Influence of Moisture Diffusion on the Dynamic Compressive Behavior of Glass/Polyester Composite Joints for Marine Engineering Applications

Abstract

1. Introduction

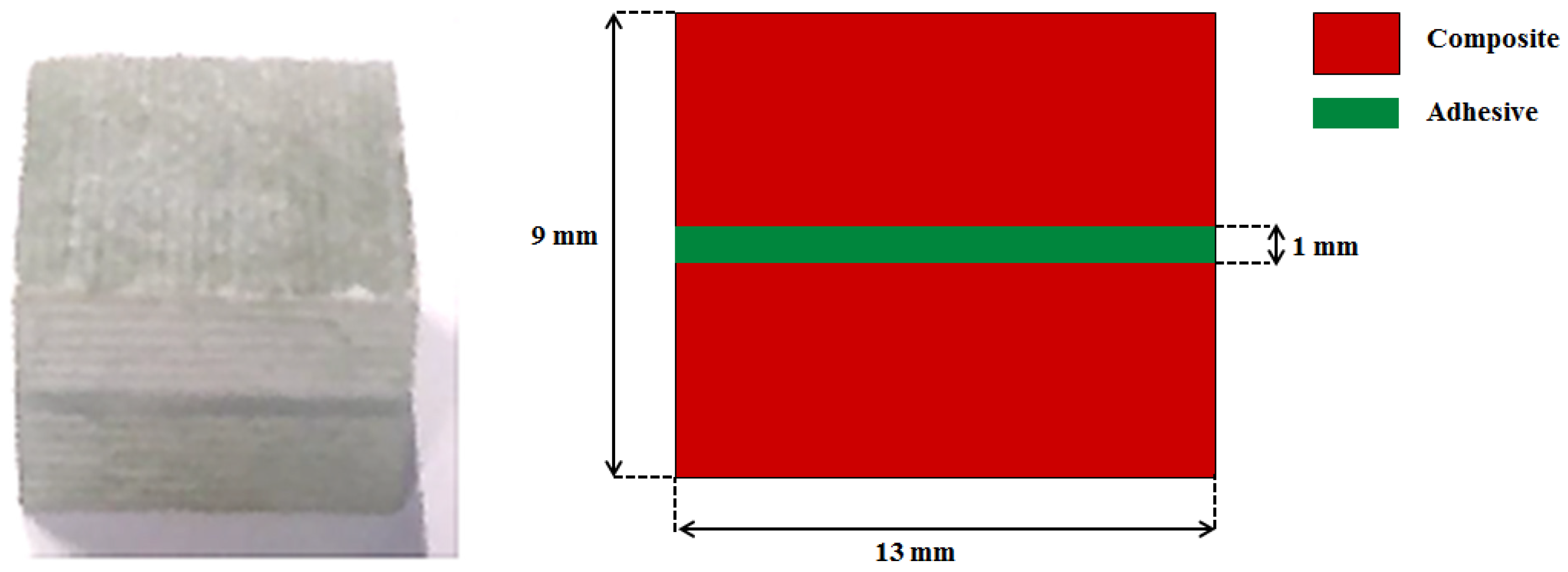

2. Materials and Methods

2.1. Materials

2.2. Methods

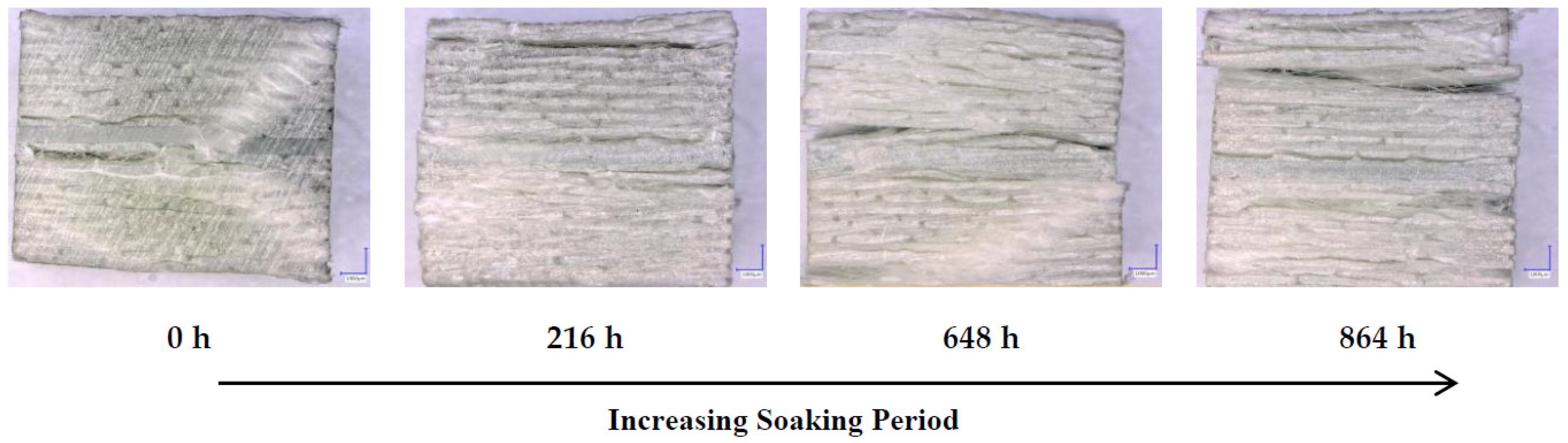

2.2.1. Hygrothermal Aging Test

2.2.2. Moisture Absorption

3. Dynamic Response in Moisture Absorption

