Use of Pressure in Rotational Molding to Reduce Cycle Times: Comparison of the Thermomechanical Behavior of Rotomolded Reed/Polyethylene Composites

Abstract

1. Introduction

- Introduction of the material inside the mold

- Rotational molding itself: the mold is introduced into an oven and the rotation starts. During this time, the internal air temperature is usually monitored, observing three stages:

- Induction, where the material starts increasing temperature.

- Sintering, the powder starts melting and sticking in the mold walls.

- Densification: the temperature increases quickly, until reaching the peak internal air temperature (PIAT), which is the maximum temperature reached in the process, and the molten material is consolidated. In this stage, air bubbles trapped in the molten material migrate towards the inside of the part and escape through the mold vent [12,13,14]

- Once the desired temperature is reached, the mold is removed from the oven, while still rotating, and the cooling stage starts.

- Demolding of the part, once the polymer is solidified, the part is extracted from the mold.

2. Materials and Methods

2.1. Materials

2.2. Rotational Molding Trials

2.3. Materials Characterization

3. Results and Discussion

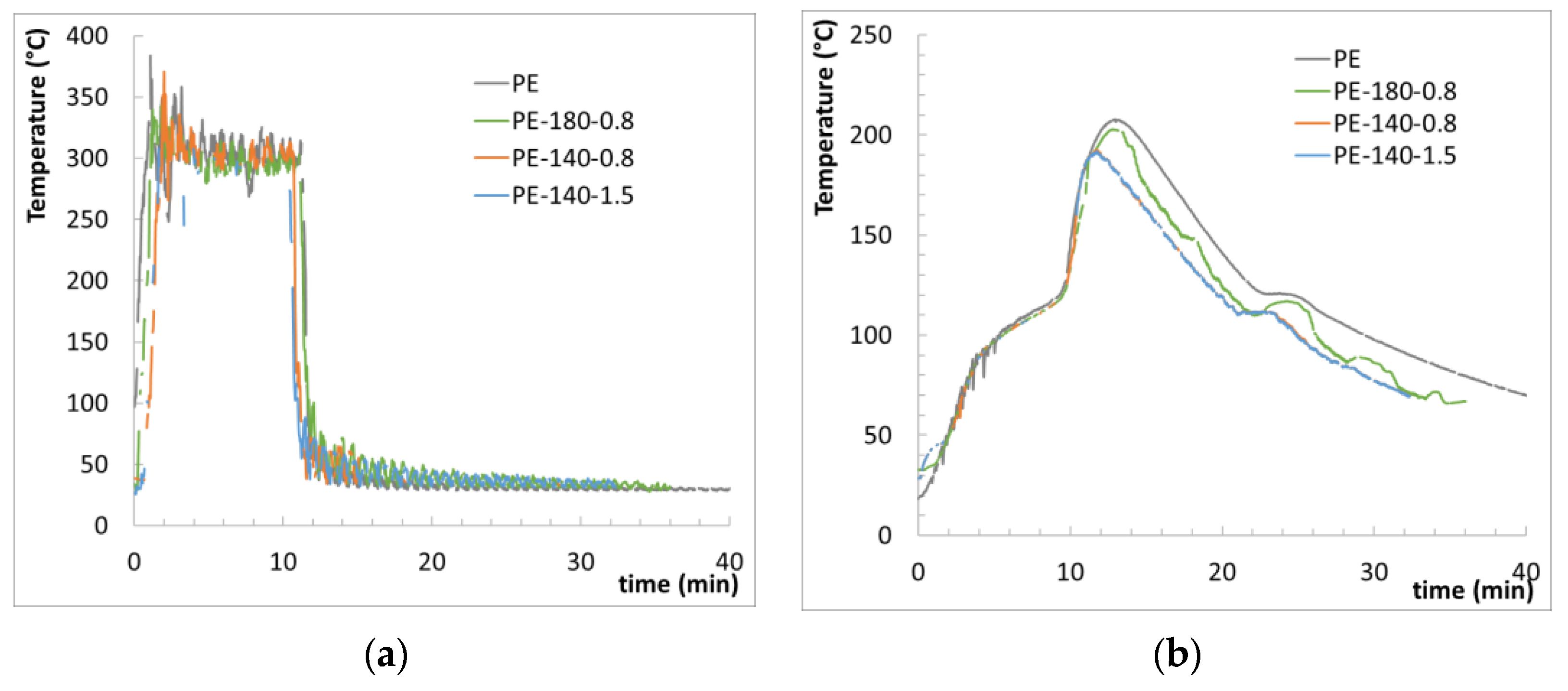

3.1. Cycle Time Analysis

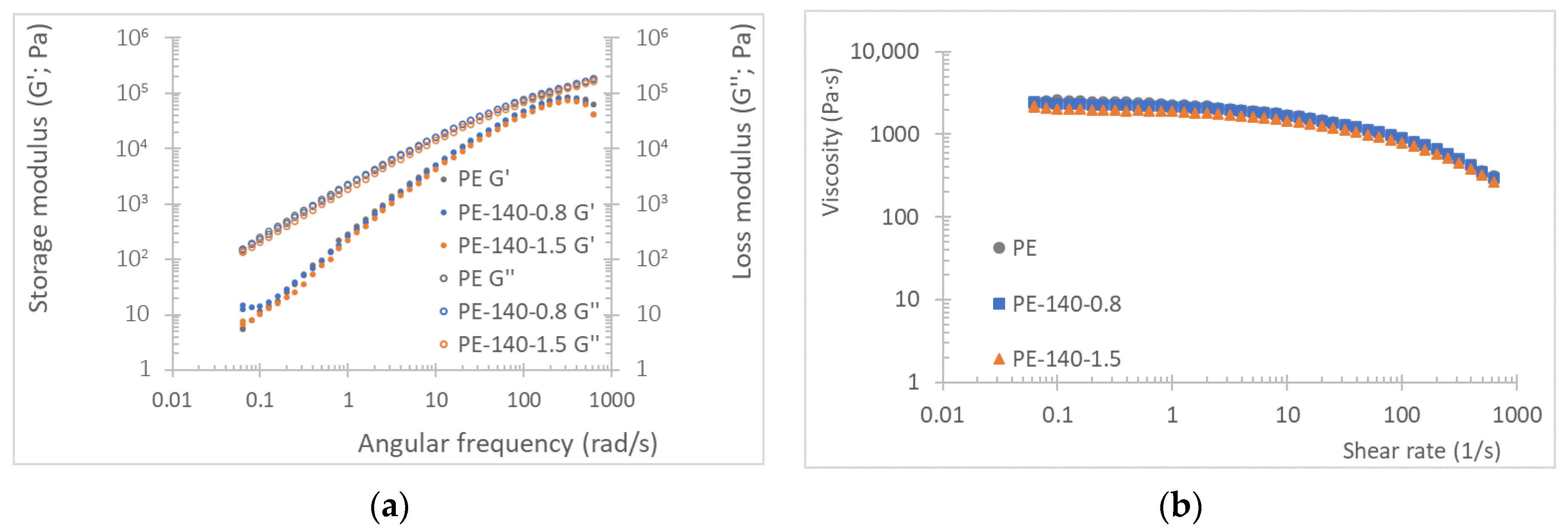

3.2. Rheology Assessment of Rotomolded Samples

3.3. Thermomechanical Performance of Rotomolded Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gogos, C.; Tadmor, Z. Principles of Polymer Processing, 1st ed.; John Wiley & Sons, Inc.: Toronto, ON, Canada, 1979; Volume 1. [Google Scholar]

- Crawford, R.J. Kearns, M.P. Practical Guide to Rotational Moulding, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 9780128224069. [Google Scholar]

- Cramez, M.C.; Oliveira, M.J.; Crawford, R.J. Optimization of the Rotational Moulding Process for Polyolefins. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2003, 217, 323–334. [Google Scholar] [CrossRef]

- Billmeyer, F. Textbook of Polymer Science, 3rd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1984. [Google Scholar]

- Rotomolding Market|Global Industry Report 2023. Available online: https://www.transparencymarketresearch.com/rotomolding-market.html (accessed on 5 December 2022).

