Ethiopian Bamboo Fiber Aging Process and Reinforcement: Advancing Mechanical Properties of Bamboo Fiber-Epoxy Composites for Automobile Applications

Abstract

:1. Introduction

- Urethane composites;

- Fiberglass composites;

- Formable Styrene Laminate composites;

- Corrugated Kraft Liner composites;

- Resonated Felt Headliner composites;

- Thermoplastic Felt Headliner composites [9].

- -

- High strength;

- -

- Energy intensity (the ability to absorb impact energy in the event of a collision);

- -

- Manufacturability (the ability to manufacture complex parts with a minimal number of operations);

- -

- Minimum car body weight (the lower the mass, the lower the gas flow, and the lower the number of congenital emissions);

- -

- Corrosion resistance;

- -

- Maintainability [13].

2. Materials and Procedures

2.1. Study Area

2.2. Technique of Sampling

2.3. Epoxy and Hardener

2.4. Polypropylene

2.5. Tensile Test

2.6. Flexural Test

2.7. Izod Impact Test

3. Results and Discussion

3.1. Mechanical Properties of BFEPCs

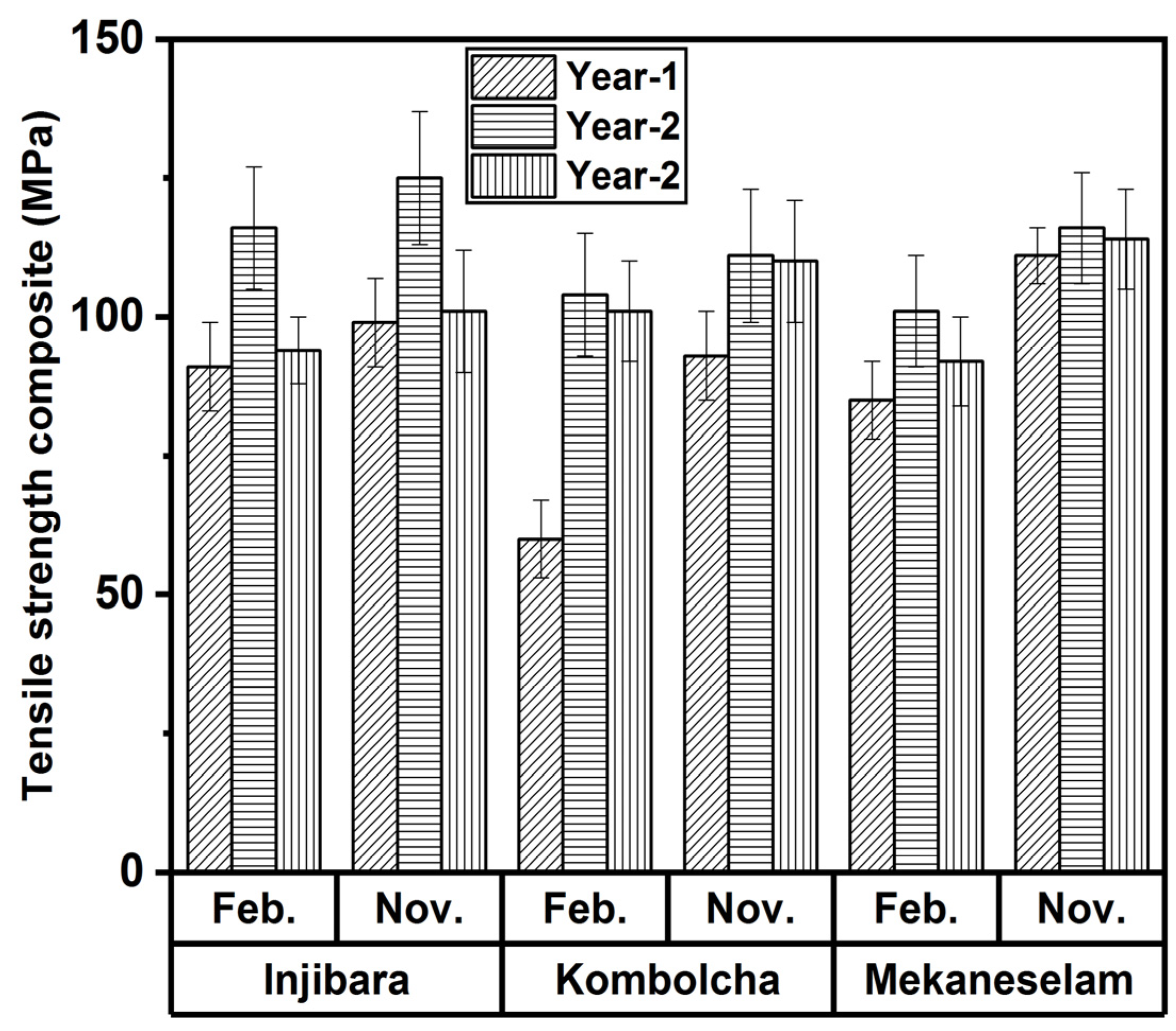

3.1.1. Tensile Strength of BFEPCs

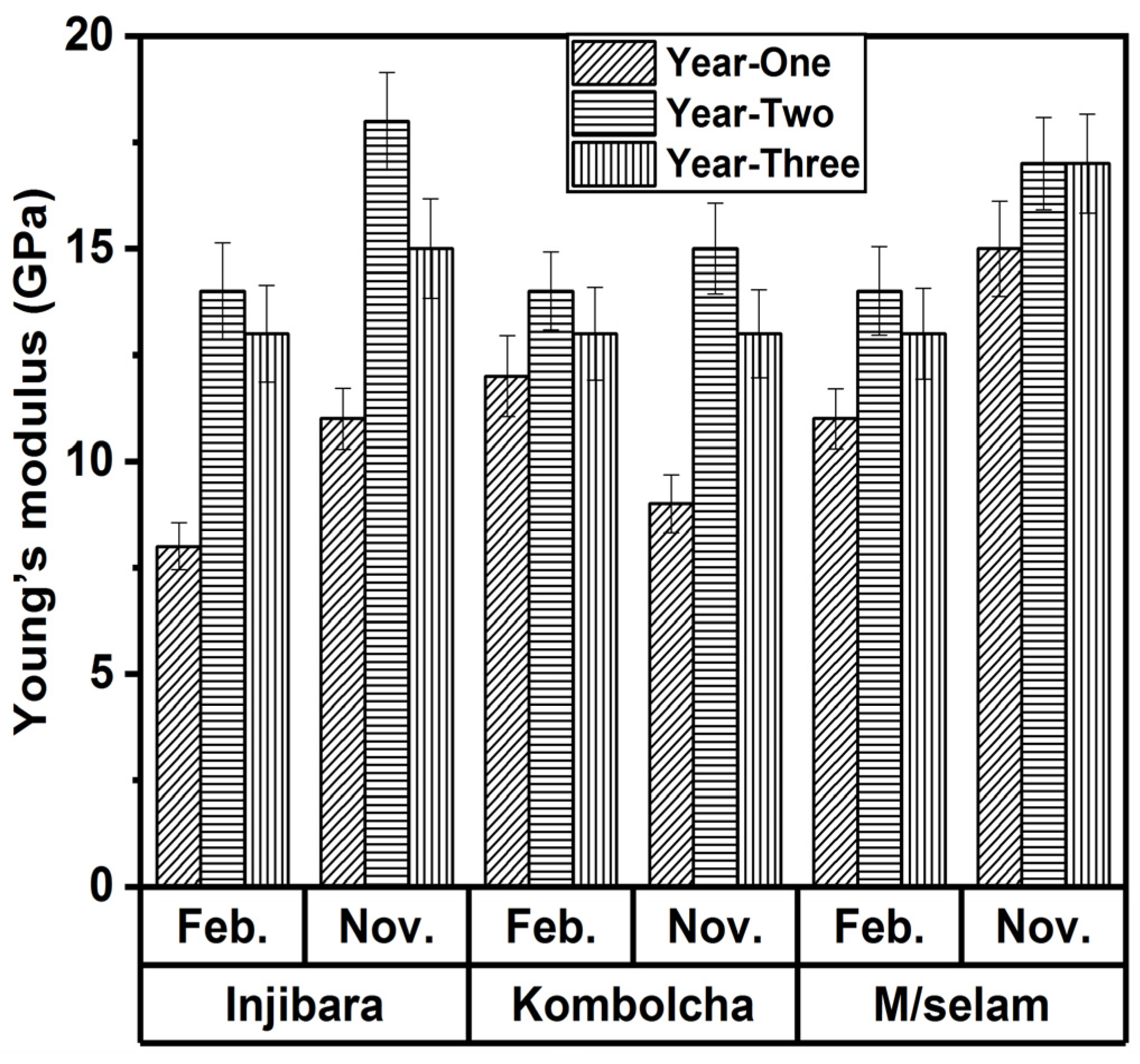

3.1.2. Tensile Modulus of BFEPCs

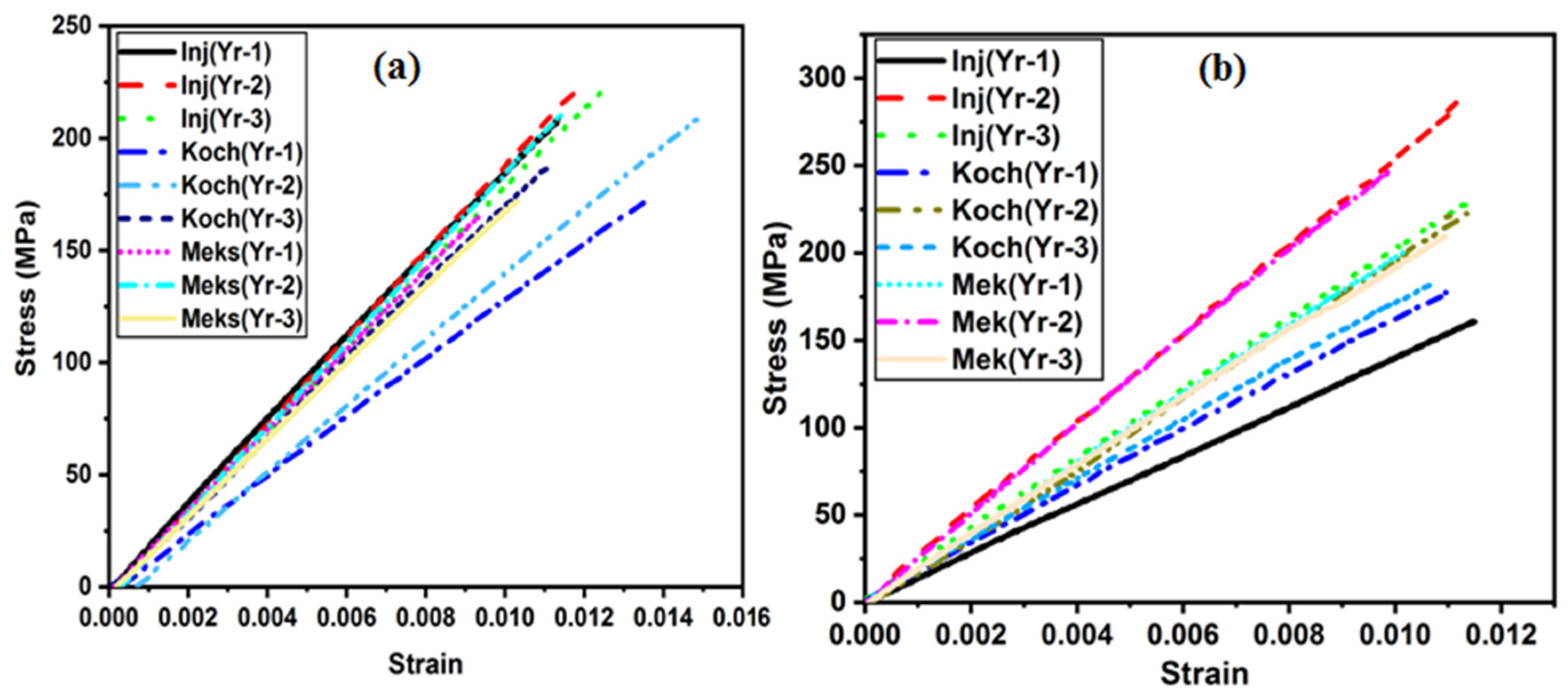

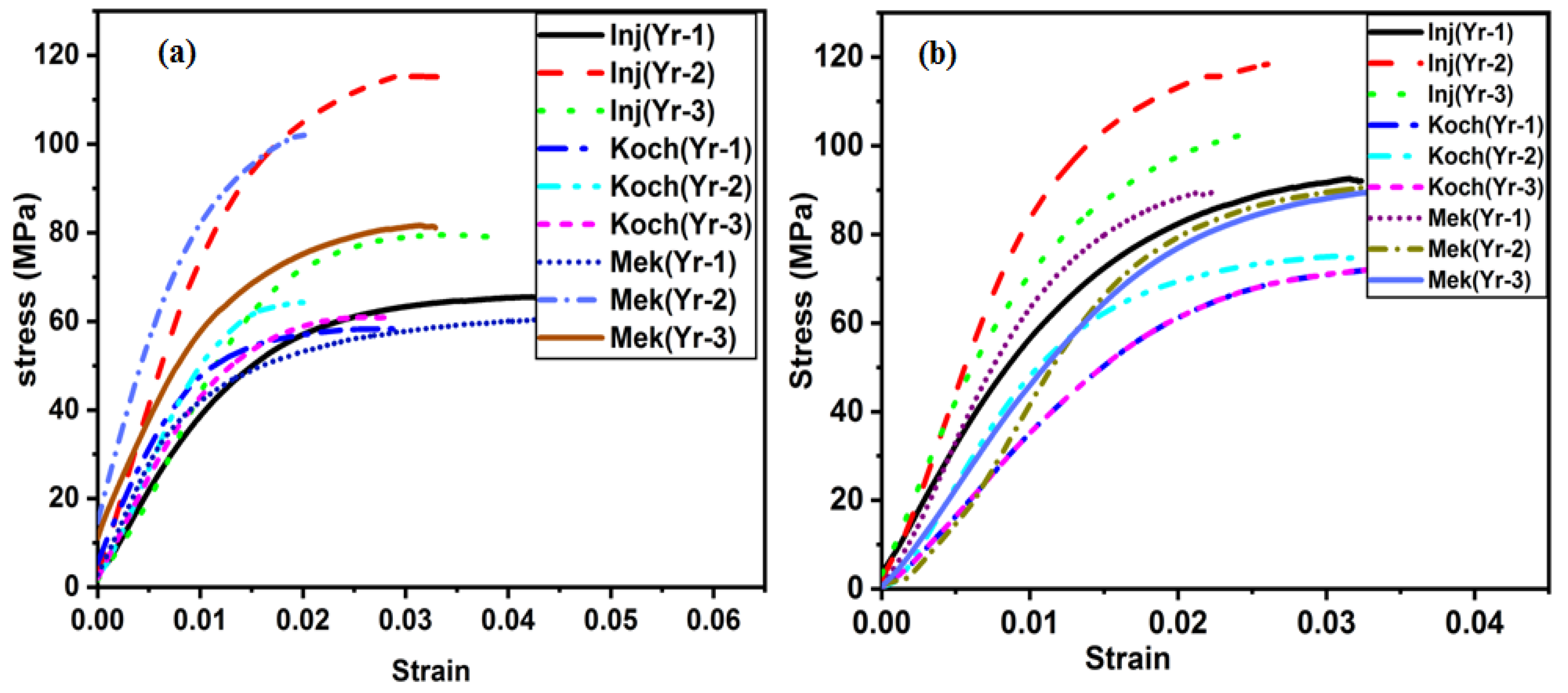

3.1.3. Stress-Strain of Ultimate Tensile Strength

