Fatigue Damage Assessment and Lifetime Prediction of Short Fiber Reinforced Polymer Composites—A Review

Abstract

:1. Introduction

- Interfacial debonding;

- Matrix microcracking;

- Interfacial sliding;

- Fiber breakage;

- Fiber microbuckling;

- Particle cleavage;

- Void growth.

- 8.

- 9.

- 10.

- 11.

- 12.

- 13.

- 14.

- 15.

- 16.

- 17.

2. General Considerations

3. Direct Methods for Damage Assessment

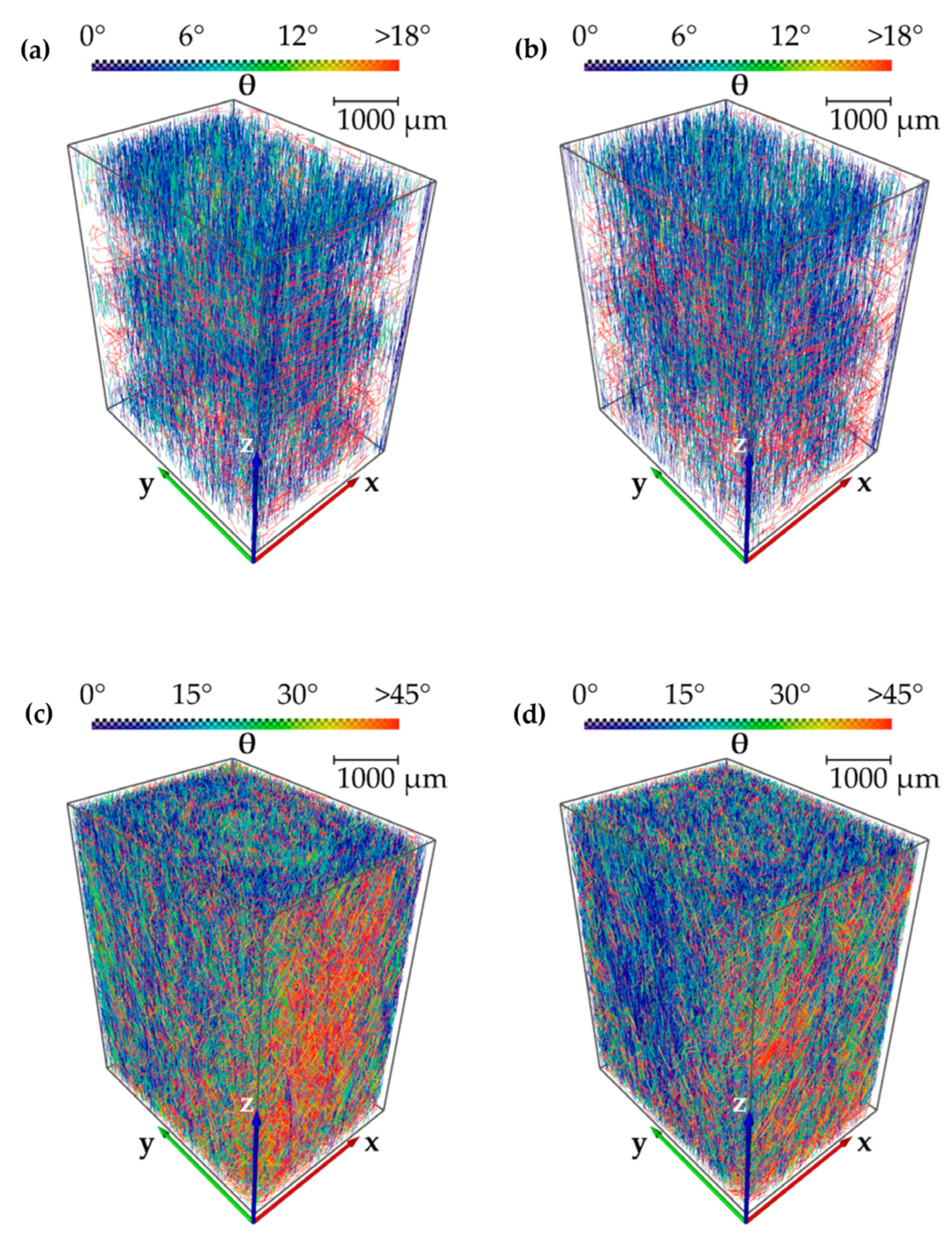

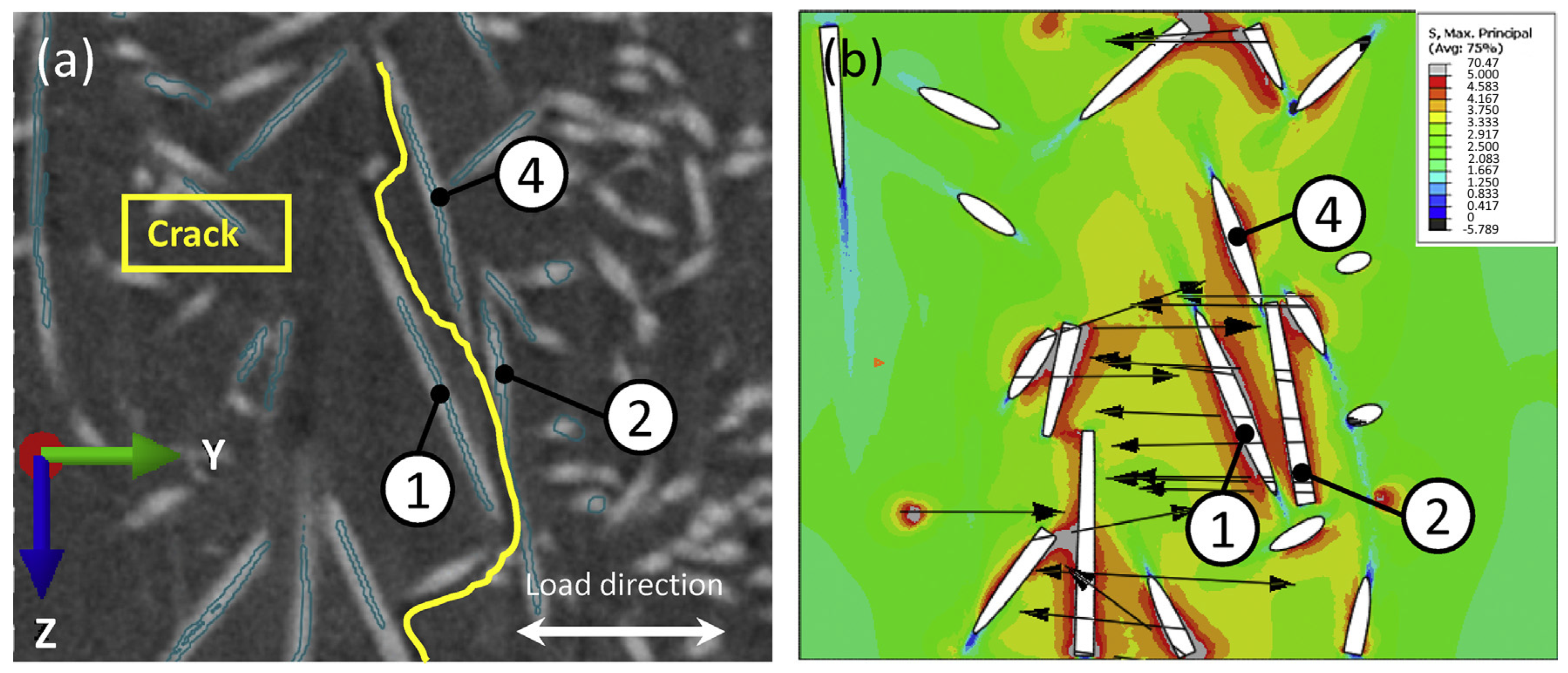

3.1. Computed Tomography

3.2. Visualization of Surface Damages

4. Indirect Methods for Fatigue Monitoring and Damage Assessment

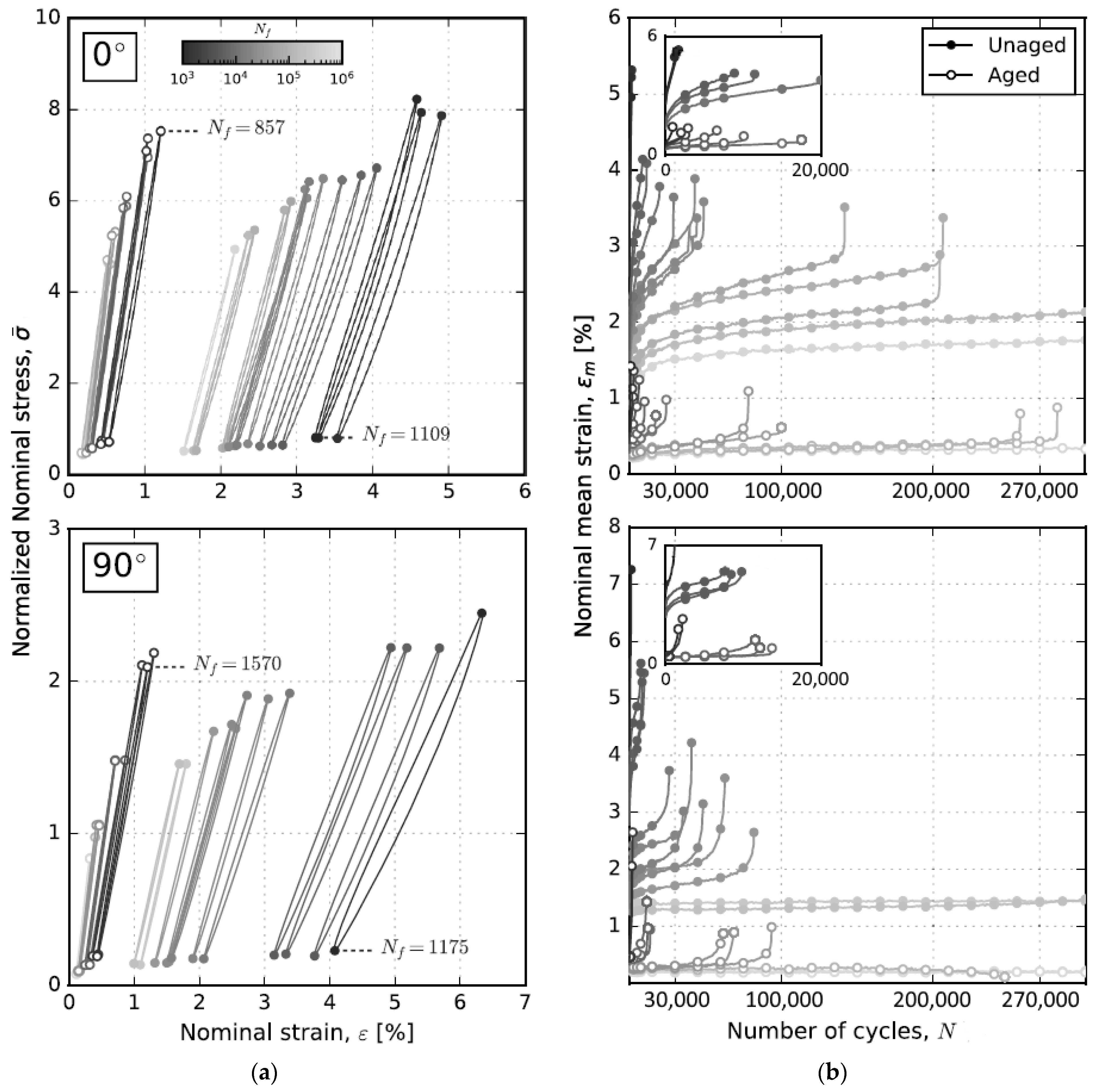

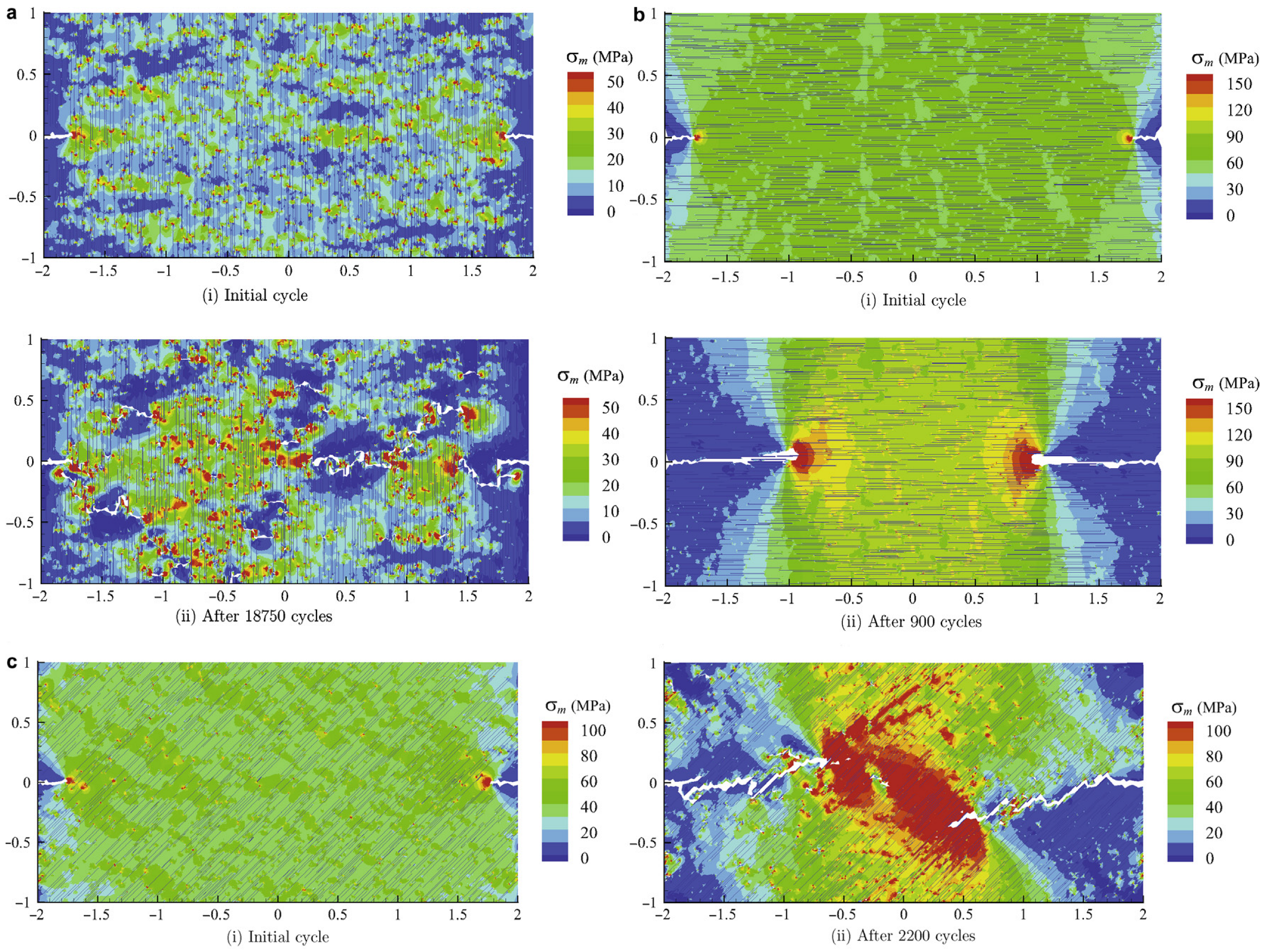

4.1. The Stiffness Degradation

4.2. Ultrasonic Methods, including AE

4.3. Energy Dissipation (Heat Release)

- An area of slowing down the energy rapid growth;

- The linear damage accumulation, so its rate can be defined as a function of the potential of variation of the applied stress;

- Accelerated damaging and failure.

4.4. Plastic Strain Development (Creep)

5. Fatigue Prediction Models

5.1. Based on the Results of Static Tests

5.2. Based on Experimental Fatigue Curves

5.3. Based on the Stiffness Degradation

5.4. Plastic Strain Development (Creep)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AE | Acoustic emission |

| AF | Aramid fiber |

| CF | Carbon fiber |

| DMA | Dynamic mechanical analysis |

| FEM | Finite Element Method |

| GF | Glass fiber |

| HDPE | High-density polyethylene |

| HPPs | High performance polymers |

| μCT | Computed micro tomography |

| MSNC | Master SN curve |

| NDT | Non-destructive testing |

| PA | Polyamide |

| PBT | Polybutylene terephthalate |

| PC | Polycarbonate |

| PEEK | Polyether ether ketone |

| POM | Polyoxymethylene |

