. 2023, 4, 106–109. [Google Scholar]

- Patel, D.; Parmar, A.; Tank, D.S. Experimental study on triple blended high performance concrete with silica fume and metakaolin. J. Technol. 2023, 11, 92–100. [Google Scholar]

- Tahwia, A.M.; Mokhles, M.; Elemam, W.E. Optimizing Characteristics of High-performance Concrete Incorporating Hybrid Polypropylene Fbers. Innov. Infrastruct. Solut. 2023, 8, 297. [Google Scholar] [CrossRef]

- Zhou, X.; Shi, Y.; Hu, Q.; Zhang, S.; Zhang, X.; Meng, L. Discrete Element Simulation of the Relationship between Composition, ITZ Property, and Tensile Behavior of Eco-Friendly UHPC Matrix. Materials 2023, 16, 3844. [Google Scholar] [CrossRef]

- Ghazy, M.; Abdelatty, M.; Sakr, M.; Arafa, E. Mechanical properties of ultra- high-performance fiber concret. Int. Conf. Adv. Struct. Geotech. Eng. 2023, 73, 267–280. [Google Scholar]

- Han, Y.; Zhou, T. Performance Analysis of High-Performance Concrete Materials in Civil Construction. Materials 2023, 16, 5711. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Wang, B.; Zheng, Y.; Mo, S.; Zhang, Q.; Zhou, P. Experimental and Computational Research on the Shear Performance of Partially Filled Narrow-Width Steel Box-UHPC-Combined Girders under Negative Moment Action. Buildings 2023, 13, 2749. [Google Scholar] [CrossRef]

- Fan, L.; Meng, W.; Teng, L.; Khayat, K.H. Effect of Steel Fibers with Galvanized Coatings on Corrosion of Steel Bars Embedded in UHPC. Compos. Part B 2019, 177, 107445. [Google Scholar] [CrossRef]

- Azmee, N.M.; Nuruddin, M.F. Impact Performance of Low Cement Ultra-High-Performance Concrete. WIT Trans. Ecol. Environ. 2017, 223, 481–488. [Google Scholar]

- Fennis, S.A.A.M.; Walraven, J.C.; Den Uijl, J.A. The Use of Particle Packing Models to Design Ecological Concrete. Heron 2009, 54, 185–204. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix Design and Properties Assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Teng, L.; Meng, W.; Khayat, K.H. Rheology Control of Ultra-High-Performance Concrete Made with Different Fiber Contents. Cem. Concr. Res. 2020, 138, 106222. [Google Scholar] [CrossRef]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of Ultra-High Performance Concrete with Common Technology and Materials. Cem. Concr. Compos 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of Nano-Silica on the Hydration and Microstructure Development of Ultra-High Performance Concrete (UHPC) with a Low Binder Amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef]

- Mo, Z.; Wang, R.; Gao, X. Hydration and Mechanical Properties of UHPC Matrix Containing Limestone and Different Levels of Metakaolin. Constr. Build. Mater. 2020, 256, 119454. [Google Scholar] [CrossRef]

- Behfarnia, K.; Rostami, M. Effects of Micro and Nanoparticles of SiO2 on the Permeability of Alkali Activated Slag Concrete. Constr. Build. Mater. 2017, 131, 205–213. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Farhat, M.; Issa, M.A.; Hasse, J.A. Effect of Material Constituents on Mechanical and Fracture Mechanics Properties of Ultra-High-Performance Concrete. ACI Mater. J. 2017, 114, 453–465. [Google Scholar] [CrossRef]

- Li, Q.; Geng, H.; Huang, Y.; Shui, Z. Chloride Resistance of Concrete with Metakaolin Addition and Seawater Mixing: A Comparative Study. Constr. Build. Mater. 2015, 101, 184–192. [Google Scholar] [CrossRef]

- Ferdosian, I.; Camões, A.; Ribeiro, M. High-Volume Fly Ash Paste for Developing Ultra-High Performance Concrete (UHPC). Ciência Tecnol. Mater. 2017, 29, e157–e161. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Razveeva, I.; Kozhakin, A.; Pembek, A.; Kondratieva, T.N.; Elshaeva, D.; Chernil’nik, A.; Beskopylny, N. Prediction of the Properties of Vibro-Centrifuged Variatropic Concrete in Aggressive Environments Using Machine Learning Methods. Buildings 2024, 14, 1198. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; Pembek, A.; Elshaeva, D.; Chernil’nik, A.; et al. Prediction of the Compressive Strength of Vibrocentrifuged Concrete Using Machine Learning Methods. Buildings 2024, 14, 377. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; Beskopylny, N. Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods. Materials 2022, 15, 6740. [Google Scholar] [CrossRef] [PubMed]

