Rock Wool Fiber-Reinforced and Recycled Concrete Aggregate-Imbued Hot Asphalt Mixtures: Design and Moisture Susceptibility Evaluation

Abstract

:1. Introduction

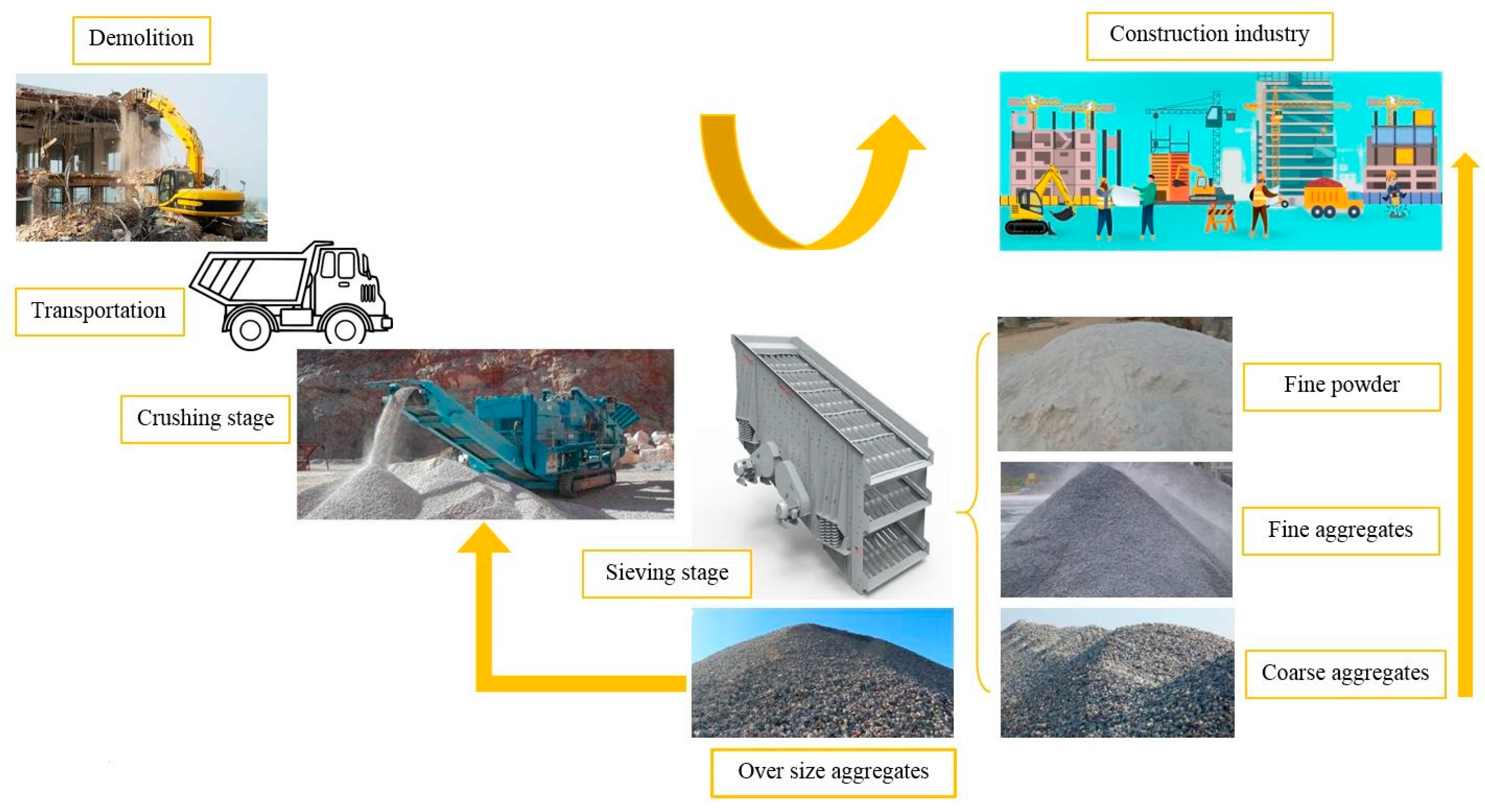

2. Materials and Methods

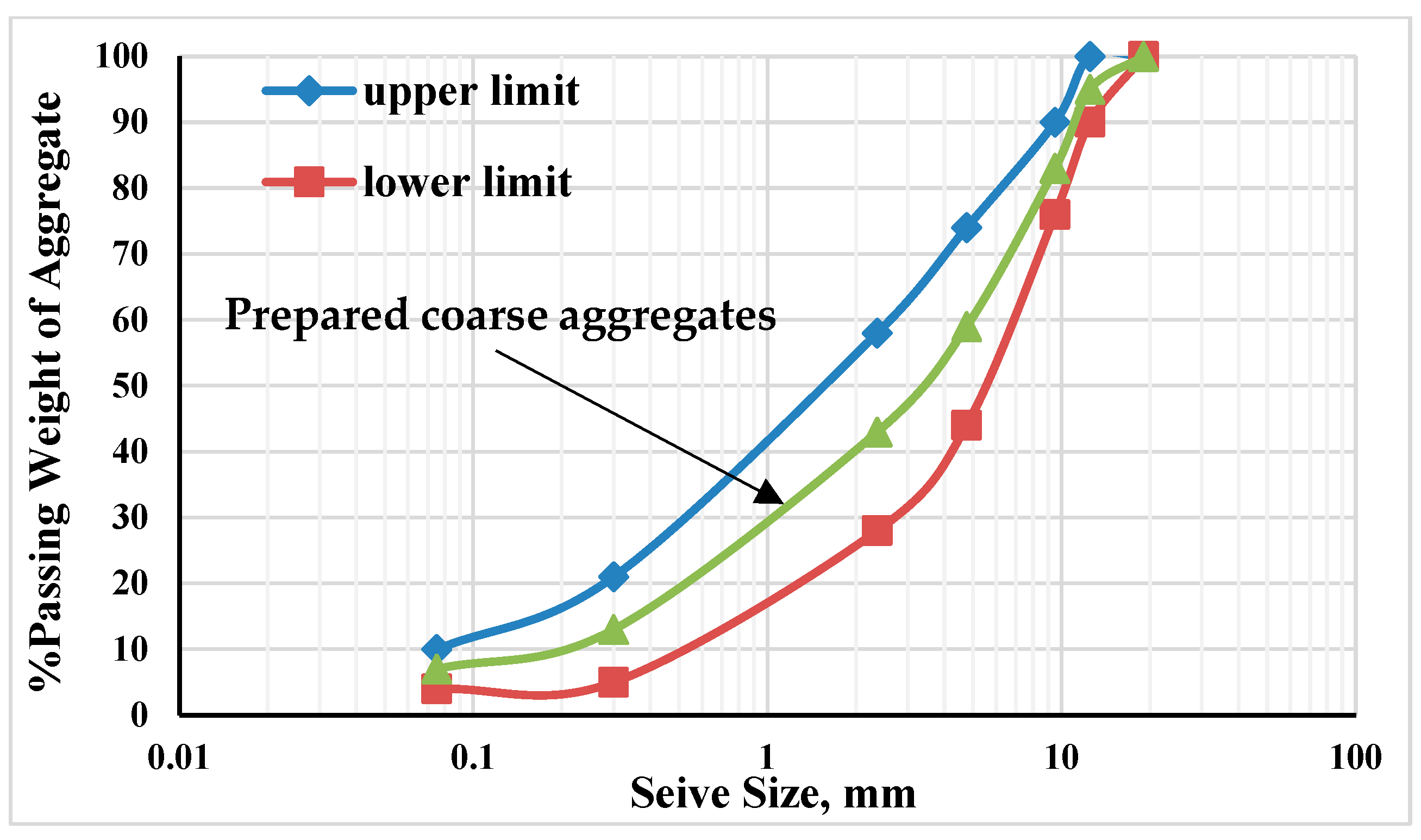

