Abstract

In recent years, there has been growing interest in using plant fibers to reinforce materials in modern manufacturing. This study focuses on the development of a novel biocomposite made from an enset fiber (EF) and polylactic acid (PLA) matrix using compression molding at a hot-pressing temperature of 170 °C and pressure of 7 MPa for 7 min. Before preparing the biocomposites, the fibers were chemically modified with different concentrations of sodium hydroxide (NaOH) and cut into shorter fibers with a 40 mm average length in size. Then, the extent of modifications on the mechanical properties, dynamic mechanical behavior, morphology, and water absorption were investigated. The tensile, flexural, and Charpy impact tests were carried out to evaluate the mechanical properties of the samples as per ASTM standards. Moreover, dynamic mechanical analysis (DMA) and the water absorbency of the biocomposites were investigated, and the results were graphically shown and explained. The results indicate that the biocomposite treated with 5% NaOH exhibited significant improvements in tensile strength, flexural strength, and impact strength compared to the untreated composite. The tensile modulus and flexural modulus of 5% NaOH-modified enset fiber biocomposite were also enhanced by 55.8% and 70.3% compared to untreated enset fiber biocomposite. The highest tensile strength, flexural strength, and impact strength found for the PLA composite reinforced by EF treated with 5% w/v NaOH solution were 20.16 MPa, 30.21 MPa, and 12.02 kJ/m2, respectively. In general, the modification of natural fibers improves adhesion at the interface and therefore decreases the water absorption and improves the dynamic mechanical properties of biocomposites.

1. Introduction

The use of cellulose fibers from natural plant resources as reinforcing materials for the development of polymer-based composites has increased as a result of people paying more attention to environmentally friendly materials for a variety of industrial and domestic applications [1,2,3,4]. Scientists, academics, and researchers were more environmentally conscious as a result, and they started looking for alternatives to synthetic fibers [5]. Natural plant fibers used as reinforcement with polymers have become research hotspots because of their high specific strength and specific modulus, cheap cost, low density, biodegradability, renewability, and eco-friendly properties [6,7]. As a result, natural fiber-reinforced plastic composites are being used extensively in engineering industries like the automotive, aircraft, sports, packaging, medical, and construction industries as the globe moves toward an eco-friendly environment [8,9]. In recent years, lingo-cellulosic fibers like hemp, bananas, coir, and kenaf have drawn attention as potential alternatives to develop fiber-reinforced composites [10,11,12]. However, according to the current knowledge, research on enset fiber-reinforced composites is still very inadequate and there is no recent study about the enset fiber-incorporated PLA biocomposites properties.

Enset (Ensete ventricosum) also called false banana because its physical appearance is similar to the stem of banana plant, and it is a suitable plant with high potential for manufacturing natural fibers [13,14]. Enset is primarily domestically farmed in Ethiopia’s southern region to produce starchy foods from pseudostems and corms [15]. In southern Ethiopia, over 20% of the population relies on enset for food, fiber fodder, construction supplies, and medications [15,16]. After food has been mechanically removed from agricultural waste via decortication, enset fiber is retrieved [17,18]. Numerous investigations about the annual use of agricultural waste as an alternative source of fibers have been undertaken over the years. Agro-residues, which are classified as lignocellulosic biomass, primarily contain cellulose, hemicelluloses, and lignin in addition to other organic materials [19,20]. Introducing a new, underutilized agricultural waste fiber like enset fiber for the production of green composites will minimize industrial hazardous waste and improve human health [21]. Natural fibers gained from the Ensete ventricosum plant have many advantages similar to most plant fibers, such as abundance, availability, low cost, age resistance, low density, and low abrasiveness during processing [22].

In research studies, enset fiber polymeric composites have been discussed as a topic because fiber extraction from enset stem is inexpensive and abundant as a byproduct [23,24]. To develop hybrid composites, enset fiber was additionally blended with other fibers [25]. Batu, T. and Lemu, H.G. (2020) [26] studied the tensile, compression, and bending strengths of a false banana (enset fiber)- and glass fiber-reinforced epoxy hybrid polymer composite that was made using hand layup and compression molding with various fiber orientations. Analysis was performed on how fiber orientation as well as volume fraction impacted the characteristics of the fiber composites. However, no studies have yet been performed to investigate the use of this agro-waste fiber in the fabrication of PLA polymer composites. Therefore, this work aims to show and effectively utilize EF as a new alternative natural fiber to reinforce with a PLA matrix.

Plant fiber-based polymer composites have benefits; however, they also have certain drawbacks, like a higher hydroxyl group content, which results in the high absorption of moisture and a weak interphase between the fillers and the hydrophobic polymer [21,27,28]. Fortunately, such problems can be solved via the physical, chemical, thermal, and biological modification of threads [29,30,31]. Alkali modification is one of the accessible, affordable, and efficient techniques for enhancing the bonding performance of natural fibers and the matrix [32]. Oushabi et al. [33] performed alkali modification of date palm fiber and developed a polyurethane-based composite material reinforced with date palm fiber. The authors revealed that the non-cellulosic materials were easily eliminated after treatment, increased the adhesion between the components, and improved the tensile strength of DPFs. According to Kamarudin, Siti Hasnah et al., the mechanical and morphological properties of PLA-based biocomposites developed from kenaf fibers and a plasticizer based on EJO vegetable oil were investigated [34]. The findings demonstrated that kenaf fiber alkali modification significantly increased biocomposites’ tensile strength and stiffness properties compared to unmodified composites.

