Advances in Embedded Sensor Technologies for Impact Monitoring in Composite Structures

Abstract

1. Introduction

2. Impact Events on Composites

3. Embedded Sensor Technologies and Applications

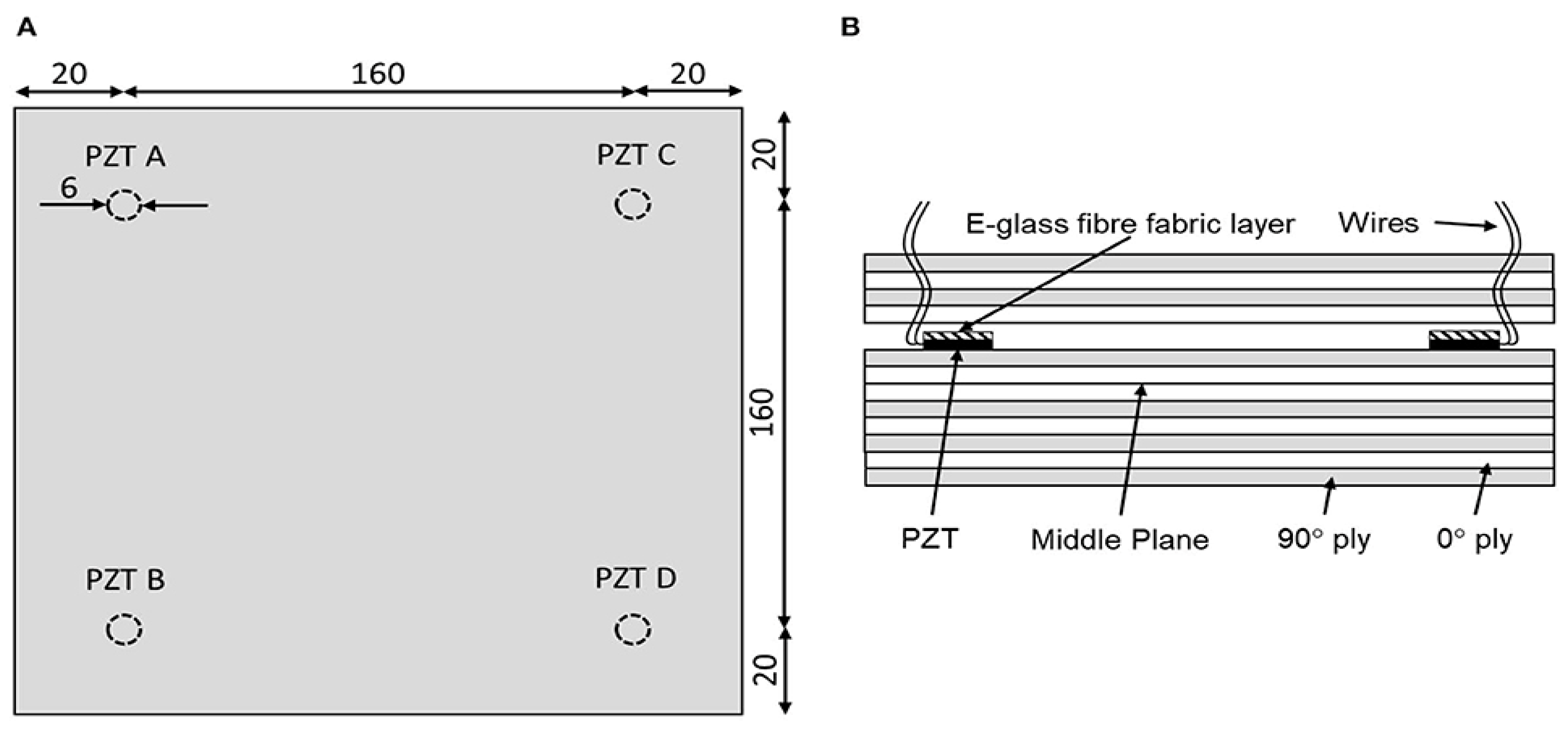

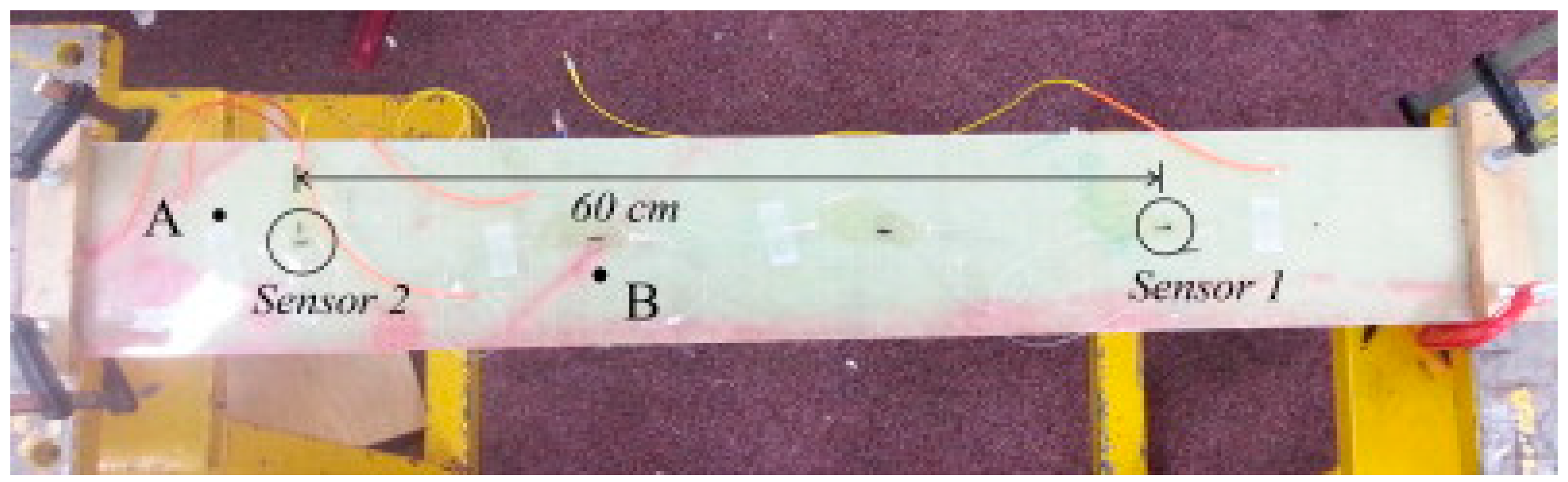

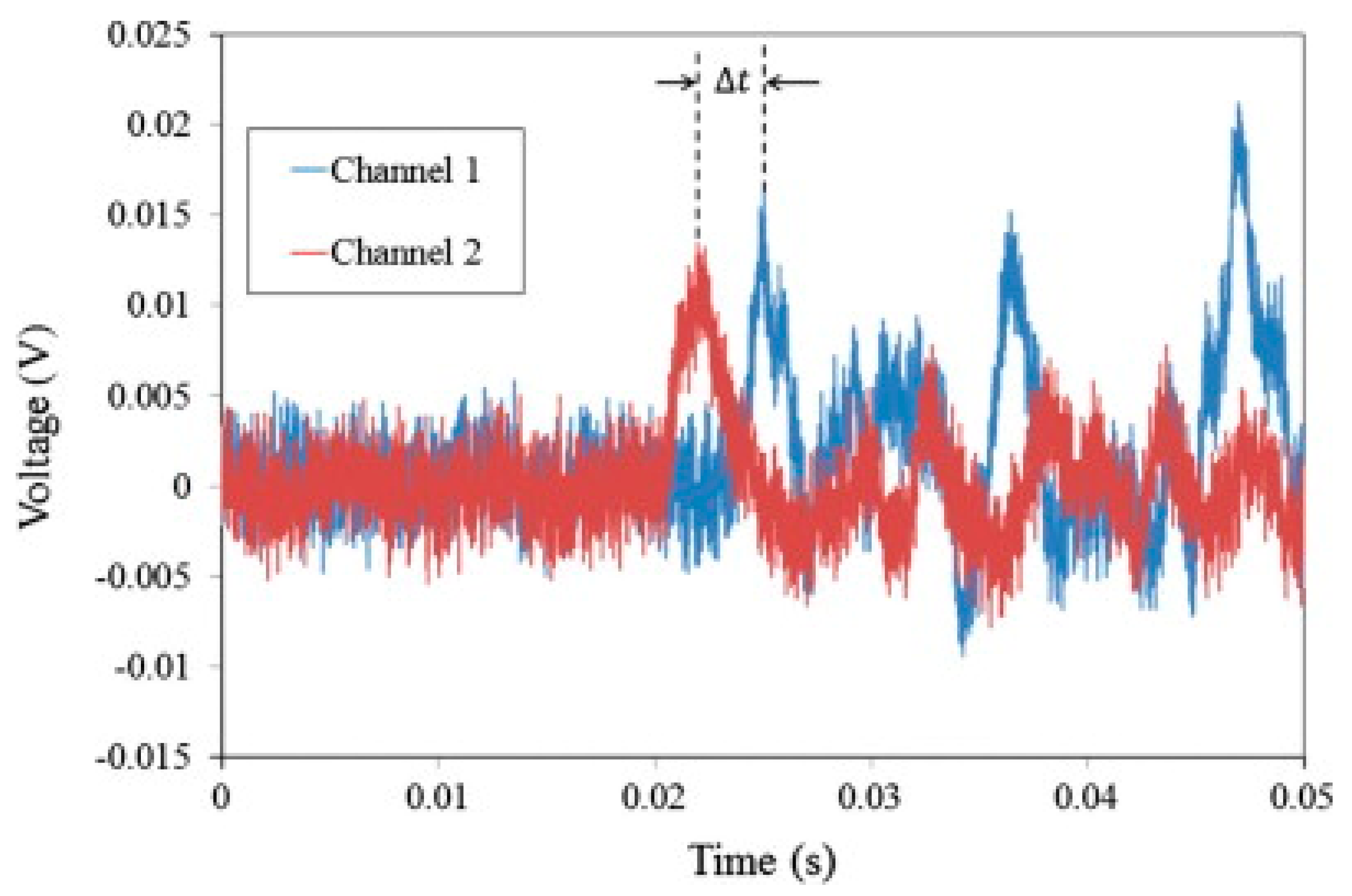

3.1. Piezoelectric Sensors

3.2. FBG Sensors

3.3. Other Sensing Technologies

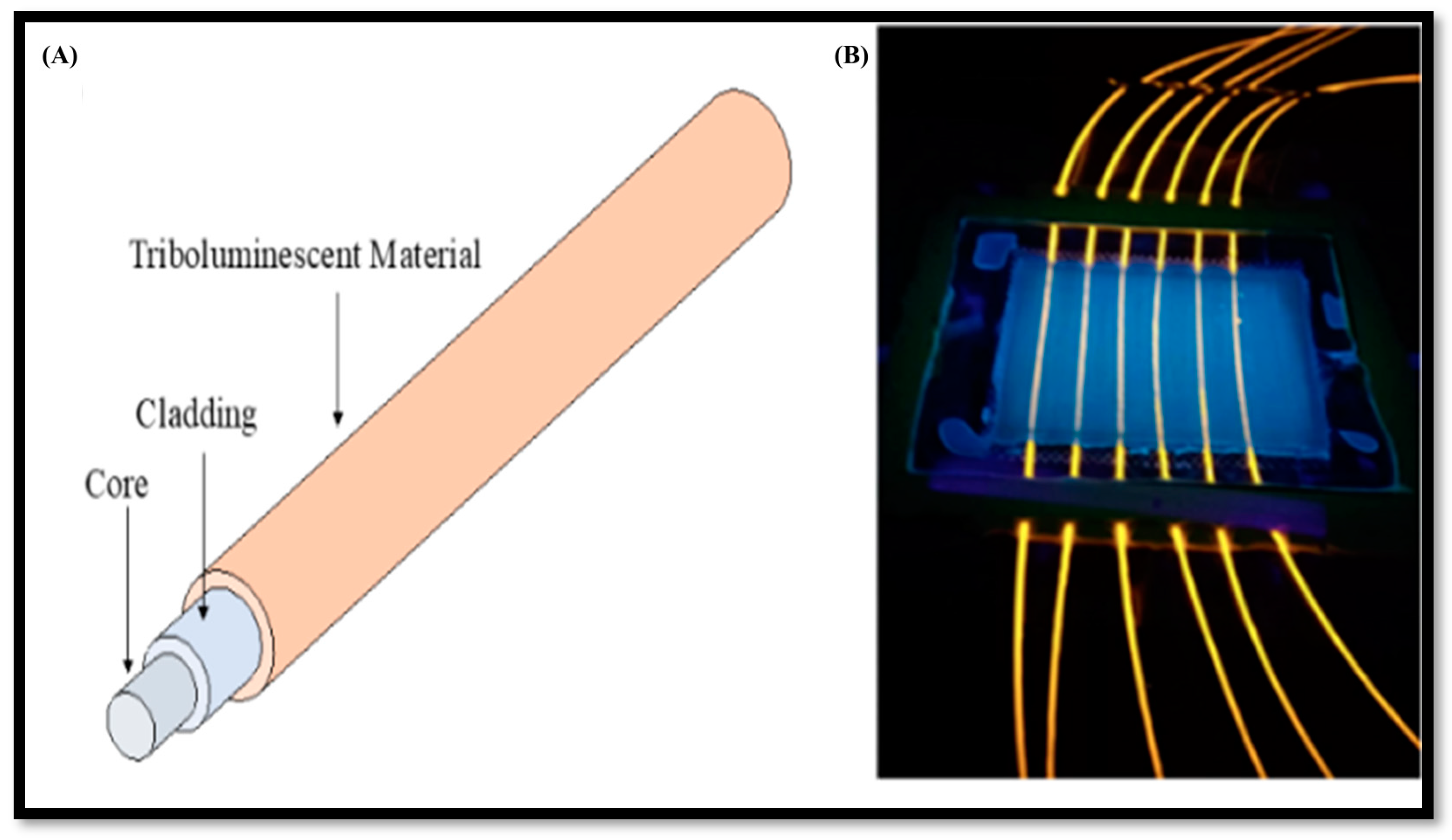

3.3.1. ML–Perovskite Sensors

3.3.2. Mechanochromic Sensors

3.3.3. MXenes

4. Challenges and Prospects

4.1. Durability of Embedded Sensors under Mechanical Stress

4.2. Piezoresistive Sensors under Cyclic Loading

5. Future Directions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shirvanimoghaddam, K.; Hamim, S.U.; Karbalaei Akbari, M.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H.; Ghasali, E.; Zabet, M.; Munir, K.S.; Jia, S.; et al. Carbon Fiber Reinforced Metal Matrix Composites: Fabrication Processes and Properties. Compos. Part Appl. Sci. Manuf. 2017, 92, 70–96. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Satheeshkumar, S.; Naveen, J. Glass Fiber-Reinforced Polymer Composites—A Review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer Composite Materials: A Comprehensive Review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Hamdan, A.; Sultan, M.T.H.; Mustapha, F. Structural Health Monitoring of Biocomposites, Fibre-Reinforced Composites, and Hybrid Composite. In Structural Health