Modeling of a Process Window for Tailored Reinforcements in Overmolding Processes

Abstract

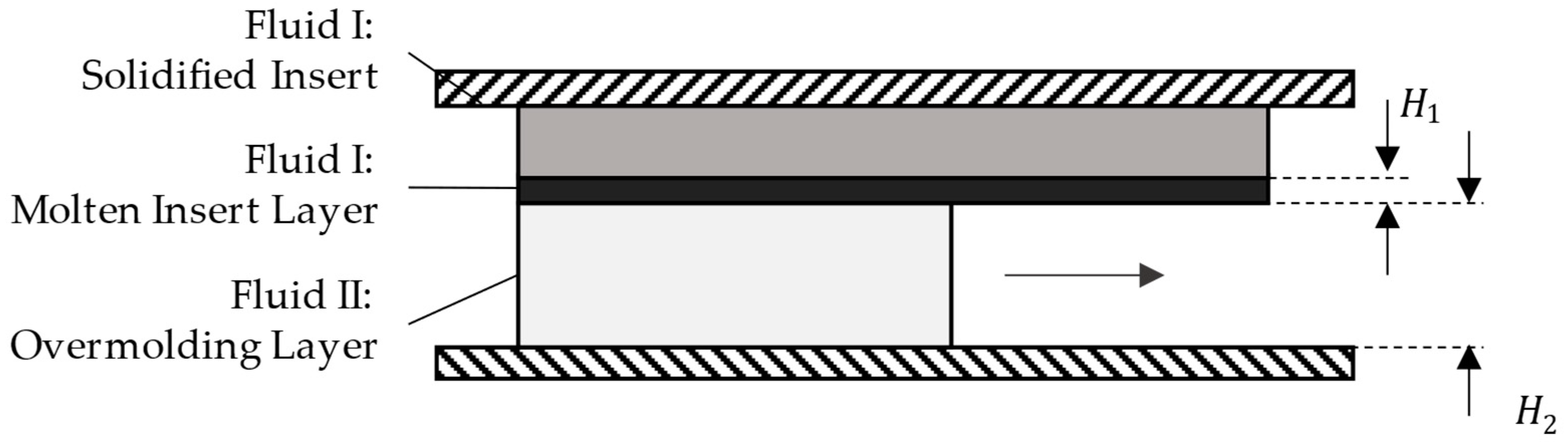

1. Introduction

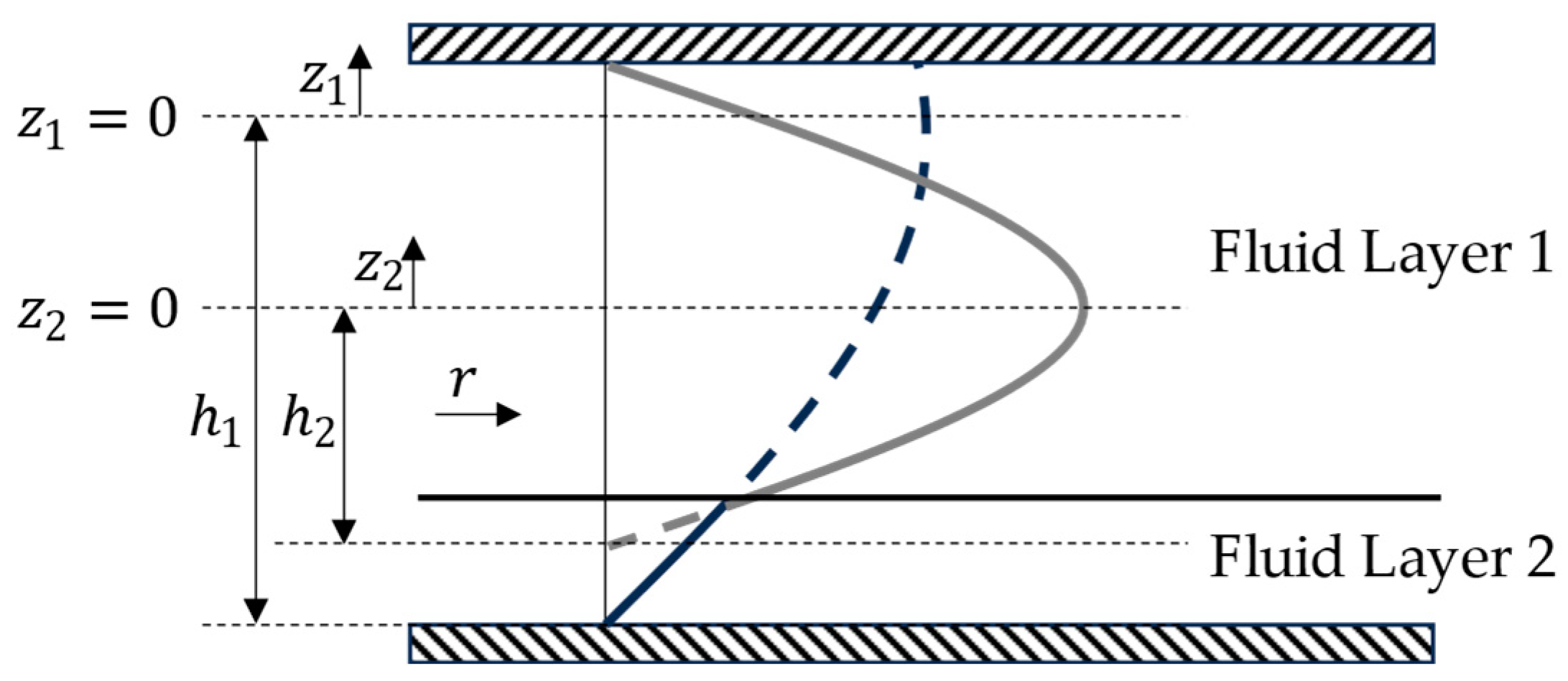

2. A Model for the Transverse Flow of Composite Inserts

3. Constitutive Equations for Squeeze Flow of Two Layered Power-Law Fluids

4. Solution and Model Validation

4.1. Resulting Solution and Dimensionless Numbers of the Model

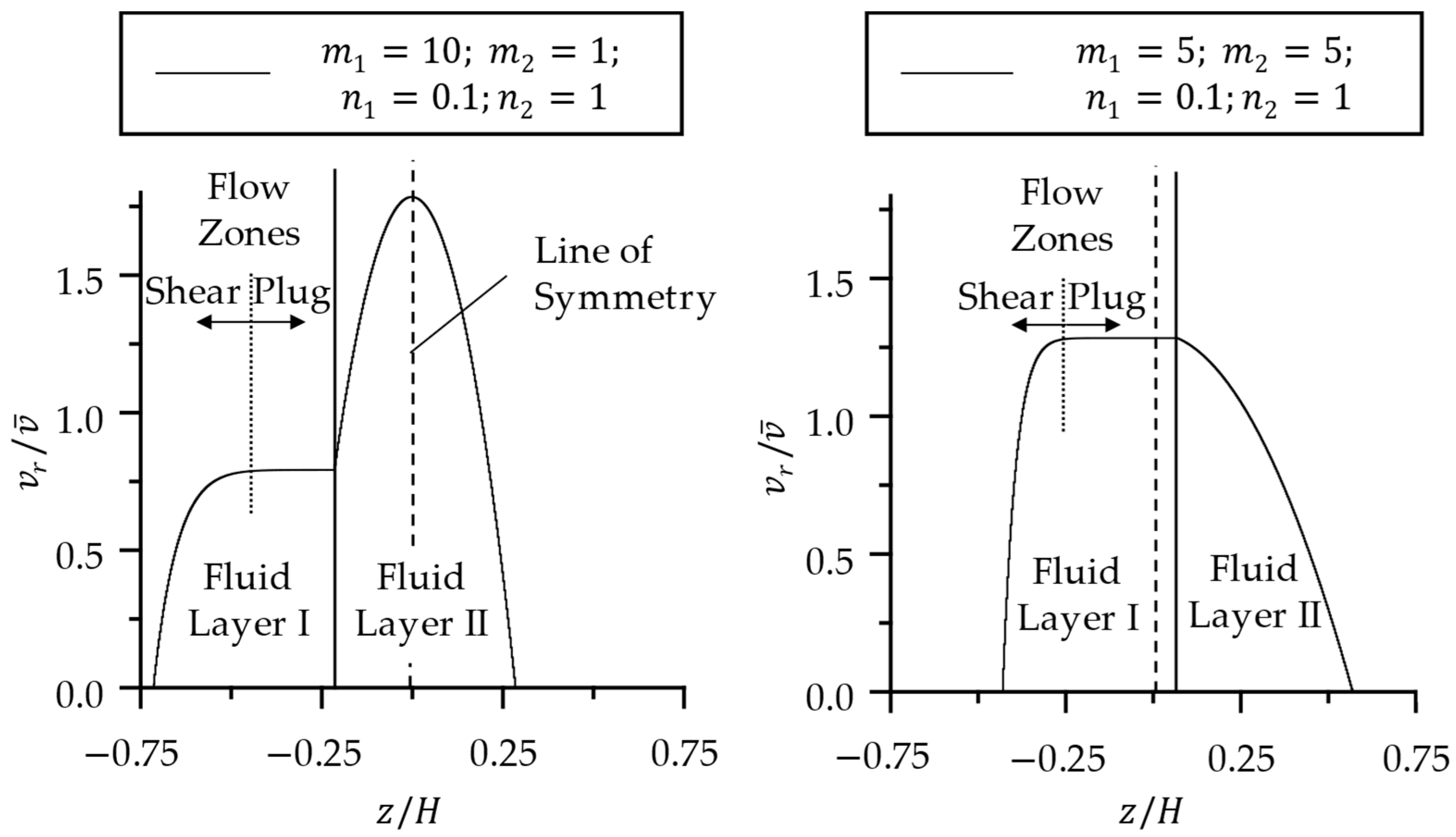

4.2. Model Validation—Flow Fields

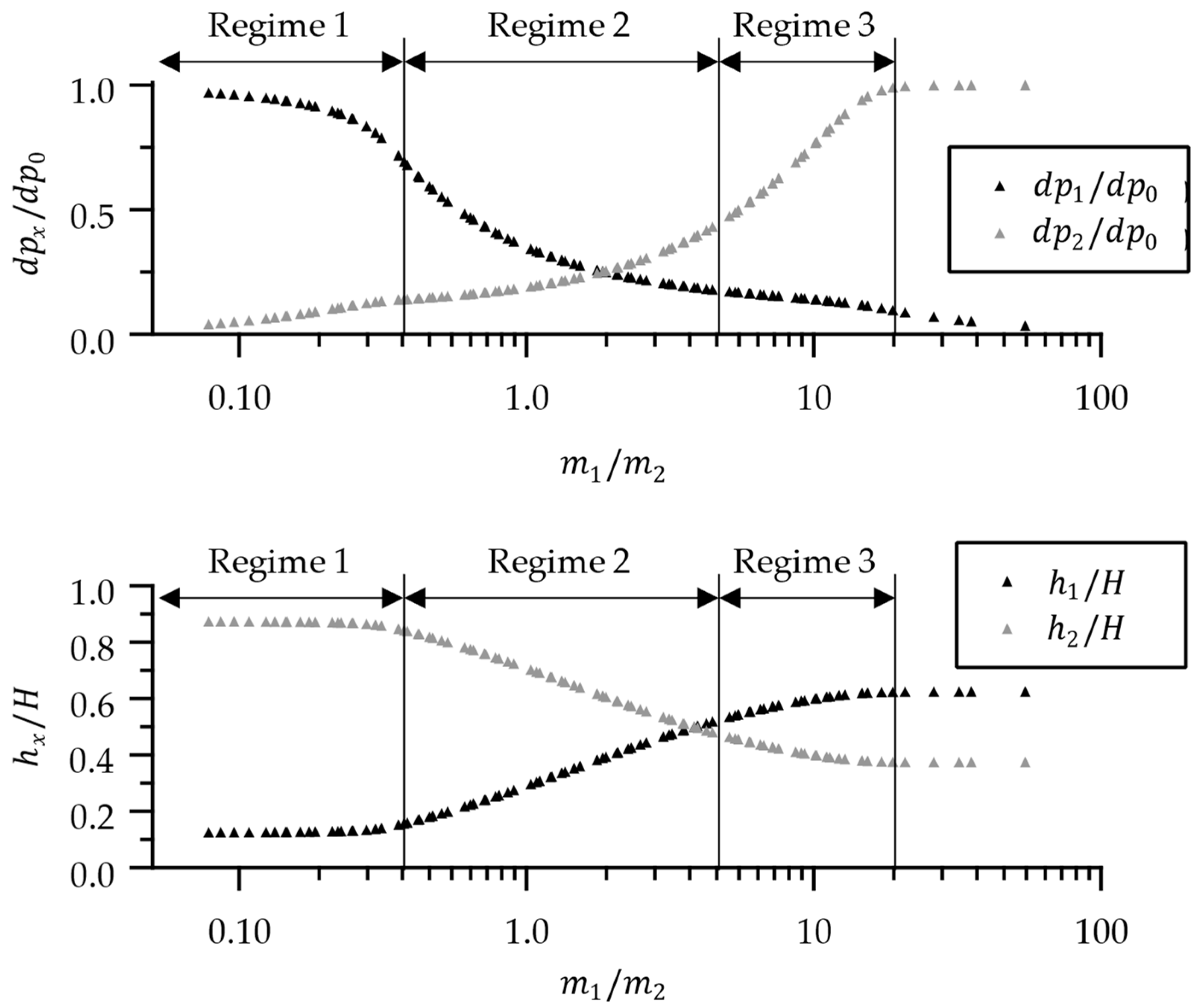

4.3. Effect of Newtonian and Non-Newtonian Layer Combinations

5. Implications for the Application of Tailored Reinforcement Inserts

5.1. Flow Behavior of Pseudo-Plastic Inserts

5.2. Processing Window Resutling from Part and Material Designs

5.3. Model-Based Optimization of Process and Part Design