This study aims to explore the potential of sustainable and unutilized agro-waste natural fibers (enset fibers) as reinforcement to produce a new green composite. There are many studies on natural fiber-reinforced polymer matrix biocomposites, while research on enset fiber-reinforced polymer matrix composites is still very inadequate. However, the characteristics of alkali-modified and unmodified enset fiber-incorporated PLA biocomposites have not yet been studied or documented. A new type of biocomposite material was prepared via hot pressing, and the influence of fiber surface modification on the performance of the composite material was studied using multiple characterizations such as mechanics, dynamic mechanics, and water absorption. According to the test results, compared with untreated fiber, the treated fibers enhance the mechanical, thermomechanical, and water absorption resistance of enset fiber biocomposites. SEM analysis of the tensile fracture surface shows that modified enset fiber and PLA resin have better interfacial adhesion compared to unmodified enset fiber with PLA resin. In the Results and Discussion section of this work, outcomes are described in detail.

2. Materials and Methods

2.1. Materials

Polylactic acid (PLA), specifically in the short fiber form, was used as the polymer matrix for this study. These fibers, obtained from Lotte Chemical Titan (M) Sdn. Bhd, had a length of 38–40 mm, a density of 1.25 g/cm3, and a melt flow index of 4–10 m/min. On the other hand, the reinforcing material used was enset fiber sourced from bast fiber plants in rural areas of the southern region of Ethiopia. These fibers had a length ranging from 1 to 4 m and diameters in the range of 194–206 μm. The chemical composition and mechanical, and physical properties of enset fiber is shown in Table 1. For this experiment, the enset fibers were cut into short fibers of 40 mm length. The chemical modification of the fiber surface involved the use of sodium hydroxide (NaOH) pellets, provided by Pinghu Chemical Reagent Factory from Zhejiang, China. Acetic acid glacial was obtained from Shanghai (Ling Feng Chemical Reagent Co., Ltd., Shanghai, China).

Table 1.

Composition and properties of EFs.

2.2. EF Modification

The surface modification of plant fibers is an essential stage in the fabrication of composite materials to address the root cause of the weak interface strength between fillers and the thermoplastic matrix. In this investigation, different concentrations of NaOH were utilized to alter the fiber’s surface. To prepare the treated enset fibers, EFs were dipped in a separate tray containing a solution of 3, 5, and 7% sodium hydroxide (corresponding to 3, 5, and 7 g/100 mL water) for a duration of two hours at room temperature. After the treatment, the enset fibers were rinsed several times with tap water along with a drop of acetic acid to neutralize the extra sodium hydroxide left on the fiber surface. Subsequently, the fibers were thoroughly cleaned using distilled water until they reached a pH level of 7. After the cleaning process, the fibers were air-dried for 48 h and then further dried in a hot oven at 80 °C for 6 h. The sample code and corresponding concentrations of NaOH are provided in Table 2.

Table 2.

Mercerization of EF with different concentrations of NaOH and their sample code.

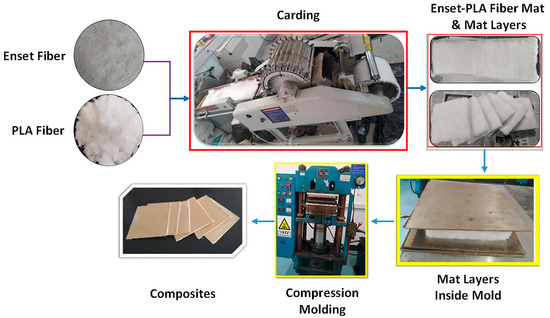

2.3. Enset–PLA Fiber Mat Preparation

The 30% chopped dried enset fibers and 70% PLA fibers were combined and opened on an enset–PLA fiber mat using a fiber-opening drum carder machine. The mixing steps of enset–PLA fibers were performed at various times to obtain the best alignment and uniform distribution of EFs in PLA fibers. Blended and opened enset–PLA fiber mats that may serve as a raw material for the fabrication of composite specimens were successfully obtained on the drum of the carder machine. According to the size of the mold, the resulting enset–PLA fiber mats were cut into 200 mm × 200 mm square pieces with scissors.

2.4. Fabrication of Enset Fibers PLA Biocomposites

The biocomposite specimens were fabricated using a hot press compression molding method. Enset–PLA fiber mat layers were dried in a hot oven drier at 70 °C for two hours before compression molding. Layers of the enset–PLA fiber mat were placed one on top of the other in a steel mold with stainless steel plates covering the top and bottom sides. A mold release agent was used before the raw material was put into the mold to prevent the sheets from sticking to the steel plates. To fabricate each composite sample, the whole system was then placed into a hot press molding machine at a temperature and pressure of 170 °C and 7 MPa, respectively, for 7 min to obtain each sample. After the procedure was finished, the mold was taken off from the heating panel and allowed to cool down to ambient temperature before de-molding. Finally, the manufactured biocomposites were rectangular with dimensions of 200 mm × 200 mm × 3 mm. Furthermore, the developed EF/PLA composites were cut into different shapes and sizes according to their respective characterizations. The EF/PLA biocomposite experiment was set up and performed as illustrated in Figure 1.