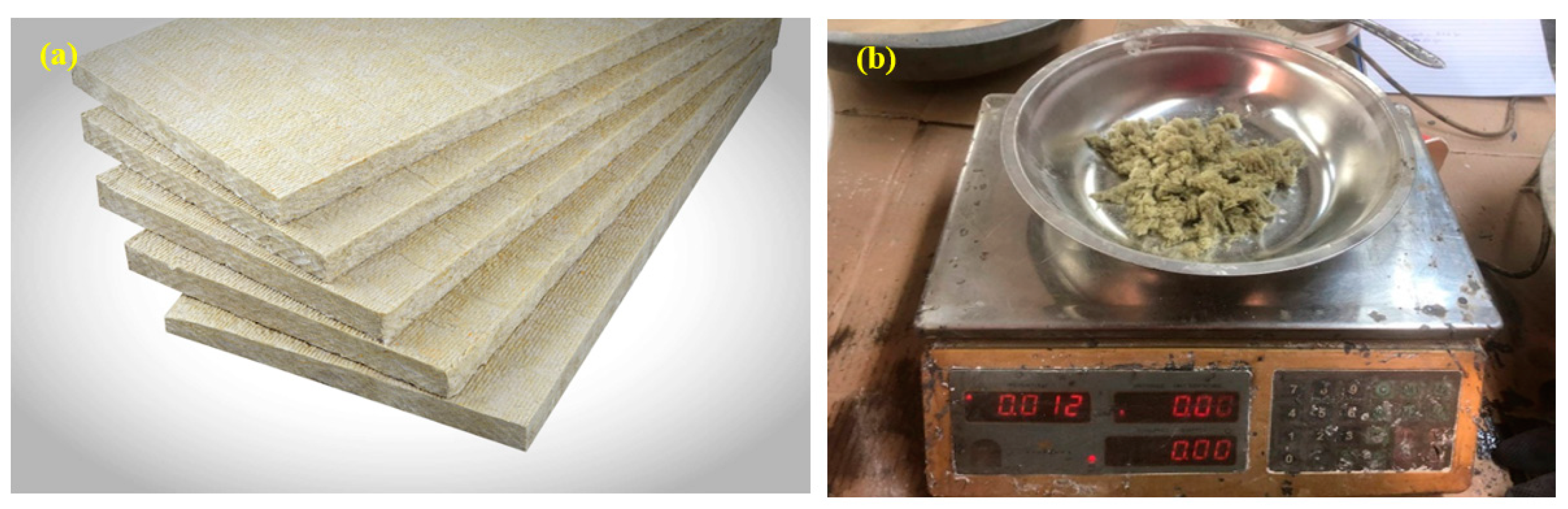

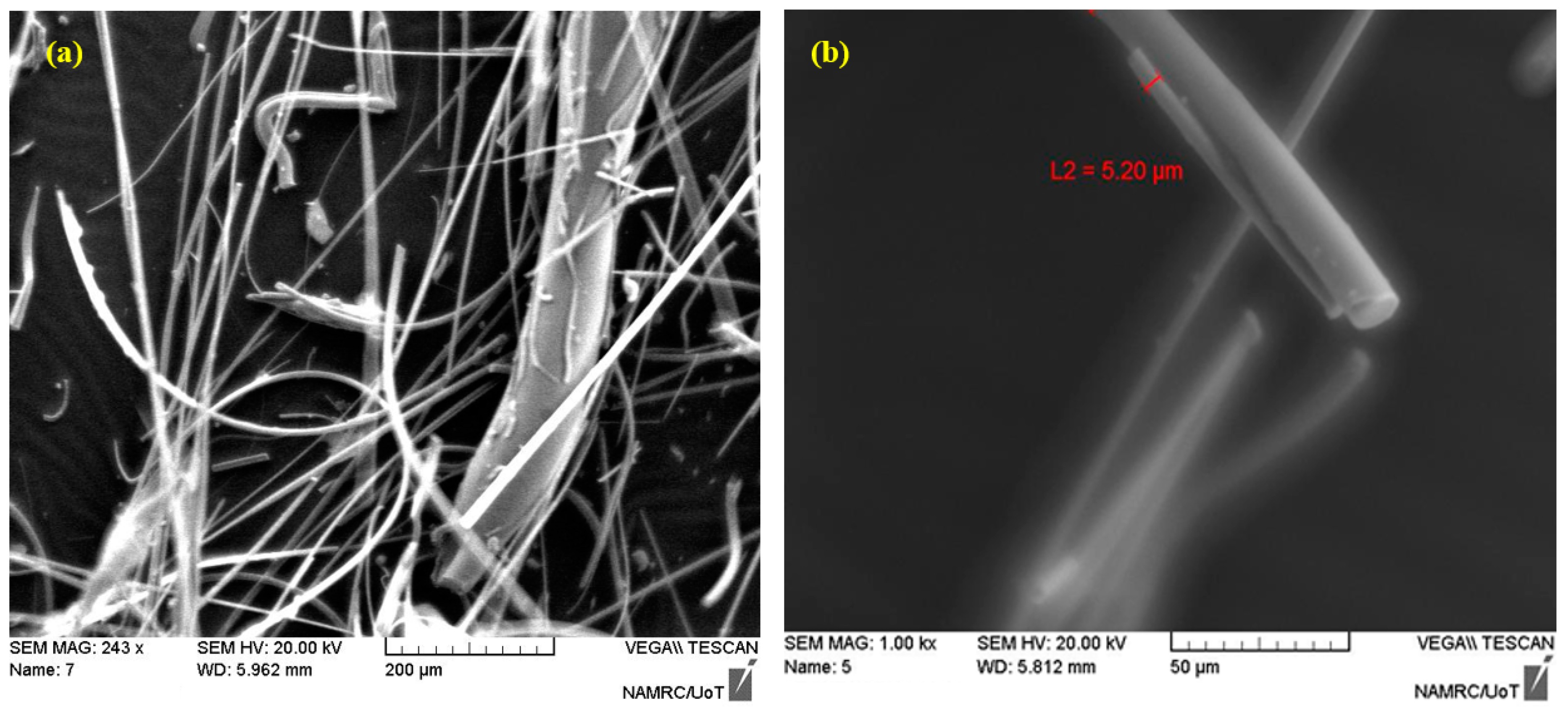

2.1. Materials Characterization

2.2. Mix Design

2.3. Marshall Test

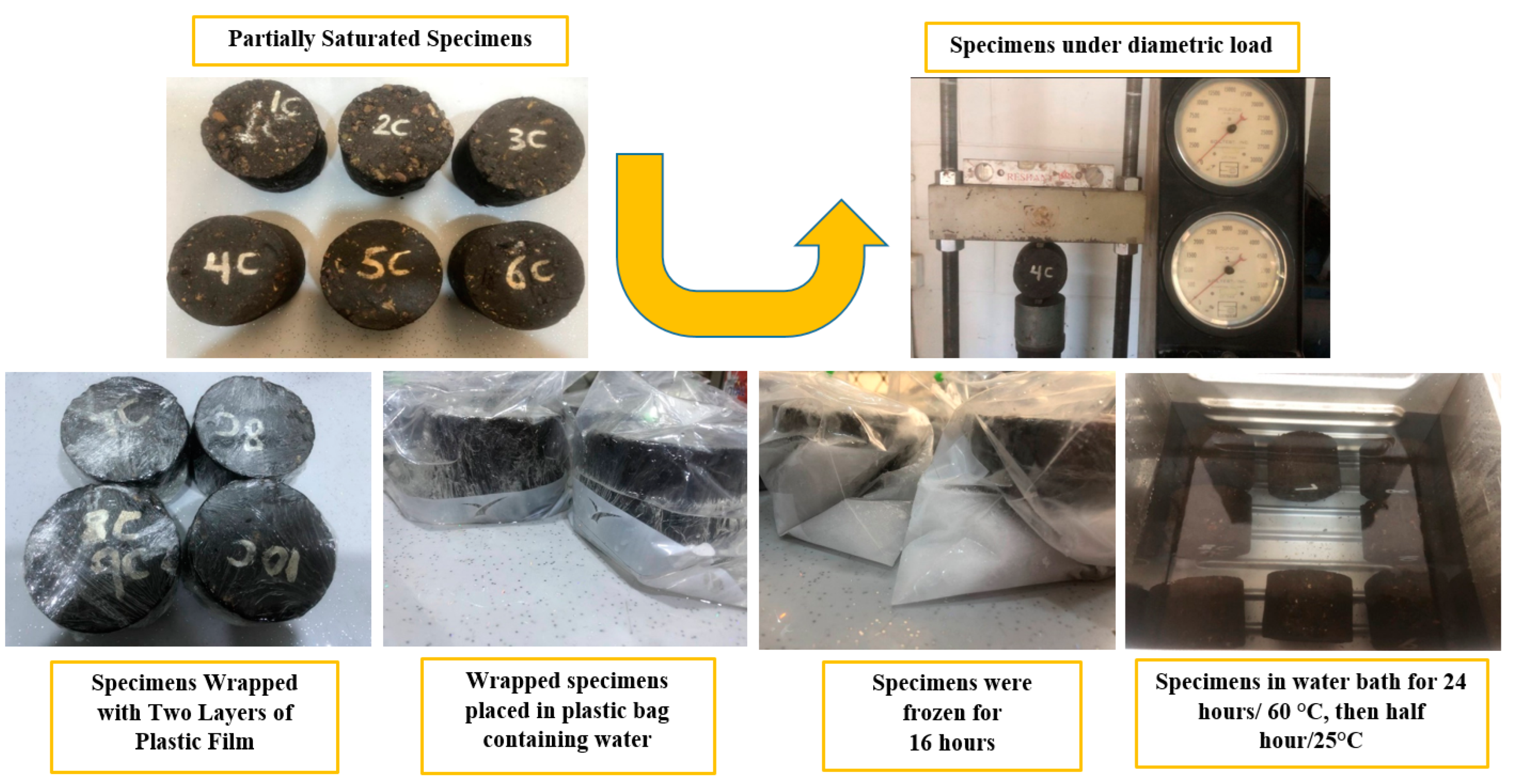

2.4. Tensile Strength Ratio Test

