Influence of Spatially Distributed Out-of-Plane CFRP Fiber Waviness on the Estimation of Knock-Down Factors Based on Stochastic Numerical Analysis

Abstract

1. Introduction

1.1. Out-of-Plane Waviness

1.2. Spatial Stochastic Analysis

2. Multiscale Analysis for Computation of Knock-Down-Factors

3. Random Field Analysis

3.1. Covariance Function

3.2. Numerical Discretization

4. Probabilistic Analysis

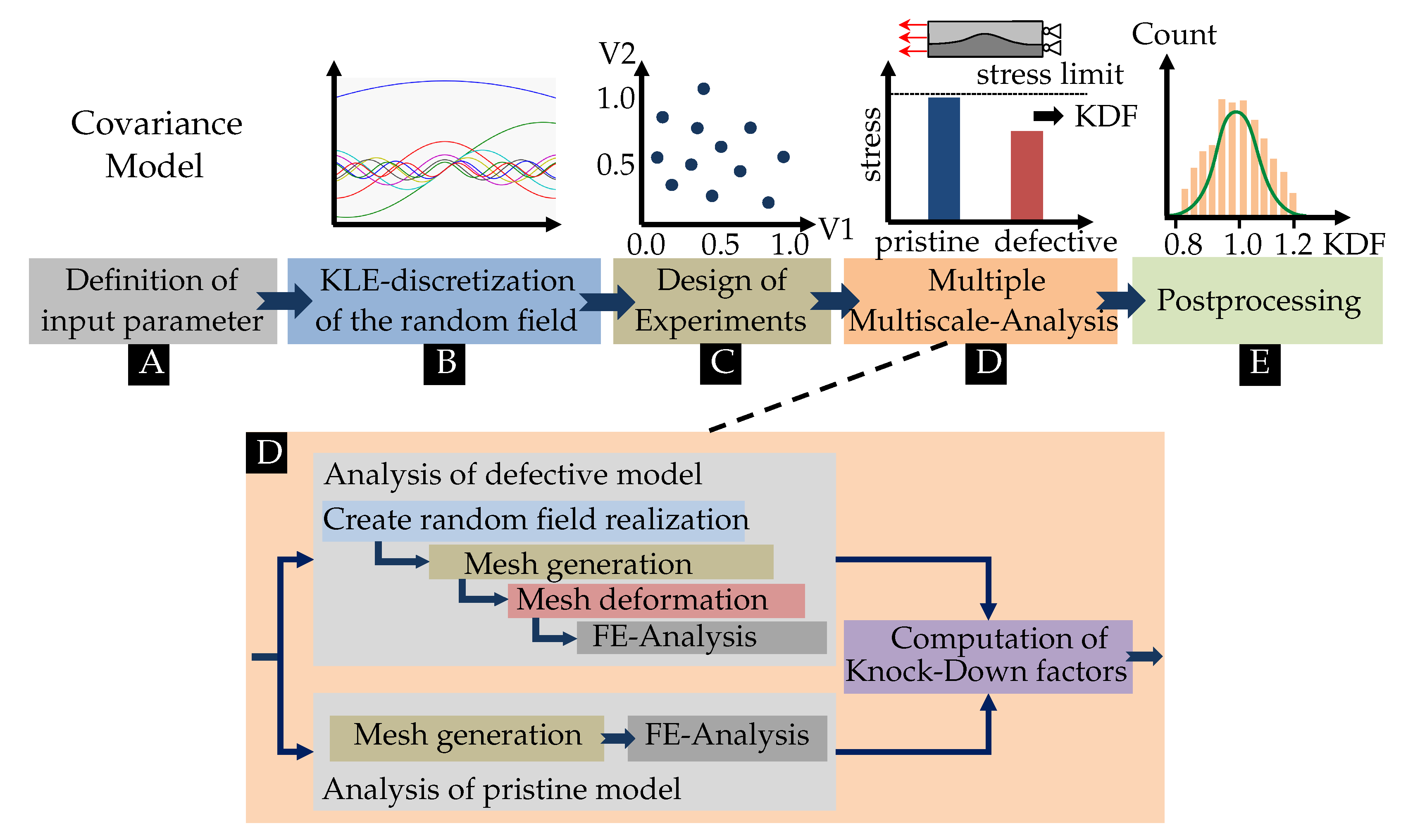

4.1. Process Description