| PPE | Polyphenylene Ether |

| PPS | Polyphenylene sulfide |

| PTFE | Polytetrafluoroethylene |

| SEM | Scanning electron microscopy |

| SMC | Sheet Molding Compounds |

| SN | Stress vs. Number of cycles (Völler/fatigue) curve |

References

- De, S.K.; White, J.R. (Eds.) Short Fibre-Polymer Composites, 1st ed.; Woodhead Publishing: Sawston, UK, 1996; ISBN 9781855732209. [Google Scholar]

- Buragohain, M.K. (Ed.) Composite Structures: Design, Mechanics, Analysis, Manufacturing, and Testing; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781351974929. [Google Scholar]

- Xu, Z.; Zhang, M.; Wang, G.; Luan, J. Bending Property and Fracture Behavior of Continuous Glass Fiber-Reinforced PEEK Composites Fabricated by the Wrapped Yarn Method. High Perform. Polym. 2019, 31, 321–330. [Google Scholar] [CrossRef]

- Miller, A.; Wei, C.; Gibson, A.G. Manufacture of Polyphenylene Suifide (PPS) Matrix Composites via the Powder Impregnation Route. Compos. Part A Appl. Sci. Manuf. 1996, 27, 49–56. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Overall Investigation of Poly (Phenylene Sulfide) from Synthesis and Process to Applications—A Review. Macromol. Mater. Eng. 2019, 304, 1800686. [Google Scholar] [CrossRef]

- Sun, B.; Yu, J. High-Performance Composites and Their Applications. In Porous Lightweight Composites Reinforced with Fibrous Structures; Springer: Berlin/Heidelberg, Geremany, 2017; pp. 341–368. ISBN 9783662538043. [Google Scholar]

- Harris, B. Fatigue in Composites: Science and Technology of the Fatigue Response of Fibre-Reinforced Plastics; Harris, B., Ed.; Woodhead Publishing: Sawston, UK, 2003; ISBN 9781855736085. [Google Scholar]

- Guedes, R.M. Creep and Fatigue in Polymer Matrix Composites; Woodhead Publishing: Sawston, UK, 2019; ISBN 9780081026014. [Google Scholar]

