Effect of Printing Direction and Post-Printing Conditions on Bending Properties of ULTEM 9085

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Manufacturing of the Test Samples

2.2. Methods

2.2.1. Cooling of the Test Samples

2.2.2. Morphological Analysis

2.2.3. Static Bending Tests

2.2.4. Fatigue Tests

3. Results

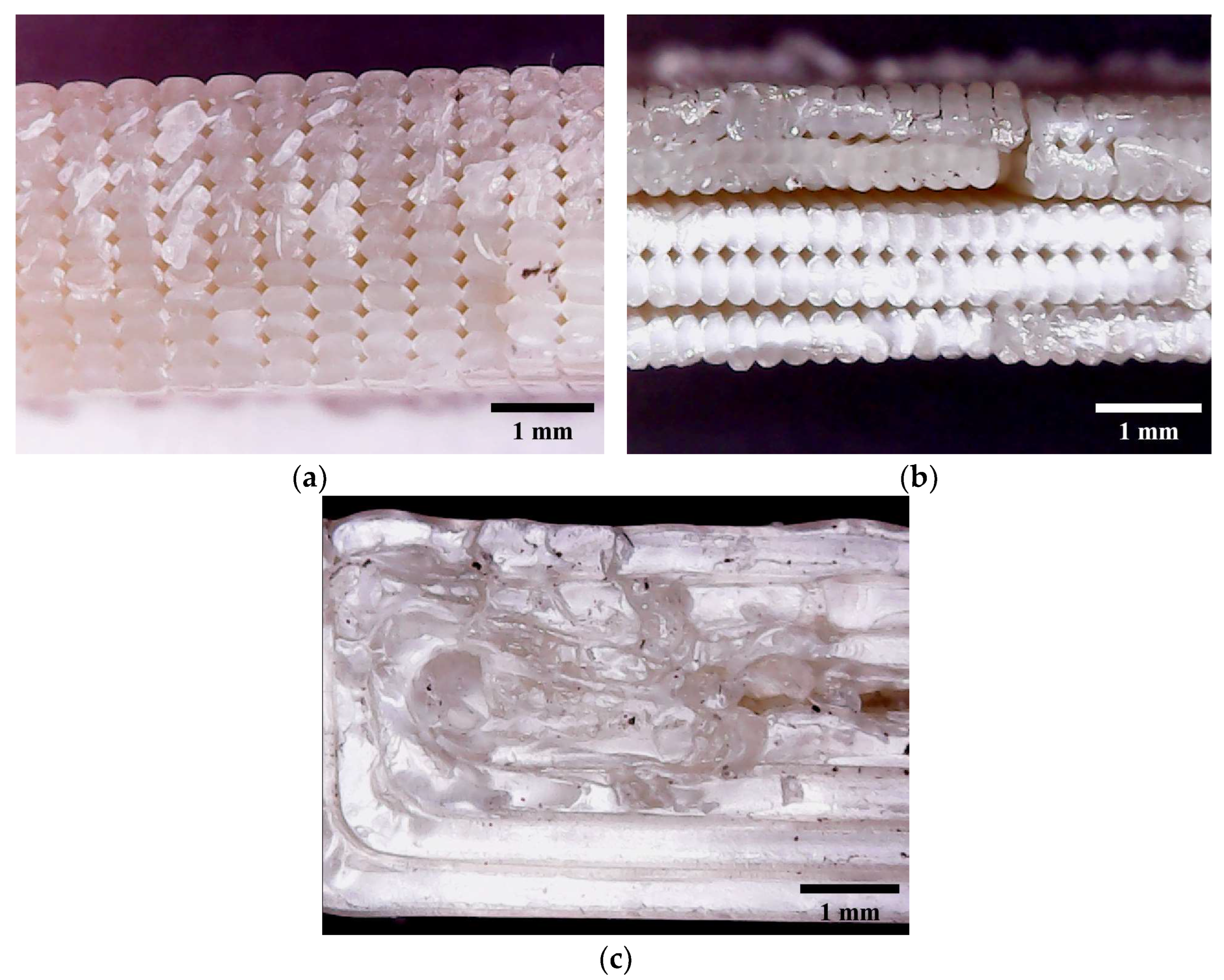

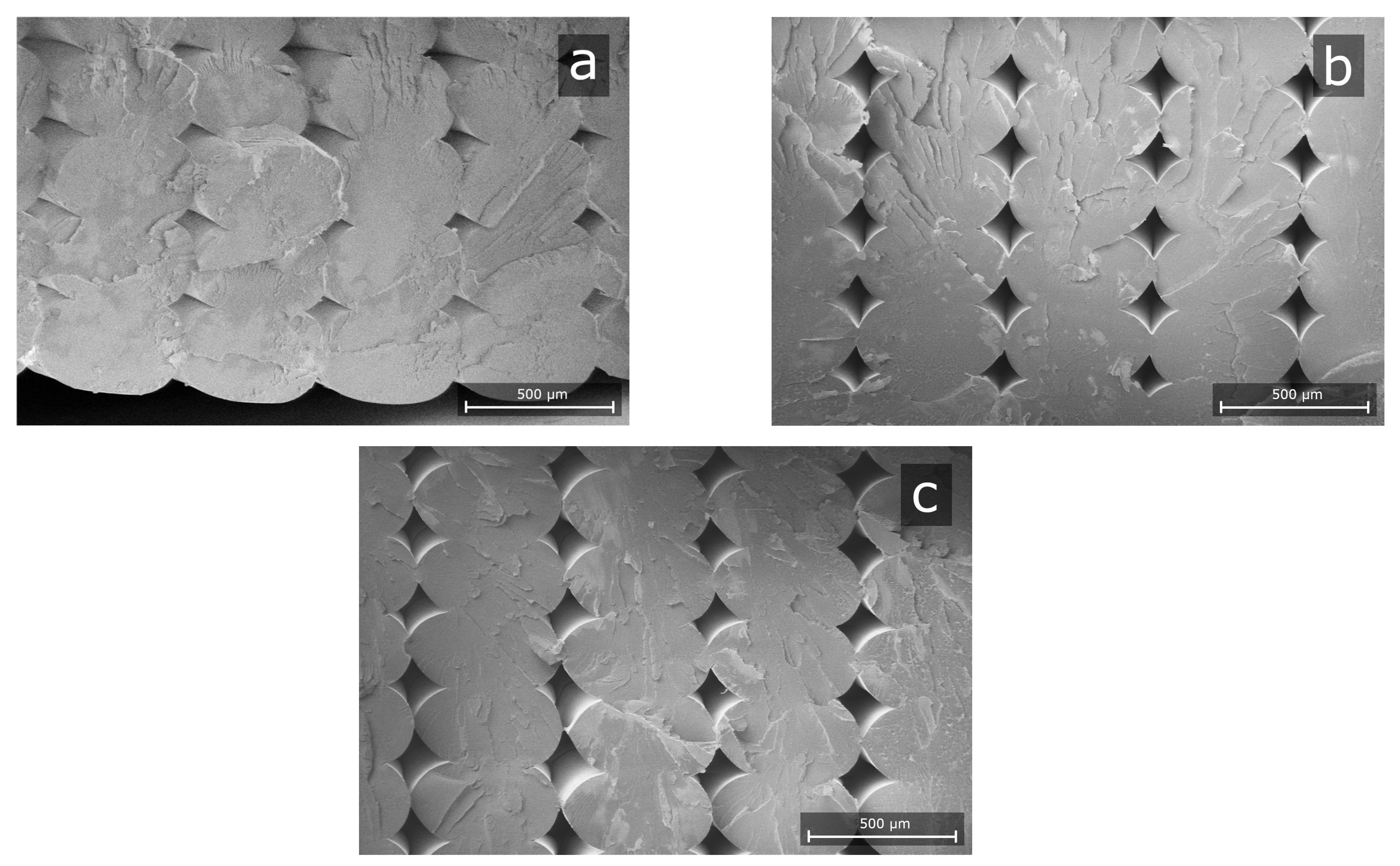

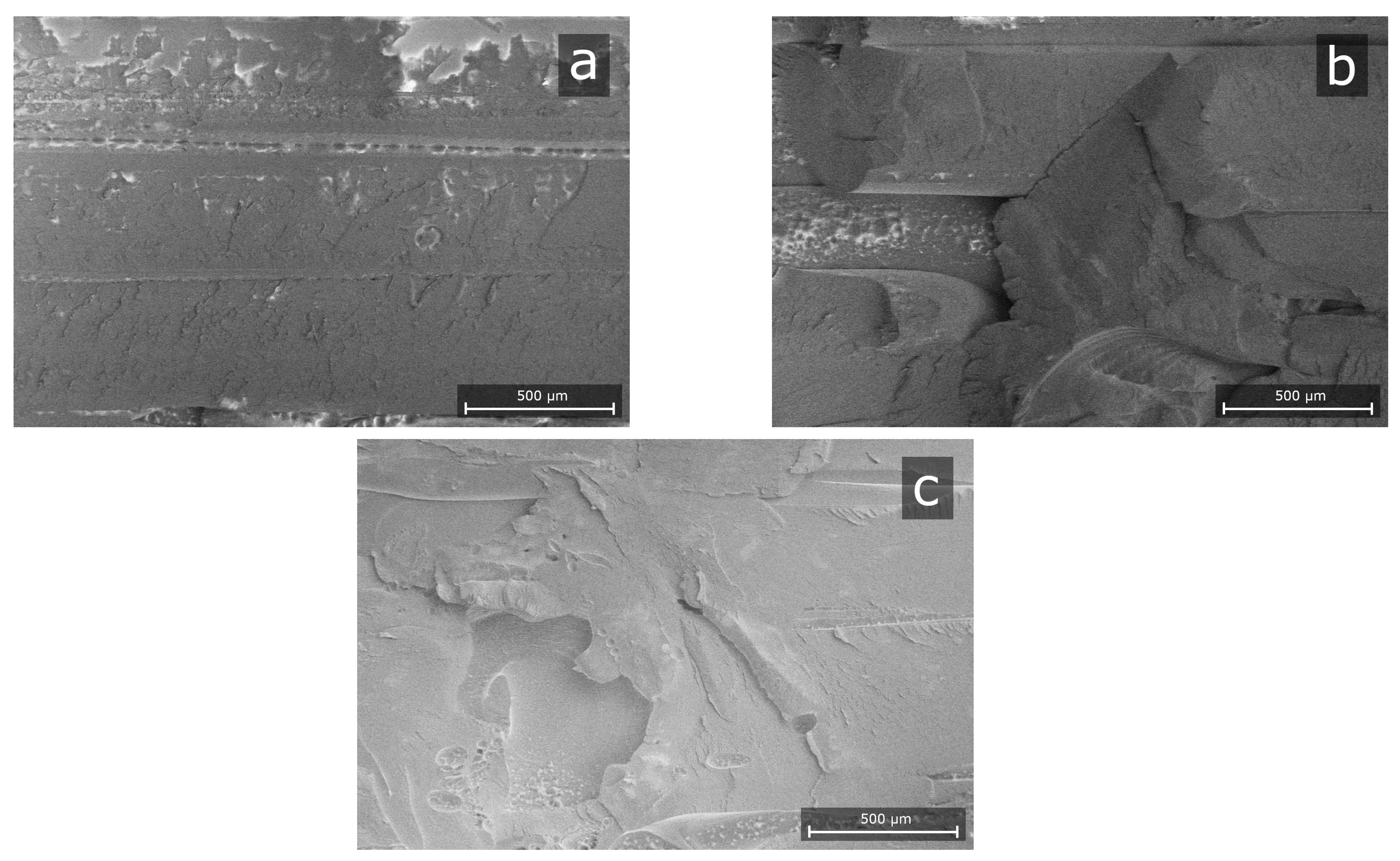

3.1. Morphological Analysis

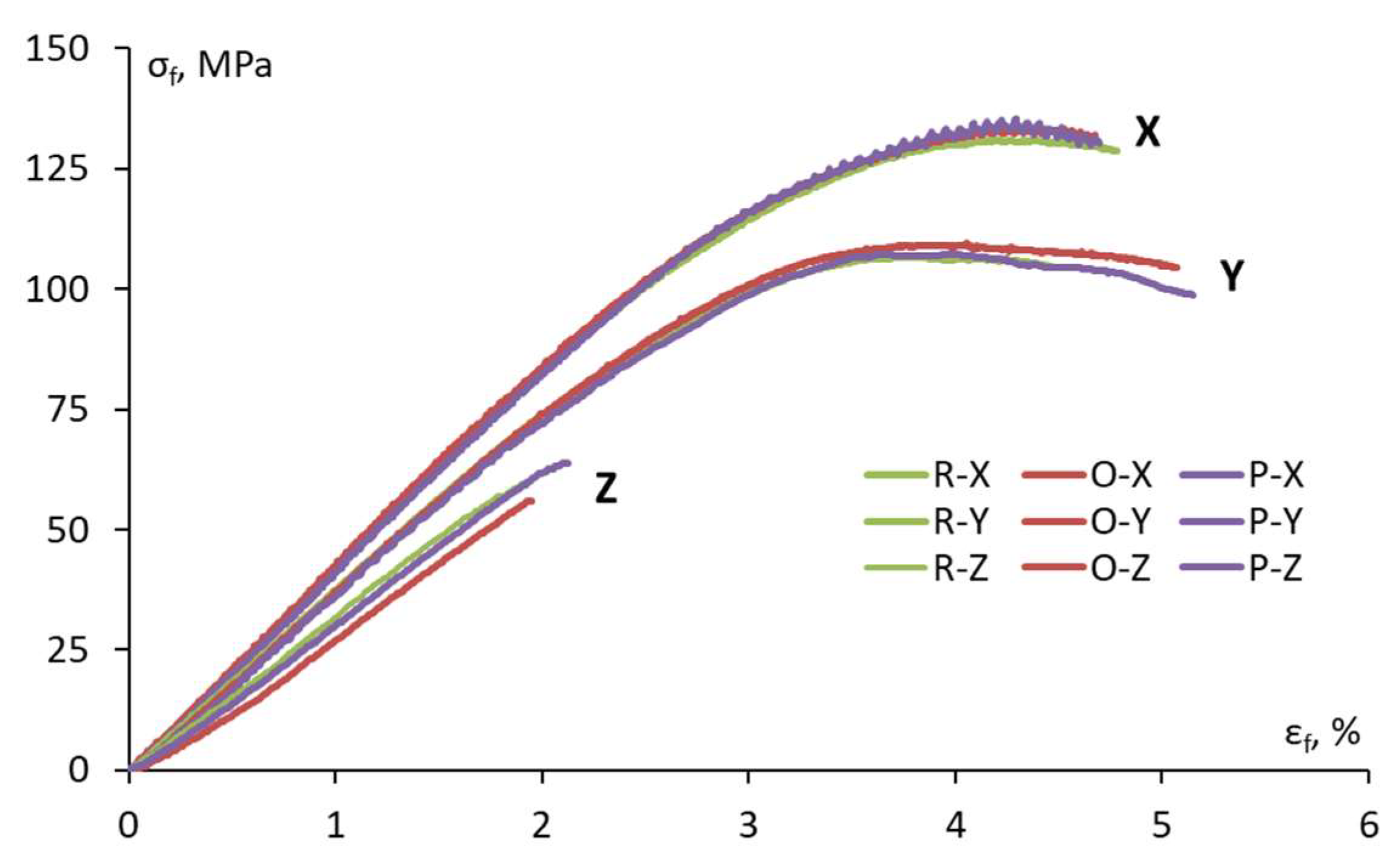

3.2. Static 3-Point Bending Tests

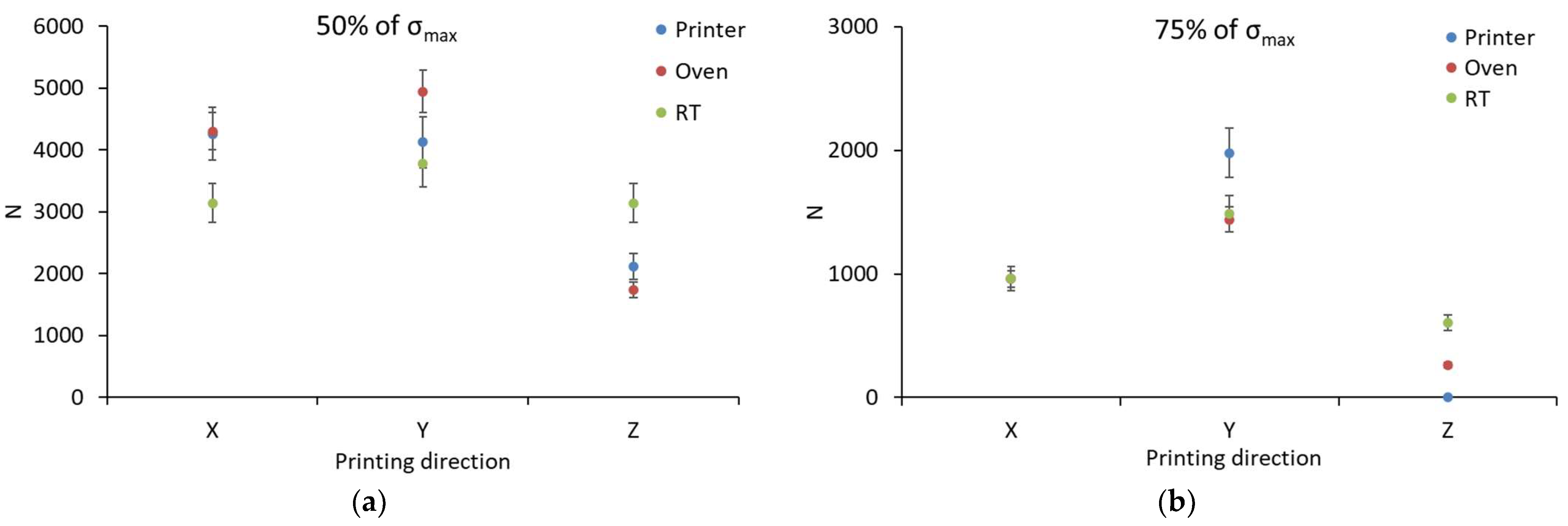