- Shirinbayan, M.; Montazeri, A.; Nouri Sedeh, M.; Abbasnezhad, N.; Fitoussi, J.; Tcharkhrtchi, A. Rotational Molding of Polyamide-12 Nanocomposites: Modeling of the Viscoelastic Behavior. Int. J. Mater. Form. 2021, 14, 143–152. [Google Scholar] [CrossRef]

- Lucas, A.; Danlos, A.; Shirinbayan, M.; Motaharinejad, V.; Paridaens, R.; Benfriha, K.; Bakir, F.; Tcharkhtchi, A. Conventional Rotational Molding Process and Aerodynamic Characteristics of an Axial-Flow Hollow Blades Rotor. Int. J. Adv. Manuf. Technol. 2019, 104, 1183–1194. [Google Scholar] [CrossRef]

- Pereira, M.; Zirak, N.; Shirinbayan, M.; Zywica, G.; Tcharkhtchi, A. Design, Fabrication, and Evaluation of a Small Turbine Blade Manufactured by Rotational Molding. Int. J. Adv. Manuf. Technol. 2023, 128, 3441–3450. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Andrzejewski, J.; Kosmela, P.; Piasecki, A.; Szostak, M.; Kuang, T. Rotational Molding of Linear Low-Density Polyethylene Composites Filled with Wheat Bran. Polymer 2020, 12, 1004. [Google Scholar] [CrossRef]

- Greco, A.; Ferrari, F.; Maffezzoli, A. Processing of Super tough Plasticized PLA by Rotational Molding. Adv. Polym. Technol. 2019, 2019, 3835829. [Google Scholar] [CrossRef]

- Greco, A.; Maffezzoli, A. Rotational Molding of Biodegradable Composites Obtained with PLA Reinforced by the Wooden Backbone of Opuntia Ficus Indica Cladodes. J. Appl. Polym. Sci. 2015, 132, 42447. [Google Scholar] [CrossRef]

- Ogila, K.O.; Shao, M.; Yang, W.; Tan, J. Rotational Molding: A Review of the Models and Materials. Express Polym. Lett. 2017, 11, 778–798. [Google Scholar] [CrossRef]

- Chaudhary, B.I.; Takács, E.; Vlachopoulos, J. Processing Enhancers for Rotational Molding of Polyethylene. Polym. Eng. Sci. 2001, 41, 1731–1742. [Google Scholar] [CrossRef]

- Bellehumeur, C.T.; Bisaria, M.K.; Vlachopoulos, J. An Experimental Study and Model Assessment of Polymer Sintering. Polym. Eng. Sci. 1996, 36, 2198–2207. [Google Scholar] [CrossRef]

- Greco, A.; Maffezzoli, A.; Forleo, S. Rotational Molding of Bio-Polymers. In Proceedings of the PPS-29—AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2014; Volume 1593, pp. 333–337. [Google Scholar]

- Hanana, F.E.; Chimeni, D.Y.; Rodrigue, D. Morphology and Mechanical Properties of Maple Reinforced LLDPE Produced by Rotational Moulding: Effect of Fibre Content and Surface Treatment. Polym. Polym. Compos. 2018, 26, 299–308. [Google Scholar] [CrossRef]

- Suárez, L.; Ortega, Z.; Romero, F.; Paz, R.; Marrero, M.D. Influence of Giant Reed Fibers on Mechanical, Thermal, and Disintegration Behavior of Rotomolded PLA and PE Composites. J. Polym. Env. 2022, 30, 4848–4862. [Google Scholar] [CrossRef]

- Ortega, Z.; Romero, F.; Paz, R.; Suárez, L.; Benítez, A.N.; Marrero, M.D. Valorization of Invasive Plants from Macaronesia as Filler Materials in the Production of Natural Fiber Composites by Rotational Molding. Polymer 2021, 13, 2220. [Google Scholar] [CrossRef] [PubMed]

- Cisneros-López, E.O.; Pérez-Fonseca, A.A.; González-García, Y.; Ramírez-Arreola, D.E.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Polylactic Acid-Agave Fiber Biocomposites Produced by Rotational Molding: A Comparative Study with Compression Molding. Adv. Polym. Technol. 2018, 37, 2528–2540. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Krawczak, A.; Wesoły, K.; Szostak, M. Rotational Molding of Biocomposites with Addition of Buckwheat Husk Filler. Structure-Property Correlation Assessment for Materials Based on Polyethylene (PE) and Poly(Lactic Acid) PLA. Compos. B Eng. 2020, 202, 108410. [Google Scholar] [CrossRef]

