Microstructural and Mechanical Characterization of the Dissimilar AA7075 and AA2024 Aluminum Alloys Reinforced with Different Carbide Particles Welded by Friction Stir Welding

Abstract

:1. Introduction

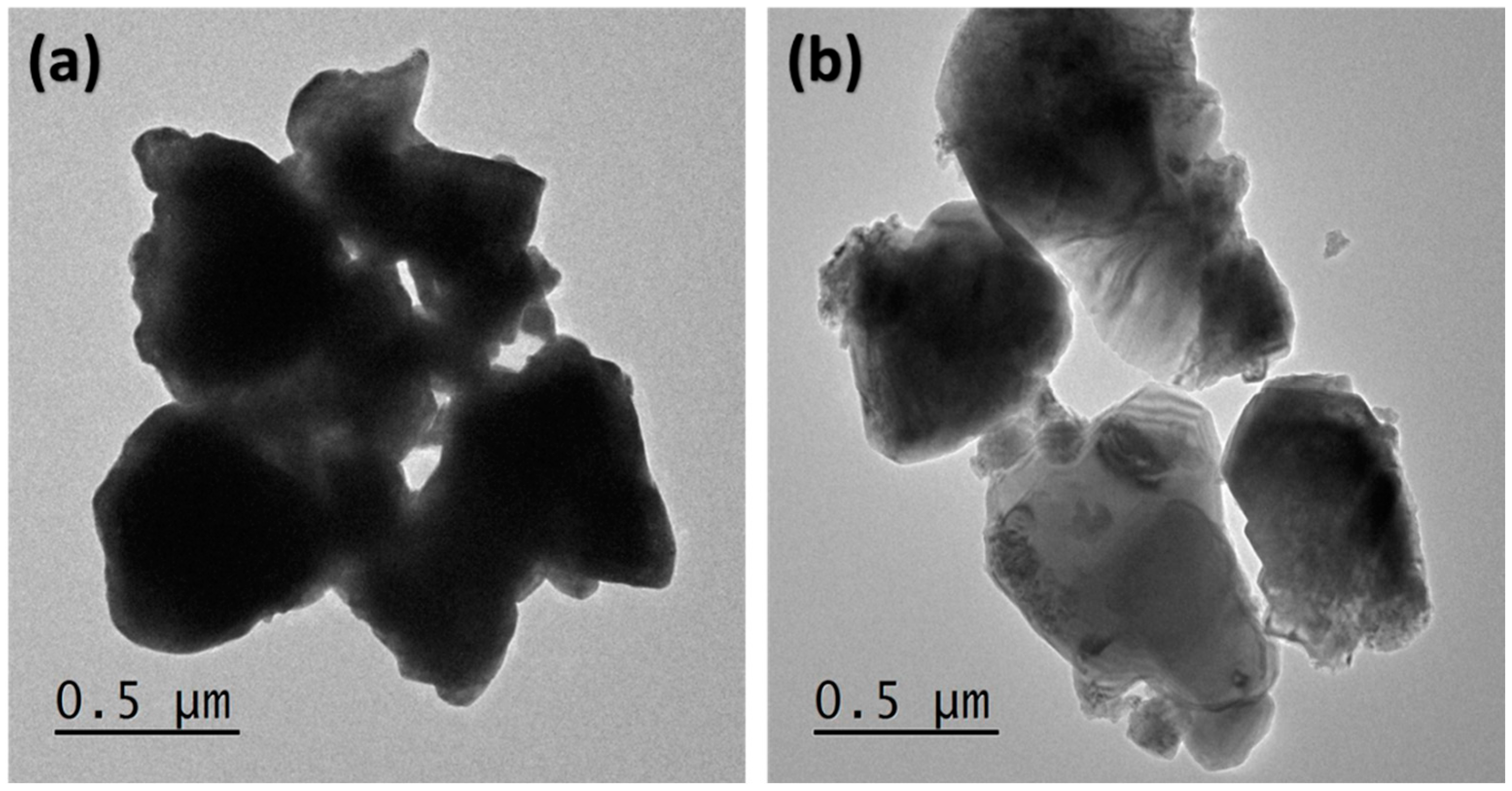

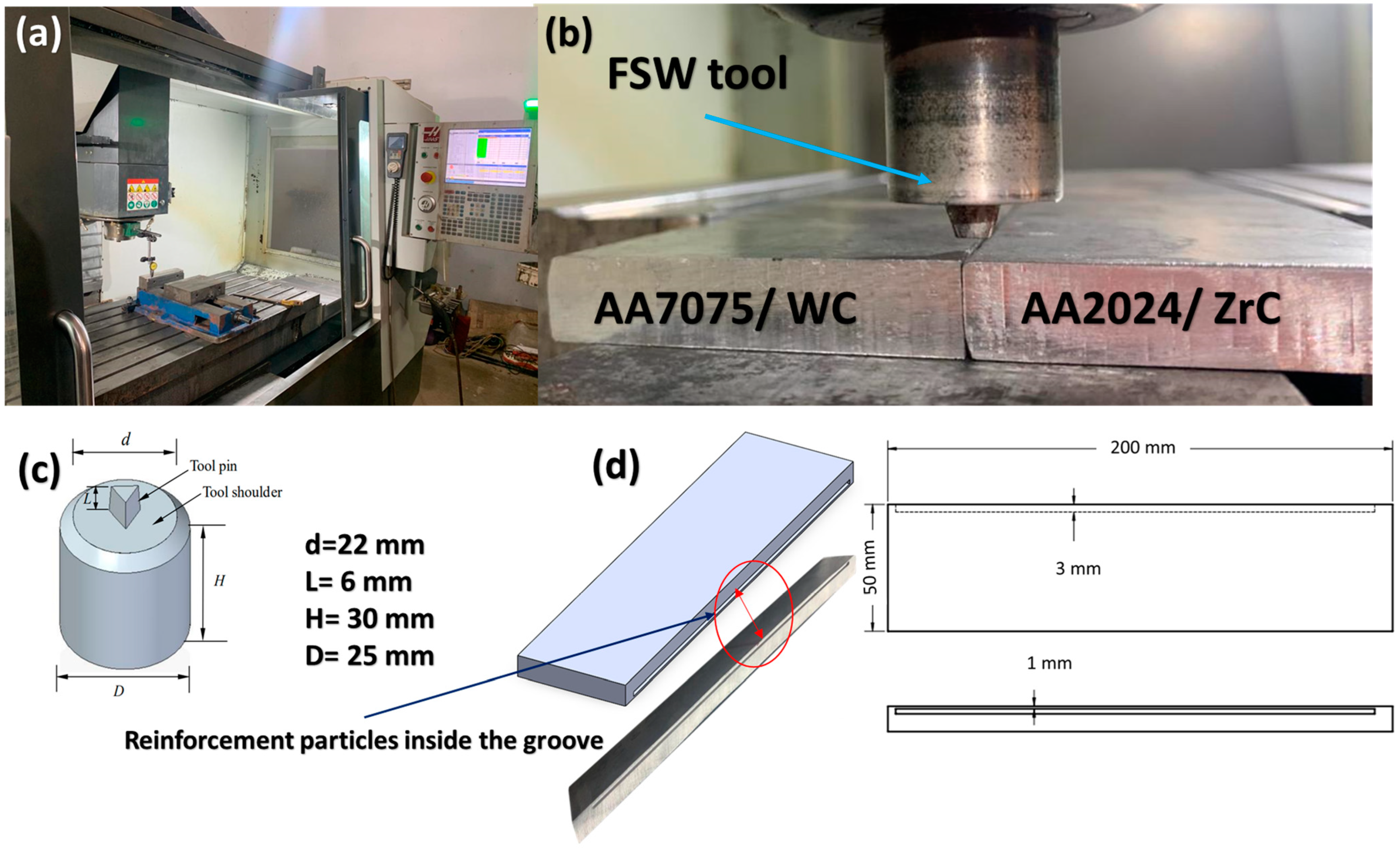