Figure 1.

Fabrication procedure of EF-reinforced PLA biocomposites.

3. Characterizations

The characteristics of enset fiber–PLA biocomposites were studied using the following characterization methods.

3.1. Tensile Test

According to the ASTM D3039 test technique, the tensile test of biocomposites has been determined using a computer-based instrument utilizing an INSTRON 4302 machine (Instron, Norwood, MA, USA). With a 30 kN load cell, the crosshead speed was kept at 2 mm/min, and the testing was performed at room temperature with 50 ± 5% relative humidity. The testing specimens were put in a conditioning room at 50% relative humidity and a temperature of 23 °C for 24 h before testing. A rectangular-shaped specimen was prepared, set within the testing machine, and stretched up to the breaking point. Tensile strength and modulus values were evaluated. Five samples of each test were tested, and the mean value of each set of tests was reported with standard deviations for further examination.

3.2. Flexural Test

The three-point flexural testing method was used to assess the flexural characteristics of all the composites that were manufactured via hot compression molding. Using a saw cutter machine, the composite samples were cut into 130 × 13 mm2 squares. On the same IN-STRON 4302 testing machine as the tensile test, at a cross-head speed of 2 mm/min, the bending test was conducted in accordance with the ASTM D790 standard. The testing specimens were put in a conditioning room at 50% relative humidity and a temperature of 23 °C for 24 h before testing. The equipment was changed to hold horizontally so that the force could be applied over the sample within the center. The bending strength and bending modulus values of the composite materials were evaluated. To induce the exact results, five duplicate samples of each composite test were analyzed, and the average of those values was recorded with standard deviations for further explanation.

3.3. Impact Test

To assess the load-carrying capability of the materials, impact tests were conducted on untreated and alkali-treated EF-reinforced composites. Rectangular specimens with specific dimensions (64 mm × 13 mm × 3 mm) were prepared and tested using an XCJ-50 (PTE, Weifang, China) test machine according to the GB 1451-83 standard. Five specimens were tested for each composite, and impact energy and cross-sectional area were used to calculate the results.

3.4. Water Absorption Test

The water absorption rate of the untreated and treated EF/PLA biocomposites was evaluated following the ASTM D570 standard and determined according to Equation (1) [37,38]. After being weighed and dried, the samples were soaked in distilled water. The samples were taken away at predetermined times and wiped with cotton fabric, and the change in weight gain was recorded as shown in Equation (1). Then, the results were reported as the mean.

where WA (%) represents the total water absorbed, and wi and wf, represent the weight of the composite before and after immersion.

3.5. Dynamic Mechanical Analysis (DMA) Test

Using the DMA Q800 dynamic mechanical analyzer (TA Instruments, New Castle, DE, USA), it was investigated how the dynamic mechanical test of untreated and treated EF/PLA biocomposites was performed. The rectangular test was cut to a measurement of 30 × 6 mm2, and testing was carried out in the temperature range of 30–150 °C at a strain rate of 0.05% and a heating rate of 5 °C/min with a frequency of 1 Hz.

3.6. Morphological Characterization

A scanning electron microscopic (SEM) investigation was carried out using “SEMFLEX1000 HACHI” (Semflex, Mesa, AZ, USA) equipment on fractured samples after a tensile test to analyze the fiber–matrix interface of untreated and treated EF/PLA biocomposites. The fractured composite sample was coated in a thin gold layer prior to imaging so as to improve the visual inspection during the examination [39]. The device was operated at an emission current of 100 μA with an acceleration voltage of 10 kV.

4. Results and Discussion

4.1. Mechanical Properties

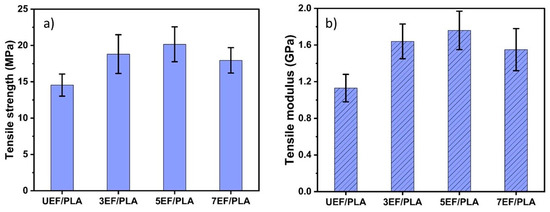

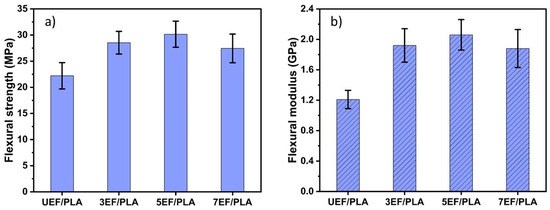

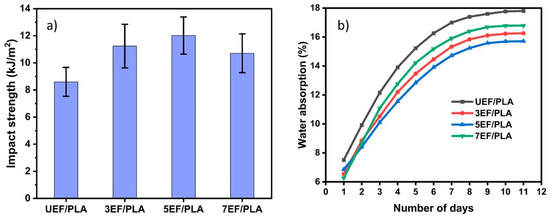

The mechanical (tensile, flexural, and impact) properties evaluated for unmodified and NaOH-modified enset fiber–PLA composites are shown in Table 3 and Figure 2, Figure 3 and Figure 4. Compared to untreated EF/PLA composites, the treated EF/PLA composites had higher mechanical properties, but in degrees that varied depending on the treatment.

Table 3.

Experimental mechanical outcomes of untreated and treated EF/PLA biocomposites.

Figure 2.

(a) Tensile strength and (b) tensile modulus of unmodified and alkali-modified EF/PLA biocomposites.