2.5. Index of Retained Strength Test

3. Results and Discussion

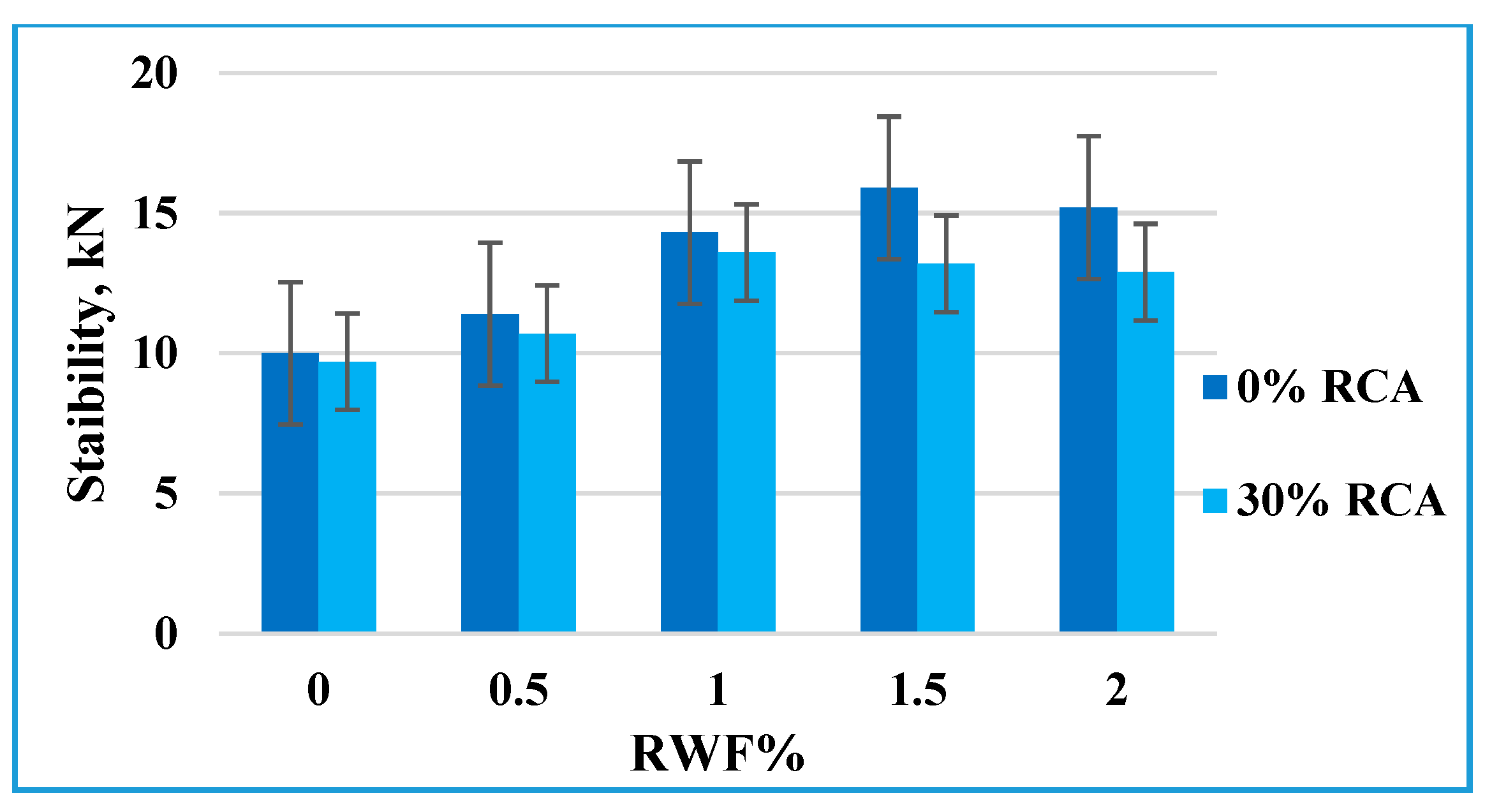

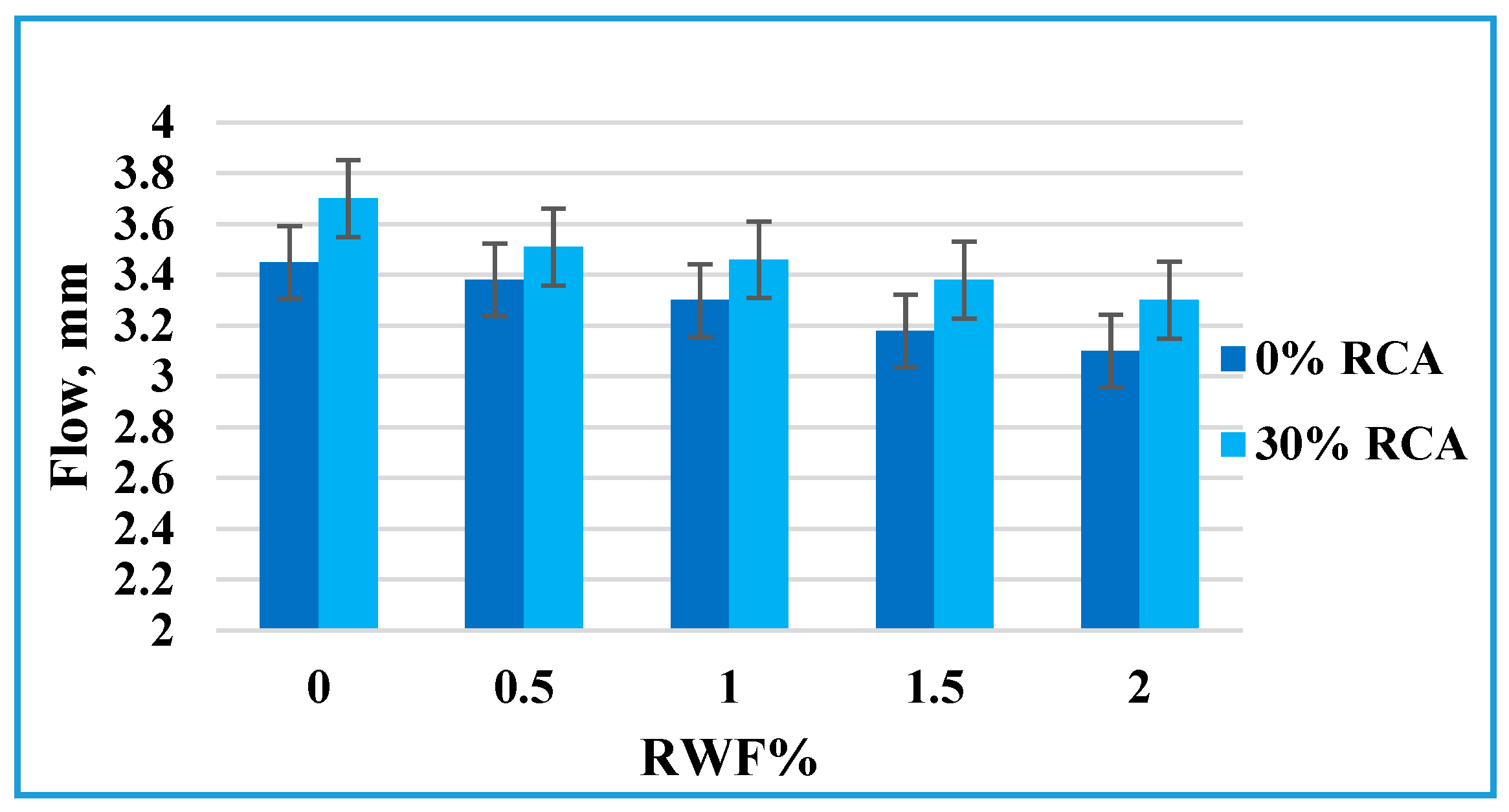

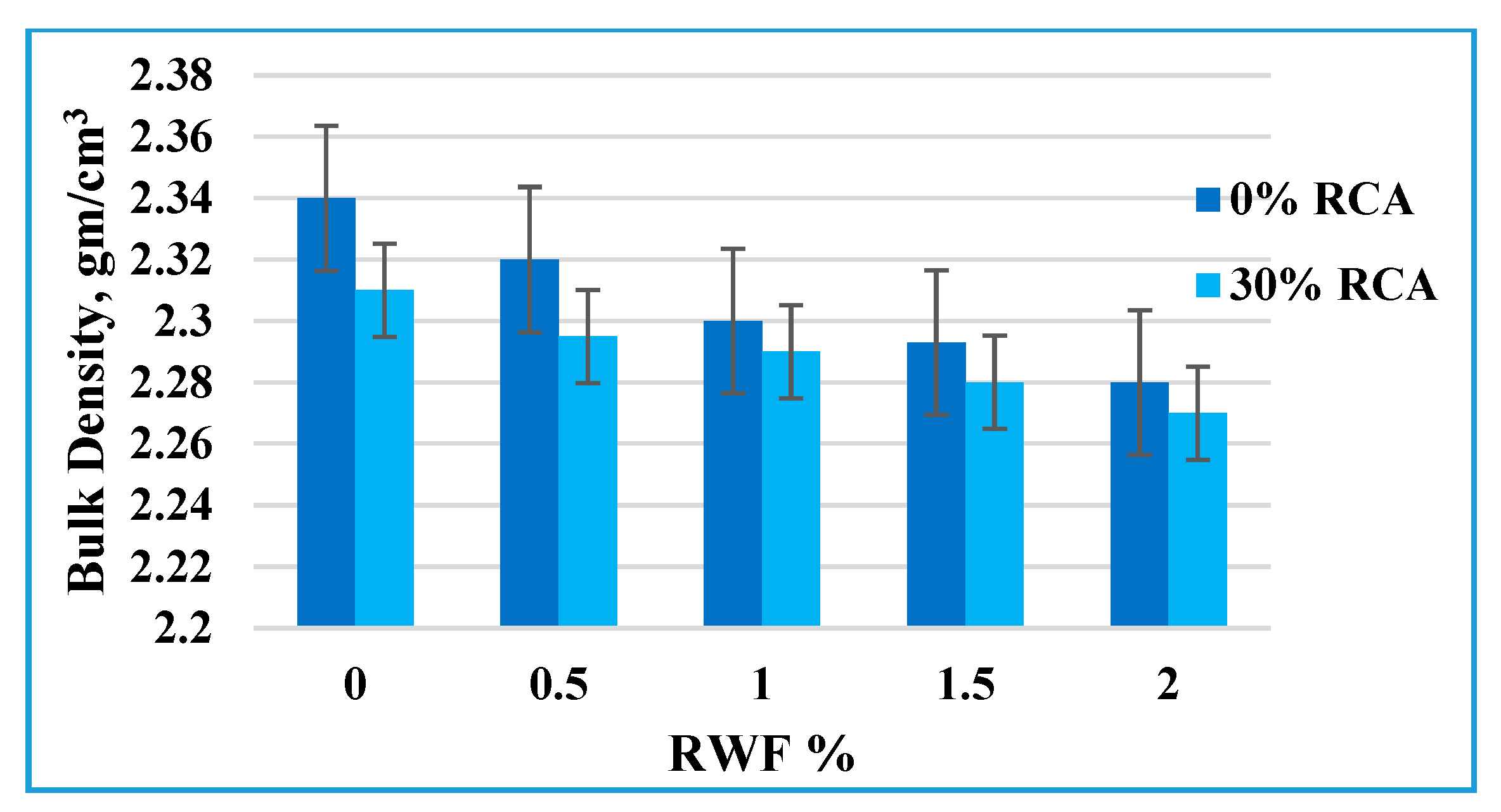

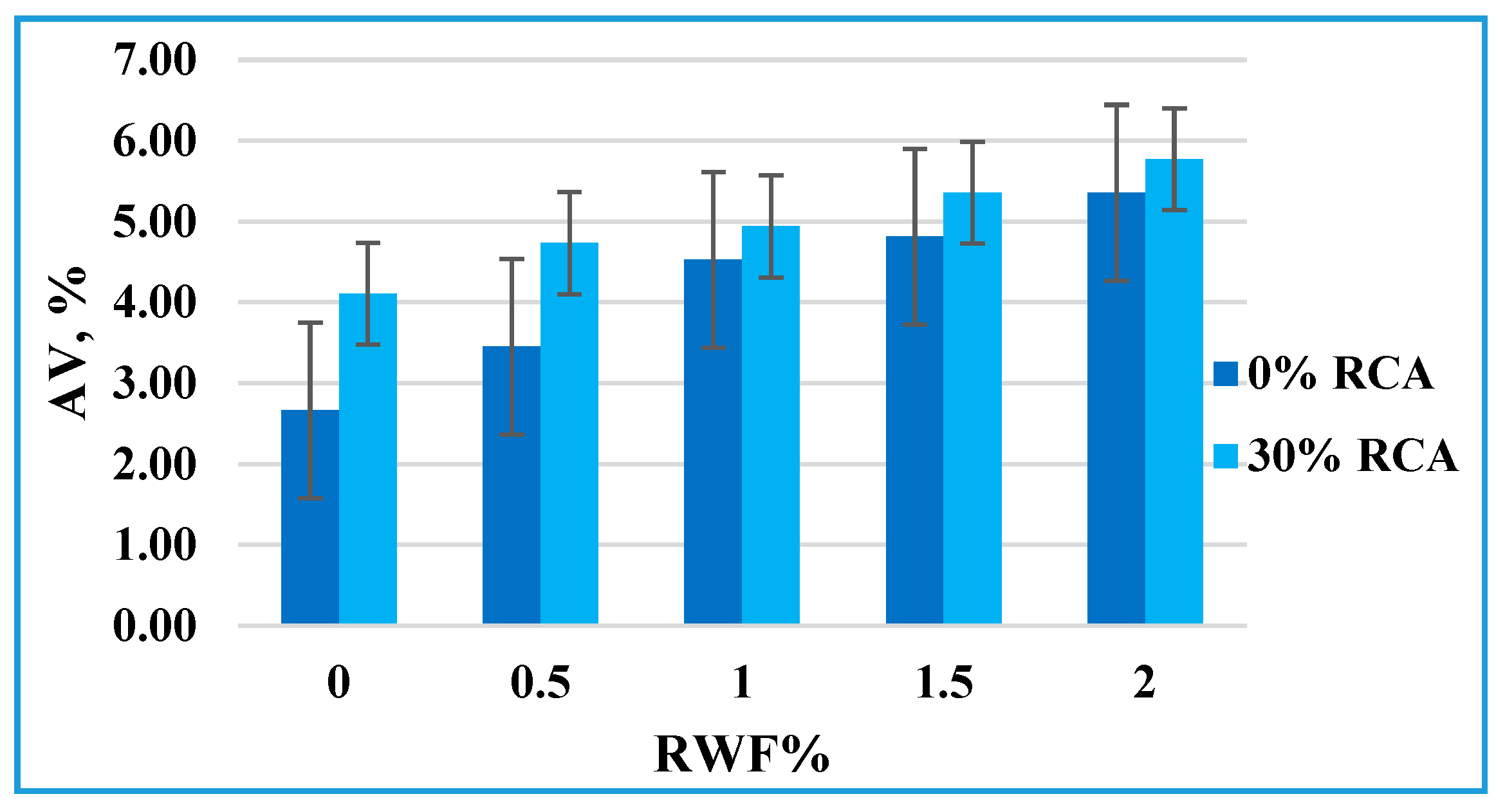

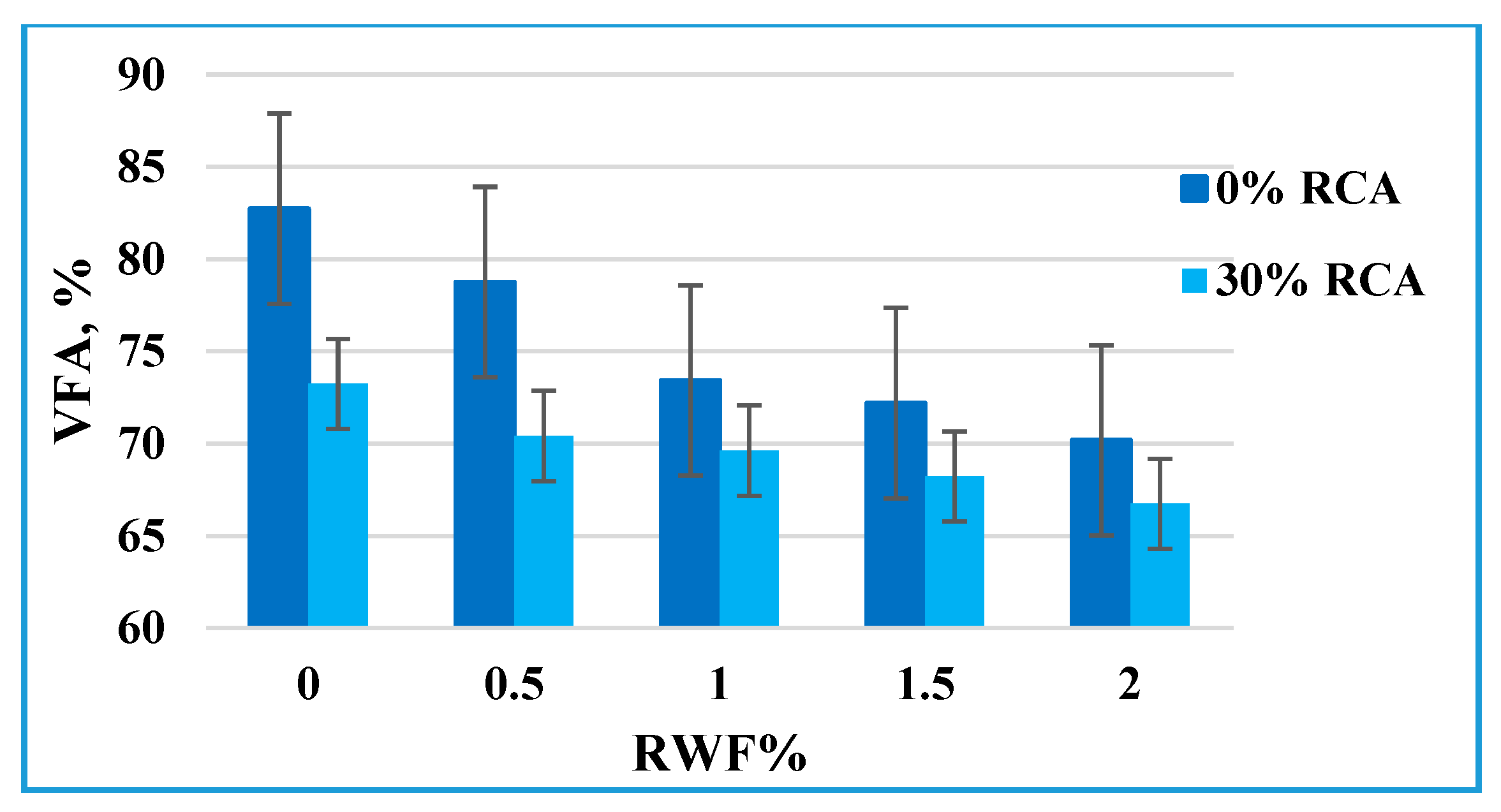

