Prediction of Damage in Non-Crimp Fabric Composites Subjected to Transverse Crushing: A Comparison of Two Constitutive Models

Abstract

1. Introduction

2. Physical Experiments

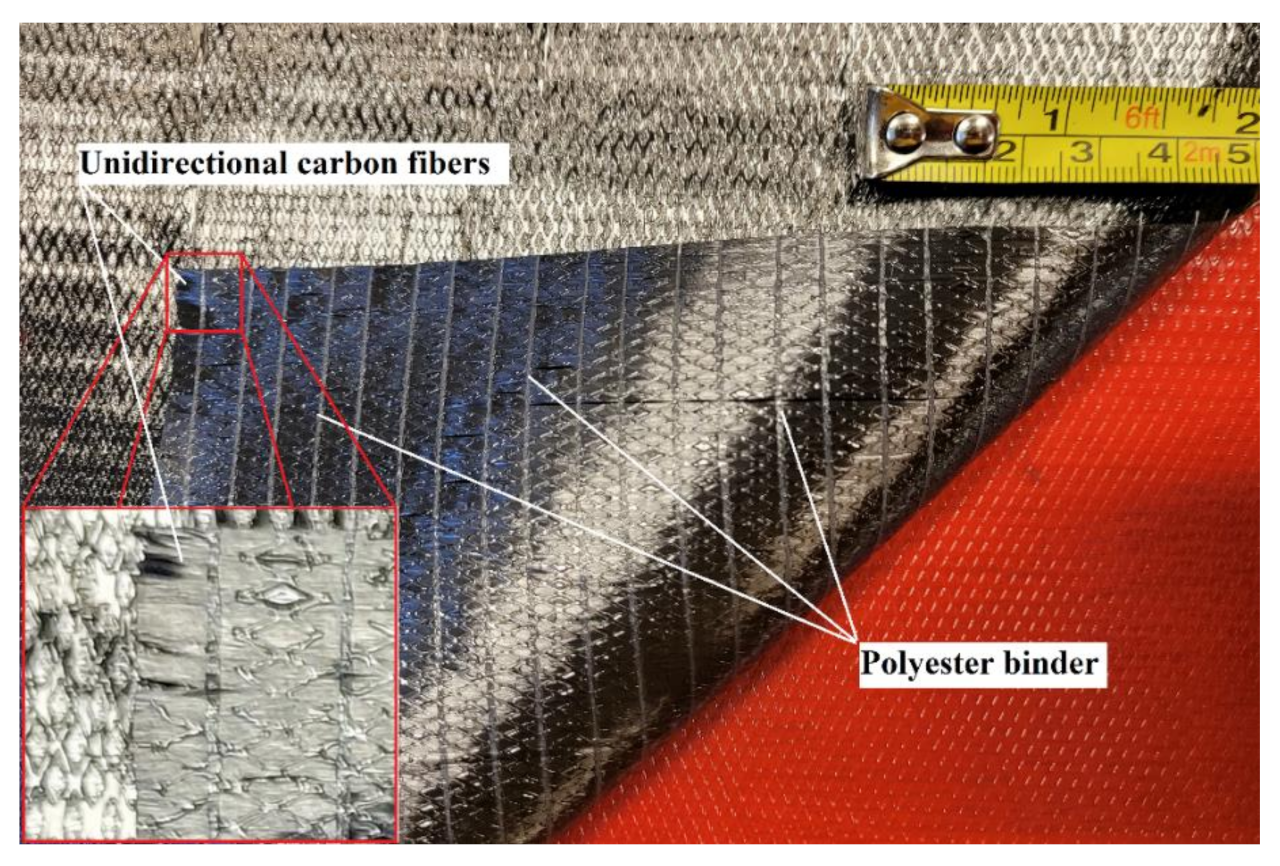

2.1. Materials and Manufacturing

2.2. Material Characterization

2.3. Component Testing

3. Numerical Model

3.1. General Description of the Numerical Model

3.2. Modeling of Intra-Ply Damage

3.2.1. MAT54—*MAT_ENHANCED_COMPOSITE_DAMAGE

- (1)

- (element deletion) parameters;

- (2)

- parameters controlling crashfront softening;

- (3)

- those characterizing material behavior after failure initiation.

