Abstract

In this paper several aspects of profound modifications caused by high energy exposures are presented as possible candidates for the efficient adjusting processing of polymer materials. The class of hybrid composites receives special attention due to the large spectrum of formulations, where the interphase interaction decisively influences the material properties. They represent potential start points for the intimate uniformity of hybrid morphologies. Their radiation processing turns composites onto hybrid morphology with expected features, because the transferred energy is spent for the modification of components and for their compatibility. The essential changes achieved in radiation processed composites explain the new material behavior and durability based on the peculiar restructuring of polymer molecules that occurred in the polymer phase. During high energy irradiation, the interaction between intermediates born in the constitutive phases may convert the primary composites into hybrids, integrating them into large applicability spheres. During the radiation exposure, the resulting hybrids gain a continuous dispersion by means of new chemical bonds. This type of compounds achieves some specific structural modifications in the polymer phase, becoming stable hybrid composites. The functional properties of hybrids definitely influence the material behavior due to the molecular changes based on the structural reasons. The radiolysis of the vulnerable component becomes an appropriate opportunity for the creation of new material with improved stability. The radiation treatment is a proper conversion procedure by which common mixtures may become continuously reorganized. This review presents several examples for the radiation modifications induced by radiation exposure that allow the compatibilization and binding of components as well as the creation of new structures with improved properties. This approach provides the reference patterns for the extension of radiation processing over the well-conducted adjustments of polymer composites, when certain material features are compulsorily required. From this review, several solutions for the adjustment of regular polymer composites into hybrid systems may become conceivable by the extended radiation processing.

1. Introduction

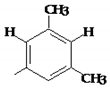

The discussion of radiation effects on polymer composites as the precursors of hybrids, the innovative materials, has opened a large door for the extended applications in several areas of the following activities: modeling [1,2], medicine [3,4], transport [5,6], energy [7,8], electronic devices [9,10], sensors [11,12], food packaging [13,14], building composite materials [15], water desalinization [16] and many others. The inclusion of hybrids through the composite category depends undoubtedly on the deep interpenetration and the specific association of the constituent phases [17]; an explanatory example for the capacity of ionizing radiation for the adjustment of polymer blends into hybrid structuration is the irradiation of chitosan/poly(vinyl alcohol) systems [18]. The stable configuration of hybrids supposes the interphase compatibility and the formation of bridges between the host polymer and filler [19]. The behavior of fillers and the stability of polymer matrix in hybrid materials are the essential features that characterize the wearability of hybrids [20]. The preparation routes of added nanoparticles challenge options for the appropriate solutions that open new perspectives for the manufacturing conditions of the homogenous multiphase products [21]. The ascending interest paid on the complex approach on the subject of engineering polymer hybrids creates optimal support for the publication of relevant reviews [22,23,24,25,26,27]. However, the radiation effects are only scarcely caught. The complexity of the interaction between incidental high energy radiation and biphasic polymer-based hybrids gathering a broad variety of compounds is inviting the academic sphere to detailed assays, because the structural modifications may lead to a new concept of materials [28]. Starting from the radiation stability of the C–C backbone, molecular changes are related to the fate of radical intermediates [29], which follows the polymer radiation chemistry [30]. The utilization of polymer hybrid materials processed by high energy irradiation depends intrinsically on the stability class from where they belong: crosslinkable or degradable compounds. The prediction of long term behavior of irradiated materials is based on the ratios between the crosslinking and scission radiochemical yields that are illustrated by the width of irradiation range practice [31,32]. The radiation processing may become a persuasive and economical method through which polymeric blends may gain a hybrid texture [33]. The extension of operation areas is allowed by the presence of filler, which may scavenge the former radicals forming by the fragmentation of the degradation chain [34]. The irradiation conditions (integrated dose, dose rate, environment, additives) are the main parameters that define the availability of materials to keep the initial functional features constant. The general mechanism that describes the progress in the degradation of polymers is initiated by the scission of weaker bonds followed by the oxidation of radical intermediates [35,36]. The inhibition attained in the progress of oxidation is effectively obtained at any stage of degradation (Figure 1), when the radicals can be physically or chemically scavenged on the surface of nanoparticles.

Figure 1.

Scheme of oxidative degradation of irradiated polymers, the major component of hybrids.

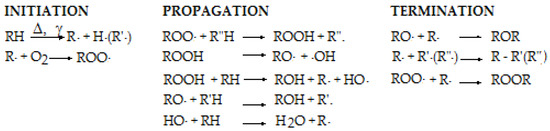

The potentiality of polymer hybrids to improve their properties by radiation processing is controlled by the superficial interaction between the radical intermediates and the defects that are formed during this aggressive treatment [37]. The exposure of polymer systems to the action of high energy radiation tends to assist in the preparation of new materials as well as the application of extended quality control, by which the inspected products are examined [38]. The most important advantage that is offered by the radiation technologies is the modification of interphase structuration in polymer [39] or on the nanoparticle surface [40], allowing a more appropriate compatibility that improves the material stability (Figure 2). The controlled irradiation procedures may satisfy the energetic and restructuring requirements that are essential for the transformation of regular polymer mixtures into the fully compatibilized systems. The conversion of pristine polymer into its hybrid assisted by radiation treatment is a convenient and ecological way for the adjustment of functional properties, to the benefit of customers [41,42]. However, the exposure to high energy radiation is not always beneficial, because the amplitude of chemical modifications is associated with an advanced accumulation of degradation products and, consequently, the processed material drops onto the instability region [43]. One aid for the extension of application range for any macromolecular compound, either in the monocomponent state or as a blend, is offered by polyfunctional monomers that significantly increase the insoluble fraction, better achieving the suitable functionalization of polymer hybrid [28,44,45].

Figure 2.

Summary scheme for the formation of bridges between the polymer phase and nanoparticle that convert polymer composites into hybrid materials.

The polymer hybrid compositions may gain high performance after their irradiation because the radiolysis products act predominantly on the nanoparticles by the interconnection revealed as promoted changes in material microstructure [46] and on the long term stability [47]. This amelioration trend is effectively sustained by the reactions of intermediates included in the radiolysis scheme as the active units appearing in polymer phase [48]. Therefore, this class of materials subjected to the controlled modification by high energy irradiation becomes an excellent candidate for the large scale commercial products with demonstrated suitability for various special applications.

This review presents several examples for the structural modifications of composites and hybrids to apply radiation processing for achieving new expected features. The pertinent ideas for the preparation or conversion of hybrids based on the presence of nanoparticles in polymer substrates would lead to new materials and advanced functional systems to accomplish market goals for high-tech equipment with reasonable expenditure of effort.

2. Main Aspects of Radiation Processing

The lack of selectivity that characterizes the interaction between the incidental high energy radiation (γ- and X-rays, accelerated electrons) and exposed materials, especially polymers, is a great disadvantage that does not allow the behavior differentiation between composites and hybrids, but it provides a convenient method through which the conversion of the first compounds into the second ones may be easily accomplished. The basic approach that may be employed for the characterization of radiation effects in polymer based compounds (composites and hybrids) consists of the unlike consequences noticed simultaneously in the polymer phase (ionizing and bond scission followed by scission and crosslinking [49] or the creation of defects [50]) and inorganic filler (formation of lattice defects [51]) as the result of energy transfer along the radiation tracks [52]. The conceptual survey on the physical consequences of irradiation in hybrid systems reveals the connection between the interaction between the free radicals born from the fragmentation of macromolecules and the defects existing on the nanoparticle surface [53]. In essence, the manner through which the energetic spots are formed in hybrid polymers by the passing of incidental radiation includes the formation of bridges between macromolecules and nanoparticles [54] or the penetration of radicals into the free space of lattice (cage effect [55]). The research on radiation chemistry discloses the fundamental processes through which the polymers are the potential providers of valuable materials by irradiation [56]. The specificity of each structure belonging to the different classes of polymers raises thresholds between the predominant reactions that are involved in the mechanisms of modifications. The peculiarities of the host substrate as a basic component of hybrids define the recommended route that must be followed for the appropriate outcome in the creation of novel hybrids [57]. The fate of radicals is accurately described by their reactions, that are the starting points of the degradation stable products [30,34,58]. The presence of additives (fillers and/or antioxidants) points the processing method towards the foreseen target, if the processing is carefully conducted with the aid of an expected application. The changing depth depends, to a large extent, on the radiochemical scission yields of backbones generating a local concentration of initiators as the result of the interaction between the energetic rays and molecular chains. The progress of any adjustment will define the material properties, where the contribution of filler is essential, even though it is not subjected to the structural changes, but it is involved in the conversion of free radicals onto stable molecular structures. The radiation effects induced in polymers and their hybrids are tributary to the strength of bonds existing in the macromolecules (the bond energy does not exceed 10–15 eV). The weaker bonds require low activation energies for scission in comparison with high energy carried by penetrating radiation. Accordingly, the structure of host polymers in their hybrids is a proper source of information for the mechanistic approach of radiation processing [59]. On this background, the fillers are the constitutive elements [60], which receive certain features to obtain hybrids starting from composites.

