Adjunctive Damage Model to Describe the Interaction of Different Defect Types in Textile Composites on the Strain-Rate-Dependent Material Behaviour

Abstract

:1. Introduction

2. Materials and Methods

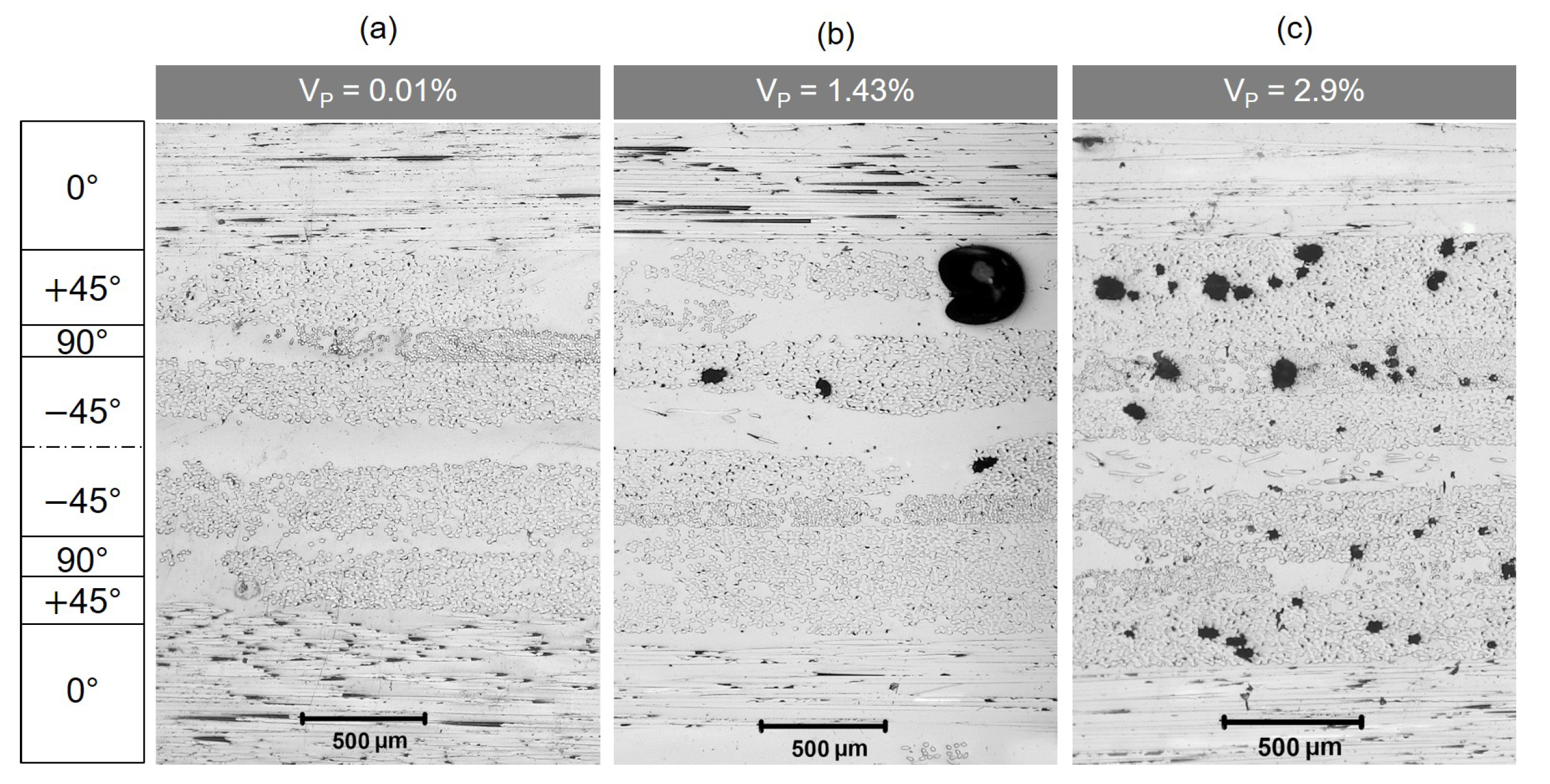

2.1. Materials and Pre-Damaged Methods

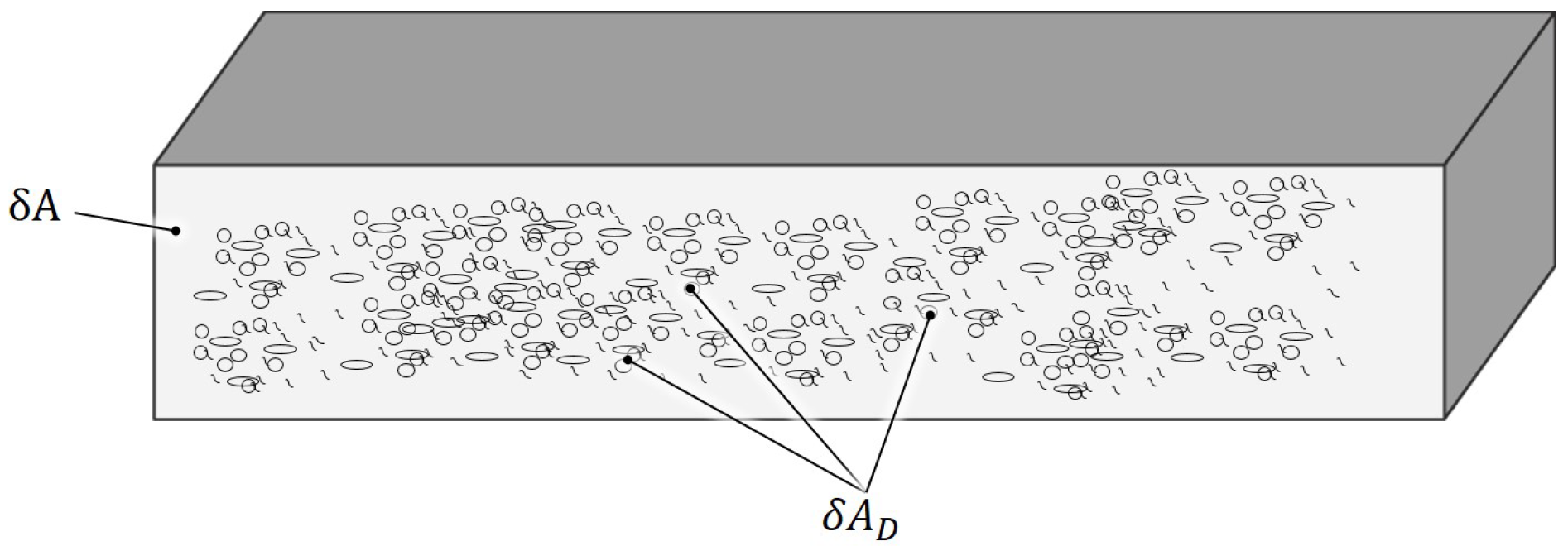

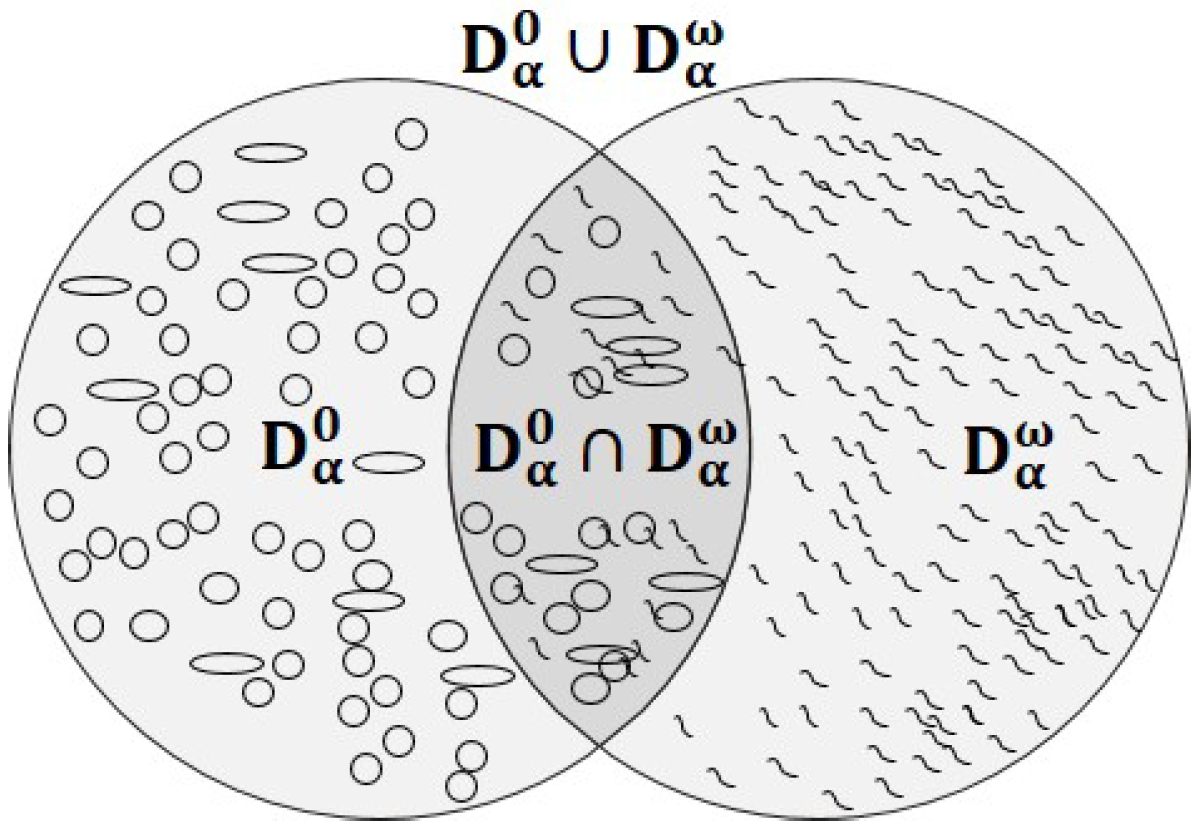

2.2. Adjunctive Damage Model

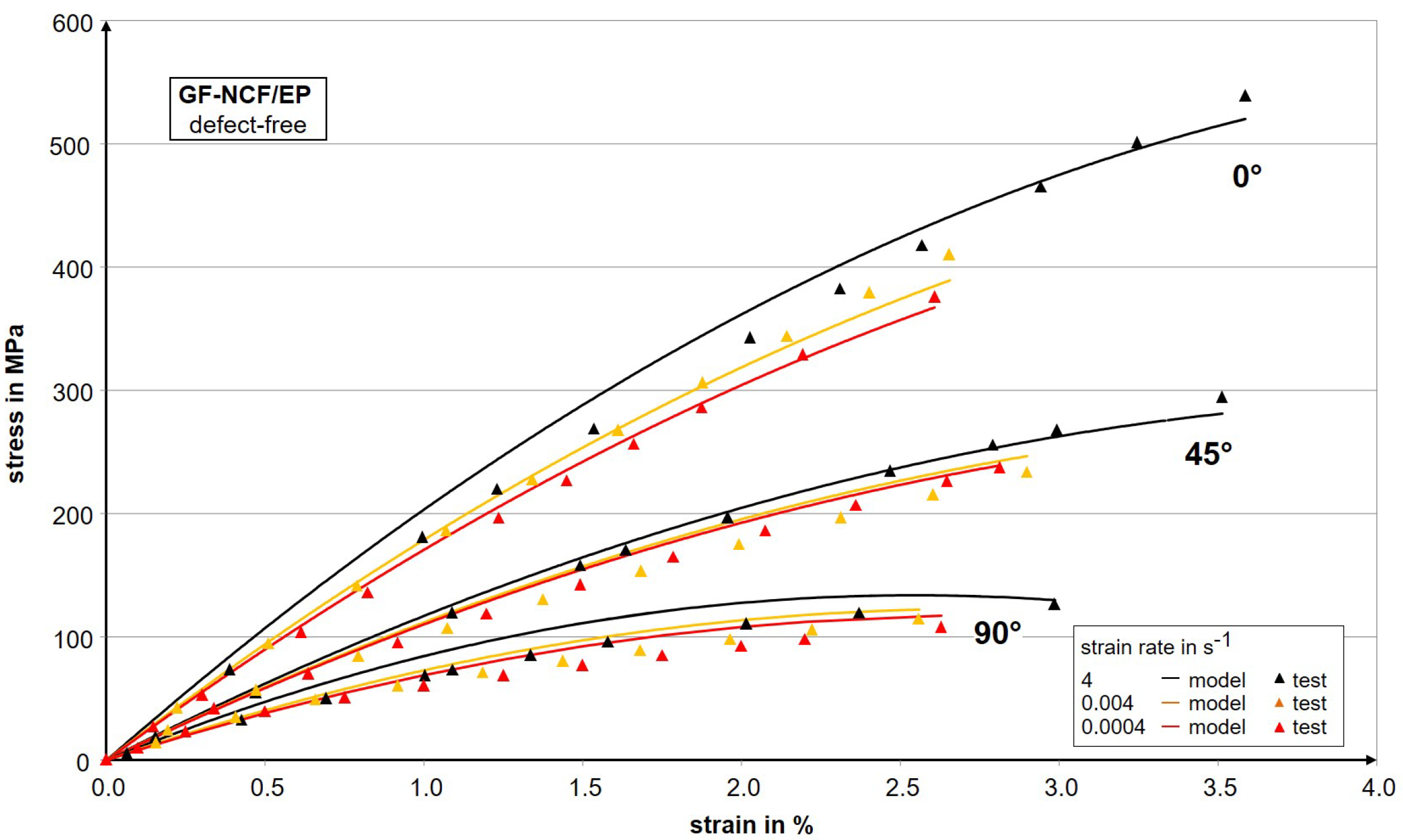

2.3. Parameter Identification

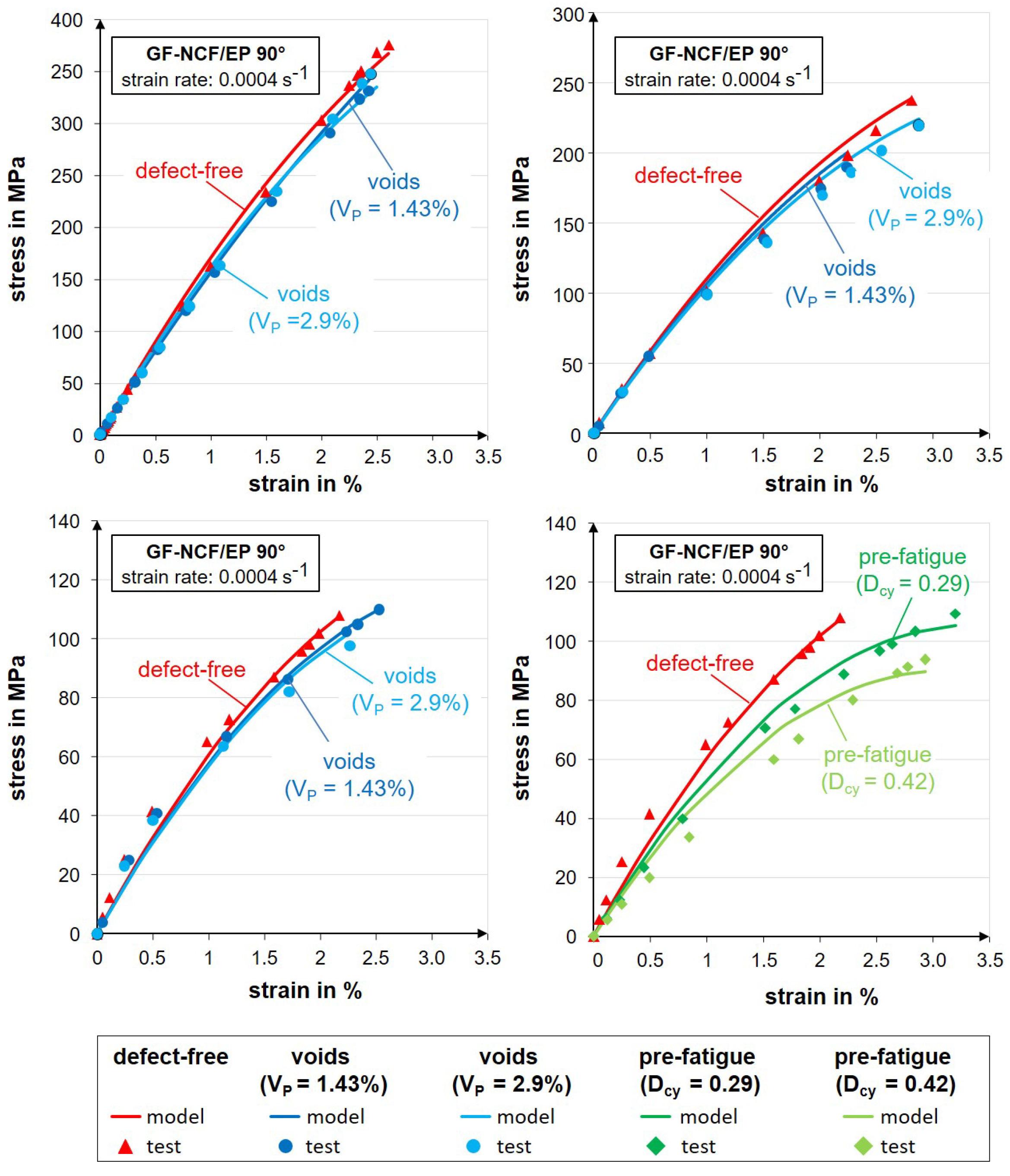

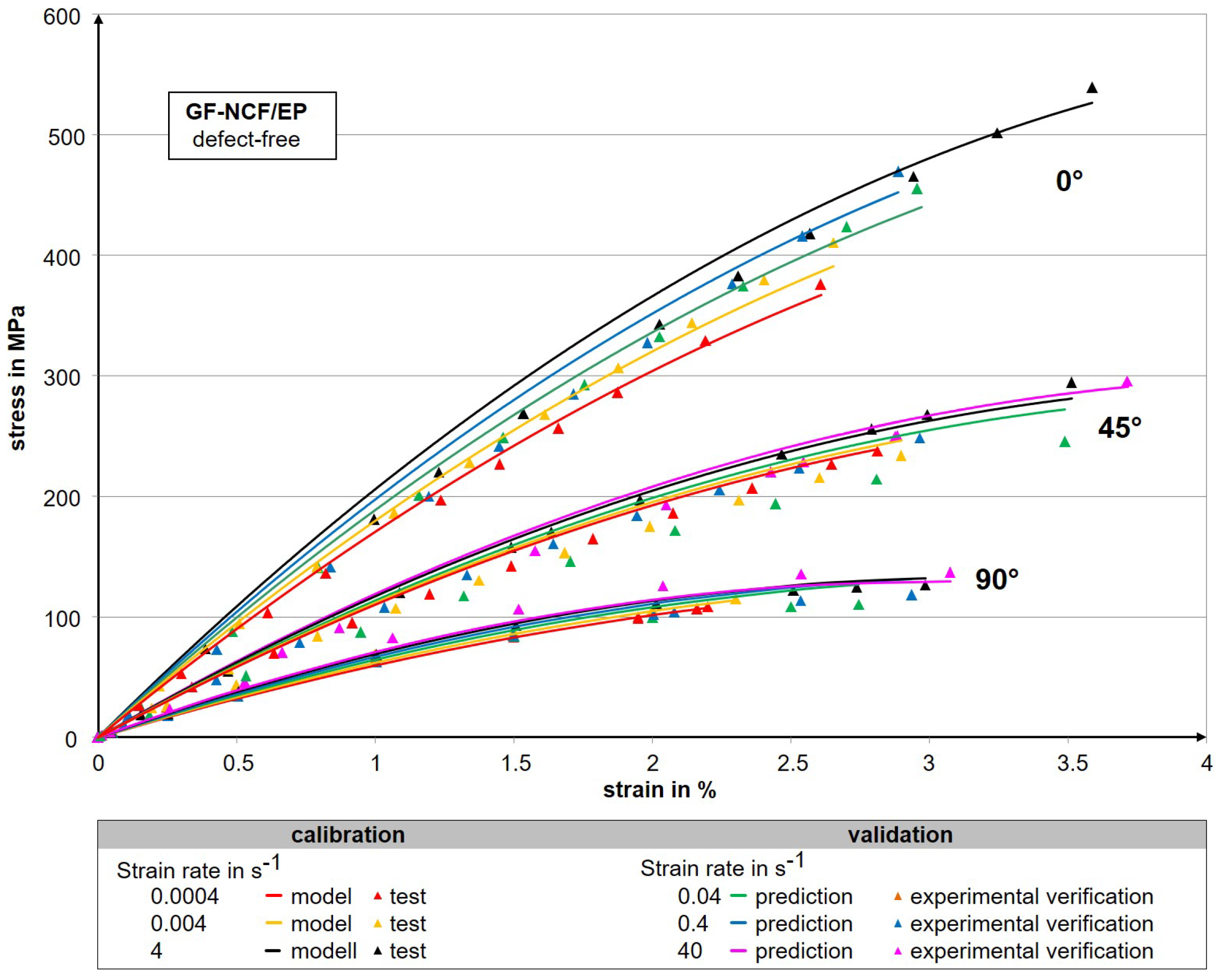

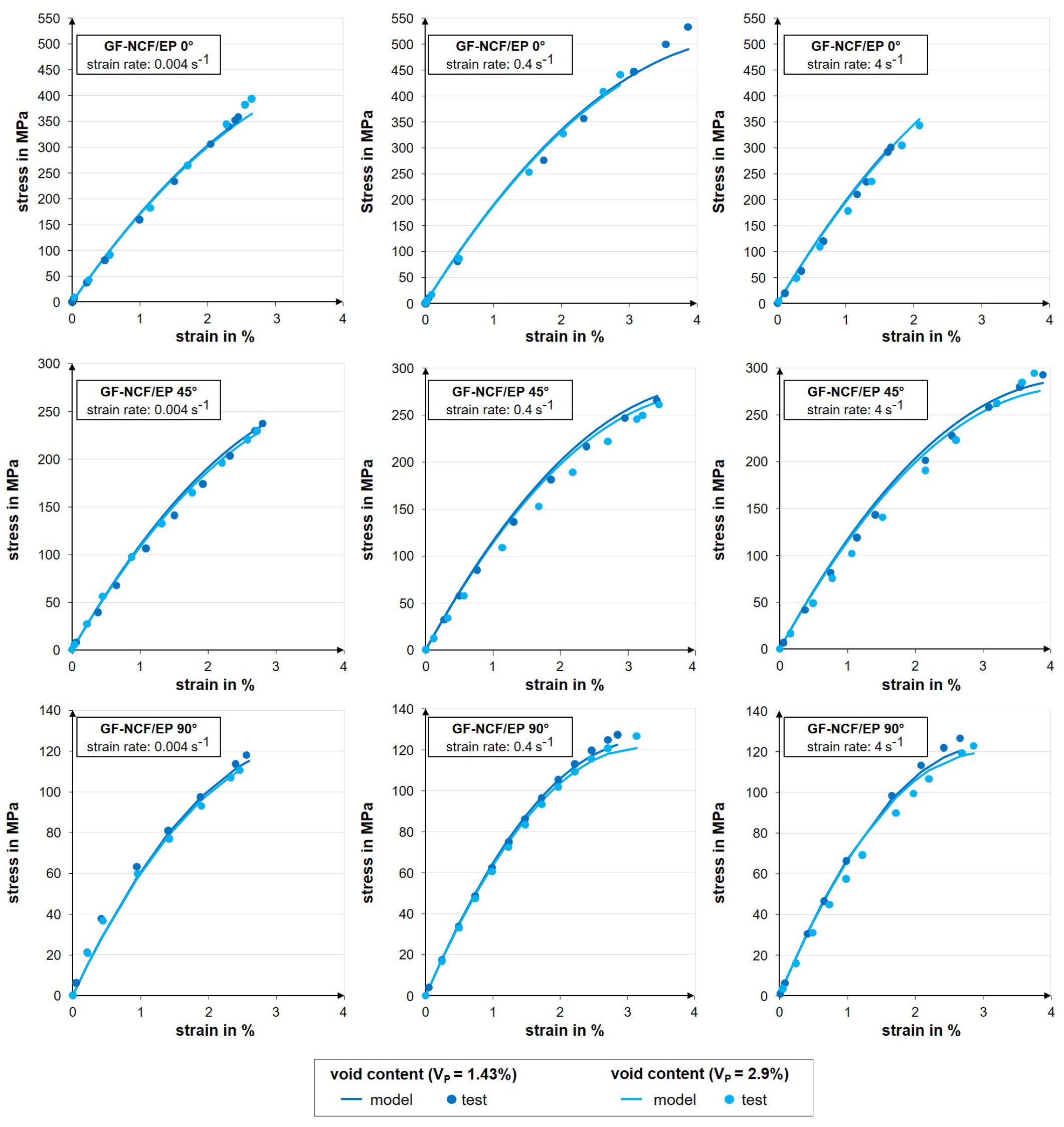

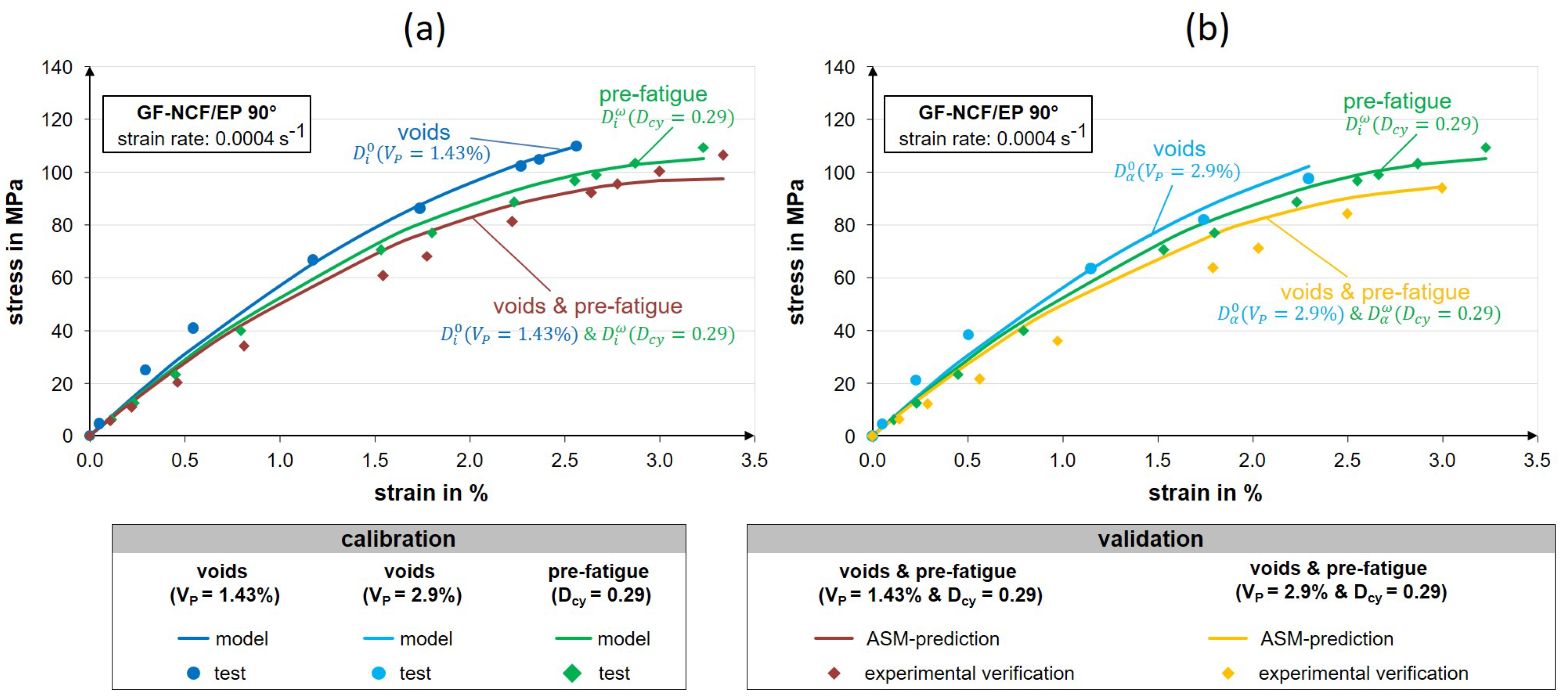

3. Results and Discussion

Model Validation