Monitoring of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 227–242. ISBN 978-0-08-102291-7. [Google Scholar]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for Process and Structural Health Monitoring of Aerospace Composites: A Review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Structural Health Monitoring of Aerospace Composites; Elsevier Science and Technology Books, Inc.: Amsterdam, The Netherlands, 2016; ISBN 978-0-12-410441-9. [Google Scholar]

- Ferreira, P.M.; Machado, M.A.; Carvalho, M.S.; Vidal, C. Embedded Sensors for Structural Health Monitoring: Methodologies and Applications Review. Sensors 2022, 22, 8320. [Google Scholar] [CrossRef]

- Janeliukstis, R.; Mironovs, D. Smart Composite Structures with Embedded Sensors for Load and Damage Monitoring—A Review. Mech. Compos. Mater. 2021, 57, 131–152. [Google Scholar] [CrossRef]

- Tuloup, C.; Harizi, W.; Aboura, Z.; Meyer, Y.; Khellil, K.; Lachat, R. On the Use of In-Situ Piezoelectric Sensors for the Manufacturing and Structural Health Monitoring of Polymer-Matrix Composites: A Literature Review. Compos. Struct. 2019, 215, 127–149. [Google Scholar] [CrossRef]

- Tuloup, C.; Harizi, W.; Aboura, Z.; Meyer, Y. Integration of Piezoelectric Transducers (PZT and PVDF) within Polymer-Matrix Composites for Structural Health Monitoring Applications: New Success and Challenges. Int. J. Smart Nano Mater. 2020, 11, 343–369. [Google Scholar] [CrossRef]