Several recent papers presenting the preparation of NP by radiation processing as the main subject in the area of polymers were reported [61,62,63,64,65,66,67,68]. The innovative aspects of this subject are related to the “clean” experimental procedures involving radiation processing, the resulting accurate size, the homogenous incorporated phase in products and the reproducibility of the method by which the raw nanoparticles are appropriately added in polymer hybrids. The explored features related to the compatibility of nanoparticles with the polymer supports are largely presented in those papers concerning the stability of radiochemical preparation of hybrids [69,70] by which the extended durability of hybrid products is demonstrated. The nanoparticle phase as the minor component of hybrids is a decisive key in the proper applications of nanocomposite materials [71]. Although the incident radiation has no selectivity in respect to the chemical nature of the exposed material, the most sensible part of the composite remains the organic moieties, which may be weakly transformed into the desired configuration of the envisaged material [30,72].

3. Polyethylene

The preparation of polyethylene nanocomposites and their conversion into hybrids by radiation treatment is based on the appropriate radiation crosslinking, rather than on the oxidative degradation [73], if the processing is appropriately conducted. The radiation resistance of polyethylenes is depicted by the availability of these polyolefins to be improved by passing high energy radiation through them and the increase in their own insoluble fraction that justifies the interphase co-operation in their hybrids.

The electron beam irradiation of low density polyethylene in the presence of clay nanoparticles (organically modified montmorillonite—OMMT, Cloisite 15 A [74]) is an opportunity to increase the stability of basic polymer as a hybrid structure for the extension of material life. The formation of several bridges between the structured filler and the molecular chain fragments ameliorate the material resistance against oxidation as any hybrid performs. The EB exposure at a medium dose of 100 kGy enhances the insoluble content from 36.5% to 43.2%, while at a higher dose (200 kGy), the difference between the insoluble fraction of pristine and modified LDPE is stated at 3%. The LDPE filled with Bi2O3 may follow an accelerated crosslinking, because the nanoparticles scavenge the free radicals on the filler surface and, consequently, their oxidation is hindered. In this manner, the polymer phase surrounds the nanoparticles and the stability is effectively increased. The proof of the positive effect of Bi2O3 on the stability of polyethylene is the proper attenuation of gamma rays, as a shielding product ensures the radiation protection in the radiological conditions [75,76]. The interaction between the filler nanoparticles and the host polymer is based on the formation of bridges that catch radicals near the particle surface [77]. Simultaneously with the progress in the crosslinking state, the crystallinity is also increasing [78].

The inclusion of alumina (Al2O3) in the composition of polyethylene hybrids is a convenient choice for several electrical applications. If this combination is destined to the preparation of separators in lithium secondary batteries [79], the contribution of nanocomposites is significant for the conductive behavior, if this kind of membrane is subjected to electron beam irradiation. High performances similar to the properties of alumina hybrids [80] are obtained after irradiation because the alumina nanoparticles are covered with a crosslinked polyethylene thin sheet, assuring a convenient value for the discharge voltage.

As the dielectric material, the hybrid polyethylene containing alumina behaves satisfactorily after gamma irradiation [81]. The alumina concentration less 5% and the γ-irradiation of less 20 kGy are the favorable parameters for the characterization of relative permittivity and tan δ. It means that alumina allows the charge carriers to be continuously decelerated, when this kind of insulation is placed at the beginning of its ageing period.

The polymeric electrical insulation with specific conduction properties may be obtained by the addition of variously structured types of carbon, such as pristine nanotubes [82] or multi walled carbon nanotubes [83], with the representative components of electrical semiconducting hybrids based on elementary carbon black. The thermal stability investigations on HDPE/MWCNT samples pointed out that the increasing carbon content brings about a real improvement in the hindering oxidation at all irradiation doses up the 100 kGy, a sufficient high dose covering all radiation processes involved in the radiation crosslinking treatments. In the same time, the γ-exposure of low density polyethylene/carbon black significantly modifies the temperature coefficients related to the degree of curing and the temperature variation (25–160 °C) (Table 1) when the assayed materials were irradiated over a large dose range up to 1000 kGy [84]. These results indicate possible applications in the development of temperature sensors that are comparable with the hybrid materials containing a homogenously dispersed or dotted carbon phase [85].

Table 1.

Modification of oxidation index in HDPE against MWCNT loading at various doses [83].

The microstructure of UHMWPE/graphene oxide nanocomposites is essentially changed into hybrids by the radiation treatment [86], when meaningful effects were noticed. While the graphene oxide content increases and the mechanical properties are effectively improved based on the radiation crosslinking of polyethylene support, the radiation treatment tends to worsen the oxidation state, because the diffusion coefficient for outer molecular oxygen becomes inappropriate. Accordingly, only a low sterilization dose (about 25 kGy) would be recommended for biological applications, when the deterioration in the mechanical properties is placed within good tolerance limits. Similar behavior can be noticed in the UHMWPE modified with carbon nanotubes [87]. The presence of MWCNT in the polyethylene matrix diminishes the rate of oxidative degradation due to the superficial adsorption of intermediates as the result of the hybridization effect. This conclusion is confirmed by ESR and TEM inspections on γ-irradiated samples, where the crystallinity drops down simultaneously due to the lamellar distribution of scavenged free radicals prior their crosslinking. It was demonstrated that the addition of MWCNT is an efficient filler for the stabilization of γ-irradiated UHMWPE [88,89]. It means that this inorganic additive becomes a proper stabilization agent for high performance UHMWPE in the irradiation dose range up to 90 kGy. Therefore, the irradiated UHMWPE serves as a conspicuous polymer material for bone restoration under long duration of wearing.

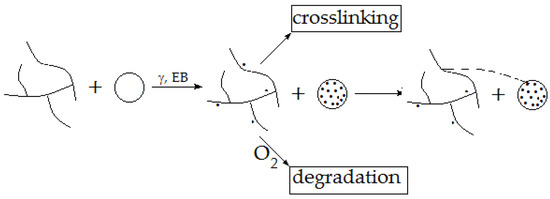

The irradiation technique applied to polyethylene/carbon black nanocomposites is able to establish the correlation between the content of insoluble fraction that appeared at different doses and the crystallinity degree (Figure 3) [90]. The randomization in the molecular distribution that follows the irradiation step may be explained by the radiolysis fragmentation, which allows the inclusion of nanoparticles in the polyethylene to form a continuous phase.

Figure 3.

Correlation between the gel fraction and crystallinity in irradiated HDPE/CB [90].

In the multicomponent nanosystems, each component brings its oxidation susceptibility that influences the evolution of mechanical properties and thermal strength [91]. For the formulation LDPE/PS/MA/Mg(OH)2:70/30/10/5 wt%, the changing amplitude of tensile strength and elongation at break follows the trends in the modifications of polyethylene/polystyrene ratios. The compositions enriched in a styrene component present better mechanical parameters while the increase in the inorganic phase lightly diminishes the mechanical behavior, even though the dose becomes greater up to 40 kGy. This behavior is ascribed to the radiation stability of benzene rings, where the received energy may be stored by means of delocalized π electrons.

The mobility measurements of metallic nanoparticles in irradiated LDPE [92] reveal the dependence of the acquired level in their process of diffusion on the oxidation state of material achieved during an accelerated degradation. The presence of trace amounts of a degrading product such as acetic acid accelerates the penetration of metallic nanoparticles. This observation is a suitable indication for the elimination of contamination during food storage.

The γ-irradiation of TiO2NPs/NWCNTs/LDPE nanocomposites induces a slight oxidative degradation because the carbonic phase acts as an antioxidant and anatase nanoparticles uptake polyethylene backbones by means of oxygen bridges, protecting them against fragmentation [93,94]. This behavior is very visible at the samples that received 25 kGy, a low dose promoting stabilization rather than degradation. At higher doses, the mechanical properties become poorer, because the stabilization activities of fillers are not sufficiently sustained and the higher content of radicals exceeds a critical threshold, depicting the good protection of nanoparticles. This feature may be ameliorated by the presence of one functional monomer that leads the material toward the behavior of hybrids.

The great interest paid to the magnetite for its application in the research of magnetic fluids was extended to the polyethylene hybrid [95], whose performances are similar, with the characteristics of the intimate system based on tight coalescent islands [96]. The interface adhesion that characterizes the interaction between the embedded nanoparticles and the host material is characterized by a fluidization factor. If the values of melting points for unirradiated and exposed samples at 50 kGy are compared, introducing 30% of Fe3O4 produces an increase of 33% from 110 °C in the values of Tm, while the pristine material presents an increase of only 9% in respect to the same reference temperature. It means that this composite can be successfully used as a hybrid material for the fine magnetization of surfaces when the environmental pollution attains alarming level. Similar effects were obtained by γ-irradiation of HDPE modified with HAp [97,98], where viscoelasticity depends on the filler loading and irradiation dose (Table 2).

Table 2.

Modification of MFI in HDPE/HAp nanocomposites [97].

The development of insulating polymer hybrid materials is based on the electrical investigations under hard operation conditions such as high energy irradiation [99]. After the application of a γ-exposure dose, these hybrids are characterized by an increase in electrical conductivity of the basic polymer (UHMWPE, a very radiochemical stable material) at all four concentrations of SiO2. The exponential dependencies of conductivity and tan δ on the filler concentration were noticed because of the partial oxidation of polymer matrix and the orientation of dipoles formed during irradiation in the electrical fields.

The largely used polyethylene pipes for the manufacture of electrical protection and fluid transport ask for the evaluation of thermal conduction properties under an accelerated ageing regime, such as γ-radiation exposure. The presence of TMPTA in polyethylene/Al2O3 nanocomposite initiates the improvement in oxidation resistance, explained by the increase in the gelation degree and the hardening polymer material surrounding alumina nanoparticles, if the systems are subjected to crosslinking by γ-irradiation with a moderate dose (120 kGy) [100].