- Robinson, P.; Greenhalgh, E.; Pinho, S. (Eds.) Failure Mechanisms in Polymer Matrix Composites: Criteria, Testing and Industrial Applications; Woodhead Publishing: Sawston, UK, 2012; pp. 1–450. ISBN 9781845697501. [Google Scholar]

- Friedrich, K.; Schlarb, A.K. Tribology of Polymeric Nanocomposites: Friction and Wear of Bulk Materials and Coatings, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 9780444594556. [Google Scholar]

- Arash, B.; Wang, Q.; Varadan, V.K. Mechanical Properties of Carbon Nanotube/Polymer Composites. Sci. Rep. 2014, 4, 6479. [Google Scholar] [CrossRef] [PubMed]

- Raza, K.; Siddiqui, M.U.; Arif, A.F.M.; Akhtar, S.S.; Hakeem, A.S. Design and Development of Thermally Conductive Hybrid Nano-Composites in Polysulfone Matrix. Polym. Compos. 2019, 40, 1419–1432. [Google Scholar] [CrossRef]

- Jain, A. Hybrid Multiscale Modelling of Fatigue and Damage in Short Fibre Reinforced Composites. In Multi-Scale Continuum Mechanics Modelling of Fibre-Reinforced Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2020; pp. 691–720. ISBN 9780128189849. [Google Scholar]

- Fouchier, N.; Nadot-Martin, C.; Conrado, E.; Bernasconi, A.; Castagnet, S. Fatigue Life Assessment of a Short Fibre Reinforced Thermoplastic at High Temperature Using a Through Process Modelling in a Viscoelastic Framework. Int. J. Fatigue 2019, 124, 236–244. [Google Scholar] [CrossRef]

- Belmonte, E.; De Monte, M.; Riedel, T.; Quaresimin, M. Local Microstructure and Stress Distributions at the Crack Initiation Site in a Short Fiber Reinforced Polyamide under Fatigue Loading. Polym. Test. 2016, 54, 250–259. [Google Scholar] [CrossRef]

- Mandell, J.F. Fatigue Behavior of Short Fiber Composite Materials, 2nd ed.; Elsevier Science Publishers B.V.: Amsterdam, The Netherlands, 1991; Volume 4. [Google Scholar]

- Talreja, R. Damage and Failure of Composite Materials; Cambridge University Press: Cambridge, UK, 2023; Volume 605, ISBN 9780521819428. [Google Scholar]

- Mallick, P.K. Particulate Filled and Short Fiber Reinforced Polymer Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 2, ISBN 9780081005330. [Google Scholar]

- Vassilopoulos, A.P. (Ed.) Fatigue Life Prediction of Composites and Composite Structures, 2nd ed.; Woodhead Publishing: Sawston, UK, 2020; ISBN 9780081025758. [Google Scholar]

- Matthews, F.L.; Davies, G.A.O.; Hitchings, D.; Soutis, C. Finite Element Modelling of Composite Materials and Structures. In Finite Element Modelling of Composite Materials and Structures; Woodhead Publishing: Sawston, UK, 2000; ISBN 978-1-85573-422-7. [Google Scholar]

- Panin, S.V.; Bogdanov, A.A.; Eremin, A.V.; Buslovich, D.G.; Alexenko, V.O. Estimating Low-and High-Cyclic Fatigue of Polyimide-CF-PTFE Composite through Variation of Mechanical Hysteresis Loops. Materials 2022, 15, 4656. [Google Scholar] [CrossRef]

- Bogdanov, A.A.; Panin, S.V.; Lyubutin, P.S.; Eremin, A.V.; Buslovich, D.G.; Byakov, A.V. An Automated Optical Strain Measurement System for Estimating Polymer Degradation under Fatigue Testing. Sensors 2022, 22, 6034. [Google Scholar] [CrossRef]

- Panin, S.V.; Bogdanov, A.A.; Eremin, A.V.; Buslovich, D.G.; Shilko, I.S. Effect of Polymer Matrix on Inelastic Strain Development in PI- and PEI-Based Composites Reinforced with Short Carbon Fibers under Low-Cyclic Fatigue. Polymers 2023, 15, 1228. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Mai, Y.W. Science and Engineering of Short Fibre Reinforced Polymer Composites; Woodhead Publishing: Sawston, UK, 2009; ISBN 9781845692698. [Google Scholar]

- Volpe, V.; Lanzillo, S.; Affinita, G.; Villacci, B.; Macchiarolo, I.; Pantani, R. Lightweight High-Performance Polymer Composite for Automotive Applications. Polymers 2019, 11, 326. [Google Scholar] [CrossRef]

- Marathe, U.N.; Bijwe, J. High Performance Polymer Composites—Influence of Processing Technique on the Fiber Length and Performance Properties. Wear 2020, 446–447, 203189. [Google Scholar] [CrossRef]

- Temnikova, N.E.; Chalykh, A.E.; Gerasimov, V.K.; Rusanova, S.N.; Stoyanov, O.V.; Sofina, S.Y. Influence of the Phase Structure of Double and Triple Copolymers of Ethylene Modified by Glycidoxyalkoxysilane on the Properties of the Compositions; Mukbaniani, O.V., Abadie, M.J.M., Tatrishvili, T., Eds.; Apple Academic Press: Palm Bay, FL, USA, 2015; ISBN 9781498727372. [Google Scholar]

- Cao, W.; Yang, X.; Zhang, O. Development and Prospect of High Performance Polymer Composites in China. Chin. J. Eng. Sci. 2020, 22, 112. [Google Scholar] [CrossRef]

- Al-Azad, N.; Asril, M.F.M.; Shah, M.K.M. A Review on Development of Natural Fibre Composites for Construction Applications. J. Mater. Sci. Chem. Eng. 2021, 9, 1–9. [Google Scholar] [CrossRef]

- Sathees Kumar, S.; Sridhar Babu, B.; Chankravarthy, C.N.; Prabhakar, N. Review on Natural Fiber Polymer Composites. Mater. Today Proc. 2021, 46, 777–782. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef] [PubMed]

- Boisse, P. (Ed.) Composite Reinforcements for Optimum Performance, 2nd ed.; Woodhead Publishing: Sawston, UK, 2020; ISBN 9780128190050. [Google Scholar]

- Papthanasiou, T.A.; Bénard, A. (Eds.) Flow-Induced Alignment in Composite Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2022; ISBN 9780128185742. [Google Scholar]

- Pradeep Kumar, G.S.; Sachith, T.S.; Jangam, S.; Shivakumar, S.; Hebbar, G.S. Development of High Performance Polymer Composites by Additive Manufacturing. In Development, Properties, and Industrial Applications of 3D Printed Polymer Composites; IGI Global: Hershey, PA, USA, 2023; pp. 220–238. ISBN 9781668460115. [Google Scholar]

- Bonnard, R.; Hascoët, J.Y.; Mognol, P.; Stroud, I. STEP-NC Digital Thread for Additive Manufacturing: Data Model, Implementation and Validation. Int. J. Comput. Integr. Manuf. 2018, 31, 1141–1160. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.S.; Rumpf, R.C.; Kim, N.S. Thermo-Mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2015, 44, 771–777. [Google Scholar] [CrossRef]

- Cloonan, A.J.; Shahmirzadi, D.; Li, R.X.; Doyle, B.J.; Konofagou, E.E.; McGloughlin, T.M. 3D-Printed Tissue-Mimicking Phantoms for Medical Imaging and Computational Validation Applications. 3D Print. Addit. Manuf. 2014, 1, 14–23. [Google Scholar] [CrossRef]

- Verma, D.; Sharma, M.; Goh, K.L.; Jain, S.; Sharma, H. (Eds.) Sustainable Biopolymer Composites; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 9780128222911. [Google Scholar]

- Siddiqui, M.U.; Arif, A.F.M. Estimation and Optimisation of Effective Thermal Conductivity for Polymer Matrix Composites with Hybrid Inclusions. J. Compos. Mater. 2018, 52, 2139–2148. [Google Scholar] [CrossRef]

- Mittal, V. (Ed.) Manufacturing of Nanocomposites with Engineering Plastics; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9781782423218. [Google Scholar]

- Aidi, B.; Philen, M.K.; Case, S.W. Progressive Damage Assessment of Centrally Notched Composite Specimens in Fatigue. Compos. Part A Appl. Sci. Manuf. 2015, 74, 47–59. [Google Scholar] [CrossRef]

- Talreja, R. Damage and Fatigue in Composites—A Personal Account. Compos. Sci. Technol. 2008, 68, 2585–2591. [Google Scholar] [CrossRef]

- Im, K.H.; Hsu, D.K.; Chiou, C.P.; Barnard, D.J. T-Ray NDE Inspections on the Fiber Direction of Thermoplastic PPS-Based CFRP Composites. Adv. Mater. Res. 2013, 650, 253–257. [Google Scholar] [CrossRef]

- Karbhari, V.M. (Ed.) Non-Destructive Evaluation (NDE) of Polymer Matrix Composites, 1st ed.; Woodhead Publishing: Sawston, UK, 2013; ISBN 978-0-85709-344-8. [Google Scholar]

- Gholizadeh, S. A Review of Non-Destructive Testing Methods of Composite Materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Bossi, R.H.; Giurgiutiu, V. Nondestructive Testing of Damage in Aerospace Composites. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 413–448. ISBN 9780857099181. [Google Scholar]