3.2.2. MAT58–*MAT_LAMINATED_COMPOSITE_FABRIC

3.3. Modeling of Delamination

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Middendorf, P.; Metzner, C. Aerospace application of non-crimp fabric composites. In Non-Crimp Fabric Composites, Philadelphia; Woodhead Publishing: Sawston, UK, 2011; pp. 441–449. [Google Scholar]

- Sköck-Hartmann, B.; Gries, T. Automotive applications of non-crimp fabric composites. In Non-Crimp Fabric Composites, Philadelphia; Woodhead Publishing: Sawston, UK, 2011; pp. 461–480. [Google Scholar]

- Adolphs, G.; Skinner, C. Non-crimp fabric composites in wind turbines. In Non-Crimp Fabric Composites, Philadelphia; Woodhead Publishing: Sawston, UK, 2011; pp. 481–493. [Google Scholar]

- Mouli, Y.S.C.; Upadhyay, C.S.; Mohite, P.M. Intra-ply Damage Modeling of Low-Velocity Impact on Composite Laminates. In Proceedings of the 1st International Conference on Emerging Trends in Engineering (ICETE), Hyderabad, India, 22–23 March 2020. [Google Scholar]

- Moncayo, E.; Wagner, H.; Drechsler, K. Benchmarks for Composite Delamination Using LS-Dyna 971: Low Velocity Impact. In Proceedings of the 6th LS-DYNA Anwenderforum, Frankental, Germany, 11 October 2007. [Google Scholar]

- Cherniaev, A.; Pavlova, S.; Pavlov, A.; Komarov, V. Prediction of Load-Bearing Capacity of Composite Parts with Low-Velocity Impact Damage: Identification of Intra- and Inter-Ply Constitutive Models. Appl. Mech. 2020, 1, 5. [Google Scholar] [CrossRef]

- Heimbs, S.; Heller, S.; Middendorf, P. Simulation of low velocity impact on composite plates with compressive preload. In LS-DYNA Anwenderforum; DYNAmore GmbH: Banberg, Germany, 2008. [Google Scholar]

- Aymerich, F.; Dore, F.; Priolo, P. Prediction of impact-induced delamination in cross-ply composite laminates using cohesive interface elements. Compos. Sci. Technol. 2008, 68, 2383–2390. [Google Scholar] [CrossRef]

- Di Caprio, F.; Langella, A.; Lopresto, V.; Caprino, G. Numerical, Experimental and Analytical Correlation for Predicting the Structural Behavior of Composite Structures under Impact. Procedia Eng. 2016, 167, 80–87. [Google Scholar] [CrossRef]

- Long, S.; Yao, X.; Zhang, X. Delamination prediction in composite laminates under low-velocity impact. Compos. Struct. 2015, 132, 290–298. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Zhang, Q.; Huili, Y. Study of fiber modulus effect on impact energy absorption characteristics of composite laminates at normal and oblique impacts. Mater. Res. Express 2019, 6, 085610. [Google Scholar] [CrossRef]

- Cherniaev, A.; Butcher, C.; Montesano, J. Predicting the axial crush response of CFRP tubes using three damage-based constitutive models. Thin-Walled Struct. 2018, 129, 349–364. [Google Scholar] [CrossRef]

- Geier, N.; Szalay, T.; Takács, M. Analysis of thrust force and characteristics of uncut fibres at non-conventional oriented drilling of unidirectional carbon fibre-reinforced plastic (UD-CFRP) composite laminates. Int. J. Adv. Manuf. Technol. 2018, 100, 3139–3154. [Google Scholar] [CrossRef]

