Date Palm Cellulose Nanocrystals (CNCs)/Polyamide Composites: Tailoring Morphological, Mechanical, and Thermal Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Cellulose Nanocrystal Production from Date Palm Leaves

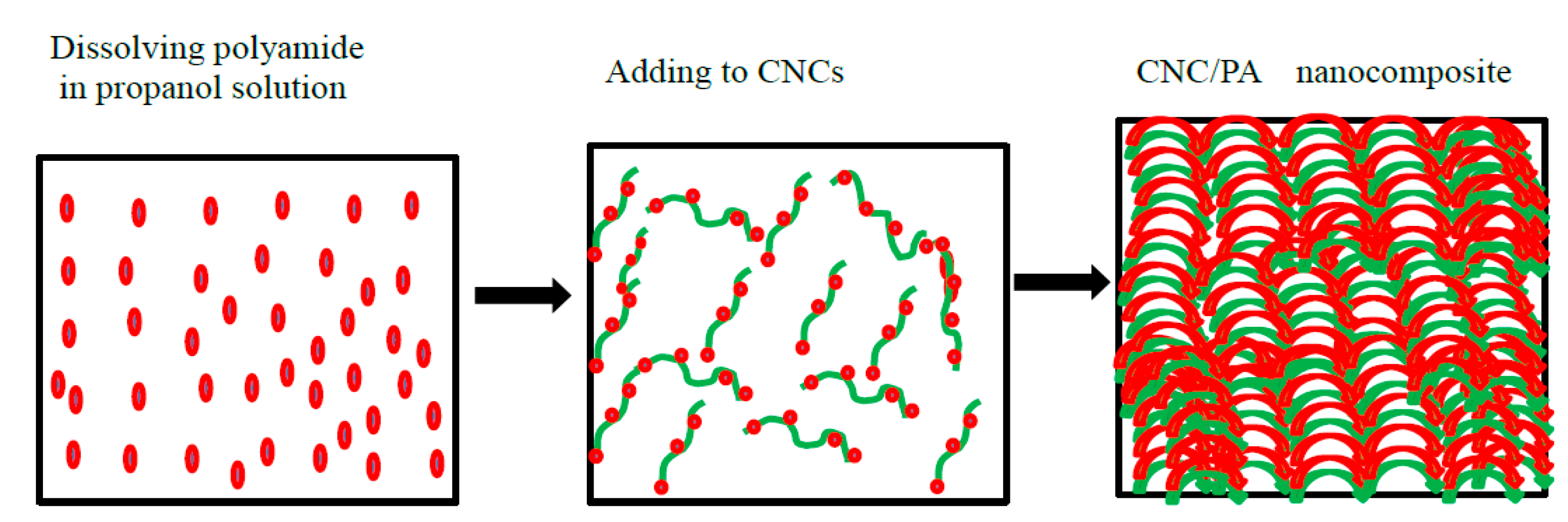

2.2. Processing of CNC/PA Nanocomposites Film by Electrospinning Method

2.3. Processing of CNC/PA Nanocomposite Films by Solution Casting

2.4. Characterization Techniques

2.4.1. Microscopy

2.4.2. Thermogravimetric Analysis (TGA)

2.4.3. Contact Angle Studies

2.4.4. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.5. Nanoindentation Studies