- Katunin, A.; Dragan, K.; Dziendzikowski, M. Damage Identification in Aircraft Composite Structures: A Case Study Using Various Non-Destructive Testing Techniques. Compos. Struct. 2015, 127, 1–9. [Google Scholar] [CrossRef]

- Bull, D.J.; Spearing, S.M.; Sinclair, I.; Helfen, L. Three-Dimensional Assessment of Low Velocity Impact Damage in Particle Toughened Composite Laminates Using Micro-Focus X-ray Computed Tomography and Synchrotron Radiation Laminography. Compos. Part A Appl. Sci. Manuf. 2013, 52, 62–69. [Google Scholar] [CrossRef]

- Tan, K.T.; Watanabe, N.; Iwahori, Y. X-ray Radiography and Micro-Computed Tomography Examination of Damage Characteristics in Stitched Composites Subjected to Impact Loading. Compos. Part B Eng. 2011, 42, 874–884. [Google Scholar] [CrossRef]

- Raza, K.; Akhtar, S.S.; Arif, A.F.M.; Hakeem, A.S. Computational Design and Development of High-Performance Polymer-Composites as New Encapsulant Material for Concentrated PV Modules. Sci. Rep. 2020, 10, 5304. [Google Scholar] [CrossRef]

- Talreja, R.; Varna, J. Modeling Damage, Fatigue and Failure of Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9781782422860. [Google Scholar]

- Soutis, C.; Beaumont, P.W.R. (Eds.) Multi-Scale Modelling of Composite Material Systems: The Art of Predictive Damage Modelling, 1st ed.; Woodhead Publishing: Sawston, UK, 2005; ISBN 9781855739369. [Google Scholar]

- Friedrich, K.; Walter, R.; Voss, H.; Karger-Kocsis, J. Effect of Short Fibre Reinforcement on the Fatigue Crack Propagation and Fracture of PEEK-Matrix Composites. Composites 1986, 17, 205–216. [Google Scholar] [CrossRef]

- Quaresimin, M.; Talreja, R. Fatigue of Fiber Reinforced Composites under Multiaxial Loading. In Fatigue Life Prediction of Composites and Composite Structures; Woodhead Publishing: Sawston, UK, 2010; pp. 334–389. [Google Scholar] [CrossRef]

- Krause, M.; Hausherr, J.M.; Krenkel, W. (Micro)-Crack Detection Using Local Radon Transform. Mater. Sci. Eng. A 2010, 527, 7126–7131. [Google Scholar] [CrossRef]

- Martulli, L.M.; Muyshondt, L.; Kerschbaum, M.; Pimenta, S.; Lomov, S.V.; Swolfs, Y. Morphology-Induced Fatigue Crack Arresting in Carbon Fibre Sheet Moulding Compounds. Int. J. Fatigue 2020, 134, 105510. [Google Scholar] [CrossRef]

- Rolland, H.; Saintier, N.; Raphael, I.; Lenoir, N.; King, A.; Robert, G. Fatigue Damage Mechanisms of Short Fiber Reinforced PA66 as Observed by In-Situ Synchrotron X-ray Microtomography. Compos. Part B Eng. 2018, 143, 217–229. [Google Scholar] [CrossRef]

- Mrzljak, S.; Delp, A.; Schlink, A.; Zarges, J.C.; Hülsbusch, D.; Heim, H.P.; Walther, F. Constant Temperature Approach for the Assessment of Injection Molding Parameter Influence on the Fatigue Behavior of Short Glass Fiber Reinforced Polyamide 6. Polymers 2021, 13, 1569. [Google Scholar] [CrossRef] [PubMed]

- Cosmi, F.; Bernasconi, A. Micro-CT Investigation on Fatigue Damage Evolution in Short Fibre Reinforced Polymers. Compos. Sci. Technol. 2013, 79, 70–76. [Google Scholar] [CrossRef]

- Bernasconi, A.; Cosmi, F.; Taylor, D. Analisys of the Fatigue Properties of Different Specimens of a 10% by Weight Short Glass Fibre Reinforced Polyamide 6.6. Solid State Sci. 2014, 37, 108–113. [Google Scholar] [CrossRef]

- Bernasconi, A.; Cosmi, F.; Zappa, E. Combined Effect of Notches and Fibre Orientation on Fatigue Behaviour of Short Fibre Reinforced Polyamide. Strain 2010, 46, 435–445. [Google Scholar] [CrossRef]

- Ayadi, A.; Nouri, H.; Guessasma, S.; Roger, F. An Original Approach to Assess Elastic Properties of a Short Glass Fibre Reinforced Thermoplastic Combining X-Ray Tomography and Finite Element Computation. Compos. Struct. 2015, 125, 277–286. [Google Scholar] [CrossRef]

- Arif, M.F.; Saintier, N.; Meraghni, F.; Fitoussi, J.; Chemisky, Y.; Robert, G. Multiscale Fatigue Damage Characterization in Short Glass Fiber Reinforced Polyamide-66. Compos. Part B Eng. 2014, 61, 55–65. [Google Scholar] [CrossRef]

- Rudolph, H.V.; Ivers, H.; Harbich, K.W. Application of X-ray Refraction Topography to Fibre Reinforced Plastics. Compos. Part A Appl. Sci. Manuf. 2001, 32, 473–476. [Google Scholar] [CrossRef]

- Raphael, I.; Saintier, N.; Robert, G.; Béga, J.; Laiarinandrasana, L. On the Role of the Spherulitic Microstructure in Fatigue Damage of Pure Polymer and Glass-Fiber Reinforced Semi-Crystalline Polyamide 6.6. Int. J. Fatigue 2019, 126, 44–54. [Google Scholar] [CrossRef]

- Drummond, J.L. Degradation, Fatigue, and Failure of Resin Dental Composite Materials. J. Dent. Res. 2008, 87, 710–719. [Google Scholar] [CrossRef] [PubMed]

- Blais, P.; Toubal, L. Single-Gear-Tooth Bending Fatigue of HDPE Reinforced with Short Natural Fiber. Int. J. Fatigue 2020, 141, 105857. [Google Scholar] [CrossRef]

- Yamamoto, T.; Hyakutake, H. Comparison of Strength and Damage for Notched FRP Plates Made by Injection Molding with That from Machining. Adv. Compos. Mater. Off. J. Jpn. Soc. Compos. Mater. 2003, 11, 351–363. [Google Scholar] [CrossRef]

- Palmstingl, M.; Salaberger, D.; Koch, T. Morphology and Fatigue Behaviour of Short-Glass Fibre-Reinforced Polypropylene. Springer Ser. Mater. Sci. 2017, 247, 315–334. [Google Scholar] [CrossRef]

- Casado, J.A.; Gutiérrez-Solana, F.; Polanco, J.A.; Carrascal, I. The Assessment of Fatigue Damage on Short-Fiber-Glass Reinforced Polyamides (PA) through the Surface Roughness Evolution. Polym. Compos. 2006, 27, 349–359. [Google Scholar] [CrossRef]

- Casado, J.A.; Gutiérrez-Solana, F.; Carrascal, I.; Diego, S.; Ferreño, D. Analysis of Fatigue Behaviour of Notched Specimens Made of Fibreglass Reinforced Polyamide by Means of a Cohesive Model. Polym. Test. 2017, 64, 337–344. [Google Scholar] [CrossRef]

- Klimkeit, B.; Castagnet, S.; Nadot, Y.; El Habib, A.; Benoit, G.; Bergamo, S.; Dumas, C.; Achard, S. Fatigue Damage Mechanisms in Short Fiber Reinforced PBT+PET GF30. Mater. Sci. Eng. A 2011, 528, 1577–1588. [Google Scholar] [CrossRef]

- Ha, J.C.; Yokobori, A.T.; Takeda, H. Effect of Fatigue Damage on Toughening of Short-Fiber-Reinforced Polymer Composites. J. Mater. Sci. 1999, 34, 2103–2111. [Google Scholar] [CrossRef]

- Subramanian, C.; Senthilvelan, S. Fatigue Performance of Discontinuous Fibre-Reinforced Thermoplastic Leaf Spring. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2010, 224, 93–100. [Google Scholar] [CrossRef]

- Laribi, M.A.; Tamboura, S.; Fitoussi, J.; Tié Bi, R.; Tcharkhtchi, A.; Ben Dali, H. Fast Fatigue Life Prediction of Short Fiber Reinforced Composites Using a New Hybrid Damage Approach: Application to SMC. Compos. Part B Eng. 2018, 139, 155–162. [Google Scholar] [CrossRef]

- Wäber, R. Characterisation of Fatigue Damage in Reinforced Thermoplastics under Dynamic Loads. Materwiss. Werksttech. 1997, 28, 25–33. [Google Scholar] [CrossRef]

- Imaddahen, M.A.; Shirinbayan, M.; Ayari, H.; Foucard, M.; Tcharkhtchi, A.; Fitoussi, J. Multi-Scale Analysis of Short Glass Fiber-Reinforced Polypropylene under Monotonic and Fatigue Loading. Polym. Compos. 2020, 41, 4649–4662. [Google Scholar] [CrossRef]

- Nony-Davadie, C.; Peltier, L.; Chemisky, Y.; Surowiec, B.; Meraghni, F. Mechanical Characterization of Anisotropy on a Carbon Fiber Sheet Molding Compound Composite under Quasi-Static and Fatigue Loading. J. Compos. Mater. 2019, 53, 1437–1457. [Google Scholar] [CrossRef]

- Sieberer, S.; Nonn, S.; Schagerl, M. Fatigue Behaviour of Discontinuous Carbon-Fibre Reinforced Specimens and Structural Parts. Int. J. Fatigue 2020, 131, 105289. [Google Scholar] [CrossRef]