3.1. Dynamic Compression Test

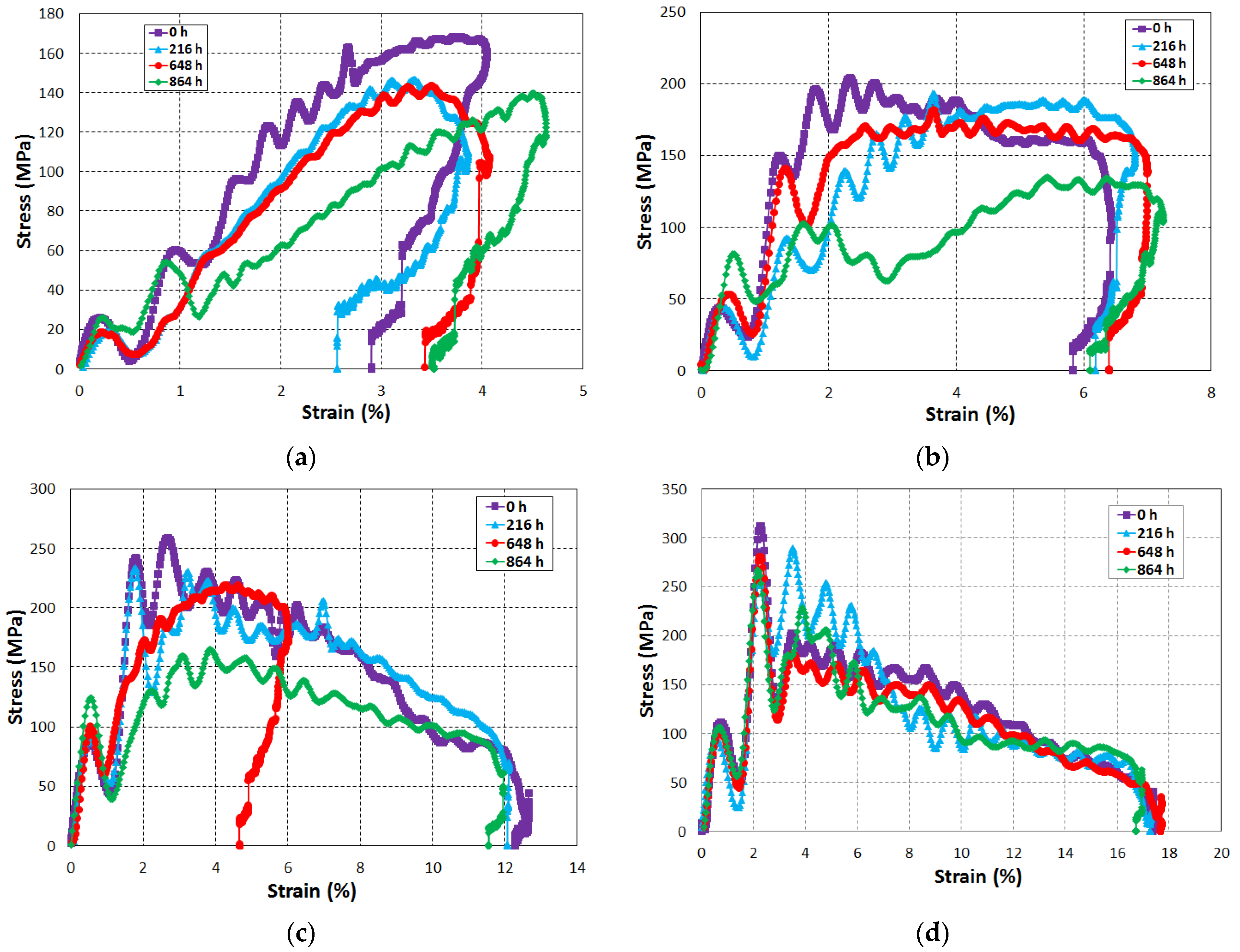

3.2. Mechanical Behavior

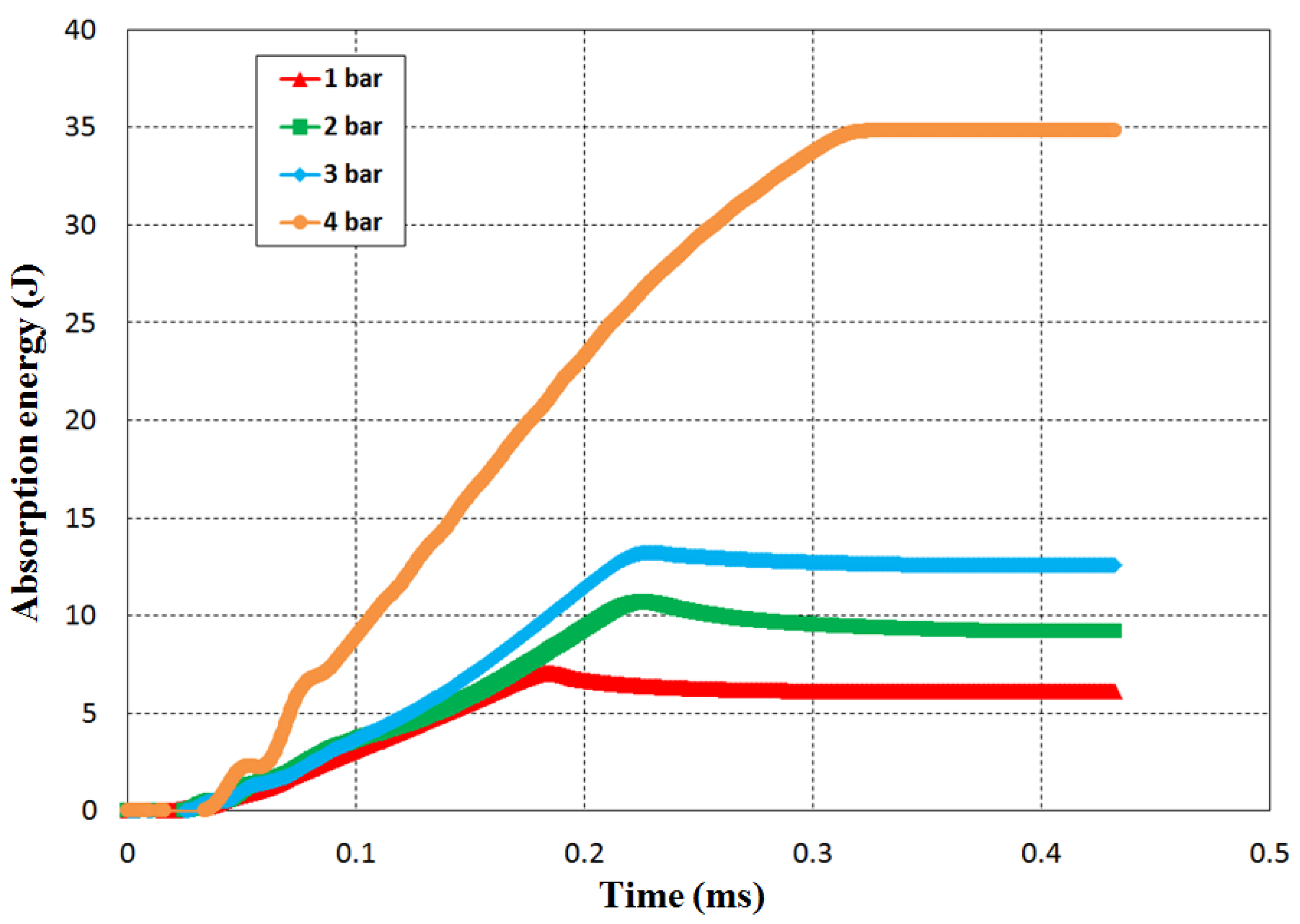

3.3. Theoretical Characterization of Absorbed Energy

- As the impact energy increases, the number of damage cracks is large and its distribution becomes more uniform, while the energy absorbed also increases as shown in Figure 10.