- Elshamy, M.M.M.; Tiraturyan, A.N.; Uglova, E.V.; Elgendy, M.Z. Evaluation of Pavement Condition Deterioration Using Artificial Intelligence Models. Adv. Eng. Res. 2022, 22, 272–284. [Google Scholar] [CrossRef]

- Elhishi, S.; Elashry, A.M.; El-Metwally, S. Unboxing Machine Learning Models for Concrete Strength Prediction Using XAI. Sci. Rep. 2023, 13, 19892. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Varavka, V.; Beskopylny, N.; El’shaeva, D. A Study on the Cement Gel Formation Process during the Creation of Nanomodified High-Performance Concrete Based on Nanosilica. Gels 2022, 8, 346. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Smolyanichenko, A.S.; Beskopylny, N. High-Performance Concrete Nanomodified with Recycled Rice Straw Biochar. Appl. Sci 2022, 12, 5480. [Google Scholar] [CrossRef]

- Georgiev, S.V.; Mailyan, D.R.; Solovyova, A.I. Studying the Efficiency of Composite Longitudinal and Transverse Reinforcement for Increasing the Strength and Rigidity of Flexible Eccentrically Compressed Reinforced Concrete Poles, Modern Trends in Construction. Urban Territ. Plan. 2023, 2, 7–18. [Google Scholar] [CrossRef]

| Studies | Specimens | Compressive Strength (MPa) | Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|---|

| Ayub et al. [9] | P-0 | 88.73 | 5.16 | 5 |

| PB-1 | 84.71 | 5.16 | 6.42 | |

| PB-2 | 89.66 | 5.40 | 7.46 | |

| PB-3 | 89.36 | 6 | 5.99 | |

| S-0 | 102.37 | 6.65 | 5.66 | |

| SB-1 | 103.43 | 6.71 | 6.54 | |

| SB-2 | 101.3 | 6.72 | 7.16 | |

| SB-3 | 100.97 | 7.99 | 6.84 | |

| MB-1 | 103.43 | 5.49 | 7.09 | |

| MB-2 | 101.3 | 5.89 | 7.16 | |

| MB-3 | 100.97 | 7.18 | 6.86 | |

| Mohaghegh et al. [83] | S-I-0 | 79.5 | - | - |

| S-II-0 | 81.2 | - | - | |

| S-III-0.5 | 81.6 | - | - | |

| S-IV-1 | 78.6 | - | - | |

| S-V-1.33 | 79.8 | - | - | |

| S-VI-1.67 | 78.6 | - | - | |

| S-VII-2 | 77 | - | - | |

| Nguyen et al. [94] | A | 97.8 | 8.2 | - |

| B | 98.5 | 8.6 | - | |

| C | 99 | 12.1 | - | |

| Kharun et al. [32] | HPC0 | 101.43 | 5.53 | 14 |

| HPC06 | 92.78 | 5.3 | 15.6 | |

| HPC09 | 92.68 | 5.29 | 17.4 | |

| HPC12 | 102.3 | 5.56 | 18.9 | |

| HPC15 | 97.6 | 5.41 | 18.1 | |

| HPC18 | 95.68 | 5.37 | 18.3 | |

| Alaraza et al. [84] | HPC0 | 101.43 | - | 14.1 |

| HPC06 | 101.43 | - | 16.8 | |

| HPC09 | 105.39 | - | 19.8 | |

| HPC12 | 90.50 | - | 17.2 | |

| HPC15 | 89.51 | - | 16.4 | |

| HPC18 | 92.30 | - | 17.1 |

| Studies | Sample | Compressive Strength (MPa) | Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|---|