Figure 3.

(a) Flexural strength and (b) flexural modulus of unmodified and alkali-modified EF/PLA biocomposites.

Figure 4.

(a) Impact strength and (b) water absorption rate of unmodified and alkali-modified EF/PLA biocomposites.

4.1.1. Tensile Properties

Figure 2 shows the tensile strength and tensile modulus of untreated and NaOh-treated enset fiber–PLA biocomposites. As shown in Table 3, a 5% NaOH-modified fiber biocomposite has a higher tensile strength and tensile modulus than unmodified or 3% and 7% NaOH-modified fiber biocomposites. This is because impurities in the fiber are not removed, leading to a weak fiber–matrix interface and a more highly desirable condition for delignification, which weakens and damages the fibers [25]. As Figure 2a shows, the tensile strength enhanced from 14.5 MPa for untreated fiber composite to a value of 18.81, 20.16, and 17.95 MPa for 3%, 5%, and 7% NaOH-treated enset fiber biocomposites, correspondingly. These results indicated that 5% NaOH-treated enset fiber had a better interface with the polylactic acid matrix, yielding improved stiffness, a better distribution of tension, and therefore, improved tensile testing results [40,41]. As Figure 2b shows, the tensile modulus of the untreated fiber biocomposite was 1.13 GPa, which increased to 1.64, 1.76, and 1.55 GPa for 3%, 5%, and 7% NaOH-treated fiber biocomposites.

When the treatment with NaOH solutions was increased from 5% to 7%, the tensile strength and modulus of the NaOH-treated enset fiber biocomposites fell from 20.16 MPa to 17.95 MPa and from 1.76 GPa to 1.55 GPa, respectively. As can be seen, the degradation of lignocellulose and the rupture of the fiber surface during the mercerization of fibers at a concentration of 7% NaOH led to a decrease in tensile strength and tensile modulus [42]. It is indicated that the optimal setting for the elimination of impurities from fibers is 5% NaOH treatment.

4.1.2. Flexural Properties

Flexural properties, which are crucial for composites, refer to a material’s capacity to withstand bending loads [43]. In a three-point bend test, the specimen is bent using the loading nose at a predetermined span and crosshead speed until failure. Figure 3 displays the results for the bending strength and bending modulus of the unmodified and NaOH-modified enset fiber biocomposites. All alkali-treated enset fiber biocomposites showed better flexural properties than untreated fiber composites. When compared to unmodified fiber composites, the bending strengths of the alkali-treated fiber biocomposites (3EF/PLA, 5EF/PLA, and 7EF/PLA) improved by 28.5%, 35.8%, and 23.6%, respectively. These results showed that the 5% NaOH-treated enset fiber composite had the highest value of bending strength among all biocomposites, which exhibited a flexural strength of 30.16 MPa. However, in the 7% NaOH-treated enset fiber biocomposites, flexural strength declined to 27.45 MPa. This might result from fiber damage caused by excessive NaOH concentrations.

The bending modulus of the enset fiber biocomposites was additionally found to be greater after alkali modification (Figure 3b). The bending modulus of the untreated enset fiber composite was 1.21 GPa, which is increased to 1.92, 2.06, and 1.88 GPa for 3%, 5%, and 7% NaOH-modified fiber-incorporated biocomposites, respectively. The results shown are about 58.7, 70.3, and 55.4% higher than the value of the untreated fiber composite. Due to mercerization, which eliminates unwanted materials like gums and waxes and thus improves fiber surface properties while enhancing matrix–fiber adhesion, the alkali-treated composite samples showed higher flexural performance [44].

4.1.3. Impact Property

A measure of the capacity of a material to resist breaking under impact loading could be its impact resistance [45,46]. The overall sustainability of composites is especially correlated with their impact characteristics, which are significantly influenced by the material components, the fiber/matrix interface, the structure and geometry of the composite, as well as the test conditions [47]. Figure 4a illustrates the impact test results of untreated and NaOH-treated fiber-reinforced composites. The impact test was used to record the impact properties. From the figure, it can be observed that the modified fiber biocomposites achieved better impact strength than the biocomposites with unmodified fiber incorporation. The impact strength of the unmodified enset fiber biocomposite is 8.6 kJ/m2, while it increased to 11.24 kJ/m2, 12.02 kJ/m2, and 10.71 kJ/m2 for 3%, 5%, and 7% NaOH-modified fiber-incorporated biocomposites. This finding indicates that among all alkali-modified EF/PLA biocomposites, the 5% NaOH-modified biocomposite has the maximum impact strength. It is clear that mercerizing agricultural waste plant fibers (EFs) increased impact strength and has proven effective.

As illustrated in Table 3 of the manuscript, it is visualized that the difference between the untreated fiber composite and 5% NaOH-treated fiber composite is a difference of 5.62 MPa, 8 MPa, and 3.42 kJ/m2 in tensile, flexural, and impact strength, respectively. Statistically, it was proven that it has a significant difference between the untreated fiber composite and the 5% NaOH-treated composite (p < 0.05).

4.2. Water Absorption Property

As plant fiber composite materials gain weight, more water molecules become intertwined in the composites, making the evaluation of water absorption characteristics extremely important [48]. The water absorption percentage of the reinforced PLA biocomposites containing enset fibers after 11 days of immersion in distilled water is shown in Figure 4b. It is evident that as the number of soaking days rises, the composite absorbs more water until a steady state is reached.

