Biopolymer-Based Composites: An Eco-Friendly Alternative from Agricultural Waste Biomass

Abstract

1. Introduction

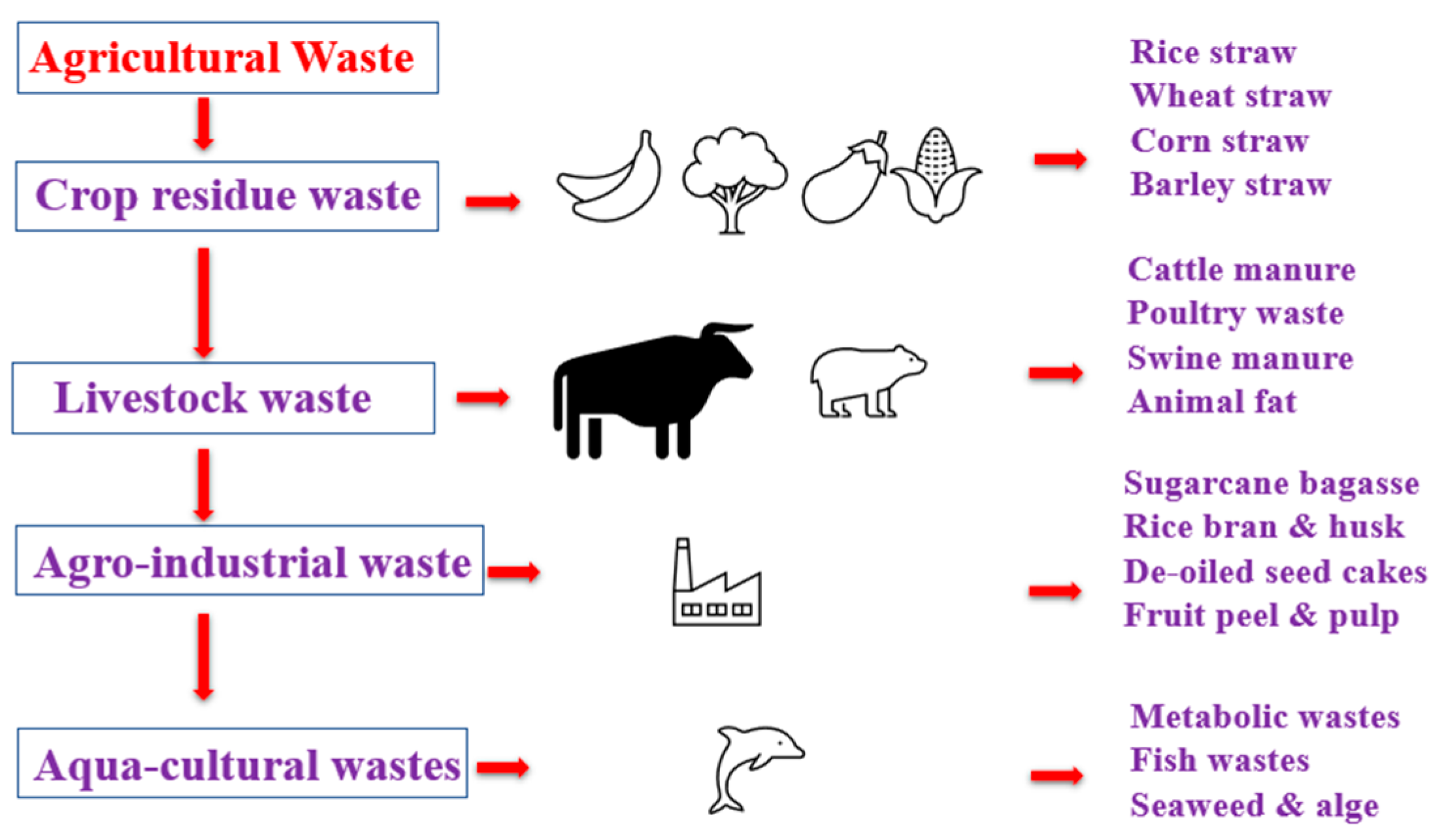

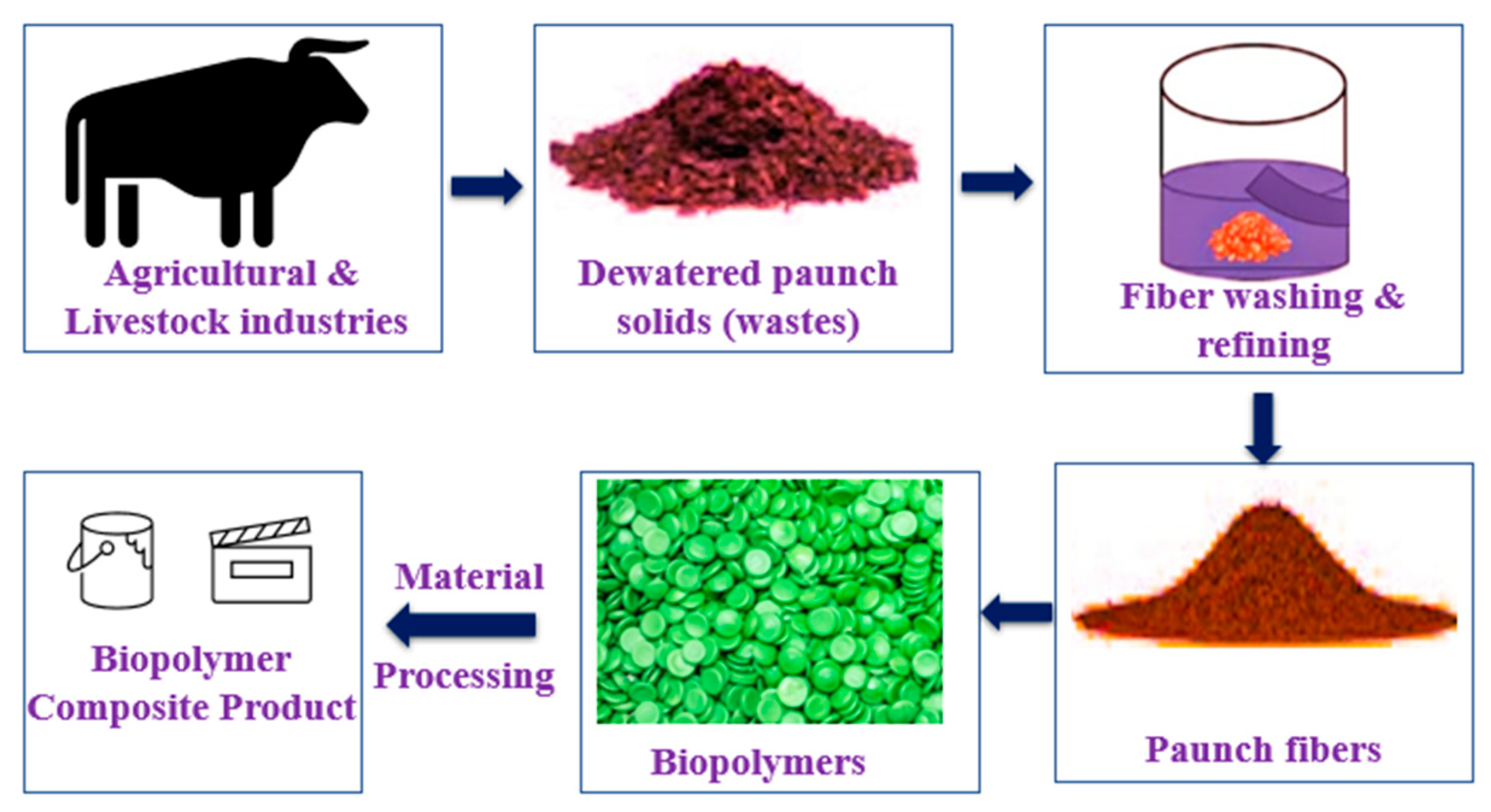

2. Fibers from Agricultural Wastes

2.1. Rice Straw Fiber

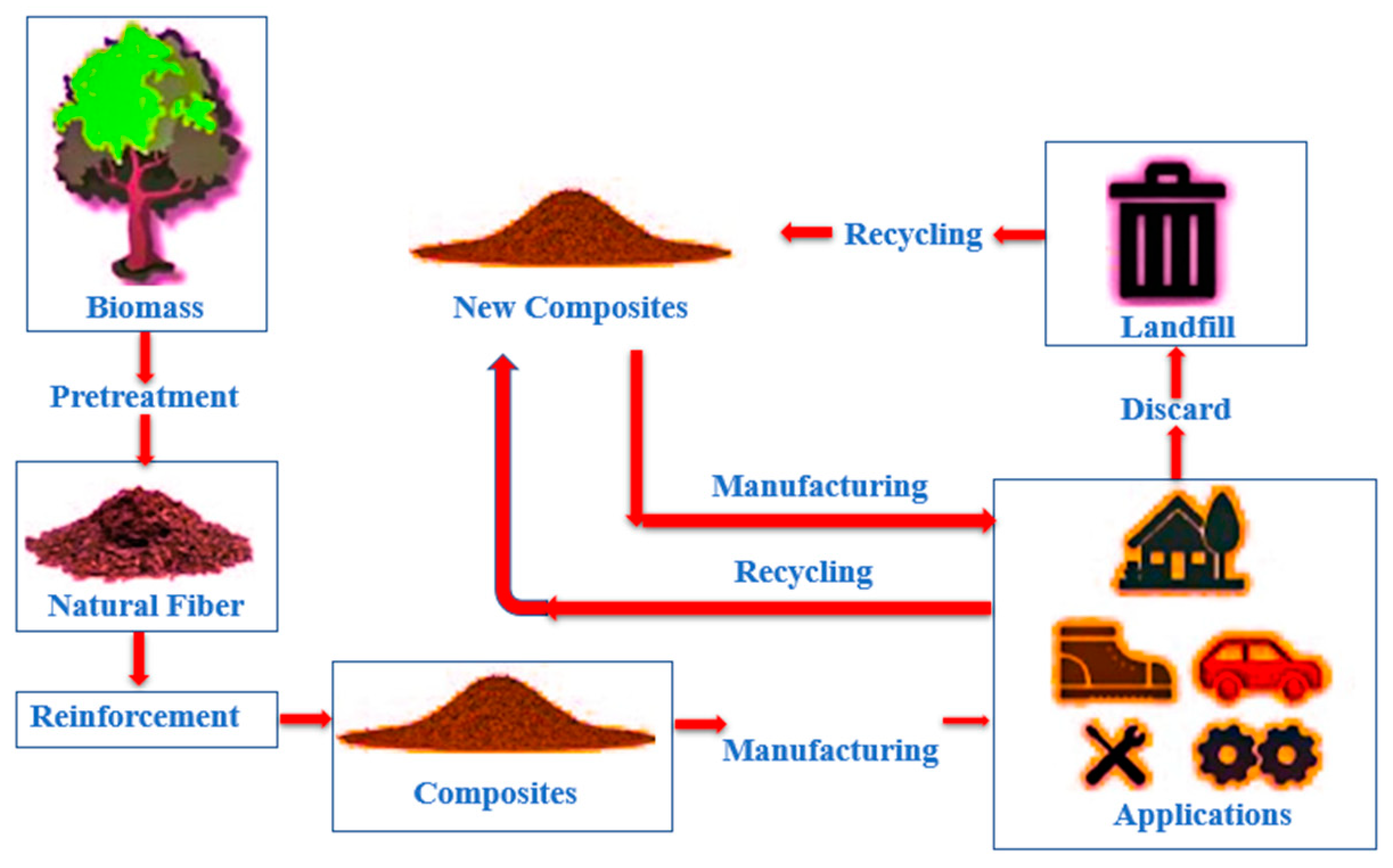

2.2. Bamboo Fiber

2.3. Bagasse

2.4. Banana Fiber

2.5. Kenaf Fibers

2.6. Jute Fiber

2.7. Hemp Fiber

2.8. Sisal Fiber

2.9. Abaca Fiber

3. Composition of the Natural Fibers from Agricultural Waste Biomass

4. Chemical Treatments

4.1. Acid Treatment

4.2. Alkali Treatment

4.3. Bleaching

4.4. Silane Treatment

5. Biopolymer-Based Composites from Agricultural Waste Biomass

6. Applications

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Singh, R.P.; Singh, P.; Araujo, A.S.; Ibrahim, M.H.; Sulaiman, O. Management of urban solid waste: Vermicomposting a sustainable option. Resour. Conserv. Recycl. 2011, 55, 719–729. [Google Scholar] [CrossRef]

- Khalil, H.A.; Bhat, A.H.; Yusra, A.I. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Verma, A.; Singh, C.; Singh, V.K.; Jain, N. Fabrication and characterization of chitosan-coated sisal fiber–Phytagel modified soy protein-based green composite. J. Compos. Mater. 2019, 53, 2481–2504. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Yashas Gowda, T.G.; Sanjay, M.R.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer matrix-natural fiber composites: An overview. Cogent Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Puttegowda, M.; Rangappa, S.M.; Jawaid, M.; Shivanna, P.; Basavegowda, Y.; Saba, N. Potential of natural/synthetic hybrid composites for aerospace applications. In Sustainable Composites for Aerospace Applications; Woodhead Publishing: Sawston, UK, 2018; pp. 315–351. [Google Scholar]

