Experimental Comparative Analysis of the Through-Thickness and In-Plane Compression Moduli of Unidirectional CFRP Laminates

Abstract

1. Introduction

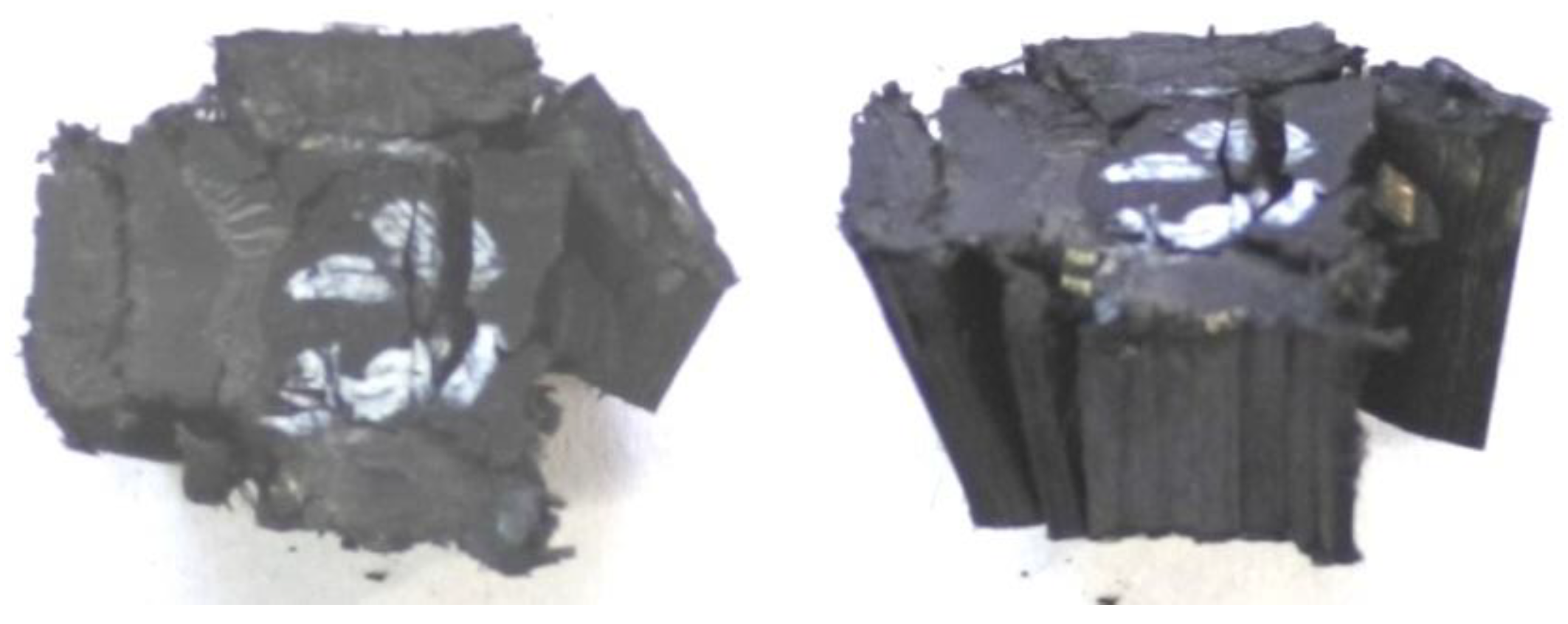

Experimental Characterization of the Out-of-Plane Properties

2. Methods and Procedures

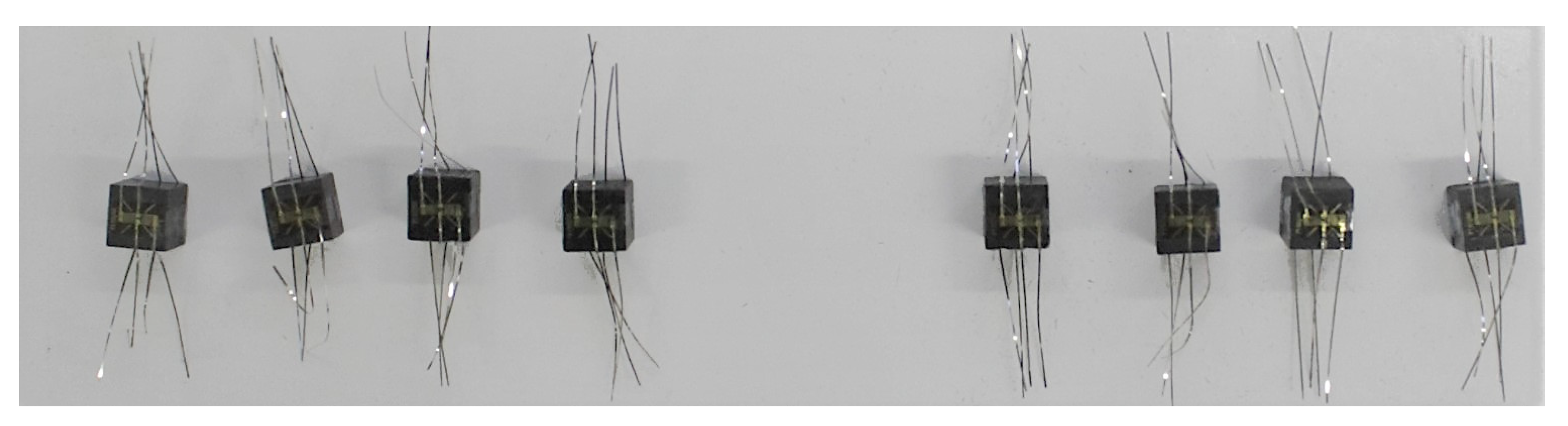

2.1. Experimental Set-Up

2.2. Specimen Configurations

- Thickness: ;

- In-plane dimensions: .