When a fiber is used as reinforcement in a composite material, the expansion ignited by water absorption weakens the material’s mechanical characteristics through causing micro-cracks in the fiber-reinforced material. There is only one logical conclusion that can be made: natural fiber composites can absorb less water if the fiber orientation, fiber treatment, and matrix compatibility are all favorable [25]. According to the results of the tests for water absorption, the NaOH-modified enset fiber biocomposites absorb less water compared to the unmodified fiber biocomposites, while 5% NaOH-treated enset fiber composite absorbs less water than 3% and 7% NaOH-treated fiber biocomposites.

The untreated EF/PLA composite had the highest water absorption (17.8%), followed by 7EF/PLA and 3EF/PLA (with lower values of 16.78 and 16.2%, respectively). This high WA indicates that the untreated composite has voids and porosity, and it also signifies that the composite’s weight has increased due to water being trapped in these voids [49]. The results also demonstrated that alkali treatment eliminated hydroxyl groups, which reduced the treated biocomposites’ ability to absorb water. Bisanda [50] investigated that NaOH-modified sisal fiber-incorporated polylactic acid composites improved mechanical interlocking through removing lignin and waxy materials. According to numerous studies, the presence of hydroxyl groups in natural fibers provides a channel for water molecules to enter composites. Besides this pore fraction, void content, diameter of (micro) channels, and fiber–matrix adhesion also contribute to WA [51]. The water absorption behavior can be shown to benefit from the base change, which is compatible with the tensile and bending performances.

4.3. Dynamic Mechanical Properties

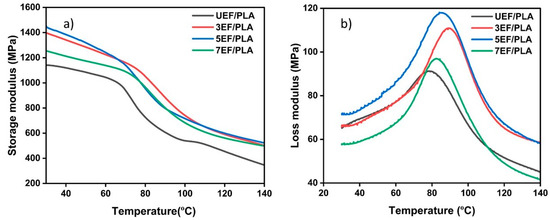

The thermomechanical properties of EF/PLA biocomposites were evaluated, and the effects of mercerizing treatment on the storage modulus (E′), loss modulus (E″), and tan δ of the composites were investigated in response to temperature. The storage modulus provides a precise description of the degree of crosslinking, the stiffness of the composite, and the link between the filler and matrix [52].

In contrast to the PLA composite with unmodified fiber reinforcement, the storage modulus of alkali-modified biocomposites is greater, as shown in Figure 5a. The untreated fiber-reinforced PLA composite had the lowest E′ value with 1142 MPa, while the fiber-incorporated PLA composite modified with 5% NaOH achieved the highest E′ value with 1451 MPa, followed by the composites modified with 3% and 7% NaOH, which had E′ values of 1400 and 1255 MPa, respectively. This outcome is likewise highly congruent with the idea that relies on the relationship between tensile and flexural strength. The enhanced fiber–matrix interfacial adhesion indicates that the alkali-modified fiber and PLA matrix is more compatible than the unmodified fiber–PLA matrix.

Figure 5.

(a) Storage modulus curves and (b) loss modulus curves of unmodified and alkali-modified EF/PLA biocomposites.

Figure 5b illustrates the temperature dependency of the loss modulus of the unmodified and modified EF/PLA biocomposites. Regarding the loss modulus (E″), it is evident that treated biocomposites had more extraordinary E″ peaks than untreated ones, which had lower E″ values. The E″ peak of the 5EF/PLA composite attained a value of 118 MPa, ahead of that of the biocomposites 3EF/PLA (111 MPa), 7EF/PLA (97 MPa), and UEF/PLA (91 MPa). The glass transition temperature of an untreated composite is approximately 78 °C from the E″ peak, and it considerably rose for 3EF/PLA, 5EF/PLA, and 7EF/PLA biocomposites when the fibers were alkali-treated to 89, 84, and 82 °C, respectively. This exhibits the apparent impact of fiber surface treatment on the loss modulus behavior of biocomposites.

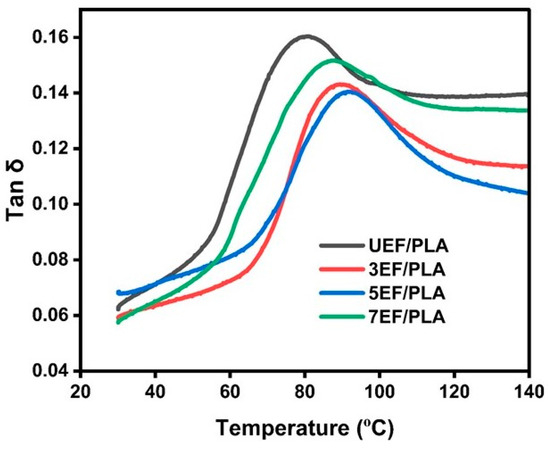

The mechanical tanδ can be used to calculate the ratio of the storage modulus (E′) to the loss modulus (E″). The tanδ peaks of the alkali-treated biocomposites are seen to be pushed to higher temperatures in comparison to the untreated composite (Figure 6).

Figure 6.

Tanδ curve of untreated and alkali-treated EF/PLA biocomposites.