- Sohn, M.S.; Hu, X.Z.; Kim, J.K.; Walker, L. Impact Damage Characterisation of Carbon Fibre/Epoxy Composites with Multi-Layer Reinforcement. Compos. Part B Eng. 2000, 31, 681–691. [Google Scholar] [CrossRef]

- He, C.; Li, Y.; Zhang, Z.; Sun, Z. Impact Damage Modes and Residual Flexural Properties of Composites Beam. J. Reinf. Plast. Compos. 2008, 27, 1163–1175. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, K.K.; Sarkar, P. Impact Damage on Fibre-Reinforced Polymer Matrix Composite—A Review. J. Compos. Mater. 2014, 48, 317–332. [Google Scholar] [CrossRef]

- English: Bird Strike–Aircraft AMX–Brazilian Air Force; 2007. (Bird Strike—Amazing Damage|Aircraft, Bird Strike, Fighter Jets). Available online: https://www.pinterest.com/#top (accessed on 20 April 2024).

- Petit, S.; Bouvet, C.; Bergerot, A.; Barrau, J.-J. Impact and Compression after Impact Experimental Study of a Composite Laminate with a Cork Thermal Shield. Compos. Sci. Technol. 2007, 67, 3286–3299. [Google Scholar] [CrossRef]

- Sadighi, M.; Alderliesten, R. Impact Fatigue, Multiple and Repeated Low-Velocity Impacts on FRP Composites: A Review. Compos. Struct. 2022, 297, 115962. [Google Scholar] [CrossRef]

- Tai, N.H.; Yip, M.C.; Lin, J.L. Effects of Low-Energy Impact on the Fatigue Behavior of Carbon/Epoxy Composites. Compos. Sci. Technol. 1998, 58, 1–8. [Google Scholar] [CrossRef]

- Talreja, R. Damage and Fatigue in Composites—A Personal Account. Compos. Sci. Technol. 2008, 68, 2585–2591. [Google Scholar] [CrossRef]