- Sapozhnikov, S.; Swolfs, Y.; Lomov, S. Pseudo-ductile unidirectional high modulus/high strength carbon fibre hybrids using conventional ply thickness prepregs. Compos. Part B Eng. 2020, 198, 108213. [Google Scholar] [CrossRef]

- Sy, B.L.; Fawaz, Z.; Bougherara, H. Damage evolution in unidirectional and cross-ply flax/epoxy laminates subjected to low velocity impact loading. Compos. Part A Appl. Sci. Manuf. 2018, 112, 452–467. [Google Scholar] [CrossRef]

- Liv, Y.; Guillamet, G.; Costa, J.; González, E.; Marín, L.; Mayugo, J. Experimental study into compression after impact strength of laminates with conventional and nonconventional ply orientations. Compos. Part B Eng. 2017, 126, 133–142. [Google Scholar] [CrossRef]

- Sabah, S.A.; Kueh, A.; Al-Fasih, M. Comparative low-velocity impact behavior of bio-inspired and conventional sandwich composite beams. Compos. Sci. Technol. 2017, 149, 64–74. [Google Scholar] [CrossRef]

- Vignjevic, R.; Campbell, J.; Hughes, K.; Orłowski, M.; Garcea, S.; Withers, P.; Reed, J. Soft body impact resistance of composite foam core sandwich panels with unidirectional corrugated and tubular reinforcements. Int. J. Impact Eng. 2019, 132, 103320. [Google Scholar] [CrossRef]

- Liu, H.; Falzon, B.; Tan, W. Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Compos. Part B Eng. 2018, 136, 101–118. [Google Scholar] [CrossRef]

- Shyr, T.-W.; Pan, Y.-H. Impact resistance and damage characteristics of composite laminates. Compos. Struct. 2003, 62, 193–203. [Google Scholar] [CrossRef]

- Greve, L.; Pickett, A. Modelling damage and failure in carbon/epoxy non-crimp fabric composites including effects of fabric pre-shear. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1983–2001. [Google Scholar] [CrossRef][Green Version]

- Lomov, S.V.; Bogdanovich, A.E.; Ivanov, D.S.; Mungalov, D.; Karahan, M.; Verpoest, I. A comparative study of tensile properties of non-crimp 3D orthogonal weave and multi-layer plain weave E-glass composites. Part 1: Materials, methods and principal results. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1134–1143. [Google Scholar] [CrossRef]

- Segreto, T.; Bottillo, A.; Teti, R. Advanced ultrasonic non-destructive evaluation for metrological analysis and quality assessment of impact damaged non-crimp fabric composites. Procedia CIRP 2016, 41, 1055–1060. [Google Scholar] [CrossRef]

- Bibo, G.; Hogg, P.; Backhouse, R.; Mills, A. Carbon-fibre non-crimp fabric laminates for cost-effective damage-tolerant structures. Compos. Sci. Technol. 1998, 58, 129–143. [Google Scholar] [CrossRef]

- Berketis, K.; Tzetzis, D. The compression-after-impact strength of woven and non-crimp fabric reinforced composites subjected to long-term water immersion ageing. J. Mater. Sci. 2010, 45, 5611–5623. [Google Scholar] [CrossRef]

- Zhao, L.; Warrior, N.; Long, A. Finite element modelling of damage progression in non-crimp fabric reinforced composites. Compos. Sci. Technol. 2006, 66, 36–50. [Google Scholar] [CrossRef]

- Yin, H.; Li, Q.; Iannucci, L. Meso-scale Finite Element (FE) modelling of biaxial carbon fibre non-crimp-fabric (NCF) based composites under uniaxial tension and in-plane shear. Compos. Struct. 2022, 290, 115538. [Google Scholar] [CrossRef]