When 3, 5, and 7% NaOH-treated fibers were incorporated, the temperature of the EF/PLA biocomposite improved from 79 °C to 89 °C, 91 °C, and 87 °C, respectively. Table 4 shows that the untreated enset fiber biocomposite had the greatest peak value (0.284), followed by the biocomposites made of 7% NaOH-treated composite (0.273), 3% NaOH-treated composite (0.268), and 5% NaOH-treated composite (0.265). According to a study, solid component bonding results in less polymer chain movement, which lowers tanδ [53].

Table 4.

Experimental thermomechanical results of developed unmodified and NaOH-modified EF/PLA biocomposites.

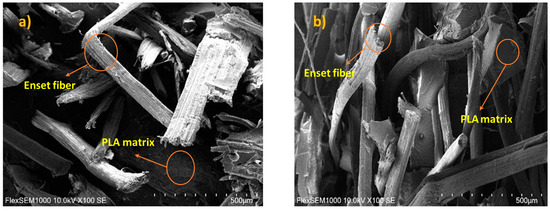

4.4. Composite Morphology

The application of natural fibers with a biodegradable matrix is aimed to improve the mechanical properties, biodegradability, and other properties such as water absorption or barrier efficiency. However, natural fibers without surface treatment result in low compatibility with the polymer matrix, due to the hydrophobic nature of polymers. Therefore, enset fiber (a strong fiber from the class of bast fiber) modified with different concentrations of NaOH showed better compatibility with the PLA matrix. The SEM images are presented in Figure 7.

Figure 7.

SEM image of (a) untreated EF/PLA and (b) treated EF/PLA composites.

The images show that fiber pull-out from the PLA matrix was more pronounced in the untreated composites (Figure 7a) and reveal that unmodified fibers exhibited poor interfacial adhesion with the PLA. Impurities were the reason for the poor interfacial adhesion between the unaltered fibers and the PLA polymer matrix [30].

However, after modification with alkaline solutions, particles including non-cellulosic components were removed, and the fiber surface became clean and rough. This builds a strong and direct bond between the fiber and PLA [54]. According to the SEM examination of Figure 7b, the filler pull-out from the PLA matrix was reduced and showed a cleaner image compared to the untreated specimen. This suggests better filler–matrix adhesion than in untreated composites. This could be the reason for in the resulting higher tensile and flexural properties compared to untreated fiber composites.

5. Conclusions

This study demonstrated the fabrication of an EF/PLA composite with improved overall properties using a hot press compression molding technique. The result shows that alkali-modified fiber biocomposites exhibited higher mechanical properties than unmodified EF/PLA composites. The maximum tensile and flexural strength were recorded after 5% alkali-treated enset fiber was incorporated into the polylactic acid resin. The tensile modulus of 5EF/PLA and flexural modulus of 3EF/PLA biocomposites were found to be higher compared to other composites. The improved impact strength of modified fiber biocomposites makes them suitable for high-impact loading applications over untreated enset fiber composites. The 5EF/PLA composite can absorb more impact energy due to improved interaction with the PLA matrix compared to other composites. The water absorption test revealed that reinforcement with mercerized EF reduced the WA tendency of the EF/PLA system. Additionally, the dynamic performance of fiber-incorporated PLA biocomposites modified with alkali was enhanced, and those outcomes are compatible with the data on water absorption. These findings, validated via SEM examination, showed that PLA and alkali-treated fibers exhibited good interphase since there was less fiber pull-out. The overall mode of the results showed that compared to biocomposites made of untreated fibers, those reinforced with alkali-treated fibers performed better in all measured properties. It was concluded that the incorporation of 5% treated fibers improved the interaction of EF with the PLA matrix and, as a result, improved the mechanical and dynamic properties of the composite and can be as a potential replacement to lignocellulose fibers and synthetic fiber-filled polymer composites in various applications, including automobiles, household, packaging, and other lightweight-based industrial products.

Author Contributions

K.G.A.; Conceptualization, methodology, investigation, writing—original draft preparation, data analysis and revision, D.K.D.; revision and editing, formal analysis, M.U.G.; writing—review and editing, visualization, A.A.T.; software, J.G.; supervision, resources, project administration, funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The first author would like to acknowledge financial support from the Donghua University (No. 101-08-0241012).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Vinod, A.; Sanjay, M.; Suchart, S.; Jyotishkumar, P. Renewable and sustainable biobased materials: An assessment on biofibers, biofilms, biopolymers and biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Gheith, M.H.; Aziz, M.A.; Ghori, W.; Saba, N.; Asim, M.; Jawaid, M.; Alothman, O.Y. Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J. Mater. Res. Technol. 2019, 8, 853–860. [Google Scholar] [CrossRef]

- Sanjay, M.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Ammar, Z.; Ibrahim, H.; Adly, M.; Sarris, I.; Mehanny, S. Influence of natural fiber content on the frictional material of brake pads—A review. J. Compos. Sci. 2023, 7, 72. [Google Scholar] [CrossRef]

- Vinod, A.; Rangappa, S.M.; Srisuk, R.; Tengsuthiwat, J.; Ramnath, A.; Siengchin, S. Agro-waste Capsicum Annum stem: An alternative raw material for lightweight composites. Ind. Crop. Prod. 2023, 193, 116141. [Google Scholar] [CrossRef]