- Mahir, F.I.; Keya, K.N.; Sarker, B.; Nahiun, K.M.; Khan, R.A. A brief review on natural fiber used as a replacement of synthetic fiber in polymer composites. Mater. Eng. Res. 2019, 1, 86–97. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable biobased composites for advanced applications: Recent trends and future opportunities—A critical review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Leão, A.; Sartor, S.M.; Caraschi, J.C. Natural fibers based composites–technical and social issues. Mol. Cryst. Liq. Cryst. 2006, 448, 161–763. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. (Eds.) Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Wu, F.; Misra, M.; Mohanty, A.K. Sustainable green composites from biodegradable plastics blend and natural fibre with balanced performance: Synergy of nano-structured blend and reactive extrusion. Compos. Sci. Technol. 2020, 200, 108369. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Manimaran, P.; Verma, A.; Sanjay, M.R.; Siengchin, S.; Kandakodeeswaran, K.; Geetha, M. A novel palm sheath and sugarcane bagasse fiber based hybrid composites for automotive applications: An experimental approach. Polym. Compos. 2021, 42, 512–521. [Google Scholar] [CrossRef]

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of natural fiber composites: Challenges and opportunities. Resour. Conserv. Recycl. 2022, 177, 105962. [Google Scholar] [CrossRef]

- Athith, D.; Sanjay, M.R.; Yashas Gowda, T.G.; Madhu, P.; Arpitha, G.R.; Yogesha, B.; Omri, M.A. Effect of tungsten carbide on mechanical and tribological properties of jute/sisal/E-glass fabrics reinforced natural rubber/epoxy composites. J. Ind. Text. 2018, 48, 713–737. [Google Scholar] [CrossRef]