- Rouf, K.; Worswick, M.J.; Montesano, J. A multiscale framework for predicting the mechanical properties of unidirectional non-crimp fabric composites with manufacturing induced defects. J. Compos. Mater. 2020, 55, 741–757. [Google Scholar] [CrossRef]

- Costa, S.; Bru, T.; Olsson, R.; Portugal, A. Improvement and validation of a physically based model for the shear and transverse crushing of orthotropic composites. J. Compos. Mater. 2018, 53, 1681–1696. [Google Scholar] [CrossRef]

- Gouskos, D.; Iannucci, L. A failure model for the analysis of cross-ply Non-Crimp Fabric (NCF) composites under in-plane loading: Experimental & numerical study. Eng. Fract. Mech. 2022, 271, 108575. [Google Scholar]

- Senner, T.; Kreissl, S.; Merklein, M.; Meinhardt, M.; Lipp, A. Bending of unidirectional non-crimp-fabrics: Experimental characterization, constitutive modeling and application in finite element simulation. Prod. Eng. 2015, 9, 1–10. [Google Scholar] [CrossRef]

- Soto, A.; González, E.V.; Maimí, P.; Escalera, F.M.D.L.; Aja, J.S.D.; Alvarez, E. Low velocity impact and compression after impact simulation of thin ply laminates. Compos. Part A Appl. Sci. Manuf. 2018, 109, 413–427. [Google Scholar] [CrossRef]

- Feraboli, P.; Wade, B.; DeLeo, F.; Rassaian, M.; Higgins, M.; Byar, A. LS-DYNA MAT54 modeling of the axial crushing of a composite tape sinusoidal specimen. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1809–1825. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, B.; Zheng, D.; Li, Z. Experimental and numerical study on energy absorption performance of CFRP/aluminum hybrid square tubes under axial loading. Thin-Walled Struct. 2020, 155, 106948. [Google Scholar] [CrossRef]

- Liu, Q.; Fu, J.; Ma, Y.; Zhang, Y.; Li, Q. Crushing responses and energy absorption behaviors of multi-cell CFRP tubes. Thin-Walled Struct. 2020, 155, 106930. [Google Scholar] [CrossRef]

- Zhou, G.; Tang, H.; Sun, Q.; Li, D.; Peng, Y.; Zeng, D.; Su, X. Analysis of the crushing behaviors of woven carbon fiber reinforced plastic hat section component under dynamic bending and axial crushing loading. Thin-Walled Struct. 2021, 161, 107426. [Google Scholar] [CrossRef]

- Pohl, C.; Toenjes, M.; Liebold, C.; Ploeckl, M.; Koerber, H.; Gray, L.A.; Colin, D.; Drechsler, K. Numerical prediction of composite damage behavior: A modeling approach including the strain-rate-dependent material response. Compos. Struct. 2022, 292, 115628. [Google Scholar] [CrossRef]

- Mansor, M.; Ahmad, Z.; Abdullah, M. Crashworthiness capability of thin-walled fibre metal laminate tubes under axial crushing. Eng. Struct. 2021, 252, 113660. [Google Scholar] [CrossRef]

- Lanzi, L. Composite stiffened panels in postbuckling: Experiments and dynamic explicit analyses with LS-DYNA. In Proceedings of the 30th Europian Rotor Craft Forum, Marseilles, France, 14–16 September 2004. [Google Scholar]

- Xiao, X.; McGregor, C.; Vaziri, R.; Poursartip, A. Progress in braided composite tube crush simulation. Int. J. Impact Eng. 2009, 36, 711–719. [Google Scholar] [CrossRef]

- Jackson, K.E.; Fasanella, E.L.; Littell, J.D. Development of a continuum damage mechanics material model of a graphite-kevlar hybrid fabric for simulating the impact response of energy absorbing subfloor concepts. In Proceedings of the 73rdAHS International Annual Forum & Technology Display, Fort Worth, TX, USA, 9–11 May 2017. [Google Scholar]