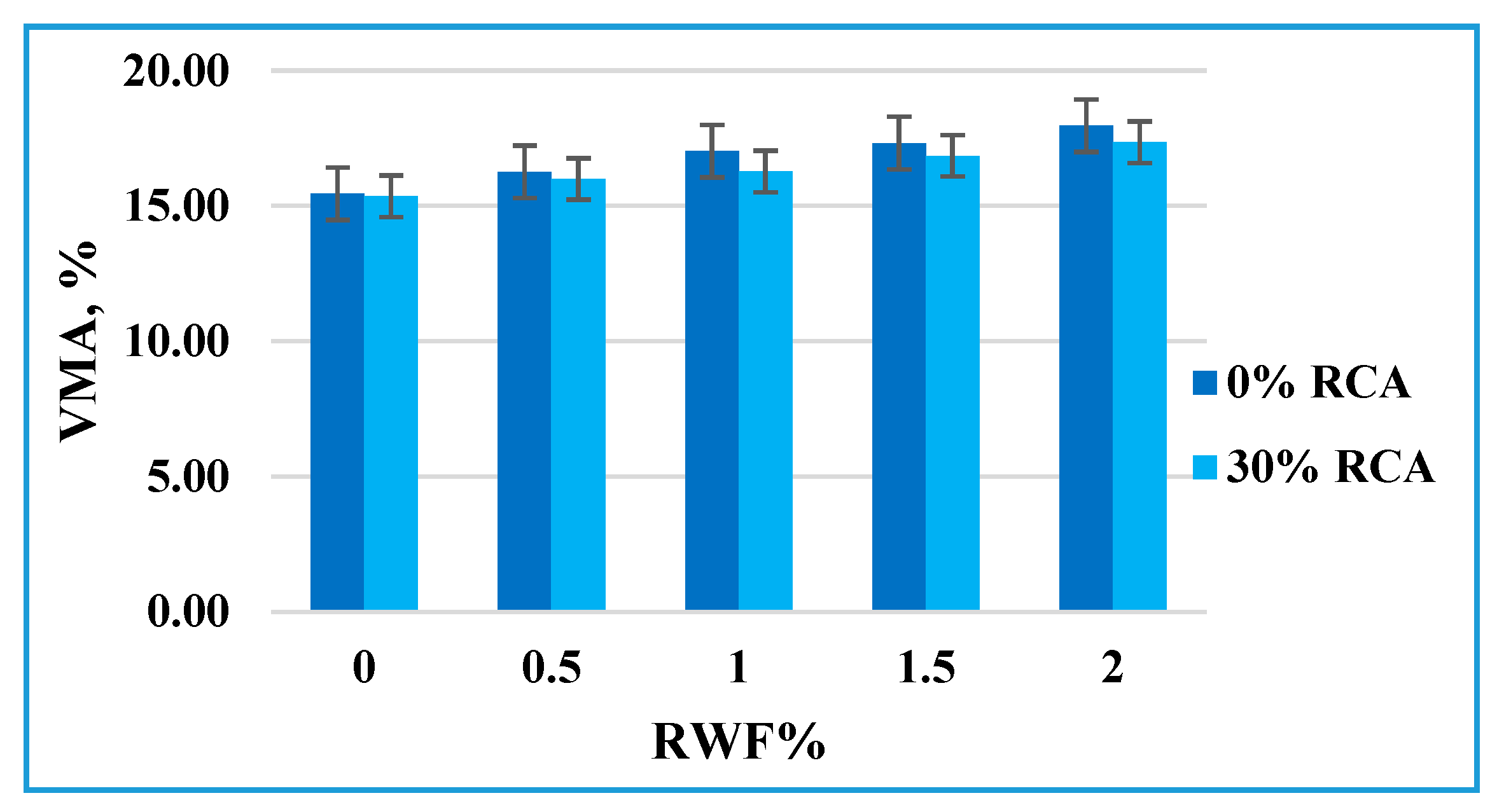

3.1. Marshall Stability and Volumetric Properties

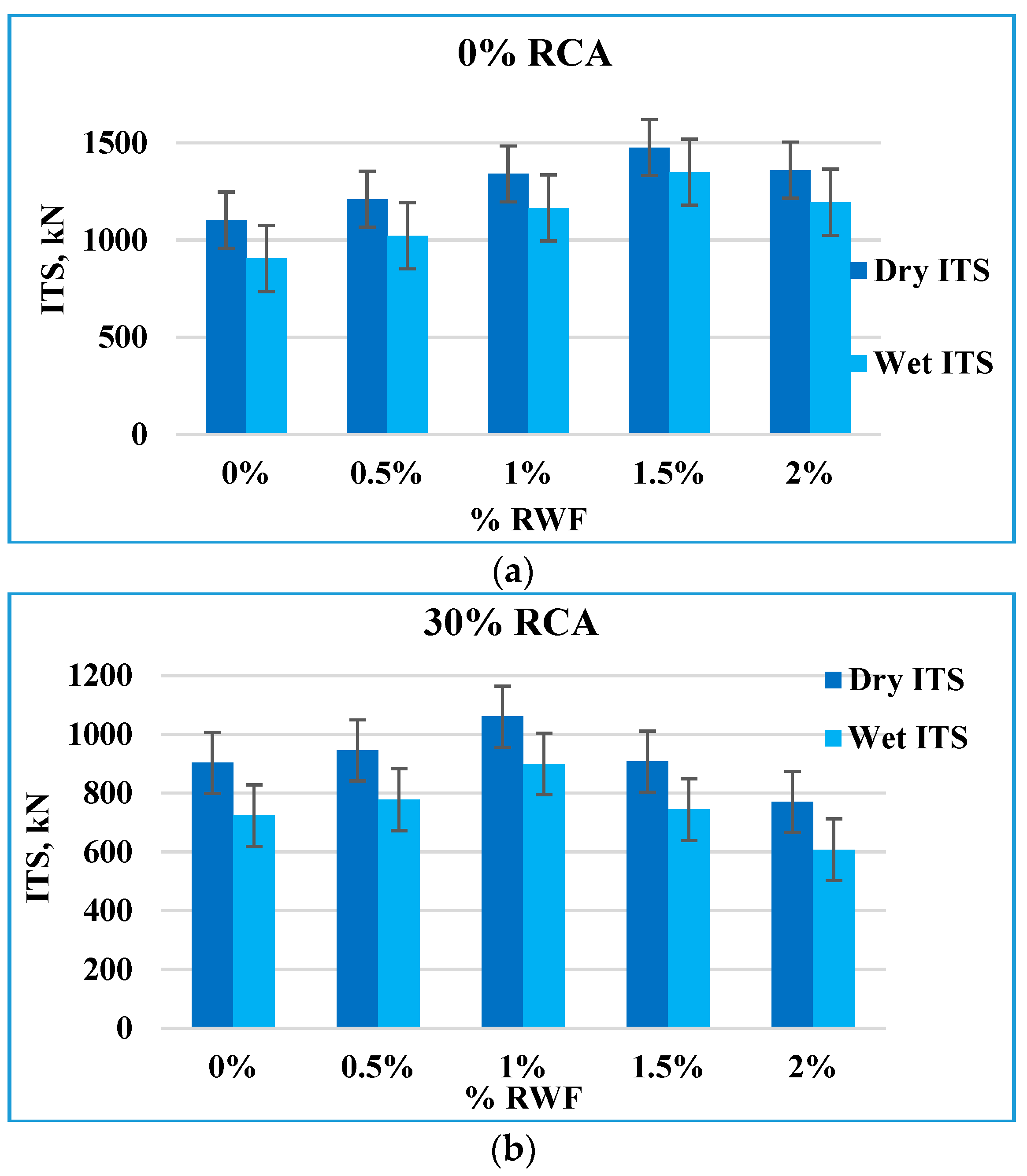

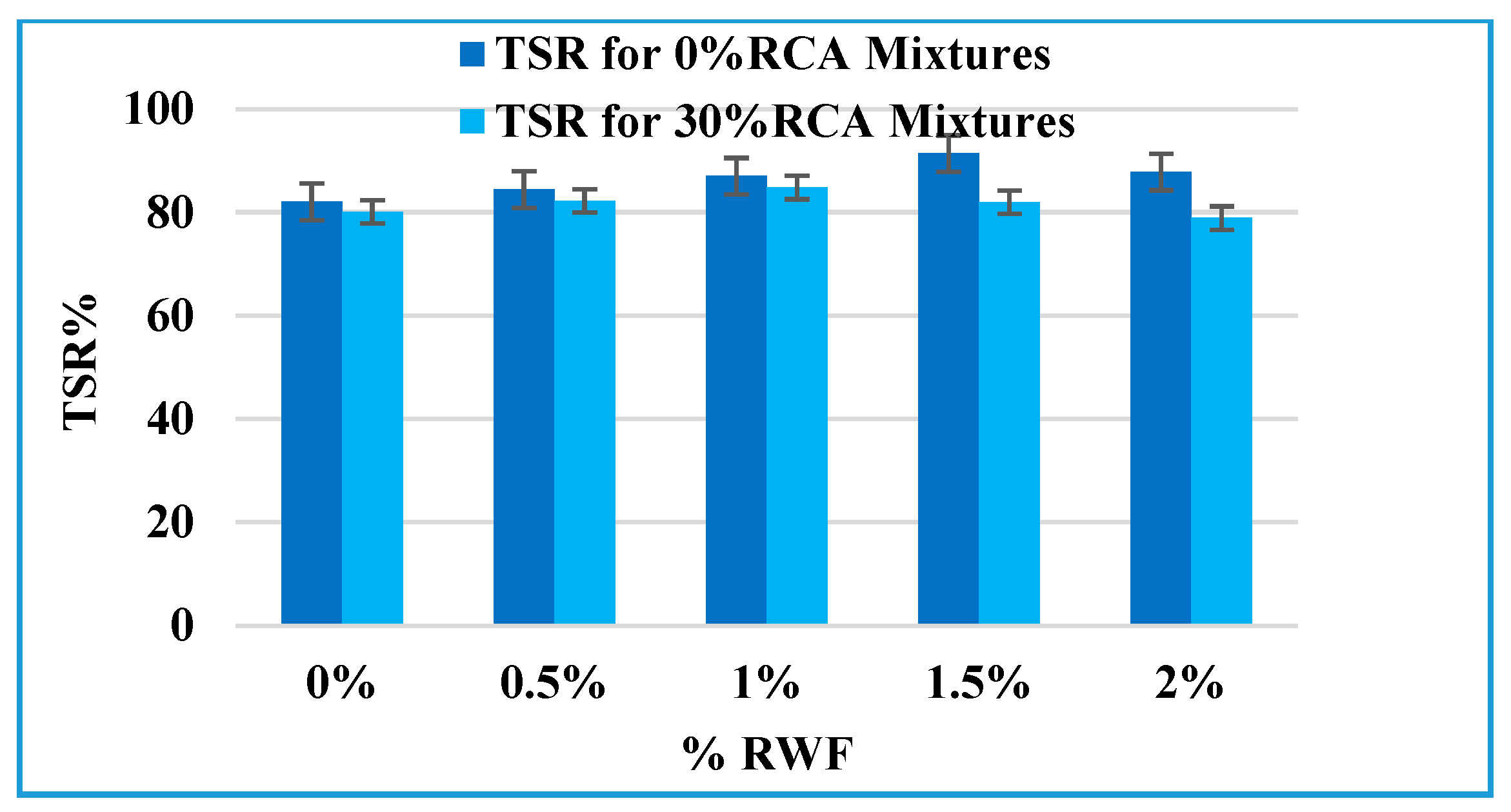

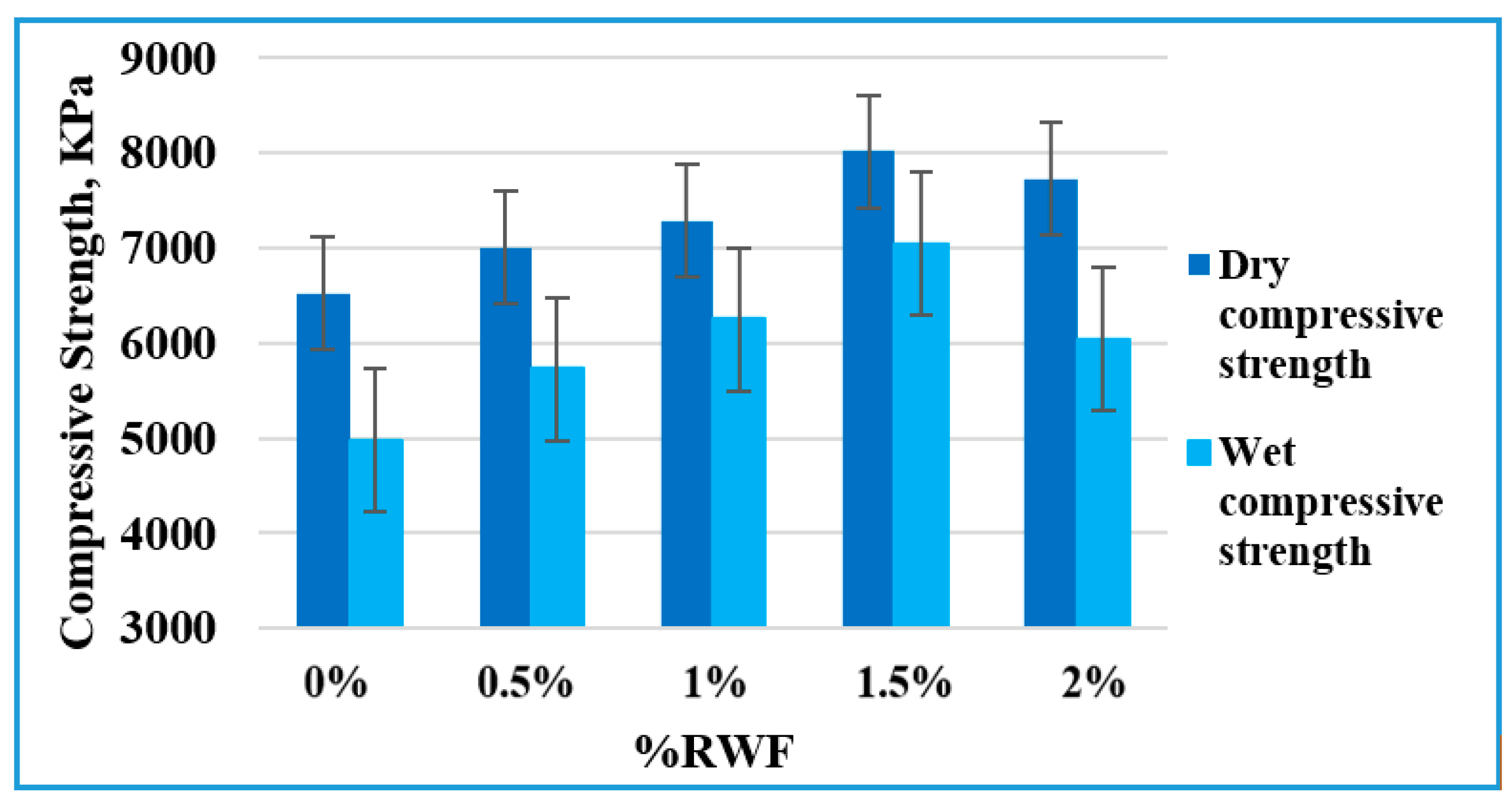

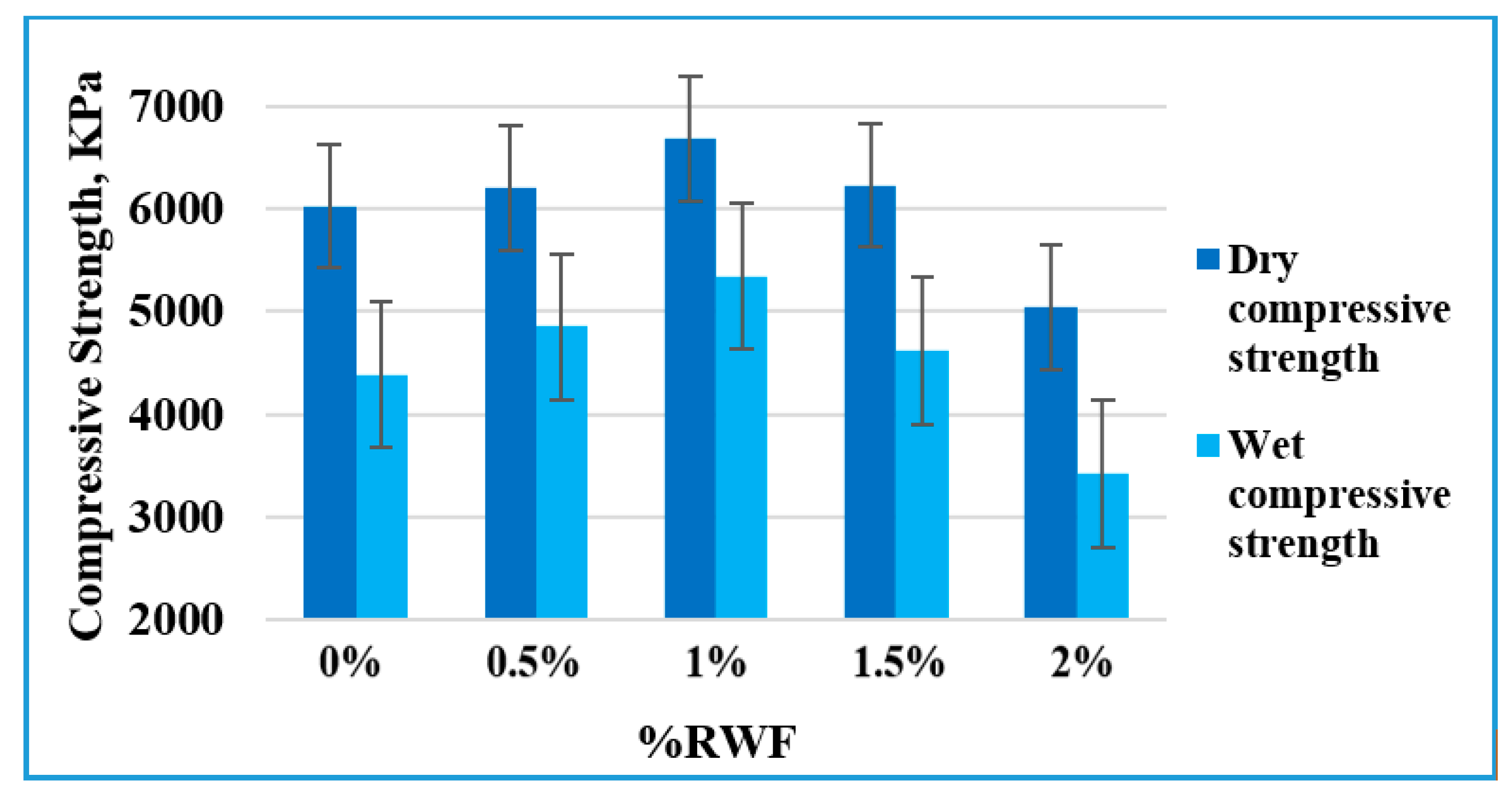