- Most of the incident energy is absorbed due to the effect of aging and the low impedance of composites.

- Zone 1 represents the loading phase (AB): The sample is absorbing energy at point B (), and this energy is composed of an elastic component and an unrecovered dissipative component.

- Zone 2 represents the progressive discharge part: The elastic energy is realized up to point C ().

- Zone 3 represents the final stage of the charge/discharge cycle: corresponds to the energy permanently dissipated in the material.

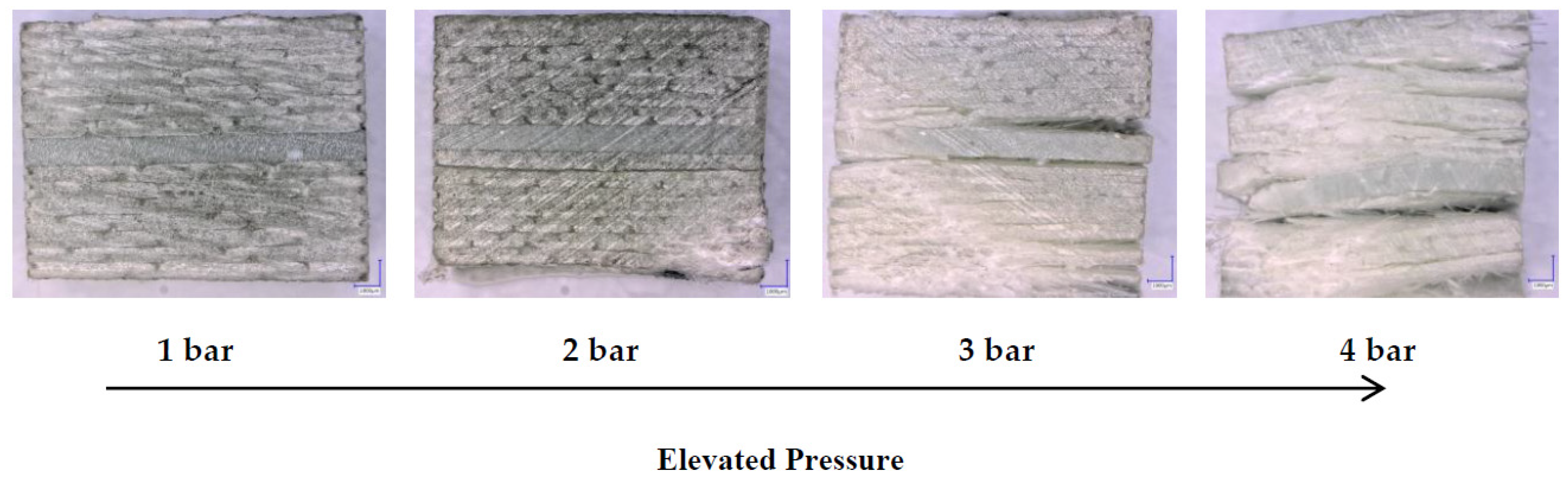

3.4. Damage Mechanisms and Failure Modes

3.5. Microstructural Analysis of Adhesively Bonded Composite

4. Conclusions

- Matrix plasticization is the major factor in the high strain rate properties when materials are partially or fully wet-immersed in a room temperature bath.