2.3. Test Procedure

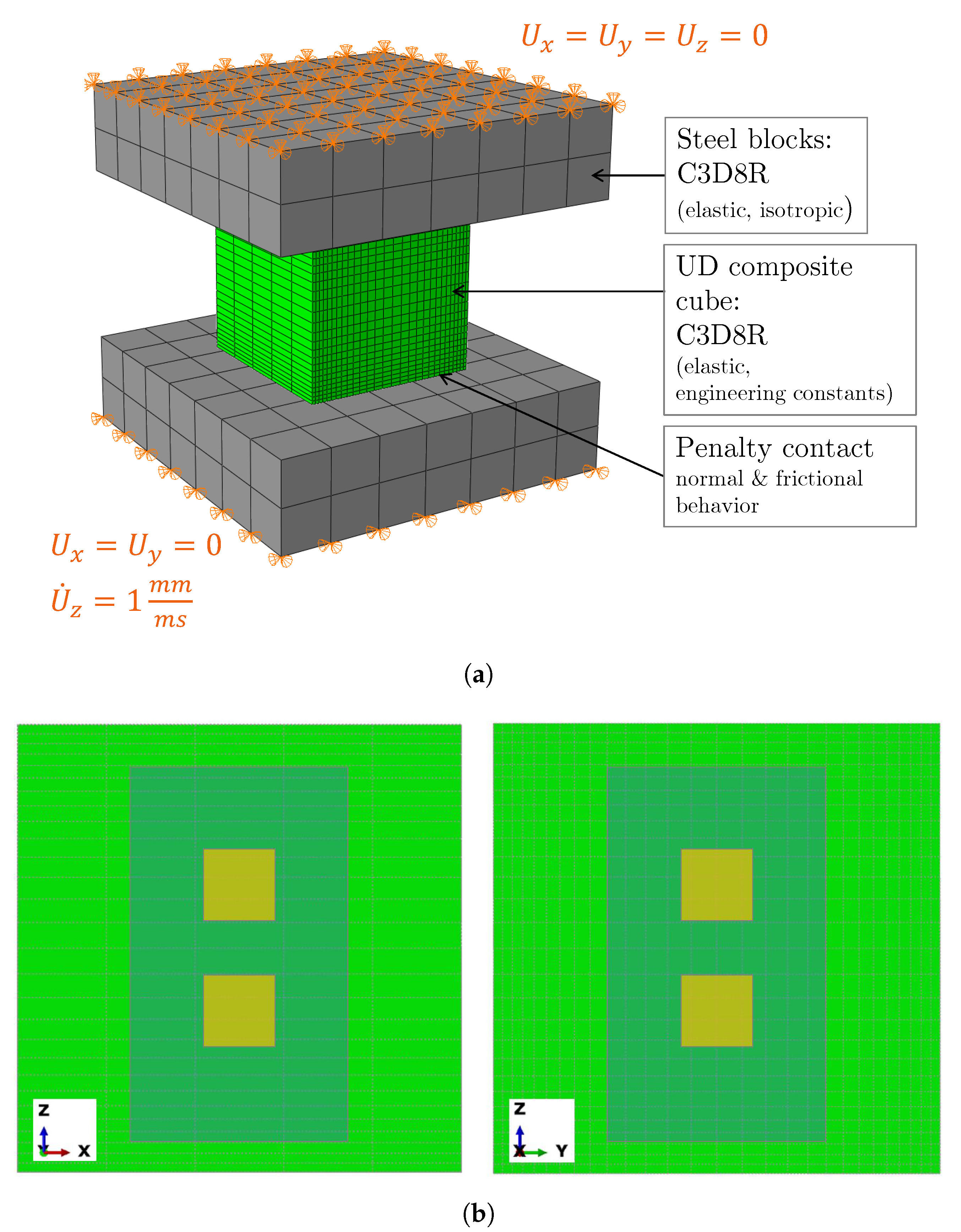

2.4. Finite Element Model of the Test Set-Up

2.5. Numerically Obtained Scaling Factors

3. Results and Discussion

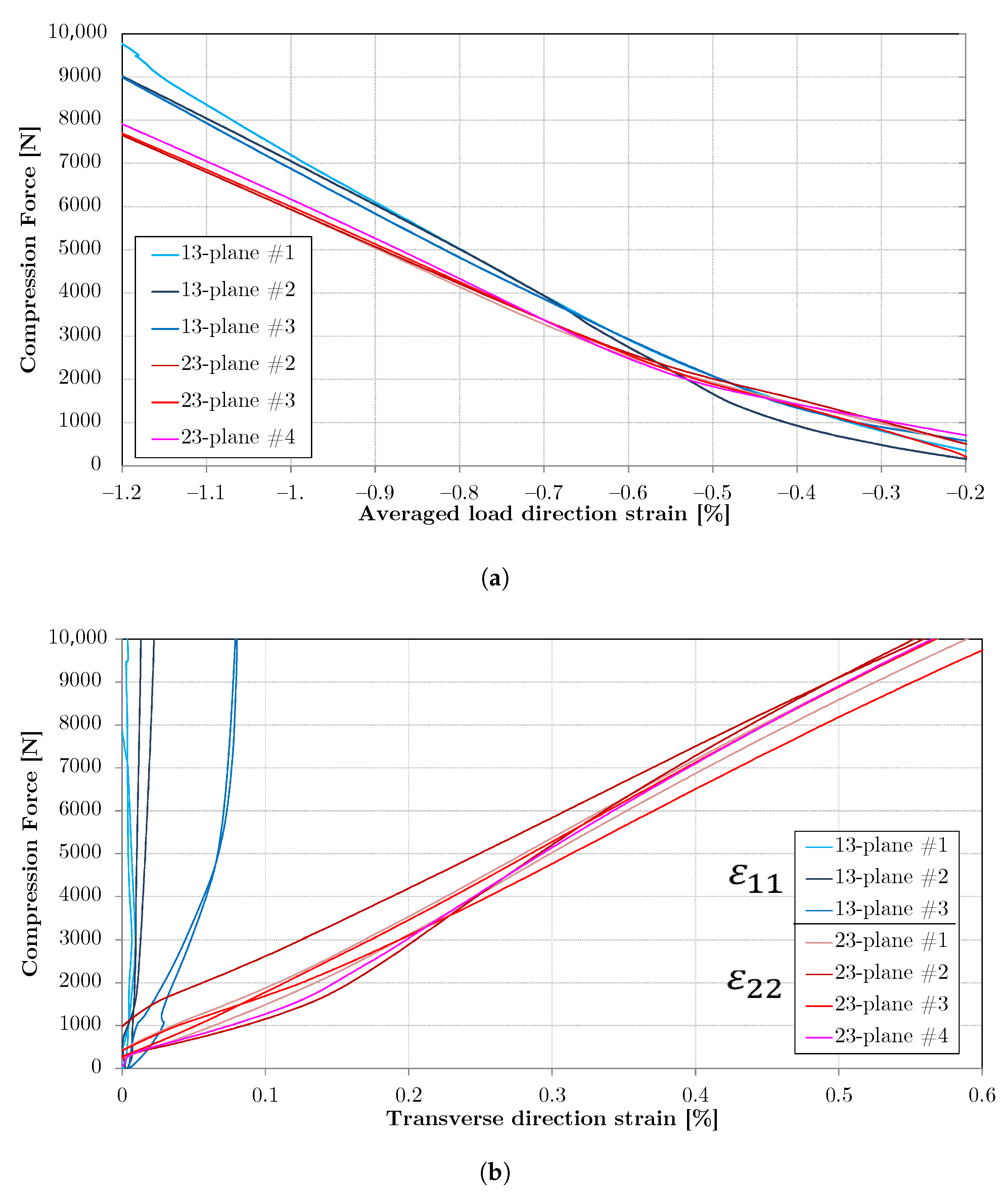

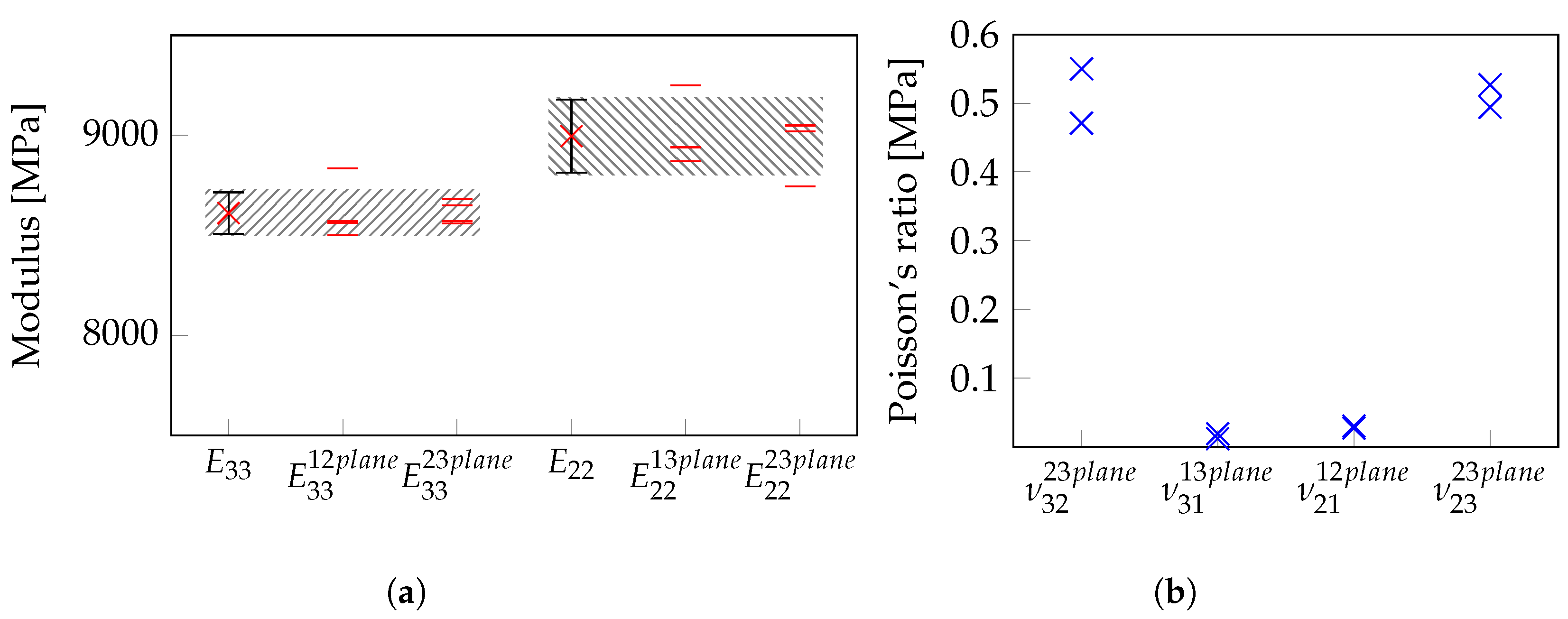

3.1. Stiffness Determination

3.2. Strength Determination

3.3. Comparison with the Standard Test

3.4. The 1-Direction Cube Compression Test

4. Conclusions and Outlook

- To enhance the accuracy of the experiment results, the stiffness measurements were scaled according to the results from a virtual test set-up in FE analysis. This approach enabled the precise determination of and .

- A comparative analysis of the in-plane and out-of-plane properties revealed a slightly lower out-of-plane modulus () and strength () compared with their in-plane counterparts ( and . The results indicate deteriorations of and from and by margins of 5% and 7%, respectively.

