Flame-Retardant and Tensile Properties of Polyamide 12 Processed by Selective Laser Sintering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

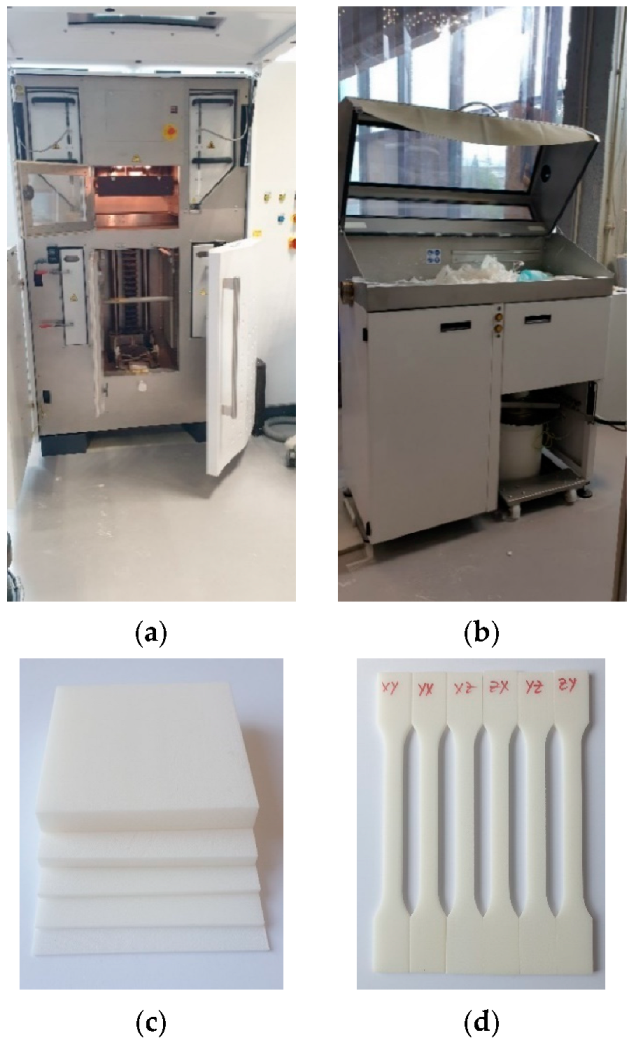

2.2. Manufacturing of the Test Samples

2.2.1. Test Samples for Vertical Burn Test

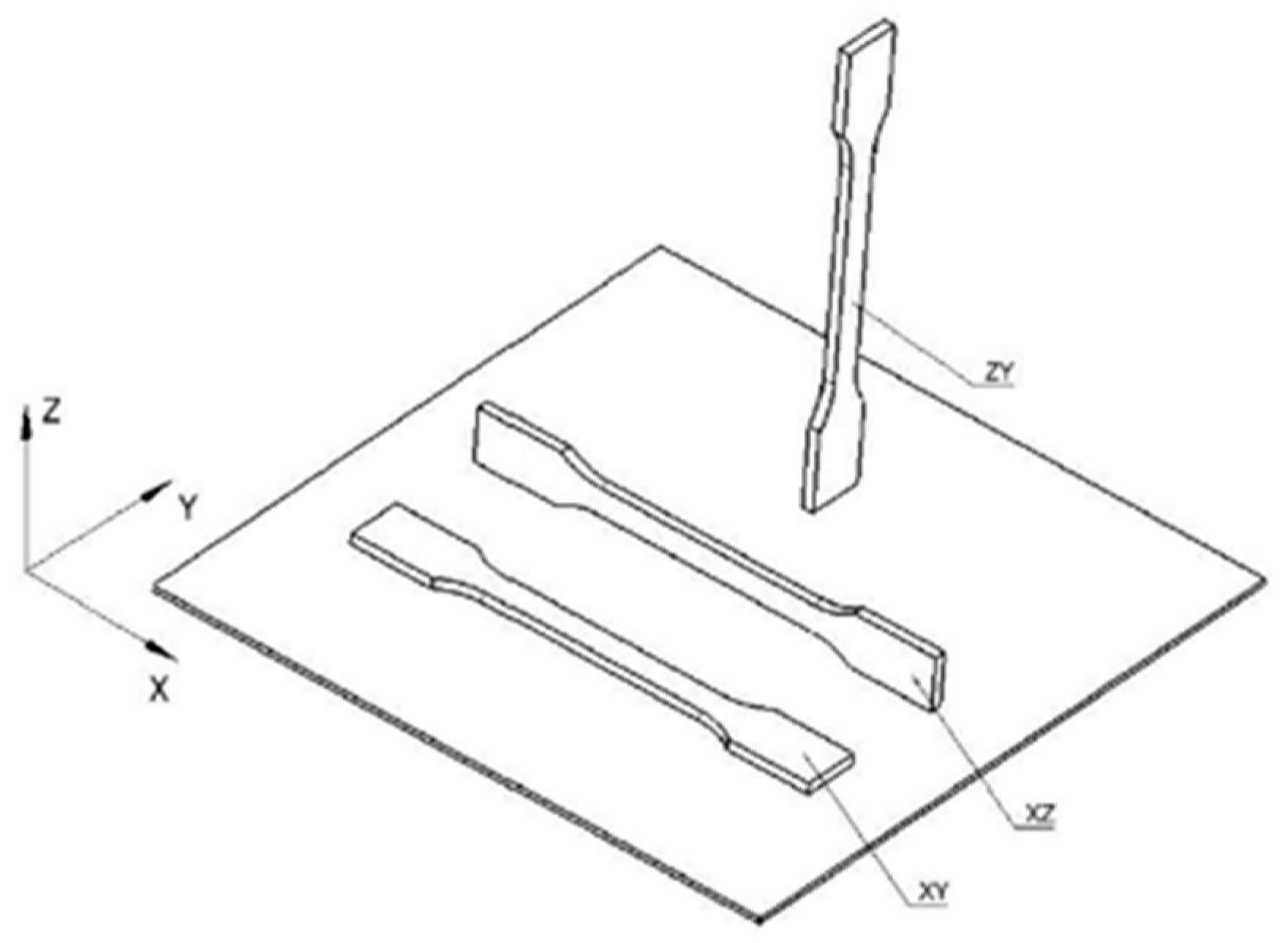

2.2.2. Test Samples for Tensile Tests

2.3. Vertical Burn Tests

2.4. Quasistatic Tensile Tests

2.5. Density Measurements

2.6. Microscopy Analysis

3. Results and Discussion

3.1. Vertical Burn Tests

3.2. Tensile Tests

3.3. Density Evaluation

3.4. Microscopy Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bacciaglia, A.; Ceruti, A.; Liverani, A. Towards large parts manufacturing in additive technologies for aerospace and automotive applications. Procedia Comput. Sci. 2022, 200, 1113–1124. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Xiao, B. A market assessment of additive manufacturing potential for the aerospace industry. J. Manuf. Processes 2021, 68, 728–738. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ashraff Ali, K.S.; Ranganathan, K.; Allen Jeffrey, J.; Ravikumar, M.M.; Rajkumar, S. The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater. Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- Kobenko, S.; Dejus, D.; Jātnieks, J.; Pazars, D.; Glaskova-Kuzmina, T. Structural integrity of the aircraft interior spare parts produced by additive manufacturing. Polymers 2022, 14, 1538. [Google Scholar] [CrossRef]

- Hajare, D.M.; Gajbhiye, T.S. Additive manufacturing (3D printing): Recent progress on advancement of materials and challenges. Mater. Today Proc. 2022, in press. [Google Scholar] [CrossRef]

- Federal Aviation Regulation (FAR). Standard No. 25.853 Fire Test to Aircraft Material: Fire Protection for Compartment Interior. Available online: https://www.federalregister.gov/documents/2019/07/03/2019-13646/interior-parts-and-components-fire-protection-for-transport-category-airplanes (accessed on 15 April 2022).