- The matrix is more sensitive to deformation rate, and therefore, plays a more important role than the fiber in identifying the high deformation rate material behavior of polymer matrix composites.

- The deterioration of the interface fiber/matrix leads to a decrease in the favorable impact of the plasticization of the matrix.

- An overall increase in material properties occurs due to absorption of moisture, except in high-temperature baths, due to the extreme degradation of the interface.

- There is an amount of absorbed moisture that gives optimum material properties that correspond to the highest matrix plasticization with minimal degradation of the interface between fiber and matrix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Nachtane, M.; Tarfaoui, M.; Saifaoui, D.; El Moumen, A.; Hassoon, O.H.; Benyahia, H. Evaluation of Durability of Composite Materials Applied to Renewable Marine Energy: Case of Ducted Tidal Turbine. Energy Rep. 2018, 4, 31–40. [Google Scholar] [CrossRef]

- Mangalgiri, P.D. Composite Materials for Aerospace Applications. Bull. Mater. Sci. 1999, 22, 657–664. [Google Scholar] [CrossRef]

- Nachtane, M.; Tarfaoui, M.; Saifaoui, D.; El Moumen, A.; Boudounit, H. Caractérisation Mécanique d’une Hydrolienne En Matériau Composite Dans Un Environnement Marin. In Proceedings of the 2017 23e Congrès français de Mécanique-CFM, Lille, France, 28 August–1 September 2017; Association Française de Mécanique (AFM): Courbevoie, France, 2017. [Google Scholar]

- Nachtane, M.; Tarfaoui, M.; El Moumen, A.; Saifaoui, D. Numerical Investigation of Damage Progressive in Composite Tidal Turbine for Renewable Marine Energy. In Proceedings of the 2016 International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 14–17 November 2016; pp. 559–563. [Google Scholar]

- Nachtane, M.; Tarfaoui, M.; Goda, I.; Rouway, M. A Review on the Technologies, Design Considerations and Numerical Models of Tidal Current Turbines. Renew. Energy 2020, 157, 1274–1288. [Google Scholar] [CrossRef]

- Maziz, A.; Tarfaoui, M.; Gemi, L.; Rechak, S.; Nachtane, M. A Progressive Damage Model for Pressurized Filament-Wound Hybrid Composite Pipe under Low-Velocity Impact. Compos. Struct. 2021, 276, 114520. [Google Scholar] [CrossRef]

- Maziz, A.; Tarfaoui, M.; Rechak, S.; Nachtane, M.; Gemi, L. Finite Element Analysis of Impact-Induced Damage in Pressurized Hybrid Composites Pipes. Int. J. Appl. Mech. 2021, 13, 2150074. [Google Scholar] [CrossRef]

- Nachtane, M.; Tarfaoui, M.; Ledoux, Y.; Khammassi, S.; Leneveu, E.; Pelleter, J. Experimental Investigation on the Dynamic Behavior of 3D Printed CF-PEKK Composite under Cyclic Uniaxial Compression. Compos. Struct. 2020, 247, 112474. [Google Scholar] [CrossRef]

- Shahawy, M.A.; Beitelman, T.; Arockiasamy, M.; Sowrirajan, R. Experimental Investigation on Structural Repair and Strengthening of Damaged Prestressed Concrete Slabs Utilizing Externally Bonded Carbon Laminates. Compos. Part B Eng. 1996, 27, 217–224. [Google Scholar] [CrossRef]