The potential inhibition on the propagation of fire is highlighted by the polymer hybrids, whose protection activity is improved by irradiation [101,102]. When the matrix is a bicomponent blend, the crosslinking is promoted by the free radicals simultaneously formed. Thus, the hardened materials attain a high level of insoluble fraction (Table 3). The accumulation of the crosslinked phase is faster for the first 50 kGy because the availability of free radicals appearing during radiolysis is higher due to the intimate interaction with nanoparticle promoting recombination rather than oxidation.

Table 3.

Modification of gel fraction in LDPE/EVA nanocomposites for various MMT loadings [100].

The association between the filler nature and the modification degree in polymer matrices is seldom analyzed in hybrid microstructures [103], but the differences that exist in the processed hybrids must be taken into consideration for comparison, when the manufacturer starts the production of a new material composition.

4. Polypropylene

Polypropylene is an engineering material that belongs to the radiodegradable class of polymers because its value of scission radiochemical yield is much greater than the figure of crosslinking radiochemical yield [30] when the exposure to high energy radiation occurs in air. However, it can be processed as hybrids by irradiation [104] if, in the material formulation, an appropriate component that delays oxidation is present, such as an antioxidant [105], inorganic filler [106] or multifunctional monomer [107]. The presence of an inorganic filler in polypropylene nanohybrids brings double effects: withdraws the reactive intermediates from their reaction with diffusing oxygen and decreases the diffusion rate of oxidizing fluids [108]. At the same time, some additive nanoparticles tightly surrounded by polypropylene macromolecules may improve the material performances by their involvement in the fate of radiolysis fragments, blocking them on the large particle surface of nanophase [109]. The stabilization action of antioxidative silver nanoparticles allows the enlarging mechanical properties and lifespan after the exposure of modified polypropylene to be exposed to gamma irradiation at 12.5 kGy in acetylene environment [110]. The acetylene plays the role of radical provider, which is able to interact with the hydrocarbon radicals appeared during irradiation. This low dose is justified by the limitation of degradation of newly formed intermolecular bridges.

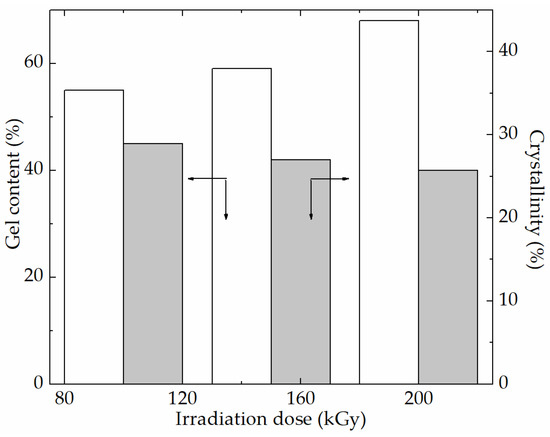

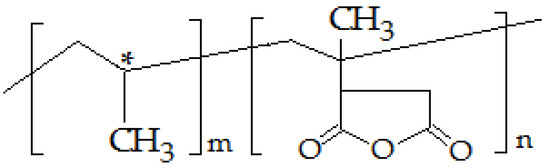

The accelerated degradation is hindered by the grafting of maleic anhydride on PP backbones and the addition of montmorillonite (Cloisite 15A) nanoparticles as a minor component (15%) of a hybrid structure [111]. The susceptibility of PP to radiation degradation is illustrated in Figure 4, where the star marks the radical position. The FTIR analysis on the progress of radiochemical degradation in these hybrids reveals the significant contribution of OMMT relative to MA in the inhibition of oxidation during γ-irradiation. For avoiding fast progress in the oxidation of irradiated polypropylene, the added OMMT is loaded as interlayer sheets [112], when it may interact simultaneously on both faces of filler planes.

Figure 4.

The radical position in the PP molecules grafted with MA.

The application of polypropylene sensors for the detection of heat transfer is possible due to the improved thermal conductivity of polypropylene, assisted by copper nanowire as an added component with a good dispersion, such as hybrid materials [113]. CuNW becomes efficient for the samples with a copper concentration containing 3 vol% when the loading content increases by two times for “in-plane” measurements and by five times for “through-thickness” determinations, while the thermal conductivity is diminished at half of initial value.

The low irradiation dose that induces the structural modification of PP is an argument for the preparation of nanohybrids containing acrylic acid [114], TAC or TMPTA [115] as binding agents. These monomers are positive solutions for efficient gelation of support and for the increase in the PP stability by radiation crosslinking. The configuration of PP grafted with acrylonitrile and acrylic acid (PP-g-(AN-co)AAc-H2PO3), assuring a good interphase between mixed components, is a pertinent solution for the environmental depollution, as is illustrated in Table 4. As it is suggested from these data, the optimal operation conditions indicate the dose of 20 kGy as appropriate exposure applicable to PP. In the medical areas, where polypropylene is largely used as the hybrid material, several vinyl monomers are successfully radiation-grafted on polypropylene for closing surgical wounds [116].

Table 4.

Co(II) uptake by radiation processed (PP-g-(AN-co)AAc-H2PO3) [114].

In the same manner, the POSS structures as hybrid components are incorporated in PP as the proper promoters of advanced stability [117]. This inorganic structure increases the thermal stability of irradiated PP [118,119], when the dose increases up to 100 kGy due to the interaction between macromolecules and nanoparticle powder loading. The great difference between the measured decomposition temperatures is obtained at the irradiation dose of 20 kGy, when the modified POSS component is added in the concentration of 2%. The increase in the amount of POSS, the component containing vinyl substituents, does not bring about a significant augmentation of this decomposition temperature. The explanation of the stabilization effect is the mechanistic argument through which the double bonds formed in the substituent branches by radiation processing are involved in the grafting of POSS on the PP backbone.

On the early irradiation stage of PP, the unsaturation is formed in the low extent due to the disproportionation and proton subtraction reactions involving intermediates [36]. This minimal amount is not sufficient for the initiation of crosslinking. The addition of trifunctional monomers provides the reactive spots for the significant increase in the insoluble fraction [120]. The loading of TAIC (6%) in CFRTP provides an increase in gel content from about 2% in pristine samples to 62% at an irradiation dose of 200 kGy. This sharp jump is normally explained by the radiation curing of radicals formed either in PP or in TAIC. This unexpected accumulation of dense material improves the mechanical properties, which are certainly favorable for the products used in severe conditions of operation, including nuclear applications. An analogous effect is obtained when the PP matrix is reinforced with untreated and superficial modified CF [121]. While a γ-dose of 5 kGy drastically decreases the tensile strength of nanocompound containing untreated CF, the modification of surface reactivity increases the values of tensile strength by about 60% and E-modulus by about 80% at 15 kGy. This behavior is foreseen because the treated fibers are spread through PP macromolecules and they create long islands with strong bridges throughout.

Notwithstanding the percolation effect that occurred in PP/CNT [122], when the electrical conductivity is limited to a medium value (log σdc = 7) at carbon loadings exceeding 1%, the γ-irradiated system presents an unchanged morphology that determines an increasing electrical conductivity of several orders of magnitude, sustained by the material homogeneity. This behavior may be noticed in polypropylene hybrids, where the concentration of MWCNT increasing from 1% to 8% caused a sharp increase in the electrical conductivity [123]. This would be due to the fragmentation of PP backbones, followed by the presumable crossinking on the surface of carbon nanoparticles. On the opposite side, the PP hybrids contained polymer backbones modified with maleic anhydride and OMMT that present a monotone increase in σdc as the concentration of filler is extended from 1% to 5%.

The preparation of PP/starch as nanohybrids offers a useful procedure for the γ-processing of the polypropylene wastes. When the formulations containing pro-oxidants are subjected to the action of γ-rays, the degradation achieved by bacteria in a natural environment is a proper way for biodegradation of PP support [124]. This paper shows a convenient route for the waste treatment assisted by γ-processing, when polymer chains are scissed as a preliminary step in the depollution actions.

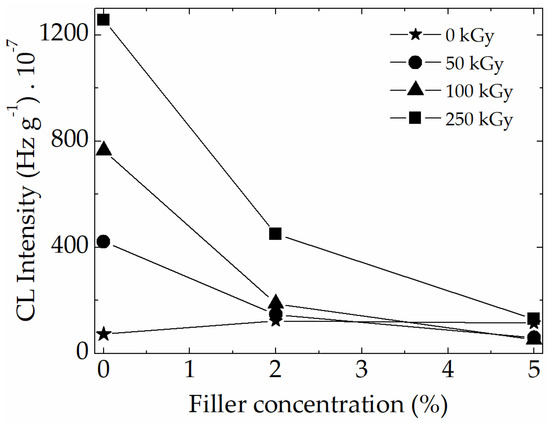

The addition of inorganic phase in a polypropylene surrounding allows the application under a convenient manner for the improvement in the material stability during accelerated oxidation after γ-irradiation [125]. The stability measurements by chemiluminescence (Figure 5) stated that the presence of this inorganic compound substantially improves the oxidation strength. This contribution in the production of dielectric polypropylene as high-performance products may be taken into consideration for the application of PP in the areas of electrical hybrid insulators. Other similar effects of additives incorporated in PP substrates are provided by the algal extracts nanoparticles that are homogenously dispersed in the polymer substrate. [126]. The nanoparticles of organic extracts certify them as pertinent oxidation inhibitors in polypropylene subjected to an aggressive ageing induced by γ-irradiation (Figure 6).