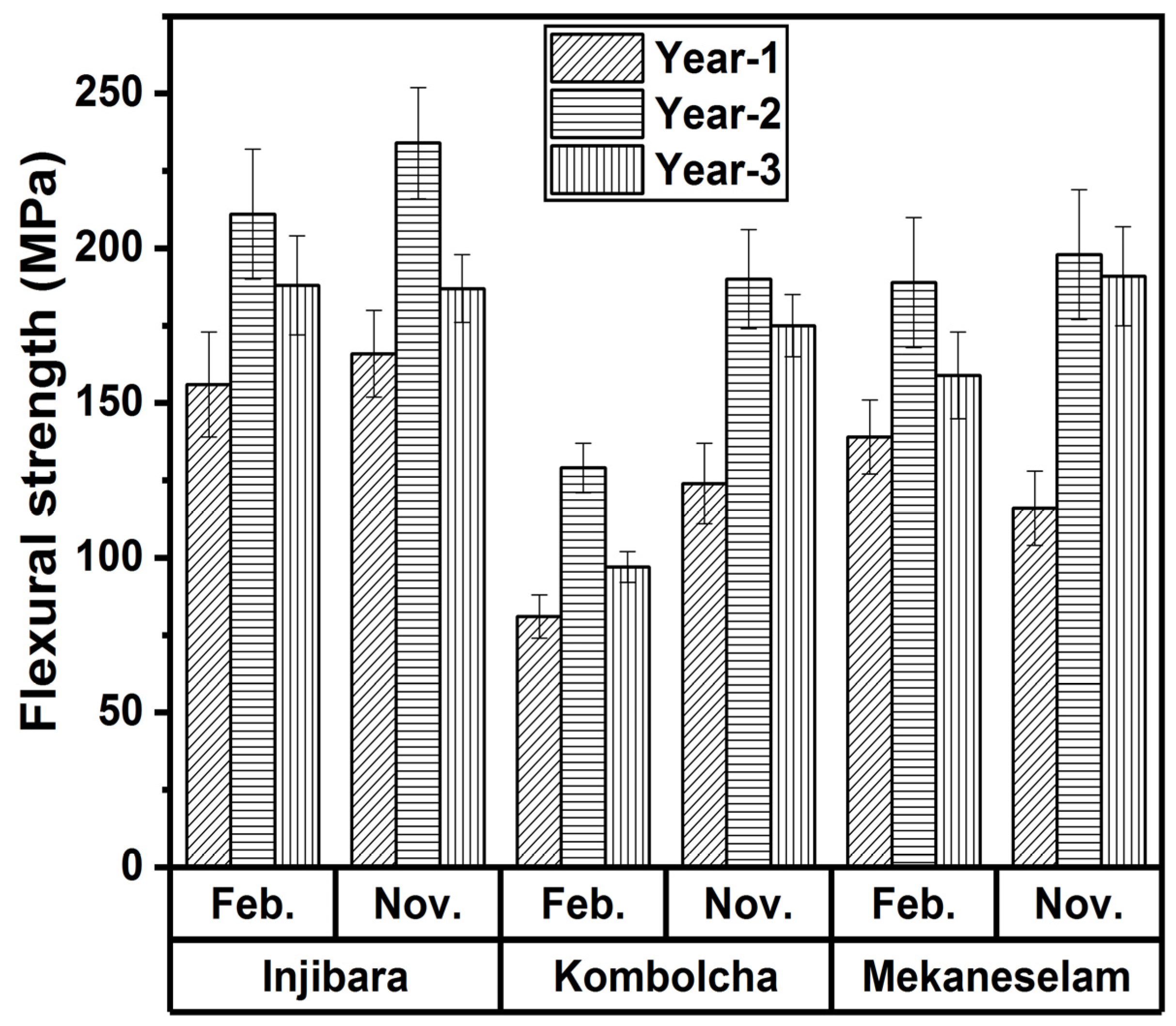

3.1.4. Flexural Strength of BFEPCs

3.1.5. Flexural Modulus of BFEPCs

3.1.6. Stress-Strain of Three-Point Bending Test

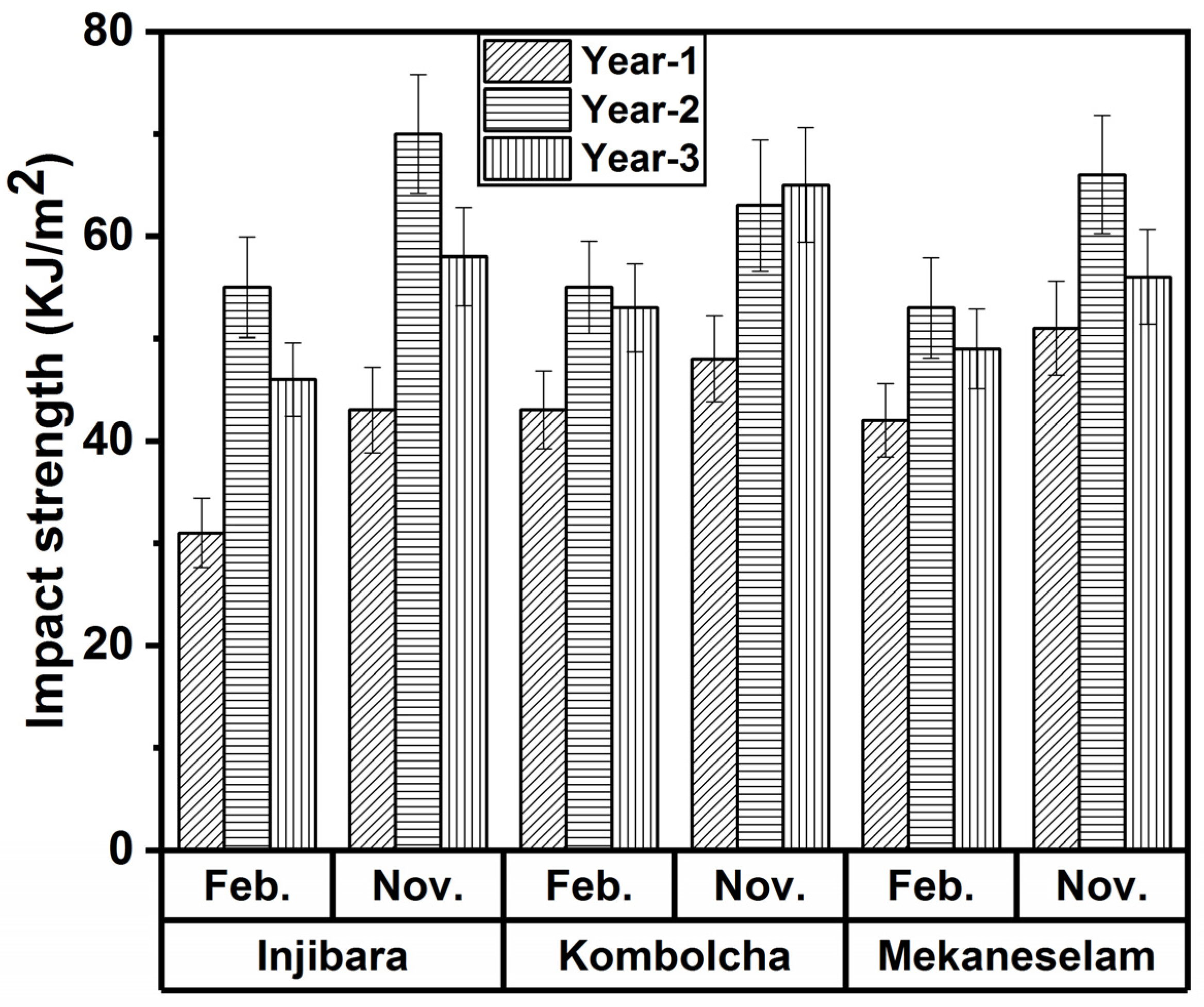

3.1.7. Impact Strength of BFEPCs

3.2. Mechanical Properties of BFPPCs

3.2.1. Tensile Strength of BFPPCs

3.2.2. Tensile Modulus of BFPPCs

| Composite Materials | Tensile Strength (MPa) | Young’s Modulus (GPa) | Strain to Failure (%) | Reference |

