Dielectric Properties and Energy Storage of Hybrid/Boron Nitride/Titanium Carbide/Epoxy Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

3. Results

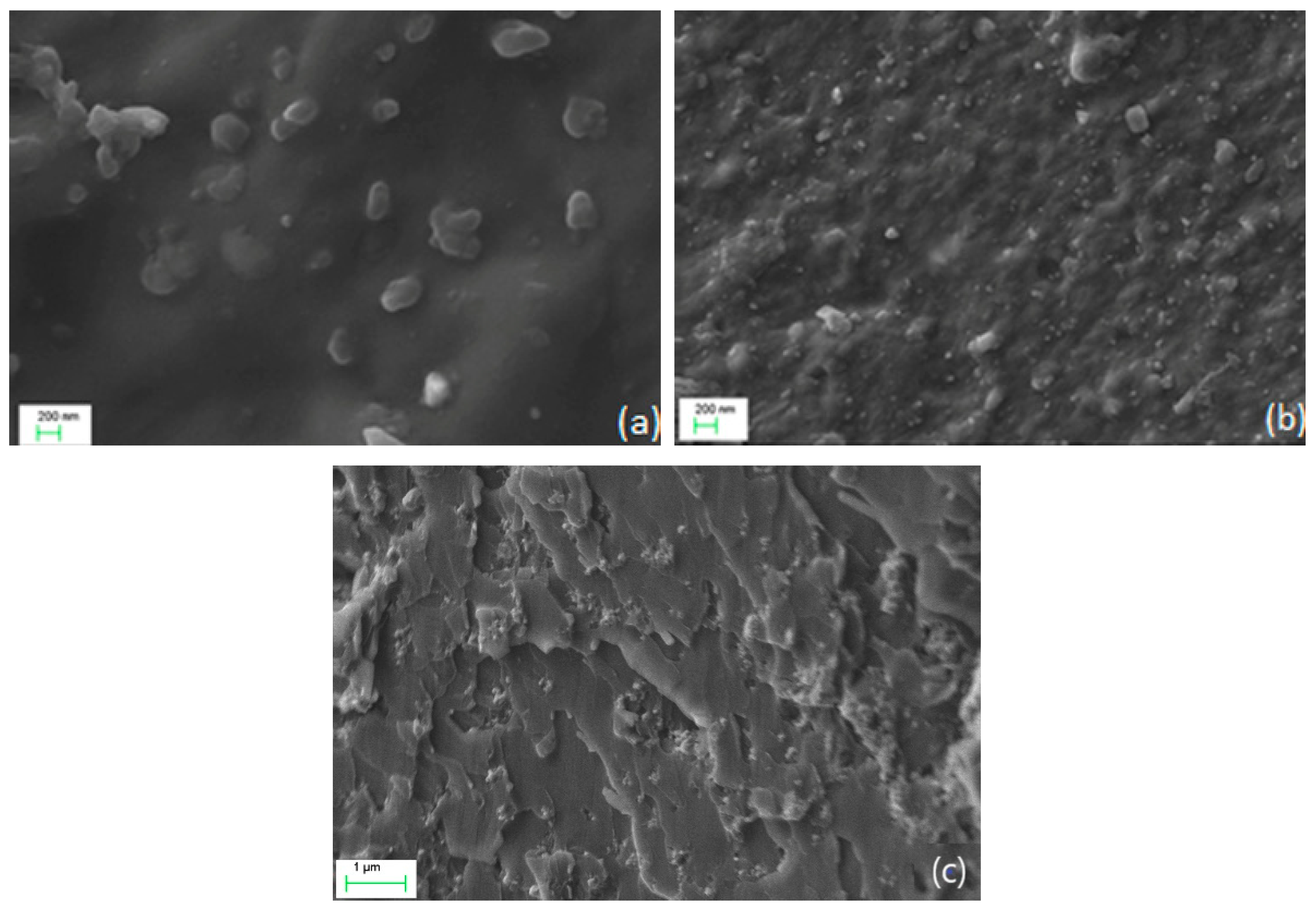

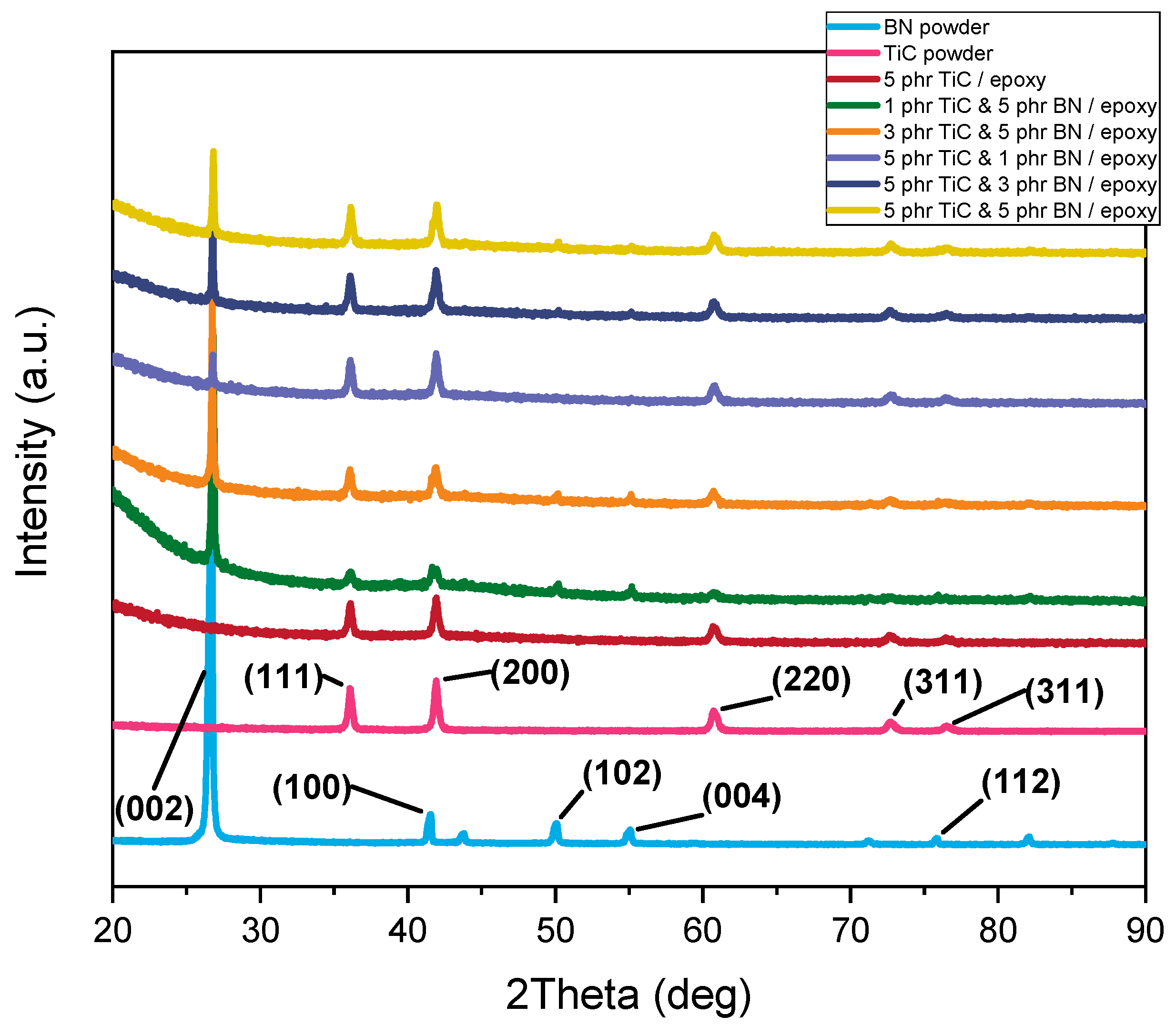

3.1. Morphological and Structural Characterization of TiC/h-BN/Epoxy Systems