- Nachtane, M.; Tarfaoui, M.; El Moumen, A.; Saifaoui, D. Damage Prediction of Horizontal Axis Marine Current Turbines under Hydrodynamic, Hydrostatic and Impacts Loads. Compos. Struct. 2017, 170, 146–157. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M.; Yahia, H.B. In-Situ Heat Dissipation Monitoring in Adhesively Bonded Composite Joints under Dynamic Compression Loading Using SHPB. Compos. Part B Eng. 2018, 154, 64–76. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M.; Yahia, H.B. Thermomechanical Behavior of Adhesively Bonded Joints under Out-of-Plane Dynamic Compression Loading at High Strain Rate. J. Compos. Mater. 2018, 52, 4171–4184. [Google Scholar] [CrossRef]

- Laaouidi, H.; Tarfaoui, M.; Nachtane, M.; Lagdani, O. Modal Analysis of Composite Nozzle for an Optimal Design of a Tidal Current Turbine. J. Nav. Archit. Mar. Eng. 2021, 18, 39–54. [Google Scholar]

- Lagdani, O.; Tarfaoui, M.; Nachtane, M.; Trihi, M.; Laaouidi, H. Modal Analysis of an Iced Offshore Composite Wind Turbine Blade. Wind Eng. 2021, 46, 134–149. [Google Scholar] [CrossRef]

- Komai, K.; Minoshima, K.; Shibutani, T.; Nomura, T. The Influence of Water on the Mechanical Properties and Fatigue Strength of Angle-Ply Carbon/Epoxy Composites. JSME Int. J. Ser. 1 Solid Mech. Strength Mater. 1989, 32, 588–595. [Google Scholar] [CrossRef][Green Version]

- Ashik, K.P.; Sharma, R.S.; Guptha, V.J. Investigation of Moisture Absorption and Mechanical Properties of Natural/Glass Fiber Reinforced Polymer Hybrid Composites. Mater. Today Proc. 2018, 5, 3000–3007. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Inluence of Water Up-Take on Interlaminar Fracture Properties of Carbon Fibre-Reinforced Polymer Composites. J. Mater. Sci. 1995, 30, 334–338. [Google Scholar] [CrossRef]

- Wu, L.; Hoa, S.V.; Ton-That, M.-T. Effects of Water on the Curing and Properties of Epoxy Adhesive Used for Bonding FRP Composite Sheet to Concrete. J. Appl. Polym. Sci. 2004, 92, 2261–2268. [Google Scholar] [CrossRef]

- Buehler, F.U.; Seferis, J.C. Effect of Reinforcement and Solvent Content on Moisture Absorption in Epoxy Composite Materials. Compos. Part A Appl. Sci. Manuf. 2000, 31, 741–748. [Google Scholar] [CrossRef]

- Schutte, C.L. Environmental Durability of Glass-Fiber Composites. Mater. Sci. Eng. R Rep. 1994, 13, 265–323. [Google Scholar] [CrossRef]

- Mijović, J.; Zhang, H. Molecular Dynamics Simulation Study of Motions and Interactions of Water in a Polymer Network. J. Phys. Chem. B 2004, 108, 2557–2563. [Google Scholar] [CrossRef]

- Khalilullah, I.; Reza, T.; Chen, L.; Mazumder, A.M.H.; Fan, J.; Qian, C.; Zhang, G.; Fan, X. In-Situ Characterization of Moisture Absorption and Hygroscopic Swelling of Silicone/Phosphor Composite Film and Epoxy Mold Compound in LED Packaging. In Proceedings of the 2017 18th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Dresden, Germany, 3–5 April 2017; Institute of Electrical and Electronics Engineers IEEE: Piscataway Township, NJ, USA, 2017; pp. 1–9. [Google Scholar]

- Megel, M.; Kumosa, L.; Ely, T.; Armentrout, D.; Kumosa, M. Initiation of Stress-Corrosion Cracking in Unidirectional Glass/Polymer Composite Materials. Compos. Sci. Technol. 2001, 61, 231–246. [Google Scholar] [CrossRef]

- Jiang, X.; Kolstein, H.; Bijlaard, F.; Qiang, X. Effects of Hygrothermal Aging on Glass-Fibre Reinforced Polymer Laminates and Adhesive of FRP Composite Bridge: Moisture Diffusion Characteristics. Compos. Part A Appl. Sci. Manuf. 2014, 57, 49–58. [Google Scholar] [CrossRef]