- Mansouri, L.; Djebbar, A.; Khatir, S.; Ali, H.T.; Behtani, A.; Wahab, M.A. Static and Fatigue Behaviors of Short Glass Fiber–Reinforced Polypropylene Composites Aged in a Wet Environment. J. Compos. Mater. 2019, 53, 3629–3647. [Google Scholar] [CrossRef]

- Solfiti, E.; Solberg, K.; Gagani, A.; Landi, L.; Berto, F. Static and Fatigue Behavior of Injection Molded Short-Fiber Reinforced PPS Composites: Fiber Content and High Temperature Effects. Eng. Fail. Anal. 2021, 126, 105429. [Google Scholar] [CrossRef]

- Subramanian, C.; Senthilvelan, S. Short-Term Flexural Creep Behavior and Model Analysis of a Glass-Fiber-Reinforced Thermoplastic Composite Leaf Spring. J. Appl. Polym. Sci. 2011, 120, 3679–3686. [Google Scholar] [CrossRef]

- Anaya-Ramirez, R.C.; Rios-Soberanis, C.R.; Herrera-Franco, P.J. Effect of Fiber Surface Treatments in HDPE-Henequen Short Fiber-Reinforced Composites: Static Characterization and Fatigue. J. Mater. Sci. 2022, 57, 15762–15776. [Google Scholar] [CrossRef]

- Stadler, G.; Primetzhofer, A.; Jerabek, M.; Pinter, G.; Grün, F. Investigation of the Influence of Viscoelastic Behaviour on the Lifetime of Short Fibre Reinforced Polymers. Polymers 2020, 12, 2874. [Google Scholar] [CrossRef]

- Shahzad, A.; Isaac, D.H. Fatigue Properties of Hemp and Glass Fiber Composites. Polym. Compos. 2014, 35, 1926–1934. [Google Scholar] [CrossRef]

- Zhong, J.; Luo, Z.; Hao, Z.; Guo, Y.; Zhou, Z.; Li, P.; Xue, B. Enhancing Fatigue Properties of Styrene Butadiene Rubber Composites by Improving Interface Adhesion between Coated Aramid Fibers and Matrix. Compos. Part B Eng. 2019, 172, 485–495. [Google Scholar] [CrossRef]

- Kasap, S.O.; Yannacopoulos, S.; Mirehandani, V.; Hildebrandt, J.R. Ultrasonic Evaluation of Thermal Fatigue of Composites. J. Eng. Mater. Technol. Trans. ASME 1992, 114, 132–136. [Google Scholar] [CrossRef]

- Krummenacker, J.; Hausmann, J. Determination of Fatigue Damage Initiation in Short Fiber-Reinforced Thermoplastic through Acoustic Emission Analysis. J. Compos. Sci. 2021, 5, 221. [Google Scholar] [CrossRef]

- Suzuki, M.; Imura, M.; Jinen, E.; Iwamoto, M. A Study on Fatigue Fracture Mechanisms of Short Fiber Reinforced PET Composite by the Acoustic Emission Methed (Effects of Loading Direction and Fiber Content). Trans. Jpn. Soc. Mech. Eng. Ser. A 1990, 56, 1036–1043. [Google Scholar] [CrossRef]

- Blais, P.; Toubal, L. Fatigue of Short-Natural-Fiber-Reinforced High-Density Polyethylene: Stochastic Modeling of Single-Gear-Tooth Bending. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 1241–1256. [Google Scholar] [CrossRef]

- Sekine, H.; Nemura, M. The Micromechanics Study of Fracture of a Glass Fiber Reinforced SMC Composite under Fatigue Loading. Trans. Jpn. Soc. Mech. Eng. Ser. A 1989, 55, 756–764. [Google Scholar] [CrossRef]

- Barré, S.; Benzeggagh, M.L. On the Use of Acoustic Emission to Investigate Damage Mechanisms in Glass-Fibre-Reinforced Polypropylene. Compos. Sci. Technol. 1994, 52, 369–376. [Google Scholar] [CrossRef]

- Watanabe, T.; Fujii, T. Long Fiber Effect on Static and Fatigue Strengths of Discontinuous Fiber Reinforced Thermoplastics with Polypropylene Matrix. Trans. Jpn. Soc. Mech. Eng. Part A 1998, 64, 1976–1983. [Google Scholar] [CrossRef]

- Mechakra, H.; Nour, A.; Lecheb, S.; Chellil, A. Mechanical Characterizations of Composite Material with Short Alfa Fibers Reinforcement. Compos. Struct. 2015, 124, 152–162. [Google Scholar] [CrossRef]

- Kuriyama, T.; Mizoguchi, M.; Ogawa, T. Effect of Injection Speed on Internal Structure and Mechanical Properties in Short Glass Fibre Reinforced Polyamide Injection Mouldings. Polym. Polym. Compos. 2004, 12, 423–431. [Google Scholar] [CrossRef]

- Yamashita, A.; Takahara, A.; Kajiyama, T. Aggregation Structure and Fatigue Characteristics of (Nylon 6/Clay) Hybrid. Compos. Interfaces 1999, 6, 247–258. [Google Scholar] [CrossRef]

- Hachiya, H.; Takayama, S.; Takeda, K. Effect of Interface Entanglement on Fatigue Life of Polymer Alloy and Composites. Compos. Interfaces 1999, 6, 187–200. [Google Scholar] [CrossRef]

- Shiozawa, D.; Sakagami, T.; Nakamura, Y.; Tamashiro, T.; Nonaka, S.; Hamada, K.; Shinchi, T. Fatigue Damage Evaluation of Short Carbon Fiber Reinforced Plastics Based on Thermoelastic Temperature Change and Second Harmonic Components of Thermal Signal. Materials 2021, 14, 4941. [Google Scholar] [CrossRef] [PubMed]

- Casado, J.A.; Carrascal, I.; Polanco, J.A.; Gutiérrez-Solana, F. Fatigue Failure of Short Glass Fibre Reinforced PA 6.6 Structural Pieces for Railway Track Fasteners. Eng. Fail. Anal. 2006, 13, 182–197. [Google Scholar] [CrossRef]

- Carrascal, I.A.; Casado, J.A.; Diego, S.; Polanco, J.A.; Gutiérrez-Solana, F. Fatigue Damage Analysis Based on Energy Parameters in Reinforced Polyamide. Fatigue Fract. Eng. Mater. Struct. 2012, 35, 683–691. [Google Scholar] [CrossRef]

- Li, A.; Huang, J.; Zhang, C. Enabling Rapid Fatigue Life Prediction of Short Carbon Fiber Reinforced Polyether-Ether-Ketone Using a Novel Energy Dissipation–Based Model. Compos. Struct. 2021, 272, 114227. [Google Scholar] [CrossRef]

- Meneghetti, G.; Quaresimin, M. Fatigue Strength Assessment of a Short Fiber Composite Based on the Specific Heat Dissipation. Compos. Part B Eng. 2011, 42, 217–225. [Google Scholar] [CrossRef]

- Meneghetti, G.; Ricotta, M.; Lucchetta, G.; Carmignato, S. An Hysteresis Energy-Based Synthesis of Fully Reversed Axial Fatigue Behaviour of Different Polypropylene Composites. Compos. Part B Eng. 2014, 65, 17–25. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. On the Strengthening Effect of Increasing Cycling Frequency on Fatigue Behavior of Some Polymers and Their Composites: Experiments and Modeling. Int. J. Fatigue 2016, 87, 153–166. [Google Scholar] [CrossRef]

- Aglan, H.A.; Gan, Y.X.; Zhong, W.H. Fatigue Fracture Resistance Analysis of Polymer Composites Based on the Energy Expended on Damage Formation. J. Reinf. Plast. Compos. 2003, 22, 339–360. [Google Scholar] [CrossRef]

- Laiarinandrasana, L.; Morgeneyer, T.F.; Cheng, Y.; Helfen, L.; Le Saux, V.; Marco, Y. Microstructural Observations Supporting Thermography Measurements for Short Glass Fibre Thermoplastic Composites under Fatigue Loading. Contin. Mech. Thermodyn. 2020, 32, 451–469. [Google Scholar] [CrossRef]

- Kuroshima, Y.; Nishikawa, H.; Konishi, K.; Harada, S.; Takeda, H. Evaluation of Fatigue Strength of Short Carbon Fiber Reinforced Thermo Plastics by Monitoring Temperature Rise in Fatigue Process. Trans. Jpn. Soc. Mech. Eng. Part A 1999, 65, 1105–1109. [Google Scholar] [CrossRef]

- Hiwa, C.; Nakai, Y.; Kawamura, T. Effect of Surface Treatment for Fibers on Fatigue Behavior of (GF/PP) Fuel-Injection Short-Fiber Reinforced Plastics. Trans. Jpn. Soc. Mech. Eng. Part A 1999, 65, 643–648. [Google Scholar] [CrossRef]

- Noda, K.; Takahara, A.; Kajiyama, T. Fatigue Failure Mechanisms of Short Glass-Fiber Reinforced Nylon 66 Based on Nonlinear Dynamic Viscoelastic Measurement. Polymer 2001, 42, 5803–5811. [Google Scholar] [CrossRef]

- Alexis, F.; Castagnet, S.; Nadot-Martin, C.; Robert, G.; Havet, P. Effect of Severe Thermo-Oxidative Aging on the Mechanical Behavior and Fatigue Durability of Short Glass Fiber Reinforced PA6/6.6. Int. J. Fatigue 2023, 166, 107280. [Google Scholar] [CrossRef]