3.3. Fatigue Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Daminabo, S.C.; Goel, S.; Grammatikos, S.A.; Nezhad, H.Y.; Thakur, V.K. Fused deposition modeling-based additive manufacturing (3D printing): Techniques for polymer material systems. Mater. Today Chem. 2020, 16, 100248. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. A systematic review of additive manufacturing-based remanufacturing techniques for component repair and restoration. J. Manuf. Process. 2023, 89, 220–283. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Ganetsos, T.; Petrescu, F.I.T. Applying a combination of cutting-edge industry 4.0 processes towards fabricating a customized component. Processes 2023, 11, 1385. [Google Scholar] [CrossRef]

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Haq, M.I.U. 3D printing—A review of processes, materials and applications in industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Singh, T.; Kumar, S.; Sehgal, S. 3D printing of engineering materials: A state of the art review. Mater. Today Proc. 2020, 28, 1927–1931. [Google Scholar] [CrossRef]

- Wu, Y.; Fang, J.; Wu, C.; Li, C.; Sun, G.; Li, Q. Additively manufactured materials and structures: A state-of-the-art review on their mechanical characteristics and energy absorption. Int. J. Mech. Sci. 2023, 246, 108102. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 3D and 4D printing as integrated manufacturing methods of industry 4.0. Am. J. Eng. Appl. Sci. 2023, 16, 12–22. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A. Ten challenges in 3D printing. Eng. Comput. 2016, 32, 135–148. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D printing: Making an innovative technology widely accessible through makerspaces and outsourced services. Mater. Today Proc. 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Doshi, M.; Mahale, A.; Singh, S.K.; Deshmukh, S. Printing parameters and materials affecting mechanical properties of FDM-3D printed Parts: Perspective and prospects. Mater. Today Proc. 2022, 50, 2269–2275. [Google Scholar] [CrossRef]

- Patel, R.; Desai, C.; Kushwah, S.; Mangrola, M.H. A review article on FDM process parameters in 3D printing for composite materials. Mater. Today Proc. 2022, 60, 2162–2166. [Google Scholar] [CrossRef]

- Fischer, M. and Schöppner V. Fatigue behavior of FDM parts manufactured with Ultem 9085. JOM 2017, 69, 563–568. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. Effect of material and process specific factors on the strength of printed parts in fused filament fabrication: A review of recent developments. Materials 2019, 12, 1664. [Google Scholar] [CrossRef] [PubMed]