| Saji and Unnikrishnan [81] | MC | 71.11 | 5.94 | 7.6 |

| MK10 | 72.88 | 6.22 | 8.4 | |

| MK20 | 71.15 | 5.62 | 8 | |

| MK30 | 69.77 | 5.37 | 7.2 | |

| MK10D5 | 73.77 | 6.08 | 8.8 | |

| MK10D7.5 | 74.66 | 6.29 | 8.4 | |

| MK10D10 | 72.44 | 5.98 | 7.2 | |

| MK10D12.5 | 70.22 | 5.85 | 6.4 | |

| Patel et al. [106] | C0 | 62.73 | - | - |

| C1 | 64.3 | - | - | |

| C2 | 70.66 | - | - | |

| C3 | 66.85 | - | - | |

| C4 | 62.33 | - | - | |

| C5 | 65.5 | - | - | |

| C7 | 63.66 | - | - | |

| Ghazy et al. [109] | UHPC | 120 | 9 | 18.66 |

| UHPC 1-C | 130 | 10.5 | 22.65 | |

| UHPC 1-HE | 127 | 9.85 | 21.66 | |

| UHPC 2-C | 138 | 11.75 | 28.66 | |

| UHPC 2-HE | 132 | 11 | 26.02 | |

| UHPC 3-C | 150 | 12.55 | 30 | |

| UHPC 3-HE | 139 | 11.55 | 28 | |

| Tahwia et al. [107] | Co | 67.2 | - | 10.5 |

| CO-SF | 67.6 | - | 10.8 | |

| CO-MF | 68 | - | 11 | |

| M1 | 72 | - | 13 | |

| M2 | 73 | - | 13.6 | |

| M3 | 72 | - | 13 | |

| M4 | 74 | - | 13.9 | |

| M5 | 76 | - | 14.5 | |

| M6 | 76.8 | - | 14.9 | |

| M7 | 70 | - | 12 | |

| M8 | 71 | - | 12.4 | |

| M9 | 72 | - | 13 | |

| M10 | 69 | - | 12.2 | |

| M11 | 72 | - | 13 | |

| M12 | 72 | - | 12.5 | |

| M13 | 72 | - | 13 | |

| Han and Zhou [110] | A | 46 | - | 6.1 |

| B | 46 | - | 5.8 | |

| C | 43 | - | 5.2 | |

| D | 41 | - | 4.8 | |

| E | 39 | - | 4.6 | |

| Zhou et al. [108] | PC-80 | - | 7.3 | - |

| PC-55 | - | 4.7 | - | |

| PC-35 | - | 4.2 | - | |

| PC-35-NS | - | 4.7 | - | |

| PC-35-NA | - | 7 | - | |

| PC-35-AA | - | 6.7 | - | |

| Liu et al. [111] | A | 84.9 | 6.9 | - |

| Fan et al. [112] | ST-0 | 145 | - | - |

| ST-0.5 | 157 | - | - | |

| ST-2 | 132 | - | - |

| UHPC Cement | UHPC Water | UHPC Aggregates | HPC Cement | HPC Water | HPC Aggregates | UHPC Compressive Strength | HPC Compressive Strength | |