- Federal Aviation Regulation (FAR). Standard No. 25.855 Fire Test to Aircraft Material: Cargo or Baggage Compartments. Available online: https://www.govinfo.gov/content/pkg/CFR-2010-title14-vol1/pdf/CFR-2010-title14-vol1-sec25-855.pdf (accessed on 15 April 2022).

- Chai, M. Flammability Performance of Bio-Derived Composite Materials for Aircraft Interiors 2014. Ph.D. Thesis, University of Auckland, Auckland, New Zealand. Available online: https://researchspace.auckland.ac.nz/handle/2292/24756?msclkid=903aa79abcb011ecabb550fdeea7dd12 (accessed on 15 April 2022).

- Lv, Y.; Dejus, D.; Kobenko, S.; Singamneni, S.; Glaskova-Kuzmina, T. Evaluation of the fire-retardancy of ULTEM 9085 polymer composites processed by fused deposition modelling. Mater. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Babrauskas, V.; Peacock, R.D. Heat Release Rate. The Single Most Important Variable in Fire Hazard. Fire Saf. J. 1992, 18, 255–272. [Google Scholar] [CrossRef]

- Price, D.; Anthony, G.; Carty, P. Introduction: Polymer Combustion, Condensed Phase Pyrolysis and Smoke Formation. In Fire Retardant Materials; Horrocks, R., Price, D., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2001; pp. 1–30. [Google Scholar] [CrossRef]

- Awad, A.; Fina, F.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D printing: Principles and pharmaceutical applications of selective laser sintering. Int. J. Pharm. 2020, 586, 119594. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, H.; Hon, K.K.B.; Gong, Q. An optimization approach of selective laser sintering considering energy consumption and material cost. J. Clean. Prod. 2018, 199, 529–537. [Google Scholar] [CrossRef]

- Batistella, M.; Regazzi, A.; Pucci, M.F.; Lopez-Cuesta, J.-M.; Kadri, O.; Bordeaux, D.; Ayme, F. Selective laser sintering of polyamide 12/flame retardant compositions. Polym. Degrad. Stab. 2020, 181, 109318. [Google Scholar] [CrossRef]

- Schneider, K.; Wudy, K.; Drummer, D. Flame-retardant polyamide powder for laser sintering: Powder characterization, processing behavior and component properties. Polymers 2020, 12, 1697. [Google Scholar] [CrossRef]

- Durgun, I.; Ertan, R. Experimental investigation of FDM process for improvement of mechanical properties and production cost. Rapid Prototyp. J. 2014, 20, 228–235. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef] [PubMed]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modeling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Salazar, A.; Rico, A.; Rodríguez, J.; Segurado Escudero, J.; Seltzer, R.; Martin de la Escalera Cutillas, F. Fatigue crack growth of SLS polyamide 12: Effect of reinforcement and temperature. Compos. Part B 2014, 59, 285–292. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Paggi, R.A.; Lago, A.; Beal, V.E. Microstructural and mechanical characterization of PA12/MWCNTs nanocomposite manufactured by selective laser sintering. Polym. Test. 2011, 30, 611–615. [Google Scholar] [CrossRef] [Green Version]

- Technical Data Sheet for PA 2241 FR. EOS. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-plastic/sls-polymer-materials/polyamide-pa-12-alumide (accessed on 15 April 2022).

- Technical Data Sheet for EOS P 396 SLS Machine. EOS. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-plastic/eos-polymer-systems/eos-p-396 (accessed on 15 April 2022).

- ISO 527-1; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: London, UK, 2019. Available online: https://www.iso.org/standard/75824.html (accessed on 3 May 2022).

- Rasband, W. ImageJ-National Institute of Health, USA. 1997. Available online: http://rsb.info.nih.gov/ij/ (accessed on 25 May 2022).