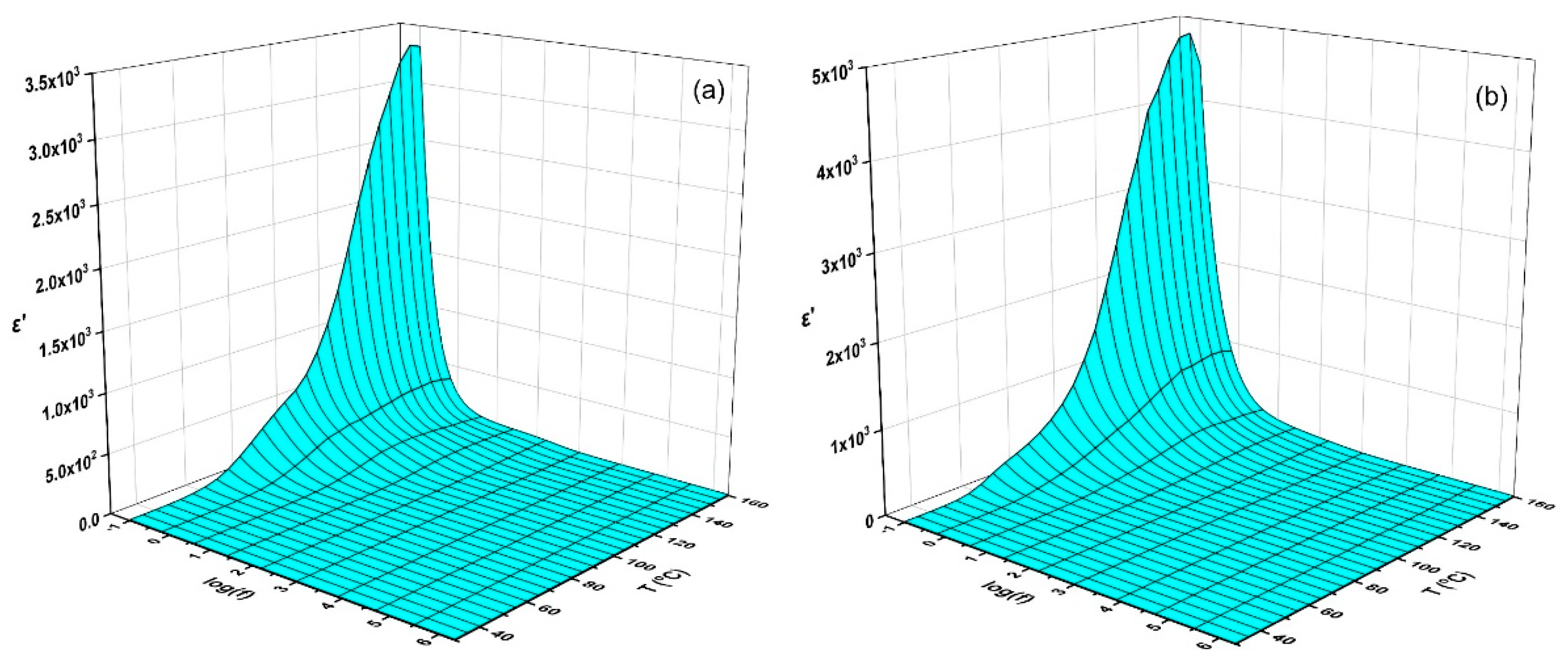

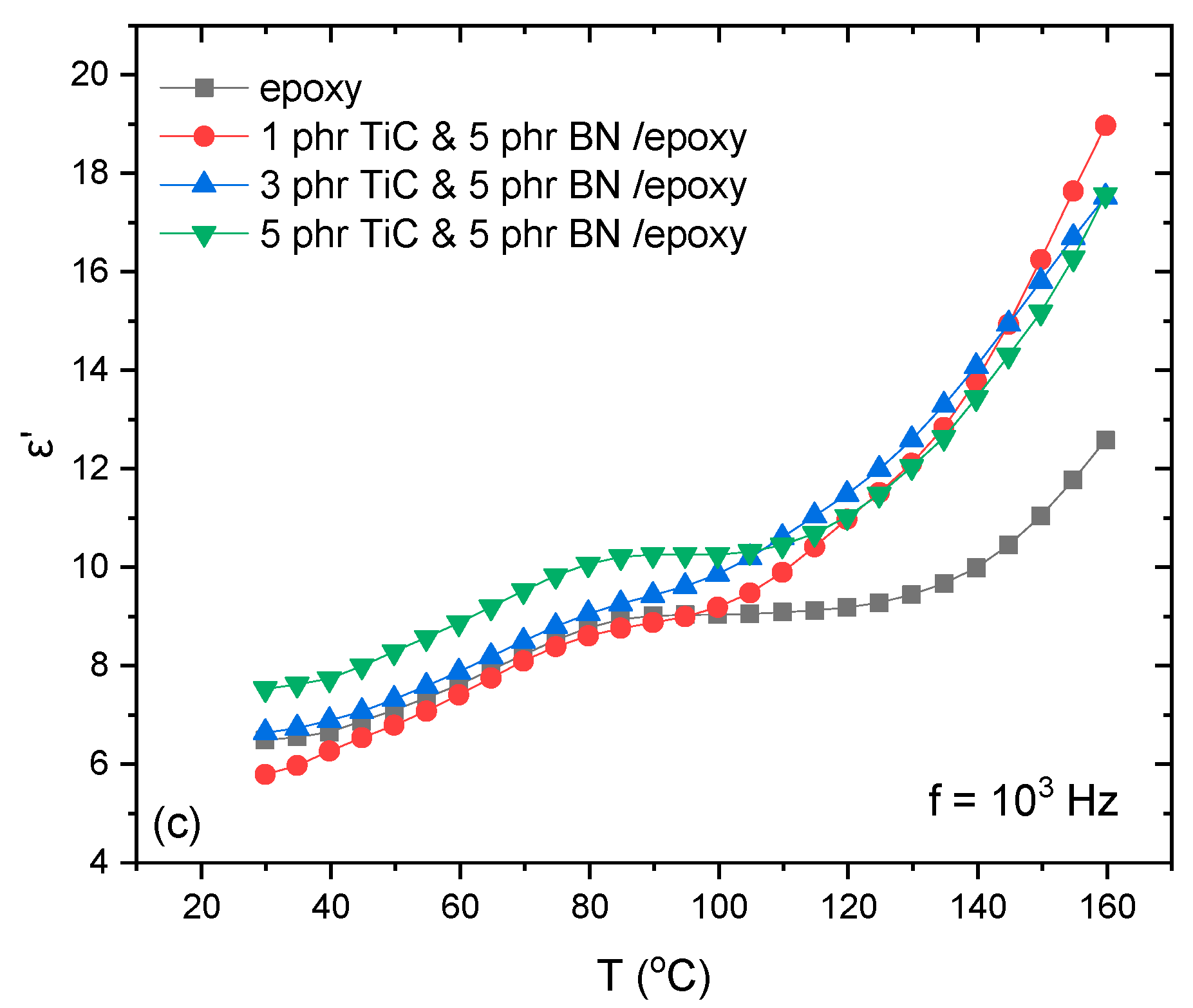

3.2. Dielectric Response of TiC/h-BN/Epoxy Systems

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, K.; Guo, J.Z.; Liu, C. Polymer-Based Multifunctional Nanocomposites and Their Applications; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128150672. [Google Scholar]

- Friedrich, K. Routes for achieving multifunctionality in reinforced polymers and composite structures. In Multifunctionality of Polymer Composites; Friedrich, K., Breuer, U., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 3–41. ISBN 978-0-323-26434-1. [Google Scholar]

- Chen, S.; Skordos, A.; Thakur, V. Functional nanocomposites for energy storage: Chemistry and new horizons. Mater. Today Chem. 2020, 17, 100304. [Google Scholar] [CrossRef]