5.4. Comparison to Applications and Experimental Results

6. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A review of carbon fiber materials in automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Mehl, K.; Schmeer, S.; Motsch-Eichmann, N.; Bauer, P.; Müller, I.; Hausmann, J. Structural Optimization of Locally Continuous Fiber-Reinforcements for Short Fiber-Reinforced Plastics. J. Compos. Sci. 2021, 5, 118. [Google Scholar] [CrossRef]

- Lowe, J. Woodhead Publishing Series in Textiles, Design and Manufacture of Textile Composites; Long, A.C., Ed.; Woodhead Publishing: Cambridge, UK, 2005; Chapter 11; pp. 405–423. [Google Scholar]

- Jespersen, S.T. Methodology for evaluating new high volume composite manufacturing technologies. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2008. [Google Scholar] [CrossRef]

- Lässig, R.; Eisenhut, M.; Mathias, A.; Schulte, R.T.; Peters, F.; Kühmann, T.; Waldmann, T.; Begemann, W. Serienproduktion von hochfesten Faserverbundbauteilen: Perspektiven für den Deutschen Maschinen- und Anlagenbau; Roland Berger: Munich, Germany, 2012. [Google Scholar]

- Akkerman, R.; Bouwman, M.; Wijskamp, S. Analysis of the Thermoplastic Composite Overmolding Process: Interface Strength. Front. Mater. 2020, 7, 27. [Google Scholar] [CrossRef]

- Bird, R.B.; Armstrong, R.C.; Hassager, O. Dynamics of Polymeric Liquids, 2nd ed.; Wiley: New York, NY, USA, 2010. [Google Scholar]

- Gibson, A.G.; Toll, S. Mechanics of the squeeze flow of planar fibre suspensions. J. Non-Newton. Fluid Mech. 1999, 82, 1–24. [Google Scholar] [CrossRef]

- Nadai, A.; Hodge, P. Theory of Flow and Fracture of Solids, vol. II. J. Appl. Mech. 1963, 30, 640. [Google Scholar] [CrossRef]

- Servais, C.; Luciani, A.; Manson, J.E. Squeeze flow of concentrated long fibre suspensions: Experiments and model. J. Non-Newton. Fluid Mech. 2002, 104, 165–184. [Google Scholar] [CrossRef]

- Coussot, P. Yield stress fluid flows: A review of experimental data. J. Non-Newton. Fluid Mech. 2014, 211, 31–49. [Google Scholar] [CrossRef]

- Yang, F.; Pitchumani, R. Healing of Thermoplastic Polymers at an Interface under Nonisothermal Conditions. Macromolecules 2002, 35, 3213–3224. [Google Scholar] [CrossRef]

- Tierney, J.; Gillespie, J.W. Modeling of In Situ Strength Development for the Thermoplastic Composite Tow Placement Process. J. Compos. Mater. 2006, 40, 1487–1506. [Google Scholar] [CrossRef]

- Lee, W.I.; Springer, G.S. A Model of the Manufacturing Process of Thermoplastic Matrix Composites. J. Compos. Mater. 1987, 21, 1017–1055. [Google Scholar] [CrossRef]