3. Results and Discussions

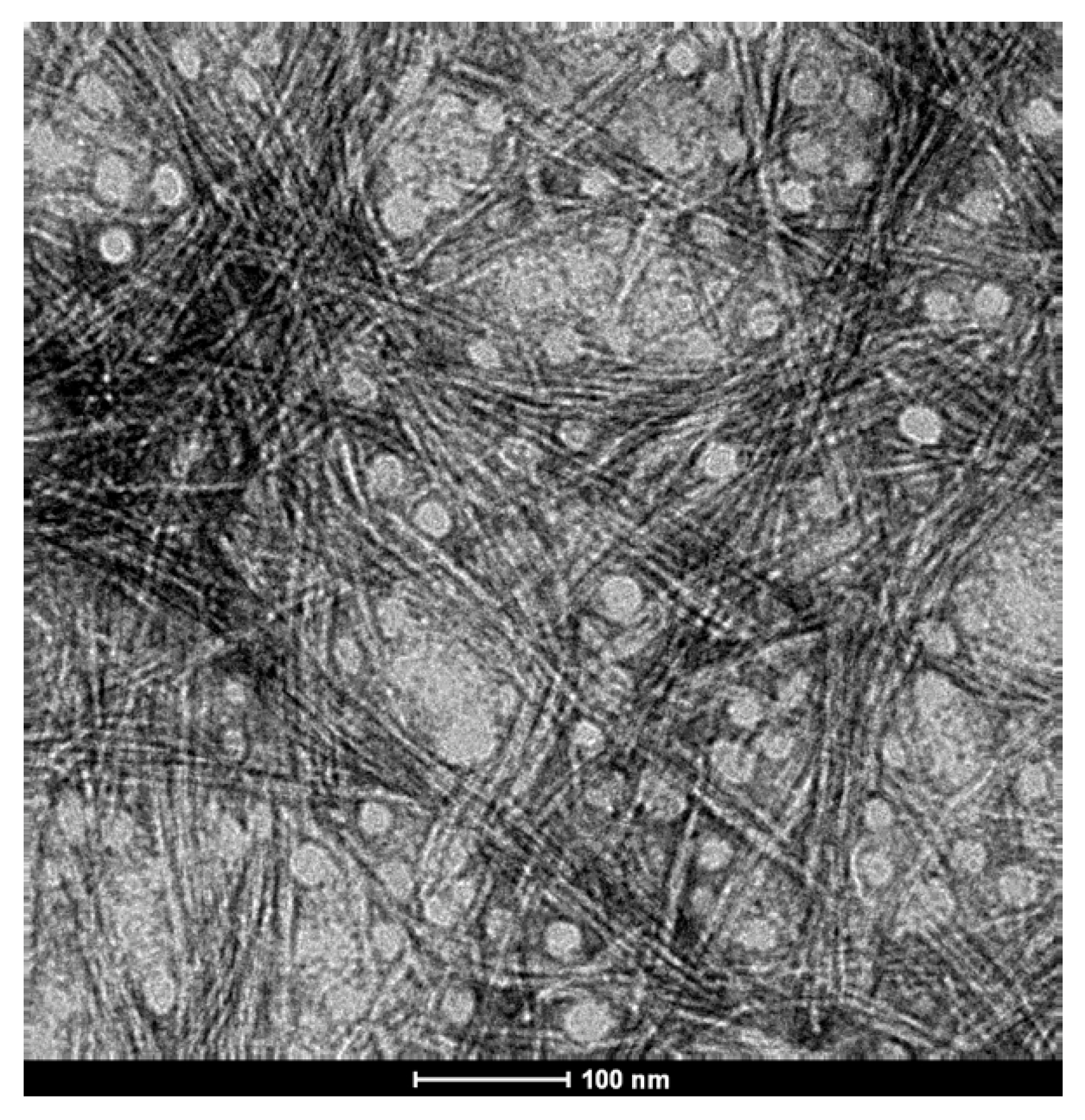

3.1. Morphology of Cellulosic Nanocrystals (CNC) from Date Palm Leaf

3.2. Films Prepared by Electrospinning Method

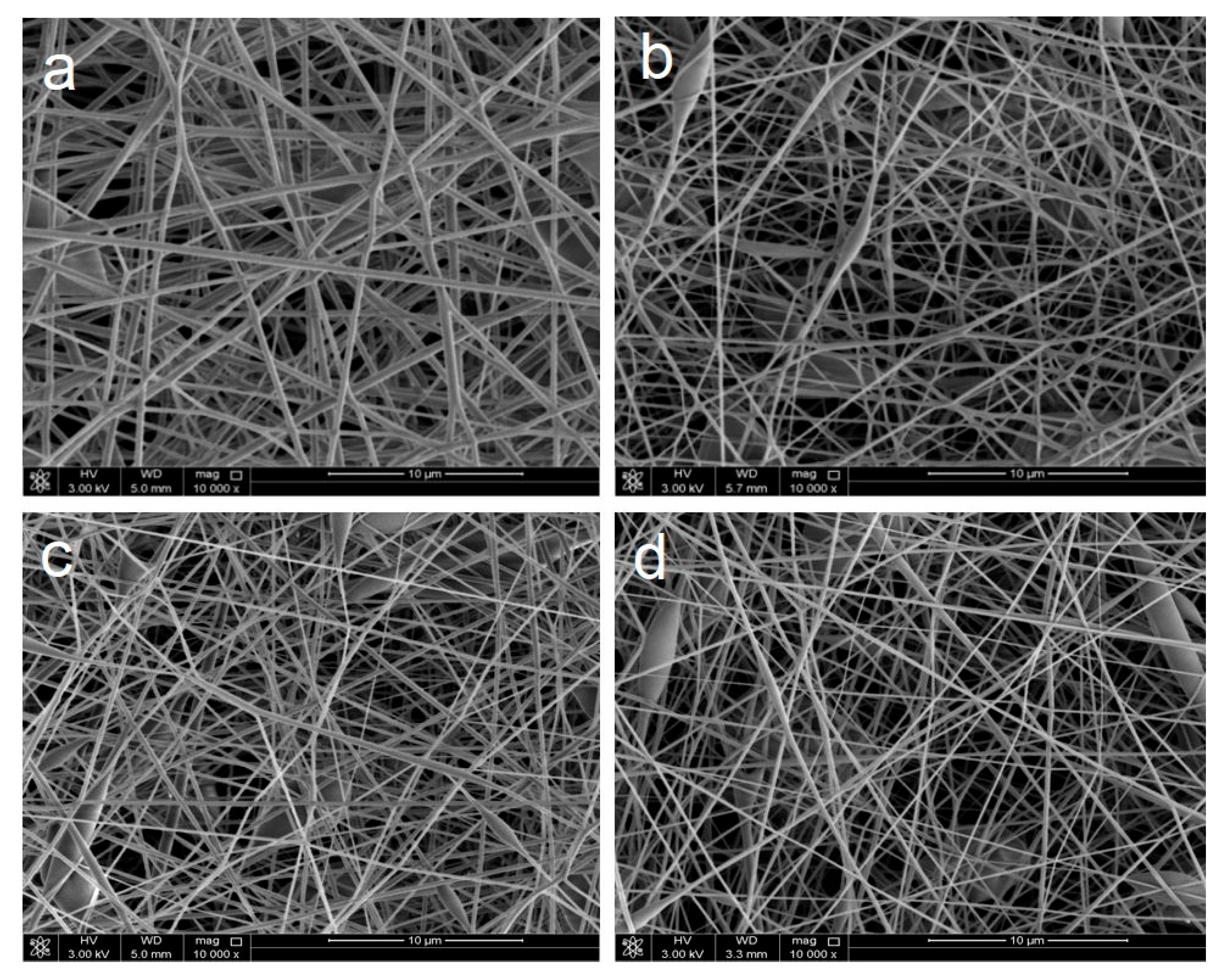

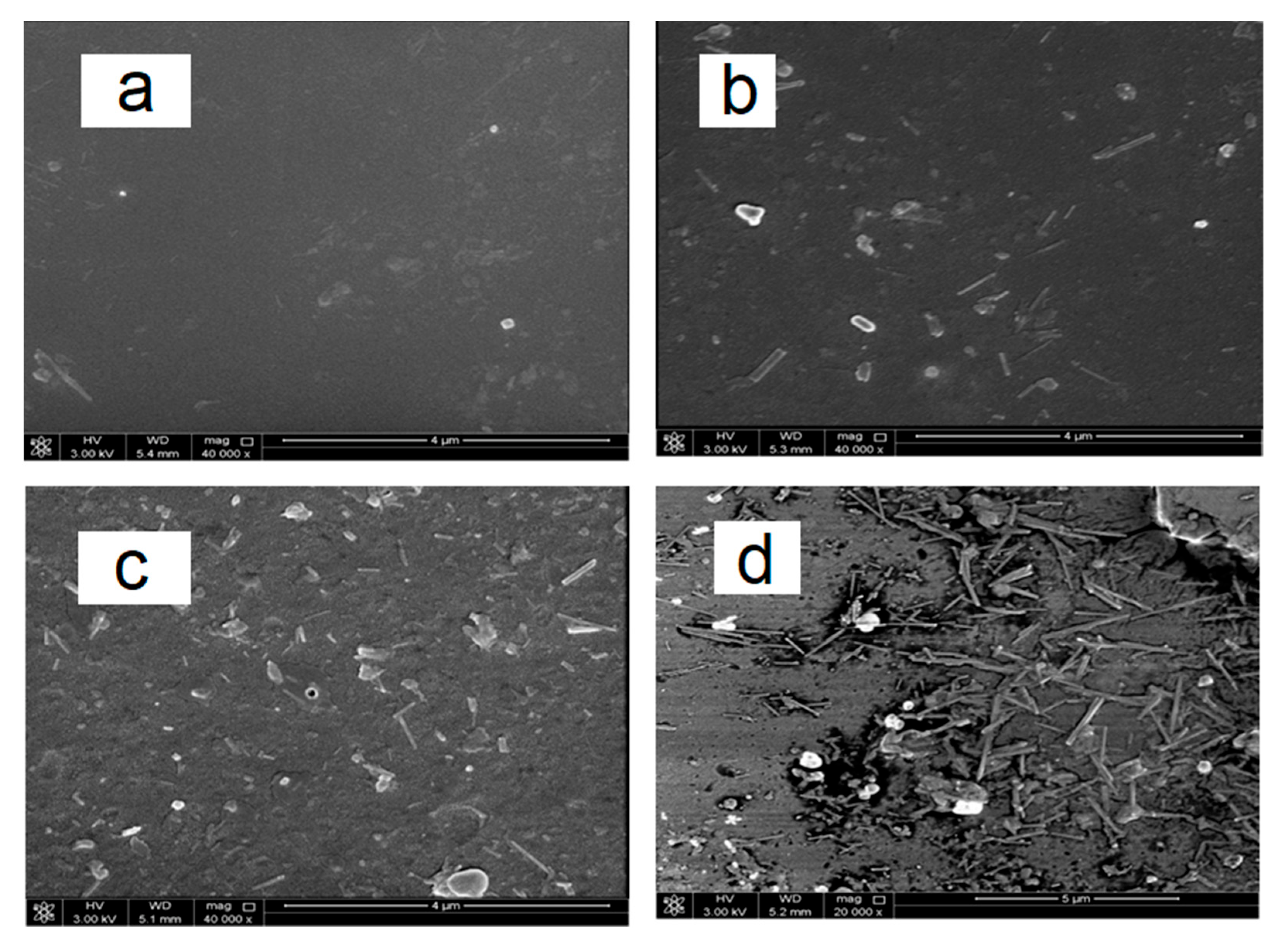

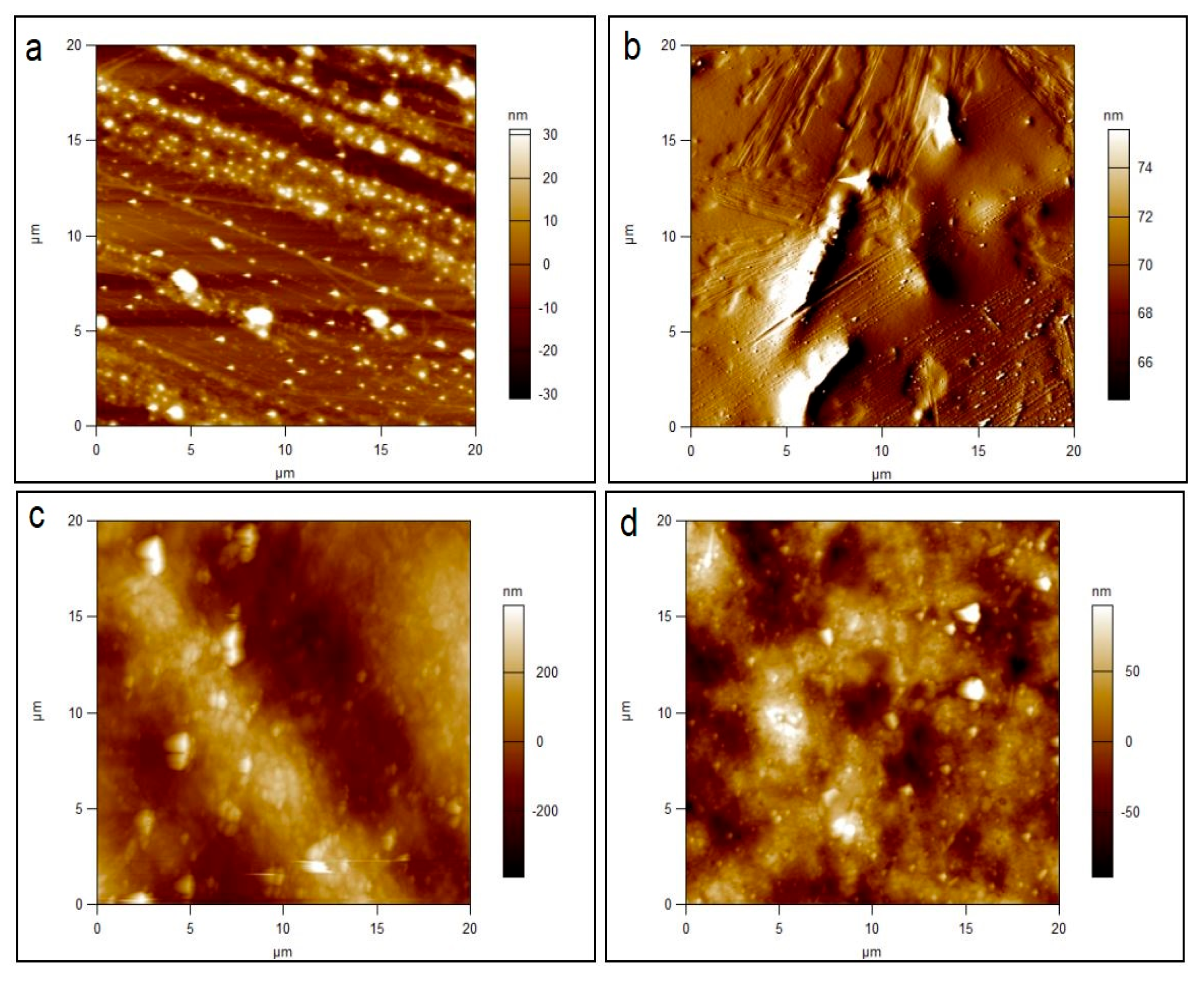

3.2.1. Morphological Analysis of PA/CNC Nanocomposites

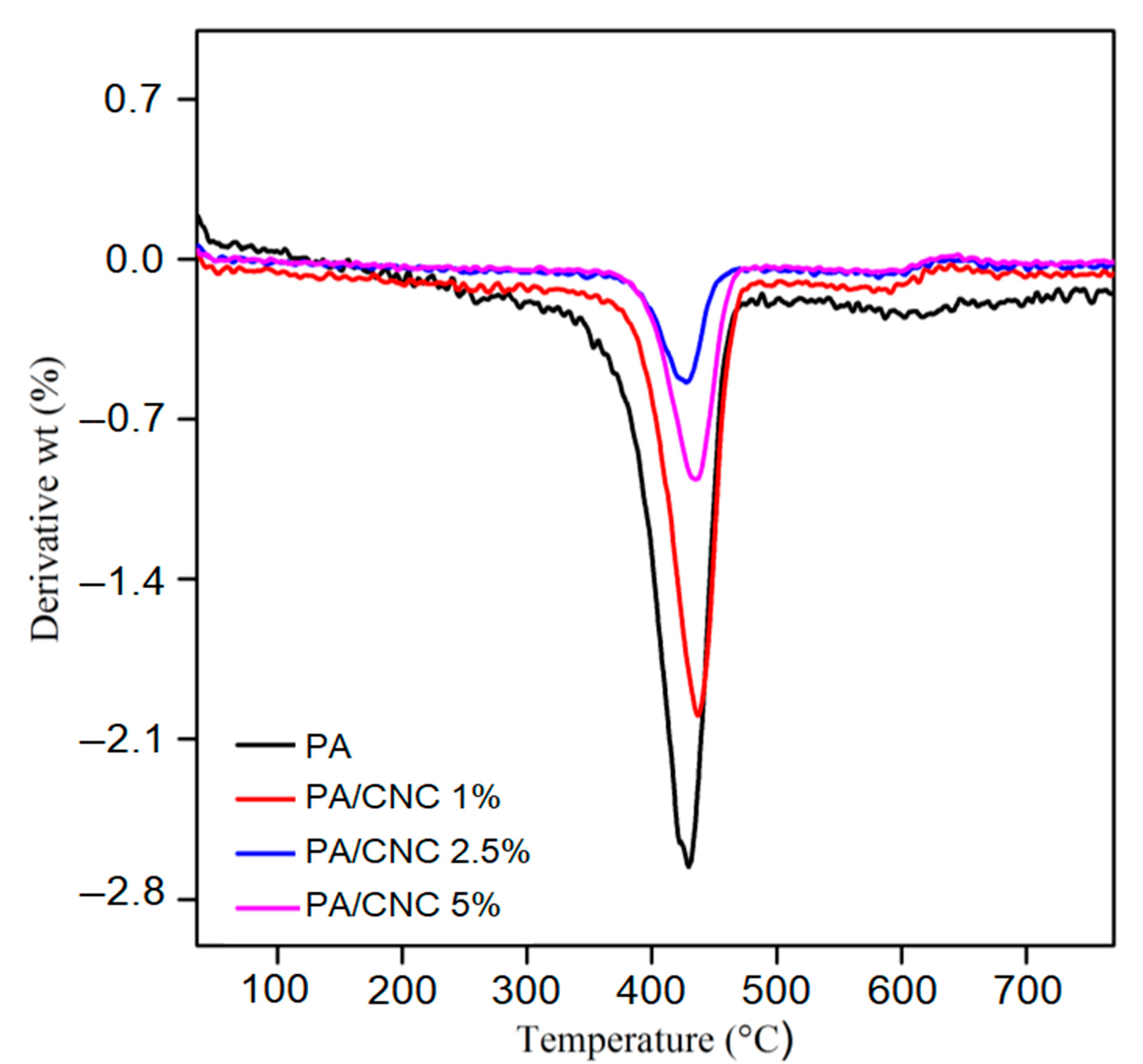

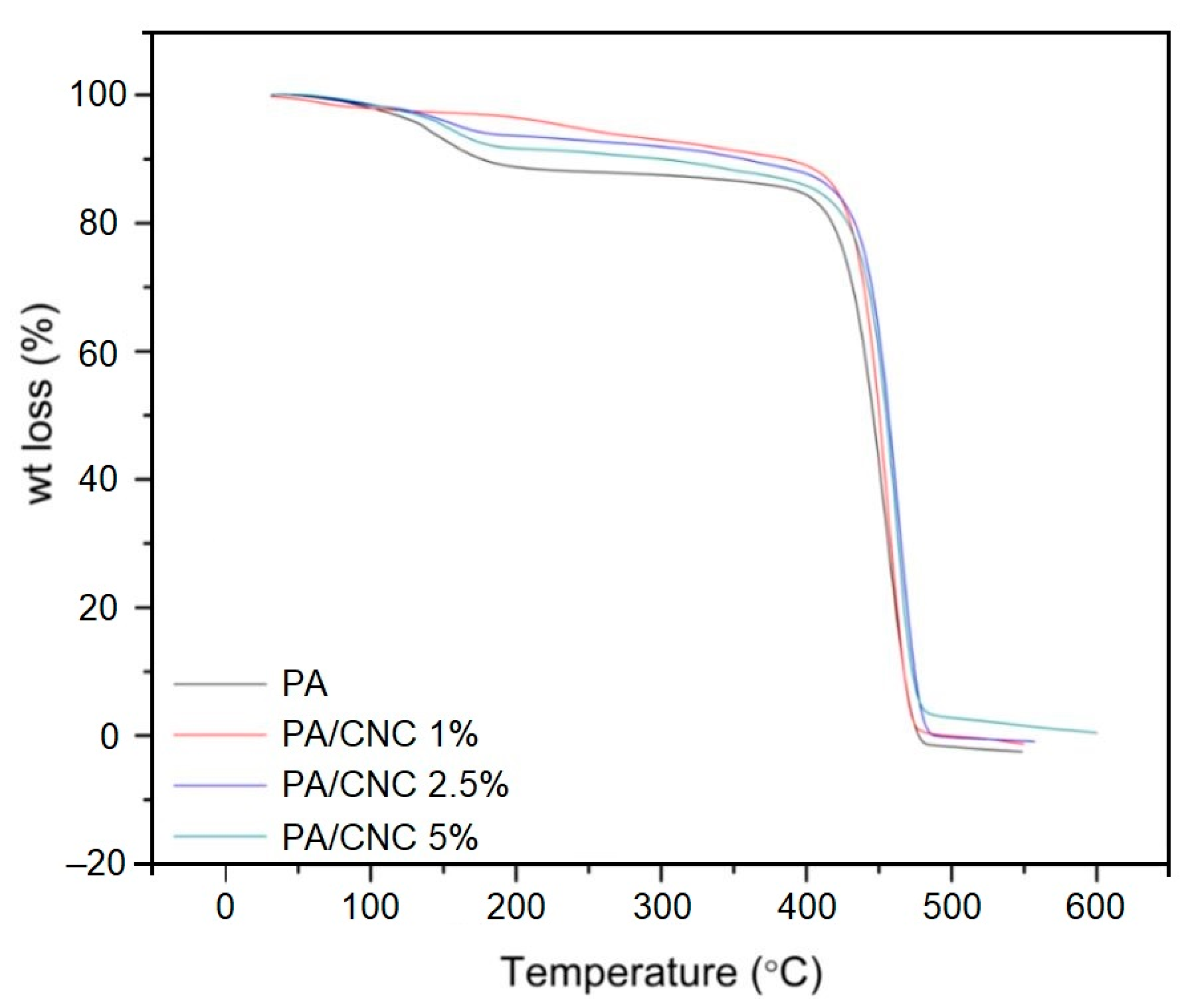

3.2.2. Thermal Behavior of the Electrospun PA/CNC Films

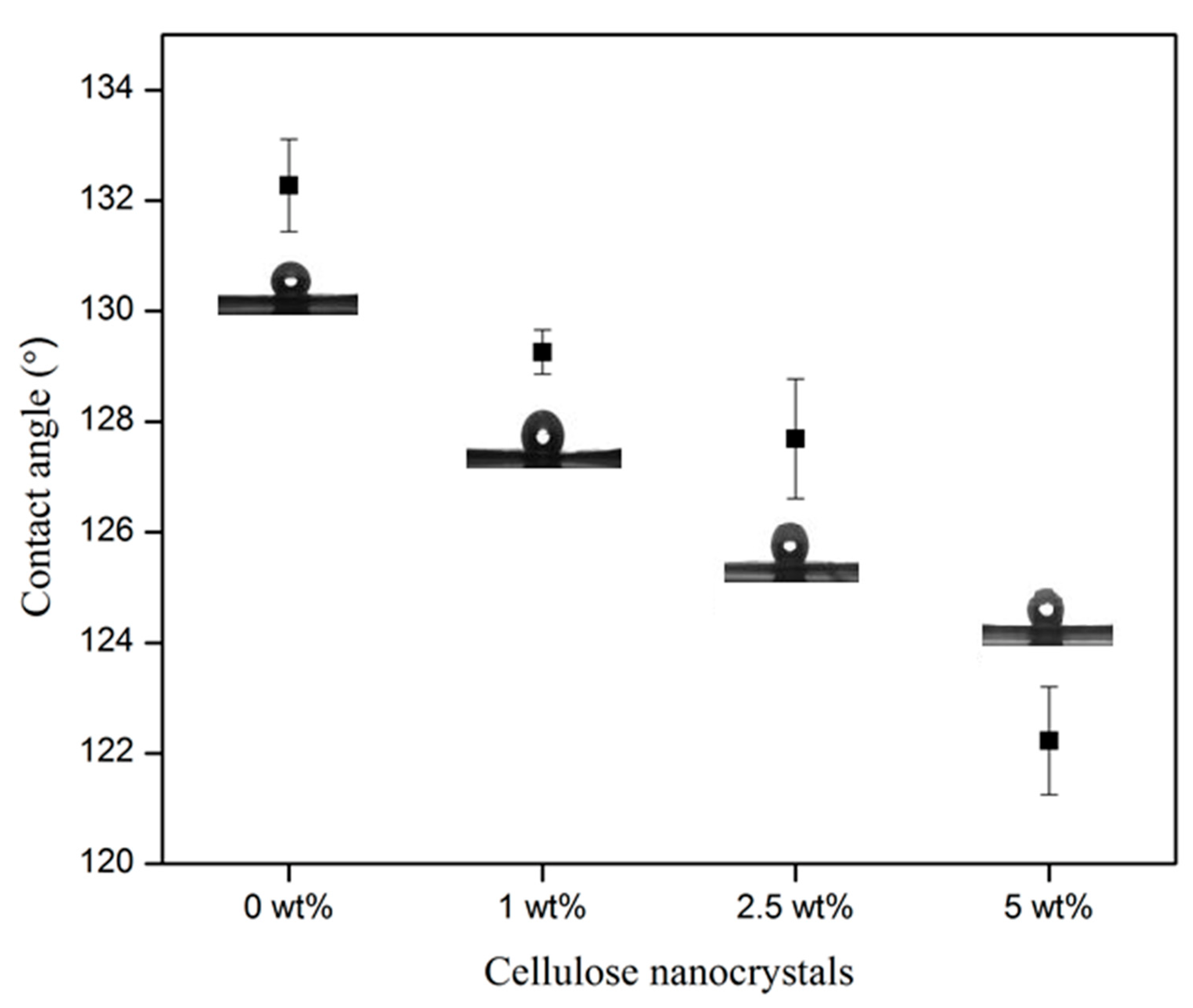

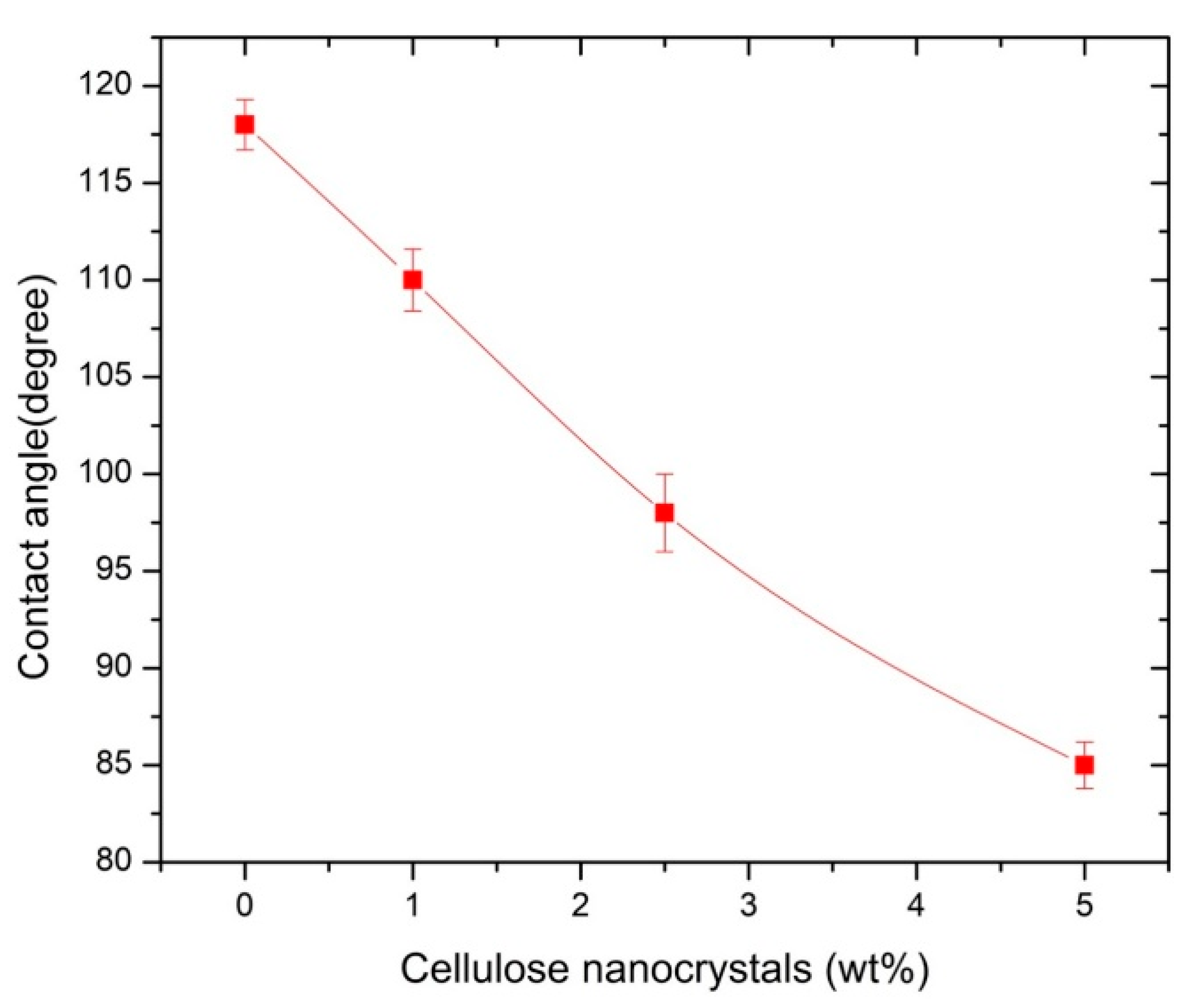

3.2.3. Surface Wettability of the Electrospun PA/CNC Films

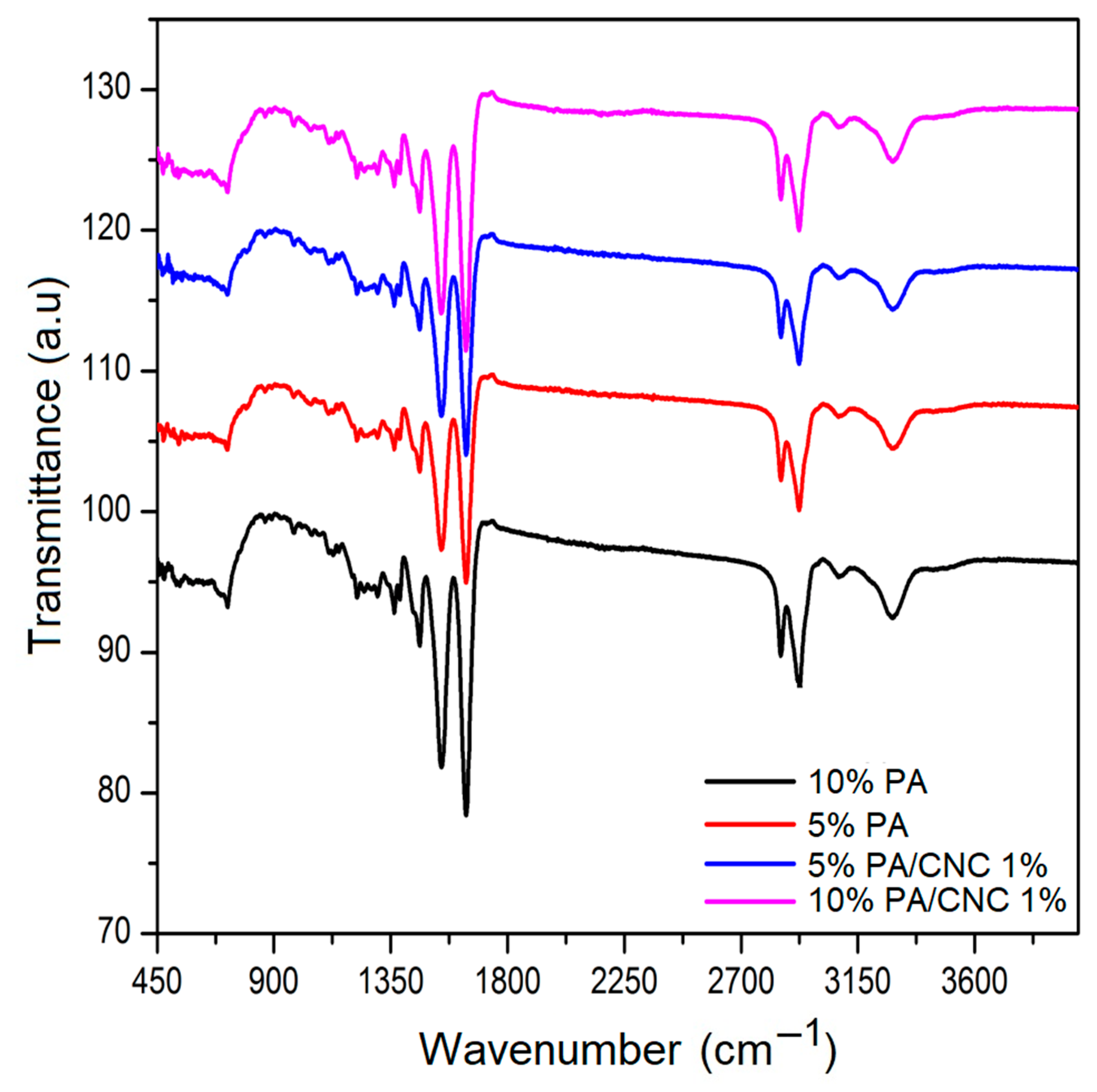

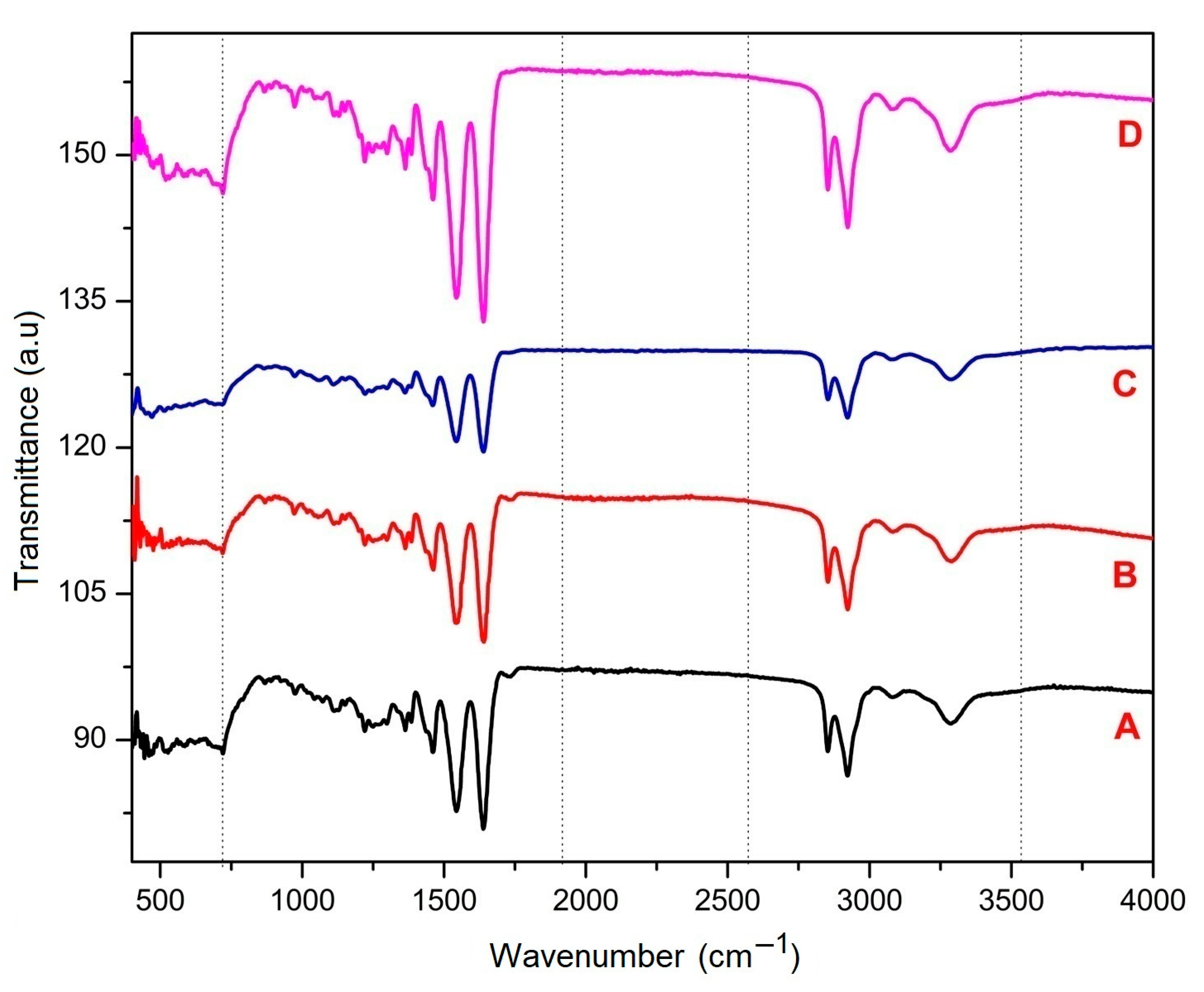

3.2.4. Spectroscopic Studies of Electrospun PA/CNC Films

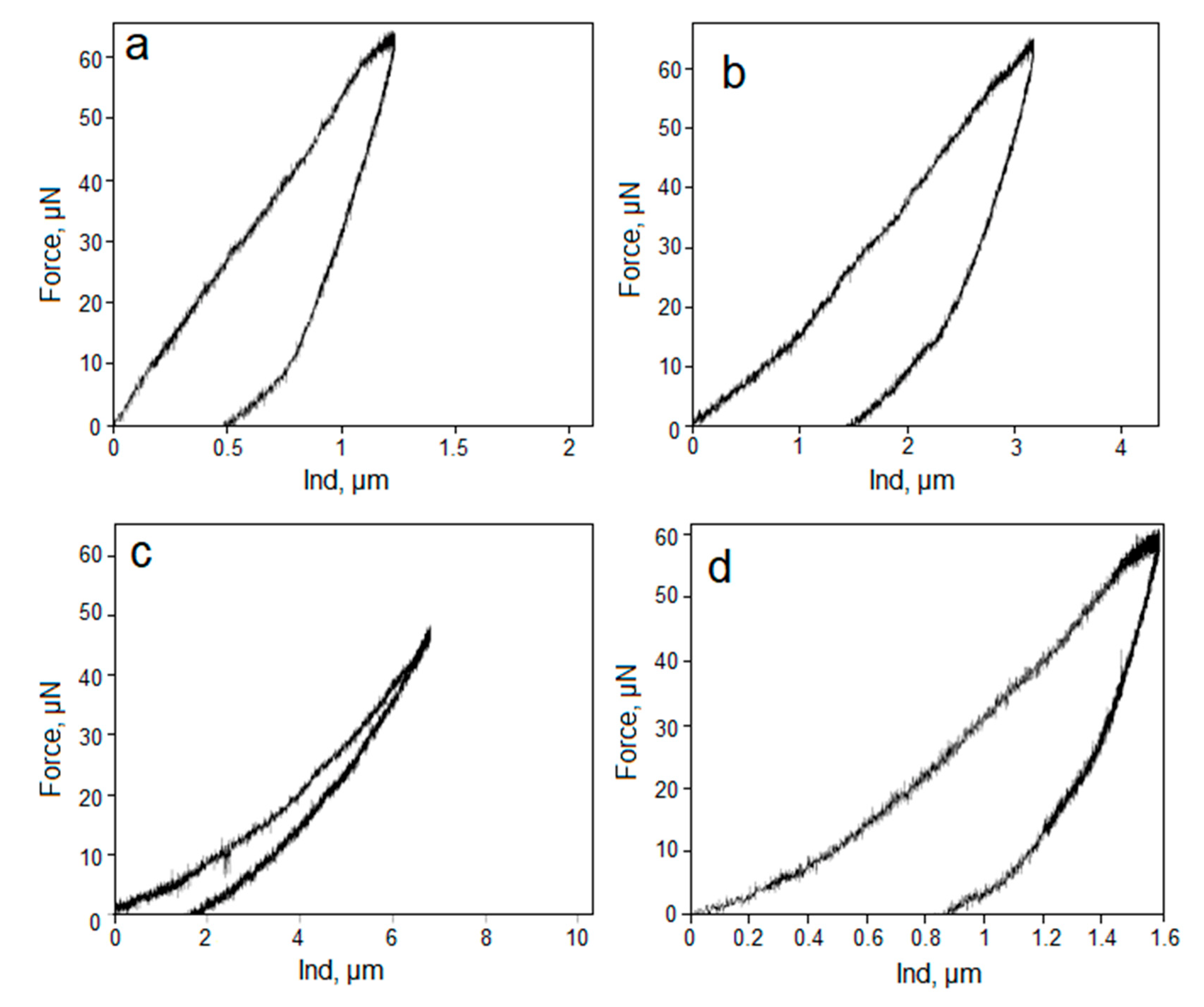

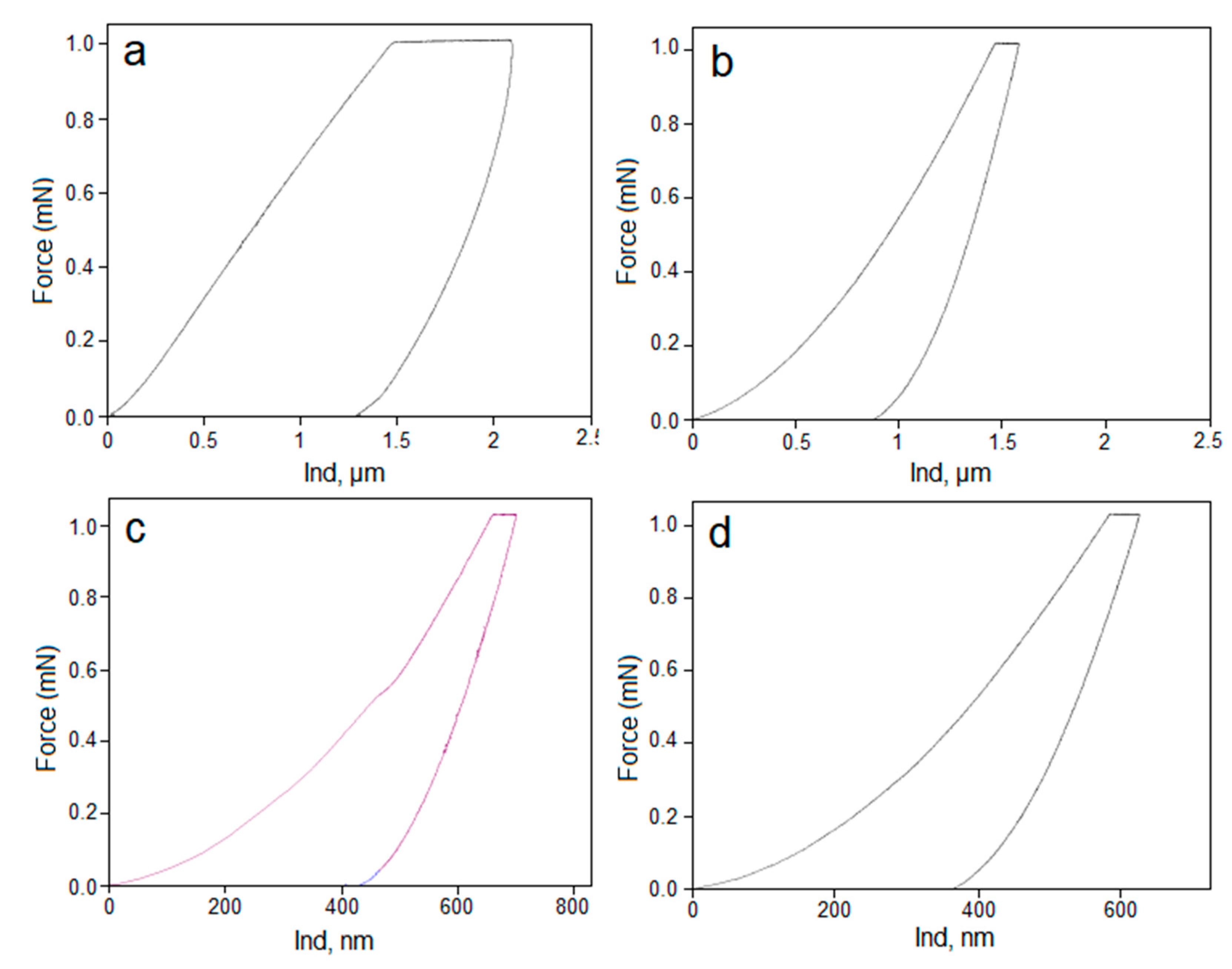

3.2.5. Nanoindentation Studies of Electrospun Nanocomposites

3.3. Films Prepared by Solution Casting

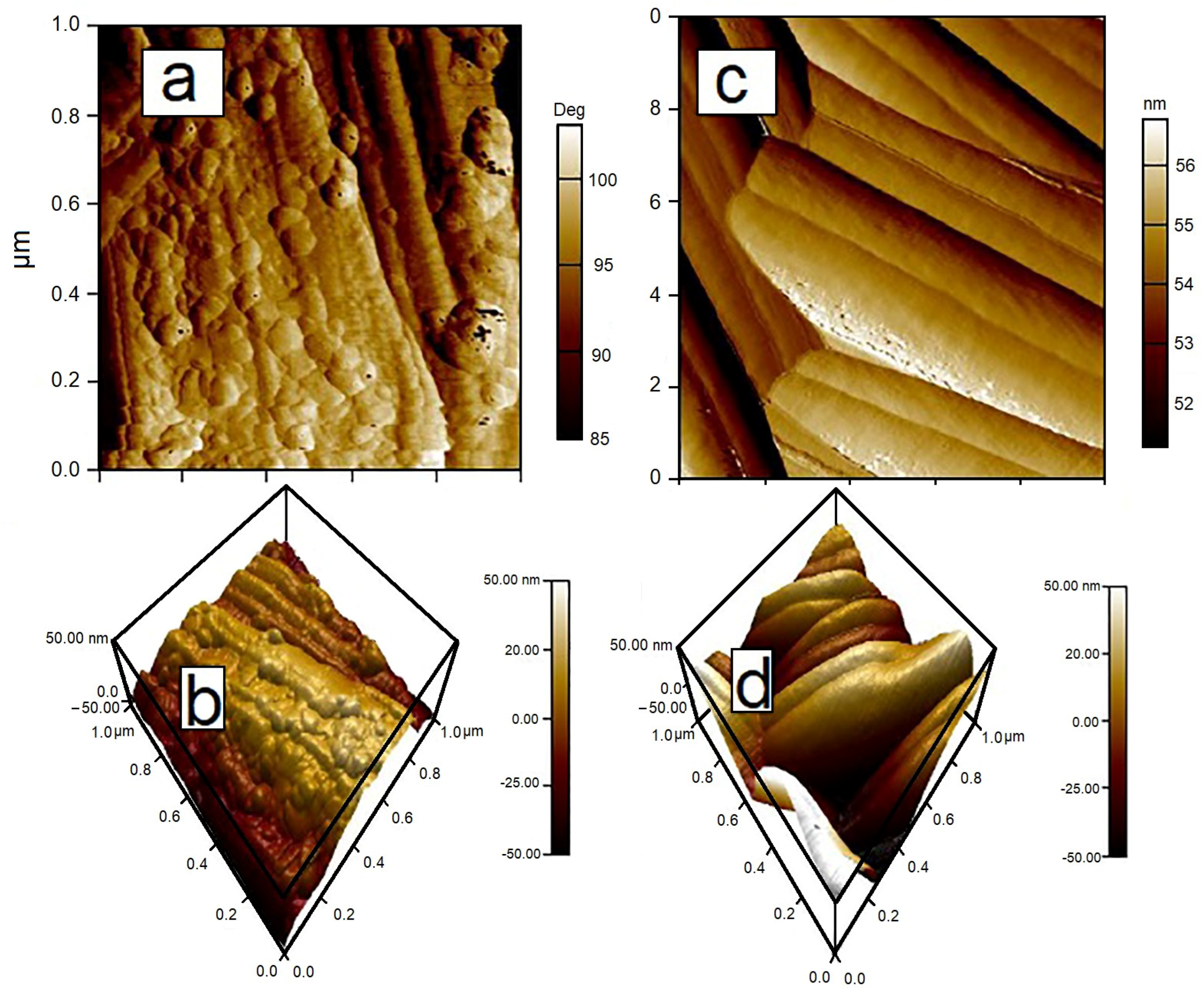

3.3.1. Morphological Analysis of CNC/PA Nanocomposites

3.3.2. Thermal Behavior of the CNC/PA Films by Solution Casting

3.3.3. Surface Wettability of CNC/PA Films by Solution Casting

3.3.4. Spectroscopic Studies of CNC/PA Films by Solution Casting