- Saeedifar, M.; Najafabadi, M.A.; Zarouchas, D.; Toudeshky, H.H.; Jalalvand, M. Barely Visible Impact Damage Assessment in Laminated Composites Using Acoustic Emission. Compos. Part B Eng. 2018, 152, 180–192. [Google Scholar] [CrossRef]

- Dolbeer, R.A.; Begier, M.J.; Miller, P.R.; Weller, J.R.; Anderson, A.L. Wildlife Strikes to Civil Aircraft in the United States 1990–2022; Federal Aviation Administration: Washington, DC, USA, 2023. [Google Scholar]

- Chen, X.; Cheng, S.; Wen, K.; Wang, C.; Zhang, J.; Zhang, H.; Ma, H.; Wu, L.; Li, T.; Li, B.; et al. In-situ damage self-monitoring of fiber-reinforced composite by integrating self-powered ZnO nanowires decorated carbon fabric. Compos. B Eng. 2023, 248, 110368. [Google Scholar] [CrossRef]

- Gino, M.E.; Selleri, G.; Cocchi, D.; Brugo, T.M.; Testoni, N.; De Marchi, L.; Zucchelli, A.; Fabiani, D.; Focarete, M.L. On the Design of a Piezoelectric Self-Sensing Smart Composite Laminate. Mater. Des. 2022, 219, 110783. [Google Scholar] [CrossRef]

- Dziendzikowski, M.; Kurnyta, A.; Dragan, K.; Klysz, S.; Leski, A. In Situ Barely Visible Impact Damage Detection and Localization for Composite Structures Using Surface Mounted and Embedded PZT Transducers: A Comparative Study. Mech. Syst. Signal Process. 2016, 78, 91–106. [Google Scholar] [CrossRef]

- Dziendzikowski, M.; Dragan, K.; Katunin, A. Localizing Impact Damage of Composite Structures with Modified RAPID Algorithm and Non-Circular PZT Arrays. Arch. Civ. Mech. Eng. 2017, 17, 178–187. [Google Scholar] [CrossRef]

- Feng, T.; Bekas, D.; Aliabadi, M.H.F. Active Health Monitoring of Thick Composite Structures by Embedded and Surface-Mounted Piezo Diagnostic Layer. Sensors 2020, 20, 3410. [Google Scholar] [CrossRef]

- Hornig, A.; Frohberg, R.; Bätzel, T.; Gude, M.; Modler, N. Embedded Sensing and Actuating in CFRP Composite Structures—Concept and Technology Demonstration for Tailored Embeddable Sensor-Actuator Layers (TEmSAL). Smart Mater. Struct. 2022, 31, 095007. [Google Scholar] [CrossRef]

- Qing, X.P.; Beard, S.J.; Ikegami, R.; Chang, F.-K.; Boller, C. Aerospace Applications of SMART Layer Technology. In Encyclopedia of Structural Health Monitoring; Boller, C., Chang, F.-K., Fujino, Y., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2008; p. shm152. ISBN 978-0-470-05822-0. [Google Scholar]

- Lin, M.; Kumar, A.; Beard, S.J.; Xinlin, Q. Built-in Structural Diagnostic with the SMART LayerTM and SMART SuitcaseTM. Smart Mater. Bull. 2001, 2001, 7–11. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Zagrai, A.N. Embedded Self-Sensing Piezoelectric Active Sensors for On-Line Structural Identification. J. Vib. Acoust. 2002, 124, 116–125. [Google Scholar] [CrossRef]

- Ikegami, R.; Boller, C. History of SHM for Commercial Transport Aircraft. In Encyclopedia of Structural Health Monitoring; Boller, C., Chang, F.-K., Fujino, Y., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2008; p. shm125. ISBN 978-0-470-05822-0. [Google Scholar]

- Kumar, A.; Wu, H.F.; Lin, M.; Beard, S.; Qing, X.; Zhang, C.; Hamilton, M.; Ikegami, R. Potential Applications of SMART Layer Technology for Homeland Security; Doctor, S.R., Bar-Cohen, Y., Aktan, A.E., Wu, H.F., Eds.; SPIE: San Diego, CA, USA, 2004; pp. 61–69. [Google Scholar]

- Qing, X.P.; Ikegami, R.; Beard, S.J.; Zhang, D.; Das, S.; Banerjee, S.; Chang, F.-K. Multifunctional Sensor Network for Structural State Sensing and Structural Health Monitoring; Tomizuka, M., Ed.; SPIE: San Diego, CA, USA, 2010; p. 764711. [Google Scholar]

- Garg, D.P.; Zikry, M.A.; Anderson, G.L.; Stepp, D. Health Monitoring and Reliability of Adaptive Heterogeneous Structures. Struct. Health Monit. 2002, 1, 23–39. [Google Scholar] [CrossRef]

- Coles, A.; De Castro, B.A.; Andreades, C.; Baptista, F.G.; Meo, M.; Ciampa, F. Impact Localization in Composites Using Time Reversal, Embedded PZT Transducers, and Topological Algorithms. Front. Built Environ. 2020, 6, 27. [Google Scholar] [CrossRef]

- Tsai, J.T.; Dustin, J.S.; Mansson, J.A. Cure strain monitoring in composite laminates with distributed optical sensor. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105503. [Google Scholar] [CrossRef]

- Zhan, Y.; Han, M.; Wang, Z.; Xu, L.; Song, Z.; Lu, A.; Guo, X.; Deng, W.; Huang, S. Distributed strain monitoring for different composites structures with high resolution based on optical fiber sensing. Optik 2021, 248, 168113. [Google Scholar] [CrossRef]

- Qi, Y.; Jiang, D.; Ju, S.; Zhang, J. Investigation of strain history in fast and conventional curing epoxy matrix composites by FBGs. Compos. Sci. Technol. 2018, 159, 18–24. [Google Scholar] [CrossRef]

- Qu, X.; Li, J.; Shan, Y.; Yang, Z.; Yang, L.; Xu, H.; Liu, M.; Wu, Z.; Zhao, S. Various static loading condition monitoring of carbon fiber composite cylinder with integrated optical fiber sensors. Opt. Fiber Technol. 2024, 83, 103685. [Google Scholar] [CrossRef]

- Su, H.; Drissi-Habti, M.; Carvelli, V. New Concept of Dual-Sinusoid Distributed Fiber-Optic Sensors Antiphase-Placed for the SHM of Smart Composite Structures for Offshore. Appl. Sci. 2024, 14, 932. [Google Scholar] [CrossRef]