- Khan, T.; Hameed Sultan, M.T.B.; Ariffin, A.H. The challenges of natural fiber in manufacturing, material selection, and technology application: A review. J. Reinf. Plast. Compos. 2018, 37, 770–779. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Pradeep, S.; Bhat, K.S.; Yogesha, B.; Siengchin, S. Characterization of cellulosic fibre from Phoenix pusilla leaves as potential reinforcement for polymeric composites. J. Mater. Res. Technol. 2019, 8, 2597–2604. [Google Scholar] [CrossRef]

- Muhammad, S.; Abdul Khalil, H.P.S.; Abd Hamid, S.; Albadn, Y.M.; Suriani, A.B.; Kamaruzzaman, S.; Mohamed, A.; Allaq, A.A.; Yahya, E.B. Insights into Agricultural-Waste-Based Nano-Activated Carbon Fabrication and Modifications for Wastewater Treatment Application. Agriculture 2022, 12, 1737. [Google Scholar] [CrossRef]

- Dungani, R.; Karina, M.; Sulaeman, A.; Hermawan, D.; Hadiyane, A. Agricultural waste fibers towards sustainability and advanced utilization: A review. Asian J. Plant Sci. 2016, 15, 42–55. [Google Scholar] [CrossRef]

- Samrot, A.V.; Ngaakudzwe, K.T.; Rajalakshmi, D.; Prakash, P.; Suresh Kumar, S.; Chandramohan, M.; Alex Anand, D.; Lilly Mercy, J.; Simon, Y.; Saigeetha, S. Waste-derived cellulosic fibers and their applications. Adv. Mater. Sci. Eng. 2022, 2022, 7314694. [Google Scholar] [CrossRef]

- Dixit, S.; Goel, R.; Dubey, A.; Shivhare, P.R.; Bhalavi, T. Natural fibre reinforced polymer composite materials—A review. Polym. Renew. Resour. 2017, 8, 71–78. [Google Scholar] [CrossRef]

- Tayfun, U.; Dogan, M.; Bayramli, E. Effect of surface modification of rice straw on mechanical and flow properties of TPU-based green composites. Polym. Compos. 2016, 37, 1596–1602. [Google Scholar] [CrossRef]