- Raphael, I.; Saintier, N.; Rolland, H.; Robert, G.; Laiarinandrasana, L. A Mixed Strain Rate and Energy Based Fatigue Criterion for Short Fiber Reinforced Thermoplastics. Int. J. Fatigue 2019, 127, 131–143. [Google Scholar] [CrossRef]

- Komatsu, S.; Takahara, A.; Kajiyama, T. Effect of Interfacial Interaction between Glass-Fiber and Matrix Nylon-6 on Nonlinear Dynamic Viscoelasticity and Fatigue Behavior for Glass-Fiber Reinforced Nylon-6. Polym. J. 2002, 34, 897–904. [Google Scholar] [CrossRef]

- Ahmadzadeh, G.R.; Varvani-Farahani, A. Ratcheting Assessment of GFRP Composites in Low-Cycle Fatigue Domain. Appl. Compos. Mater. 2014, 21, 417–428. [Google Scholar] [CrossRef]

- Hour, K.Y.; Hour, K.Y.; Sehitoglu, H.; Sehitoglu, H. Damage Development in a Short Fiber Reinforced Composite. J. Compos. Mater. 1993, 27, 782–805. [Google Scholar] [CrossRef]

- Jinen, E. Accumulated Strain in Low Cycle Fatigue of Short Carbon-Fibre Reinforced Nylon 6. J. Mater. Sci. 1986, 21, 435–443. [Google Scholar] [CrossRef]

- Jinen, E. Influence of Fatigue Damage on Tensile Creep Properties of Short Carbon Fibre Reinforced Nylon-6-Plastic. Composites 1989, 20, 329–339. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, B.; Gu, B. Creep and Stress Relaxation Performance of Rubber Matrix Sealing Composites after Fatigue Loading. Fibers Polym. 2022, 23, 471–477. [Google Scholar] [CrossRef]

- Jain, A.; Verpoest, I.; Hack, M.; Lomov, S.; Adam, L.; Paepegem, W. Fatigue Life Simulation on Fiber Reinforced Composites—Overview and Methods of Analysis for the Automotive Industry. SAE Int. J. Mater. Manuf. 2012, 5, 205–214. [Google Scholar] [CrossRef]

- Kabir, M.R.; Lutz, W.; Zhu, K.; Schmauder, S. Fatigue Modeling of Short Fiber Reinforced Composites with Ductile Matrix under Cyclic Loading. Comput. Mater. Sci. 2006, 36, 361–366. [Google Scholar] [CrossRef]

- Bourgogne, Q.C.P.; Bouchart, V.; Chevrier, P. Prediction of the Wöhler Curves of Short Fibre Reinforced Composites Considering Temperature and Water Absorption. Mater. Today Commun. 2022, 33, 104655. [Google Scholar] [CrossRef]

- Laribi, M.A.; Tamboura, S.; Fitoussi, J.; Shirinbayan, M.; Bi, R.T.; Tcharkhtchi, A.; Dali, H. Ben Microstructure Dependent Fatigue Life Prediction for Short Fibers Reinforced Composites: Application to Sheet Molding Compounds. Int. J. Fatigue 2020, 138, 105731. [Google Scholar] [CrossRef]

- Fatemi, A.; Mortazavian, S.; Khosrovaneh, A. Fatigue Behavior and Predictive Modeling of Short Fiber Thermoplastic Composites. Procedia Eng. 2015, 133, 5–20. [Google Scholar] [CrossRef]

- Kawai, M.; Funaki, S.; Taketa, I.; Hirano, N. Temperature-Dependent Constant Fatigue Life Diagram for Press-Formed Short Carbon Fiber Reinforced Polyamide Composite. Adv. Compos. Mater. 2019, 28, 1–28. [Google Scholar] [CrossRef]

- D’Amore, A.; Grassia, L.; Verde, P. Modeling the Fatigue Behavior of Glass Fiber Reinforced Thermoplastic and Thermosetting Matrices. AIP Conf. Proc. 2012, 1459, 372–374. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. A Fatigue Damage Model for Life Prediction of Injection-Molded Short Glass Fiber-Reinforced Thermoplastic Composites. Polymers 2021, 13, 2250. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. Fatigue Behaviour and Modelling of Talc-Filled and Short Glass Fibre Reinforced Thermoplastics, Including Temperature and Mean Stress Effects. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 333–348. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of Mean Stress and Stress Concentration on Fatigue Behavior of Short Fiber Reinforced Polymer Composites. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 149–166. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Multiaxial Fatigue Behavior of Thermoplastics Including Mean Stress and Notch Effects: Experiments and Modeling. Int. J. Fatigue 2020, 136, 105571. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Fatigue Behavior and Modeling of Short Fiber Reinforced Polymer Composites Including Anisotropy and Temperature Effects. Int. J. Fatigue 2015, 77, 12–27. [Google Scholar] [CrossRef]

- Pietrogrande, R.; Carraro, P.A.; De Monte, M.; Quaresimin, M. Modelling the Influence of the Micrustructure on the High Cycle Fatigue Crack Initiation in Short Fibre Reinforced Thermoplastics. Compos. Sci. Technol. 2021, 201, 108533. [Google Scholar] [CrossRef]

- Jain, A.; Van Paepegem, W.; Verpoest, I.; Lomov, S.V. A Feasibility Study of the Master SN Curve Approach for Short Fiber Reinforced Composites. Int. J. Fatigue 2016, 91, 264–274. [Google Scholar] [CrossRef]

- Jain, A.; Veas, J.M.; Straesser, S.; Van Paepegem, W.; Verpoest, I.; Lomov, S.V. The Master SN Curve Approach—A Hybrid Multi-Scale Fatigue Simulation of Short Fiber Reinforced Composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 510–518. [Google Scholar] [CrossRef]

- Jain, A. On the Multi-Axial Fatigue Modelling of Short Fibre Reinforced Composites: Extensions to the Master SN Curve Approach. Int. J. Fatigue 2021, 145, 106106. [Google Scholar] [CrossRef]

- Primetzhofer, A.; Stadler, G.; Pinter, G.; Grün, F. Lifetime Assessment of Anisotropic Materials by the Example Short Fibre Reinforced Plastic. Int. J. Fatigue 2019, 120, 294–302. [Google Scholar] [CrossRef]

- Hoppel, C.P.R.; Pangborn, R.N.; Thomson, R.W. Damage Accumulation during Multiple Stress Level Fatigue of Short-Glass-Fiber Reinforced Styrene-Maleic Anhydride. J. Thermoplast. Compos. Mater. 2001, 14, 84–94. [Google Scholar] [CrossRef]

- Noguchi, H.; Nisitani, H.; Nishizawa, A.; Kim, Y.H. Miner’s Rule for Fatigue Life of Short Carbon Fiber Reinforced Poly-Ether-Ether-Ketone. J. Soc. Mater. Sci. Jpn. 1994, 43, 672–678. [Google Scholar] [CrossRef]

- Laribi, M.A.; Tamboura, S.; Fitoussi, J.; Shirinbayan, M.; Bi, R.T.; Tcharkhtchi, A.; Dali, H. Ben Modeling of Short Fiber Reinforced Polymer Composites Subjected to Multi-block Loading. Appl. Compos. Mater. 2021, 28, 973–990. [Google Scholar] [CrossRef]

- Dick, T.M.; Jar, P.Y.B.; Cheng, J.J.R. Prediction of Fatigue Resistance of Short-Fibre-Reinforced Polymers. Int. J. Fatigue 2009, 31, 284–291. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, B.; Gu, B. Interfacial Fatigue Damage Behavior of Fiber Reinforced Rubber—A Combined Experimental and Cohesive Zone Model Approach. Polym. Eng. Sci. 2020, 60, 1316–1323. [Google Scholar] [CrossRef]

- Pantano, A.; Bongiorno, F.; Marannano, G.; Zuccarello, B. Enhancement of Static and Fatigue Strength of Short Sisal Fiber Biocomposites by Low Fraction Nanotubes. Appl. Compos. Mater. 2021, 28, 91–112. [Google Scholar] [CrossRef]

- Chen, Q.; Chatzigeorgiou, G.; Robert, G.; Meraghni, F. Viscoelastic-Viscoplastic Homogenization of Short Glass-Fiber Reinforced Polyamide Composites (PA66/GF) with Progressive Interphase and Matrix Damage: New Developments and Experimental Validation. Mech. Mater. 2022, 164, 104081. [Google Scholar] [CrossRef]

- Batu, T.; Lemu, H.G. Fatigue Life Study of False Banana/Glass Fiber Reinforced Composite for Wind Turbine Blade Application; Springer: Singapore, 2021; Volume 737, ISBN 9789813363175. [Google Scholar]

- Eftekhari, M.; Fatemi, A. Variable Amplitude Fatigue Behavior of Neat and Short Glass Fiber Reinforced Thermoplastics. Int. J. Fatigue 2017, 98, 176–186. [Google Scholar] [CrossRef]

- Nishikawa, M.; Okabe, T. Microstructure-Dependent Fatigue Damage Process in Short Fiber Reinforced Plastics. Int. J. Solids Struct. 2010, 47, 398–406. [Google Scholar] [CrossRef]