- Zīle, E.; Zeleniakiene, D.; Aniskevich, A. Characterization of polylactic acid parts produced using fused deposition modelling. Mech. Compos. Mater. 2022, 58, 169–180. [Google Scholar] [CrossRef]

- Popescua, D.; Zapciua, A.; Amzab, C.; Baciuc, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Gebisa, A.W.; Lemu, H.G. Investigating effects of fused-deposition modeling (FDM) processing parameters on flexural properties of ULTEM 9085 using designed experiment. Materials 2018, 11, 500. [Google Scholar] [CrossRef]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical properties optimization of poly-ether-ether-ketone via fused deposition modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef]

- Safai, L.; Cuellar, J.S.; Smit, G.; Zadpoor, A.A. A review of the fatigue behavior of 3D printed polymers. Addit. Manuf. 2019, 28, 87–97. [Google Scholar] [CrossRef]

- D’Amore, A.; Califano, A.; Grassia, L. Modelling the loading rate effects on the fatigue response of composite materials under constant and variable frequency loadings. Int. J. Fatigue 2021, 150, 106338. [Google Scholar] [CrossRef]

- ASTM E606/E606M-21; Standard Test Method for Strain-Controlled Fatigue Testing. 2021. Available online: https://www.astm.org/e0606_e0606m-21.html (accessed on 23 March 2023).

- ASTM D3479/D3479M-19; Standard Test Method for Tension-Tension Fatigue of Polymer Matrix Composite Materials. 2019. Available online: https://www.astm.org/d3479_d3479m-19.html (accessed on 23 March 2023).

- ISO 13003:2003; Fibre-Reinforced Plastics—Determination of Fatigue Properties under Cyclic Loading Conditions. 2019. Available online: https://www.iso.org/standard/32190.html (accessed on 23 March 2023).

- Kluczynski, J.; Szachogłuchowicz, I.; Torzewski, J.; Sniezek, L.; Grzelak, K.; Budzik, G.; Przeszłowski, L.; Małek, M.; Łuszczek, J. Fatigue and fracture of additively manufactured polyethylene terephthalate glycol and acrylonitrile butadiene styrene polymers. Int. J. Fatigue 2022, 165, 107212. [Google Scholar] [CrossRef]

- Frascio, M.; Avalle, M.; Monti, M. Fatigue strength of plastics components made in additive manufacturing: First experimental results. Procedia Struct. Integr. 2018, 12, 32–43. [Google Scholar] [CrossRef]

- Dolzyk, G.; Jung, S. Tensile and fatigue analysis of 3D-printed polyethylene terephthalate glycol. J. Fail. Anal. Prev. 2019, 19, 511–518. [Google Scholar] [CrossRef]

- Bakhtiari, H.; Aamir, M.; Tolouei-Rad, M. Effect of 3D printing parameters on the fatigue properties of parts manufactured by fused filament fabrication: A review. Appl. Sci. 2023, 13, 904. [Google Scholar] [CrossRef]

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- He, F.; Khan, M. Effects of printing parameters on the fatigue behaviour of 3D-printed ABS under dynamic thermo-mechanical loads. Polymers 2021, 13, 2362. [Google Scholar] [CrossRef]

- Ziemian, C.W.; Ziemian, R.D.; Haile, K.V. Characterization of stiffness degradation caused by fatigue damage of additive manufactured parts. Mater. Des. 2016, 109, 209–218. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood1, S.H.; Iovenitti, P.; Nikzad, M.; Sbarski, I. Effects of part build orientations on fatigue behaviour of FDM-processed PLA material. Prog Addit Manuf 2016, 1, 21–28. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Llumà, J.; Traver-Ramos, O.; Gomez-Gras, G.; Rovira, J.J.R. Mechanical properties of 3D-printing polylactic acid parts subjected to bending stress and fatigue testing. Materials 2019, 12, 3859. [Google Scholar] [CrossRef]

- Glaskova-Kuzmina, T.; Dejus, D.; Jātnieks, J.; Aniskevich, A.; Sevcenko, J.; Sarakovskis, A.; Zolotarjovs, A. Effect of post-printing cooling conditions on the properties of ULTEM printed parts. Polymers 2023, 15, 324. [Google Scholar] [CrossRef]

- Stratasys Inc., in Ultem 9085 (Product Information, 2023). Available online: https://www.stratasys.com/en/materials/materials-catalog/fdm-materials/ultem-9085 (accessed on 4 March 2023).