3.3.5. Nanoindentation Studies of PA/CNC Films by Solution Casting

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Babu, R.P.; Oconnor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [PubMed]

- Kargarzadeh, H.; Mariano, M.; Huang, J.; Lin, N.; Ahmad, I.; Dufresne, A.; Thomas, S. Recent developments on nanocellulose reinforced polymer nanocomposites: A review. Polymer 2017, 132, 368–393. [Google Scholar] [CrossRef]

- Kargarzadeha, H.; Huang, J.; Lin, N.; Ahmad, I.; Mariano, M.; Dufresne, A.; Thomas, S.; Gałęski, A. Recent developments in nanocellulose-based biodegradablepolymers, thermoplastic polymers, and porous nanocomposites. Prog. Polym. Sci. 2018, 87, 197–227. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Mohamed, Y.S.; El-Gamal, H. Fatigue and tensile behaviors of fiber-reinforced thermosetting composites embedded with nanoparticles. J. Compos. Mater. 2019, 53, 709–718. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Sheltami, R.M.; Ahmad, I.; Abdullah, I.; Dufresne, A. Cellulose nanocrystal: A promising toughening agent for unsaturated polyester nanocomposite. Polymer 2015, 56, 346–357. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.M.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Developments in polyester composite materials–An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Yu, F.; Fei, X.; He, Y.; Li, H. Poly(lactic acid)-based composite film reinforced with acetylated cellulose nanocrystals and ZnO nanoparticles for active food packaging. Int. J. Biol. Macromol. 2021, 186, 770–779. [Google Scholar] [CrossRef]

- Sunny, T.; Pickering, K.L. Cellulose nanocrystal treatment of aligned short hemp fibre mats for reinforcement in polypropylene matrix composites. Cellulose 2021, 28, 8429–8444. [Google Scholar] [CrossRef]

- Kaboorani, A.; Gray, N.; Hamzeh, Y.; Abdulkhani, A.; Shirmohammadli, Y. Tailoring the low-density polyethylene—thermoplastic starch composites using cellulose nanocrystals and compatibilizer. Polym. Test. 2021, 93, 107007. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Johar, N.; Ahmad, I. Starch biocomposite film reinforced by multiscale rice husk fiber. Compos. Sci. Technol. 2017, 151, 147–155. [Google Scholar] [CrossRef]

- Sheltami, R.M.; Kargarzadeh, H.; Abdullah, I. Effects of silane surface treatment of cellulose nanocrystals on the tensile properties of cellulose-polyvinyl chloride nanocomposite. Sains Malays. 2015, 44, 801–810. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Pinkl, S.; Gindl-Altmutter, W. Application of surface chemical functionalized cellulose nanocrystals to improve the performance of UF adhesives used in wood based composites—MDF type. Carbohydr. Polym. 2019, 206, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Rafique, F.Z.; Vasanthan, N. Crystallization, Crystal Structure, and Isothermal Melt Crystallization Kinetics of Novel Polyamide 6/SiO2 Nanocomposites Prepared Using the Sol–Gel Technique. J. Phys. Chem. 2014, 118, 9486–9495. [Google Scholar] [CrossRef] [PubMed]

- Kausar, A. Polyamide/nanosilica nanocomposite: A chronicle of design and high-tech progressions. Mater. Res. Innov. 2022, 26, 52–63. [Google Scholar] [CrossRef]

- Zhang, X.; Loo, L.S. Morphology and mechanical properties of a novel amorphous polyamide/nanoclay nanocomposite. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 2605–2617. [Google Scholar] [CrossRef]

- Lee, H.S.; Im, S.J.; Kim, J.H.; Kim, H.J.; Min, B.R. Polyamide thin-film nanofiltration membranes containing TiO2 nanoparticles. Desalination 2008, 219, 48–56. [Google Scholar] [CrossRef]

- Mahmood, N.; Islam, M.; Hameed, A.; Saeed, S. Polyamide 6/multiwalled carbon nanotubes nanocomposites with modified morphology and thermal properties. Polymers 2013, 5, 1380–1391. [Google Scholar] [CrossRef]