4. Conclusions and Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gude, M.; Hufenbach, W.; Ebert, C. The strain-rate-dependent material and failure behaviour of 2D and 3D non-crimp glass-fibre-reinforced composites. Mech. Compos. Mater. 2009, 45, 467–476. [Google Scholar] [CrossRef]

- Gerritzen, J.; Hornig, A.; Gröger, B.; Gude, M. A Data Driven Modelling Approach for the Strain Rate Dependent 3D Shear Deformation and Failure of Thermoplastic Fibre Reinforced Composites: Experimental Characterisation and Deriving Modelling Parameters. J. Compos. Sci. 2022, 6, 318. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Protz, R.; Koch, I.; Gude, M. In-situ computer tomography for analyzing the effect of voids on the damage behavior of composite materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012013. [Google Scholar] [CrossRef]

- Kulkarni, P.; Mali, K.D.; Singh, S. An overview of the formation of fibre waviness and its effect on the mechanical performance of fibre reinforced polymer composites. Compos. Part A 2020, 137, 106013. [Google Scholar] [CrossRef]

- Drummer, J.; Tafesh, F.; Fiedler, B. Effect of Fiber Misalignment and Environmental Temperature on the Compressive Behavior of Fiber Composites. Polymers 2023, 13, 2833. [Google Scholar] [CrossRef]

- Schmidt, F. Defekteinflüsse bei Faser-Kunststoff-Verbunden unter Multiaxialer Belastung. Ph.D. Thesis, Technische Universität Braunschweig, Braunschweig, Germany, 2013. [Google Scholar]

- Hufenbach, W.; Gude, M.; Protz, R. Modeling of the strain rate dependent material behavior of 3D-textile composites with production and operational defects. Adv. Mater. Res. 2012, 403, 651–655. [Google Scholar] [CrossRef]