- Reiner, J.; Vaziri, R. Progressive Axial Crushing of Composite Laminates: A Comparison Between LS-DYNA Continuum Damage Models. In Proceedings of the American Society for Composites—Thirty-Third Annual Technical Conference, Seattle, WA, USA, 24–26 September 2018. [Google Scholar]

- Panciroli, R.; Giannini, O. Comparing the impact resistance of flax/epoxy and glass/epoxy composites through experiments and numerical simulations. Compos. Struct. 2021, 264, 113750. [Google Scholar] [CrossRef]

- Metin, F.; Avcı, A. In-plane quasi-static and out-of-plane dynamic behavior of nanofiber interleaved glass/epoxy composites and finite element simulation. Compos. Struct. 2021, 270, 114085. [Google Scholar] [CrossRef]

- Yan, J.; Liu, Y.; Yan, Z.; Bai, F.; Shi, Z.; Si, P.; Huang, F. Ballistic characteristics of 3D-printed auxetic honeycomb sandwich panel using CFRP face sheet. Int. J. Impact Eng. 2022, 164, 104186. [Google Scholar] [CrossRef]

- Wei, Q.; Gu, B.; Sun, B. Ballistic penetration damages and energy absorptions of stacked cross-plied composite fabrics and laminated panels. Int. J. Damage Mech. 2020, 29, 1465–1484. [Google Scholar] [CrossRef]

- Yu, H.; Zhao, H.; Shi, F. Bending Performance and Reinforcement of Rocker Panel Components with Unidirectional Carbon Fiber Composite. Materials 2019, 12, 3164. [Google Scholar] [CrossRef]

- No. D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2017.

- Chamis, C.C.; Sinclair, J.H. Ten Deg. Off-Axis Tensile Test for Intralaminar Shear Characterization of Fiber Composites; NASA Technical Note (TN-D-8215); National Aeronautics and Space Administration: Washington, DC, USA, 1976.

- No. D 5528-01 (Reapproved 2007); Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites1. Annual Book of ASTM: West Conshohocken, PA, USA, 2007.

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Characterization of Delamination Failure. In Experimental Characterization of Advanced Composite Materials; CRC Press: Boca Raton, FL, USA, 2014; pp. 250–262. [Google Scholar]

- Lo, K.; Chim, E.-M. Compressive Strength of Unidirectional Composites. J. Reinf. Plast. Compos. 1992, 11, 838–896. [Google Scholar] [CrossRef]

- Chamis, C.C. Simplified composite micromechanics equations for hygral, thermal and mechanical properties. In Proceedings of the Thirty-Eight Annual Conference of Society of the Plastics Industry (SPI) Reinforced Plastics/Composites Institute, Houston, TX, USA, 7–11 February 1983. [Google Scholar]

- Livermore Software Technology Corporation (LSTC). LS-DYNA ® Keyword User’s Manual Volume II: Material Models; LSTC: Canonsburg, PA, USA, 2013. [Google Scholar]

- Matzenmiller, A.; Lubliner, J.; Taylor, L.R. A constitutive model for anisotropic damage in fiber-composites. Mech. Mater. 1995, 20, 125–152. [Google Scholar] [CrossRef]

- Livermore Software Technology Corporation (LSTC). LS-DYNA ® Keyword User’s Manual Volume I; LSTC: Canonsburg, PA, USA, 2019. [Google Scholar]