- Zuppolini, S.; Cruz-Maya, I.; Guarino, V.; Borriello, A. Optimization of polydopamine coatings onto poly–ε–caprolactone electrospun fibers for the fabrication of bio-electroconductive interfaces. J. Funct. Biomater. 2020, 11, 19. [Google Scholar] [CrossRef]

- Thakkar, S.; Misra, M. Electrospun polymeric nanofibers: New horizons in drug delivery. Eur. J. Pharm. Sci. 2017, 107, 148–167. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Tanvir, A.; Popelka, A.; Moffat, J.; Mahmoud, K.A.; Krupa, I. The preparation, properties and applications of electrospun co-polyamide 6,12 membranes modified by cellulose nanocrystals. Mater. Des. 2017, 132, 314–323. [Google Scholar] [CrossRef]

- Qua, E.H.; Hornsby, P.R.; Sharma, H.S.S.; Lyons, G. Preparation and characterisation of cellulose nanofibres. J. Mater. Sci. 2011, 46, 6029–6045. [Google Scholar] [CrossRef]

- Sridhara, P.K.; Masso, F.; Olsén, P.; Vilaseca, F. Strong polyamide-6 nanocomposites with cellulose nanofibers mediated by green solvent mixtures. Nanomaterials 2021, 11, 2127. [Google Scholar] [CrossRef] [PubMed]

- Aitha, S.; Vasanthan, N. Effect of cellulose nanocrystals on crystallization, morphology and phase transition of polyamide 6. Compos. Interfaces 2019, 27, 371–384. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Park, B.