- Ismail, M.R.; Yassen, A.A.; Afify, M.S. Mechanical properties of rice straw fiber-reinforced polymer composites. Fibers Polym. 2011, 12, 648–656. [Google Scholar] [CrossRef]

- Jayamani, E.; Hamdan, S.; Rahman, M.R.; Bakri, M.K.B. Study of sound absorption coefficients and characterization of rice straw stem fibers reinforced polypropylene composites. BioResources 2015, 10, 3378–3392. [Google Scholar] [CrossRef]

- Poonia, N.; Kadam, V.; Rose, N.M.; Yadav, S.; Shanmugam, N. Effect of Fiber Chemical Treatments on Rice Straw Fiber Reinforced Composite Properties. J. Nat. Fibers 2022, 19, 14044–14054. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Senthamaraikannan, P.; Pradeep, S.; Saravanakumar, S.S.; Yogesha, B. A review on synthesis and characterization of commercially available natural fibers: Part-I. J. Nat. Fibers 2019, 16, 1132–1144. [Google Scholar] [CrossRef]

- Prabowo, I.; Pratama, J.N.; Chalid, M. The effect of modified ijuk fibers to crystallinity of polypropylene composite. IOP Conf. Ser. Mater. Sci. Eng. 2017, 223, 012020. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Jawaid, M.; Siengchin, S.; Khan, A.; Pruncu, C.I. A new study on effect of various chemical treatments on Agave Americana fiber for composite reinforcement: Physico-chemical, thermal, mechanical and morphological properties. Polym. Test. 2020, 85, 106437. [Google Scholar] [CrossRef]

- Khalil, H.A.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y.S. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Pandey, J.K.; Ahn, S.H.; Lee, C.S.; Mohanty, A.K.; Misra, M. Recent advances in the application of natural fiber based composites. Macromol. Mater. Eng. 2010, 295, 975–989. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Anderson, D.P.; Chang, P.R.; Hua, Y. Bamboo fiber and its reinforced composites: Structure and properties. Cellulose 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Jawaid, M.; Chee, S.S.; Asim, M.; Saba, N.; Kalia, S. Sustainable kenaf/bamboo fibers/clay hybrid nanocomposites: Properties, environmental aspects and applications. J. Clean. Prod. 2022, 330, 129938. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Senthamaraikannan, P.; Pradeep, S.; Siengchin, S.; Jawaid, M.; Kathiresan, M. Effect of various chemical treatments of Prosopis juliflora fibers as composite reinforcement: Physicochemical, thermal, mechanical, and morphological properties. J. Nat. Fibers 2020, 17, 833–844. [Google Scholar] [CrossRef]

- Bharath, K.N.; Madhu, P.; Gowda, T.Y.; Sanjay, M.R.; Kushvaha, V.; Siengchin, S. Alkaline effect on characterization of discarded waste of Moringa oleifera fiber as a potential eco-friendly reinforcement for biocomposites. J. Polym. Environ. 2020, 28, 2823–2836. [Google Scholar] [CrossRef]

- Balaji, A.; Karthikeyan, B.; Raj, C.S. Bagasse fiber–the future biocomposite material: A review. Int. J. ChemTech Res. 2014, 7, 223–233. [Google Scholar]

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites-a review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.A.; Richardson, M.O. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Vilay, V.; Mariatti, M.; Taib, R.M.; Todo, M. Effect of fiber surface treatment and fiber loading on the properties of bagasse fiber–reinforced unsaturated polyester composites. Compos. Sci. Technol. 2008, 68, 631–638. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.C.; Maheshwari, M.K.; Sharma, R.K. Bagasse fiber composites—A review. J. Mater. Environ. Sci 2012, 3, 1079–1092. [Google Scholar]

- Bharath, K.N.; Madhu, P.; Gowda, T.G.; Verma, A.; Sanjay, M.R.; Siengchin, S. A novel approach for development of printed circuit board from biofiber based composites. Polym. Compos. 2020, 41, 4550–4558. [Google Scholar] [CrossRef]

- Puttegowda, M.; Rangappa, S.M.; Khan, A.; Al-Zahrani, S.A.; Al Otaibi, A.; Shivanna, P.; Moure, M.M.; Siengchin, S. Preparation and characterization of new hybrid polymer composites from phoenix pusilla fibers/e-glass/carbon fabrics on potential engineering applications: Effect of stacking sequence. Polym. Compos. 2020, 41, 4572–4582. [Google Scholar] [CrossRef]

- Atmakuri, A.; Palevicius, A.; Kolli, L.; Vilkauskas, A.; Janusas, G. Development and analysis of mechanical properties of caryota and sisal natural fibers reinforced epoxy hybrid composites. Polymers 2021, 13, 864. [Google Scholar] [CrossRef]

- Ray, D.P.; Nayak, L.K.; Ammayappan, L.; Shambhu, V.B.; Nag, D. Energy conservation drives for efficient extraction and utilization of banana fibre. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 296–310. [Google Scholar]

- Pothan, L.A.; Oommen, Z.; Thomas, S. Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos. Sci. Technol. 2003, 63, 283–293. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Babu, R.P.; O’connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 1–16. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khalid, M.Y.; Imran, R.; Ali, U.; Koc, M. Utilization of banana fiber-reinforced hybrid composites in the sports industry. Materials 2020, 13, 3167. [Google Scholar] [CrossRef] [PubMed]

- Venkateshwaran, N.; Elayaperumal, A. Banana fiber reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2010, 29, 2387–2396. [Google Scholar] [CrossRef]

- Hossain, M.S.; Mobarak, M.B.; Rony, F.K.; Sultana, S.; Mahmud, M.; Ahmed, S. Fabrication and characterization of banana fiber reinforced unsaturated polyester resin based composites. Nano Hybrids Compos. 2020, 29, 84–92. [Google Scholar]