- Barnes, J.A.; Cogswell, F.N. Transverse flow processes in continuous fibre-reinforced thermoplastic composites. Composites 1989, 20, 38–42. [Google Scholar] [CrossRef]

- Jones, R.S.; Wheeler, A.B. Transverse Flow of Fibre-Reinforced Composites. In Third European Rheology Conference and Golden Jubilee Meeting of the British Society of Rheology; Springer: Berlin/Heidelberg, Germany, 1990; pp. 258–260. [Google Scholar]

- Heinle, M.; Drummer, D. Measuring mechanical stresses on inserts during injection molding. Adv. Mech. Eng. 2015, 7, 1–6. [Google Scholar] [CrossRef]

- Lee, S.J.; Peleg, M. Lubricated and nonlubricated squeezing flow of a double layered array of two power-law liquids. Rheol. Acta 1990, 29, 360–365. [Google Scholar] [CrossRef]

- Aliyeva, N.; Sas, H.S.; Okan, B.S. Recent developments on the overmolding process for the fabrication of thermoset and thermoplastic composites by the integration of nano/micron-scale reinforcements. Compos. Part A 2021, 149, 106525. [Google Scholar] [CrossRef]

- Polychronopoulos, N.D.; Vlachopoulos, J. Polymer Processing and Rheology. In Polymers and Polymeric Composites: A Reference Series Book Series; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Giusti, R.; Lucchetta, G. Analysis of the welding strength in hybrid polypropylene composites as a function of the forming and overmolding parameters. Polym. Eng. Sci. 2017, 58, 592–600. [Google Scholar] [CrossRef]

- Joppich, T.; Menrath, A.; Henning, F. Advanced Molds and Methods for the Fundamental Analysis of Process Induced Interface Bonding Properties of Hybrid, Thermoplastic Composites. Procedia CIRP 2017, 66, 137–142. [Google Scholar] [CrossRef]

- Fu, L.; Ding, Y.; Weng, C.; Zhai, Z.; Jiang, B. Effect of working temperature on the interfacial behavior of overmolded hybrid fiber reinforced polypropylene composites. Polymer Testing 2020, 91, 106870. [Google Scholar] [CrossRef]

- Andrzejewski, J. The Use of Recycled Polymers for the Preparation of Self-Reinforced Composites by the Overmolding Technique: Materials Performance Evaluation. Sustainability 2023, 15, 11318. [Google Scholar] [CrossRef]

- Joo, S.-J.; Yu, M.-H.; Kim, W.S.; Lee, J.-W.; Kim, H.-S. Design and manufacture of automotive composite front bumper assemble component considering interfacial bond characteristics between over-molded chopped glass fiber polypropylene and continuous glass fiber polypropylene composite. Compos. Struct. 2020, 236, 111849. [Google Scholar] [CrossRef]

- Matsumoto, K.; Ishikawa, T.; Tanaka, T. A novel joining method by using carbon nanotube-based thermoplastic film for injection over-molding process. J. Reinf. Plast. Compos. 2019, 38, 616–627. [Google Scholar] [CrossRef]

- Stefan, J. Versuche über die scheinbare Adhäsion. Ann. Physik. 1875, 230, 316–318. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Picard, P.K.W.; Osswald, T.A.; Zaremba, S.; Drechsler, K. Modeling of a Process Window for Tailored Reinforcements in Overmolding Processes. J. Compos. Sci. 2024, 8, 65. https://doi.org/10.3390/jcs8020065

Picard PKW, Osswald TA, Zaremba S, Drechsler K. Modeling of a Process Window for Tailored Reinforcements in Overmolding Processes. Journal of Composites Science. 2024; 8(2):65. https://doi.org/10.3390/jcs8020065

Chicago/Turabian StylePicard, Philipp K. W., Tim A. Osswald, Swen Zaremba, and Klaus Drechsler. 2024. "Modeling of a Process Window for Tailored Reinforcements in Overmolding Processes" Journal of Composites Science 8, no. 2: 65. https://doi.org/10.3390/jcs8020065

APA StylePicard, P. K. W., Osswald, T. A., Zaremba, S., & Drechsler, K. (2024). Modeling of a Process Window for Tailored Reinforcements in Overmolding Processes. Journal of Composites Science, 8(2), 65. https://doi.org/10.3390/jcs8020065