-D. Optimum oxidation for direct and efficient extraction of carboxylated cellulose nanocrystals from recycled MDF fibers by ammonium persulfate. Carbohydr. Polym. 2020, 251, 117029. [Google Scholar] [CrossRef] [PubMed]

- Khanjanzadeh, H.; Park, B.-D. Characterization of Carboxylated Cellulose Nanocrystals from Recycled Fiberboard Fibers Using Ammonium Persulfate Oxidation. J. Korean Wood Sci. Technol. 2020, 48, 231–244. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Ioelovich, M.; Ahmad, I.; Thomas, S.; Dufresne, A. Methods fro extraction of nanocellulose from various sources. In Hanbook of Nanocellulose and Cellulose Nanocomposites; Kargarzadeh, H., Ed.; Wiley: Weinheim, Germany, 2017; pp. 1–49. [Google Scholar]

- Nasser, R.A.; Salem, M.Z.M.; Hiziroglu, S.; Al-Mefarrej, H.A.; Mohareb, A.S.; Alam, M.; Aref, I.M. Chemical Analysis of Different Parts of Date Palm (Phoenix dactylifera L.) Using Ultimate, Proximate and Thermo-Gravimetric Techniques for Energy Production. Energies 2016, 9, 374. [Google Scholar] [CrossRef]

- Sheltami, R.M.; Abdullah, I.; Ahmad, I.; Dufresne, A.; Kargarzadeh, H. Extraction of cellulose nanocrystals from mengkuang leaves (Pandanus tectorius). Carbohydr. Polym. 2012, 88, 772–779. [Google Scholar] [CrossRef]