- Glaskova, T.; Zarrelli, M.; Borisova, A.; Timchenko, K.; Aniskevich, A.; Giordano, M. Method of quantitative analysis of filler dispersion degree in composite systems with spherical inclusions. Compos. Sci. Technol. 2011, 71, 1543–1549. [Google Scholar] [CrossRef]

- Glaskova, T.; Zarrelli, M.; Aniskevich, A.; Giordano, M.; Trinkler, L.; Berzina, B. Quantitative optical analysis of filler dispersion degree in MWCNT-epoxy nanocomposite. Compos. Sci. Technol. 2012, 72, 477–481. [Google Scholar] [CrossRef]

- Ngoa, T.D.; Kashania, A.; Imbalzanoa, G.; Nguyena, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Glaskova, T.; Aniskevich, A. Moisture effect on deformability of epoxy/montmorillonite nanocomposite. J. Appl. Polym. Sci. 2010, 116, 493–498. [Google Scholar] [CrossRef]

| Thickness, mm | Printing Direction |

|---|---|

| 1.00 | X, Y, Z, XY ± 45°, ZX ± 45° |

| 1.25 | X, XY ± 45°, ZX ± 45° |

| 1.50 | XY ± 45°, ZX ± 45° |

| 1.75 | XY ± 45°, ZX ± 45° |

| 2.00 | X, Y, Z, XY ± 45°, ZX ± 45° |

| 2.50 | XY ± 45°, ZX ± 45° |

| 3.00 | XY ± 45°, ZX ± 45° |

| 4.00 | XY ± 45°, ZX ± 45° |

| 5.00 | XY ± 45°, ZX ± 45° |

| 6.00 | XY ± 45°, ZX ± 45° |

| 7.00 | XY ± 45°, ZX ± 45° |

| 8.00 | XY ± 45°, ZX ± 45° |

| 10.00 | XY ± 45°, ZX ± 45° |

| Printing Direction | Density, g/cm3 |

|---|---|

| XY | 1.027 ± 0.007 |

| YX | 1.026 ± 0.005 |

| XZ | 1.023 ± 0.008 |

| ZX | 1.023 ± 0.006 |

| YZ | 1.023 ±0.005 |

| ZY | 1.023 ±0.007 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glaskova-Kuzmina, T.; Dejus, D.; Jātnieks, J.; Kruuv, P.-P.; Lancere, L.; Kobenko, S.; Sarakovskis, A.; Zolotarjovs, A. Flame-Retardant and Tensile Properties of Polyamide 12 Processed by Selective Laser Sintering. J. Compos. Sci. 2022, 6, 185. https://doi.org/10.3390/jcs6070185

Glaskova-Kuzmina T, Dejus D, Jātnieks J, Kruuv P-P, Lancere L, Kobenko S, Sarakovskis A, Zolotarjovs A. Flame-Retardant and Tensile Properties of Polyamide 12 Processed by Selective Laser Sintering. Journal of Composites Science. 2022; 6(7):185. https://doi.org/10.3390/jcs6070185

Chicago/Turabian StyleGlaskova-Kuzmina, Tatjana, Didzis Dejus, Jānis Jātnieks, Partel-Peeter Kruuv, Linda Lancere, Stepans Kobenko, Anatolijs Sarakovskis, and Aleksejs Zolotarjovs. 2022. "Flame-Retardant and Tensile Properties of Polyamide 12 Processed by Selective Laser Sintering" Journal of Composites Science 6, no. 7: 185. https://doi.org/10.3390/jcs6070185

APA StyleGlaskova-Kuzmina, T., Dejus, D., Jātnieks, J., Kruuv, P.-P., Lancere, L., Kobenko, S., Sarakovskis, A., & Zolotarjovs, A. (2022). Flame-Retardant and Tensile Properties of Polyamide 12 Processed by Selective Laser Sintering. Journal of Composites Science, 6(7), 185. https://doi.org/10.3390/jcs6070185