- Wu, X.F.; Zholobko, O. Experimental study of the probabilistic fatigue residual strength of a carbon fiber-reinforced polymer matrix composite. J. Compos. Sci. 2020, 4, 173. [Google Scholar] [CrossRef]

- Witzgall, C.; Steck, P.; Wartzack, S. On the Influence of Fatigue Damage in Short-Fibre Reinforced Thermoplastic PBT GF30 on Its Residual Strength under High Strain Rates: An Approach towards Simulative Prediction. J. Compos. Sci. 2023, 7, 23. [Google Scholar] [CrossRef]

- Abrate, S. Composite structures: Impact on composites. Compos. Struct. 2003, 61, 309–334. [Google Scholar] [CrossRef]

- Kristnama, A.R.; Xu, X.; Nowell, D.; Wisnom, M.R.; Hallett, S.R. Experimental investigation of high velocity oblique impact and residual tensile strength of carbon/epoxy laminates. Compos. Sci. Technol. 2019, 182, 107772. [Google Scholar] [CrossRef]

- Bogenfeld, R.; Gorsky, C. An experimental study of the cyclic compression after impact behavior of CFRP composites. J. Compos. Sci. 2021, 5, 296. [Google Scholar] [CrossRef]

- Fu, Y.; Yao, X.; Gao, X. Micro-mesoscopic prediction of void defect in 3D braided composites. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106450. [Google Scholar] [CrossRef]

- Talreja, R. Effects of manufacturing induced defects on composite damage and failure. Polym. Compos. Mater. Wind. Power Turbines 2006, 83–96, ISBN 87-550-3528-0. [Google Scholar]

- Gehrig, F. Einfluss von Poren auf das Schädigungsverhalten von kohlenstofffaserverstärkten Kunststoffen. Ph.D. Thesis, Technische Universität Hamburg-Harburg, Hamburg, Germany, 2011. [Google Scholar]

- Grunenfelder, L.K.; Nutt, S.R. Void formation in composite prepregs-Effect of dissolved moisture. Compos. Sci. Technol. 2010, 70, 2304–2309. [Google Scholar] [CrossRef]

- Alves, F.C.; Monticeli, F.M.; Neves, R.M.; Voorwald, H.J.C.; Cioffi, M.O.H.; Ornaghi, H.L. Influence of void content and morphology on the creep behavior on glass/epoxy composites. Compos. Commun. 2021, 25, 100712. [Google Scholar] [CrossRef]

- Kreikemeier, J.; Chrupalla, D.; Khattab, I.A.; Krause, D. Experimentelle und Numerische Untersuchungen von CFK mit Herstellungsbedingten Fehlstellen. In 10. Magdeburger Maschinenbautage. 2011. Available online: https://elib.dlr.de/71096/ (accessed on 27 August 2023).