- Rangappa, S.M.; Puttegowda, M.; Parameswaranpillai, J.; Siengchin, S.; Gorbatyuk, S.M. (Eds.) Advances in Bio-Based Fiber: Moving Towards a Green Society; Woodhead Publishing: Sawston, UK, 2021. [Google Scholar]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric analysis properties of cellulosic natural fiber polymer composites: A review on influence of chemical treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef] [PubMed]

- Rashdi, A.A.; Sapuan, S.M.; Ahmad, M.M.; Khalina, A. Review of kenaf fiber reinforced polymer composites. Polimery 2009, 54, 777–780. [Google Scholar] [CrossRef]

- Akil, H.; Omar, M.F.; Mazuki, A.M.; Safiee, S.Z.A.M.; Ishak, Z.M.; Bakar, A.A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.T.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Sreenivas, H.T.; Krishnamurthy, N.; Arpitha, G.R. A comprehensive review on light weight kenaf fiber for automobiles. Int. J. Lightweight Mater. Manuf. 2020, 3, 328–337. [Google Scholar] [CrossRef]

- Yusuff, I.; Sarifuddin, N.; Ali, A.M. A review on kenaf fiber hybrid composites: Mechanical properties, potentials, and challenges in engineering applications. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 66–83. [Google Scholar] [CrossRef]

- Shaker, K.; Nawab, Y.; Jabbar, M. Bio-composites: Eco-friendly substitute of glass fiber composites. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Springer: Cham, Switzerland, 2020; pp. 1–25. [Google Scholar]

- Rangappa, S.M.; Puttegowda, M.; Parameswaranpillai, J.; Siengchin, S.; Ozbakkaloglu, T.; Wang, H. Introduction to plant fibers and their composites. In Plant Fibers, Their Composites, and Applications; Woodhead Publishing: Sawston, UK, 2022; pp. 1–24. [Google Scholar]

- Shahinur, S.; Sayeed, M.A.; Hasan, M.; Sayem, A.S.M.; Haider, J.; Ura, S. Current development and future perspective on natural jute fibers and their biocomposites. Polymers 2022, 14, 1445. [Google Scholar] [CrossRef]

- Shah, S.S.; Shaikh, M.N.; Khan, M.Y.; Alfasane, M.A.; Rahman, M.M.; Aziz, M.A. Present status and future prospects of jute in nanotechnology: A review. Chem. Rec. 2021, 21, 1631–1665. [Google Scholar] [CrossRef] [PubMed]

- Gupta, M.K.; Srivastava, R.K.; Bisaria, H. Potential of jute fibre reinforced polymer composites: A review. Int. J. Fiber Text. Res 2015, 5, 30–38. [Google Scholar]

- Kabir, M.M.; Islam, M.M.; Wang, H. Mechanical and thermal properties of jute fibre reinforced composites. J. Multifunct. Compos. 2013, 1, 71–77. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Singh, S.; Dhawan, V. Effect of curing temperature on mechanical properties of natural fiber reinforced polymer composites. J. Nat. Fibers 2018, 15, 687–696. [Google Scholar] [CrossRef]

- Kong, I.; Shang, J.T.B.; Tshai, K.Y. Study of properties of coconut fibre reinforced poly (vinyl alcohol) as biodegradable composites. ARPN J. Eng. Appl. Sci. 2016, 11, 135–143. [Google Scholar]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Shekar, H.S.; Ramachandra, M.J.M.T.P. Green composites: A review. Mater. Today Proc. 2018, 5, 2518–2526. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Ismail, S.O.; Zhang, Z.; Barber, A.; Welsh, E.; Maigret, J.E.; Beaugrand, J. Development of sustainable biodegradable lignocellulosic hemp fiber/polycaprolactone biocomposites for light weight applications. Compos. Part A Appl. Sci. Manuf. 2018, 113, 350–358. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. J. Polym. Process. Inst. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Pinheiro, I.F.; de Souza, S.F.; Mei, L.H.; Lona, L.M. Polymer composites reinforced with natural fibers and nanocellulose in the automotive industry: A short review. J. Compos. Sci. 2019, 3, 51. [Google Scholar] [CrossRef]

- Kangokar Mukesh, S.; Bettagowda, N.; Praveenkumara, J.; Thyavihalli Girijappa, Y.G.; Puttegowda, M.; Mavinkere Rangappa, S.; Siengchin, S.; Gorbatyuk, S. Influence of stacking sequence on flax/kevlar hybrid epoxy composites: Mechanical and morphological studies. Polym. Compos. 2022, 43, 3782–3793. [Google Scholar] [CrossRef]

- Ngaowthong, C.; Borůvka, M.; Běhálek, L.; Lenfeld, P.; Švec, M.; Dangtungee, R.; Siengchin, S.; Rangappa, S.M.; Parameswaranpillai, J. Recycling of sisal fiber reinforced polypropylene and polylactic acid composites: Thermo-mechanical properties, morphology, and water absorption behavior. Waste Manag. 2019, 97, 71–81. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I. Processing of PLA/sisal fiber biocomposites using direct-and extrusion-injection molding. Mater. Manuf. Process. 2017, 32, 468–474. [Google Scholar] [CrossRef]

- Jariwala, H.; Jain, P. A review on mechanical behavior of natural fiber reinforced polymer composites and its applications. J. Reinf. Plast. Compos. 2019, 38, 441–453. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B.J.N.R. Applications of natural fibers and its composites: An overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef]

- Shalwan, A.; Yousif, B.F. In state of art: Mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater. Des. 2013, 48, 14–24. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef] [PubMed]