|---|---|---|---|---|

| GF epoxy | 330 | 3.29 | 0.1 | [33] |

| 10% jute felt PU | 4.15 | 0.104 | - | [40] |

| 10% carbon fibres PU | 14.86 | 0.156 | - | [40] |

| 10% Glass fibres mat PU | 4.51 | 0.066 | - | [40] |

| GFPU840871 composite | 351.77 | 19.53 | 0.024 | [34] |

| GFPU 90IK01 composite | 309.06 | 21.43 | 0.023 | [34] |

| 20% BPP | 21.92 | 2.31 | - | [27] |

| BFEP, Vf 65% | 87–165 | 3–15 | - | [28] |

| GFEP, Vf 65% | 180–220 | 5–10 | - | [28] |

| BFPP, 40% | 26.27 | 1.776 | - | [7] |

| BFEP | 86 | 6.736 | - | [29] |

| BFEP | 138.88 | 4.96 | 2.7 | [29] |

| BFPP, 39% | 16.9 | 2.9 | - | [25] |

| BFPP, 50% | 14.4 | 2.8 | - | [25] |

| BFPP | 40.25 | 1.29 | - | [21] |

| BFPP | 5.43 | 1.3 | - | [31] |

| PP foam | 20 | 0.795 | - | [16] |

| 40% E glass PU | 225 | 1.5 | - | [3] |

| Glass laminated | 321 | 5.166 | - | [17] |

| Glass laminated PE | 178 | 16.328 | 0.856 | [32] |

| PP foam | 23.83 | 1.528 | 4.29 | [15] |

| TPU | 26.27 | 20.84 | - | [32] |

| Inji-bara BFREP, Feb. | 191–206 | 17–19 | 1.07–1.13 | Study |

| Inji-bara BFREP, Nov. | 171–227 | 16–21 | 1.01–1.08 | Study |

| Inji-bara BFRPP, Feb. | 111–166 | 16.71–26.18 | 0.41–0.95 | Study |

| Inji-bara BFRPP, Nov. | 85–101 | 11.07–25.9 | 0.46–0.89 | Study |

| Kom-bolcha BFREP, Feb. | 139–198 | 11.31–18.1 | 1.16–1.35 | Study |

| Kom-bolcha BFREP, Nov. | 129–255 | 11.51–18.8 | 1.14–1.17 | Study |

| Kom-bolcha BFRPP, Feb. | 93–111 | 10.92–14.95 | 0.83–0.98 | Study |

| Kom-bolcha BFRPP, Nov. | 60–104 | 7.51–19.56 | 0.63–0.96 | Study |

| Mekane-selam BFREP, Feb. | 151–199 | 16.82–18.92 | 0.98–1.07 | Study |

| Mekane-selam BFREP, Nov. | 166–206 | 17.75–18.86 | 0.92–1.13 | Study |

| Mekane-selam BFRPP, Feb. | 99–125 | 9.82–17.85 | 0.76–1.32 | Study |

| Mekane-selam BFRPP, Nov. | 91–116 | 8.75–15.86 | 0.71–1.21 | Study |

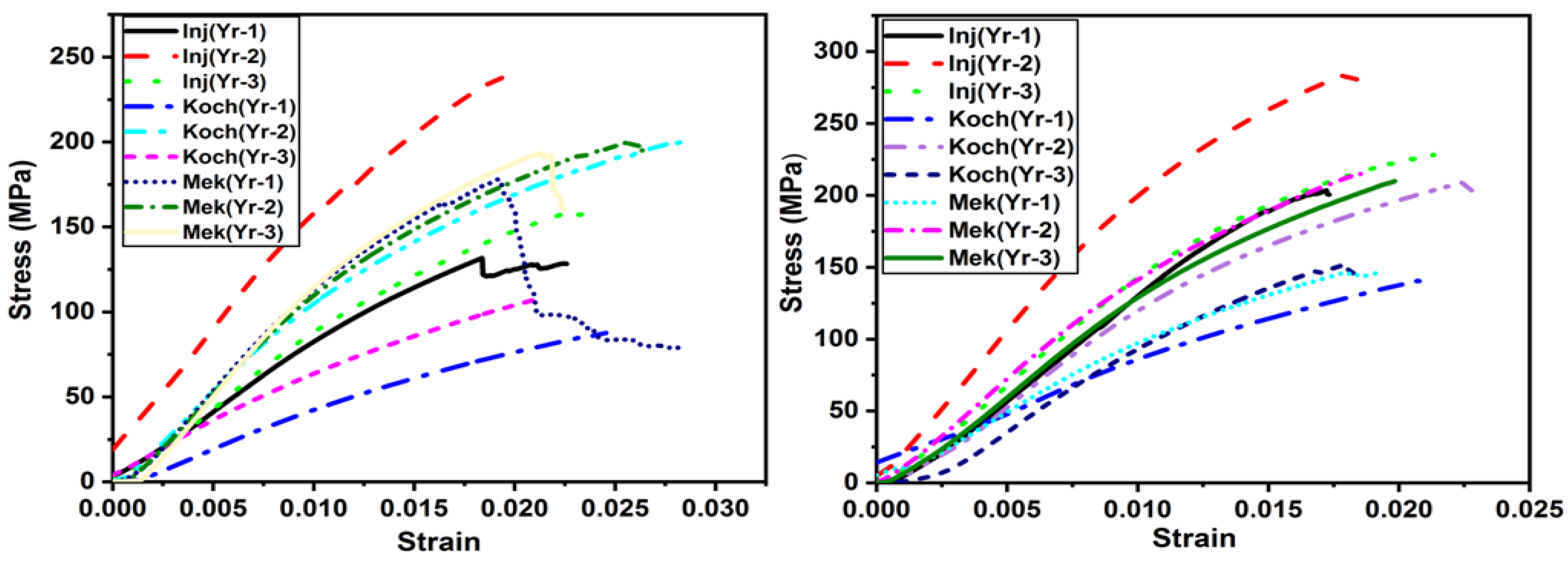

3.2.3. Stress-Strain of BFRPPCs

3.2.4. Flexural Strength of BFPPCs

3.2.5. Flexural Modulus of BFPPCs

| Composite Materials | FS (MPa) | MOE (GPa) | Strain to Failure (%) | Reference |

|---|---|---|---|---|

| GF epoxy | 255 | 8.47 | 0.0279 | [12] |

| 10% jute felt PU | 6.99 | 0.214 | - | [40] |

| 10% carbon fibres PU | 13.47 | 0.308 | - | [40] |

| 10% Glass fibres mat PU | 7.86 | 0.358 | - | [40] |

| GFPU840871 composite | 642.34 | 14.56 | 4.96 | [34] |

| FPU 90IK01 composite | 618.88 | 17.11 | 3.82 | [34] |

| UDMA | 133.8 | 1.8 | - | [12] |

| 20% BPP | 38.74 | 1.27 | - | [27] |

| BFEP, Vf 65% | 107–140 | 12–10 | - | [28] |

| GFEP, Vf 65% | 195–250 | 7–12 | - | [28] |

| BFPP, 40% | 46.6 | 2.432 | - | [7] |

| BFEP | 107 | 11.901 | - | [37] |