- Quaresimin, M.; Susmel, L.; Talreja, R. Fatigue behaviour and life assessment of composite laminates under multiaxial loadings. Int. J. Fatigue 2010, 32, 2–16. [Google Scholar] [CrossRef]

- Schell, J.S.U.; Deleglise, M.; Binetruy, C.; Krawczak, P.; Ermanni, P. Numerical prediction and experimental characterisation of meso-scale-voids in liquid composite moulding. Compos. Part A 2007, 38, 2460–2470. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Monticeli, F.M.; Neves, R.M.; Zattera, A.J.; Cioffi, M.O.H.; Voorwald, H.J.C. Effect of stacking sequence and porosity on creep behavior of glass/epoxy and carbon/epoxy hybrid laminate composites. Compos. Commun. 2020, 19, 210–219. [Google Scholar] [CrossRef]

- Kosmann, N.; Karsten, J.M.; Schuett, M.; Schulte, K.; Fiedler, B. Determining the effect of voids in GFRP on the damage behaviour under compression loading using acoustic emission. Compos. Part B 2015, 70, 184–188. [Google Scholar] [CrossRef]

- Ashir, M.; Nocke, A.; Bulavinov, A.; Pinchuk, R.; Cherif, C. Influence of defined amount of voids on the mechanical properties of carbon fiber-reinforced plastics. Polym. Compos. 2018, 40, 1049–1056. [Google Scholar] [CrossRef]

- Varna, J.; Joffe, R.; Berglund, L.A.; Lundström, T.S. Effect of voids on failure mechanisms in RTM laminates. Compos. Sci. Technol. 1995, 53, 241–249. [Google Scholar] [CrossRef]

- Schmidt, F.; Rheinfurth, M.; Horst, P.; Busse, G. Multiaxial fatigue behaviour of GFRP with evenly distributed or accumulated voids monitored by various NDT methodologies. Int. J. Fatigue 2012, 43, 207–216. [Google Scholar] [CrossRef]

- Maragoni, L.; Carraro, P.A.; Peron, M.; Quaresimin, M. Fatigue behaviour of glass/epoxy laminates in the presence of voids. Int. J. Fatigue 2017, 95, 18–28. [Google Scholar] [CrossRef]

- Protz, R.; Kosmann, N.; Gude, M.; Hufenbach, W.; Schulte, K.; Fiedler, B. Voids and their effect on the strain rate dependent material properties and fatigue behaviour of non-crimp fabric composites materials. Compos. Part B 2015, 83, 346–351. [Google Scholar] [CrossRef]

- Sisodia, S.M.; Garcea, S.C.; George, A.R.; Fullwood, D.T.; Spearing, S.M.; Gamstedt, E.K. High-resolution computed tomography in resin infused woven carbon fibre composites with voids. Compos. Sci. Technol. 2016, 131, 12–21. [Google Scholar] [CrossRef]

- Hyde, A.; He, J.; Cui, X.; Lua, J.; Liu, L. Effects of microvoids on strength of unidirectional fiber-reinforced composite materials. Compos. Part B 2020, 187, 107844. [Google Scholar] [CrossRef]

- Gao, X.; Yuan, L.; Fu, Y.; Yao, X.; Yang, H. Prediction of mechanical properties on 3D braided composites with void defects. Compos. Part B 2020, 197, 108164. [Google Scholar] [CrossRef]

- Wang, K.; Lu, Y.; Rao, Y.; Wei, N.; Ban, J.; Peng, Y.; Yao, S.; Ahzi, S. New insights into the synergistic influence of voids and interphase characteristics on effective properties of unidirectional composites. Compos. Struct. 2021, 255, 112862. [Google Scholar] [CrossRef]

- Suhot, M.A. The Effect of Voids on the Flexural Fatigue Properties of Carbon/Epoxy Composites. Ph.D. Thesis, University of Southampton, Southampton, UK, 2010. [Google Scholar]

- Huang, H.; Talreja, R. Effects of void geometry on elastic properties of unidirectional fiber reinforced composites. Compos. Sci. Technol. 2005, 65, 1964–1981. [Google Scholar] [CrossRef]

- Vajari, D.A.; González, C.; Llorca, J.; Legarth, B.N. A numerical study of the influence of microvoids in the transverse mechanical response of unidirectional composites. Compos. Sci. Technol. 2014, 97, 46–54. [Google Scholar] [CrossRef]

- Gao, J.; Yuan, Y. Probabilistic modeling of stiffness degradation for fiber reinforced polymer under fatigue loading. Eng. Fail. Anal. 2020, 116, 104733. [Google Scholar] [CrossRef]

- Li, P.; Yao, W.; Chen, F.; Zong, J. Residual stiffness characterization of FRP laminates under random block spectrum. Polym. Test. 2021, 95, 107101. [Google Scholar] [CrossRef]

- Pakdel, H.; Mohammadi, B. Stiffness degradation of composite laminates due to matrix cracking and induced delamination during tension-tension fatigue. Eng. Fract. Mech. 2019, 216, 106489. [Google Scholar] [CrossRef]

- Epaarachchi, J.A.; Clausen, P.D. A new cumulative fatigue damage model for glass fibre reinforced plastic composites under step/discrete loading. Compos. Part A 2005, 36, 1236–1245. [Google Scholar] [CrossRef]