Figure 5.

Modification of CL intensity in PP modified with PbZrO3 nanoparticles [125].

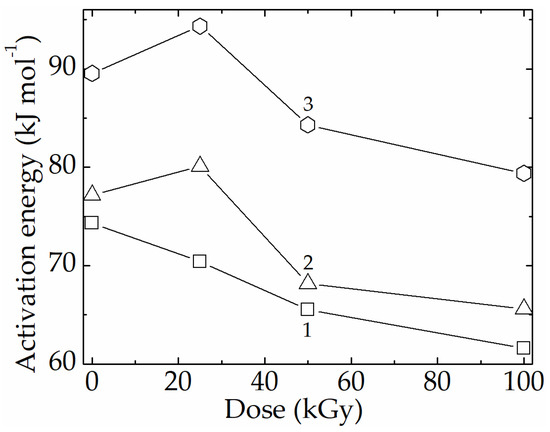

Figure 6.

The variation of activation energy for the radiooxidation of polypropylene in the presence of microalgal masses [126]. (1) None; (2) chlorella vulgaris; (3) spirulina platensis.

Figure 6 proves that the nanoparticles of algal extracts behave as an organic phase, co-existing in polymer bulk creating hybrid systems, with an improved stability for hazardous application in the safety handling of food.

5. Ethylene–Propylene Copolymers

The radiation stability of ethylene–propylene elastomers is defined by the contributions of ethylene and propylene units. It places these elastomers through the strengths of polyethylene and polypropylene, where the most vulnerable sites on the backbones are the higher substituted carbon atoms [127]. According to the radiolytic behavior of EPDM [128], which has an unsaturated component (diene as the third structural unit), this thermoplastic material may gain a high oxidation strength by the addition of homogenously spread compounds playing the roles of microcomponent with a perfect interphase compatibility: synthesis antioxidants [129], substituted POSS structures [130], metallic oxides [47] and organically modified MMT [131]. The stability of the POSS modified structures characterized by the activation energies required for the oxidation of POSS filler—filled EPDM (Table 5) offers versatile solutions for the application of EPDM in the areas of beverage bottles, medical wear, food packaging and commodities that may be sterilized by γ-irradiation. If the activation energy value found for EPDM/Irganox 1076 is considered as a reference for the stabilized EPDM (Ea = 65 kJ mol−1) during oxidative degradation, the effect of all POSS structures mentioned in Table 5 is more efficient.

Table 5.

Modified POSS structures and the activation energy (kJ mol−1) for their oxidation [130].

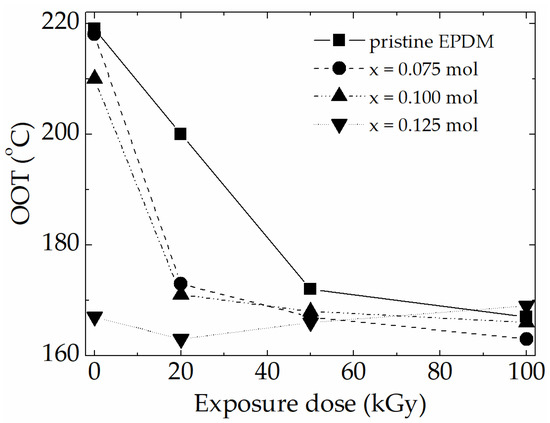

The inclusion of a certain composition of mixed oxides, such as Pb(Zr0.65-xCexTi0.35), where x takes the three values: 0.075, 0.1 and 0.125 mol in polymer composites with high radiation stabilities, is explicitly proved by means of nonisothermal chemiluminescence measurements [132] (Figure 7). This efficient effect on radiation stabilization is an optimal solution for the improvement in polymers’ durability when they operate in hazardous conditions such as space inspection or maintenance of the in-core NPP zone. The decomposition enthalpy decreases sharply as the concentration of cesium from filler molecules grows significantly. This behavior is explained by the scavenging action of lattice defects that attract, in their gap, the free radicals formed during γ-irradiation of EPDM.

Figure 7.

Modification in OOT values for the radiation oxidation of EPDM modifies with Pb(Zr0.65-xCexTi0.35) [132].

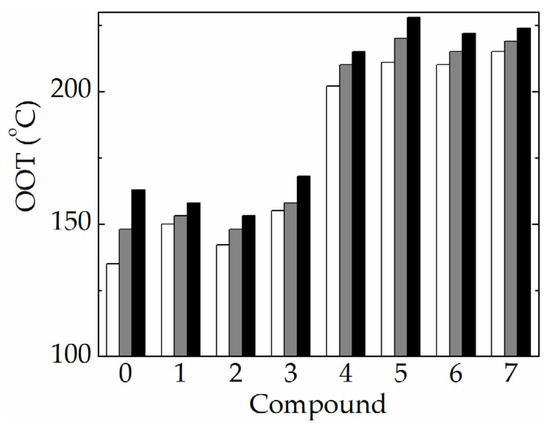

An unusual option by which thermoplastics such as EPDM gain a high radiation strength is the addition of metallic complexes such as nanopowders [133,134], with hybrid morphology based on the closed vicinity of components. The double layer configuration of metallic complexes, where an inner deficit of electrons may be satisfied by the unpaired electrons of free radicals, allows for their jointing to the central atoms. This blocking action is shown by the modification of OOT values (Figure 8), in direct correlation with the ligand structure that influences the electron density on the central metallic atoms for all seven investigated configurations. However, the protection efficiency of metallic complexes proved by isothermal and nonisothermal chemiluminescence can be invoked when this kind of compound is applied in the detection of diseases by the trace technique.

Figure 8.

The histogram of OOT values obtained for eight coordinative compounds of copper with various ligands at three heating rates (°C min−1): (white) 5; (dark grey) 10; (black) 15 [134].

The evidence on the radiation effects on EPDM nanohybrids is provided by the ageing investigation achieved on the EPDM/silica composites [135]. The destructive effect of diene content (EBN at 0.5 phr) is annihilated by the contribution of nanoparticle silica loading, which reinforces the EPDM microstructure by the formation of multiple bridges between polymer macromolecules. The high proportion of propylene units in the EPDM backbones (29.9%) brings about a decomposition susceptibility by which the γ-irradiation allows access to the reactive intermediated for the crosslinking on the surface of silica nanoparticles, though the molecular branching acts as a cage in the hybrid materials.

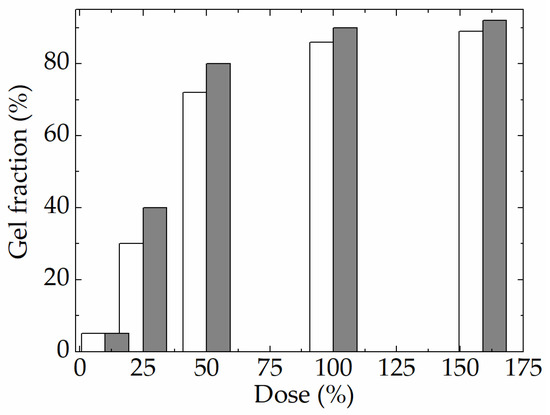

The polymer blends with a continuous morphology, where both components playing the role of radical source, such as SBR and EPDM, are the suitable hybrid materials for many products that demand a dense but elastic material showing a convenient oxidation strength. An appropriate example is the formulation consisting of SBR/EPDM = 50:50 and nanoclay particles crosslinked with sulfur or by γ-irradiation [136], where filler distribution is comparable to the consistency of hybrid composites. The evolution of crosslinking density (Figure 9) offers an illustrative benefit by which the bicomponent polymer blends can be provided for the certain special usage, especially in nuclear areas. Nevertheless, the radiation processing has a convenient advantage of chemical clean technology when the total reproducibility is always obtained. Similar conclusions may be drawn on the radiation effects of γ-exposed EPDM/HAp nanohybrids [137]. The mechanical properties of these irradiated composites suggest them as the adequate materials for medical wear, where mechanical charge and oxidation act simultaneously on the essential long-life products.

Figure 9.

The percentage of gel fraction formed in irradiated EPDM [47]. (white) pristine polymer, (light grey) polymer with PbZrO3/Nb doped nanoparticles.

The doped oxide nanoparticles with a semiconductor behavior may be taken into consideration for the stability improvement of EPDM and other similar polyolefins [47] because the protection activity against oxidation of the polymer substrate extends the oxidation induction time by about three times when filler content is 5 phr. Due to the increase in the lattice defect concentration that tightly traps radical intermediates, the doped inorganic fillers can be considered as a successful attempt for the production of long life materials with the features of hybrids.

6. Elastomers

The polymer structure that plays a decisive role in the interaction between hybrid components is always the basic source of breakable bonds placed in the interfacial zone of the composites. In the γ- or EB-irradiated hybrid systems, the enormous phase boundary threshold stimulates the jointing radiolysis fragments on the nanoparticle surface, being known that the reactive intermediates may be trapped by the available attachment positions on the polymer backbones [138]. The implementation of large areas of elastomeric nanocomposites after their radiation processing is closely related with the displayed performances, reliability and durability. By their applications in electronics, aerospace, corrosion protection and sealing products, they adequately serve as praxis targets with convenient functional features [52,139,140].

The hybrid materials with certain electrical properties required by the low conductivity of multishell insulations are optimally obtained with the addition of CuO nanoparticles [141]. The functionality assay in the range of medium irradiation doses (0–100 kGy) certifies the desirable processing dose as 75 kGy when the NBR/CuO nanocomposites simultaneously reach the best mechanical characteristics, thermal strength and electrical resistance. The quality of this formulation would be earned if satisfactory active antioxidants are added [142].