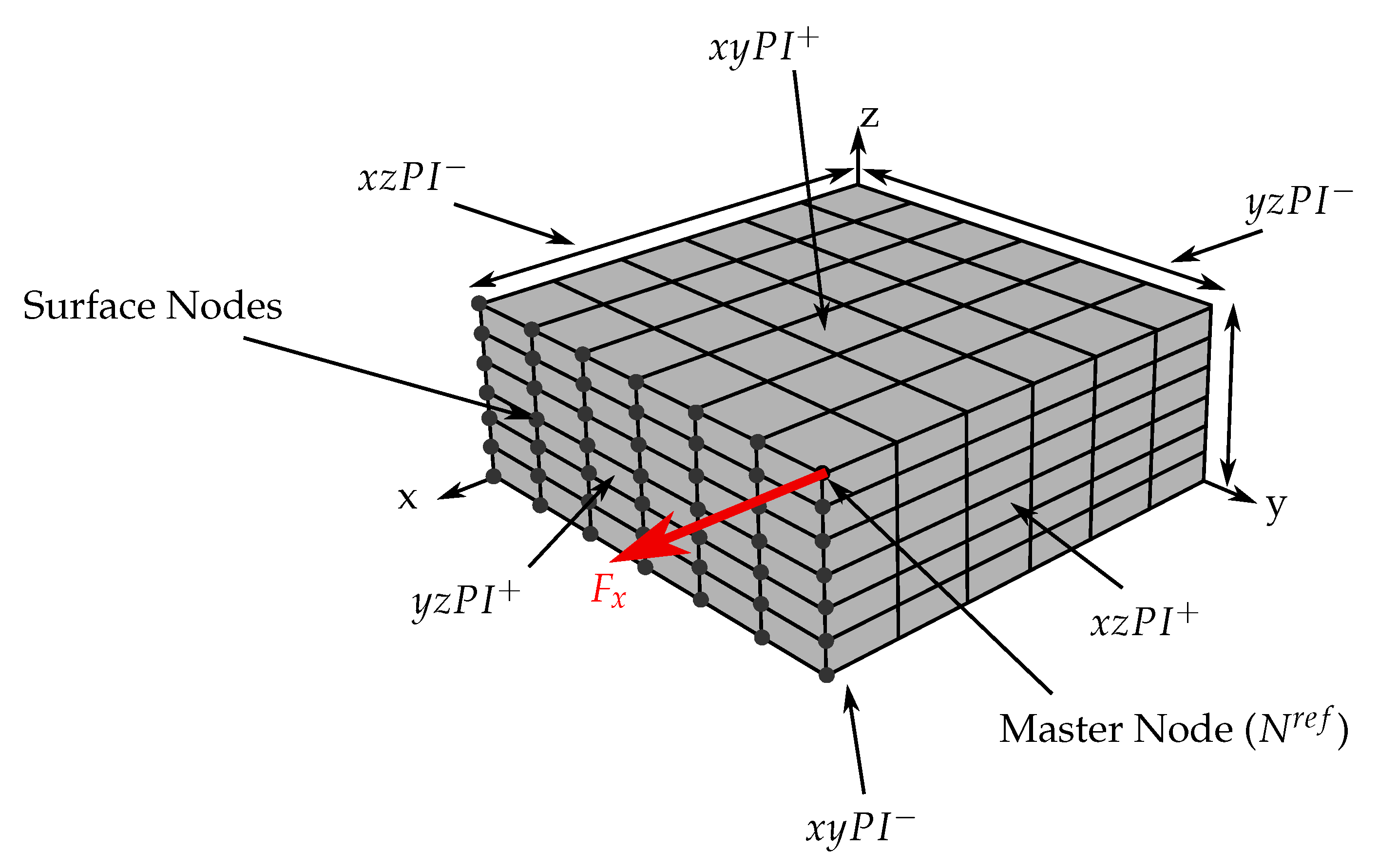

4.2. FEM Modeling

5. Results

5.1. Parameters

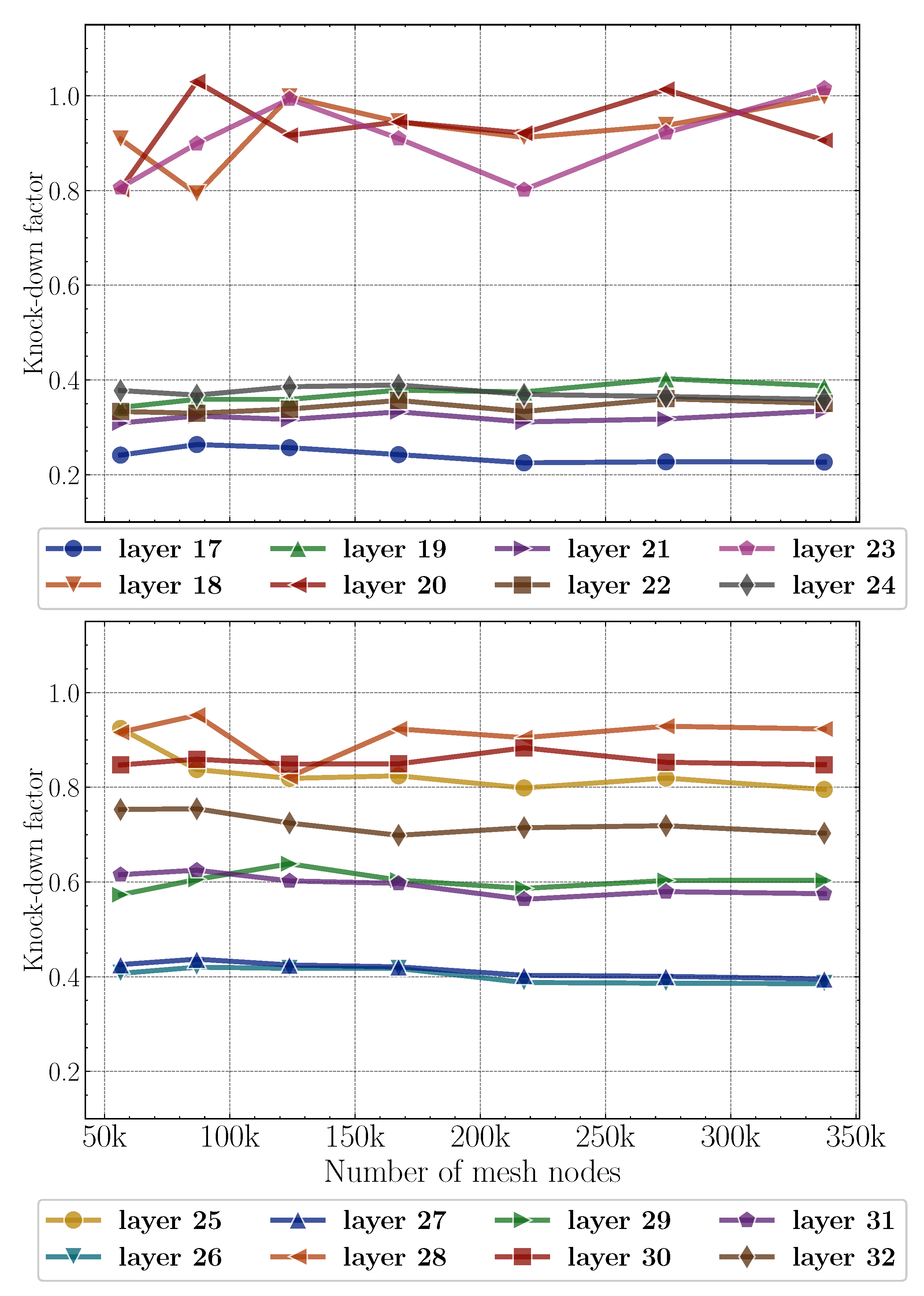

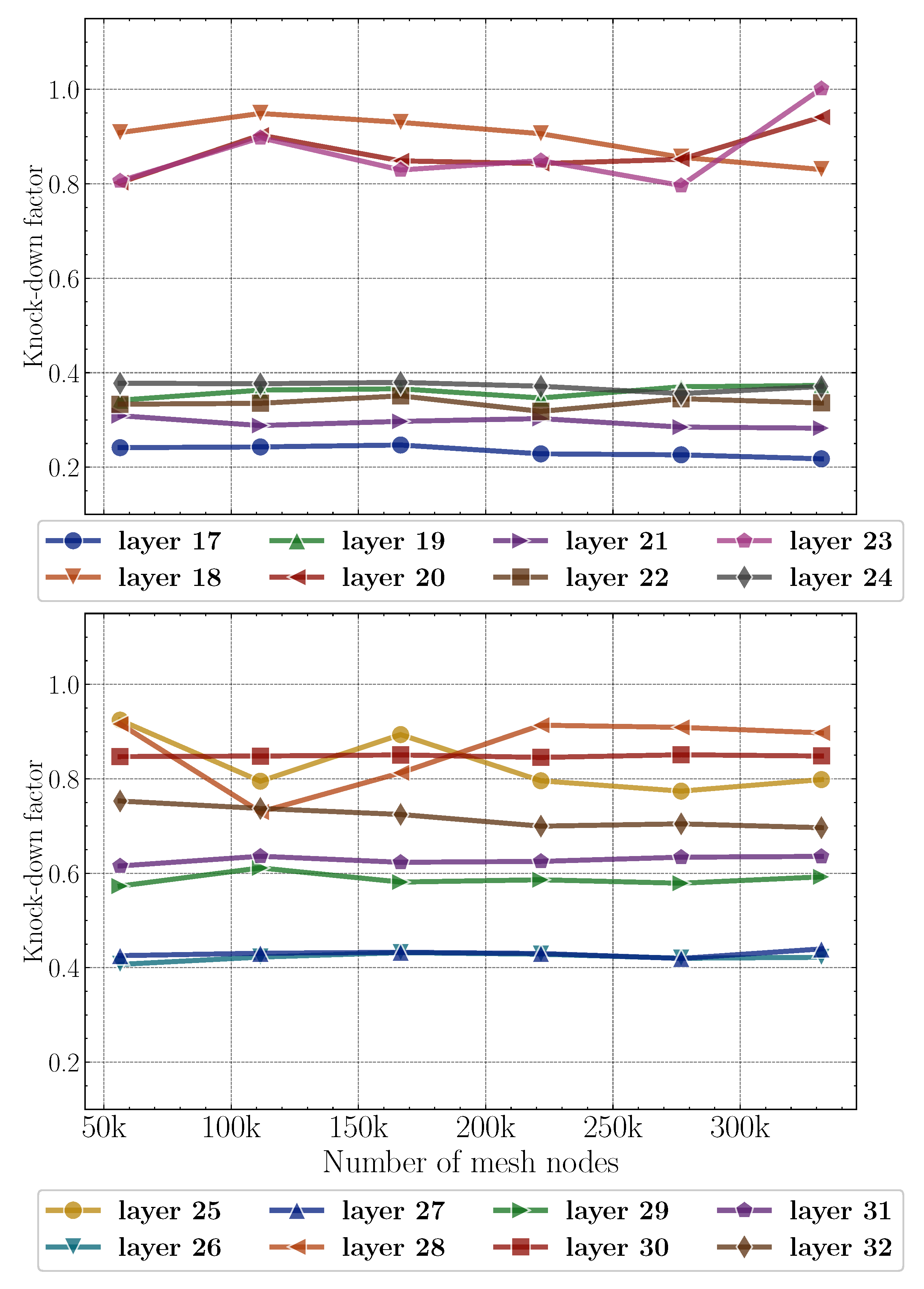

5.2. Deterministic FE Analysis

5.3. Probabilistic Analysis

5.3.1. Statistical Distribution of KDF across Layers

5.3.2. Relation between KDF and Waviness Parameters

- (1)

- Ratio of waviness amplitude to laminate thickness;

- (2)

- Maximum curvature in the fiber orientation direction.