- Kim, Y.M.; Kim, Y.H. Numerical Analysis of Notch Effect on Fatigue Behavior of Short Fiber Reinforced Plastics Using Multi-Scale Material Modeling. Int. J. Automot. Technol. 2021, 22, 701–711. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Danesh, M.; Esmkhani, M. A Combined Micromechanical-Energy Method to Predict the Fatigue Life of Nanoparticles/Chopped Strand Mat/Polymer Hybrid Nanocomposites. Compos. Struct. 2015, 133, 886–891. [Google Scholar] [CrossRef]

- Avanzini, A.; Donzella, G.; Gallina, D. Failure Analysis and Life Prediction of Polymeric Rollers for Industrial Applications. Int. J. Mater. Prod. Technol. 2010, 38, 362–385. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, X.; Gu, B. Modeling and Experimental Validation of Interfacial Fatigue Damage in Fiber-Reinforced Rubber Composites. Polym. Eng. Sci. 2018, 58, 920–927. [Google Scholar] [CrossRef]

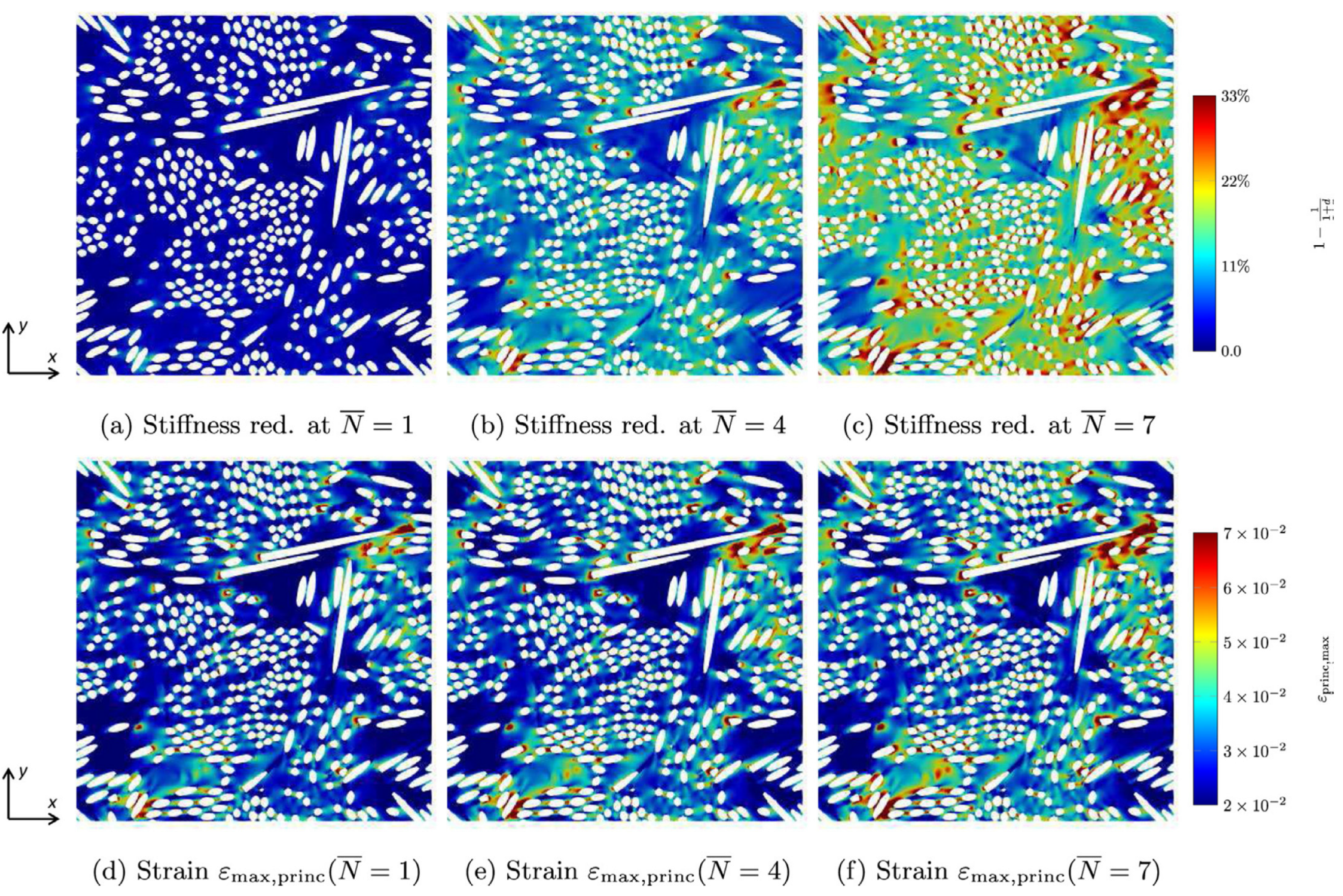

- Magino, N.; Köbler, J.; Andrä, H.; Welschinger, F.; Müller, R.; Schneider, M. A Multiscale High-Cycle Fatigue-Damage Model for the Stiffness Degradation of Fiber-Reinforced Materials Based on a Mixed Variational Framework. Comput. Methods Appl. Mech. Eng. 2022, 388, 114198. [Google Scholar] [CrossRef]

- Köbler, J.; Magino, N.; Andrä, H.; Welschinger, F.; Müller, R.; Schneider, M. A Computational Multi-Scale Model for the Stiffness Degradation of Short-Fiber Reinforced Plastics Subjected to Fatigue Loading. Comput. Methods Appl. Mech. Eng. 2021, 373, 113522. [Google Scholar] [CrossRef]

- Samareh-Mousavi, S.S.; Taheri-Behrooz, F. A Novel Creep-Fatigue Stiffness Degradation Model for Composite Materials. Compos. Struct. 2020, 237, 111955. [Google Scholar] [CrossRef]

- Sul, J.H.; Prusty, B.G.; Pan, J.W. A Fatigue Life Prediction Model for Chopped Strand Mat GRP at Elevated Temperatures. Fatigue Fract. Eng. Mater. Struct. 2010, 33, 513–521. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Haghighatkhah, A.R.; Esmkhani, M. Flexural Fatigue Modeling of Short Fibers/Epoxy Composites. Struct. Eng. Mech. 2017, 64, 287–292. [Google Scholar] [CrossRef]

- Brighenti, R.; Carpinteri, A.; Scorza, D. Micromechanical Model for Preferentially-Oriented Short-Fibre-Reinforced Materials under Cyclic Loading. Eng. Fract. Mech. 2016, 167, 138–150. [Google Scholar] [CrossRef]

- Tamboura, S.; Laribi, M.A.; Fitoussi, J.; Shirinbayan, M.; Bi, R.T.; Tcharkhtchi, A.; Dali, H. Ben Damage and Fatigue Life Prediction of Short Fiber Reinforced Composites Submitted to Variable Temperature Loading: Application to Sheet Molding Compound Composites. Int. J. Fatigue 2020, 138, 105676. [Google Scholar] [CrossRef]

- Nouri, H.; Meraghni, F.; Lory, P. Fatigue Damage Model for Injection-Molded Short Glass Fibre Reinforced Thermoplastics. Int. J. Fatigue 2009, 31, 934–942. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. Creep-Fatigue Interaction and Thermo-Mechanical Fatigue Behaviors of Thermoplastics and Their Composites. Int. J. Fatigue 2016, 91, 136–148. [Google Scholar] [CrossRef]

- Magino, N.; Köbler, J.; Andrä, H.; Welschinger, F.; Müller, R.; Schneider, M. Accounting for Viscoelastic Effects in a Multiscale Fatigue Model for the Degradation of the Dynamic Stiffness of Short-Fiber Reinforced Thermoplastics. Comput. Mech. 2023, 71, 493–515. [Google Scholar] [CrossRef]

- Krairi, A.; Doghri, I.; Robert, G. Multiscale High Cycle Fatigue Models for Neat and Short Fiber Reinforced Thermoplastic Polymers. Int. J. Fatigue 2016, 92, 179–192. [Google Scholar] [CrossRef]

- Drozdov, A.D. Cyclic Viscoelastoplasticity and Low-Cycle Fatigue of Polymer Composites. Int. J. Solids Struct. 2011, 48, 2026–2040. [Google Scholar] [CrossRef]

- Li, W.; Xin, Z. Flexural Fatigue Life Prediction of a Tooth V-Belt Made of Fiber Reinforced Rubber. Int. J. Fatigue 2018, 111, 269–277. [Google Scholar] [CrossRef]