- Sanida, A.; Stavropoulos, S.G.; Speliotis, T.; Psarras, G.C. Evaluating the multifunctional performance of polymer matrix nanodielectrics incorporating magnetic nanoparticles: A comparative study. Polymer 2021, 236, 124311. [Google Scholar] [CrossRef]

- Gioti, S.; Sanida, A.; Mathioudakis, G.N.; Patsidis, A.C.; Speliotis, T.; Psarras, G.C. Multitasking Performance of Fe3O4/BaTiO3/Epoxy Resin Hybrid Nanocomposites. Materials 2022, 15, 1784. [Google Scholar] [CrossRef] [PubMed]

- Dang, Z.-M.; Yuan, J.-K.; Yao, S.-H.; Liao, R.-J. Flexible Nanodielectric Materials with High Permittivity for Power Energy Storage. Adv. Mater. 2013, 25, 6334–6365. [Google Scholar] [CrossRef] [PubMed]

- Thakur, V.K.; Gupta, R.K. Recent Progress on Ferroelectric Polymer-Based Nanocomposites for High Energy Density Capacitors: Synthesis, Dielectric Properties, and Future Aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar]

- Manika, G.C.; Psarras, G.C. Barium titanate/epoxy resin composite nanodielectrics as compact capacitive energy storing systems. Express Polym. Lett. 2019, 13, 749–758. [Google Scholar] [CrossRef]

- Psarras, G.C. Nanodielectrics: An emerging sector of polymer nanocomposites. Express Polym. Lett. 2008, 2, 460. [Google Scholar] [CrossRef]

- Gibson, G. Epoxy Resins, Brydson’s Plastics Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 773–797. [Google Scholar]

- Patsidis, A.C.; Psarras, G.C. Dielectric and Conductivity Studies of Epoxy Composites. In Epoxy Composites: Fabrication, Characterization and Applications, 1st ed.; Parameswaranpillai, J., Pulikkalparambil, H., Rangappa, S.M., Siengchin, S., Eds.; WILEY-VCH GmbH: Weinheim, Germany, 2021; pp. 299–348. ISBN 9783527824083. [Google Scholar]

- Wang, J.; Ma, F.; Sun, M. Graphene, hexagonal boron nitride, and their heterostructures: Properties and applications. RSC Adv. 2017, 7, 16801–16822. [Google Scholar] [CrossRef]

- Chang, H.; Wu, H. Graphene-based nanocomposites: Preparation, functionalization, and energy and environmental applications. Energy Environ. Sci. 2013, 6, 3483–3507. [Google Scholar] [CrossRef]

- Raptis, C.G.; Patsidis, A.; Psarras, G.C. Electrical response and functionality of polymer matrix-titanium carbide composites. Express Polym. Lett. 2010, 4, 234–243. [Google Scholar] [CrossRef]

- Liu, Y.; Oshima, K.; Yamauchi, T.; Shimomura, M.; Miyauchi, S. Temperature-conductivity characteristics of the composites consisting of fractionated poly(3-hexylthiophene) and conducting particles. J. Appl. Polym. Sci. 2000, 77, 3069–3076. [Google Scholar] [CrossRef]

- Sung, Y.K.; El-Tantawy, F. Novel smart polymeric composites for thermistors and electromagnetic wave shielding effectiveness from TiC loaded styrene-butadiene rubber. Macromol. Res. 2002, 10, 345–358. [Google Scholar] [CrossRef]

- El-Tantawy, F. New double negative and positive temperature coefficients of conductive epdm rubber TiC ceramic composites. Eur. Polym. J. 2002, 38, 567–577. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, D.; Gong, S. Dielectric behavior of TiC-PVDF nanocomposites. Phys. Status Solid Rapid Res. Lett. 2009, 3, 22–24. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Qin, S.; Xue, Q.; Zhao, H.; Wang, L. Non-covalent functionalized hexagonal boron nitride nanoplatelets to improve corrosion and wear resistance of epoxy coatings. RSC Adv. 2017, 7, 44043–44053. [Google Scholar] [CrossRef]

- Chen, T.M.; Xiao, J.; Yang, G.W. Cubic boron nitride with an intrinsic peroxidase-like activity. RSC Adv. 2016, 6, 70124. [Google Scholar] [CrossRef]

- Swanson, H.E.; McMurdie, H.F.; Morris, M.C.; Evans, E.H. Standard X-ray Diffraction Powder Patterns: NBS Monograph 25—Section 5; National Bureau of Standards Reports; Government Printing Office: Gaithersburg, MD, USA; Washington, DC, USA, 1967.