| BFEP | 119 | 11.901 | - | [29] |

| GFPE, vf 30% | 80 | 6.01 | 2.22 | [38] |

| BFPP | 43.8 | 1.975 | - | [21] |

| BFPP | 26.1 | 1.43 | - | [31] |

| 40% E glass PU | 95 | 0.50 | - | [3] |

| Glass laminated PE | 289 | 14.222 | - | [32] |

| Inji-bara BFEPCs, Feb. | 139–198 | 6.56–11.51 | 2.11–2.22 | Study |

| Inji-bara BFEPCs, Nov. | 116–191 | 4.73–10.49 | 2.01–2.31 | Study |

| Inji-bara BFPPCs, Feb. | 89–152 | 6.5–13.2 | 3.02–3.61 | Study |

| Inji-bara BFPPCs, Nov. | 105–127 | 6.8–13.4 | 3.31–4.25 | Study |

| Kom-bolcha BFEPCs, Feb. | 81–190 | 5.36–10.87 | 2.08–2.64 | Study |

| Kom-bolcha BFEPCs, Nov. | 124–175 | 8.05–12.18 | 1.96–2.05 | Study |

| Kom-bolcha BFPPCs, Feb. | 92–138 | 6.7–12.12 | 2.61–3.63 | Study |

| Kom-bolcha BFPPCs, Nov. | 113–159 | 13.6–19.4 | 2.61–3.02 | Study |

| Mekane-selam BFEPCs, Feb. | 188–234 | 14.37–19.06 | 1.75–2.07 | Study |

| Mekane-selam BFEPCs, Nov. | 156–187 | 11.09–13.88 | 1.96–2.05 | Study |

| Mekane-selam BFPPCs, Feb. | 72–96 | 8.45–10.15 | 2.43–3.31 | Study |

| Mekane-selam BFPPCs, Nov. | 66–99 | 6.42–12.42 | 2.23–3.04 | Study |

3.2.6. Flexural Stress-Strain of a Three-Point Bending Test

3.2.7. Impact Strength of BFPPCs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, M.; Pu, Y.; Thomas, V.M.; Geun, C.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Khanlou, H.M.; Hall, W.; Öchsner, A.; Francucci, G. Environmental effects on the durability and the mechanical performance of flax fiber/bio-epoxy composites. Compos. Part B Eng. 2019, 171, 284–293. [Google Scholar] [CrossRef]

- Suresh, G.; Jayakumari, L.S. Evaluating the mechanical properties of E-Glass fiber/carbon fiber reinforced interpenetrating polymer networks. Polimeros 2015, 25, 49–57. [Google Scholar] [CrossRef]

- Shashank, M. Material Qualification in the Automotive Industry; Center for Automate Research: Ann Arbor, MI, USA, 2016; pp. 1–22. [Google Scholar]

- Kayode, O.; Akinlabi, E.T. An overview on joining of aluminium and magnesium alloys using friction stir welding (FSW) for automotive lightweight applications. Mater. Res. Express 2019, 6, 112005. [Google Scholar] [CrossRef]

- Baek, S.W.; Lee, S.W.; Kim, C.S. Experimental verification of use of vacuum insulating material in electric vehicle headliner to reduce thermal load. Appl. Sci. 2019, 9, 4207. [Google Scholar] [CrossRef]

- Da Silva, C.A.G.; Calçada, M.; Massarelli, L.C. Vehicle Interior Noise Reduction Using Innovative Roof Trim Structure. In Proceedings of the SAE Brasil International Noise and Vibration Colloquium 2014, Sao Paulo, Brazil, 4–5 November 2014. [Google Scholar] [CrossRef]