- Zhan, J.; Li, J.; Wang, G.; Guan, Y.; Zhao, G.; Lin, J.; Naceur, H.; Coutellier, D. Review on the performances, foaming and injection molding simulation of natural fiber composites. Polym. Compos. 2021, 42, 1305–1324. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Text. 2022, 51, 5518S–5542S. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Refate, A.; Mohamed, Y.; Mohamed, M.; Sobhy, M.; Samhy, K.; Khaled, O.; Eidaroos, K.; Batikh, H.; El-Kashif, E.; El-Khatib, S. Influence of electrospinning parameters on biopolymers nanofibers, with emphasis on cellulose & chitosan. Heliyon 2023, 9, e17051. [Google Scholar]

- Imran, M.; Khan, R.; Rafiullah, S. Vibration analysis of cracked composite laminated plate: A review. Mehran Univ. Res. J. Eng. Technol. 2019, 38, 705–716. [Google Scholar] [CrossRef]

- Santhosh, J.; Balanarasimman, N.; Chandrasekar, R.; Raja, S. Study of properties of banana fiber reinforced composites. Int. J. Res. Eng. Technol 2014, 3, 144–150. [Google Scholar]

- Jogi, S.A.; Baloch, M.M.; Chandio, A.D.; Memon, I.A.; Chandio, G.S. Evaluation of impact strength of epoxy based hybrid composites reinforced with E-Glass/Kevlar 49. Mehran Univ. Res. J. Eng. Technol. 2017, 36, 1009–1016. [Google Scholar] [CrossRef]

- Rashan, L.; Hakkim, F.L.; Idrees, M.; Essa, M.; Velusamy, T.; Al-Baloshi, M.; Al-Bulushi, B.; Al Jabri, A.; Alrizeiki, M.; Guillemin, G. Boswellia gum resin and essential oils: Potential health benefits−An evidence based review. Int. J. Nutr. Pharmacol. Neurol. Dis. 2019, 9, 53–71. [Google Scholar] [CrossRef]

- Mizera, Č.; Hrabě, P.; Müller, M.; Herák, D. Creep behaviour of the polymer composite with false banana’s fibres (Ensete ventricosum). Manuf. Technol. 2016, 16, 188–192. [Google Scholar] [CrossRef]

- Mohammed, B.; Gabel, M.; Karlsson, L.M. Nutritive values of the drought tolerant food and fodder crop enset. Afr. J. Agric. Res. 2013, 8, 2326–2333. [Google Scholar] [CrossRef]

- Ayele, A.; Sahu, O. Extension of Enset plant product for rural development in Ethiopia. J. Agric. Econ. Ext. Rural Dev. 2014, 2, 31–40. [Google Scholar]

- Blomme, G.; Sebuwufu, G.; Addis, T.; Turyagyenda, L. Relative performance of root and shoot development in enset and east African highland bananas. Afr. Crop Sci. J. 2008, 16, 51–57. [Google Scholar] [CrossRef]

- Birmeta, G. Genetic Variability and Biotechnological Studies for the Conservation and Improvement of Ensete ventricosum. Ph.D. Thesis, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2004. [Google Scholar]

- Hemida, M.H.; Moustafa, H.; Mehanny, S.; Morsy, M.; Dufresne, A.; Rahman, E.N.A.E.; Ibrahim, M. Cellulose nanocrystals from agricultural residues (Eichhornia crassipes): Extraction and characterization. Heliyon 2023, 9, e16436. [Google Scholar] [CrossRef]

- Anwar, Z.; Gulfraz, M.; Irshad, M. Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: A brief review. J. Radiat. Res. Appl. Sci. 2014, 7, 163–173. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Pupure, L.; Varna, J.; Joffe, R. Natural fiber composite: Challenges simulating inelastic response in strain-controlled tensile tests. J. Compos. Mater. 2016, 50, 575–587. [Google Scholar] [CrossRef]

- Temesgen, A.G.; Recep, E.; Aykut, Y.; Süvari, F. Evaluation of Enset fabric reinforced green composite as sound absorber structure. Text. Appar. 2021, 31, 73–81. [Google Scholar] [CrossRef]

- Zeleke, Y.; Rotich, G.K. Design and development of false ceiling board using polyvinyl acetate (PVAc) composite reinforced with false banana fibres and filled with sawdust. Int. J. Polym. Sci. 2021, 2021, 5542329. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Study of the effects of alkali treatment and fiber orientation on mechanical properties of enset/sisal polymer hybrid composite. J. Compos. Sci. 2023, 7, 37. [Google Scholar] [CrossRef]

- Batu, T.; Lemu, H.G. Investigation of mechanical properties of false banana/glass fiber reinforced hybrid composite materials. Results Mater. 2020, 8, 100152. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Sundarakannan, R.; John, K.; Johnson, R.D.J.; Prasath, K.A.; Ajith, S.; Arumugaprabu, V.; Uthayakumar, M. Recent advancement in the natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2020, 277, 124109. [Google Scholar] [CrossRef]

- Shanmugam, V.; Mensah, R.A.; Försth, M.; Sas, G.; Restás, Á.; Addy, C.; Xu, Q.; Jiang, L.; Neisiany, R.E.; Singha, S.; et al. Circular economy in biocomposite development: State-of-the-art, challenges and emerging trends. Compos. Part C Open Access 2021, 5, 100138. [Google Scholar] [CrossRef]

- Sanjay, M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar]