The relevant options for the manufacture of sealing gaskets, buffers or sound attenuators are the nanocomposites based on NBR and SBR resins modified with organically modified montmorillonite [143]. These nanocomposites show a maximum crosslinking degree at 75 kGy, when the clay plays the role of radical scavenger and the concentration of intermediates is not high enough for the initiation of radiochemical oxidation. The service parameters attained by the γ-irradiated ethylene acrylic elastomer/MWCNT are convenient for the creation of long-life dielectrics for supercapacitors, solar cells or any others where notable polarization can be induced [144]. The great gel fraction is obtained after the exposure of these hybrid composites to a gamma dose of 200 kGy, which is accompanied by the best mechanical features at the nanophase loading of 6%. Due to the excellent behavior of the blends containing ethylene acrylic elastomer/millable polyurethane/SWCNT and EB-crosslinked by TAC it may be achieved high crosslink densities (9 × 10−2 mol cm−3 at 5 phr of SWCNT) at 300 kGy [145]. Thus, the efficiency of electromagnetic shielding is conspicuously adjusted due to the proficient radiation treatment that modifies dielectric relaxation. Similar results are also obtained by the radiation processing of PCR/EPDM/MWCNT [146] or LDPE/EVA/PCR ternary blends [147], where the polyolefinic fraction plays the role of support for crosslinking of free radical fragments created by radiolysis of polychloroprene.

Epoxy resins are the polymer materials that accessibly incorporate nanofillers. The traps that appear in the filler during γ-exposure of ER/Al2O3 nanocomposites are active in the energy range of 0.752–0.758 eV [148]. This depth characterizes the scavenging of organic radicals formed by the structural decomposition of epoxy macromolecules. The interaction of these traps with radicals that are charge carriers (the fragments with unpaired electrons) affords an efficient radiation protection of surfaces during LOCA events, avoiding the progress in the anticorrosive layer. The most satisfactory effect is achieved when the alumina loading is 3 phr.

A meaningful consequence on the impedance of epoxy/TiO2 nanocomposites destined to electrical power insulation is efficiently correlated with the photoelectrical behavior of titania. The noticeable increase in the impedance value is obtained when the filler is added in the concentration of 3% [149]. If a comparison between the stability effects brought about by TiO2 and SiO2 nanocomposites in γ-irradiated epoxy resin is performed after the chemiluminescence measurements [150], the most efficient effect is found when the nanocomposites include titania (Table 6).

Table 6.

CL intensities measured on γ-irradiated epoxy nanocomposites [150].

The sharp increase in the CL intensity from nonirradiated samples to the samples that received 20 kGy may be explained by the larger distances between the appearing radicals and the nanoparticle surface. When the dose grows to 100 kGy, the concentration of degradation intermediates is higher and the attraction on the nanoparticle defects is much more evident, being stimulated by the interaction between nanoparticles and oxidized fragments.

Through the elastomers that are extensively applied, natural rubber is placed on the top position because of its versatile properties. Its availability to the profound modifications by high energy treatment is demonstrated by the efficient crosslinking, with or without binding monomers [151]. By the association of two kinds of filler particles, silica and graphenes in NB matrix, the EB irradiated SBR presents convenient values of tensile stress (Table 7) and tensile strength after the accelerated electron irradiation in air at 150 kGy [152].

Table 7.

Tensile strength value for EB-irradiated NR/SiO2-GE nanoplatelets. Dose: 150 kGy [152].

According to the results reported by Makuuchi [152], the mechanistic approach of structure modification during irradiation is presented as the formation of radicals near the double bond, which are protected and preserved. However, the short-lived free radicals are attracted by –C=C– forming H bridges on the early processing stage followed by crosslinking [153].

Relevant differences that exist between two sorts of elastomers, EPDM and SBR [154], point out the dissimilar degradation mechanism under EB exposure. In spite of the same evolution of gel fraction, whose accumulation is more accelerated over the first 100 kGy, the final insoluble content is higher in EPDM filled with OMMT, assuring confidence in the performance, as with hybrids. The reliable explanation is provided by the more sustained contribution of crosslinking, indicated by the corresponding radiochemical yield in EPDM/OMMT substrate. The judicious increase in the crosslinking density of irradiated EPDM/OMMT is expected for the first 75 kGy, because the contribution of oxidation has a slower rate when the concentration of free radicals is moderate.

A comparison between the polymers with various structures initially filled with silica nanoparticles emphasizes the influence of crosslinker (TMPT) and SiO2 nanophase [155] (Table 8). The involvement of crosslinker creates a hybrid conformity in the bulk of material.

Table 8.

Crosslinking density of some irradiated elastomers * [155].

The radiation behavior of these elastomers is adequately illustrated by the evolution of hardness, contact angle and vulcanized fraction, which confirm the influence of halosubstitution on the material stability. The difference between the slopes of the soluble fraction on reciprocal dose (Charlesby–Pinner representation) is a proof of the filler effect on the gelation attained in these elastomers under γ-irradiation. According to these results, it may be stated that the addition of silica improves the radiation strength, but the material structure is a determinate factor that characterizes the evolution of degradation in hybrids.

7. Poly(Lactic Acid)

The ampleness of the ecological concern in the production of plastics increases the significance of biopolymers, including them through the omnipresent packaging materials [156,157]. The special attention paid to the modification of their hybrids by γ- or EB-irradiation anticipates the advantages that may be gained by the application of this clean procedure for the assessment of durability [158].

The ester structure of PLA does not guarantee advanced thermal and radiation stabilities. The moderate values of activation energies required for the oxidation of pristine PLA [159] call the assays for investigations of stability warranty. Therefore, the initiation of detailed efforts for the increase in material performances related to its durability may define new ways for the preparation of PLA hybrids, as well as the characterization of main features by which these compounds earn market.

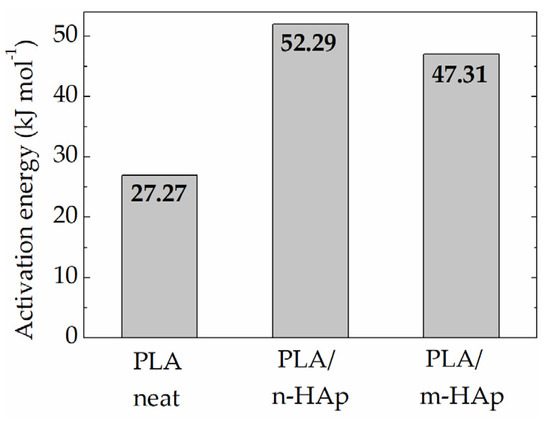

The influence of the particle size and the stability effects of fillers under irradiation were investigated in PLA/HAp composites [160]. The interphase surface is a main factor that controls the amplitudes of component interaction. The oxidability and water penetration are the properties that delimit the performances of PLA hybrids and their application ranges. The differences in the activation energies demanded that the degradation of PLA/HAp hybrids (Figure 10) may be reflected in the thermal characteristics, which obtain corresponding figures in the dependence on size and concentration of filler.

Figure 10.

Activation energies for the thermal oxidation of unirradiated PLA/HAp hybrid. Filler loading: 2% [160].

The contributions of several fillers such as montmorillonite nanoparticles and carbon nanotubes may be envisaged by the modification in thermal amd mechanical characteristics of composites [161] similarly occurring in hybrids. A blend consisting of PLA, liquid natural rubber and natural rubber (PLA/LNR/NR = 70/10/20) loaded with CNTs and MMT of 2.5% each destined to the production of ecological electronic packaging and domestic commodities presents maximum Tg and σ values of −60 °C and 1.41 × 10−9 S m−1, respectively, at the dose of 150 kGy, while the elongation at break decreases monotonically as the exposure dose is extended up to 250 kGy. The optimal processing dose of 150 kGy, a moderate industrial condition of radiation treatment for economical purposes, brings into account the participation of components, PLA as structurally degraded and natural rubber as free radical provider, where LNR plays the role of compatibilizer. The TEM investigations show the particular initiation of percolation as the dose is enhanced, when the threshold of 150 kGy separates the two regime domains: the inferior one characterizing the agglomeration of entangled macromolecules around filler nanocomponents, and the superior one, where the abundant radicals designate the aggregation of material around crystalline spots of PLA.

Based on the behavior of PLA/HAp nanocomposites that demonstrates the increase in the crystallinity degree under γ-irradiation [162], the scission of double bonds from monomer (TAIC) and from Ov-POSS [163] is the first step in the increase in the mechanical peculiarities, suggesting the extension of material durability and the routine practice of ecological packaging products. In the DSC thermograms [164] accomplished on the PLA/HAp (particle size—less 200 nm and Ca/P ratio of 1.67) nanocomposites, where the hydroxyapatite loading varies from 0 (pristine polymer) to 70 pph, the best features (crystallinity and melting temperature) were obtained for the unexposed patterns or irradiated at 30 kGy. The nanoparticles of HAp play the role of nucleation agent, as in hybrids. The convenient amount of this filler becomes 6 pph, where the specimens exhibit the best property of assembly. Similar ideas may be found by the analysis of the results provided by the irradiated PLA/MMT nanosystems [165], which turn the concept of irradiated nanocomposites onto their suitable purposes in the manufacture of hybrids for food packaging. The most relevant feature is suggested by the barrier function of the filler phase on the penetration ways of various fluids. By γ-irradiation, the hybrid sheet gains an appropriate penetrability for oxygen and water vapors after an exposure of 10 kGy that recommends this treatment as a good technological choice destined to the safety preservation of food.