2. Materials and Methods

3. Results and Discussions

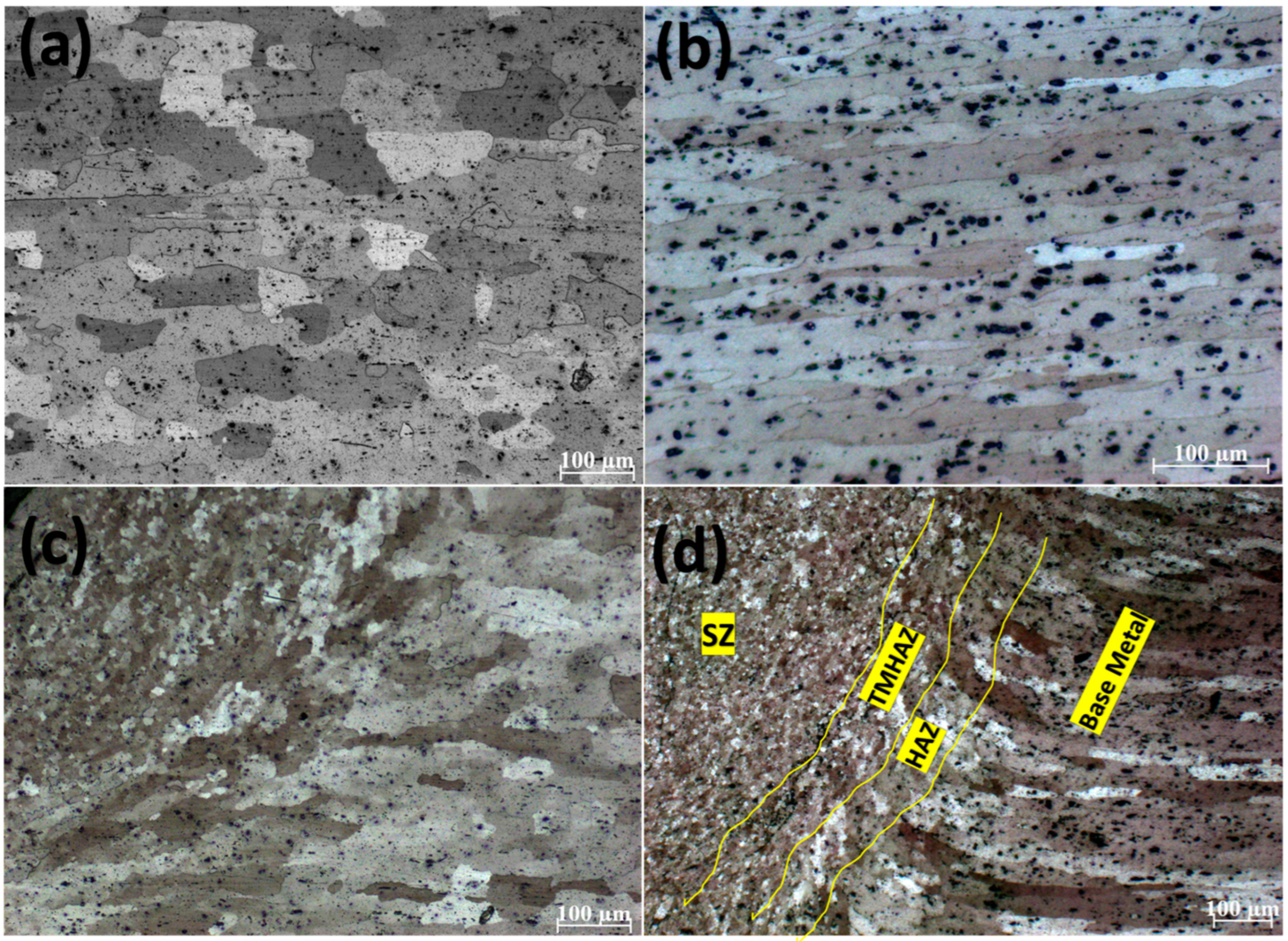

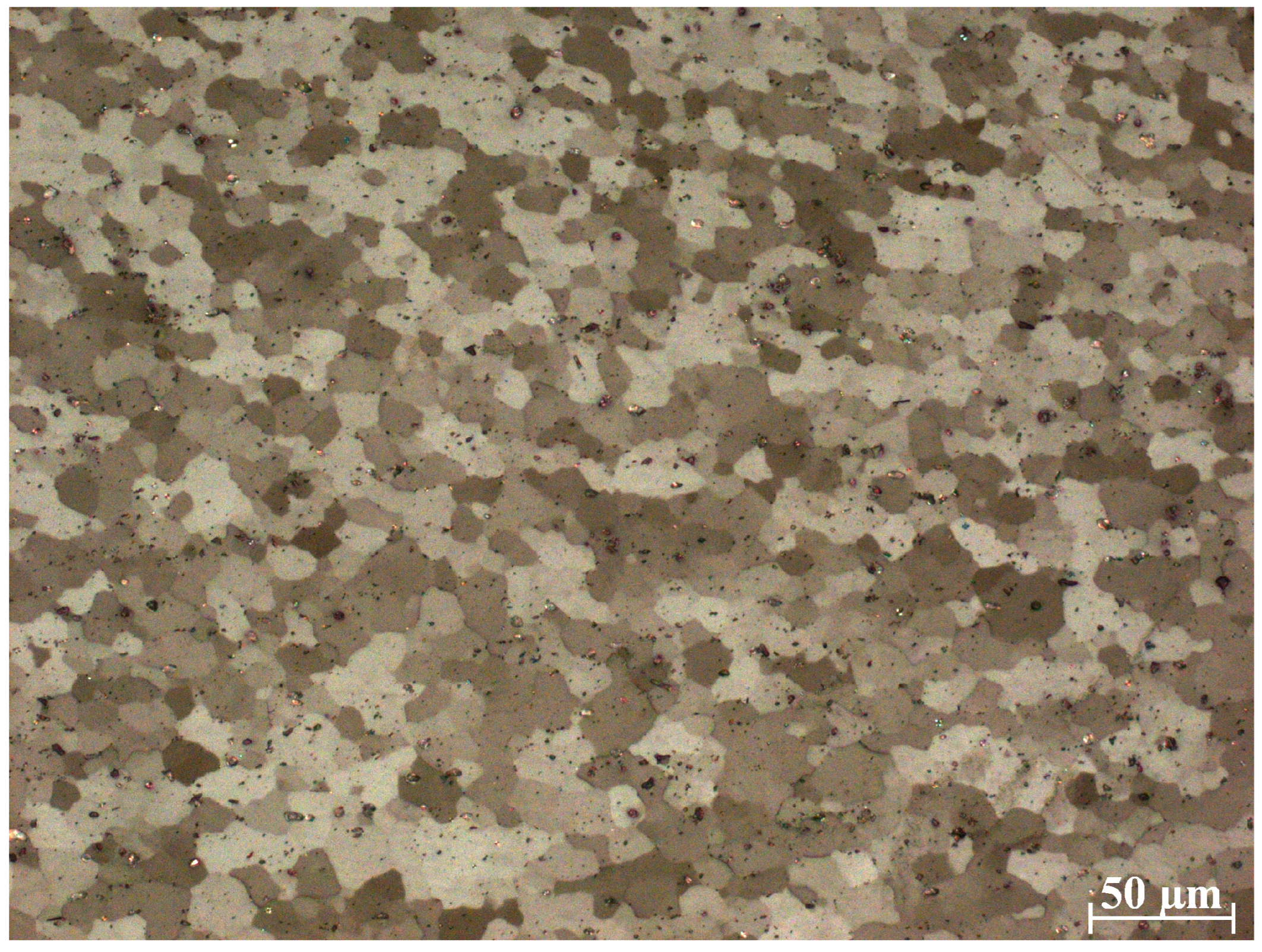

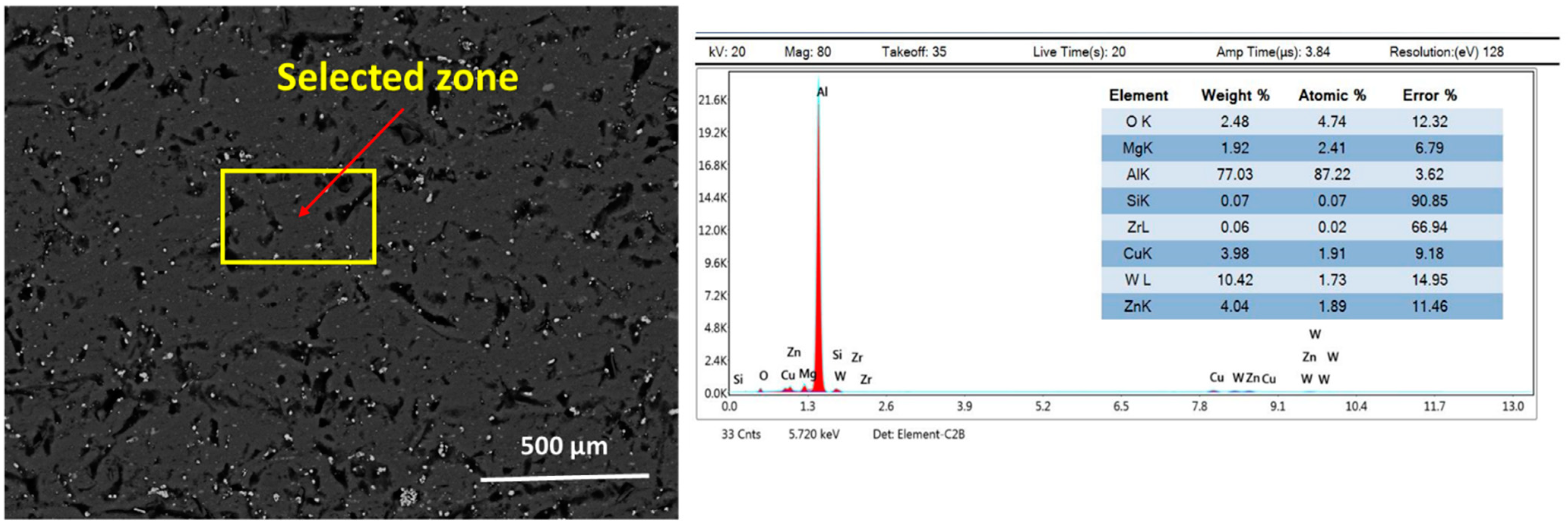

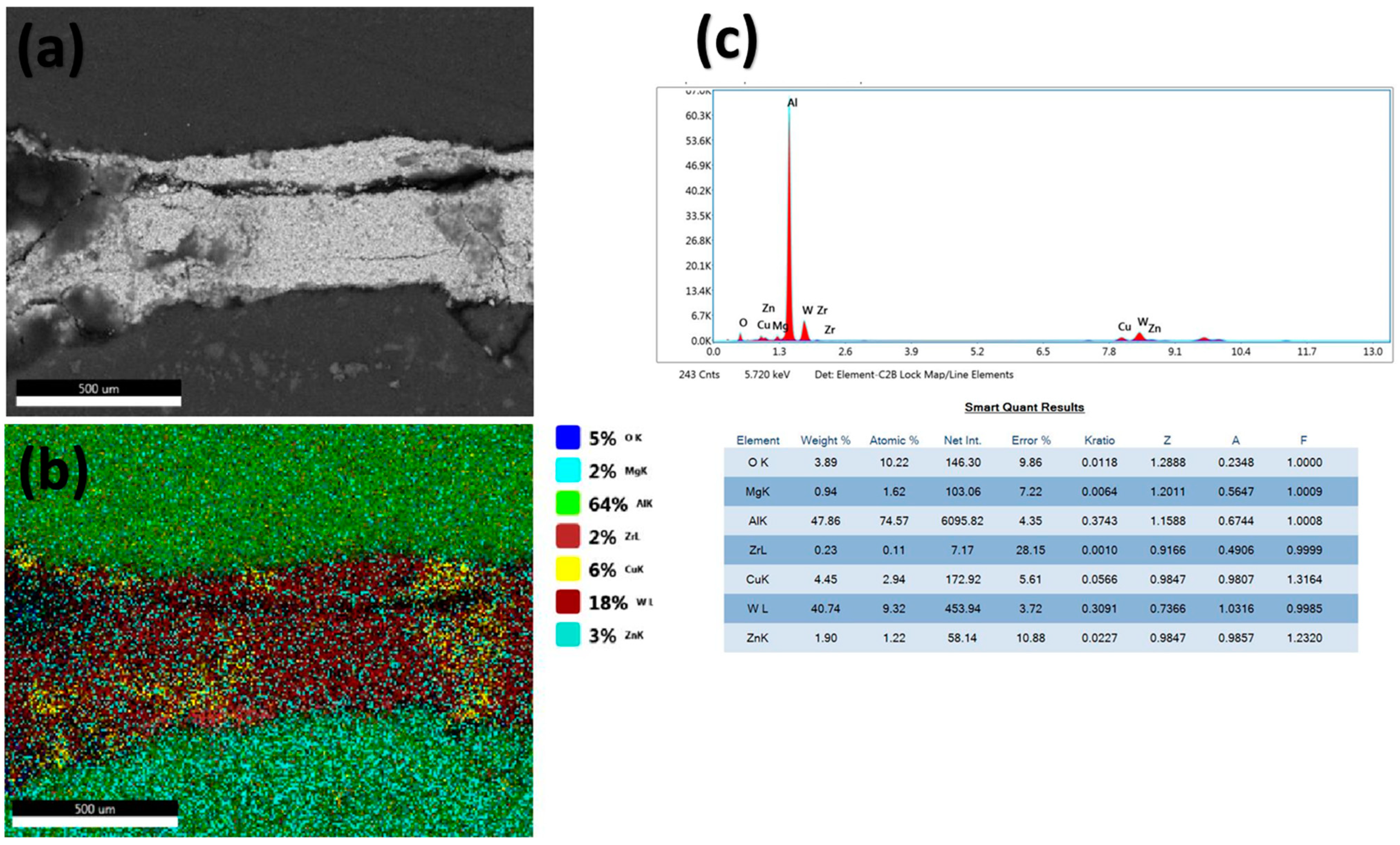

3.1. Optical Microstructure Examination