- Hegde, G.; Asokan, S.; Hegde, G. Fiber Bragg Grating Sensors for Aerospace Applications: A Review. ISSS J. Micro Smart Syst. 2022, 11, 257–275. [Google Scholar] [CrossRef]

- Rocha, H.; Lafont, U.; Nunes, J.P. Optimisation of Through-Thickness Embedding Location of Fibre Bragg Grating Sensor in CFRP for Impact Damage Detection. Polymers 2021, 13, 3078. [Google Scholar] [CrossRef]

- Hafizi, Z.M.; Epaarachchi, J.; Lau, K.T. Impact Location Determination on Thin Laminated Composite Plates Using an NIR-FBG Sensor System. Measurement 2015, 61, 51–57. [Google Scholar] [CrossRef]

- Li, J.; Yu, Y.; Qing, X. Embedded FBG Sensor Based Impact Identification of CFRP Using Ensemble Learning. Sensors 2021, 21, 1452. [Google Scholar] [CrossRef]

- Gilbert, M.; Bhavsar, K.; Ivanov, O.V. Robustness of embedded fibre optic sensor mesh configurations for monitoring composite structures. Sens. Actuators A Phys. 2024, 373, 115445. [Google Scholar] [CrossRef]

- Shohag, M.A.; Dessureault, Y.-S.; Joshi, K.; Ndebele, T.; Olawale, D.; Dickens, T.; Okoli, O. Enhanced Fabrication Process for in Situ Triboluminescent Optical Fiber Sensor for Multifunctional Composites. Measurement 2018, 121, 240–248. [Google Scholar] [CrossRef]

- Shohag, M.A.S.; Okoli, O.I. Nonparasitic Behavior of Embedded Triboluminescent Sensor in Multifunctional Composites. Compos. Part Appl. Sci. Manuf. 2019, 116, 114–125. [Google Scholar] [CrossRef]

- Shohag, M.A.; Ndebele, T.; Olawale, D.; Okoli, O. Advances of Bio-Inspired In-Situ Triboluminescent Optical Fiber Sensor for Damage and Load Monitoring in Multifunctional Composite. In Proceedings of the Structural Health Monitoring 2017, Stanford, CA, USA, 12–14 September 2017; DEStech Publications, Inc.: Lancaster, PA, USA, 2017. [Google Scholar]

- Braga Carani, L. Investigation of Single Crystal Perovskite for Mechanoluminescence-Based Sensor Application; Florida State University: Tallahassee, FL, USA, 2019. [Google Scholar]

- Braga Carani, L.; Shohag, M.A.; Obiozo Eze, V.; Adams, G.R.; Okoli, O. Embedded Perovskite-Mechanoluminescent Sensor for Applications in Composite Materials. In European Workshop on Structural Health Monitoring; Rizzo, P., Milazzo, A., Eds.; Lecture Notes in Civil Engineering; Springer International Publishing: Cham, Switzerland, 2021; Volume 128, pp. 603–611. ISBN 978-3-030-64907-4. [Google Scholar]

- Carani, L.B.; Eze, V.O.; Iwuagwu, C.; Okoli, O.I. Performance Analysis of Embedded Mechanoluminescence-Perovskite Self-Powered Pressure Sensor for Structural Health Monitoring. J. Compos. Sci. 2020, 4, 190. [Google Scholar] [CrossRef]

- Shohag, M.A.; Adams, G.R.; Eze, V.O.; Ichite, T.; Carani, L.B.; Okoli, O. Mechanoluminescent-Perovskite Pressure Sensor for Structural Health Monitoring. In Proceedings of the Structural Health Monitoring 2019, Stanford, CA, USA, 10–12 September 2019; DEStech Publications, Inc.: Lancaster, PA, USA, 2019. [Google Scholar]

- Shohag, M.A.S.; Eze, V.O.; Braga Carani, L.; Okoli, O.I. Fully Integrated Mechanoluminescent Devices with Nanometer-Thick Perovskite Film as Self-Powered Flexible Sensor for Dynamic Pressure Sensing. ACS Appl. Nano Mater. 2020, 3, 6749–6756. [Google Scholar] [CrossRef]

- Braga Carani, L.; Eze, V.O.; Okoli, O. Effect of Interface Modification on Mechanoluminescence-Inorganic Perovskite Impact Sensors. Sensors 2022, 23, 236. [Google Scholar] [CrossRef]

- Carani, L.B.; Martin, T.D.; Eze, V.O.; Okoli, O.I. Impact Sensing and Localization in Composites Structures with Embedded Mechanoluminescence-Perovskite Sensors. Sens. Actuators Phys. 2022, 346, 113843. [Google Scholar] [CrossRef]

- Tabatabaeian, A.; Liu, S.; Harrison, P.; Schlangen, E.; Fotouhi, M. A Review on Self-Reporting Mechanochromic Composites: An Emerging Technology for Structural Health Monitoring. Compos. Part Appl. Sci. Manuf. 2022, 163, 107236. [Google Scholar] [CrossRef]

- Wan, Y.; Yang, H.; Yuan, Y.; Shen, X.; Yang, B.; Guo, Y.; Xie, Y. Low-Velocity Impact Damage Localization of GF/Epoxy Laminates by the Embedded MWCNT@GF Sensor Network. J. Mater. Res. Technol. 2020, 9, 9253–9261. [Google Scholar] [CrossRef]