If the neat nanocomposites based on PLA support [166,167] are considered as the backgrounds for bioplastics, the radiation procedure applied on the hybridized polymers brings about a redesign of the development strategy and approaching manner for a successful evolution of material performances. By the limitation of technological sight with the low cost equipments, the radiation processing of biopolymers still receives reduced attention. An illustrative example may be offered by the presence of silver nanoparticles on the stability of PLA/collagen mixtures [168]. The increase in the concentration of AgNPs produces an improvement in the thermal stability at 10 and 20 kGy, especially on the high temperature range exceeding 150 °C. It demonstrates that these nanoparticles are efficient oxidation inhibitors and they provide a long shelf life for medical, pharmaceutical and human handling products.

8. Polyurethanes

The nanomodified polyurethanes destined for medical wear, textile materials, corrosion protection, shape memory materials and flame retardant thermoplastics are receiving extensive attention due to their high performances and wearability. The adopted modifications in polyurethane by high energy irradiation optimize the service regimes required for very different applications.

The radiation stability of polyurethanes is unattractive due to the easy scission of soft fragments [169,170]. However, this state can be ameliorated by the addition of nanoparticles in irradiated polyurethane elastomer [171]. The mechanical assays on γ-exposed polyurethane at 200 kGy confirm the increase in material stability as well as the augmentation of maximum decomposition temperature and degradation rate, with about 37 °C and 10 %/°C, respectively, when the nanoparticle content is 5%. A similar protective effect of the cyanate ester resin phase is obtained for the diffusion of penetrating fluids during nuclear applications [172].

The correction of thermal behaviors by the action of γ-processing of polyurethane structures is supported by the dynamical mechanical measurements and broadband dielectric relaxation spectroscopy [173], when the incidental ray beam increases the temperature of α-relaxation involved in the dielectric characteristics, even at 200 kGy. Consequently, the reported information certainly explains the molecular scissions that occurred during radiolysis in the soft units (poly(tetramethylene glycole)), while the crosslinking is also achieved in the soft units (poly(butylene adipate)).

The hybrids consisting of polyurethane resulting from the condensation of 4,4′-diphenylmethane diisocyanate with poly(tetramethylene glycole) and POSS nanoparticles prove that their γ-irradiation at a moderate dose rate increases the thermal stability, demonstrated in the terms of enthalpy and OOT values [174]. A small amount of POSS (2 phr) preserves the stability of material presumable due to some extent of polyols that appeared due to the radiation damaging of polyurethane chains.

The stability investigations of polyurethane elastomers draw attention for several versions of durability adjustment by the intimate interaction with fillers [175]. The irradiation of polyurethane hybrids may launch the prevention of oxidation when the filler content does not exceed 6 phr [43]. The scavenging action of polyhedral structure in respect to the fragment of radiolytic degradation withdraws oxidation intermediated (either hydrocarbon or peroxyl radicals). The propagation of ageing is significantly removed in the formulation with 2, 4 and 6 phr of POSS. Favorable effects of stabilization are achieved by the irradiation of polyurethane/POSS nanocomposites at moderate γ-doses, not exceeding 60 kGy [176]. The longer exposure, when the reactive intermediates present greater local concentration, increases the probability of oxidation, even though the filler is limited by the cage effect.

The integration of carbon quantum dots in the polyurethane structural morphology creates the possibility of generation for oxygen active units by low power blue light irradiation after the γ-exposure of polyurethane support. The antiseptic activity is continuously enhanced on the large dose range (0–200 kGy) [177]. This radiation pre-treatment is recommended for the activation of oxygen release by the antimicrobial tapes. These composites are extremely efficient for combating microorganisms free of any hazardous chemicals.

The reference results concerning the radiation dose range over which polyurethanes may be modified are reported for its hybrid with nanopowder of HAp [178]. The irradiation regime is delimitated by the value of 25 kGy, when the low oxidation level proved by FTIR analysis and the mechanical properties of scaffolds is optimal.

9. Miscellaneous

Nanogels gain a wide perspective in various ranges of applications, but the most representative field is medicine, with its tissue engineering, drug delivery, cell adhesion and replacing scaffolds [179]. The irradiated hybrids consist of soluble polymer as support and include the filler that is the active component for the foreseen purpose. The often used water soluble polymer is poly(vinyl alcohol), whose swelling equilibrium is directly influenced by the other present component [180]. The clay (clay laponite RD coding S/11176/10) associated with agar in the PVAl loading of 1–1.5% increases the osmotic pressure after the application of an γ-irradiation dose of 25 kGy. The intercalation of clay particles through the irradiated PVAl molecules decreases the degree of swelling and the proportion of solvent that remains in the “dried” sheets. The presence of nanoparticles of silver [181] provides an increase in the crystallinity degree that improves the thermal and radiation stability of this hydrogel along the nuclear treatments, it being known that the degradation occurs exclusively in the amorphous phase of materials. The good electrical properties are achieved when the PVAl embeds nanoparticles [182]. The loading inside the range of 0.5–1.0% G/CNTs offers excellent mechanical properties of polymer support that makes it suitable for electrical applications after γ-irradiation at 25 kGy, the optimal gelation dose.

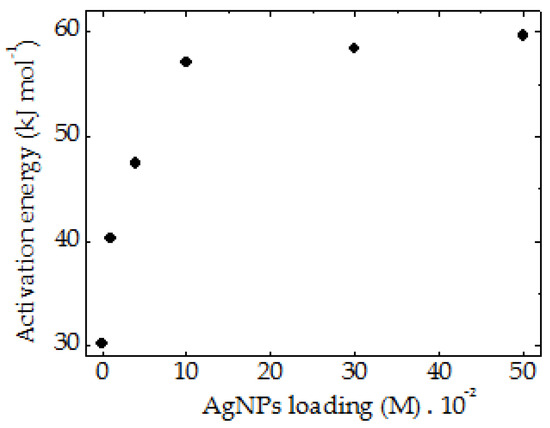

Another significant polymer for the preparation of hybrid hydrogels is PVP [183]. The clay content of 1% in the PVP/chitosan (0.5%) hampers the swelling in various fluids after receiving the 25 kGy of γ-dose. This means that the radiation treatment increases the insoluble fraction, leading to a more resistant material. If AgNPs are in the PVP/PS structure, the stability increases sharply when the concentration of nanoparticles is ten times higher (Figure 11) [184].

Figure 11.

Activation energies for the thermal oxidation of unirradiated PVP/AgNPs hybrid [184].

Hyaluronic acid/chondroitin sulfate-based hydrogel represents another illustration of the involvement of high energy exposure for the preparation of high-performance hydrogel hybrids [185]. The proper irradiation dose for an appropriate gelation is 15 kGy, a low value, which permits the good retention of water and enzymes for cell treatment.

The irradiation of PDMS embedded with silanol-terminated tetraethylortosilicate (TEOS) [186] provides a silicone rubber widely used in electronic applications and the anticorrosive protection. The blending proportion TEOS/PDMS of 4–5%wt of filler produces highly thermal resistant material after receiving 450 kGy of γ-dose. Even though this value is high enough, the main radiation effect is decisive for the advanced structuration instead of degradation. The γ-exposure PDMS containing silica and zirconia at this high dose (450 kGy) generates a monolith material which is stable at very high temperatures [187]. The coagulation of polymer around inorganic nanoparticles takes place during irradiation. The polar functions that are generated during radiolysis establish strong connections with the defects that appeared simultaneously on the particle surface. This treatment may be assimilated as a fusion because the consistency of the cured fraction is a good characteristic for its applications as rigid dielectrics.

10. Conclusions

This review presents several conclusive aspects describing the modification of hybrid composite by radiation processing. The appraisal on the behavior of polymer hybrids asks two main keys, the availability of polymers to interact with an inorganic phase for an intimate compatibility generating pertinent bridges and the profound structural modifications that provide the material with improved stability. The radiation exposure significantly modifies the great surface of nanoparticles, which affords the extension of durability, the property by which the products become appropriate for more and more applications. The radiation treatment, which has a relevant pertinence based to the intense energetic supply, the lack of material excess or the processing celerity, is a suitable technological version for attaining foreseen performances and proficient technology. The choice of materials that are potentially ameliorated based on the properties of pristine compounds must not be subjected to a random selection. The most important aspects that must be considered as a starting point include the radiation effects on polymers related to their radiochemical yields of scission and degradation, the blending proportion and the presence of convenient binder or stabilizer. Apart from these considerations, the filler powder must be carefully checked in relation to the generation of structural defects or morphological modifications. The modifications that occur in polymer phase due to γ- or electron beam-irradiation are decided either by the structure of organic component or by the interphase interaction that creates the new field of behavior.

Radiation processing is a convenient way to achieve the new version of old materials, if the technology is well conducted. The selection of materials and irradiation conditions may provide solutions where classical chemistry is not able, because the high concentration of intermediates, usually free radicals, contributes to their reactions immediately after their formation in the spur. This procedure is low cost and versatile, with high reproducibility and free of wastes. The radiation alternative applied for the modification of polymers and their hybrids is the best choice for the preparation of high purity products, the achievement of successful modifications and the guarantee of the efficiency for the foreseen improvement of material properties.