- Ramnath, B.V.; Kokan, S.J.; Raja, R.N.; Sathyanarayanan, R.; Elanchezhian, C.; Prasad, A.R.; Manickavasagam, V.M. Evaluation of mechanical properties of abaca–jute–glass fibre reinforced epoxy composite. Mater. Des. 2013, 51, 357–366. [Google Scholar] [CrossRef]

- Ren, H.; Zhang, Y.; Zhai, H.; Chen, J. Production and evaluation of biodegradable composites based on polyhydroxybutyrate and polylactic acid reinforced with short and long pulp fibers. Cellul. Chem. Technol. 2015, 49, 641–652. [Google Scholar]

- Jonoobi, M.; Harun, J.; Mishra, M.; Oksman, K. Chemical composition, crystallinity and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofiber. BioResources 2009, 4, 626–639. [Google Scholar]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.B.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Kumar Gupta, G.; De, S.; Franco, A.; Balu, A.M.; Luque, R. Sustainable biomaterials: Current trends, challenges and applications. Molecules 2015, 21, 48. [Google Scholar] [CrossRef]

- Selva, M. Nanotechnologies for the sustainable valorization of biowastes. Curr. Opin. Green Sustain. Chem. 2020, 24, 38–41. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical review of natural fiber reinforced hybrid composites: Processing, properties, applications and cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Nurazzi, N.M.; Norrrahim, M.N.F.; Ibrahim, R.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; Izwan, S.; Azammi, A.N.; et al. Macro to nanoscale natural fiber composites for automotive components: Research, development, and application. In Biocomposite and Synthetic Composites for Automotive Applications; Woodhead Publishing: Sawston, UK, 2021; pp. 51–105. [Google Scholar]

- Chan, C.M.; Martin, D.; Gauthier, E.; Jensen, P.; Laycock, B.; Pratt, S. Utilisation of Paunch Waste as a Natural Fibre in Biocomposites. Polymers 2022, 14, 3704. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Sultan, M.T.; Ariffin, A.H.; Shah, A.U. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Cantero, G.; Llano-Ponte, R.; Valea, A.; Mondragon, I. Mechanical properties of flax fibre/polypropylene composites. Influ. Fibre/Matrix Modif. Glass Fibre Hybrid. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1637–1644. [Google Scholar] [CrossRef]

- Sutharson, B.; Rajendran, M.; Devadasan, S.R.; Selvam, B. Effect of chemical treatments on mechanical properties of jute fiber hybrid composite laminates. ARPN J. Eng. Appl. Sci. 2012, 7, 760–765. [Google Scholar]

- Cisneros-López, E.O.; González-López, M.E.; Pérez-Fonseca, A.A.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of fiber content and surface treatment on the mechanical properties of natural fiber composites produced by rotomolding. Compos. Interfaces 2017, 24, 35–53. [Google Scholar] [CrossRef]

- Panyasart, K.; Chaiyut, N.; Amornsakchai, T.; Santawitee, O. Effect of surface treatment on the properties of pineapple leaf fibers reinforced polyamide 6 composites. Energy Procedia 2014, 56, 406–413. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M.K. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, Z.; Zhang, Z.; You, L.; Xu, L.; Huang, H.; Wang, X.; Gao, Y.; Cui, X. Treatment of the saline-alkali soil with acidic corn stalk biochar and its effect on the sorghum yield in western Songnen Plain. Sci. Total Environ. 2021, 797, 149190. [Google Scholar] [CrossRef] [PubMed]

- Nadzri, S.N.I.H.A.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Talib, A.R.A.; Jawaid, M.; Basri, A.A. A comprehensive review of coconut shell powder composites: Preparation, processing, and characterization. J. Thermoplast. Compos. Mater. 2022, 35, 2641–2664. [Google Scholar] [CrossRef]

- Punyamurthy, R.; Sampathkumar, D.; Ranganagowda, R.P.G.; Bennehalli, B.; Srinivasa, C.V. Mechanical properties of abaca fiber reinforced polypropylene composites: Effect of chemical treatment by benzenediazonium chloride. J. King Saud Univ.-Eng. Sci. 2017, 29, 289–294. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K. Characterization of alkali-treated jute fibers for physical and mechanical properties. J. Appl. Polym. Sci. 2001, 80, 1013–1020. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- Madhu, P.; Praveenkumara, J.; Sanjay, M.R.; Siengchin, S.; Gorbatyuk, S. Introduction to bio-based fibers and their composites. In Advances in Bio-Based Fiber; Woodhead Publishing: Sawston, UK, 2022; pp. 1–20. [Google Scholar]

- Martínez-Barrera, G.; Garduño-Jaimes, I.Z.; Vigueras-Santiago, E.; Cruz-Olivares, J.; González-Rivas, N.; Gencel, O. Green Composites from Sustainable Cellulose Nanofibrils. In Green Composites; Springer: Singapore, 2021; pp. 135–150. [Google Scholar]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.S.; Margem, F.M. Thermogravimetric behavior of natural fibers reinforced polymer composites-An overview. Mater. Sci. Eng. A 2012, 557, 17–28. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Yashas Gowda, T.G.; Madhu, P.; Kushvaha, V.; Rangappa, S.M.; Siengchin, S. Comparative evaluation of areca/carbon/basalt fiber reinforced epoxy/bio epoxy based hybrid composites. Polym. Compos. 2022, 43, 4179–4190. [Google Scholar] [CrossRef]

- Yashas Gowda, T.G.; Vinod, A.; Madhu, P.; Sanjay, M.R.; Siengchin, S.; Jawaid, M. Areca/synthetic fibers reinforced based epoxy hybrid composites for semi-structural applications. Polym. Compos. 2022, 43, 5222–5234. [Google Scholar] [CrossRef]

- Cruz, J.; Fangueiro, R. Surface modification of natural fibers: A review. Procedia Eng. 2016, 155, 285–288. [Google Scholar] [CrossRef]