- Brito, B.S.L.; Pereira, F.; Putaux, J.-L.; Jean, B. Preparation, morphology and structure of cellulose nanocrystals from bamboo fibers. Cellulose 2012, 19, 1527–1536. [Google Scholar] [CrossRef]

- Lu, P.; Hsieh, Y. Preparation and characterization of cellulose nanocrystals from rice straw. Carbohydr. Polym. 2012, 87, 564–573. [Google Scholar] [CrossRef]

- Elazzouzi-Hafraoui, S.; Nishiyama, Y.; Putaux, J.-L.; Heux, L.; Dubreuil, F.; Rochas, C. The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 2008, 9, 57–65. [Google Scholar] [CrossRef]

- Silvério, H.A.; Neto, W.P.F.; Dantas, N.O.; Pasquini, D. Extraction and characterization of cellulose nanocrystals from corncob for application as reinforcing agent in nanocomposites. Ind. Crop. Prod. 2013, 44, 427–436. [Google Scholar] [CrossRef]

- Mbuli, B.S.; Nxumalo, E.N.; Mhlanga, S.D.; Krause, R.W.; Pillay, V.L.; Oren, Y.; Linder, C.; Mamba, B.B. Development of antifouling polyamide thin-film composite membranes modified with amino-cyclodextrins and diethylamino-cyclodextrins for water treatment. J. Appl. Polym. Sci. 2014, 131, 1–10. [Google Scholar] [CrossRef]

- Adeniyi, A.; Onyango, M.; Bopape, M. Impact of nodular structure in characterization of three thin film composite membranes made from 1, 2-benzisothiazol-3 (2H)-one, sodium salt. J. Mater. Environ. Sci. 2019, 10, 213–224. [Google Scholar]

- Raposo, M.; Ferreira, Q.; Ribeiro, P. A Guide for Atomic Force Microscopy Analysis of Soft- Condensed Matter. Mod. Res. Educ. Top. Microsc. 2007, 1, 758–769. [Google Scholar]

- Ghobeira, R.; Asadian, M.; Vercruysse, C.; Declercq, H.; De Geyter, N.; Morent, R. Wide-ranging diameter scale of random and highly aligned PCL fibers electrospun using controlled working parameters. Polymer 2018, 157, 19–31. [Google Scholar] [CrossRef]

- Jordan, J.H.; Easson, M.W.; Condon, B.D. Alkali hydrolysis of sulfated cellulose nanocrystals: Optimization of reaction conditions and tailored surface charge. Nanomaterials 2019, 9, 1232. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Sinha-Ray, S. A review on biopolymer-based fibers via electrospinning and solution blowing and their applications. Fibers 2018, 6, 45. [Google Scholar]

- Gong, X.; Kalantari, M.; Aslanzadeh, S.; Boluk, Y. Interfacial interactions and electrospinning of cellulose 524 nanocrystals dispersions in polymer solutions: A review. J. Dispers. Sci. Technol. 2020, 43, 945–977. [Google Scholar] [CrossRef]

- Rosace, G.; Castellano, A.; Trovato, V.; Iacono, G.; Malucelli, G. Thermal and flame retardant behaviour of cotton fabrics treated with a novel nitrogen-containing carboxyl-functionalized organophosphorus system. Carbohydr. Polym. 2018, 196, 348–358. [Google Scholar] [CrossRef]

- Ng, H.-M.; Sin, L.T.; Bee, S.-T.; Tee, T.-T.; Rahmat, A.R. Review of Nanocellulose Polymer Composite Characteristics and Challenges. Polym.-Plast. Technol. Eng. 2017, 56, 687–731. [Google Scholar] [CrossRef]

- Shim, M.H.; Kim, J.; Park, C.-H. The effects of surface energy and roughness on the hydrophobicity of woven fabrics. Text. Res. J. 2014, 4, 1268–1278. [Google Scholar] [CrossRef]

- Gan, P.G.; Sam, S.T.; Bin Abdullah, M.F.; Omar, M.F. Thermal properties of nanocellulose-reinforced composites: A review. J. Appl. Polym. Sci. 2020, 137, 48544. [Google Scholar] [CrossRef]

- Rogulska, M.; Kultys, A.; Olszewska, E. New thermoplastic poly(thiourethane-urethane) elastomers based on hexane-1,6-diyl diisocyanate (HDI). J. Therm. Anal. Calorim. 2013, 114, 903–916. [Google Scholar] [CrossRef]

- De Campos Vidal, B.; Mello, M.L.S. Collagen type I amide I band infrared spectroscopy. Micron 2011, 42, 283–289. [Google Scholar] [CrossRef] [PubMed]

- Balan, V.; Mihai, C.-T.; Cojocaru, F.-D.; Uritu, C.-M.; Dodi, G.; Botezat, D.; Gardikiotis, I. Vibrational spectroscopy fingerprinting in medicine: From molecular to clinical practice. Materials 2019, 12, 2884. [Google Scholar] [CrossRef] [PubMed]

- Tharayil, A.; Banerjee, S.; Kar, K.K. Dynamic mechanical properties of zinc oxide reinforced linear low density polyethylene composites. Mater. Res. Express 2019, 6, 055301. [Google Scholar] [CrossRef]

| Chemical Composition of Date Palm Leaves | ||

|---|---|---|

| 1 | Cellulose(%) | 47.14 |

| 2 | Hemicellulose (%) | 16.13 |

| 3 | Lignin (%) | 36.73 |

| 4 | Total extractive (%) | 32.86 |

| 5 | Ash content (%) | 15.2 |

| Physical Properties of Date Palm Leaves | ||

| 1 | Ignition Temperature (°C) | 279 |

| 2 | Peak Temperature (°C) | 467 |

| 3 | Energetic density (GJ/m3) | 820 |

| 4 | Fuel value index | 53 |

| Sample | Max Depth (µm) | Stiffness (N/m) | Hardness |

|---|---|---|---|

| Neat PA | 0.68 | 136.84 ± 5.50 | 2.62 ± 0.15 MPa |

| 1 wt% CNC | 1.97 | 65.00 ± 2.00 | 452.00 ± 3.00 kPa |

| 2.5 wt% CNC | 1.15 | 14.87 ± 1.00 | 103.00 ± 2.50 kPa |

| 5 wt% CNC | 0.92 | 139.00 ± 4.00 | 1.54 ± 0.10 MPa |

| Sample | Max Depth | Stiffness (kN/m) | Hardness (MPa) |

|---|---|---|---|

| Neat PA | 1.21 µm | 1.72 ± 0.50 | 15 ± 2.00 |

| 1 wt% CNC | 343 nm | 6.36 ± 1.50 | 158 ± 3.00 |

| 2.5 wt% CNC | 443 nm | 6.12 ± 1.00 | 158 ± 3.00 |

| 5 wt% CNC | 350 nm | 6.73 ± 1.00 | 161 ± 2.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jose, C.; Anju, T.R.; Tharayil, A.; Sobolciak, P.; Krupa, I.; Al Maadeed, M.A.A.; Kargarzadeh, H.; Thomas, S. Date Palm Cellulose Nanocrystals (CNCs)/Polyamide Composites: Tailoring Morphological, Mechanical, and Thermal Properties. J. Compos. Sci. 2023, 7, 17. https://doi.org/10.3390/jcs7010017

Jose C, Anju TR, Tharayil A, Sobolciak P, Krupa I, Al Maadeed MAA, Kargarzadeh H, Thomas S. Date Palm Cellulose Nanocrystals (CNCs)/Polyamide Composites: Tailoring Morphological, Mechanical, and Thermal Properties. Journal of Composites Science. 2023; 7(1):17. https://doi.org/10.3390/jcs7010017

Chicago/Turabian StyleJose, Cintil, Thoppil Raveendran Anju, Abhimanyu Tharayil, Patrik Sobolciak, Igor Krupa, Mariam Al Ali Al Maadeed, Hanieh Kargarzadeh, and Sabu Thomas. 2023. "Date Palm Cellulose Nanocrystals (CNCs)/Polyamide Composites: Tailoring Morphological, Mechanical, and Thermal Properties" Journal of Composites Science 7, no. 1: 17. https://doi.org/10.3390/jcs7010017

APA StyleJose, C., Anju, T. R., Tharayil, A., Sobolciak, P., Krupa, I., Al Maadeed, M. A. A., Kargarzadeh, H., & Thomas, S. (2023). Date Palm Cellulose Nanocrystals (CNCs)/Polyamide Composites: Tailoring Morphological, Mechanical, and Thermal Properties. Journal of Composites Science, 7(1), 17. https://doi.org/10.3390/jcs7010017