The radiation treatment converts composites into hybrids by structural modifications and, then, they may become useful for several purposes:

- gaskets, O-rings for the sealing of fluid pipes, screening surfaces for electromagnetic protection, membranes for batteries, items for buildings, aircraft, automotive and greenhouse articles or engineering applications in branches such as chemistry,

- polymer waste recycling and fire retardants,

- medical supports and wear, drug delivery structures, bone-tissue regeneration, scaffolds and implants,

- sensors

- package materials for beverage and food handling,

- various commodities and toys.

The main expectations from the radiation treatment of composites and hybrids are related to the facile modification by simple exposure, easy processing of any material or composition, large scale and multiple versions of products, lack of technological wastes and damages and high performances of final products. This irradiation technique can be applied on every formulation, if the foreseen changes are professionally conducted.

The future is open for a multitude of assays that are capable of successfully transforming every polymer blend (multicomponent systems, composites, hybrids) into a product suitable for the anticipated purposes.

Author Contributions

Conceptualization, T.Z.; methodology, M.M.; software, T.Z. and M.M.; validation, T.Z. and M.M.; writing—original draft preparation, T.Z.; writing—review and editing, T.Z. and M.M.; visualization, M.M.; supervision, T.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AAc | acrylic acid |

| AgNP | silver nanoparticle |

| AN | acrylonitrile |

| CB | carbon black |

| CF | carbon fiber |

| CFRTP | carbon fiber reinforced thermoplastic |

| CL | chemiluminescence |

| CuNW | copper nanowire |

| Ea | activation energy |

| EB | electron beam |

| EBN | ethylidene norbornene |

| EPDM | Ethylene–propylene–diene monomer |

| ER | epoxy resin |

| ESR | electron spin resonance |

| EVA | poly(ethylene-co-vinylacetate) |

| FTIR | Fourier Transformed Infrared spectroscopy |

| G | graphene |

| HAp | hydroxyapatite |

| HDPE | high density polyethylene |

| LDPE | low density polyethylene |

| LNR | liquid natural rubber |

| LOCA | loss of coolant accident |

| MA | maleic anhydride |

| MFI | melting flow index |

| MMT | montmorillonite |

| MWCNT | multi-walled carbon nanotubes |

| NP | nanoparticle |

| NPP | nuclear power plant |

| NBR | nitrile rubber |

| NR | natural rubber |

| OMMT | organomodified montorillonite |

| OOT | onset oxidation temperature |

| Ov-POSS | octavinyl polyhedral oligomeric silsequioxane |

| PCR | polychloroprene |

| PDMS | polydimethyl siloxane |

| phr | parts per hundred rubber |

| PLA | poly(lactic acid) |

| POSS | polyhedral oligomeric silsequioxane |

| pph | parts per hundred percent |

| PS | polystyrene |

| PVAl | poly(vinyl alcohol) |

| PVP | poly(2-vinyl pyrrolidone) |

| SBR | styrene-butadiene rubber |

| TAC | triallylcyanurate |

| TEM | transmission electron microscopy |

| TMPT | trimethylolpropane trimethyacrylate |

| TMPTA | trimethylolpropane triacrylate |

| Tg | glass transition temperture |

| Tm | melting temperature |

| σ | electrical conductivity |

References

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. Predicting effective electrical resistivity and conductivity of carbon nanotube/carbon black-filed polymer matrix hybrid nanocomposites. J. Phys. Chem. Solids 2022, 161, 110444. [Google Scholar] [CrossRef]

- Kumar Shukla, M.; Sharma, K. Molecular modeling and experimental investigation of graphene/CNT hybrid epoxy composites for characterization of tensile properties. Mater. Today-Proc. 2020, 26, 3234–3237. [Google Scholar] [CrossRef]

- Ahlhem, M.; Lattorre, S.H.; Mayr, H.O.; Storch, C.; Freytag, C.; Werner, D.; Schwarzer-Fisher, E.; Seidenstücher, M. Mechanically stable β-TCP structural hybrids scaffolds for potential bone replacement. J. Compos. Sci. 2021, 5, 281. [Google Scholar] [CrossRef]

- de Oliviera Machado, V.; Andrade, A.L.; Domingos Fabris, J.; Fraga Freitas, E.T.; da Fonte Ferreira, J.M.; Simon, S.; Zacarias Domingues, R.; Fernandez-Outon, L.E.; Almada do Carmo, F.; dos Santos Souza, A.C.; et al. Preparation of hybrid nanocomposite particles for medical practices. Colloid Surf. A 2021, 624, 126706. [Google Scholar] [CrossRef]

- Aiza Jaafar, C.N.; Zainol, I.; Ishak, N.S.; Ilyas, R.R.; Sapuan, S.M. Effects of the liquid natural rubber (LNR) on the mechanical properties and microstructure of epoxy/silica/kenaf hybrid composites for potential automotive applications. J. Mater. Res. Tech. 2021, 12, 1026–1038. [Google Scholar] [CrossRef]

- Dilip Kumar, K.; Shantharaja, M.; Kumar, N.; Manj, G. Morphological and mechanical properties of short fiber reinforced hybrid composites for automotive applications. Mater. Today-Proc. 2021, 52, 957–962. [Google Scholar] [CrossRef]

- Kausar, A. Green nanocomposites for energy storage. J. Compos. Sci. 2021, 5, 202. [Google Scholar] [CrossRef]

- Liu, J.; Chen, X.; Cao, S.; Yang, H. Overview on hybrid solar photovoltaic-electrical energy storage technologies for power supply to buildings. Energy Convers. Manag. 2019, 187, 103–121. [Google Scholar] [CrossRef]

- Truc Nguyen, K.; Zhao, Y. Integrated graphene/nanoparticle hybrid for biological and electronic applications. Nanoscale 2014, 6, 6245–6266. [Google Scholar] [CrossRef]

- Wu, W. Biodegradable polymer nanocomposites for electronics. In Polymer Nanocomposite Materials: Applications in Integrated Electronic Devices, 1st ed.; Zhou, Y., Ding, G.L., Eds.; Wiley-VCH GmbH: Weinheim, Germany, 2021; Chapter 3; pp. 53–75. [Google Scholar]

- Hu, L.; Wu, H.; You, H.; Wang, Y.; Gao, A. Smart hybrid sensor for magnetic field and vibration detection based on PMN-PT/Terfenol-D magnetoelectric composites and suspended magnetic vibrator. Sens. Actuators A-Phys. 2021, 332, 113100. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, L.; Ma, Y.; Huang, H.; He, H.; Ji, H.; Wang, Z.; Qiu, J. Highly sensitive, reliable and flexible pressure sensor based on piezoelectric PVDF hybrid film using MXene nanosheets reinforcement. J. Alloys Compd. 2021, 886, 161069. [Google Scholar] [CrossRef]

- Dong, W.; Su, J.; Chen, Y.; Xu, D.; Cheng, L.; Mao, L.; Gao, Y.; Yoan, F. Characterization and antioxidant properties of chitosan film incorporated with modified silica as an active food packaging. Food Chem. 2022, 373, 131414. [Google Scholar] [CrossRef] [PubMed]

- Zaharescu, T.; Mateescu, C. Stability efficiency of POSS and microalgae extracts on the durability of ethylene-propylene-diene monomer bas hybrids. Polymers 2022, 14, 187. [Google Scholar] [CrossRef] [PubMed]

- Muc, A. Introduction to macroscopic optional design in the mechanics of composite materials and structures. J. Compos. Sci. 2021, 5, 36. [Google Scholar] [CrossRef]

- Rafii, A.; Loni, R.; Mahadzir, S.B.; Najaf, G.; Sadeghzadeh, M.; Mazlan, M.; Ahmadi, M.H. Hybrid solar desalinization system for generation electricity and freshwater with nanofluid application: Energy, exergy, and environmental aspects. Sustain. Energy Technol. Asses. 2022, 50, 101716. [Google Scholar]

- Noor, H.A.; Suha, K.S.; Muzher Taha, M. Mechanical and physical characteristics of hybrid particles/fiber-polymer composites. A review. Mater. Today-Proc 2022, in press. [Google Scholar] [CrossRef]

- Islam, A.; Yasin, T.; Ur Rehman, I. Synthesis of hybrid polymer networks of irradiated chitosan/poly(vinyl alcohol) for biomedical applications. Radiat. Phys. Chem. 2014, 96, 115–119. [Google Scholar] [CrossRef]

- Devaraju, S.; Alagar, M. POSS nanoparticles: Synthesis, characterization, and properties. In Polyhedral Oligomeric Silsesquioxane (POSS) Polymer Nanocomposites, From Synthesis to Applications, 1st ed.; Thomas, S., Somasekharan, L., Eds.; Elsevier: New York, NY, USA, 2021; Chapter 1; pp. 1–25. [Google Scholar]

- Amjadi, M.; Rowshanzamir, S.; Peighambardoust, S.J.; Sedghi, S. Preparation, characterization and cell performances of durable nafion/SiO2 hybrid membrane for high-temperature polymeric fuel cells. J. Power Sources 2012, 210, 350–357. [Google Scholar] [CrossRef]

- Hood, M.A.; Mari, M.; Muñoz-Espí, R. Synthetic strategies in the preparation of polymer/inorganic hybrid nanoparticles. Materials 2014, 7, 4057–4087. [Google Scholar] [CrossRef]

- Zagho, M.M.; Husein, E.A.; Elzatahry, A.A. Recent overview in functional polymer composites for biomedical applications. Polymers 2018, 10, 739. [Google Scholar] [CrossRef]