- The cube compression test results for and were compared with the results from a standard test, revealing 12% enhanced strength for and 4% underestimated stiffness for in the cube compression test.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gruebler, K.; Thomson, D.; Petrinic, N.; Wisnom, M.R.; Hallett, S.R. Fibre reinforcement and stacking sequence influence on the through-thickness compression behaviour of polymer composites. Compos. Struct. 2023, 319, 117160. [Google Scholar] [CrossRef]

- Camanho, P.P.; Matthews, F.L. Delamination Onset Prediction in Mechanically Fastened Joints in Composite Laminates. J. Compos. Mater. 1999, 33, 906–927. [Google Scholar] [CrossRef]

- Park, D.C.; Lee, S.M.; Kim, B.C.; Kim, H.S.; Lee, D.G. Development of heavy duty hybrid carbon–phenolic hemispherical bearings. Compos. Struct. 2006, 73, 88–98. [Google Scholar] [CrossRef]

- Fualdes, C. Composites @ Airbus damage tolerance methodology. In Proceedings of the FAA Workshop for Composite Damage Tolerance and Maintance, Chicago, IL, USA, 19–21 July 2006. [Google Scholar]

- Faivre, V.; Morteau, E. Damage tolerant composite fuselage sizing–Chacterisation of accidental damage threat. Airbus SAS 2011, 48, 10–16. [Google Scholar]

- Xu, L.R.; Hassan, M.M.; Anderoglu, O.; Zhao, K.; Flores, M. Influence of the stacking sequence on the through-thickness Young’s moduli of fibrous composite laminates measured by nanoindentation. J. Compos. Mater. 2020, 55, 1179–1184. [Google Scholar] [CrossRef]

- Bogenfeld, R. A Combined Analytical and Numerical Analysis Method for Low-Velocity Impact on Composite Structures. Ph.D. Thesis, Technische Universität Carola-Wilhelmina zu Braunschweig, Braunschweig, Germany, 2019. [Google Scholar]

- Abrate, S. Impact on Composite Structures; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Hertz, H. Ueber die Berührung fester elastischer Körper. J. Die Reine Angew. Math. 1881, I, 156–171. [Google Scholar] [CrossRef]

- Bogenfeld, R.; Freund, S.; Dähne, S.; Wunderlich, T.; Wille, T. Damage tolerance allowable calculation for the aircraft design with static ultimate load. Compos. Struct. 2023, 329, 117803. [Google Scholar] [CrossRef]

- Lopes, C.; Sádaba, S.; González, C.; Llorca, J.; Camanho, P.P. Physically-Sound Simulation of Low-Velocity Impact on Fibre Reinforced Laminates. Int. J. Impact Eng. 2015, 92, 1–15. [Google Scholar] [CrossRef]