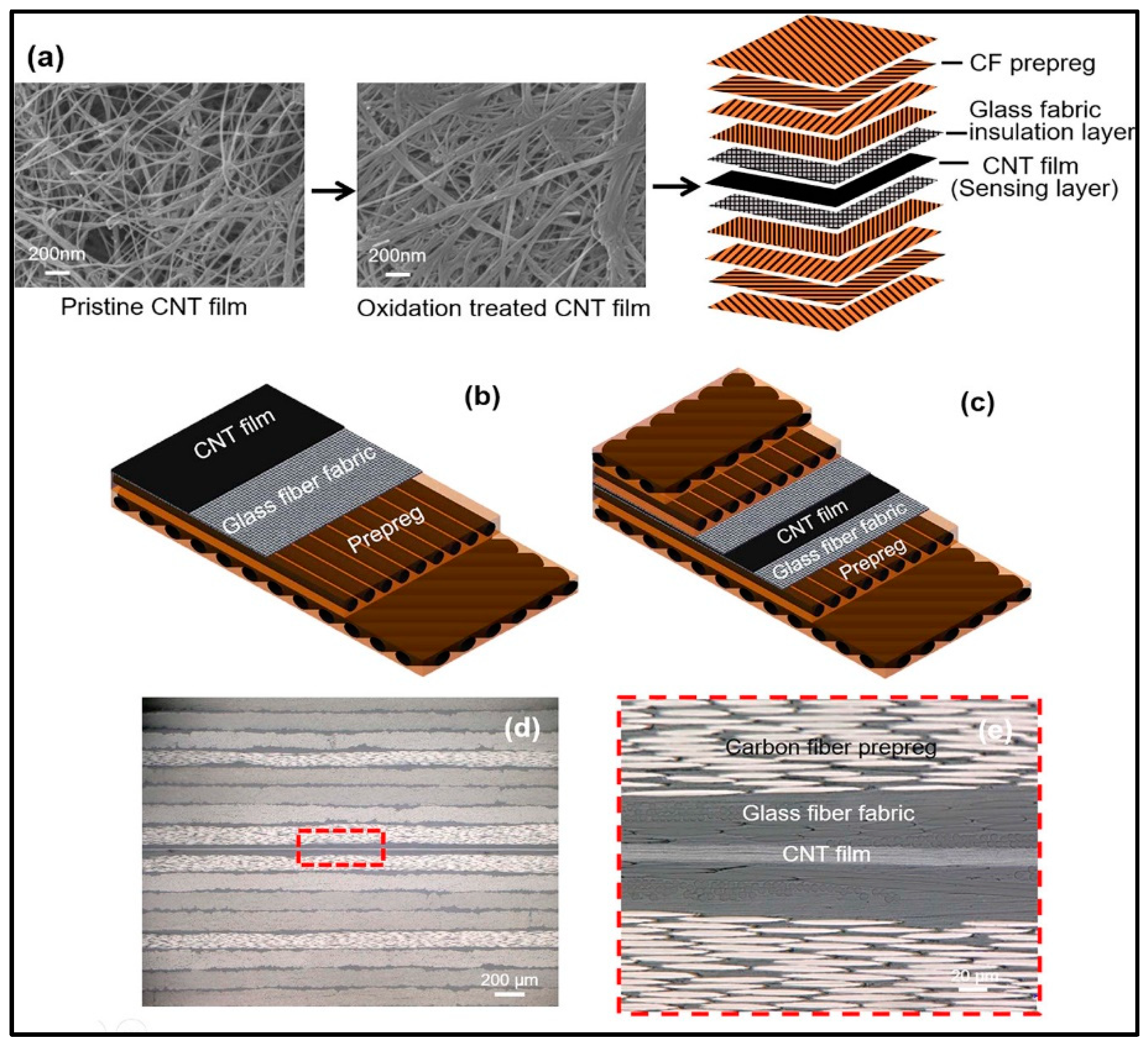

- Hao, F.; Wang, S.; Xing, F.; Li, M.; Li, T.; Gu, Y.; Zhang, W.; Zhang, J. Carbon-Nanotube-Film-Based Electrical Impedance Tomography for Structural Damage Detection of Carbon-Fiber-Reinforced Composites. ACS Appl. Nano Mater. 2021, 4, 5590–5597. [Google Scholar] [CrossRef]

- Aly, K.; Bradford, P.D. Real-Time Impact Damage Sensing and Localization in Composites through Embedded Aligned Carbon Nanotube Sheets. Compos. Part B Eng. 2019, 162, 522–531. [Google Scholar] [CrossRef]

- Kuang, K.S.C.; Kenny, R.; Whelan, M.P.; Cantwell, W.J.; Chalker, P.R. Embedded Fibre Bragg Grating Sensors in Advanced Composite Materials. Compos. Sci. Technol. 2001, 61, 1379–1387. [Google Scholar] [CrossRef]

- Lin, L.; Wang, X.; Yang, B.; Zhang, L.; Zhao, Z.; Qu, X.; Lu, Y.; Jiang, X.; Lu, S. Condition monitoring of Composite Overwrap Pressure Vessels Based on Buckypaper Sensor and MXene Sensor. Compos. Commun. 2021, 25, 100699. [Google Scholar] [CrossRef]

- Grabowski, K.; Srivatsa, S.; Vashisth, A.; Mishnaevsky, L.; Uhl, T. Recent Advances in MXene-Based Sensors for Structural Health Monitoring Applications: A Review. Measurement 2022, 189, 110575. [Google Scholar] [CrossRef]

- Wang, X.; Lu, J.; Lu, S.; Li, B.; Zhang, L.; Ma, C.; Ma, K.; Lin, L.; Jiang, X.; Yang, B. Health Monitoring of Repaired Composite Structure Using MXene Sensor. Compos. Commun. 2021, 27, 100850. [Google Scholar] [CrossRef]

- Zhang, L.; Qu, X.; Lu, S.; Liu, X.; Ma, C.; Jiang, X.; Wang, X. Damage Monitoring and Locating of COPV under Low Velocity Impact Using MXene Sensor Array. Compos. Commun. 2022, 34, 101241. [Google Scholar] [CrossRef]

- Kwon, H.; Park, Y.; Shin, C.; Kim, J.-H.; Kim, C.-G. Embedded Silicon Carbide Fiber Sensor Network Based Low-Velocity Impact Localization of Composite Structures. Smart Mater. Struct. 2020, 29, 055030. [Google Scholar] [CrossRef]

- Bowland, C.C.; Nguyen, N.A.; Naskar, A.K. Roll-to-Roll Processing of Silicon Carbide Nanoparticle-Deposited Carbon Fiber for Multifunctional Composites. ACS Appl. Mater. Interfaces 2018, 10, 26576–26585. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Wei, T.; Dong, H.; Song, Y. Damage Detection in 2.5D C/SiC Composites Using Electrical Resistance Tomography. J. Eur. Ceram. Soc. 2019, 39, 3583–3593. [Google Scholar] [CrossRef]

- Kwon, H.; Park, Y.; Shrestha, P.; Kim, C.-G. Application of Silicon Carbide Fibers as a Sensor for Low-Velocity Impact Detection and Localization. Struct. Health Monit. 2019, 18, 1372–1382. [Google Scholar] [CrossRef]