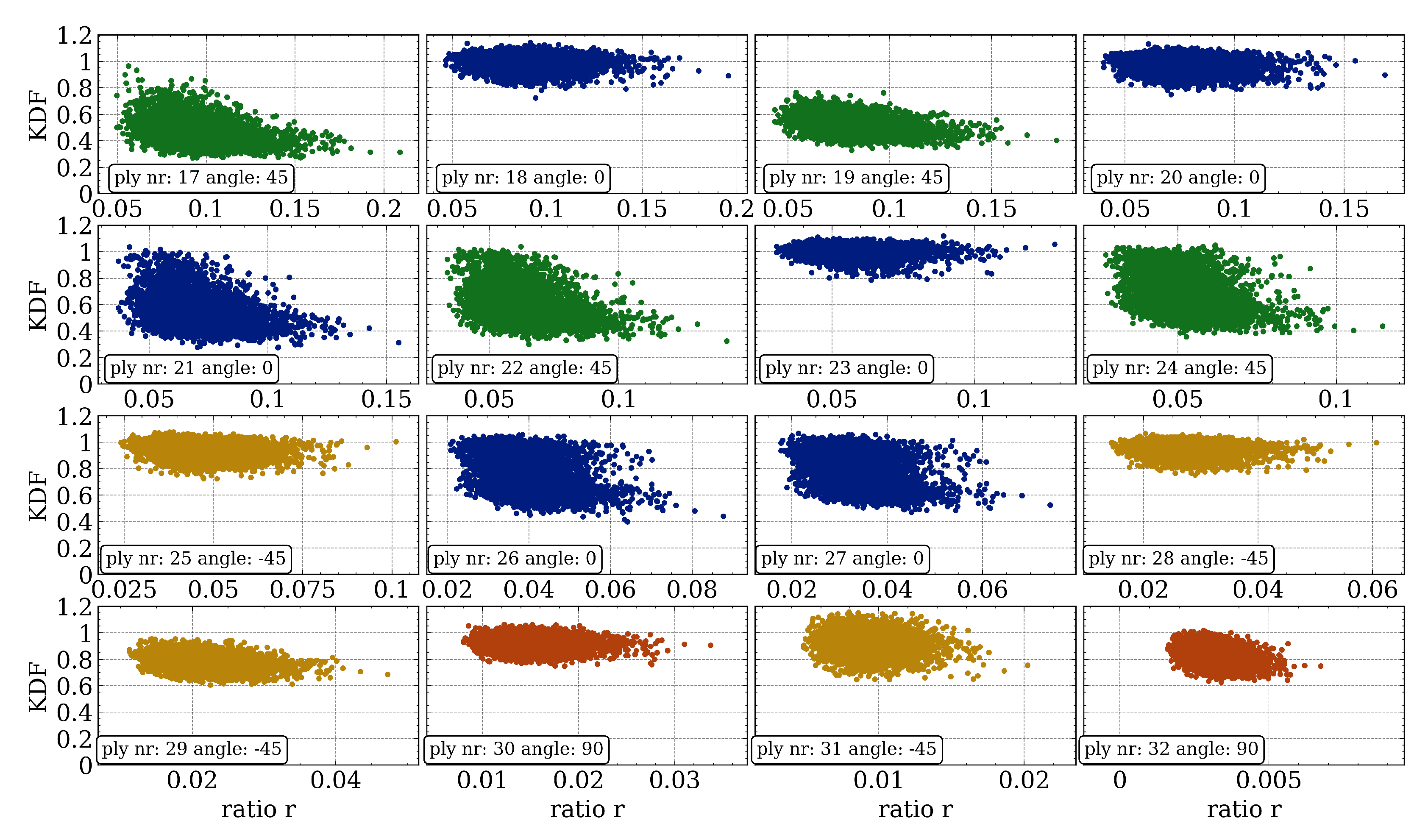

Ratio of Waviness Amplitude to Laminate Thickness

- Only a minor ply fraction of the full laminate is subjected to a large decrease (>30 percent) of the KDF for higher waviness ratios.

- A large decrease of the KDF occurs only on plies with orientation angles of zero degrees and 45 degrees.

- For all different ply orientations except zero degrees, a similar result pattern (decreasing, constant within some range) can be observed.

- A large reduction due to a low KDF can already be identified for small to moderate waviness ratios ().

- Even for moderate waviness ratios () there is a large remaining scatter in the KDF for different random field samples between an unaffected resulting material behavior (KDF ) and a large degradation of the tensile strength property.

Maximum Curvature in Fiber Orientation Direction

Summary of the Metric Assessment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Heinecke, F.; Willberg, C. Manufacturing-Induced Imperfections in Composite Parts Manufactured via Automated Fiber Placement. J. Compos. Sci. 2019, 3, 56. [Google Scholar] [CrossRef]

- Hallander, P.; Akermo, M.; Mattei, C.; Petersson, M.; Nyman, T. An experimental study of mechanisms behind wrinkle development during forming of composite laminates. Compos. Part A Appl. Sci. Manuf. 2013, 50, 54–64. [Google Scholar] [CrossRef]

- Krämer, E.; Grouve, W.; Koussios, S.; Warnet, L.L.; Akkerman, R. Real-time observation of waviness formation during C/PEEK consolidation. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105872. [Google Scholar] [CrossRef]