- Haque, E.; Ickes, S. Development of low density glass mat thermoplastic composites for headliner applications. In Proceedings of the SAE 2000 World Congress, Detroit, MI, USA, 6–9 March 2000. [Google Scholar] [CrossRef]

- Aggarwal, A.; Khan, H.; Crepeau, H. New headliner composites with improved acoustical performance. In Proceedings of the International Congress & Exposition, Detroit, MI, USA, 23 February 1998. [Google Scholar] [CrossRef]

- Sivasaravanan, S.; Bupesh Raja, V.K. Manikandan Impact characterization of epoxy LY556/E-Glass Fibre/Nano clay hybrid nano composite materials. Procedia Eng. 2014, 97, 968–974. [Google Scholar] [CrossRef]

- Muralishwara, K.; Kini, U.A.; Sharma, S. Epoxy-clay nanocomposite coatings: A review on synthesis and characterization. Mater. Res. Express 2019, 6, 082007. [Google Scholar] [CrossRef]

- Naik, V.; Kumar, M.; Kaup, V. A Review on Natural Fiber Composite Materials in Automotive Applications. Eng. Sci. 2022, 18, 1–10. [Google Scholar] [CrossRef]

- Hovorun, T.P.; Berladir, K.V.; Pererva, V.I.; Rudenko, S.G.; Martynov, A.I. Modern materials for automotive industry. J. Eng. Sci. 2017, 4, f8–f18. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y. The Evaluation of Noise Based on the Frictional Phenomena Using Automotive Interior Materials. Tribol. Trans. 2021, 64, 777–783. [Google Scholar] [CrossRef]

- Dou, Y.; Rodrigue, D. Morphological, thermal and mechanical properties of polypropylene foams via rotational molding. Cell. Polym. 2021, 40, 198–211. [Google Scholar] [CrossRef]

- Muñoz-Pascual, S.; Saiz-Arroyo, C.; Vuluga, Z.; Corobea, M.C.; Rodriguez-Perez, M.A. Foams with enhanced ductility and impact behavior based on polypropylene composites. Polymer 2020, 12, 943. [Google Scholar] [CrossRef] [PubMed]

- Nayak, R.K. Evaluation of Mechanical Properties of Glass Fibre and Carbon Fibre Reinforced Polymer Composite. J. Commun. Eng. Syst. 2018, 8, 66–74. [Google Scholar]

- Birara, H.; Pandey, R.P.; Mishra, S.K. Trend and variability analysis of rainfall and temperature in the tana basin region, Ethiopia. J. Water Clim. Chang. 2018, 9, 555–569. [Google Scholar] [CrossRef]

- Rosell, S.; Holmer, B. Rainfall change and its implications for Belg harvest in South Wollo, Ethiopia. Geogr. Ann. Ser. A Phys. Geogr. 2007, 89, 287–299. [Google Scholar] [CrossRef]

- Shiferaw, A. Estimating Soil Loss Rates for Soil Conservation Planning in Borena Woreda Of South Wollo 540 Highlands of Ethiopia: The Case from the Legemara Watershed. Ethiop. J. Bus. Econ. (The) 2012, 2, 1–34. [Google Scholar]

- Depuydt, D.E.C.; Sweygers, N.; Appels, L.; Ivens, J.; van Vuure, A.W. Bamboo fibres sourced from three global locations: A microstructural, mechanical and chemical composition study. J. Reinf. Plast. Compos. 2019, 38, 397–412. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–13.

- ASTM D790-03; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulation Materials. ASTM International: West Conshohocken, PA, USA, 2015; pp. 1–11.

- ISO 179-1; Plastics—Determination of Charpy Impact Properties. International Organization for Standardization: Geneva, Switzerland, 2010; pp. 1–11.

- Liu, D.; Song, J.; Anderson, D.P.; Chang, P.R.; Hua, Y. Bamboo fiber and its reinforced composites: Structure and properties. Cellulose 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Throne, J.L.; Progelhof, R.C.; Kumar, S. Closed-cell foam behavior under dynamic loading-III. Impact loading of high-density foams. J. Cell. Plast. 1985, 21, 123–140. [Google Scholar] [CrossRef]

- Vaidya, U. Biobased Bamboo Composite Development; ORNL Report; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2017; p. ORNL/TM-20.

- Abdul Khalil, H.P.S.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y.S. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Ababu, M.; Husen, E.; Awraris, B.; Bashawal, N. Review of the Applications and Properties of Bamboo Fiber Reinforced Composite Materials. Glob. Sci. J. 2021, 9, 1196–1204. [Google Scholar]

- Yeh, S.K.; Liu, Y.C.; Chu, C.C.; Chang, K.C.; Wang, S.F. Mechanical Properties of Microcellular and Nanocellular Thermoplastic Polyurethane Nanocomposite Foams Created Using Supercritical Carbon Dioxide. Ind. Eng. Chem. Res. 2017, 56, 8499–8507. [Google Scholar] [CrossRef]

- Cabrera De Lima, L.D.P.F.; Chamorro Rodríguez, C.D.; Mina Hernandez, J.H. Use of organic acids in bamboo fiber-reinforced polypropylene composites: Mechanical properties and interfacial morphology. Polymers 2021, 13, 2007. [Google Scholar] [CrossRef]

- Karnoub, A.; Huang, H.; Antypas, I. Mechanical properties of composite material laminates reinforced by woven and non-woven glass fibers. E3S Web Conf. 2020, 175, 12005. [Google Scholar] [CrossRef]

- Manickavasagam, V.M.; Ramnath, B.V.; Elanchezhian, C. A Review on Natural and Bamboo Fiber Composites. Int. J. Adv. Res. Sci. Eng. Technol. 2015, 2, 1076–1080. [Google Scholar]

- Mohamed, M.; Hawkins, S.; Chandrashekhara, K. Manufacturing and performance evaluation of polyurethane composites using one-part and two-part resin systems. Polym. Polym. Compos. 2015, 23, 333–344. [Google Scholar] [CrossRef]

- Marhoon, I.I. Mechanical and Physical Properties of Polyurethane Composites Reinforced with Carbon Black N990 Particles. Int. J. Sci. Technol. Res. 2017, 6, 225–228. Available online: https://ijstr.org/final-print/dec2017/ (accessed on 10 February 2020).