- Psarras, G.C. Conductivity and dielectric characterization of polymer nanocomposites. In Physical Properties and Applications of Polymer Nanocomposites; Tjong, S.C., Mai, Y.-W., Eds.; Woodhead Publishing: Cambridge, MA, USA, 2010; pp. 31–69. ISBN 9781845696726. [Google Scholar]

- Kalini, A.; Gatos, K.G.; Karahaliou, P.K.; Georga, S.N.; Krontiras, C.A.; Psarras, G.C. Probing the Dielectric Response of Polyurethane/Alumina Nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 2346–2354. [Google Scholar] [CrossRef]

- Vryonis, O.; Anastassopoulos, D.L.; Vradis, A.A.; Psarras, G.C. Dielectric response and molecular dynamics in epoxy-BaSrTiO3 nanocomposites: Effect of nanofiller loading. Polymer 2016, 95, 82–90. [Google Scholar] [CrossRef]

- Steeman, P.A.M.; van Turnhout, J. Dielectric properties of inhomogeneous media. In Broadband Dielectric Spectroscopy; Kremer, F., Schonhals, A., Eds.; Spinger: Berlin, Germany, 2003; pp. 495–522. ISBN 3-540-43407-0. [Google Scholar]

- Jonscher, A.K. Universal Relaxation Law; Chelsea Dielectrics Press: London, UK, 1992; Chapter 5. [Google Scholar]

- Dyre, J.C.; Schrøder, T.B. Hopping models and ac universality. Phys. Stat. Sol. B 2002, 230, 5–13. [Google Scholar] [CrossRef]

- Psarras, G.C. Hopping conductivity in polymer matrix–metal particles composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1545–1553. [Google Scholar] [CrossRef]

- Tsangaris, G.M.; Psarras, G.C.; Manolakaki, E. DC and AC conductivity in polymeric particulate composites. Adv. Comp. Letts. 1999, 8, 25–29. [Google Scholar]

- Konstantinou, A.C.; Patsidis, A.C.; Psarras, G.C. Boron nitride/epoxy resin nanocomposites: Development, characterization and functionality. J. Therm. Anal. Calorim. 2021, 145, 2925–2933. [Google Scholar] [CrossRef]

- Tsangaris, G.M.; Psarras, G.C.; Kouloumbi, N. Electric modulus and interfacial polarization in composite polymeric systems. J. Mater. Sci. 1998, 33, 2027–2037. [Google Scholar] [CrossRef]

- Hernández, M.; Carretero-González, J.; Verdejo, R.; Ezquerra, T.A.; López-Manchado, M.A. Molecular dynamics of natural rubber/layered silicate nanocomposites as studied by dielectric relaxation spectroscopy. Macromolecules 2010, 43, 643–651. [Google Scholar] [CrossRef]

- Belattar, J.; Achour, M.E.; Brosseau, C. A comparison between the permittivity and electric modulus representations of the microwave response of carbon black loaded polymer composites under uniaxial tension. J. Appl. Phys. 2011, 110, 054101. [Google Scholar] [CrossRef]

- Koufakis, E.; Mathioudakis, G.N.; Patsidis, A.C.; Psarras, G.C. ZnTiO3/epoxy resin nanocomposites: Development, dielectric behaviour and functionality. Polym. Test. 2019, 77, 105870. [Google Scholar] [CrossRef]