3.2. Indirect Tensile Strength Ratio

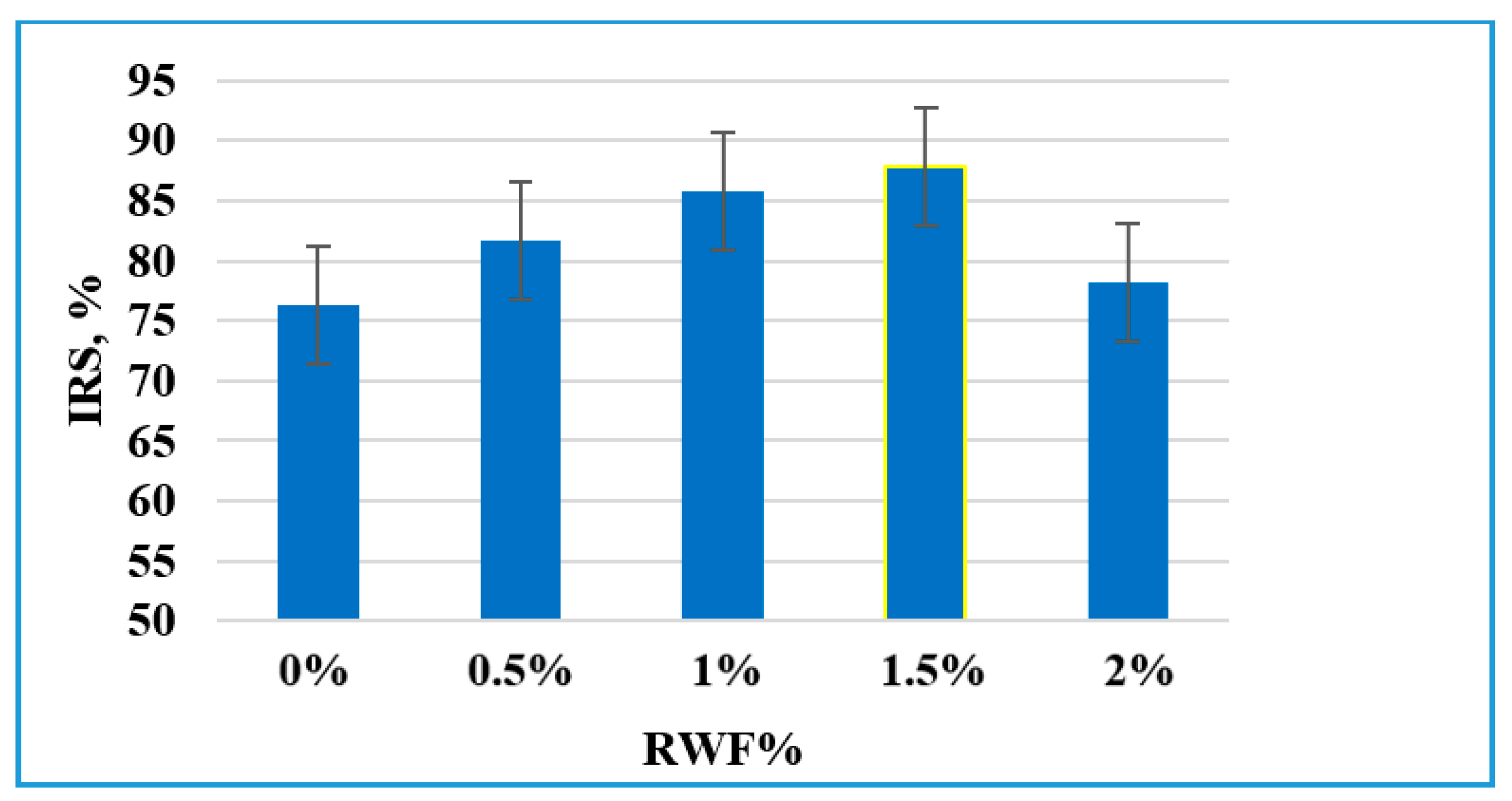

3.3. Index of Retained Strength

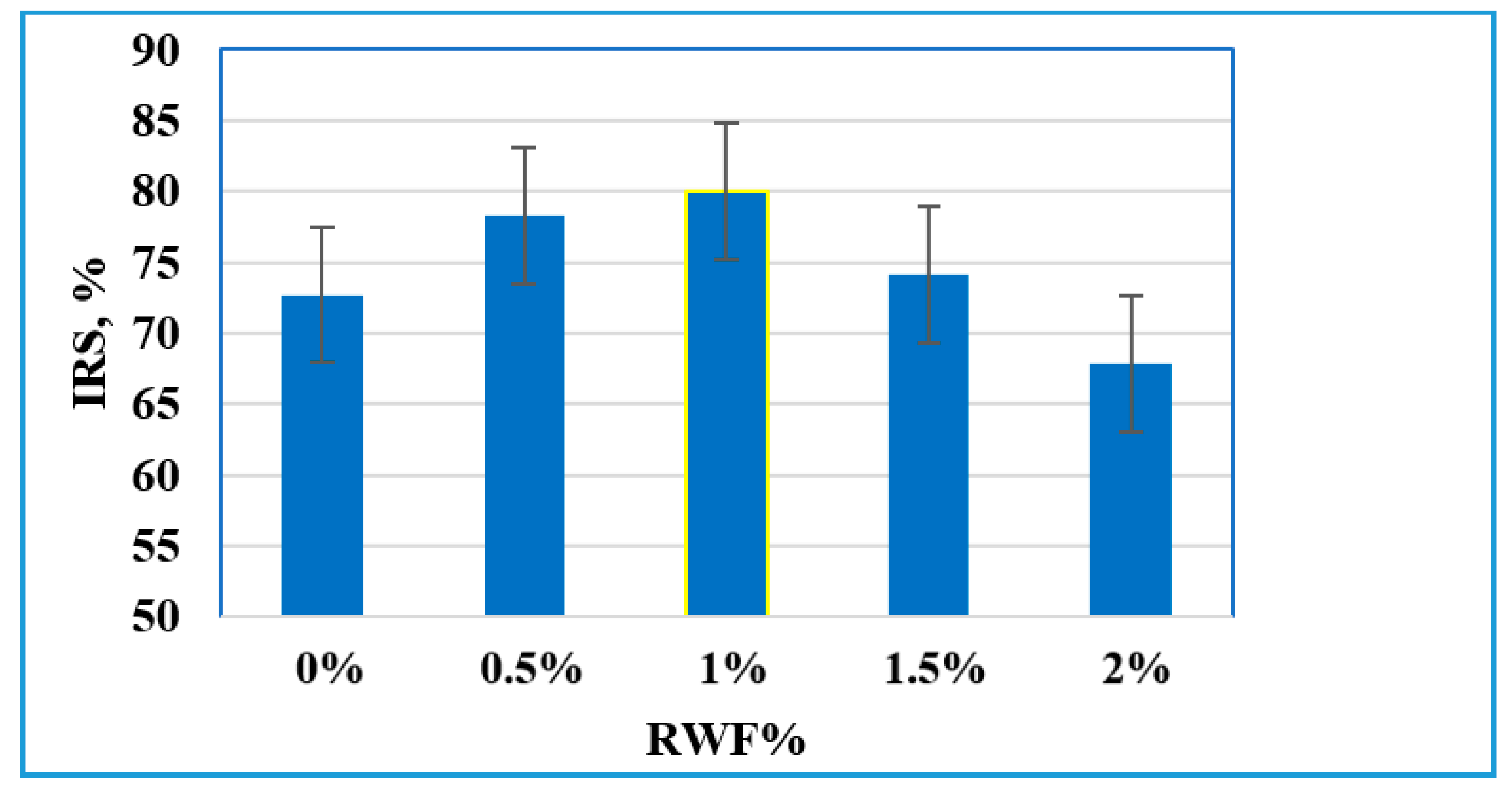

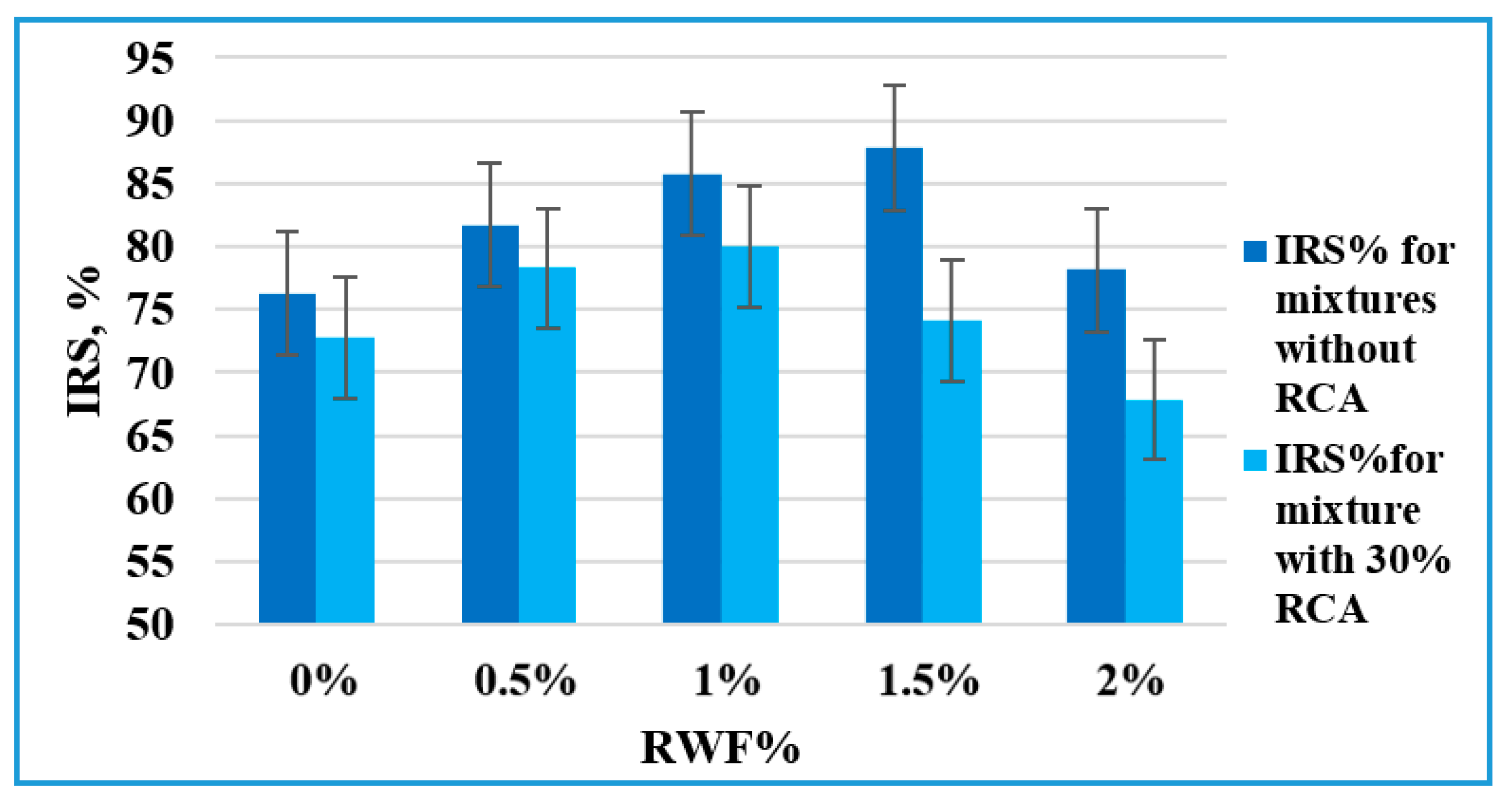

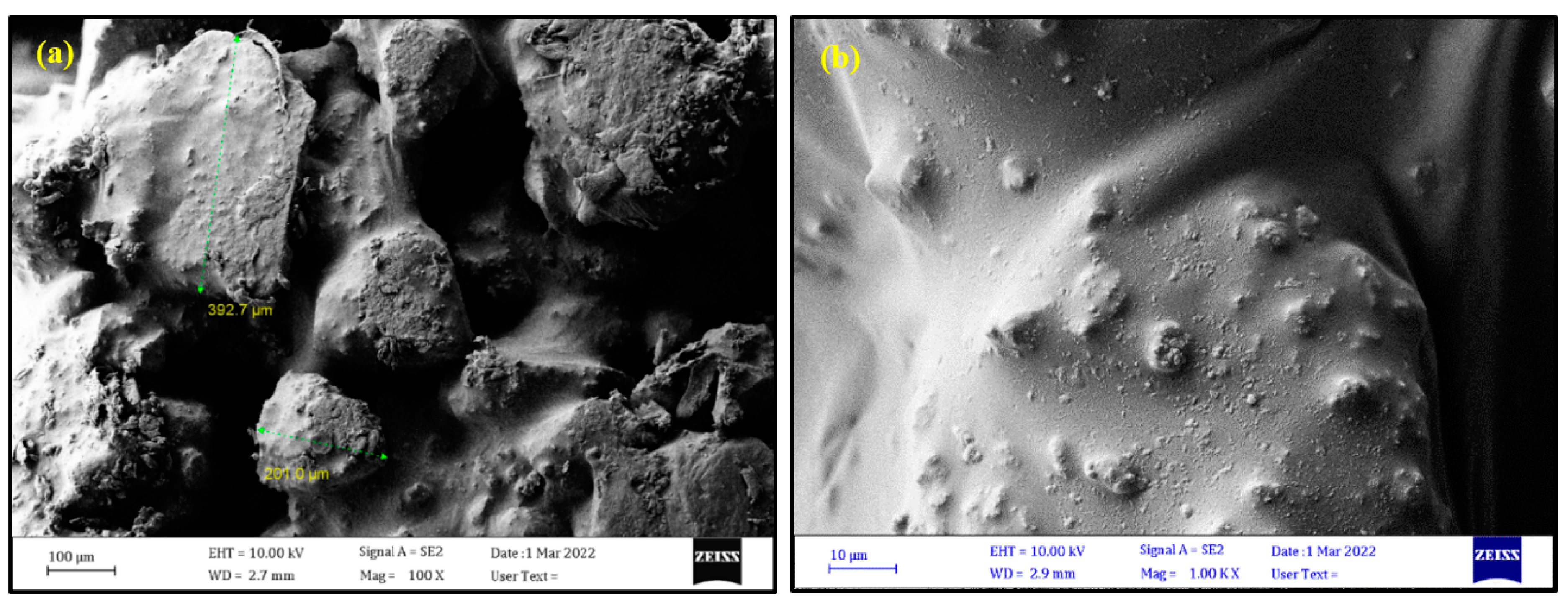