- Ortega, Z.; Suárez, L.; Kelly-Walley, J.; McCourt, M. Mechanical Properties of Rotomolded Parts with Abaca Fiber: Effect of Manufacturing with 1, 2 or 3 Layers. Compos. Theory Pract. 2023, 3, 158–166. [Google Scholar]

- Aniśko, J.; Barczewski, M. Uniaxial Rotational Molding of Bio-Based Low-Density Polyethylene Filled with Black Tea Waste. Materials 2023, 16, 3641. [Google Scholar] [CrossRef]

- Szostak, M.; Tomaszewska, N.; Kozlowski, R. Mechanical and Thermal Properties of Rotational Molded PE/Flax and PE/Hemp Composites. Lect. Notes Mech. Eng. 2019, 495–506. [Google Scholar] [CrossRef]

- Cestari, S.P.; Martin, P.J.; Hanna, P.R.; Kearns, M.P.; Mendes, L.C.; Millar, B. Use of Virgin/Recycled Polyethylene Blends in Rotational Moulding. J. Polym. Eng. 2021, 41, 509–516. [Google Scholar] [CrossRef]

- Pick, L.; Hanna, P.R.; Gorman, L. Assessment of Processibility and Properties of Raw Post-Consumer Waste Polyethylene in the Rotational Moulding Process. J. Polym. Eng. 2022, 42, 374–383. [Google Scholar] [CrossRef]

- Aniśko, J.; Barczewski, M.; Mietliński, P.; Piasecki, A.; Szulc, J. Valorization of Disposable Polylactide (PLA) Cups by Rotational Molding Technology: The Influence of Pre-Processing Grinding and Thermal Treatment. Polym. Test. 2022, 107, 107481. [Google Scholar] [CrossRef]

- Arribasplata-Seguin, A.; Quispe-Dominguez, R.; Tupia-Anticona, W.; Acosta-Sullcahuamán, J. Rotational Molding Parameters of Wood-Plastic Composite Materials Made of Recycled High Density Polyethylene and Wood Particles. Compos. B Eng. 2021, 217, 108876. [Google Scholar] [CrossRef]

- Dou, Y.; Rodrigue, D. Morphological, Thermal and Mechanical Properties of Recycled HDPE Foams via Rotational Molding. J. Cell. Plast. 2022, 58, 305–323. [Google Scholar] [CrossRef]

- McCourt, M.; Kearns, M.P.; Martin, P.; Butterfield, J. A Comparison between Conventional and Robotic Rotational Moulding Machines. In Proceedings of the IMC34—34th International Manufacturing Conference At: Sligo Institute of Technology, Sligo, Ireland, 30–31 August 2017. [Google Scholar]

- Ortega, F.; Sova, A.; Monzón, M.D.; Marrero, M.D.; Benítez, A.N.; Bertrand, P. Combination of Electroforming and Cold Gas Dynamic Spray for Fabrication of Rotational Moulds: Feasibility Study. Int. J. Adv. Manuf. Technol. 2015, 76, 1243–1251. [Google Scholar] [CrossRef]

- Luciano, G.; Vignolo, M.; Brunengo, E.; Utzeri, R.; Stagnaro, P. Study of Microwave-Active Composite Materials to Improve the Polyethylene Rotomolding Process. Polymer 2023, 15, 1061. [Google Scholar] [CrossRef] [PubMed]

- León, L.D.V.E.; Escocio, V.A.; Visconte, L.L.Y.; Junior, J.C.J.; Pacheco, E.B.A.V. Rotomolding and Polyethylene Composites with Rotomolded Lignocellulosic Materials: A Review. J. Reinf. Plast. Compos. 2020, 39, 459–472. [Google Scholar] [CrossRef]

- Torres, F.G.; Aragon, C.L. Final Product Testing of Rotational Moulded Natural Fibre-Reinforced Polyethylene. Polym. Test. 2006, 25, 568–577. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-Treatment of Flax Fibers for Use in Rotationally Molded Biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Oliveira, M.A.S.; Pickering, K.L.; Sunny, T.; Lin, R.J.T. Treatment of Hemp Fibres for Use in Rotational Moulding. J. Polym. Res. 2021, 28, 53. [Google Scholar] [CrossRef]