- Forintos, N.; Czigany, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers–A short review. Compos. Part B Eng. 2019, 162, 331–343. [Google Scholar] [CrossRef]

- Pommet, M.; Juntaro, J.; Heng, J.Y.; Mantalaris, A.; Lee, A.F.; Wilson, K.; Kalinka, G.; Shaffer, M.S.; Bismarck, A. Surface modification of natural fibers using bacteria: Depositing bacterial cellulose onto natural fibers to create hierarchical fiber reinforced nanocomposites. Biomacromolecules 2008, 9, 1643–1651. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Adekomaya, O.; Majozi, T. Sustainability of surface treatment of natural fibre in composite formation: Challenges of environment-friendly option. Int. J. Adv. Manuf. Technol. 2019, 105, 3183–3195. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Sobhan, A.; Muthukumarappan, K.; Wei, L. Biosensors and biopolymer-based nanocomposites for smart food packaging: Challenges and opportunities. Food Packag. Shelf Life 2021, 30, 100745. [Google Scholar] [CrossRef]

- Adeyeye, O.A.; Sadiku, E.R.; Babu Reddy, A.; Ndamase, A.S.; Makgatho, G.; Sellamuthu, P.S.; Perumal, A.B.; Nambiar, R.B.; Fasiku, V.O.; Ibrahim, I.D.; et al. The use of biopolymers in food packaging. In Green Biopolymers and Their Nanocomposites; Springer: Singapore, 2019; pp. 137–158. [Google Scholar]

- Wang, Y.; Hu, Y.J.; Hao, X.; Peng, P.; Shi, J.Y.; Peng, F.; Sun, R.C. Hydrothermal synthesis and applications of advanced carbonaceous materials from biomass: A review. Adv. Compos. Hybrid Mater. 2020, 3, 267–284. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Sustainable green composites: Value addition to agricultural residues and perennial grasses. ACS Sustain. Chem. Eng. 2013, 1, 325–333. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Khan, A.; Otaibi, A.A.; Al-Zahrani, S.A.; Pradeep, S.; Yogesha, B.; Boonyasopon, P.; Siengchin, S. Hybrid effect of PJFs/E-glass/carbon fabric reinforced hybrid epoxy composites for structural applications. J. Nat. Fibers 2022, 19, 3742–3752. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Thyavihalli Girijappa, Y.G.; Rangappa, S.M.; Siengchin, S. Effect of natural filler materials on fiber reinforced hybrid polymer composites: An Overview. J. Nat. Fibers 2022, 19, 4132–4147. [Google Scholar] [CrossRef]

- Yadav, P.; Yadav, H.; Shah, V.G.; Shah, G.; Dhaka, G. Biomedical biopolymers, their origin and evolution in biomedical sciences: A systematic review. J. Clin. Diagn. Res. JCDR 2015, 9, ZE21. [Google Scholar] [CrossRef]

- Biswas, M.C.; Jony, B.; Nandy, P.K.; Chowdhury, R.A.; Halder, S.; Kumar, D.; Ramakrishna, S.; Hassan, M.; Ahsan, M.A.; Hoque, M.E.; et al. Recent advancement of biopolymers and their potential biomedical applications. J. Polym. Environ. 2021, 30, 51–74. [Google Scholar] [CrossRef]

- Aslam Khan, M.U.; Abd Razak, S.I.; Al Arjan, W.S.; Nazir, S.; Sahaya Anand, T.J.; Mehboob, H.; Amin, R. Recent advances in biopolymeric composite materials for tissue engineering and regenerative medicines: A review. Molecules 2021, 26, 619. [Google Scholar] [CrossRef]

- Maitz, M.F. Applications of synthetic polymers in clinical medicine. Biosurface Biotribology 2015, 1, 161–176. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Karishma, S. Review on biopolymers and composites–evolving material as adsorbents in removal of environmental pollutants. Environ. Res. 2022, 212, 113114. [Google Scholar] [CrossRef]

- Udayakumar, G.P.; Muthusamy, S.; Selvaganesh, B.; Sivarajasekar, N.; Rambabu, K.; Sivamani, S.; Sivakumar, N.; Maran, J.P.; Hosseini-Bandegharaei, A. Ecofriendly biopolymers and composites: Preparation and their applications in water-treatment. Biotechnol. Adv. 2021, 52, 107815. [Google Scholar] [CrossRef]

- Aaliya, B.; Sunooj, K.V.; Lackner, M. Biopolymer composites: A review. Int. J. Biobased Plast. 2021, 3, 40–84. [Google Scholar] [CrossRef]

- Mtibe, A.; Motloung, M.P.; Bandyopadhyay, J.; Ray, S.S. Synthetic biopolymers and their composites: Advantages and limitations—An overview. Macromol. Rapid Commun. 2021, 42, 2100130. [Google Scholar] [CrossRef] [PubMed]

- Sadasivuni, K.K.; Saha, P.; Adhikari, J.; Deshmukh, K.; Ahamed, M.B.; Cabibihan, J.J. Recent advances in mechanical properties of biopolymer composites: A review. Polym. Compos. 2020, 41, 32–59. [Google Scholar] [CrossRef]

- Sampath, U.G.T.; Ching, Y.C.; Chuah, C.H.; Sabariah, J.J.; Lin, P.C. Fabrication of porous materials from natural/synthetic biopolymers and their composites. Materials 2016, 9, 991. [Google Scholar] [CrossRef] [PubMed]

- Bustamante-Torres, M.; Arcentales-Vera, B.; Estrella-Nuñez, J.; Yánez-Vega, H.; Bucio, E. Antimicrobial Activity of Composites-Based on Biopolymers. Macromol 2022, 2, 258–283. [Google Scholar] [CrossRef]