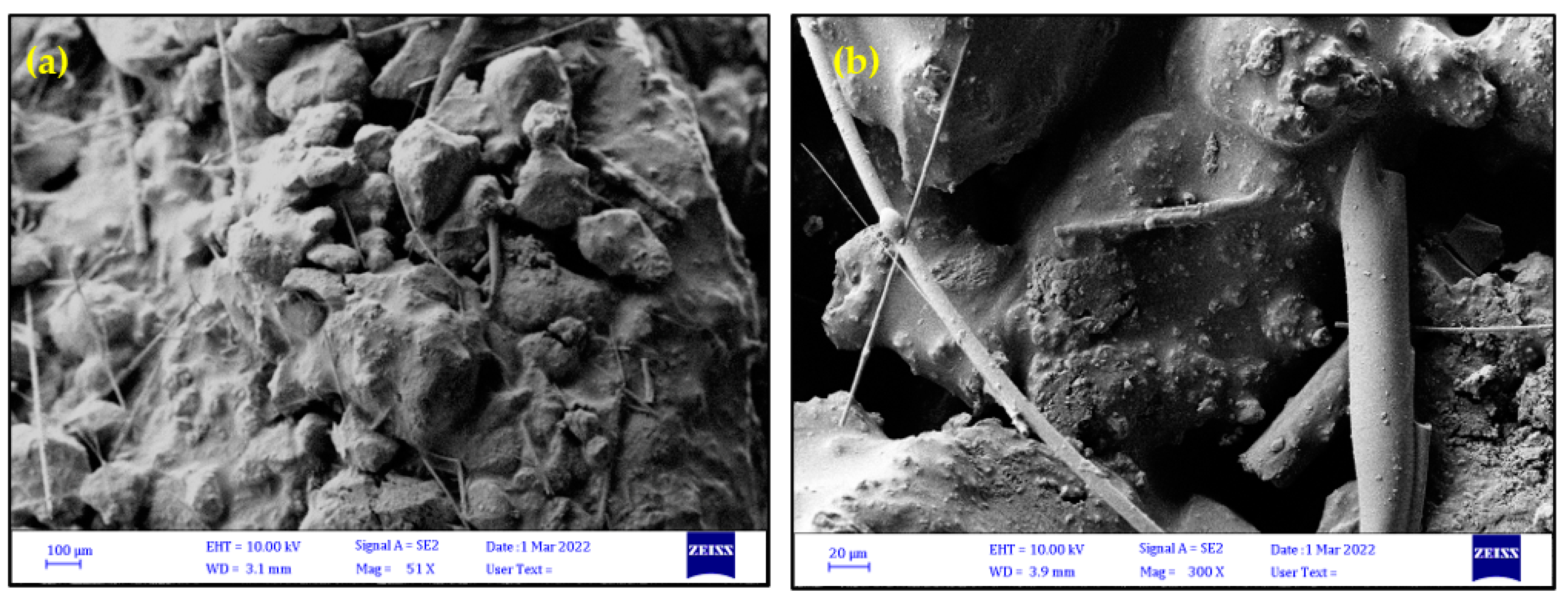

3.4. FESEM Image Analysis

4. Model Development for Prediction of Permanent Deformation of Modified Asphalt Concrete Pavement

4.1. Checking for Outliers

4.2. Stepwise Regression

4.3. Model Simulation Results

5. Conclusions

- i.