- Philippidis, T.P.; Passipoularidis, V.A. Residual strength after fatigue in composites: Theory vs. experiment. Int. J. Fatigue 2007, 29, 2104–2116. [Google Scholar] [CrossRef]

- Böhm, R. Bruchmodebezogenen Beschreibung des Degradationsverhaltens textilverstärkter Verbundwerkstoffe. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2008. [Google Scholar]

- D’amore, A.; Grassia, L. Principal features of fatigue and residual strength of composite materials subjected to constant amplitude (CA) loading. Materials 2019, 12, 2586. [Google Scholar] [CrossRef]

- Matzenmiller, A.; Lubliner, J.; Taylor, R.L. A constitutive model for anisotropic damage in fiber-composites. Mech. Mater. 1995, 20, 125–152. [Google Scholar] [CrossRef]

- Koch, I. Modellierung des Ermüdungsverhaltens Textilverstärkter Kunststoffe. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2010. [Google Scholar]

- Shokrieh, M.M.; Lessard, L.B. Fatigue under multiaxial stress systems. In Fatigue in Composites; Harris, B., Ed.; Woodhead Publishing: Sawston, UK, 2003; pp. 63–113. [Google Scholar]

- Withworth, H.A. Evaluation of the residual strength degradation in composite laminates under fatigue loading. Compos. Struct. 2000, 48, 261–264. [Google Scholar] [CrossRef]

- Broutman, L.; Sahu, S. A new theory to predict cumulative fatigue damage in fiberglass reinforced plastics. In Composite Materials: Testing and Design (Second Conference), STP27746S; Corten, H., Ed.; ASTM International, West Conshohocken: Conshohocken, PA, USA, 1972; pp. 170–188. [Google Scholar]

- Ebert, C. Werkstoffmechanische Modellierung von Textilverstärkten Thermoplastverbunden unter Hochdynamischer Belastung. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2010. [Google Scholar]

- Zscheyge, M. Zum Temperatur- und Dehnratenabhängigen Deformations- und Schädigungsverhalten von Textil-Thermoplast-Verbunden. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2015. [Google Scholar]

- Song, B.; Chen, W.; Weerasooriya, T. Quasi-static and dynamic compressive behaviors of a S-2 glass/SC15 composite. J. Compos. Mater. 2003, 37, 1723–1743. [Google Scholar] [CrossRef]

- Thiruppukuzhi, S.V.; Sun, C.T. Models for the strain-rate-dependent behavior of polymer composites. J. Compos. Sci. Technol. 2001, 61, 1–12. [Google Scholar] [CrossRef]

- Protz, R. Zum Einfluss von Defekten auf das Dehnratenabhängige Werkstoffverhalten von Faser-Kunststoff-Verbunden. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2021. [Google Scholar]

- Just, G.; Koch, I.; Gude, M. Experimental Analysis of Matrix Cracking in Glass Fiber Reinforced Composite Off-Axis Plies under Static and Fatigue Loading. Polymers 2022, 14, 2160. [Google Scholar] [CrossRef] [PubMed]

- Kachanov, L.M. On the creep fracture time. Izv. Akad. Nauk SSR Otd. Tekhn. Nauk 1958, 8, 26–31. [Google Scholar]

- Rabotnov, Y.N. Creep rupture. In Proceedings of the 12th International Congress on Applied Mechanics, Stanford, CA, USA, 26–31 August 1968. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

| Void Content | Max. Injection Pressure | Vacuum | Holding Pressure | Degassing |

|---|---|---|---|---|

| 0.01 ± 0.01% | 3 | −1 | 3 | Yes |

| 1.43 ± 0.65% | 0.5 | −0.4 | 0 | No |

| 2.9 ± 0.9% | 1 | −0.2 | 0 | No |

| Parameter | 90° | 45° | 0° |

|---|---|---|---|

| in GPa | 8.4 | 12.4 | 18.9 |

| in | 0.0004 | 0.0004 | 0.0004 |

| 0.02 | 0.01 | 0.02 | |

| 2.24 | 0.2 | 0.06 | |

| 1.12 | 1 | 1.7 | |

| 10 | 11 | 9.8 | |

| 0.17 | 0.001 | 0 | |

| 0 | 0 | 0 |

| Defect Parameter | Defect Measure | 90° | 45° | 0° |

|---|---|---|---|---|

| 0.21 | 0.025 | 0.039 | ||

| 0.22 | 0.04 | 0.046 | ||

| 0.1 | -/- 1 | -/- | ||

| 0.17 | -/- | -/- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Protz, R.; Koch, I.; Gude, M. Adjunctive Damage Model to Describe the Interaction of Different Defect Types in Textile Composites on the Strain-Rate-Dependent Material Behaviour. J. Compos. Sci. 2023, 7, 365. https://doi.org/10.3390/jcs7090365

Protz R, Koch I, Gude M. Adjunctive Damage Model to Describe the Interaction of Different Defect Types in Textile Composites on the Strain-Rate-Dependent Material Behaviour. Journal of Composites Science. 2023; 7(9):365. https://doi.org/10.3390/jcs7090365

Chicago/Turabian StyleProtz, Richard, Ilja Koch, and Maik Gude. 2023. "Adjunctive Damage Model to Describe the Interaction of Different Defect Types in Textile Composites on the Strain-Rate-Dependent Material Behaviour" Journal of Composites Science 7, no. 9: 365. https://doi.org/10.3390/jcs7090365

APA StyleProtz, R., Koch, I., & Gude, M. (2023). Adjunctive Damage Model to Describe the Interaction of Different Defect Types in Textile Composites on the Strain-Rate-Dependent Material Behaviour. Journal of Composites Science, 7(9), 365. https://doi.org/10.3390/jcs7090365