- Ortega, Z.; Monzón, M.D.; Benítez, A.N.; Kearns, M.; McCourt, M.; Hornsby, P.R. Banana and Abaca Fiber-Reinforced Plastic Composites Obtained by Rotational Molding Process. Mater. Manuf. Process. 2013, 28, 130614085148001. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Effect of Particle Size, Fiber Content, and Surface Treatment on the Mechanical Properties of Maple-Reinforced LLDPE Produced by Rotational Molding. Polym. Polym. Compos. 2021, 29, 343–353. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Rotational Molding of Polymer Composites Reinforced with Natural Fibers. Plast. Eng. 2015, 71, 28–31. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Rotational Molding of Self-Hybrid Composites Based on Linear Low-Density Polyethylene and Maple Fibers. Polym. Compos. 2018, 39, 4094–4103. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; González-López, M.E.; Pérez-Fonseca, A.A.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of Fiber Content and Surface Treatment on the Mechanical Properties of Natural Fiber Composites Produced by Rotomolding. Compos. Interfaces 2017, 24, 35–53. [Google Scholar] [CrossRef]

- Fiore, V.; Botta, L.; Scaffaro, R.; Valenza, A.; Pirrotta, A. PLA Based Biocomposites Reinforced with Arundo Donax Fillers. Compos. Sci. Technol. 2014, 105, 110–117. [Google Scholar] [CrossRef]

- Suárez, L.; Castellano, J.; Romero, F.; Marrero, M.D.; Benítez, A.N.; Ortega, Z. Environmental Hazards of Giant Reed (Arundo donax L.) in the Macaronesia Region and Its Characterisation as a Potential Source for the Production of Natural Fibre Composites. Polymer 2021, 13, 2101. [Google Scholar] [CrossRef]

- Prathap, K. A Comparative Study on the Mechanical Properties of Arundo Donax Epoxy Composites with Bamboo Epoxy Composites. Int. J. Eng. Res. Technol. 2019, 8, V8. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Vitale, G.; Valenza, A. Static and Dynamic Mechanical Properties of Arundo Donax Fillers-Epoxy Composites. Mater. Des. 2014, 57, 456–464. [Google Scholar] [CrossRef]

- Scalici, T.; Fiore, V.; Valenza, A. Effect of Plasma Treatment on the Properties of Arundo Donax L. Leaf Fibres and Its Bio-Based Epoxy Composites: A Preliminary Study. Compos. B Eng. 2016, 94, 167–175. [Google Scholar] [CrossRef]

- Malnati, P. New Era for Rotomolding? Innovative Technology and Equipment Offer Superior Process Control and Produce Better Parts with Higher Repeatability and Reproducibility. Plast. Eng. 2019, 75, 10–13. [Google Scholar]

- Suárez, L.; Barczewski, M.; Kosmela, P.; Marrero, M.D.; Ortega, Z. Giant Reed (Arundo donax L.) Fiber Extraction and Characterization for Its Use in Polymer Composites. J. Nat. Fibers 2023, 20, 2131687. [Google Scholar] [CrossRef]

- Kubát, J.; Rigdahl, M.; Welander, M. Characterization of Interfacial Interactions in High Density Polyethylene Filled with Glass Spheres Using Dynamic-Mechanical Analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

- Jyoti, J.; Singh, B.P.; Arya, A.K.; Dhakate, S.R. Dynamic Mechanical Properties of Multiwall Carbon Nanotube Reinforced ABS Composites and Their Correlation with Entanglement Density, Adhesion, Reinforcement and C Factor. RSC Adv. 2016, 6, 3997–4006. [Google Scholar] [CrossRef]

- Panwar, V.; Pal, K. An Optimal Reduction Technique for RGO/ABS Composites Having High-End Dynamic Properties Based on Cole-Cole Plot, Degree of Entanglement and C-Factor. Compos. B Eng. 2017, 114, 46–57. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Kosmela, P.; Barczewski, M.; Hejna, A. Mechanical, Thermal and Rheological Properties of Polyethylene-Based Composites Filled with Micrometric Aluminum Powder. Materials 2020, 13, 1242. [Google Scholar] [CrossRef]

- Stanciu, M.D.; Teodorescu Draghicescu, H.; Tamas, F.; Terciu, O.M. Mechanical and Rheological Behaviour of Composites Reinforced with Natural Fibres. Polymer 2020, 12, 1402. [Google Scholar] [CrossRef]