- Barra, A.; Santos, J.D.; Silva, M.R.; Nunes, C.; Ruiz-Hitzky, E.; Gonçalves, I.; Yildirim, S.; Ferreira, P.; Marques, P.A. Graphene derivatives in biopolymer-based composites for food packaging applications. Nanomaterials 2020, 10, 2077. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, L.; Ansari, M.N.; Pua, G.; Jawaid, M.; Islam, M.S. A review on natural fiber reinforced polymer composite and its applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Čolnik, M.; Knez-Hrnčič, M.; Škerget, M.; Knez, Ž. Biodegradable polymers, current trends of research and their applications, a review. Chem. Ind. Chem. Eng. Q. 2020, 26, 401–418. [Google Scholar] [CrossRef]

- Bharath, K.N.; Puttegowda, M.; Mavinkere Rangappa, S.; Basavarajappa, S.; Siengchin, S.; Khan, A.; Gorbatyuk, S.M. Study of Treatment Effect on the Cocos Nucifera Lignocellulosic Fibers as Alternative for Polymer Composites. J. Nat. Fibers 2023, 20, 2134257. [Google Scholar] [CrossRef]

- Mohite, A.S.; Jagtap, A.R.; Avhad, M.S.; More, A.P. Recycling of major agriculture crop residues and its application in polymer industry: A Review in the context of waste to energy nexus. Energy Nexus 2022, 7, 100134. [Google Scholar] [CrossRef]

- Manimaran, P.; Vignesh, V.; Khan, A.; Pillai, G.P.; Nagarajan, K.J.; Prithiviraj, M.; Al-Romaizan, A.N.; Hussein, M.A.; Puttegowda, M.; Asiri, A.M. Extraction and characterization of natural lignocellulosic fibres from Typha angustata grass. Int. J. Biol. Macromol. 2022, 222, 1840–1851. [Google Scholar] [CrossRef]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-based packaging: Materials, modifications, industrial applications and sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef]

- Arpitha, G.R.; Mohit, H.; Madhu, P.; Verma, A. Effect of sugarcane bagasse and alumina reinforcements on physical, mechanical, and thermal characteristics of epoxy composites using artificial neural networks and response surface methodology. Biomass Convers. Biorefinery 2023, 1–19. [Google Scholar] [CrossRef]

- Vinod, A.; Sanjay, M.R.; Siengchin, S.; Fischer, S. Fully bio-based agro-waste soy stem fiber reinforced bio-epoxy composites for lightweight structural applications: Influence of surface modification techniques. Constr. Build. Mater. 2021, 303, 124509. [Google Scholar] [CrossRef]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A state-of-the-art review of polymers used in soil stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Song, J.H.; Murphy, R.J.; Narayan, R.; Davies, G.B.H. Biodegradable and compostable alternatives to conventional plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2127–2139. [Google Scholar] [CrossRef] [PubMed]

- Acquavia, M.A.; Pascale, R.; Martelli, G.; Bondoni, M.; Bianco, G. Natural polymeric materials: A solution to plastic pollution from the agro-food sector. Polymers 2021, 13, 158. [Google Scholar] [CrossRef]

- Tyagi, A.; Kumar, A.; Aparna, S.V.; Mallappa, R.H.; Grover, S.; Batish, V.K. Synthetic biology: Applications in the food sector. Crit. Rev. Food Sci. Nutr. 2016, 56, 1777–1789. [Google Scholar] [CrossRef] [PubMed]

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef]

- Bhamore, J.R.; Jha, S.; Singhal, R.K.; Murthy, Z.V.P.; Kailasa, S.K. Amylase protected gold nanoclusters as chemo-and bio-sensor for nanomolar detection of deltamethrin and glutathione. Sens. Actuators B Chem. 2019, 281, 812–820. [Google Scholar] [CrossRef]

- Arpitha, G.R.; Jain, N.; Verma, A. Banana biofiber and glass fiber reinforced hybrid composite for lightweight structural applications: Mechanical, thermal, and microstructural characterization. Biomass Convers. Biorefinery 2023, 1–10. [Google Scholar] [CrossRef]

- Rawat, K.A.; Bhamore, J.R.; Singhal, R.K.; Kailasa, S.K. Microwave assisted synthesis of tyrosine protected gold nanoparticles for dual (colorimetric and fluorimetric) detection of spermine and spermidine in biological samples. Biosens. Bioelectron. 2017, 88, 71–77. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

T. G., Y.G.; Ballupete Nagaraju, S.; Puttegowda, M.; Verma, A.; Rangappa, S.M.; Siengchin, S. Biopolymer-Based Composites: An Eco-Friendly Alternative from Agricultural Waste Biomass. J. Compos. Sci. 2023, 7, 242. https://doi.org/10.3390/jcs7060242

T. G. YG, Ballupete Nagaraju S, Puttegowda M, Verma A, Rangappa SM, Siengchin S. Biopolymer-Based Composites: An Eco-Friendly Alternative from Agricultural Waste Biomass. Journal of Composites Science. 2023; 7(6):242. https://doi.org/10.3390/jcs7060242

Chicago/Turabian StyleT. G., Yashas Gowda, Sharath Ballupete Nagaraju, Madhu Puttegowda, Akarsh Verma, Sanjay Mavinkere Rangappa, and Suchart Siengchin. 2023. "Biopolymer-Based Composites: An Eco-Friendly Alternative from Agricultural Waste Biomass" Journal of Composites Science 7, no. 6: 242. https://doi.org/10.3390/jcs7060242

APA StyleT. G., Y. G., Ballupete Nagaraju, S., Puttegowda, M., Verma, A., Rangappa, S. M., & Siengchin, S. (2023). Biopolymer-Based Composites: An Eco-Friendly Alternative from Agricultural Waste Biomass. Journal of Composites Science, 7(6), 242. https://doi.org/10.3390/jcs7060242