- Pastukhov, L.V.; Kanters, M.J.W.; Engels, T.A.P.; Govaert, L.E. Influence of Fiber Orientation, Temperature and Relative Humidity on the Long-Term Performance of Short Glass Fiber Reinforced Polyamide 6. J. Appl. Polym. Sci. 2021, 138, 50382. [Google Scholar] [CrossRef]

| Methods and Their Specifics | Materials and Dimensions of Samples, mm | Refs. |

|---|---|---|

| Microtomography cannot be used for the visualization of fibers, while µ-CT is characterized by a higher resolution and makes it possible to detect them precisely. Distributions of fiber lengths and their orientations can be analyzed. | PA6/30 wt.% glass fibers; a length of 400 μm and a diameter of 12 μm; 36 × 20 × 4 mm | Mrzljak et al. [58] |

| Fatigue damages can be detected at early stages. | 93 × 25 × 3.2 mm | Raphael et al. [65] |

| After cyclic loading, cracking patterns can be observed. | Restolux/85 wt.% glass fibers Fiber lengths of 20–40 μm and diameters of 10–15 μm | Drummond [66] |

| Fiber orientations can be visualized. | PA66/35 wt.% glass fibers | Belmonte et al. [15] |

| Debonding of tows and small cracks can be detected. | Epoxy/42 vol.% carbon fibers TR50S tows; 250 × 25 × 2.5 mm | Belmonte et al. [56] |

| Microcracks, cavitation, various kinds of debonding, and the fiber failure evolution can be assessed. | PA 6.6/30 wt.% short glass fibers | Rolland et al. [57] |

| The initiation and propagation of cracks can be visualized. | Krause et al. [55] | |

| Segmentations and distributions of fibers and voids, as well as volume contents of micro-voids can be assessed. | PA66/35 wt.% glass fibers | Cosmi and Bernasconi [59] |

| Orientations of fibers can be visualized. | PA6/30 wt.% glass fibers; a fiber length of 275 μm and a diameter of 10 μm | Bernasconi et al. [61] |

| Distributions of fibers and volume stresses can be assessed under cyclic loading. | PA66/35 wt.% glass fibers; a fiber length of 250 μm and a diameter of 10 μm | Ayadi et al. [62] |

| Volume fractions, aspect ratios and orientations of fibers can be determined. Fatigue voids, fiber–matrix interfacial debonding, fiber breakages, and matrix microcracks can be visualized. | PA66/30 wt.% glass fibers | Arif et al. [63] |

| Fiber–matrix interfaces, voids, delamination and cracking of fibers, as well as microcracks can be observed. | POM/30 wt.% glass fibers | Rudolph et al. [64] |

| Detectable Damages | Material | Refs. |

|---|---|---|

| Cracks direction | HDPE/40 wt.% wood pulp fibers | Blais and Toubal [67] |

| Propagation of microcracks, damaged zone | PC/30 wt.% glass fibers 1 mm long | Yamamoto and Hyakutake [68] |

| Damage behavior | PC/30 wt.% glass fibers 0.28 mm long with a diameter of 13 μm | Ha et al. [73] |

| Fiber lengths and orientations | PP/glass fibers | Palmstingl et al. [69] |

| Surface cracking, roughness | PA6.6/35 wt.% glass fibers 150 μm long with a diameter of 10 μm | Casado et al. [70,71] |

| Macroscopic damages | PBT/PET/30 wt.% glass fibers | Klimkeit et al. [72] |

| Material | Informative Parameters, Possibility of Combining Methods | Refs. |

|---|---|---|

| PA66/30 wt.% glass fibers | Hysteresis area, cyclic creep, temperature and μ-CT | Arif et al. [63] |

| PPS/30 wt.% glass fibers/15 wt.% PTFE PPS/40 wt.% glass fibers | Cyclic mean strains | Solfiti et al. [81] |

| PP/20 wt.% glass fibers | Energy dissipation ratio, creep rate reduction | Subramanian and Senthilvelan [74,82] |

| HDPE/20 wt.% henequen fibers | AE | Anaya-Ramirez et al. [83] |

| PP/40 wt.% glass fibers | Strain rate, self-heating | Imaddahen et al. [77] |

| Vinyl-ester thermoset matrix/55 wt.% short carbon bundles | Post-mortem X-ray radiography and SEM | Nony-Davadie et al. [78] |

| PP/40 wt.% glass fibers | Secant modulus, creep rupture | Stadler et al. [84] |

| Polyester thermoset resin/short hemp fiber mat/glass fibers | SEM micrographs of fracture surfaces | Shahzad and Isaac [85] |

| Epoxy matrix/chopped carbon fibers | Component testing, DIC correlation error as crack formation | Sieberer et al. [79] |

| PP/40 wt.% glass fibers | Wohler (fatigue) curve, macroscopic and microscopic observations | Mansouri et al. [80] |

| Rubber/5.8 wt.% aramid fibers | Atomic force microscopy, dynamic mechanical analysis (DMA) | Zhong et al. [86] |

| Material | Informative Parameters, Possibility of Combining Methods | Refs. |

|---|---|---|

| Polyester resin/20 wt.% glass fibers | Residual strength assessment | Kasap et al. [87] |

| PP/20 wt.% glass fibers | Dynamic modulus | Wäber [76] |

| PA6.6/glass fibers | S–N curves | Krummenacker and Hausmann [88] |

| HDPE/40 wt.% natural fibers | High-resolution imaging and S–N curves | Blais and Toubal [67] |

| HDPE/40 wt.% natural fibers | Cracking monitored with a high-resolution camera, residual load | Blais and Toubal [90] |

| HDPE/henequen fibers | Stiffness reduction | Anaya-Ramirez et al. [83] |

| Epoxy/30 wt.% glass fibers | Stiffness reduction | Sekine and Nemura [91] |

| PP/40 wt.% glass fibers | Scanning electron microscopy | Barré and Benzeggagh [92] |

| PET/glass fibers | Fatigue Crack Growth, fractography | Suzuki et al. [89] |

| PP/glass fibers | Microscopic observation | Watanabe and Fujii [93] |

| PP/(10–30) wt.% vegetable fibers | SEM observation | Mechakra et al. [94] |

| PA66/glass fibers | Fractographic investigations | Kuriyama et al. [95] |

| Material | Informative Parameters, Possibility of Combining Methods | Refs. |

|---|---|---|

| Nylon 6/30 wt.% glass fibers | Dynamic storage modulus, surface temperature enhancement, hysteresis energy loss | Yamashita et al. [96] |

| PA66/30 wt.% glass fibers | Micro-computed tomography, evolution of dynamic modulus, strain, temperature | Arif et al. [63] |

| PPE/glass fibers | Mechanical work, heat generation | Hachiya et al. [97] |

| PA6.6/35 wt.% glass fibers | Phase lag between the load and strain signals | Casado et al. [99] |

| PTFE/25 wt.% glass fibers | Cyclic rate of energy dissipation | Aglan et al. [105] |

| PP/20 wt.% glass fibers | Stiffness degradation | Subramanian and Senthilvelan [74] |

| PA6/glass fibers | Heating rate | Carrascal et al. [100] |

| PEEK/40 wt.% glass fibers | S–N curves | Li et al. [101] |

| Epoxy/33 wt.% glass fibers | Thermoelastic temperature change ∆TE, phase of thermal signal θE, second harmonic temperature component ∆TD | Shiozawa et al. [98] |

| PA66/35 wt.% glass fibers | Infrared thermography, computed laminography | Laiarinandrasana et al. [106] |

| PP/40 wt.% glass fibers | Stiffness reduction, plastic strains | Imaddahen et al. [77] |

| PA66/35 wt.% glass fibers | Stiffness reduction | Meneghetti and Quaresimin [102] |

| PP/30 wt.% glass fibers | Creep strains | Meneghetti et al. [103] |

| PA6.6/10 wt.% glass fibers | Thermal analysis, strain evolution | Bernasconi et al. [60] |

| PP/30 wt.% glass fibers | Loss tangent (viscoelastic damping factor), hysteresis loop width, displacement amplitude | Eftekhari and Fatemi [104] |

| Thermoplastic/20 wt.% carbon fibers | Volumetric Young’s modulus | Kuroshima et al. [107] |

| Material | Informative Parameters, Possibility of Combining Methods | Refs. |

|---|---|---|

| PPS/40 wt.% glass fibers | Dynamic storage modulus, surface temperature enhancement, hysteresis energy loss | Solfiti et al. [81] |

| PP/glass fibers | Elastic modulus | Hiwa et al. [108] |

| Nylon66/glass fibers | Optical microscopy | Noda et al. [109] |

| PP/40 wt.% glass fibers | Stiffness reduction, self-heating, SEM analysis of fracture surfaces | Imaddahen et al. [77] |

| PA6.6/30 wt.% glass fibers | Apparent modulus, inelastic energy | Raphael et al. [111] |

| Polyester/30 wt.% glass fibers | Microscopic observations | Hour et al. [114] |

| Nylon6/15 wt.% carbon fibers | Creep tests | Jinen [115,116] |

| Nylon6/glass fibers | Dynamic storage modulus, loss tangent | Komatsu et al. [112] |

| Epoxy/40 wt.% glass fibers | Elastic modulus | Ahmadzadeh and Varvani-Farahani [113] |

| Rubber/5.8 wt.% aramid fibers | SEM analysis | Yu et al. [117] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogdanov, A.A.; Panin, S.V.; Kosmachev, P.V. Fatigue Damage Assessment and Lifetime Prediction of Short Fiber Reinforced Polymer Composites—A Review. J. Compos. Sci. 2023, 7, 484. https://doi.org/10.3390/jcs7120484

Bogdanov AA, Panin SV, Kosmachev PV. Fatigue Damage Assessment and Lifetime Prediction of Short Fiber Reinforced Polymer Composites—A Review. Journal of Composites Science. 2023; 7(12):484. https://doi.org/10.3390/jcs7120484

Chicago/Turabian StyleBogdanov, Alexey A., Sergey V. Panin, and Pavel V. Kosmachev. 2023. "Fatigue Damage Assessment and Lifetime Prediction of Short Fiber Reinforced Polymer Composites—A Review" Journal of Composites Science 7, no. 12: 484. https://doi.org/10.3390/jcs7120484

APA StyleBogdanov, A. A., Panin, S. V., & Kosmachev, P. V. (2023). Fatigue Damage Assessment and Lifetime Prediction of Short Fiber Reinforced Polymer Composites—A Review. Journal of Composites Science, 7(12), 484. https://doi.org/10.3390/jcs7120484