- Peng, X.; Liu, X.; Qu, P.; Yang, B. Enhanced breakdown strength and energy density of PVDF composites by introducing boron nitride nanosheets. J. Mater. Sci. Mater. Electron. 2018, 29, 16799–16804. [Google Scholar] [CrossRef]

- Mijović, J.; Lee, H.K.; Kenny, J.; Mays, J. Dynamics in polymer-silicate nanocomposites as studied by dielectric relaxation spectroscopy and dynamic mechanical spectroscopy. Macromolecules 2006, 39, 2172–2182. [Google Scholar] [CrossRef]

- Sanida, A.; Stavropoulos, S.G.; Speliotis, T.; Psarras, G.C. Development, characterization, energy storage and interface dielectric properties in SrFe12O19/epoxy nanocomposites. Polymer 2017, 120, 73–81. [Google Scholar] [CrossRef]

- Drakopoulos, S.X.; Patsidis, A.C.; Psarras, G.C. Epoxy-based/BaTiO3 nanodielectrics: Relaxation dynamics, charge transport and energy storage. Mater. Res. Bull. 2022, 145, 111537. [Google Scholar] [CrossRef]

- Stavropoulos, S.G.; Sanida, A.; Psarras, G.C. Assessing the effect of Fe3O4 nanoparticles on the thermomechanical performance of different forms of carbon allotropes/epoxy hybrid nanocomposites. Appl. Mech. 2022, 3, 560–572. [Google Scholar] [CrossRef]