- Lv, Y.; Dejus, D.; Kobenko, S.; Singamneni, S.; Glaskova-Kuzmina, T. Evaluation of the fire-retardancy of ULTEM 9085 polymer composites processed by fused deposition modelling. Mater. Sci. 2022, 28, 353–359. [Google Scholar] [CrossRef]

- Kobenko, S.; Dejus, D.; Jātnieks, J.; Pazars, D.; Glaskova-Kuzmina, T. Structural integrity of the aircraft interior spare parts produced by additive manufacturing. Polymers 2022, 14, 1538. [Google Scholar] [CrossRef]

- Byberg, K.I.; Gebisa, A.W.; Lemu, H.G. Mechanical properties of ULTEM 9085 material processed by fused deposition modeling. Polym. Test. 2018, 72, 335–347. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. 2017. Available online: https://www.astm.org/d0790-17.html (accessed on 4 April 2023).

- Einbergs, E.; Zolotarjovs, A. Programmable material testing device for mechanoluminescence measurements. HardwareX 2022, 12, e00349. [Google Scholar] [CrossRef] [PubMed]

- Padovano, E.; Galfione, M.; Concialdi, P.; Lucco, G.; Badini, C. Mechanical and thermal behavior of Ultem® 9085 fabricated by fused-deposition modeling. Appl. Sci. 2020, 10, 3170. [Google Scholar] [CrossRef]

- Forés-Garriga, A.; Pérez, M.A.; Gómez-Gras, G.; Reyes-Pozo, G. Role of infill parameters on the mechanical performance and weight reduction of PEI Ultem processed by FFF. Mater. Des. 2020, 193, 108810. [Google Scholar] [CrossRef]

- Van Paepegem, W.C. 16-Fatigue testing methods for polymer matrix composites. In Creep and Fatigue in Polymer Matrix Composites; Guedes, R.M., Ed.; Elsevier, Woodhead Publishing: Oxford, UK, 2011; pp. 461–491. ISBN 9780081014585. [Google Scholar]

- Coasey, K.; Hart, K.R.; Wetzel, E.; Edwards, D.; Mackay, M.E. Nonisothermal welding in fused filament fabrication. Addit. Manuf. 2020, 33, 101140. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glaskova-Kuzmina, T.; Dejus, D.; Jātnieks, J.; Kruuv, P.-P.; Zolotarjovs, A.; Einbergs, E.; Vanags, E. Effect of Printing Direction and Post-Printing Conditions on Bending Properties of ULTEM 9085. J. Compos. Sci. 2023, 7, 316. https://doi.org/10.3390/jcs7080316

Glaskova-Kuzmina T, Dejus D, Jātnieks J, Kruuv P-P, Zolotarjovs A, Einbergs E, Vanags E. Effect of Printing Direction and Post-Printing Conditions on Bending Properties of ULTEM 9085. Journal of Composites Science. 2023; 7(8):316. https://doi.org/10.3390/jcs7080316

Chicago/Turabian StyleGlaskova-Kuzmina, Tatjana, Didzis Dejus, Jānis Jātnieks, Partel-Peeter Kruuv, Aleksejs Zolotarjovs, Ernests Einbergs, and Edgars Vanags. 2023. "Effect of Printing Direction and Post-Printing Conditions on Bending Properties of ULTEM 9085" Journal of Composites Science 7, no. 8: 316. https://doi.org/10.3390/jcs7080316

APA StyleGlaskova-Kuzmina, T., Dejus, D., Jātnieks, J., Kruuv, P.-P., Zolotarjovs, A., Einbergs, E., & Vanags, E. (2023). Effect of Printing Direction and Post-Printing Conditions on Bending Properties of ULTEM 9085. Journal of Composites Science, 7(8), 316. https://doi.org/10.3390/jcs7080316