- Ansaloni, L.; Deng, L. Advances in polymer-inorganic hybrids as membrane materials. In Recent developments in Polymer Macro, Micro and Nano Blends, 1st ed.; Visakh, P.M., Marcovic, G., Pasquini, D., Eds.; Elsevier: New York, NY, USA, 2017; Chapter 7; pp. 163–206. [Google Scholar]

- Surmenev, R.A.; Orlova, T.; Chernozem, R.V.; Ivanovna, A.A.; Baryasyte, A.; Mathur, S.; Surmenova, M.A. Hybrid lead-free polymer-based nanocomposites with improved piezoelectric response for biomedical energy-harvesting applications: A review. Nano Energy 2019, 62, 475–506. [Google Scholar] [CrossRef]

- Bazli, M.; Heitzmann, M.; Vilacorta Hernandez, B. Hybrid fiber reinforced polymer and seawater sea sand concrete structure. Constr. Build. Mater. 2021, 301, 124335. [Google Scholar] [CrossRef]

- Prunet, G.; Pawula, F.; Fleury, G.; Cloutet, E.; Robinson, A.J.; Hadziioannou, G.; Pakdel, A. A review on conductive polymers and their hybrids for flexible and wearable thermoelectric applications. Mater. Today Phys. 2021, 18, 100402. [Google Scholar] [CrossRef]

- Abdo Saleh, T. Structural characterization of hybrid materials. In Polymer Hybrid Materials and Nanocomposites; Abdo Saleh, T., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 213–240. [Google Scholar]

- Tarawneh, M.A.; Saraireh, S.A.; Chen, S.R.; Abhmad, S.H.; Al-Tarawni, M.A.M.; Yu, L.J. Gamma irradiation influence on mechanical, thermal and conductivity properties of hybrid carbon nanotubes/montmorillonite nanocomposites. Radiat. Phys. Chem. 2021, 179, 109168. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Chmielewski, A.G. (Eds.) Applications of Ionizing Radiation in Material Processing; INCT Print House: Warsaw, Poland, 2017. [Google Scholar]

- Zaharescu, T.; Jipa, S. Radiochemical modifications in polymers. In Landolt-Börnstein Numerical Data and Functional Relationships in Science and Technology; Arndt, K.-F., Lechner, M.D., Eds.; Springer: New York, NY, USA, 2013; Group VIII; Volume 6, pp. 93–184. [Google Scholar]

- Cellina, M.C.; Assink, R.A. (Eds.) Polymer Durability and Radiation Effects; ACS: Washington, DC, USA, 2008. [Google Scholar]

- Lerouge, S. Sterilization and cleaning of metallic biomaterials. In Metals for Biomedical Devices, 3rd ed.; Niinomi, M., Ed.; Elsevier: Cambridge, MA, USA, 2010; pp. 303–326. [Google Scholar]

- Serbaya, S.H.; Abualsauod, E.H.; Salem Basingab, M.; Bukhari, H.; Rizwan, A.; Sajjad Mehmood, M. Structure and performances attributes optimization and ranking of gamma irradiated polymer hybrids for industrial applications. Polymers 2022, 14, 47. [Google Scholar] [CrossRef] [PubMed]

- Zaharescu, T.; Marinescu, V.; Hebda, E.; Pielikowski, K. Thermal stability of gamma-irradiated polyurethane/modified POSS nanoparticles. J. Therm. Anal. Calorim. 2018, 133, 49–54. [Google Scholar] [CrossRef]

- Makuuchi, K.; Cheng, S. (Eds.) Radiation Processing of Polymer Materials and Its Industrial Applications; Wiley: New York, NY, USA, 2012; pp. 26–70. [Google Scholar]

- Bernstein, R.; Thornberg, S.M.; Assink, R.A.; Mowery, D.M.; Alam, M.K.; Irwin, A.N.; Hochrein, J.M.; Derzon, D.K.; Klamo, S.B.; Clough, R.L. Insight into oxidation mechanisms in gamma-irradiated polypropylene, using selective isotopic labeling with analysis by GC/MS, NMR and FTIR. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2007, 265, 8–17. [Google Scholar] [CrossRef]

- Zaharescu, T.; Catauro, M.; Blanco, I. Kinetics of the non-isothermal degradation of POSS/EPDM hybrids compounds. Macromol. Symp. 2021, 395, 2000224. [Google Scholar] [CrossRef]

- Darwis, D.; Abbas, E.B.; Nurlidar, F.; Pribadi Putra, D. Radiation processing of polymers for medical and pharmaceutical applications. Macromol. Symp. 2015, 353, 15–23. [Google Scholar] [CrossRef]

- Ping, X.; Wang, M.; Gen, X. Surface modification of poly(ethylene terephthalate) (PET) film by gamma-ray induced grafting of poly(acrylic acid) and its application in antibacterial hybrid film. Radiat. Phys. Chem. 2011, 80, 567–572. [Google Scholar] [CrossRef]

- Zaharescu, T.; Blanco, I.; Bottino, F.A. Surface antioxidant activity of modified particles in POSS/EPDM Hybrids. Appl. Surf. Sci. 2020, 509, 144702. [Google Scholar] [CrossRef]

- Ashfac, A.; Clochard, M.-C.; Coqueret, X.; Dispenza, C.; Driscoll, M.S.; Ulański, P.; Al-Sheikhly, M. Polymerization reactions and modifications of polymers by ionizing radiation. Polymers 2020, 12, 2877. [Google Scholar] [CrossRef] [PubMed]

- Güven, O. Radiation-assisted synthesis of polymer-based nanomaterials. Appl. Sci. 2021, 11, 7913. [Google Scholar] [CrossRef]

- Zaharescu, T.; Pielichowski, K. Stabilization effect of POSS naniparticles on gamma-irradiated polyurethane. J. Therm. Anal. Calorim. 2016, 124, 767–774. [Google Scholar] [CrossRef]

- Signer Bartolomei, S.; Galvão Santana, J.; Valenzuela Díaz, F.R.; Akkas Kavalli, P.; Güven, O.; Moura, E.A.B. Investigation of the effect of titanium dioxide and clay grafted with glycidyl methacrylate by gamma radiation on the properties of EVA flexible films. Radiat. Phys. Chem. 2020, 169, 107973. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, M.; Wu, G.; Wang, Y.; Zhang, L. Radiation cross-linking and its application. In Radiation Technology for Advanced Materials: From Basic to Modern Applications; Wu, G., Zhai, M., Wang, M., Eds.; Elsevier: New York, NY, USA, 2019; Chapter 3; pp. 75–113. [Google Scholar]

- Lancastre, J.J.H.; Falcão, A.N.; Margaça, F.M.A.; Ferreira, L.M.; Miranda Salvado, I.M.; Casimiro, M.H.; Almásy, L.; Meiszterics, A. Influence of the polymer molecular weight on the microstructure of hybrid materials prepared by γ–irradiation. Radiat. Phys. Chem. 2015, 106, 126–129. [Google Scholar] [CrossRef][Green Version]

- Zaharescu, T. Stabilization effects of EPDM by doped inorganic filler for space and terrestrial applications. Mater. Chem. Phys. 2019, 234, 102–109. [Google Scholar] [CrossRef]

- Choi, J.-H.; Jung, C.-H.; Hwang, I.-T.; Choi, J.-H. Preparation and characterization of crosslinked poly(butylene adipate-coterephtalate)/polyhedral oligomeric silsesquioxane nanocomposite by electron beam irradiation. Radiat. Phys. Chem. 2013, 82, 100–105. [Google Scholar] [CrossRef]

- Ferry, M.; Ngono, Y. Energy transfer in polymers submitted to ionizing radiation. Radiat. Phys. Chem. 2021, 180, 109320. [Google Scholar] [CrossRef]

- Jipa, S.; Zaharescu, T.; Setnescu, R.; Kappel, W.; Oros, C.; Gorghiu, L.M. RTL study of structural modifications in irradiated PTFE. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2007, 265, 305–308. [Google Scholar] [CrossRef]

- Secu, M.; Jipa, S.; Secu, C.E.; Zaharescu, T.; Georgescu, R.; Cutubinis, L. Processes involved into high-temperature thermoluminescence of Mn2+—Doped MgF2 phosphor. Phys. Status Solidi B 2008, 245, 159–162. [Google Scholar] [CrossRef]

- Saif, M.J.; Naveed, M.; Asif, H.M.; Akhtar, R. Irradiation applications for polymer nano-composites: A state-of-the-art review. J. Ind. Eng. Chem. 2018, 60, 218–236. [Google Scholar] [CrossRef]

- Zaharescu, T.; Borbath, T.; Blanco, I.; Borbath, I. Stability effect of metallic traces in the degradation of materials. Macromol. Symp. 2021, 395, 2000221. [Google Scholar] [CrossRef]

- Saleh, N.G.; Alias, M.S.; Gläsel, H.-J. High performance radiation curable hybrid coatings. Radiat. Phys. Chem. 2013, 84, 70–73. [Google Scholar] [CrossRef]

- Zaharescu, T.; Râpă, M.; Lungulescu, E.M.; Butoi, N. Filler effect on the degradation of γ-processed PLA/vinyl POSS hybrid. Radiat. Phys. Chem. 2018, 153, 188–197. [Google Scholar] [CrossRef]

- Hatano, Y. Future perspectives of radiation chemistry. Radiat. Phys. Chem. 2009, 78, 1021–1025. [Google Scholar] [CrossRef]