- Thor, M.; Sause, M.G.R.; Hinterhölzl, R.M. Mechanisms of Origin and Classification of Out-of-Plane Fiber Waviness in Composite Materials—A Review. J. Compos. Sci. 2020, 4, 130. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Jones, M.I.; Hallett, S.R. Modelling of out-of-plane fibre waviness; tension and compression tests. In Proceedings of the 4th ECCOMAS Thematic Conf. on the Mechanical Response of Composites, Saint Miguel, Portugal, 25–27 September 2013; pp. 17–22. [Google Scholar]

- Davidson, P.; Waas, A.; Yerramalli, C.; Chandraseker, K.; Faidi, W. Effect of Fiber Waviness on the Compressive Strength of Unidirectional Carbon Composites. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Hawaii, 23–26 April 2012. [Google Scholar] [CrossRef]

- Hinterhölzl, R.M.; Haller, H.; Luger, M.; Klar, R. Strategy for a simulation based assessment of effects of manufacturing. In Proceedings of the 5th International Conference Supply Wings Airtech, Frankfurt, Germany, 2–4 November 2010. [Google Scholar]

- Tarnopol’skii, Y.M.; Portnov, G.G.; Zhigun, I.G. Effect of fiber curvature on the modulus of elasticity for unidirectional glass-reinforced plastics in tension. Polym. Mech. 1971, 3, 161–166. [Google Scholar] [CrossRef]

- Hsiao, H.M.; Daniel, I.M. Effect of fiber waviness on stiffness and strength reduction of unidirectional composites under compressive loading. Compos. Sci. Technol. 1996, 56, 581–593. [Google Scholar] [CrossRef]

- Piggott, M.R. The effect of fibre waviness on the mechanical properties of unidirectional fibre composites: A review. Compos. Sci. Technol. 1995, 53, 201–205. [Google Scholar] [CrossRef]

- Thor, M.; Mandel, U.; Nagler, M.; Maier, F.; Tauchner, J.; Sause, M.G.R.; Hinterhölzl, R.M. Numerical and experimental investigation of out-of-plane fiber waviness on the mechanical properties of composite materials. Int. J. Mater. Form. 2021, 14, 19–37. [Google Scholar] [CrossRef]

- Heinecke, F.; Wille, T. In-situ structural evaluation during the fibre deposition process of composite manufacturing. CEAS Aeronaut. J. 2018, 9, 123–133. [Google Scholar] [CrossRef]

- Willberg, C.; Heinecke, F. Evaluation of manufacturing deviations of composite materials. PAMM 2021, 20, e202000345. [Google Scholar] [CrossRef]

- Al-kathemi, N.; Wille, T.; Heinecke, F.; Degenhardt, R.; Wiedemann, M. Interaction effect of out of plane waviness and impact damages on composite structures—An experimental study. Compos. Struct. 2021, 276, 114405. [Google Scholar] [CrossRef]

- Khattab, I.A.d.; Kreikemeier, J.; Abdelhadi, N.S. Manufacturing of CFRP specimens with controlled out-of-plane waviness. CEAS Aeronaut. J. 2014, 5, 85–93. [Google Scholar] [CrossRef]

- Adams, D.O.; Bell, S.J. Compression strength reductions in composite laminates due to multiple-layer waviness. Compos. Sci. Technol. 1995, 53, 207–212. [Google Scholar] [CrossRef]

- Elhajjar, R.F.; Shams, S.S. Compression testing of continuous fiber reinforced polymer composites with out-of-plane fiber waviness and circular notches. Polym. Test. 2014, 35, 45–55. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.J.; Schreier, H.W. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer: New York, NY, USA, 2009. [Google Scholar]

- Sandhu, A.; Reinarz, A.; Dodwell, T.J. A Bayesian framework for assessing the strength distribution of composite structures with random defects. Compos. Struct. 2018, 205, 58–68. [Google Scholar] [CrossRef]

- Kriegesmann, B.; Balokas, G.; Wille, T. Uncertainty quantification of composite structures with manufacturing defects within the SuCoHS project. In Proceedings of the 8th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2022), Oslo, Norway, 5–9 June 2022. [Google Scholar]

- Arai, Y.; Fukuda, K.; Sakata, S.i. Random Field Modeling of Microstructure in Unidirectional Fiber–Reinforced Plastic Using SEM–Image and Image Processing for Multiscale Stochastic Stress Analysis Considering Random Fiber Arrangements. Adv. Eng. Mater. 2022, 24, 2270020. [Google Scholar] [CrossRef]