- Graf, T.; Haufe, A.; Andrade, F. Adhesives modeling with LS-DYNA: Recent developments and future work. In Proceedings of the Nordic LS-DYNA Forum, Stuttgart, Germany, 6–8 October 2014. [Google Scholar]

| # | Test Type | In-Plane Dimensions, mm × mm | Number of NCF Layers | Test Procedure |

|---|---|---|---|---|

| 1 | Longitudinal tensile test | 250 × 15 | 8 | ASTM D3039 [48] |

| 2 | Transverse tensile test | 175 × 25 | 14 | ASTM D3039 [48] |

| 3 | 10°off-axis tensile test | 250 × 15 | 8 | Ref [49] |

| 4 | Double-cantilever beam (DCB) test (specimen with Teflon insert) | 125 × 25 | 32 | ASTM 5528b [50] |

| 5 | End-notched flexure (ENF) test (specimen with Teflon insert) | 120 × 25 | 32 | Ref [51] |

| Property | Units | Mean Value |

|---|---|---|

| Longitudinal Young’s modulus, | MPa | 149,018 |

| Transverse Young’s modulus, | MPa | 6071 |

| Major in-plane Poisson’s ratio, | - | 0.32 |

| In-plane shear modulus, | MPa | 4217 |

| Longitudinal tensile strength, | MPa | 2060 |

| Longitudinal compressive strength *, | MPa | 1539 |

| Transverse tensile strength, | MPa | 29.1 |

| Transverse compressive strength *, | MPa | 126.6 |

| In-plane shear strength, | MPa | 44.5 |

| Longitudinal tensile strain-at-failure, | % | 1.37 |

| Transverse tensile strain-at-failure, | % | 0.40 |

| In-plane shear strain-at-failure, | % | 1.71 |

| Mode I strain energy release rate, GIc | 0.66 | |

| Mode II strain energy release rate, GIIc | 2.77 | |

| Shear stress at onset of non-linearity | MPa | 30 |

| Shear strain at onset of non-linearity | % | 0.711 |

| Parameter | Meaning | Units | Value | Comment for the Chosen Initial Value |

|---|---|---|---|---|

| DFAIL | Maximum strains for directional straining at which element will be eroded. | mm/mm | – | Disabled to control elements’ erosion by timestep (TFAIL) and effective strain (EPS) only. |

| TFAIL | Element is deleted when its time step is smaller than the given value. | s | 10−7 | Element is deleted when current timestep is less 10−7s |

| EPS | Effective failure strain | mm/mm | 0.55 | Chosen as to be significantly higher than any directional strain at failure initiation, as used in [12] |

| SOFT | Softening reduction factor for material strength in crash front elements | – | 0.90 | Slight (10%) reduction of strength in crashfront elements is assumed |

| SOFT2 | Optional transverse softening reduction factor | – | no input | Softening is assumed to be isotropic |

| PFL | Percentage of layers which must fail until crash front is initiated | – | 100 | Default value |

| BETA | Weighting factor for shear term in tensile fiber mode (see Equation (1)) | – | 0 | No effect of shear stresses on fiber tensile failure (max stress criterion), which usually provides good agreement with experimental data. |

| SLIMT1 | Factor to determine the minimum stress limit after stress maximum (fiber tension). | – | 0.010 | Small but non-zero residual strength is assumed after tensile failure to avoid numerical instabilities |

| SLIMC1 | Factor to determine the minimum stress limit after stress maximum (fiber tension). | – | 0.375 | A post-calibration value obtained in [12] |

| SLIMT2 | Factor to determine the minimum stress limit after stress maximum (matrix tension). | – | 0.010 | Small but non-zero residual strength is assumed after tensile failure to avoid numerical instabilities |

| SLIMC2 | Factor to determine the minimum stress limit after stress maximum (matrix compression). | – | 0.375 | A post-calibration value obtained in [12] |

| SLIMS | Factor to determine the minimum stress limit after stress maximum (shear). | – | 1.000 | A recommended value [54] |

| FBRT | Reduction factor for fiber tensile strength after matrix compressive failure | – | 0 | A zero effect of transverse matrix cracking on fiber tensile strength is assumed |

| YCFAC | Reduction factor for compressive fiber strength Xc after matrix compressive failure | – | 12 | Assume no influence of the matrix failure on the longitudinal compressive strength |