- Correa-Aguirre, J.P.; Luna-Vera, F.; Caicedo, C.; Vera-Mondragón, B.; Hidalgo-Salazar, M.A. The Effects of Reprocessing and Fiber Treatments on the Properties of Polypropylene-Sugarcane Bagasse Biocomposites. Polymer 2020, 12, 1440. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Short Bamboo Fiber-Reinforced HDPE Composites: Influence of Fiber Content and Modification on Strength of the Composite. J. Reinf. Plast. Compos. 2010, 29, 2199–2210. [Google Scholar] [CrossRef]

| Short Name | Pressure (kPa) | IAT (°C) | Fiber Content (% Weight) |

|---|---|---|---|

| PE | Ambient | 180 | 0 |

| PE180-0.8 | 80 | 180 | 0 |

| PE140-0.8 | 80 | 140 | 0 |

| PE140-1.5 | 150 | 140 | 0 |

| 10A | Ambient | 180 | 10 |

| 20A | Ambient | 180 | 20 |

| 10A-0.8 | 80 | 140 | 10 |

| 20A-0.8 | 80 | 140 | 20 |

| Cycle | Oven Time | Cooling Time | Total Cycle Time | PIAT | Time to Reach PIAT | ||||

|---|---|---|---|---|---|---|---|---|---|

| (min) | Variation (%) | (min) | Variation (%) | (min) | Variation (%) | (°C) | (min) | Variation (%) | |

| PE | 11.9 | -- | 27.3 | -- | 40.3 | -- | 206.4 | 12.3 | -- |

| PE180-0.8 | 11.0 | −7.3 | 20.2 | −25.9 | 32.0 | −20.7 | 202.3 | 11.8 | −4.5 |

| PE140-0.8 | 10.6 | −11.2 | 20.7 | −24.0 | 32.3 | −19.9 | 190.2 | 11.5 | −6.2 |

| PE140-1.5 | 10.4 | −12.4 | 20.6 | −24.0 | 32.2 | −19.9 | 190.6 | 11.6 | −6.2 |

| 10A | 11.6 | −2.9 | 27.2 | −0.4 | 39.7 | −1.6 | 211.8 | 12.5 | 1.4 |

| 20A | 12.8 | 7.6 | 12.2 | −22.4 | 35.2 | −12.7 | 220.7 | 13.9 | 12.7 |

| 10A-0.8 | 10.8 | −9.2 | 21.0 | −23.1 | 32.7 | −18.8 | 199.3 | 11.8 | −4.6 |

| 20A-0.8 | 12.0 | 0.8 | 18.9 | −30.7 | 32.3 | −19.9 | 198.0 | 11.2 | −9.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega, Z.; Suárez, L.; Kelly-Walley, J.; Hanna, P.R.; McCourt, M.; Millar, B. Use of Pressure in Rotational Molding to Reduce Cycle Times: Comparison of the Thermomechanical Behavior of Rotomolded Reed/Polyethylene Composites. J. Compos. Sci. 2024, 8, 17. https://doi.org/10.3390/jcs8010017

Ortega Z, Suárez L, Kelly-Walley J, Hanna PR, McCourt M, Millar B. Use of Pressure in Rotational Molding to Reduce Cycle Times: Comparison of the Thermomechanical Behavior of Rotomolded Reed/Polyethylene Composites. Journal of Composites Science. 2024; 8(1):17. https://doi.org/10.3390/jcs8010017

Chicago/Turabian StyleOrtega, Zaida, Luis Suárez, Jake Kelly-Walley, Paul R. Hanna, Mark McCourt, and Bronagh Millar. 2024. "Use of Pressure in Rotational Molding to Reduce Cycle Times: Comparison of the Thermomechanical Behavior of Rotomolded Reed/Polyethylene Composites" Journal of Composites Science 8, no. 1: 17. https://doi.org/10.3390/jcs8010017

APA StyleOrtega, Z., Suárez, L., Kelly-Walley, J., Hanna, P. R., McCourt, M., & Millar, B. (2024). Use of Pressure in Rotational Molding to Reduce Cycle Times: Comparison of the Thermomechanical Behavior of Rotomolded Reed/Polyethylene Composites. Journal of Composites Science, 8(1), 17. https://doi.org/10.3390/jcs8010017