- Tang, H.-Y.; Winkelmann, C.; Lestari, W.; La Saponara, V. Composite Structural Health Monitoring Through Use of Embedded PZT Sensors. J. Intell. Mater. Syst. Struct. 2011, 22, 739–755. [Google Scholar] [CrossRef]

- Park, J.-M.; Kong, J.-W.; Kim, D.-S.; Yoon, D.-J. Nondestructive Damage Detection and Interfacial Evaluation of Single-Fibers/Epoxy Composites Using PZT, PVDF and P(VDF-TrFE) Copolymer Sensors. Compos. Sci. Technol. 2005, 65, 241–256. [Google Scholar] [CrossRef]

- Andreades, C.; Mahmoodi, P.; Ciampa, F. Characterisation of Smart CFRP Composites with Embedded PZT Transducers for Nonlinear Ultrasonic Applications. Compos. Struct. 2018, 206, 456–466. [Google Scholar] [CrossRef]

- Fedorov, A.Y.; Kosheleva, N.A.; Matveenko, V.P.; Serovaev, G.S. Strain Measurement and Stress Analysis in the Vicinity of a Fiber Bragg Grating Sensor Embedded in a Composite Material. Compos. Struct. 2020, 239, 111844. [Google Scholar] [CrossRef]

- Mieloszyk, M.; Majewska, K.; Ostachowicz, W. Application of Embedded Fibre Bragg Grating Sensors for Structural Health Monitoring of Complex Composite Structures for Marine Applications. Mar. Struct. 2021, 76, 102903. [Google Scholar] [CrossRef]

- Aller, B.; Pellegrino, S.; Kinkaid, N.; Mejia-Ariza, J.; Chan, P.; Pena, F. Health Monitoring of High Strain Composites Using Embedded Fiber Bragg Grating Sensors. In Proceedings of the AIAA SCITECH 2022 Forum, Virtual, 3 January 2022; American Institute of Aeronautics and Astronautics: San Diego, CA, USA, 2022. [Google Scholar]

- Di Sante, R. Fiber Optic Sensors for Structural Health Monitoring of Aircraft Composite Structures: Recent Advances and Applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

- Cassidy, N.J.; O’Regan, P.; Luo, S.; Chapman, D.N.; Jefferson, I. The Application of High-Resolution, Embedded Fibre Optic (FO) Sensing for Large-Diameter Composite Steel/Plastic Pipeline Performance under Dynamic Transport Loads. Sensors 2024, 24, 1298. [Google Scholar] [CrossRef] [PubMed]

- Shellaiah, M.; Sun, K.W.; Thirumalaivasan, N.; Bhushan, M.; Murugan, A. Sensing Utilities of Cesium Lead Halide Perovskites and Composites: A Comprehensive Review. Sensors 2024, 24, 2504. [Google Scholar] [CrossRef]

- Zhuang, Y.; Cao, L.; Gu, X.; Miao, S.; Gao, S.; Fang, Y.; Huang, S.; He, X. Fabrication of lead-free perovskite MASnBrI2 nanocrystals-embedded polymer composites for flexible strain sensors. Ceram. Int. 2024, 50, 5766–5774. [Google Scholar] [CrossRef]

- Park, J.; Lee, J.-R. Strain Measurements of an Aircraft Wing Using Embedded CNT Fiber Sensor and Wireless SHM Sensor Node. Funct. Compos. Struct. 2022, 4, 035004. [Google Scholar] [CrossRef]

- Wang, M.; Li, N.; Wang, G.-D.; Lu, S.W.; Zhao, Q.D.; Liu, X.L. High-Sensitive Flexural Sensors for Health Monitoring of Composite Materials Using Embedded Carbon Nanotube (CNT) Buckypaper. Compos. Struct. 2021, 261, 113280. [Google Scholar] [CrossRef]

- Qiu, L.; Li, L.; Ashour, A.; Ding, S.; Han, B. Monitoring damage of concrete beams via self-sensing cement mortar coating with carbon nanotube-nano carbon black composite fillers. J. Intell. Mater. Syst. Struct. 2024, 35, 633–648. [Google Scholar] [CrossRef]

- Sung, D.H.; Doshi, S.M.; Rider, A.N.; Kimble, E.; Martin, R.; Ahmed, M.T.; Thostenson, E.T. Scalable, roll-to-roll manufacturing of multiscale nanoparticle/fiber composites using electrophoretic deposition: Novel multifunctional in situ sensing applications. Compos. Sci. Technol. 2024, 245, 110322. [Google Scholar] [CrossRef]

- Koutsotolis, L.; Karalis, G.; Voudouris Itskaras, A.; Tsirka, K.; Paipetis, A.S. A carbon nanotube-based thermoelectric generator integrated into a smart composite for structural health monitoring. Mater. Res. Express. 2024, 11, 045705. [Google Scholar] [CrossRef]

- Jiang, X.; Lu, D.; Yin, B.; Leng, Z. Advancing carbon nanomaterials-engineered self-sensing cement composites for structural health monitoring: A state-of-the-art review. J. Build. Eng. 2024, 87, 109129. [Google Scholar] [CrossRef]

- Deng, K.; Liu, H.; Yang, L.; Addepalli, S.; Zhao, Y. Classification of Barely Visible Impact Damage in Composite Laminates Using Deep Learning and Pulsed Thermographic Inspection. Neural Comput. Appl. 2023, 35, 11207–11221. [Google Scholar] [CrossRef]

- Tabatabaeian, A.; Jerkovic, B.; Harrison, P.; Marchiori, E.; Fotouhi, M. Barely Visible Impact Damage Detection in Composite Structures Using Deep Learning Networks with Varying Complexities. Compos. Part B Eng. 2023, 264, 110907. [Google Scholar] [CrossRef]

- Wei, Z.; Fernandes, H.; Herrmann, H.-G.; Tarpani, J.R.; Osman, A. A Deep Learning Method for the Impact Damage Segmentation of Curve-Shaped CFRP Specimens Inspected by Infrared Thermography. Sensors 2021, 21, 395. [Google Scholar] [CrossRef] [PubMed]

- Jung, K.-C.; Chang, S.-H. Advanced Deep Learning Model-Based Impact Characterization Method for Composite Laminates. Compos. Sci. Technol. 2021, 207, 108713. [Google Scholar] [CrossRef]