- Yorseng, K.; Rangappa, S.M.; Pulikkalparambil, H.; Siengchin, S.; Parameswaranpillai, J. Accelerated weathering studies of kenaf/sisal fiber fabric reinforced fully biobased hybrid bioepoxy composites for semi-structural applications: Morphology, thermo-mechanical, water absorption behavior and surface hydrophobicity. Constr. Build. Mater. 2020, 235, 117464. [Google Scholar] [CrossRef]

- Reddy, B.M.; Mohana Reddy, Y.V.; Mohan Reddy, B.C.; Reddy, R.M. Mechanical, morphological, and thermogravimetric analysis of alkali-treated Cordia-Dichotoma natural fiber composites. J. Nat. Fibers 2020, 17, 759–768. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Hassani, F.O.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF–Polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Abdullah, L.C.; Aung, M.M.; Ratnam, C.T.; Jusoh, E.R. A study of mechanical and morphological properties of PLA based biocomposites prepared with EJO vegetable oil based plasticiser and kenaf fibres. Mater. Res. Express 2018, 5, 085314. [Google Scholar] [CrossRef]

- Temesgen, A.G.; Sahu, O. Process ability enhancement of false banana fibre for rural development. Cellulose 2014, 1, 64–73. [Google Scholar]

- Teli, M.D.; Terega, J.M. Chemical, physical and thermal characterization of Ensete ventricosum plant fibre. Int. Res. J. Eng. Technol. 2017, 4, 67–75. [Google Scholar]

- Khalil, H.A.; Jawaid, M.; Bakar, A.A. Woven hybrid composites: Water absorption and thickness swelling behaviours. BioResources 2011, 6, 1043–1052. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Selvan, M.T.; Rajeshkumar, L.; Balaji, D.; Bhuvaneswari, V. Mechanical and water absorption properties of Calotropis gigantea plant fibers reinforced polymer composites. Mater. Today Proc. 2021, 46, 3367–3372. [Google Scholar] [CrossRef]

- Saravanakumar, S.; Kumaravel, A.; Nagarajan, T.; Sudhakar, P.; Baskaran, R. Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohydr. Polym. 2013, 92, 1928–1933. [Google Scholar] [CrossRef]

- Balaji, A.; Karthikeyan, B.; Swaminathan, J.; Raj, C.S. Effect of filler content of chemically treated short bagasse fiber-reinforced cardanol polymer composites. J. Nat. Fibers 2018, 16, 613–627. [Google Scholar] [CrossRef]

- da Silva, A.L.; da Silva, L.R.R.; de Andrade Camargo, I.; da Silva Agostini, D.L.; dos Santos Rosa, D.; de Oliveira, D.L.V.; Fechine, P.B.A.; Mazzetto, S.E. Cardanol-based thermoset plastic reinforced by sponge gourd fibers (Luffa cylindrica). Polímeros 2016, 26, 21–29. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Hassan, A.; Rafiq, M.I.M.; Ariffin, M.I.Z. Improving thermal and mechanical properties of injection moulded kenaf fibre-reinforced polyhydroxy-butyrate composites through fibre surface treatment. BioResources 2019, 14, 3101–3116. [Google Scholar] [CrossRef]

- Tran, D.; Nguyen, D.; Thuc, C.H.; Dang, T. Effect of coupling agents on the properties of bamboo fiber-reinforced unsaturated polyester resin composites. Compos. Interfaces 2013, 20, 343–353. [Google Scholar] [CrossRef]

- Nadlene, R.; Sapuan, S.; Jawaid, M.; Ishak, M.; Yusriah, L. The effects of chemical treatment on the structural and thermal, physical, and mechanical and morphological properties of roselle fiber-reinforced vinyl ester composites. Polym. Compos. 2018, 39, 274–287. [Google Scholar] [CrossRef]

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Joseph, S.; Sreekala, M.; Oommen, Z.; Koshy, P.; Thomas, S. A comparison of the mechanical properties of phenol formaldehyde composites reinforced with banana fibres and glass fibres. Compos. Sci. Technol. 2002, 62, 1857–1868. [Google Scholar] [CrossRef]

- Mylsamy, K.; Rajendran, I. Influence of alkali treatment and fibre length on mechanical properties of short Agave fibre reinforced epoxy composites. Mater. Des. 2011, 32, 4629–4640. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.; Siengchin, S.; Fouad, H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. Express Polym. Lett. 2020, 14, 717–730. [Google Scholar] [CrossRef]

- Bisanda, E. The effect of alkali treatment on the adhesion characteristics of sisal fibres. Appl. Compos. Mater. 2000, 7, 331–339. [Google Scholar] [CrossRef]

- Ashori, A.; Sheshmani, S. Hybrid composites made from recycled materials: Moisture absorption and thickness swelling behavior. Bioresour. Technol. 2010, 101, 4717–4720. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A.; Alattas, O.S. Woven hybrid biocomposites: Dynamic mechanical and thermal properties. Compos. Part A Appl. Sci. Manuf. 2012, 43, 288–293. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Hossen, M.M.; Feng, J.; Yuxiang, Y.; Jiang, W. Preparation and evaluation mechanical, chemical and thermal properties of hybrid jute and coir fibers reinforced bio-composites using poly-lactic acid and poly-caprolactone blends. Mater. Res. Express 2020, 7, 025103. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).