- Kushwaha, P.; Kumar, R. Enhanced mechanical strength of BFRP composite using modified bamboos. J. Reinf. Plast. Compos. 2009, 28, 2851–2859. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Research on the use of lignocellulosic fibers reinforced bio-polyamide 11 with composites for automotive parts: Car door handle case study. J. Clean. Prod. 2019, 226, 64–73. [Google Scholar] [CrossRef]

- Araki, Y.; Suzuki, T.; Hanatani, S. Composite material for automotive headliners-Expandable stampable sheet with light weight and high stiffness. JFE Tech. Rep. 2004, 4, 89–95. [Google Scholar]

- Kushwaha, P.K.; Kumar, R. Studies on performance of acrylonitrile-pretreated bamboo-reinforced thermosetting resin composites. J. Reinf. Plast. Compos. 2010, 29, 1347–1352. [Google Scholar] [CrossRef]

- Shahinur, S.; Alamgir Sayeed, M.M.; Hasan, M.; Sayem, A.S.M.; Haider, J.; Ura, S. Current Development and Future Perspective on Natural Jute Fibers and Their Biocomposites. Polymers 2022, 14, 1445. [Google Scholar] [CrossRef] [PubMed]

| Name of Testing Sites | Administrative Location of the Testing Site | Climate, Average Value | |||||

|---|---|---|---|---|---|---|---|

| Zone | Region | Lat-Long | Alt. (m) | An. RF (mm) | Max. Temp. (°C) | Min. Temp. (°C) | |

| Inji-bara | Awi | Amahara | 10°59′ N 36°55′ E | 2540–2865 | 1813 | 24 | 14 |

| Kom-bolcha | S/wollo | Amahara | 11°5′ N 39°44′ E | 1842–1915 | 1027 | 26 | 20 |

| Mekane-selam | S/wollo | Amahara | 10°45′ N 38°45′ E | 2605–3000 | 1048 | 21 | 10 |

| Composite Materials | Impact Strength, (KJ/m2) | Reference |

|---|---|---|

| PU | 3.39 | [36] |

| jute felt PU, Vf 10% | 3.31 | [40] |

| carbon fibres PU, Vf 10% | 8.21 | [40] |

| Glass fibres mat PU, Vf 10% | 6.73 | [40] |

| BPP, Vf 20% | 1.42 | [27] |

| BFPP, Vf 40% | 27.54 | [7] |

| BFEP | 15.56 | [37] |

| GFPE, vf 30% | 38 | [38] |

| BFPP, Vf 39% | 3.4 | [25] |

| BFPP, Vf 50% | 3.2 | [25] |

| BFPP | 48.7 | [25] |

| BFPP | 10.1 | [31] |

| E-Glass laminate | 17.82 | [1] |

| 40% glass PU | 18 | [3] |

| Glass laminated PE | 99.71 | [32] |

| Inji-bara BFEPCs, Feb. | 43–66 | Study |

| Inji-bara BFEPCs, Nov. | 31–55 | Study |

| Inji-bara BFPPCs, Feb. | 50–57 | Study |

| Inji-bara BFPPCs, Nov. | 34–52 | Study |

| Kom-bolcha BFEPCs, Feb. | 48–70 | Study |

| Kom-bolcha BFEPCs, Nov. | 43–55 | Study |

| Kom-bolcha BFPPCs, Feb. | 39–47 | Study |

| Kom-bolcha BFPPCs, Nov. | 26–38 | Study |

| Mekane-selam BFEPCs, Feb. | 51–66 | Study |

| Mekane-selam BFEPCs, Nov. | 42–66 | Study |

| Mekane-selam BFPPCs, Feb. | 37–41 | Study |

| Mekane-selam BFPPCs, Nov. | 34–39 | Study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dessalegn, Y.; Singh, B.; Safayo, B.B.; Jameel, M.; Hossain, N.; Rashedi, A.; Ahmed, G.M.S. Ethiopian Bamboo Fiber Aging Process and Reinforcement: Advancing Mechanical Properties of Bamboo Fiber-Epoxy Composites for Automobile Applications. J. Compos. Sci. 2023, 7, 375. https://doi.org/10.3390/jcs7090375

Dessalegn Y, Singh B, Safayo BB, Jameel M, Hossain N, Rashedi A, Ahmed GMS. Ethiopian Bamboo Fiber Aging Process and Reinforcement: Advancing Mechanical Properties of Bamboo Fiber-Epoxy Composites for Automobile Applications. Journal of Composites Science. 2023; 7(9):375. https://doi.org/10.3390/jcs7090375

Chicago/Turabian StyleDessalegn, Yalew, Balkeshwar Singh, Barisso Bino Safayo, Mohammed Jameel, Nazia Hossain, Ahmad Rashedi, and Gulam Mohammed Sayeed Ahmed. 2023. "Ethiopian Bamboo Fiber Aging Process and Reinforcement: Advancing Mechanical Properties of Bamboo Fiber-Epoxy Composites for Automobile Applications" Journal of Composites Science 7, no. 9: 375. https://doi.org/10.3390/jcs7090375

APA StyleDessalegn, Y., Singh, B., Safayo, B. B., Jameel, M., Hossain, N., Rashedi, A., & Ahmed, G. M. S. (2023). Ethiopian Bamboo Fiber Aging Process and Reinforcement: Advancing Mechanical Properties of Bamboo Fiber-Epoxy Composites for Automobile Applications. Journal of Composites Science, 7(9), 375. https://doi.org/10.3390/jcs7090375