- Rauter, N. A computational modeling approach based on random fields for short fiber-reinforced composites with experimental verification by nanoindentation and tensile tests. Comput. Mech. 2021, 67, 699–722. [Google Scholar] [CrossRef]

- Machina, G.; Zehn, M.W. A methodology to model spatially distributed uncertainties in thin-walled structures. ZAMM 2007, 87, 360–376. [Google Scholar] [CrossRef]

- Zein, S.; Laurent, A.; Dumas, D. Simulation of a Gaussian random field over a 3D surface for the uncertainty quantification in the composite structures. Comput. Mech. 2019, 63, 1083–1090. [Google Scholar] [CrossRef]

- Kepple, J.; Herath, M.T.; Pearce, G.; Gangadhara Prusty, B.; Thomson, R.; Degenhardt, R. Stochastic analysis of imperfection sensitive unstiffened composite cylinders using realistic imperfection models. Compos. Struct. 2015, 126, 159–173. [Google Scholar] [CrossRef]

- Dodwell, T.J.; Kinston, S.; Butler, R.; Haftka, R.T.; Kim, N.H.; Scheichl, R. Multilevel Monte Carlo Simulations of Composite Structures with Uncertain Manufacturing Defects. Probabilistic Eng. Mech. 2021, 63, 103116. [Google Scholar] [CrossRef]

- Sutcliffe, M. Modelling the effect of size on compressive strength of fibre composites with random waviness. Compos. Sci. Technol. 2013, 88, 142–150. [Google Scholar] [CrossRef]

- Sutcliffe, M.; Lemanski, S.L.; Scott, A.E. Measurement of fibre waviness in industrial composite components. Compos. Sci. Technol. 2012, 72, 2016–2023. [Google Scholar] [CrossRef]

- Heinecke, F. Strukturmechanische Auswirkung fertigungsbedingter Imperfektionen aus Faserverbundablegeprozesses. Ph.D. Thesis, Technische Universität Carola-Wilhelmina zu Braunschweig, Brunswick, Germany, 2020. [Google Scholar]

- Puck, A. Festigkeitsanalyse von Faser-Matrix-Laminaten: Modelle für die Praxis (Trength Analysis of Fibre-Matrix/Laminates, Models for Design Practice); Hanser: Munich, Germany; Vienna, Austria, 1996. [Google Scholar]

- Liu, K. A progressive quadratic failure criterion for a laminate. Compos. Sci. Technol. 1998, 58, 1023–1032. [Google Scholar] [CrossRef]

- Kolios, A.J.; Proia, S. Evaluation of the Reliability Performance of Failure Criteria for Composite Structures. World J. Mech. 2012, 2, 162–170. [Google Scholar] [CrossRef]

- Bogetti, T.A.; Gillespie, J.W.; Lamontia, M.A. Influence of Ply Waviness on the Stiffness and Strength Reduction on Composite Laminates. J. Thermoplast. Compos. Mater. 1992, 5, 344–369. [Google Scholar] [CrossRef]

- Karami, G.; Garnich, M. Effective moduli and failure considerations for composites with periodic fiber waviness. Compos. Struct. 2005, 67, 461–475. [Google Scholar] [CrossRef]

- Gichman, I.I.; Skorochod, A.V. Introduction to the Theory of Random Processes; Dover Books on Mathematics; Dover Publications: Mineola, NY, USA, 1996. [Google Scholar]

- Reinarz, A.; Dodwell, T.; Fletcher, T.; Seelinger, L.; Butler, R.; Scheichl, R. Dune-composites—A new framework for high-performance finite element modelling of laminates. Compos. Struct. 2018, 184, 269–278. [Google Scholar] [CrossRef]

- Karhunen, K. Über lineare Methoden in der Wahrscheinlichkeitsrechnung; Annales Academiae Scientiarum Fennicae: Ser. A 1; Universitat Helsinki: Helsinki, Finland, 1947. [Google Scholar]

- Betz, W.; Papaioannou, I.; Straub, D. Numerical methods for the discretization of random fields by means of the Karhunen–Loève expansion. Comput. Methods Appl. Mech. Eng. 2014, 271, 109–129. [Google Scholar] [CrossRef]