- Alhammad, M.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Torbali, M.E.; Genest, M.; Zhang, H.; Zolotas, A.; Maldgue, X.P.V. Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors 2022, 22, 9031. [Google Scholar] [CrossRef] [PubMed]

- Zargar, S.A.; Yuan, F.-G. Impact Diagnosis in Stiffened Structural Panels Using a Deep Learning Approach. Struct. Health Monit. 2021, 20, 681–691. [Google Scholar] [CrossRef]

- Hasebe, S.; Higuchi, R.; Yokozeki, T.; Takeda, S. Internal Low-Velocity Impact Damage Prediction in CFRP Laminates Using Surface Profiles and Machine Learning. Compos. Part B Eng. 2022, 237, 109844. [Google Scholar] [CrossRef]

- Hasebe, S.; Higuchi, R.; Yokozeki, T.; Takeda, S. Multi-Task Learning Application for Predicting Impact Damage-Related Information Using Surface Profiles of CFRP Laminates. Compos. Sci. Technol. 2023, 231, 109820. [Google Scholar] [CrossRef]

- Ghadarah, N.; Ayre, D. A Review on Acoustic Emission Testing for Structural Health Monitoring of Polymer-Based Composites. Sensors 2023, 23, 6945. [Google Scholar] [CrossRef]

- Caneva, C.; De Rosa, I.M.; Sarasini, F. Monitoring of impacted aramid-reinforced composites by embedded PVDF acoustic emission sensors. Strain 2008, 44, 308–316. [Google Scholar] [CrossRef]

- Ghadarah, N.S.; Ayre, D. A comparative analysis of acoustic emission sensor embedding in glass fibre composite. Compos. Sci. Technol. 2024, 247, 110392. [Google Scholar] [CrossRef]

- Allagui, S.; El Mahi, A.; Rebiere, J.L.; Bouguecha, A.; Haddar, M. In-situ health monitoring of thermoplastic bio-composites using acoustic emission. J. Thermoplast. Compos. Mater. 2023, 36, 4296–4316. [Google Scholar] [CrossRef]

- Nesser, H.; Mahmoud, H.A.; Lubineau, G. High-Sensitivity RFID Sensor for Structural Health Monitoring. Adv. Sci. 2023, 10, 2301807. [Google Scholar] [CrossRef] [PubMed]

- Vincent, S.; Leong, Z.; Morley, N. Interpretation of magnetostrictive sensor data in Mode 1 and Mode 2 of carbon fibre reinforced polymers. Sens Actuators A Phys. 2024, 365, 114888. [Google Scholar] [CrossRef]

- Fotouhi, S.; Khayatzadeh, S.; Pui, W.X.; Damghani, M.; Bodaghi, M.; Fotouhi, M. Detection of barely visible impact damage in polymeric laminated composites using a biomimetic tactile whisker. Polymers 2021, 13, 3587. [Google Scholar] [CrossRef]

- Rao, R.K.; Sindu, B.S.; Sasmal, S. Real-time monitoring of structures under extreme loading using smart composite-based embeddable sensors. J. Intell. Mater. Syst. Struct. 2022, 34, 1073–1096. [Google Scholar] [CrossRef]

| Sensor Type | Mechanism | Advantages | Disadvantages | References |

|---|---|---|---|---|

| PZT (e.g., PVDF, wafers) | Generate electrical charge in response to stress | High sensitivity, Wide frequency range, Versatility in forms (wafer, film) | Requires wiring, Possible electromagnetic interference | [9,68,69,70] |

| FBG | Optical reflection due to refractive index change | Immune to electromagnetic interference, High sensitivity, Multiplexing capability | Fragility, Costly setup | [71,72,73,74,75] |

| Mechanoluminescent-Perovskite | Conversion of light emission into electrical current due to mechanical stress | Self-powered, simple, cost-effective, no need for external collection equipment, high sensitivity | Limited research, Integration challenges | [51,53,76,77] |

| ITOF | Luminescence due to fractoluminescence | Direct optical signal, Self-powered | Limited sensitivity | |

| CNT | Electrical resistance changes due to deformation | High sensitivity, Lightweight, Flexibility | Integration challenges, Possible toxicity | [58,78,79,80,81,82,83] |

| MXenes | Conductivity changes with deformation | High sensitivity, tunable electrical properties | Limited research, Scalability concerns | [65,66,68] |

| Silicon Carbide (SiC) | Change in electrical resistance with mechanical strain. | High temperature stability, chemically inert | Costly, brittle, complex fabrication | [84,85,86,87,88,89,90,91] |

| Acoustic Emission Sensor | Generate frequency waveform signals via developing cracks. | Theoretical high sensitivity, eliminating the need for coupling. no change in sensitivity | Inability to incorporate existing structures | [92,93,94,95] |

| Radio frequency identification device (RFID) | Generates mechanical strains from nanocracks via an inductance capacitance circuit. | Easy embedment process can be deployed in a wireless sensor network, small strain detection. | Highly sensitive to external stimuli other than strain | [96] |

| Mangnetostrictive | Damage sensitivity elongation via small-scale magnetostriction theory | Easy application to material architecture in non-contact damage detection environment | Highly sensitive to external stimuli especially in high temperature environment | [97] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carani, L.B.; Humphrey, J.; Rahman, M.M.; Okoli, O.I. Advances in Embedded Sensor Technologies for Impact Monitoring in Composite Structures. J. Compos. Sci. 2024, 8, 201. https://doi.org/10.3390/jcs8060201

Carani LB, Humphrey J, Rahman MM, Okoli OI. Advances in Embedded Sensor Technologies for Impact Monitoring in Composite Structures. Journal of Composites Science. 2024; 8(6):201. https://doi.org/10.3390/jcs8060201

Chicago/Turabian StyleCarani, Lucas Braga, Johnson Humphrey, Md Mostafizur Rahman, and Okenwa I. Okoli. 2024. "Advances in Embedded Sensor Technologies for Impact Monitoring in Composite Structures" Journal of Composites Science 8, no. 6: 201. https://doi.org/10.3390/jcs8060201

APA StyleCarani, L. B., Humphrey, J., Rahman, M. M., & Okoli, O. I. (2024). Advances in Embedded Sensor Technologies for Impact Monitoring in Composite Structures. Journal of Composites Science, 8(6), 201. https://doi.org/10.3390/jcs8060201