- The HAM made with 1.5% RWF showed the highest CS and IRS values. Compared to the control mix, the HAM made with 1.5% RWF showed an optimum IRS and Marshall stability of 15.14% and 59.6%, respectively. This improvement was ascribed to the uniform distribution of the fibers into the hot asphalt network structure. Also, the flow values of the HAM dropped with increases in RWF contents, reaching a minimum at 2% RWF. The bulk density and VFA values of the HAM were decreased, and the AV% and VMA% were increased with an increase in RWF content. These results indicated that the proposed HAM is a potential candidate for pavement construction in hot climates;

- ii.

- The sensitivity of the HAM against moisture was decreased together with ITS (dry and wet) and TSR% until a certain level of RWF was reached. The maximum rate of change in the TSR% was 3.38% compared to the normal control mix and 5.89% compared to the sustainable control mix made with 1% RWF. The IRS, being an indicator of the moisture susceptibility of the HAM, showed an increase up to 4.86% with an increase in RWF content compared to the conventional control mix. Compared to the sustainable control mix, the IRS of the studied HAM was increased by 10% with addition of 1% RWF into the mix. In addition, the Marshall stability of the HAM was enhanced with the increase in RWF content, displaying a maximum of 39.39% compared to the conventional control mix and a maximum of 42.27% compared to the sustainable control mix containing 1% RWF by total weight of the mixture;

- iii.

- The inclusion of 1% RWF into the hot mix asphalt with 30% of aggregate replacement by RCAs represented the optimum use of RWFs. The moisture susceptibility was decreased, thus meeting the requirements of Iraqi specifications regarding the Marshall stability, flow, AV%, and VMA%. The HAM made with 30% of virgin aggregates and RCAs revealed a decrease in the values of ITS, TSR, CS, Marshall stability, bulk density, VMA, and VFA. However, the OAC, AV%, and Marshall flow values of the HAM were increased;

- iv.

- It was affirmed that proper recycling of demolished concrete into novel construction materials can reduce the amount of land required for waste disposal, reducing environmental pollution and global warming. In addition, recycled aggregates can minimize the energy expenditure needed to transport and produce aggregates, thus lowering greenhouse gases emissions. In places where the environment needs to be protected, this strategy can safeguard virgin aggregates and lands that serve as natural resources. Many European countries have enacted taxes on the use of virgin aggregates;

- v.

- The model simulation supported the experimental observations. It is established that the proposed HAM with excellent moisture resistance can contribute to the development of construction sectors worldwide, thus meeting the requirements of sustainable goals.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HAM | hot asphalt mixture |

| RCA | recycled concrete aggregate |

| RWF | rock wool fiber |

| OAC | optimal asphalt concentration |

| TSR | tensile strength ratio |

References

- Nazal, H.H.; Ismael, M.Q. Evaluation the moisture susceptibility of asphalt mixtures containing demolished concrete waste materials. Civ. Eng. J. 2019, 5, 845–855. [Google Scholar] [CrossRef]

- Sebaaly, P.E.; Hajj, E.Y.; Sathanathan, T.; Shivakolunthar, S. A comprehensive evaluation of moisture damage of asphalt concrete mixtures. Int. J. Pavement Eng. 2017, 18, 169–182. [Google Scholar] [CrossRef]

- Officials, T. AASHTO Guide for Design of Pavement Structures, 1993; Aashto: Washington, DC, USA, 1993; Volume 1. [Google Scholar]

- Sebaaly, P.E. Comparison of Lime and Liquid Additives on the Moisture Damage of Hot Mix Asphalt; University of Nevada, Reno: Reno, NV, USA, 2007. [Google Scholar]

- Sebaaly, P.E.; Little, D.; Hajj, E.Y.; Bhasin, A. Impact of lime and liquid antistrip agents on properties of Idaho hot-mix asphalt mixture. Transp. Res. Rec. 2007, 1998, 65–74. [Google Scholar] [CrossRef]

- Hicks, R.; Santucci, L.; Ashchenbrener, T. Introduction and Seminar Objectives on Moisture Sensitivity of Asphalt Pavements. In Proceedings of the Transportation Research Board National Seminar, San Diego, CA, USA, 4–6 February 2003; pp. 3–19. [Google Scholar]

- Epps, J.; Berger, E.; Anagnos, J.N. Treatments. In Proceedings of the Moisture Sensitivity of Asphalt Pavements-A National SeminarCalifornia Department of Transportation, Federal Highway Administration, National Asphalt Pavement Association, California Asphalt Pavement Alliance and Transportation Research Board, San Diego, CA, USA, 4–6 February 2003. [Google Scholar]

- Guo, Q.; Li, L.; Cheng, Y.; Jiao, Y.; Xu, C. Laboratory evaluation on performance of diatomite and glass fiber compound modified asphalt mixture. Mater. Des. 2015, 66, 51–59. [Google Scholar] [CrossRef]

- Klinsky, L.; Kaloush, K.; Faria, V.; Bardini, V. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef]

- Khattak, M.J.; Khattab, A.; Rizvi, H.R. Characterization of carbon nano-fiber modified hot mix asphalt mixtures. Constr. Build. Mater. 2013, 40, 738–745. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Mechanical performance of fibers in hot mix asphalt: A review. Constr. Build. Mater. 2019, 200, 756–769. [Google Scholar] [CrossRef]

- Luo, D.; Khater, A.; Yue, Y.; Abdelsalam, M.; Zhang, Z.; Li, Y.; Li, J.; Iseley, D.T. The performance of asphalt mixtures modified with lignin fiber and glass fiber: A review. Constr. Build. Mater. 2019, 209, 377–387. [Google Scholar] [CrossRef]

- Wan, J.; Wu, S.; Xiao, Y.; Liu, Q.; Schlangen, E. Characteristics of ceramic fiber modified asphalt mortar. Materials 2016, 9, 788. [Google Scholar] [CrossRef] [PubMed]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Zhang, J.; Li, V.C. Influences of fibers on drying shrinkage of fiber-reinforced cementitious composite. J. Eng. Mech. 2001, 127, 37–44. [Google Scholar] [CrossRef]

- Mahrez, A.; Karim, M.R. Fatigue characteristics of stone mastic asphalt mix reinforced with fiber glass. Int. J. Phys. Sci. 2010, 5, 1840–1847. [Google Scholar]

- Serfass, J.-P.; Joly, A.; Samanos, J. SBS-Modified Asphalts for Surface Dressing-A Comparison Between Hot-Applied and Emulsified Binders. In Polymer Modified Asphalt Binders; ASTM: West Conshohocken, PA, USA, 1992; p. 281. [Google Scholar]

- Zhang, B.; Zhu, H.; Cheng, Y.; Huseien, G.F.; Shah, K.W. Shrinkage mechanisms and shrinkage-mitigating strategies of alkali-activated slag composites: A critical review. Constr. Build. Mater. 2022, 318, 125993. [Google Scholar] [CrossRef]

- Abbas, A.-G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A state-of-the-art review on fibre-reinforced geopolymer composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- McDaniel, R.S. Fiber Additives in Asphalt Mixtures; Transportation Research Board: Washington, DC, USA, 2015. [Google Scholar]

- Gu, X.; Xu, T.; Ni, F. Rheological behavior of basalt fiber reinforced asphalt mastic. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 950–955. [Google Scholar] [CrossRef]

- Goel, A.; Das, A. Nondestructive testing of asphalt pavements for structural condition evaluation: A state of the art. Nondestruct. Test. Eval. 2008, 23, 121–140. [Google Scholar] [CrossRef]

- Jaskuła, P.; Stienss, M.; Szydłowski, C. Effect of polymer fibres reinforcement on selected properties of asphalt mixtures. Procedia Eng. 2017, 172, 441–448. [Google Scholar] [CrossRef]

- Gupta, P.K.; Khaudhair, Z.A.; Ahuja, A.K. A new method for proportioning recycled concrete. Struct. Concr. 2016, 17, 677–687. [Google Scholar] [CrossRef]

- Purushothaman, R.; Amirthavalli, R.R.; Karan, L. Influence of treatment methods on the strength and performance characteristics of recycled aggregate concrete. J. Mater. Civ. Eng. 2015, 27, 04014168. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Kaplan, G.; Shi, J.; Benli, A.; Bodur, B.; Turkoglu, M. The effect of steel fiber aspect-ratio and content on the fresh, flexural, and mechanical performance of concrete made with recycled fine aggregate. Constr. Build. Mater. 2023, 368, 130497. [Google Scholar] [CrossRef]

- Zaidi, S.A.; Khan, M.A.; Naqvi, T. A review on the properties of recycled aggregate concrete (RAC) modified with nano-silica. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Tighe, S.L.; Achebe, J. Influence of recycled concrete aggregate on volumetric properties of hot mix asphalt. Resour. Conserv. Recycl. 2018, 130, 200–214. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Wilburn, D.R.; Goonan, T.G. Aggregates from natural and recycled sources. US Geol. Surv. Circ. 1998, 1176, 36. [Google Scholar]

- Jin, R.; Chen, Q. Investigation of concrete recycling in the US construction industry. Procedia Eng. 2015, 118, 894–901. [Google Scholar] [CrossRef]

- Paranavithana, S.; Mohajerani, A. Effects of recycled concrete aggregates on properties of asphalt concrete. Resour. Conserv. Recycl. 2006, 48, 1–12. [Google Scholar] [CrossRef]

- Topal, A.; Oner, J.; Sengoz, B.; Dokandari, P.A.; Kaya, D. Evaluation of rutting performance of warm mix asphalt. Int. J. Civ. Eng. 2017, 15, 705–714. [Google Scholar] [CrossRef]

- Wong, Y.D.; Sun, D.D.; Lai, D. Value-added utilisation of recycled concrete in hot-mix asphalt. Waste Manag. 2007, 27, 294–301. [Google Scholar] [CrossRef] [PubMed]

- Mills-Beale, J.; You, Z. The mechanical properties of asphalt mixtures with recycled concrete aggregates. Constr. Build. Mater. 2010, 24, 230–235. [Google Scholar] [CrossRef]

- Radević, A.; Đureković, A.; Zakić, D.; Mladenović, G. Effects of recycled concrete aggregate on stiffness and rutting resistance of asphalt concrete. Constr. Build. Mater. 2017, 136, 386–393. [Google Scholar] [CrossRef]

- SCRB R.E. Standard Specifications for Roads and Bridges. In Section R/9, Hot-Mix Asphaltic Concrete Pavement; Department of Planning and Studies, Republic of Iraq, Ministry of Housing and Construction: Baghdad, Iraq, 2003. [Google Scholar]

- Türk Standartları Enstitüsü: Ts en 14303; Thermal Insulation Products for Building Equipment and Industrial Installations–Factory Made Mineral Wool (MW) Products–Specification. Türk Standartları Enstitüsü: Ankara, Turkey, 2015.