- Nachtane, M.; Tarfaoui, M.; Saifaoui, D.; Hilmi, K. Hygrothermal and Mechanical Performance Evaluation of Glass-Polyester Composite for Renewable Marine Energies. In Proceedings of the 13ème Congrès de Mécanique (cmm2017), Meknès, Morocco, 4–11 April 2017. [Google Scholar]

- Grace, L.R.; Altan, M.C. Characterization of Anisotropic Moisture Absorption in Polymeric Composites Using Hindered Diffusion Model. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1187–1196. [Google Scholar] [CrossRef]

- Benyahia, H.; Tarfaoui, M.; El Moumen, A.; Ouinas, D.; Hassoon, O.H. Mechanical Properties of Offshoring Polymer Composite Pipes at Various Temperatures. Compos. Part B Eng. 2018, 152, 231–240. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M.; Yahia, H.B. An Investigation of In-Plane Dynamic Behavior of Adhesively-Bonded Composite Joints under Dynamic Compression at High Strain Rate. Compos. Struct. 2018, 191, 168–179. [Google Scholar] [CrossRef]

- Firdosh, S.; Murthy, H.N.; Angadi, G.; Raghavendra, N. Investigation of Water Absorption Characteristics of Nano-Gelcoat for Marine Application. Prog. Org. Coat. 2018, 114, 173–187. [Google Scholar] [CrossRef]

- Shah, O.R.; Tarfaoui, M. Effect of Damage Progression on the Heat Generation and Final Failure of a Polyester–Glass Fiber Composite under Tension–Tension Cyclic Loading. Compos. Part B Eng. 2014, 62, 121–125. [Google Scholar] [CrossRef]

- Hassoon, O.H.; Tarfaoui, M.; Alaoui, A.E.M.; El Moumen, A. Experimental and Numerical Investigation on the Dynamic Response of Sandwich Composite Panels under Hydrodynamic Slamming Loads. Compos. Struct. 2017, 178, 297–307. [Google Scholar] [CrossRef]

- Gargano, A.; Pingkarawat, K.; Pickerd, V.; Delaney, T.; Das, R.; Mouritz, A.P. Effect of Seawater Immersion on the Explosive Blast Response of a Carbon Fibre-Polymer Laminate. Compos. Part A Appl. Sci. Manuf. 2018, 109, 382–391. [Google Scholar] [CrossRef]

- Pang, S.; Tao, W.; Liang, Y.; Liu, Y.; Huan, S. A Modified Method of Pulse-Shaper Technique Applied in SHPB. Compos. Part B Eng. 2019, 165, 215–221. [Google Scholar] [CrossRef]

- Zhao, H.; Gary, G. On the Use of SHPB Techniques to Determine the Dynamic Behavior of Materials in the Range of Small Strains. Int. J. Solids Struct. 1996, 33, 3363–3375. [Google Scholar] [CrossRef]

- Gazit, S. Dimensional Changes in Glass-Filled Epoxy Resin as a Result of Absorption of Atmospheric Moisture. J. Appl. Polym. Sci. 1978, 22, 3547–3558. [Google Scholar] [CrossRef]

- Haque, A.; Hossain, M.K. Effects of Moisture and Temperature on High Strain Rate Behavior of S2-Glass–Vinyl Ester Woven Composites. J. Compos. Mater. 2003, 37, 627–647. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M.; Nachtane, M.; Ben Yahia, H. Strain Rate Effects on the Dynamic Compressive Response and the Failure Behavior of Polyester Matrix. Compos. Part B Eng. 2019, 174, 107040. [Google Scholar] [CrossRef]

- Lee, M.C.; Peppas, N.A. Water Transport in Graphite/Epoxy Composites. J. Appl. Polym. Sci. 1993, 47, 1349–1359. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. A Review on Split Hopkinson Bar Experiments on the Dynamic Characterisation of Concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Nachtane, M. Can a Three-Dimensional Composite Really Provide Better Mechanical Performance Compared to Two-Dimensional Composite under Compressive Loading? J. Reinf. Plast. Compos. 2019, 38, 49–61. [Google Scholar] [CrossRef]