| Parameter | Meaning | Units | Value | Comment for the Chosen Initial Value |

|---|---|---|---|---|

| TFAIL | Timestep for automatic element deletion | s | 10−7 | Element is deleted when current timestep is less 10−7 s |

| ERODS | Maximum effective strain for element failure. If lower than zero, element fails when the effective strain calculated from the full strain tensor exceeds ERODS | mm/mm | −0.55 | Chosen as to be significantly higher than any directional strain at failure initiation |

| SOFT | Softening reduction factor for material strength in crash front elements | – | 0.90 | Slight (10%) reduction of strength in crashfront elements is assumed |

| SLIMT1 | Factor to determine the minimum stress limit after stress maximum (fiber tension) | – | 0.010 | Small but non-zero residual strength is assumed after tensile failure to avoid numerical instabilities |

| SLIMC1 | Factor to determine the minimum stress limit after stress maximum (fiber tension). | – | 0.375 | A post-calibration value obtained in [12] |

| SLIMT2 | Factor to determine the minimum stress limit after stress maximum (matrix tension) | – | 0.010 | Small but non-zero residual strength is assumed after tensile failure to avoid numerical instabilities |

| SLIMC2 | Factor to determine the minimum stress limit after stress maximum (matrix compression) | – | 0.375 | A post-calibration value obtained in [12] |

| SLIMS | Factor to determine the minimum stress limit after stress maximum (shear) | – | 1.000 | A recommended value [54] |

| Property | Unit | Value | Rationale |

|---|---|---|---|

| NFLS | MPa | 75.00 | The ultimate strength of bulk epoxy resin multiplied by a scaling factor of 0.95 to account for the mesh dependency (see the recommendation provided in [57] for meshes with element sizes of 0.7 mm). |

| SFLS | MPa | 43.30 | Assumed as (von Mises criterion) |

| G_Ic | 0.66 | Measured experimentally, see Table 1 | |

| G_IIc | 2.77 | Measured experimentally, see Table 1 | |

| CN | MPa/mm | 200,000 | CN = Eepoxy/δRRR, where Eepoxy is the Young’s modulus of epoxy matrix (~3650 MPa) and δRRR is the thickness of the interlaminar resin-rich region (typically within 0.01 and 0.10 mm). Thus, the lower and upper bounds for CN correspond to 36,500 MPa/mm and 365,000 MPa/mm, accordingly. This averages to 200,000 MPa/mm as an estimate for the CN parameter. |

| CT2CN | - | 0.37 | CT2CN = CT/CN = Gepoxy/Eepoxy = 1/2 × (1 + νepoxy), where Gepoxy and νepoxy are the shear modulus and the Poisson’s ratio (~0.35) of epoxy resin, correspondingly. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazemian, M.; Cherniaev, A. Prediction of Damage in Non-Crimp Fabric Composites Subjected to Transverse Crushing: A Comparison of Two Constitutive Models. J. Compos. Sci. 2022, 6, 224. https://doi.org/10.3390/jcs6080224

Kazemian M, Cherniaev A. Prediction of Damage in Non-Crimp Fabric Composites Subjected to Transverse Crushing: A Comparison of Two Constitutive Models. Journal of Composites Science. 2022; 6(8):224. https://doi.org/10.3390/jcs6080224

Chicago/Turabian StyleKazemian, Milad, and Aleksandr Cherniaev. 2022. "Prediction of Damage in Non-Crimp Fabric Composites Subjected to Transverse Crushing: A Comparison of Two Constitutive Models" Journal of Composites Science 6, no. 8: 224. https://doi.org/10.3390/jcs6080224

APA StyleKazemian, M., & Cherniaev, A. (2022). Prediction of Damage in Non-Crimp Fabric Composites Subjected to Transverse Crushing: A Comparison of Two Constitutive Models. Journal of Composites Science, 6(8), 224. https://doi.org/10.3390/jcs6080224