- Türk Standartları Enstitüsü: Ts en 822; Thermal Insulating Products for Building Applications Determination of Length and Width. Türk Standartları Enstitüsü: Ankara, Turkey, 2013.

- Türk Standartları Enstitüsü: Ts en 823; Thermal Insulating Products for Building Applications-Determination of Thickness. Türk Standartları Enstitüsü: Ankara, Turkey, 2013.

- Türk standartları enstitüsü: TS EN 13501-1; Fire Classification of Construction Products and Building Elements-Part 1: Classification Using Test Data from Reaction to Fire Tests. Türk Standartları Enstitüsü: Ankara, Turkey, 2018.

- Türk Standartları Enstitüsü: Ts en 1266; Independent Gas-Fired Convection Heaters Incorporating a Fan to Assist Transportation of Combustion Air and/or Flue Gases. Türk Standartları Enstitüsü: Ankara, Turkey, 2002.

- Türk Standartları Enstitüsü: Ts en 12939; Thermal Performance of Building Materials and Products–Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods–Thick Products of High and Medium Thermal Resistance. Türk Standartları Enstitüsü: Ankara, Turkey, 2000.

- Türk Standartları Enstitüsü: TS EN 13787; Elastomers for Gas Pressure Regulators and Associated Safety Devices for Inlet Pressures up to 100 Bar. Türk Standartları Enstitüsü: Ankara, Turkey, 2003.

- Türk Standartları Enstitüsü: Ts en 824; Thermal Insulating Products for Building Applications-Determination of Squareness. Türk Standartları Enstitüsü: Ankara, Turkey, 2013.

- Türk Standartları Enstitüsü: Ts en 12086; Thermal Insulating Products for Building Applications-Determination of long Term Water Absorption by Immersion. Türk Standartları Enstitüsü: Ankara, Turkey, 2013.

- Behbahani, H.; Najafi Moghaddam Gilani, V.; Salehfard, R.; Safari, D. Evaluation of fatigue and rutting behaviour of hot mix asphalt containing rock wool. Int. J. Civ. Eng. 2020, 18, 1293–1300. [Google Scholar] [CrossRef]

- Chen, H.; Xu, Q.; Chen, S.; Zhang, Z. Evaluation and design of fiber-reinforced asphalt mixtures. Mater. Des. 2009, 30, 2595–2603. [Google Scholar] [CrossRef]

- Jahromi, S.G.; Khodaii, A. Carbon Fiber Reinforced Asphalt Concrete. Arab. J. Sci. Eng. 2008, 33, 355–364. [Google Scholar]

- ASTM D2726-08; Standard test method for bulk specific gravity and density of non-absorptive compacted bituminous mixtures. American Society for Testing and Materials: West Conshohocken, PE, USA, 2014.

- ASTM D6927-04; Standard test method for Marshall stability and flow of bituminous mixtures. Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PE, USA, 2014.

- Hussein, A.A.; Putra Jaya, R.; Yaacob, H.; Abdul Hassan, N.; Oleiwi Aletba, S.R.; Huseien, G.F.; Shaffie, E. and Mohd Hasan, M.R. Physical, chemical and morphology characterisation of nano ceramic powder as bitumen modification. Int. J. Pavement Eng. 2021, 22, 858–871. [Google Scholar] [CrossRef]

- ASTM D2041-03; Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011; Volume 4, pp. 1–4.

- ASTM D3203-05; Standard Test Method for Percent Air Voids in Compacted Dense and Open Bituminous Paving Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2005; Volume 4, pp. 1–2.

- ASTM D4867; Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014; Volume 4, pp. 1–5.

- ASTM D1075-07; Standard Test Method for Effect of Water on Compressive Strength of Compacted Bituminous Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011; Volume 4, pp. 1–2.

- ASTM D1074-17; Standard Test Method for Compressive Strength of Asphalt Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017; Volume 4, pp. 1–5.

- Al-Saad, A.A.; Ismael, M.Q. Rutting prediction of hot mix asphalt mixtures reinforced by ceramic fibers. J. Appl. Eng. Sci. 2022, 20, 1345–1354. [Google Scholar] [CrossRef]

- Ismael, S.A.-d.M.; Ismael, M.Q. Moisture Susceptibility of Asphalt Concrete Pavement Modified by Nanoclay Additive. Civ. Eng. J. 2019, 5, 2535–2553. [Google Scholar] [CrossRef]

- Wu, S.; Pang, L.; Liu, G.; Zhu, J. Laboratory study on ultraviolet radiation aging of bitumen. J. Mater. Civ. Eng. 2010, 22, 767–772. [Google Scholar] [CrossRef]

- Mawat, H.Q.; Ismael, M.Q. Assessment of moisture susceptibility for asphalt mixtures modified by carbon fibers. Civ. Eng. J. 2020, 6, 304–317. [Google Scholar] [CrossRef]

- Ali, S.H.; Ismael, M.Q. Improving the Moisture Damage Resistance of HMA by Using Ceramic Fiber and Hydrated Lime. Al-Qadisiyah J. Eng. Sci. 2021, 13, 274–283. [Google Scholar]

- Abed, A.H. Required Criteria for Implementation of the Superpave System in Local Pavement Design. Ph.D. Thesis, Civil Engineering Department, Collage of Engineering, University of Baghdad, Baghdad, Iraq, 2010. [Google Scholar]

- Navidi, W.C. Statistics for Engineers and Scientists; McGraw-Hill: New York, NY, USA, 2006; Volume 2. [Google Scholar]

| Properties/Materials | Description | Tolerance | Standard | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Stone Wool (SL1) | Stone Wool (SL2) | ||||||||||

| Density (γ), kg/m3 | 70 | 110 | ±10% | [38] TS EN 14303 | |||||||

| Width (w), mm | 600 | ±1.5% | [39] TS EN 822 | ||||||||

| Length (l), mm | 1200 | ±2% | [39] TS EN 822 | ||||||||

| Thickness (t), mm | 25 | 40 | 50 | 60 | 80 | 100 | 120 | T4 | [40] TS EN 823 | ||

| Facing | Un-faced | - | |||||||||

| Reaction to fire | A1 | - | [41] TS EN 1350-1 | ||||||||

| Declared thermal conductivity (λo), W/m.K | T, °C | 50 | 100 | 150 | 200 | 250 | 300 | 350 | - | [42,43,44] TS EN 1266, 12939 and 13787 | |

| SL1 | 0.039 | 0.048 | 0.059 | 0.072 | 0.087 | 0.103 | 0.122 | - | |||

| SL2 | 0.037 | 0.045 | 0.053 | 0.062 | 0.073 | 0.085 | 0.097 | - | |||

| Squareness (So), mm/m | Max. 5 | - | [45] TS EN 824 | ||||||||

| Water vapor diffusion resistance coefficient (µ) | 1 | - | [46] TS EN 12086 | ||||||||

| Packaging material | PE Film | - | - | ||||||||

| Other information | Yellow–black glass tissue/aluminum foil-faced types are also available. | - | - | ||||||||

| RWF (%) | Asphalt Content (%) | Marshall Properties | Density and Voids | ||||

|---|---|---|---|---|---|---|---|

| Stability (kN) | Flow (mm) | Bulk Density (gm/cm3) | AV (%) | VMA (%) | VFA (%) | ||

| 0% of RCA | |||||||

| 0 | 4.9 | 9.9 | 3.5 | 2.32 | 3.50 | 15.89 | 77.98 |

| 0.5 | 5 | 11.5 | 3.39 | 2.3 | 4.29 | 16.70 | 74.33 |

| 1 | 5.05 | 13.2 | 3.28 | 2.297 | 4.65 | 16.85 | 72.41 |

| 1.5 | 5.1 | 15.8 | 3.32 | 2.293 | 4.82 | 17.04 | 71.74 |

| 2 | 5.3 | 15.4 | 3.4 | 2.281 | 5.31 | 17.65 | 69.89 |

| 30% of RCA | |||||||

| 0 | 5.1 | 9.7 | 3.6 | 2.304 | 4.36 | 16.64 | 73.81 |

| 0.5 | 5.2 | 10.9 | 3.45 | 2.298 | 4.61 | 16.95 | 72.81 |

| 1 | 5.3 | 13.8 | 3.41 | 2.29 | 4.94 | 17.32 | 71.48 |

| 1.5 | 5.55 | 13.5 | 4.2 | 2.285 | 5.15 | 17.72 | 70.95 |

| 2 | 5.7 | 13.2 | 5.2 | 2.2804 | 5.34 | 18.02 | 70.37 |

| RWF Additive (%) | 0% of RCA | 30% of RCA | ||||

|---|---|---|---|---|---|---|

| Dry ITS | Wet ITS | TSR (%) | Dry ITS | Wet ITS | TSR (%) | |

| 0 | 1103 | 905.137 | 82.06 | 903.04 | 723.41 | 80.10 |

| 0.5 | 1209.7 | 1021.43 | 84.43 | 945.82 | 777.83 | 82.23 |

| 1 | 1340.5 | 1165.46 | 87 | 1060.23 | 899.43 | 84.83 |

| 1.5 | 1475.9 | 1349 | 91.39 | 907.54 | 744.05 | 81.98 |

| 2 | 1360.2 | 1194.6 | 87.83 | 770.17 | 607.76 | 78.91 |

| Additive (%) | 0% of RCA | 30% of RCA | ||||

|---|---|---|---|---|---|---|

| Dry CS (kPa) | Wet CS (kPa) | IRS (%) | Dry CS (kPa) | Wet CS (kPa) | IRS (%) | |

| 0 | 6528 | 4980 | 76.28 | 6025 | 4382 | 72.73 |

| 0.5 | 7010 | 5728 | 81.71 | 6195 | 4850 | 78.28 |

| 1 | 7289 | 6254 | 85.80 | 6680 | 5344 | 80 |

| 1.5 | 8020 | 7045 | 87.84 | 6230 | 4620 | 74.15 |

| 2 | 7735 | 6045 | 78.15 | 5040 | 3420 | 67.85 |

| Dependent Variable | Minimum (Xmin) | Maximum (Xmax) | Mean (X’) | SD (S) | |(Xmin – X’)/S| | |(Xmax – X’)/S| | |(Xm – X’)/S| |

|---|---|---|---|---|---|---|---|

| TSR | 80.99 | 91.77 | 86.54 | 3.311 | 1.676 | 1.579 | 2.13 |

| Model | R | R Square | Adjusted R Square | Std. Error of Estimate |

|---|---|---|---|---|

| TSR | 0.979 | 0.958 | 0.951 | 0.73222 |

| Stepwise Regression Model | R2 | Adj. R2 | SEE |

|---|---|---|---|

| TSR = 308.114 + 11.989 (RWF) − 46.067 (OAC) | 0.958 | 0.951 | 0.73222 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussein, F.K.; Ismael, M.Q.; Huseien, G.F. Rock Wool Fiber-Reinforced and Recycled Concrete Aggregate-Imbued Hot Asphalt Mixtures: Design and Moisture Susceptibility Evaluation. J. Compos. Sci. 2023, 7, 428. https://doi.org/10.3390/jcs7100428

Hussein FK, Ismael MQ, Huseien GF. Rock Wool Fiber-Reinforced and Recycled Concrete Aggregate-Imbued Hot Asphalt Mixtures: Design and Moisture Susceptibility Evaluation. Journal of Composites Science. 2023; 7(10):428. https://doi.org/10.3390/jcs7100428

Chicago/Turabian StyleHussein, Farah Khaleel, Mohammed Qadir Ismael, and Ghasan Fahim Huseien. 2023. "Rock Wool Fiber-Reinforced and Recycled Concrete Aggregate-Imbued Hot Asphalt Mixtures: Design and Moisture Susceptibility Evaluation" Journal of Composites Science 7, no. 10: 428. https://doi.org/10.3390/jcs7100428

APA StyleHussein, F. K., Ismael, M. Q., & Huseien, G. F. (2023). Rock Wool Fiber-Reinforced and Recycled Concrete Aggregate-Imbued Hot Asphalt Mixtures: Design and Moisture Susceptibility Evaluation. Journal of Composites Science, 7(10), 428. https://doi.org/10.3390/jcs7100428