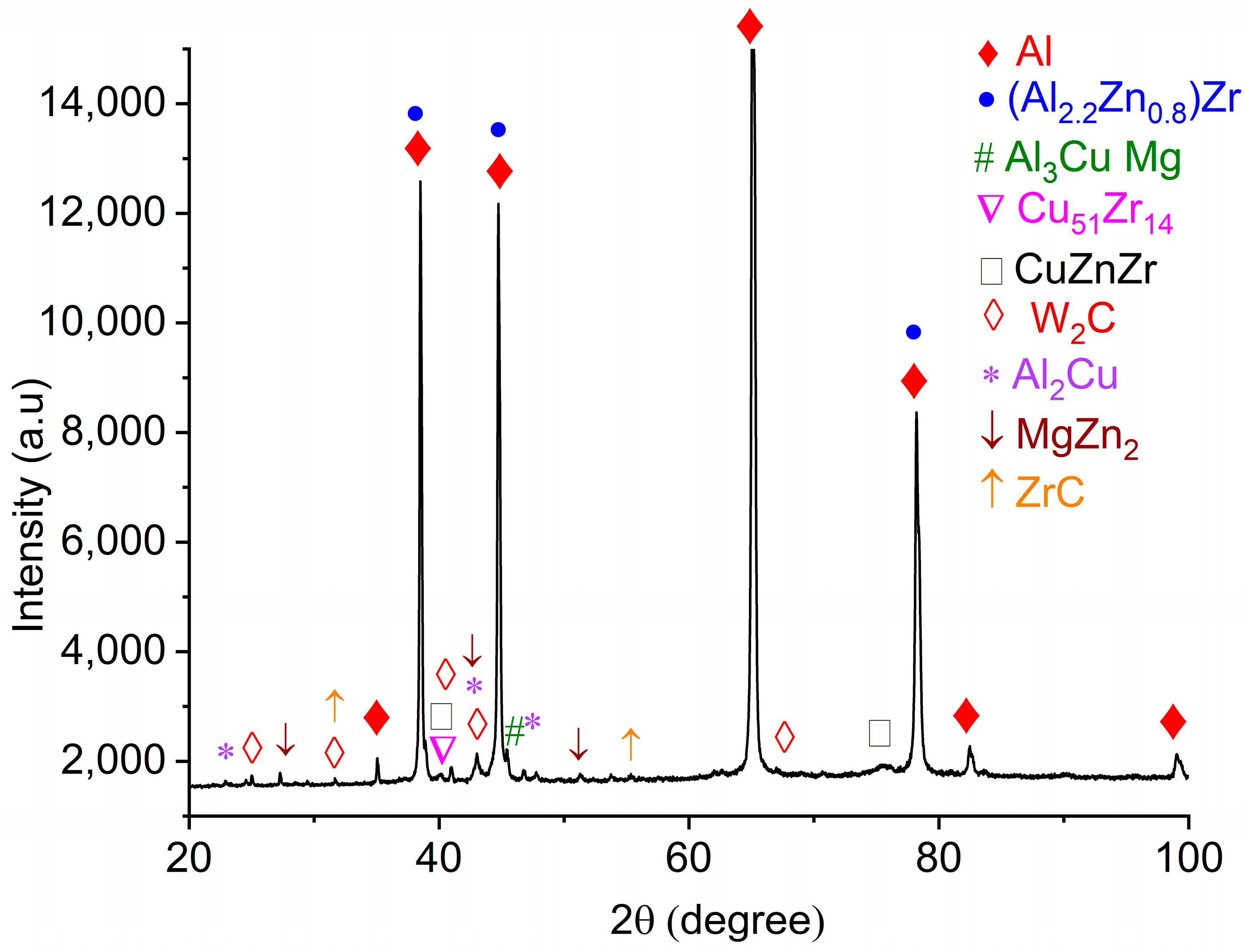

3.2. Phase Composition

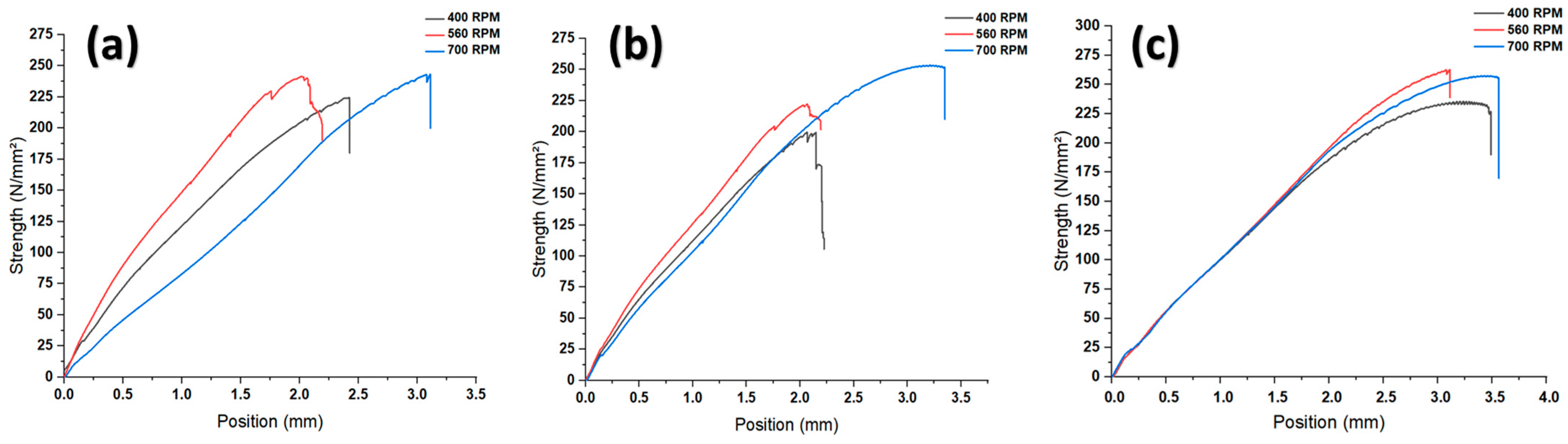

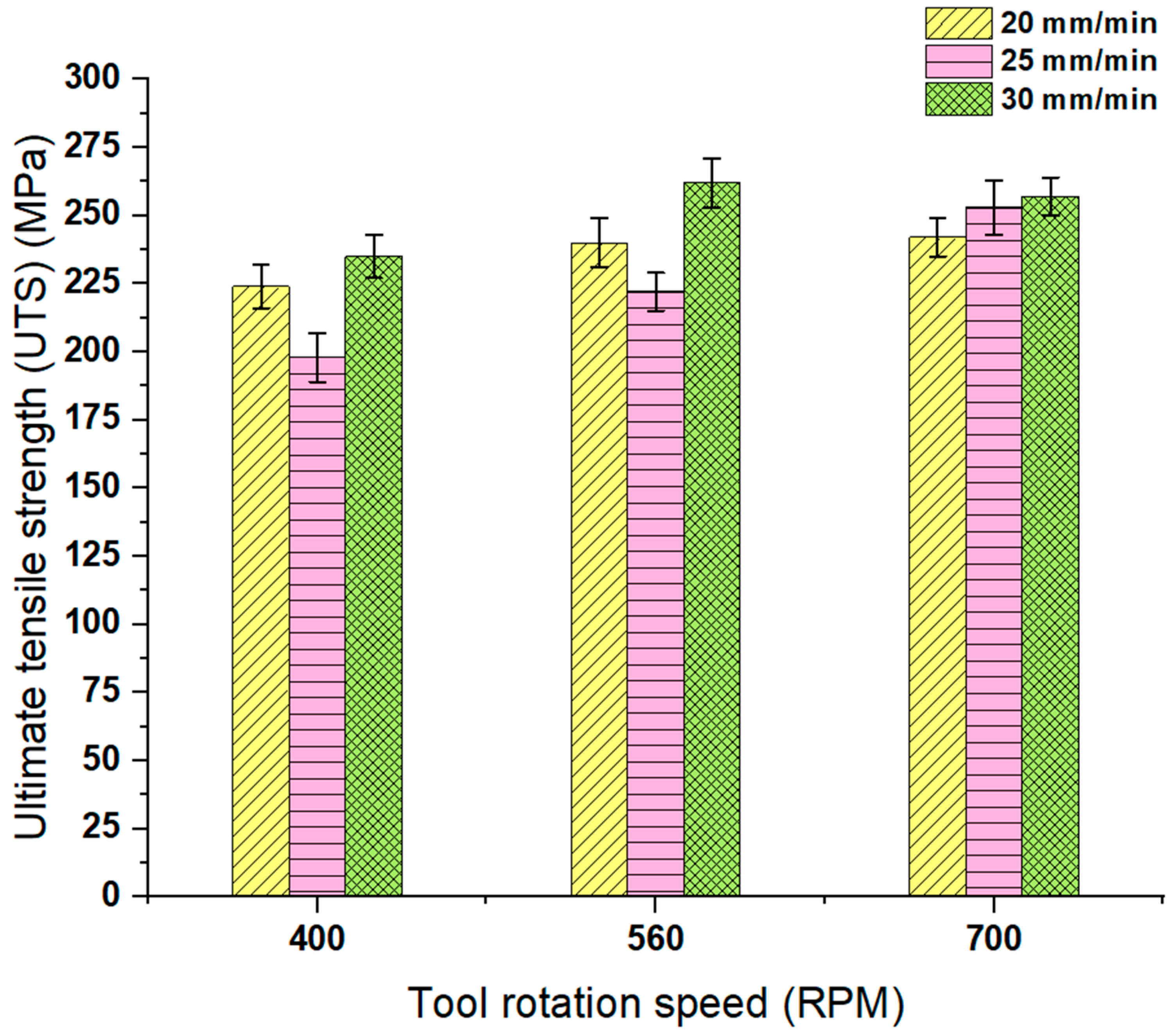

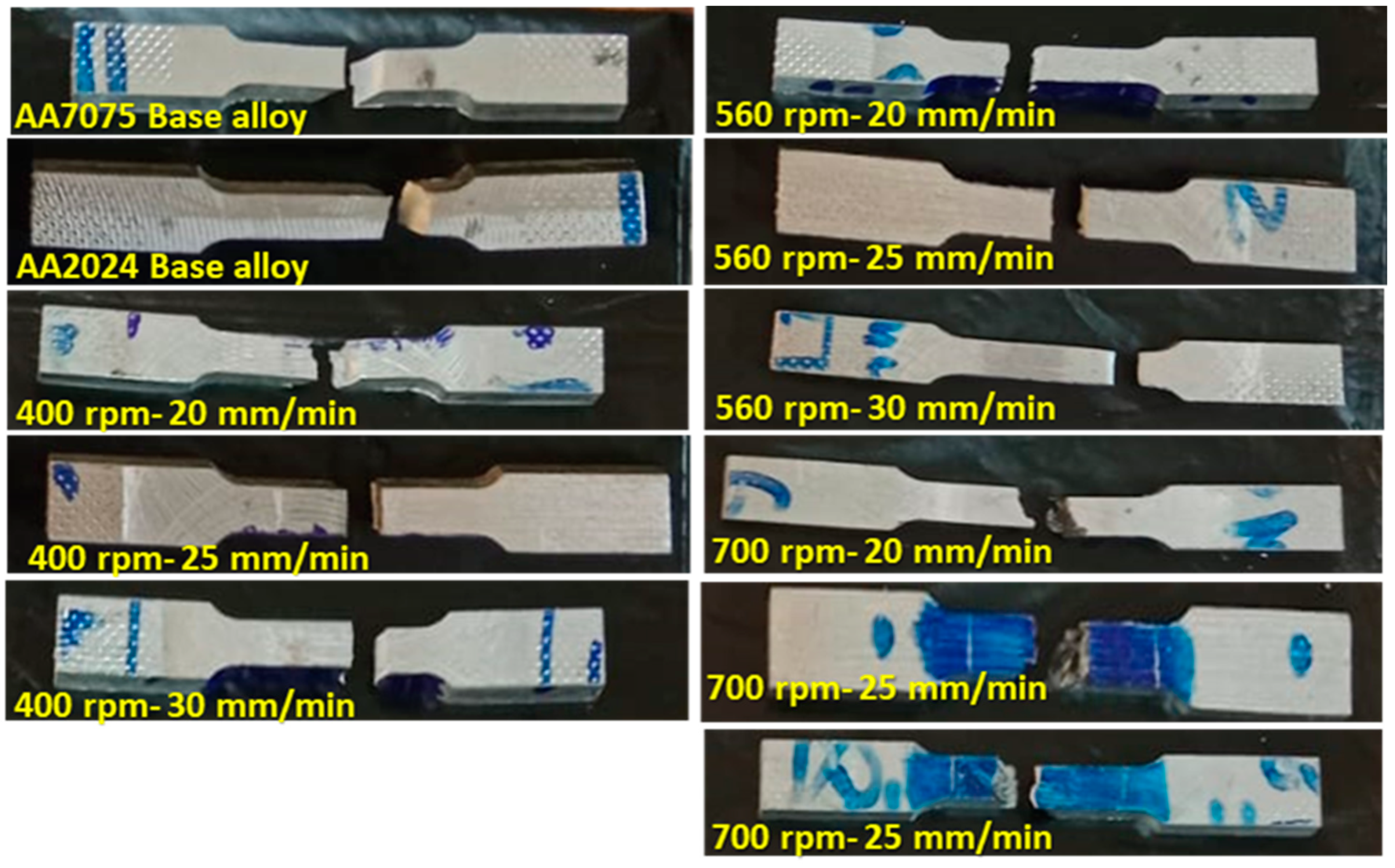

3.3. Mechanical Properties

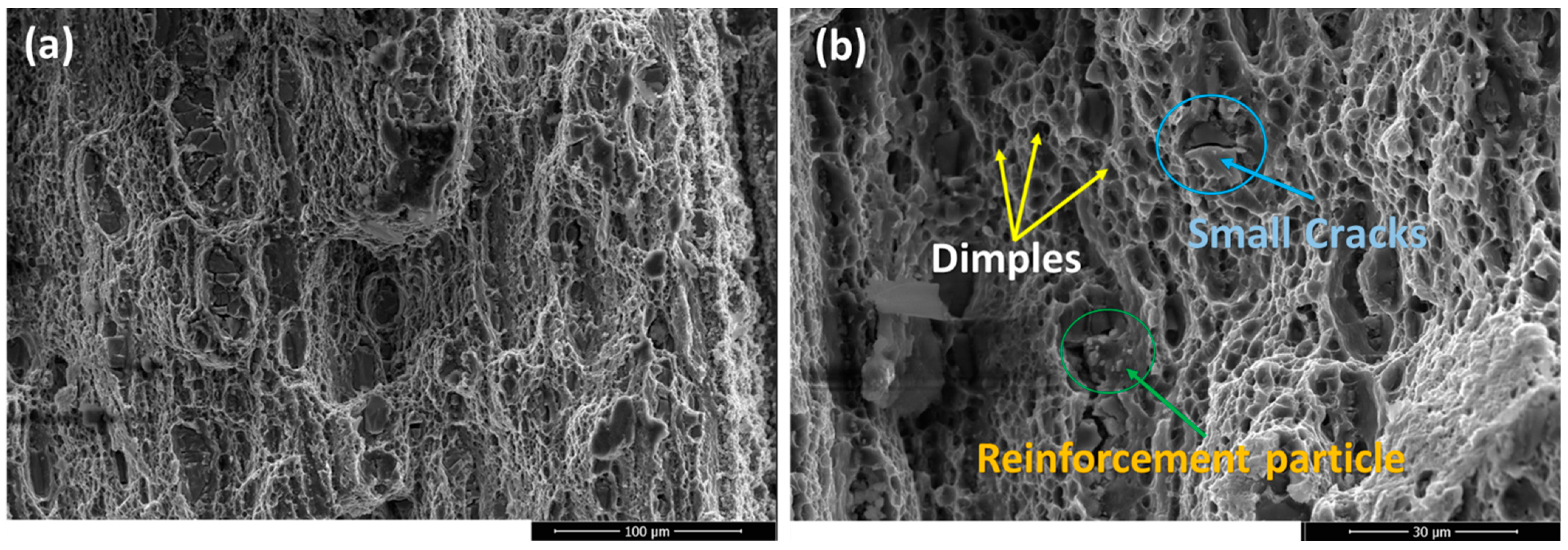

3.4. Fracture Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.N.; Cao, X.; Larose, S.; Wanjara, P. Review of tools for friction stir welding and processing. Can. Metall. Q. 2012, 51, 250–261. [Google Scholar] [CrossRef]

- Malik, V.; Sanjeev, N.K.; Hebbar, H.S.; Kailas, S.V. Investigations on the Effect of Various Tool Pin Profiles in Friction Stir Welding Using Finite Element Simulations. Procedia Eng. 2014, 97, 1060–1068. [Google Scholar] [CrossRef]

- Moreira, F.; Ferreira, P.M.; Silva, R.J.C.; Santos, T.G.; Vidal, C. Aluminium-Based Dissimilar Alloys Surface Composites Reinforced with Functional Microparticles Produced by Upward Friction Stir Processing. Coatings 2023, 13, 962. [Google Scholar] [CrossRef]

- Singh, H.; Dhindaw, B.K. Metal Matrix Composites: Aluminum. In Wiley Encyclopedia of Composites; Wiley: Hoboken, NJ, USA, 2012; pp. 1–18. [Google Scholar]