|---|---|---|---|---|---|---|---|---|

| Mean | 548.4 | 213.08 | 1007.1 | 550.5 | 235.4 | 1460.4 | 116.74 | 116.72 |

| Std. | 30.1 | 18.7 | 61.03 | 28.99 | 9.0 | 23.7 | 2.87 | 2.96 |

| Min | 436 | 180 | 900 | 500 | 220 | 1420 | 110 | 109 |

| 25% | 523 | 200 | 956 | 526.25 | 228 | 1420 | 115 | 115 |

| 50% | 552 | 213 | 1009 | 552 | 236 | 1461 | 117 | 117 |

| 75% | 574.75 | 225 | 1056.75 | 573 | 243 | 1482.75 | 119 | 119 |

| Max | 608 | 264 | 1110 | 600 | 250 | 1500 | 125 | 125 |

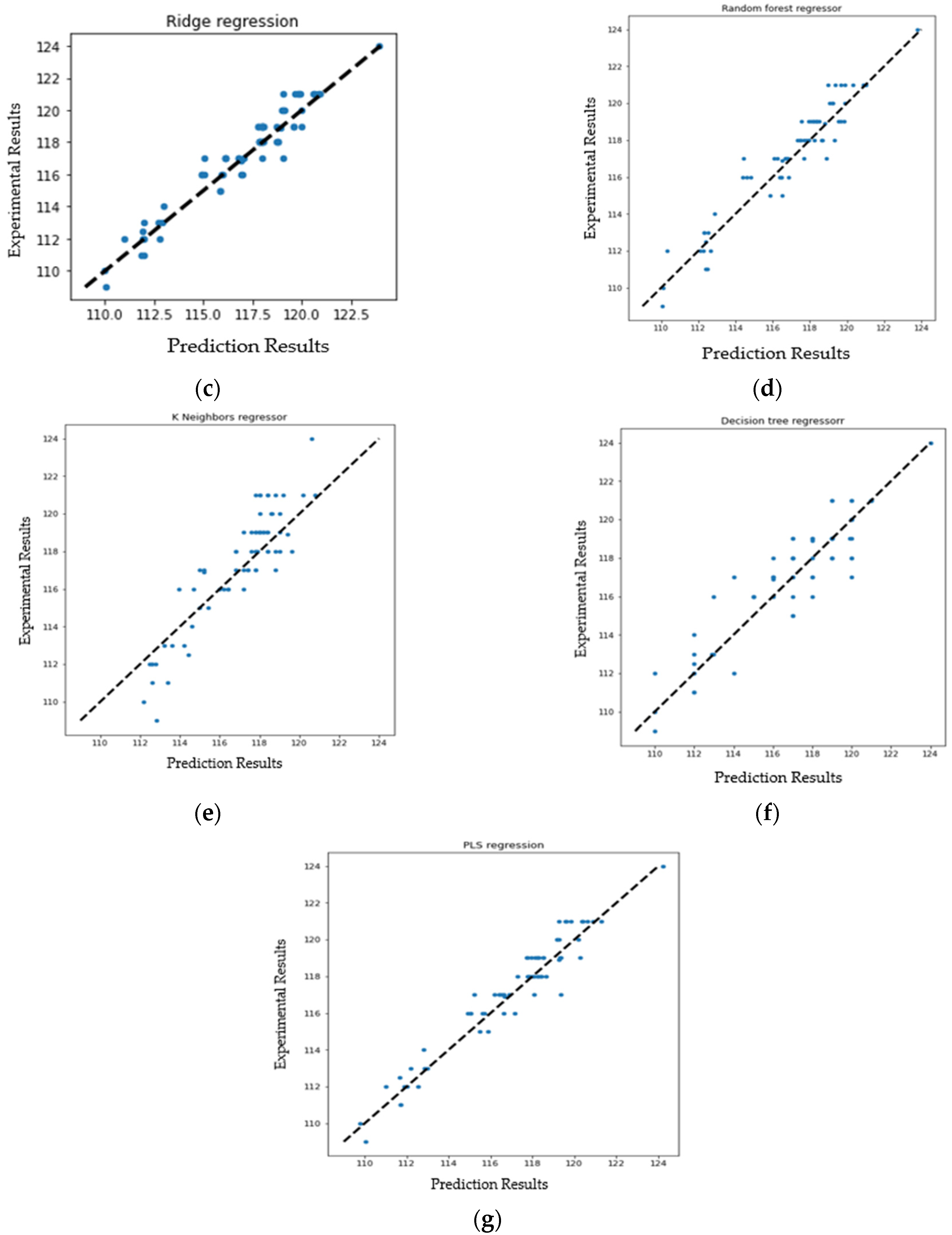

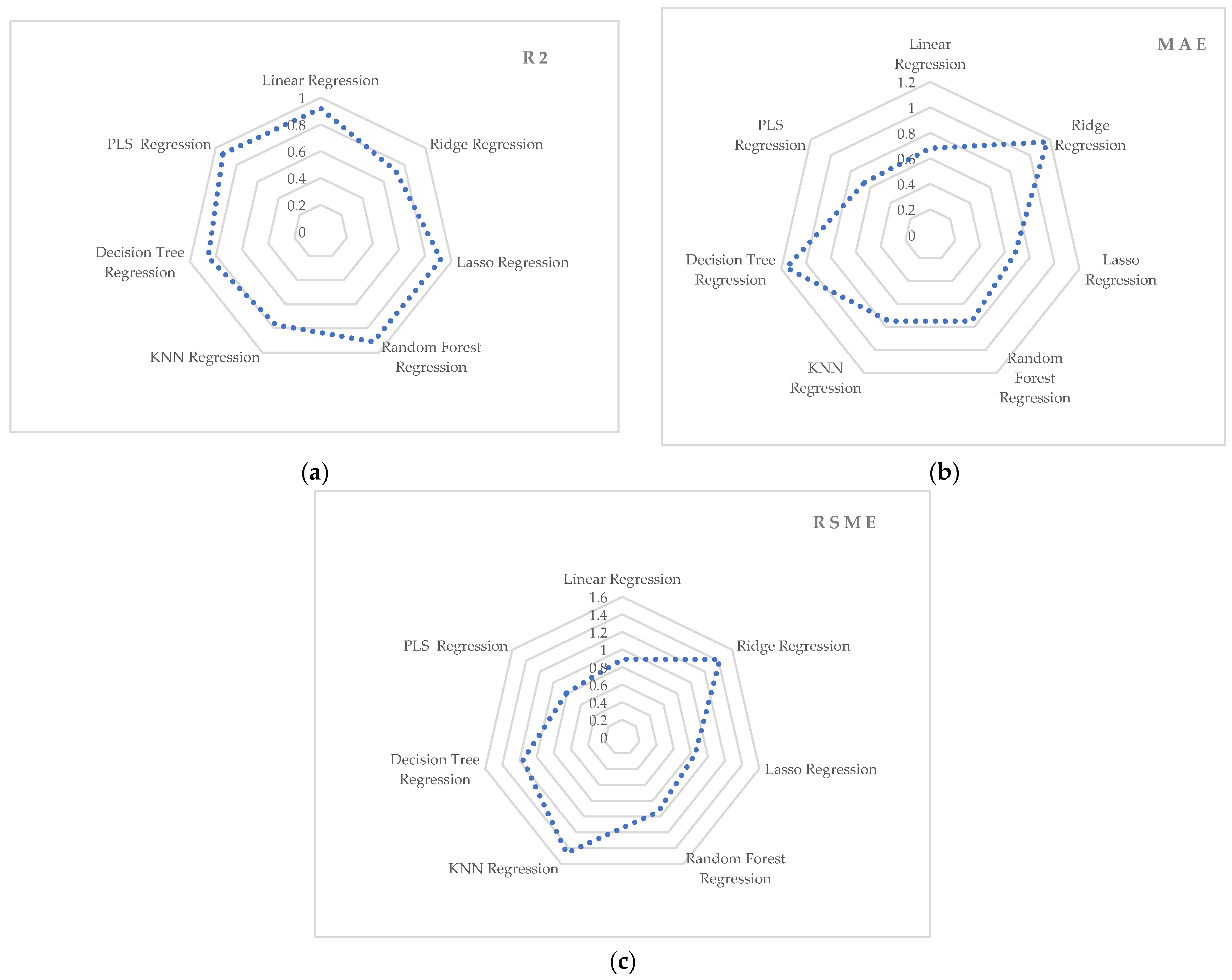

| Regression Types | RMSE | MAE | R2 |

|---|---|---|---|

| Linear Regression | 0.89 | 0.68 | 0.92 |

| Lasso Regression | 1.42 | 1.17 | 0.79 |

| Ridge Regression | 0.85 | 0.68 | 0.92 |

| Random forest Regression | 0.94 | 0.75 | 0.91 |

| K Neighbors Regression | 1.46 | 0.75 | 0.77 |

| Decision tree Regression | 1.16 | 1.16 | 0.86 |

| PLS Regression | 0.81 | 0.66 | 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hematibahar, M.; Kharun, M.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Razveeva, I. Analysis of Models to Predict Mechanical Properties of High-Performance and Ultra-High-Performance Concrete Using Machine Learning. J. Compos. Sci. 2024, 8, 287. https://doi.org/10.3390/jcs8080287

Hematibahar M, Kharun M, Beskopylny AN, Stel’makh SA, Shcherban’ EM, Razveeva I. Analysis of Models to Predict Mechanical Properties of High-Performance and Ultra-High-Performance Concrete Using Machine Learning. Journal of Composites Science. 2024; 8(8):287. https://doi.org/10.3390/jcs8080287

Chicago/Turabian StyleHematibahar, Mohammad, Makhmud Kharun, Alexey N. Beskopylny, Sergey A. Stel’makh, Evgenii M. Shcherban’, and Irina Razveeva. 2024. "Analysis of Models to Predict Mechanical Properties of High-Performance and Ultra-High-Performance Concrete Using Machine Learning" Journal of Composites Science 8, no. 8: 287. https://doi.org/10.3390/jcs8080287

APA StyleHematibahar, M., Kharun, M., Beskopylny, A. N., Stel’makh, S. A., Shcherban’, E. M., & Razveeva, I. (2024). Analysis of Models to Predict Mechanical Properties of High-Performance and Ultra-High-Performance Concrete Using Machine Learning. Journal of Composites Science, 8(8), 287. https://doi.org/10.3390/jcs8080287