- Nachtane, M. Staking Lay-up Effect on Dynamic Compression Behaviour of e-Glass/Epoxy Composite Materials: Experimental and Numerical Investigation. Adv. Mater. Lett. 2018, 9, 816–822. [Google Scholar]

- Randles, P.W.; Nemes, J.A. A Continuum Damage Model for Thick Composite Materials Subjected to High-Rate Dynamic Loading. Mech. Mater. 1992, 13, 1–13. [Google Scholar] [CrossRef]

- Park, S.W.; Schapery, R.A. A Viscoelastic Constitutive Model for Particulate Composites with Growing Damage. Int. J. Solids Struct. 1997, 34, 931–947. [Google Scholar] [CrossRef]

- Li, Y.; Ramesh, K.T.; Chin, E.S.C. Viscoplastic Deformations and Compressive Damage in an A359/SiCp Metal–Matrix Composite. Acta Mater. 2000, 48, 1563–1573. [Google Scholar] [CrossRef]

- Yang, L.M.; Shim, V.P.W.; Lim, C.T. A Visco-Hyperelastic Approach to Modelling the Constitutive Behaviour of Rubber. Int. J. Impact Eng. 2000, 24, 545–560. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Choukri, S.; Neme, A. Effect of Fibre Orientation on Mechanical Properties of the Laminated Polymer Composites Subjected to Out-of-Plane High Strain Rate Compressive Loadings. Compos. Sci. Technol. 2008, 68, 477–485. [Google Scholar] [CrossRef]

- Liu, D.; Schulz, P.; Templeton, D.; Raju, B. Dynamic Failure and Energy Absorption of Composite Materials with Geometrical Control. In Proceedings of the 16th International Conference on Composite Materials, Kyoto, Japan, 8–13 July 2007. [Google Scholar]

| Properties | Composite | Adhesive |

|---|---|---|

| Density (kg/m3) | 1960 | 1960 |

| Young’s modulus (MPa) | E1 = 48,110, E2 = E3 = 11,210 | 3100 |

| Poisson’s ratio | ν12 = ν13 = 0.28, ν23 = 0.34 | 0.3 |

| Shear modulus (MPa) | G12 = G13 = 4420, G23 = 5000 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lagdani, O.; Tarfaoui, M.; Rouway, M.; Laaouidi, H.; Jamoudi Sbai, S.; Amine Dabachi, M.; Aamir, A.; Nachtane, M. Influence of Moisture Diffusion on the Dynamic Compressive Behavior of Glass/Polyester Composite Joints for Marine Engineering Applications. J. Compos. Sci. 2022, 6, 94. https://doi.org/10.3390/jcs6030094

Lagdani O, Tarfaoui M, Rouway M, Laaouidi H, Jamoudi Sbai S, Amine Dabachi M, Aamir A, Nachtane M. Influence of Moisture Diffusion on the Dynamic Compressive Behavior of Glass/Polyester Composite Joints for Marine Engineering Applications. Journal of Composites Science. 2022; 6(3):94. https://doi.org/10.3390/jcs6030094

Chicago/Turabian StyleLagdani, Oumnia, Mostapha Tarfaoui, Marwane Rouway, Houda Laaouidi, Sara Jamoudi Sbai, Mohamed Amine Dabachi, Abdelwahed Aamir, and Mourad Nachtane. 2022. "Influence of Moisture Diffusion on the Dynamic Compressive Behavior of Glass/Polyester Composite Joints for Marine Engineering Applications" Journal of Composites Science 6, no. 3: 94. https://doi.org/10.3390/jcs6030094

APA StyleLagdani, O., Tarfaoui, M., Rouway, M., Laaouidi, H., Jamoudi Sbai, S., Amine Dabachi, M., Aamir, A., & Nachtane, M. (2022). Influence of Moisture Diffusion on the Dynamic Compressive Behavior of Glass/Polyester Composite Joints for Marine Engineering Applications. Journal of Composites Science, 6(3), 94. https://doi.org/10.3390/jcs6030094