- Shrivas, S.P.; Agrawal, G.K.; Nagpal, S.; Vishvakarma, A.K.; Khandelwal, A.K. Dissimilar aluminum alloy joint strength is effected by heat addition in friction stir welding (FSW). Mater. Today Proc. 2021, 44, 1472–1477. [Google Scholar] [CrossRef]

- Jabraeili, R.; Jafarian, H.R.; Khajeh, R.; Park, N.; Kim, Y.; Heidarzadeh, A.; Eivani, A.R. Effect of FSW process parameters on microstructure and mechanical properties of the dissimilar AA2024 Al alloy and 304 stainless steel joints. Mater. Sci. Eng. A 2021, 814, 140981. [Google Scholar] [CrossRef]

- Abd Elnabi, M.M.; Elshalakany, A.B.; Abdel-Mottaleb, M.M.; Osman, T.A.; El Mokadem, A. Influence of friction stir welding parameters on metallurgical and mechanical properties of dissimilar AA5454–AA7075 aluminum alloys. J. Mater. Res. Technol. 2019, 8, 1684–1693. [Google Scholar] [CrossRef]

- Dinaharan, I.; Kalaiselvan, K.; Vijay, S.J.; Raja, P. Effect of material location and tool rotational speed on microstructure and tensile strength of dissimilar friction stir welded aluminum alloys. Arch. Civ. Mech. Eng. 2012, 12, 446–454. [Google Scholar] [CrossRef]

- Dorbane, A.; Mansoor, B.; Ayoub, G.; Shunmugasamy, V.C.; Imad, A. Mechanical, microstructural and fracture properties of dissimilar welds produced by friction stir welding of AZ31B and Al6061. Mater. Sci. Eng. A 2016, 651, 720–733. [Google Scholar] [CrossRef]

- Siddharthan, B.; Rajiev, R.; Saravanan, S.; Naveen, T.K. Effect of Silicon Carbide in Mechanical Properties of Aluminium Alloy Based Metal Matrix Composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 764, 012040. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Taha, M.A. The Effect of Mono and Hybrid Additives of Ceramic Nanoparticles on the Tribological Behavior and Mechanical Characteristics of an Al-Based Composite Matrix Produced by Friction Stir Processing. Nanomaterials 2023, 13, 2148. [Google Scholar] [CrossRef]

- Gibson, B.T.; Lammlein, D.H.; Prater, T.J.; Longhurst, W.R.; Cox, C.D.; Ballun, M.C.; Dharmaraj, K.J.; Cook, G.E.; Strauss, A.M. Friction stir welding: Process, automation, and control. J. Manuf. Process. 2014, 16, 56–73. [Google Scholar] [CrossRef]

- Mirjavadi, S.S.; Alipour, M.; Emamian, S.; Kord, S.; Hamouda, A.M.S.; Koppad, P.G.; Keshavamurthy, R. Influence of TiO2 nanoparticles incorporation to friction stir welded 5083 aluminum alloy on the microstructure, mechanical properties and wear resistance. J. Alloys Compd. 2017, 712, 795–803. [Google Scholar] [CrossRef]

- Moustafa, E. Effect of Multi-Pass Friction Stir Processing on Mechanical Properties for AA2024/Al2O3 Nanocomposites. Materials 2017, 10, 1053. [Google Scholar] [CrossRef] [PubMed]

- Cioffi, F.; Fernández, R.; Gesto, D.; Rey, P.; Verdera, D.; González-Doncel, G. Friction stir welding of thick plates of aluminum alloy matrix composite with a high volume fraction of ceramic reinforcement. Compos. Part A Appl. Sci. Manuf. 2013, 54, 117–123. [Google Scholar] [CrossRef]

- Abnar, B.; Gashtiazar, S.; Javidani, M. Friction Stir Welding of Non-Heat Treatable Al Alloys: Challenges and Improvements Opportunities. Crystals 2023, 13, 576. [Google Scholar] [CrossRef]

- Kundu, A.K.; Gupta, M.K.; Rajput, N.S.; Rathore, R. Adhesive assisted TiB2 coating effects on friction stir welded joints. Sci. Rep. 2022, 12, 17894. [Google Scholar] [CrossRef]

- Hassanifard, S.; Ghiasvand, A.; Hashemi, S.M.; Varvani-Farahani, A. The effect of the friction stir welding tool shape on tensile properties of welded Al 6061-T6 joints. Mater. Today Commun. 2022, 31, 103457. [Google Scholar] [CrossRef]

- Rudrapati, R. Effects of welding process conditions on friction stir welding of polymer composites: A review. Compos. Part C Open Access 2022, 8, 100269. [Google Scholar] [CrossRef]

- Abdel Aziz, S.S.; Abulkhair, H.; Moustafa, E.B. Role of hybrid nanoparticles on thermal, electrical conductivity, microstructure, and hardness behavior of nanocomposite matrix. J. Mater. Res. Technol. 2021, 13, 1275–1284. [Google Scholar] [CrossRef]

- He, T.; Ertuğrul, O.; Ciftci, N.; Uhlenwinkel, V.; Nielsch, K.; Scudino, S. Effect of particle size ratio on microstructure and mechanical properties of aluminum matrix composites reinforced with Zr48Cu36Ag8Al8 metallic glass particles. Mater. Sci. Eng. A 2019, 742, 517–525. [Google Scholar] [CrossRef]

- Hassan, A.S.; Moustafa, E.B.; Mohamed, S.S. Impact of welding processing parameters on the microstructure grain refinement and hardness behavior of the aluminum AA1050 joints. Egypt. J. Chem. 2023, 66, 291–302. [Google Scholar] [CrossRef]

- Padmanaban, R.; Balusamy, V.; Vaira Vignesh, R. Effect of friction stir welding process parameters on the tensile strength of dissimilar aluminum alloy AA2024-T3 and AA7075-T6 joints. Mater. Werkst. 2020, 51, 17–27. [Google Scholar] [CrossRef]

- Devaraju, A.; Jeshrun Shalem, M.; Manichandra, B. Effect of Rotation speed on Tensile Properties & Microhardness of Dissimilar Al Alloys 6061-T6 to 2024-T6 Welded via Solid State Joining Technique. Mater. Today Proc. 2019, 18, 3286–3290. [Google Scholar] [CrossRef]

- Boopathi, M.; Arulshri, K.P.; Iyandurai, N. Evaluation of Mechanical Properties of Aluminium Alloy 2024 Reinforced with Silicon Carbide and Fly Ash Hybrid Metal Matrix Composites. Am. J. Appl. Sci. 2013, 10, 219–229. [Google Scholar] [CrossRef]