- Hongkarnjanakul, N.; Bouvet, C.; Rivallant, S. Validation of low velocity impact modelling on different stacking sequences of CFRP laminates and influence of fibre failure. Compos. Struct. 2013, 106, 549–559. [Google Scholar] [CrossRef]

- Kumar, K.V.; Reddy, P.R.; Shankar, D.R. Influence of angle ply orientation of stacking on mechanical properties of glass-polyester composite laminate. Int. J. Eng. Adv. Technol. (IJEAT) 2013, 2249, 8958. [Google Scholar]

- Dixit, A.; Mali, H.S.; Misra, R. Unit Cell Model of Woven Fabric Textile Composite for Multiscale Analysis. Procedia Eng. 2013, 68, 352–358. [Google Scholar] [CrossRef]

- Lüders, C. Mehrskalige Betrachtung des Ermüdungsverhaltens Thermisch zyklierter Faserkunststoffverbunde. Ph.D. Thesis, Technischen Universität Carolo-Wilhelmina zu Braunschweig, Braunschweig, Germany, 2020. [Google Scholar]

- Cózar, I.; Turon, A.; González, E.; Vallmajó, O.; Sasikumar, A. A methodology to obtain material design allowables from high-fidelity compression after impact simulations on composite laminates. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106069. [Google Scholar] [CrossRef]

- DIN EN ISO 14126; Bestimmung der Druckeigenschaften in der Laminatebene. Deutsches Institut für Normung: Berlin, Germany, 2000.

- Abot, J.L.; Daniel, I.M. Through-Thickness Mechanical Characterization of Woven Fabric Composites. J. Compos. Mater. 2004, 38, 543–553. [Google Scholar] [CrossRef]

- Gning, P.; Delsart, D.; Mortier, J.; Coutellier, D. Through-thickness strength measurements using Arcan’s method. Compos. Part B Eng. 2010, 41, 308–316. [Google Scholar] [CrossRef]

- Arcan, M.; Hashin, Z.; Voloshin, A. A method to produce uniform plane-stress states with applications to fiber-reinforced materials. Exp. Mech. 1978, 18, 141–146. [Google Scholar] [CrossRef]

- Zhang, C.; Ganesan, R.; Hoa, S.V. Through-the-thickness compressive strengths of graphite/epoxy laminated composites: Experimental characterization and statistical analysis. Sci. Eng. Compos. Mater. 2000, 9, 163–176. [Google Scholar] [CrossRef]

- Kim, B.C.; Park, D.C.; Kim, B.J.; Lee, D.G. Through-thickness compressive strength of a carbon/epoxy composite laminate. Compos. Struct. 2010, 92, 480–487. [Google Scholar] [CrossRef]

- Hottinger Brüel & Kjær A/S HBM Test and Measurement HBM Strain Gauges. Available online: https://www.hbm.com/fileadmin/mediapool/hbmdoc/technical/S01265.pdf (accessed on 6 February 2024).

- Schön, J. Coefficient of friction and wear of a carbon fiber epoxy matrix composite. Wear 2004, 257, 395–407. [Google Scholar] [CrossRef]

- Matsunaga, S.; Matsubara, T.; Wang, W.X.; Takao, Y. Effects of reciprocation number on the friction behaviors of carbon/epoxy for various fiber orientations and high contact pressures. In Proceedings of the International Congress of Chinese Mathematicians (ICCM-13), Beijing, China, 13 June 2001. [Google Scholar]

- Marsh, G. Automating aerospace composites production with fibre placement. Reinf. Plast. 2011, 55, 32–37. [Google Scholar] [CrossRef]

- Caminero, M.; Rodríguez, G.; Muñoz, V. Effect of stacking sequence on Charpy impact and flexural damage behavior of composite laminates. Compos. Struct. 2016, 136, 345–357. [Google Scholar] [CrossRef]

- García-Moreno, I.; Caminero, M.; Rodríguez, G.; López-Cela, J. Effect of Thermal Ageing on the Impact and Flexural Damage Behaviour of Carbon Fibre-Reinforced Epoxy Laminates. Polymers 2019, 11, 80. [Google Scholar] [CrossRef] [PubMed]

- Hexcel ®. HexPly ® M21 Data Sheet. 2020. Available online: https://www.hexcel.com/user_area/content_media/raw/HexPly_M21_global_DataSheet.pdf (accessed on 6 February 2024).