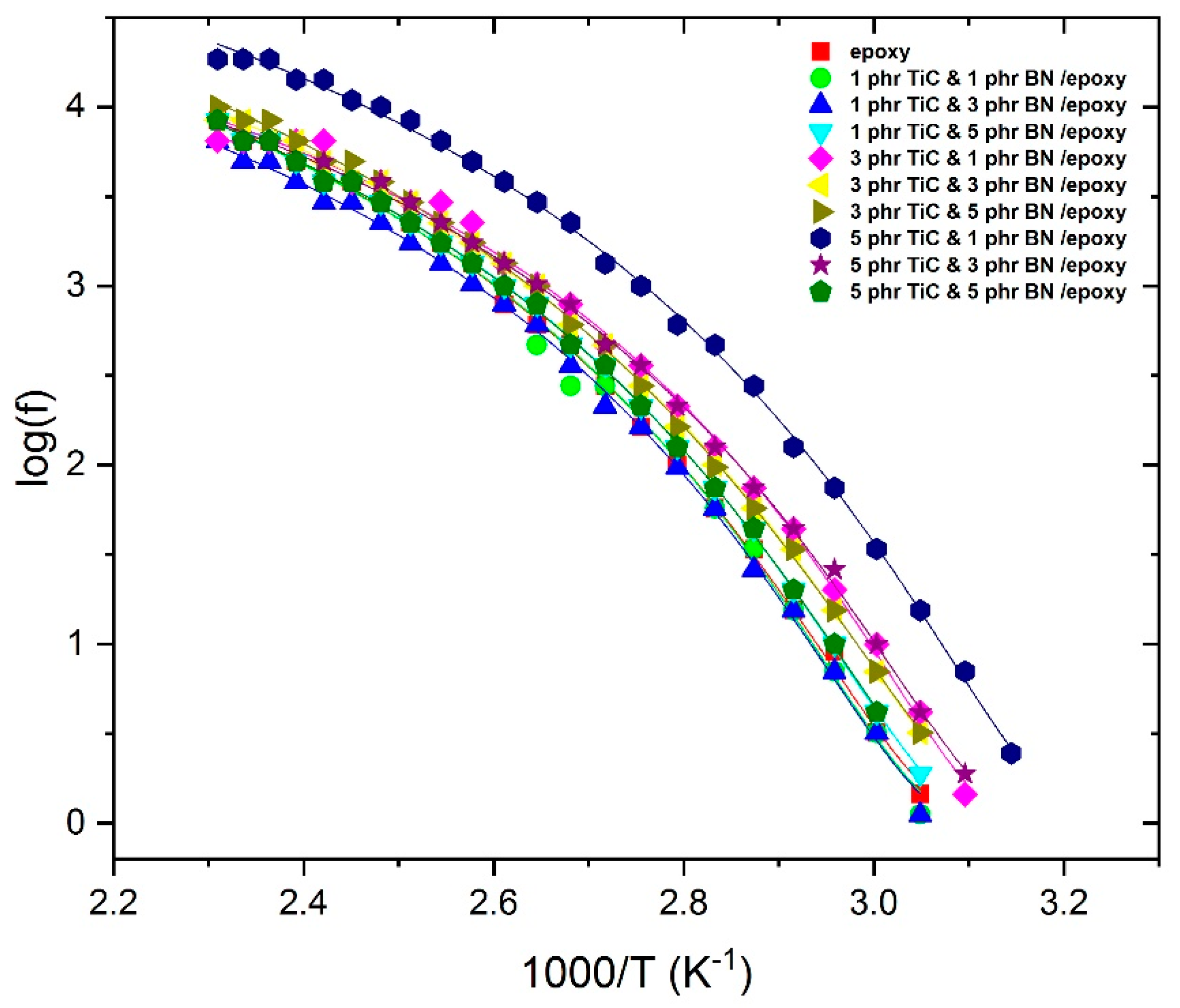

| Sample | T0 (K) | B (K) | R2 |

|---|---|---|---|

| epoxy | 313.6 ± 0.5 | 46.5 ± 0.4 | 0.998 |

| 1 phr TiC & 1 phr BN/epoxy | 315.4 ± 0.4 | 44.2 ± 0.3 | 0.997 |

| 1 phr TiC & 3 phr BN/epoxy | 315.8 ± 0.4 | 42.8 ± 0.3 | 0.997 |

| 1 phr TiC & 5 phr BN/epoxy | 313.1 ± 0.3 | 44.0 ± 0.2 | 0.998 |

| 3 phr TiC & 1 phr BN/epoxy | 310.6 ± 0.4 | 39.5 ± 0.3 | 0.998 |

| 3 phr TiC & 3 phr BN/epoxy | 309.4 ± 0.3 | 45.5 ± 0.3 | 0.998 |

| 3 phr TiC & 5 phr BN/epoxy | 308.4 ± 0.5 | 48.2 ± 0.5 | 0.997 |

| 5 phr TiC & 1 phr BN/epoxy | 302.5 ± 0.6 | 41.6 ± 0.5 | 0.997 |

| 5 phr TiC & 3 phr BN/epoxy | 308.8 ± 0.5 | 41.6 ± 0.4 | 0.998 |

| 5 phr TiC & 5 phr BN/epoxy | 312.6 ± 0.4 | 44.8 ± 0.3 | 0.998 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blatsi, C.; Patsidis, A.C.; Psarras, G.C. Dielectric Properties and Energy Storage of Hybrid/Boron Nitride/Titanium Carbide/Epoxy Nanocomposites. J. Compos. Sci. 2022, 6, 259. https://doi.org/10.3390/jcs6090259

Blatsi C, Patsidis AC, Psarras GC. Dielectric Properties and Energy Storage of Hybrid/Boron Nitride/Titanium Carbide/Epoxy Nanocomposites. Journal of Composites Science. 2022; 6(9):259. https://doi.org/10.3390/jcs6090259

Chicago/Turabian StyleBlatsi, Chryssanthi, Anastasios C. Patsidis, and Georgios C. Psarras. 2022. "Dielectric Properties and Energy Storage of Hybrid/Boron Nitride/Titanium Carbide/Epoxy Nanocomposites" Journal of Composites Science 6, no. 9: 259. https://doi.org/10.3390/jcs6090259

APA StyleBlatsi, C., Patsidis, A. C., & Psarras, G. C. (2022). Dielectric Properties and Energy Storage of Hybrid/Boron Nitride/Titanium Carbide/Epoxy Nanocomposites. Journal of Composites Science, 6(9), 259. https://doi.org/10.3390/jcs6090259