- Ceschini, L.; Minak, G.; Morri, A. Tensile and fatigue properties of the AA6061/20vol% Al2O3p and AA7005/10vol% Al2O3p composites. Compos. Sci. Technol. 2006, 66, 333–342. [Google Scholar] [CrossRef]

- Kara, M.; Coskun, T.; Gunoz, A. Influence of B4C on enhancing mechanical properties of AA2014 aluminum matrix composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 236, 2536–2545. [Google Scholar] [CrossRef]

- Uday, K.N.; Rajamurugan, G. Influence of process parameters and its effects on friction stir welding of dissimilar aluminium alloy and its composites—A review. J. Adhes. Sci. Technol. 2023, 37, 767–800. [Google Scholar] [CrossRef]

- Pookamnerd, Y.; Thosa, P.; Charonerat, S.; Prasomthong, S. Development of mechanical property prediction model and optimization for dissimilar aluminum alloy joints with the friction stir welding (FSW) process. EUREKA Phys. Eng. 2023, 3, 112–128. [Google Scholar] [CrossRef]

- Dahiya, M.S.; Kumar, V.; Verma, S. A Critical Review on Friction Stir Welding of Dissimilar Aluminium Alloys. In Proceedings of the Advances in Industrial and Production Engineering, Singapore, 24 April 2019; pp. 707–719. [Google Scholar]

- Khoshaim, A.B.; Moustafa, E.B.; Alazwari, M.A.; Taha, M.A. An Investigation of the Mechanical, Thermal and Electrical Properties of an AA7075 Alloy Reinforced with Hybrid Ceramic Nanoparticles Using Friction Stir Processing. Metals 2023, 13, 124. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Melaibari, A.; Basha, M. Wear and microhardness behaviors of AA7075/SiC-BN hybrid nanocomposite surfaces fabricated by friction stir processing. Ceram. Int. 2020, 46, 16938–16943. [Google Scholar] [CrossRef]

- Rajan, H.B.M.; Dinaharan, I.; Ramabalan, S.; Akinlabi, E.T. Influence of friction stir processing on microstructure and properties of AA7075/TiB2 in situ composite. J. Alloys Compd. 2016, 657, 250–260. [Google Scholar] [CrossRef]

- Zhou, X.; Luo, C.; Hashimoto, T.; Hughes, A.E.; Thompson, G.E. Study of localized corrosion in AA2024 aluminium alloy using electron tomography. Corros. Sci. 2012, 58, 299–306. [Google Scholar] [CrossRef]

- Hou, W.; Oheil, M.; Shen, Z.; Shen, Y.; Jahed, H.; Gerlich, A. Enhanced strength and ductility in dissimilar friction stir butt welded Al/Cu joints by addition of a cold-spray Ni interlayer. J. Manuf. Process. 2020, 60, 573–577. [Google Scholar] [CrossRef]

- Kumar, S.; Sarma, V.S.; Murty, B.S. Influence of in situ formed TiB2 particles on the abrasive wear behaviour of Al–4Cu alloy. Mater. Sci. Eng. A 2007, 465, 160–164. [Google Scholar] [CrossRef]

- Monikandan, V.V.; Jacob, J.C.; Joseph, M.A.; Rajendrakumar, P.K. Statistical Analysis of Tribological Properties of Aluminum Matrix Composites Using Full Factorial Design. Trans. Indian Inst. Met. 2015, 68, 53–57. [Google Scholar] [CrossRef]

- El-Moayed, M.H.; Shash, A.Y.; Rabou, M.A.; El-Sherbiny, M.G. Thermal-induced Residual Stresses and Distortions in Friction Stir Welds—A Literature Review. J. Weld. Join. 2021, 39, 409–418. [Google Scholar] [CrossRef]

- Öksüz, K.E.; Bağirov, H.; Şimşir, M.; Karpuzoğlu, C.; Özbölük, A.; Demirhan, Y.Z.; Bilgin, H.U. Investigation of Mechanical Properties and Microstructure of AA2024 and AA7075. Appl. Mech. Mater. 2013, 390, 547–551. [Google Scholar] [CrossRef]

- Li, J.; Cao, F.; Shen, Y. Effect of Welding Parameters on Friction Stir Welded Ti–6Al–4V Joints: Temperature, Microstructure and Mechanical Properties. Metals 2020, 10, 940. [Google Scholar] [CrossRef]

| Aluminum Alloys | Cu | Zn | Si | Fe | Mg | Others | Al |

|---|---|---|---|---|---|---|---|

| AA2024 | 4.54 | 0.34 | 0.48 | 0.53 | 1.75 | 1.53 | remain |

| AA7075 | 1.61 | 4.98 | 0.39 | 0.21 | 3.11 | 0.4 | remain |

| FSP tool steel | |||||||

| K110 | C | Mn | Cr | V | Mo | Si | Fe |

| 1.55 | 0.75 | 11.3 | 0.75 | 0.75 | 0.3 | Bal | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moustafa, E.B.; Sharaf, M.; Alsoruji, G.; Mosleh, A.O.; Mohamed, S.S.; Hussein, H. Microstructural and Mechanical Characterization of the Dissimilar AA7075 and AA2024 Aluminum Alloys Reinforced with Different Carbide Particles Welded by Friction Stir Welding. J. Compos. Sci. 2023, 7, 448. https://doi.org/10.3390/jcs7110448

Moustafa EB, Sharaf M, Alsoruji G, Mosleh AO, Mohamed SS, Hussein H. Microstructural and Mechanical Characterization of the Dissimilar AA7075 and AA2024 Aluminum Alloys Reinforced with Different Carbide Particles Welded by Friction Stir Welding. Journal of Composites Science. 2023; 7(11):448. https://doi.org/10.3390/jcs7110448

Chicago/Turabian StyleMoustafa, Essam B., Mazen Sharaf, Ghazi Alsoruji, Ahmed O. Mosleh, S. S. Mohamed, and Hossameldin Hussein. 2023. "Microstructural and Mechanical Characterization of the Dissimilar AA7075 and AA2024 Aluminum Alloys Reinforced with Different Carbide Particles Welded by Friction Stir Welding" Journal of Composites Science 7, no. 11: 448. https://doi.org/10.3390/jcs7110448

APA StyleMoustafa, E. B., Sharaf, M., Alsoruji, G., Mosleh, A. O., Mohamed, S. S., & Hussein, H. (2023). Microstructural and Mechanical Characterization of the Dissimilar AA7075 and AA2024 Aluminum Alloys Reinforced with Different Carbide Particles Welded by Friction Stir Welding. Journal of Composites Science, 7(11), 448. https://doi.org/10.3390/jcs7110448