- Bogenfeld, R.; Kreikemeier, J.; Wille, T. Validation of the low-velocity impact damage prediction through analytical scaling. Compos. Struct. 2019, 209, 715–726. [Google Scholar] [CrossRef]

- Baeker, M. SpectrumBaker–Better Contour Plots for Abaqus. 2016, Python Plugin. Available online: https://www.researchgate.net/publication/308078647_SpectrumBaker_-_better_contour_plots_for_Abaqus (accessed on 6 February 2024). [CrossRef]

- Puck, A. Festigkeitsanalyse von Faser-Matrix-Laminaten: Modelle für die Praxis; Hanser: München, Germany; Wien, Austria, 1996; p. 210. [Google Scholar]

- Puck’s Action Plane Fracture Criteria. In Analysis of Failure in Fiber Polymer Laminates: The Theory of Alfred Puck; Springer: Berlin/Heidelberg, Germany, 2008; pp. 37–115. [CrossRef]

- Shrivastava, S.; Sharma, N.; Tsai, S.W.; Mohite, P. D and DD-drop layup optimization of aircraft wing panels under multi-load case design environment. Compos. Struct. 2020, 248, 112518. [Google Scholar] [CrossRef]

- Kappel, E. Double–Double laminates for aerospace applications—Finding best laminates for given load sets. Compos. Part C Open Access 2022, 8, 100244. [Google Scholar] [CrossRef]

- Llorca, J.; González, C.; Molina-Aldareguía, J.M.; Lópes, C.S. Multiscale modeling of composites: Toward virtual testing and beyond. Jom 2013, 65, 215–225. [Google Scholar] [CrossRef]

| Material | IMA/M21e UD Composite |

| GPa | |

| , 1 | GPa |

| GPa | |

| GPa | |

| GPa | |

| , | |

| 2 | |

| mm | |

| Material | Steel blocks |

| E | GPa |

| Parameter | 23-Configuration | 13-Configuration |

|---|---|---|

| , | ||

| , | - | |

| , | - |

| Test Type | Number of Tests | Modulus (MPa) | Standard Deviation (MPa) |

|---|---|---|---|

| (Cube) | 7 | 8611 | 104 |

| (Cube) | 4 | 8617 | 129 |

| (Cube) | 3 1 | 8604 | 55 |

| (Cube) | 6 | 8996 | 183 |

| (Cube) | 3 | 8897 | 153 |

| (Cube) | 3 | 9095 | 155 |

| (EN ISO 14126) | 6 | 9370 | 115 |

| Test Type | Number of Tests | Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|---|

| (Cube) | 8 | 210 | 6 |

| (Cube) | 6 | 224 | 2 |

| (EN ISO 14126) | 6 | 200 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogenfeld, R. Experimental Comparative Analysis of the Through-Thickness and In-Plane Compression Moduli of Unidirectional CFRP Laminates. J. Compos. Sci. 2024, 8, 76. https://doi.org/10.3390/jcs8020076

Bogenfeld R. Experimental Comparative Analysis of the Through-Thickness and In-Plane Compression Moduli of Unidirectional CFRP Laminates. Journal of Composites Science. 2024; 8(2):76. https://doi.org/10.3390/jcs8020076

Chicago/Turabian StyleBogenfeld, Raffael. 2024. "Experimental Comparative Analysis of the Through-Thickness and In-Plane Compression Moduli of Unidirectional CFRP Laminates" Journal of Composites Science 8, no. 2: 76. https://doi.org/10.3390/jcs8020076

APA StyleBogenfeld, R. (2024). Experimental Comparative Analysis of the Through-Thickness and In-Plane Compression Moduli of Unidirectional CFRP Laminates. Journal of Composites Science, 8(2), 76. https://doi.org/10.3390/jcs8020076