- Stefanou, G. The stochastic finite element method: Past, present and future. Comput. Methods Appl. Mech. Eng. 2009, 198, 1031–1051. [Google Scholar] [CrossRef]

- Schuëller, G.I. Developments in stochastic structural mechanics. Arch. Appl. Mech. 2006, 75, 755–773. [Google Scholar] [CrossRef]

- Bathe, K.J. Finite-Elemente-Methoden; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Geuzaine, C.; Remacle, J.F. Gmsh: A 3-D finite element mesh generator with built-in pre- and post-processing facilities. Int. J. Numer. Methods Eng. 2009, 79, 1309–1331. [Google Scholar] [CrossRef]

- SMR. B2000++ Finite Element Analysis Environment. Available online: https://www.smr.ch/products/b2000 (accessed on 30 September 2022).

- Kaddour, A.S.; Hinton, M.J. Input data for test cases used in benchmarking triaxial failure theories of composites. J. Compos. Mater. 2012, 46, 2295–2312. [Google Scholar] [CrossRef]

- Wunderlich, T.F.; Dähne, S.; Reimer, L.; Schuster, A. Global aero-structural design optimization of composite wings with active manoeuvre load alleviation. CEAS Aeronaut. J. 2022, 13, 639–662. [Google Scholar] [CrossRef]

- Dillinger, J. Static Aeroelastic Optimization of Composite Wings with Variable Stiffness Laminate. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Baudin, M.; Dutfoy, A.; Iooss, B.; Popelin, A.L. OpenTURNS: An Industrial Software for Uncertainty Quantification in Simulation. In Handbook of Uncertainty Quantification; Ghanem, R., Higdon, D., Owhadi, H., Eds.; Springer eBook Collection; Springer: Cham, Switzerland, 2017; pp. 1–38. [Google Scholar] [CrossRef]

- McKay, M.D.; Beckman, R.J.; Conover, W.J. A Comparison of Three Methods for Selecting Values of Input Variables in the Analysis of Output from a Computer Code. Technometrics 1979, 21, 239. [Google Scholar] [CrossRef]

- O’Hare Adams, D.; Hyer, M.W. Effects of Layer Waviness on the Compression Strength of Thermoplastic Composite Laminates. J. Reinf. Plast. Compos. 1993, 12, 414–429. [Google Scholar] [CrossRef]

- Weaver, K.F.; Morales, V.C.; Dunn, S.L. An Introduction to Statistical Analysis in Research: With Applications in the Biological and Life Sciences; John Wiley & Sons Inc: Hoboken, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Edelsbrunner; Letscher; Zomorodian. Topological Persistence and Simplification. Discret. Comput. Geom. 2002, 28, 511–533. [Google Scholar] [CrossRef]

- Papaioannou, I.; Ehre, M.; Straub, D. PLS-based adaptation for efficient PCE representation in high dimensions. J. Comput. Phys. 2019, 387, 186–204. [Google Scholar] [CrossRef]

| x-Direction | y-Direction |

|---|---|

| Computation Step | Elapsed Time | |

|---|---|---|

| FE model generation | 31.75 s | |

| Defective | FE analysis | 120.09 s |

| Result postprocessing | 5.44 s | |

| FE model generation | 25.75 s | |

| Pristine | FE analysis | 112.83 s |

| Result postprocessing | 5.30 s | |

| KDF estimation | 10.53 s | |

| Total runtime | 311.69 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schuster, A.; Degenhardt, R.; Willberg, C.; Wille, T. Influence of Spatially Distributed Out-of-Plane CFRP Fiber Waviness on the Estimation of Knock-Down Factors Based on Stochastic Numerical Analysis. J. Compos. Sci. 2022, 6, 353. https://doi.org/10.3390/jcs6120353

Schuster A, Degenhardt R, Willberg C, Wille T. Influence of Spatially Distributed Out-of-Plane CFRP Fiber Waviness on the Estimation of Knock-Down Factors Based on Stochastic Numerical Analysis. Journal of Composites Science. 2022; 6(12):353. https://doi.org/10.3390/jcs6120353

Chicago/Turabian StyleSchuster, Andreas, Richard Degenhardt, Christian Willberg, and Tobias Wille. 2022. "Influence of Spatially Distributed Out-of-Plane CFRP Fiber Waviness on the Estimation of Knock-Down Factors Based on Stochastic Numerical Analysis" Journal of Composites Science 6, no. 12: 353. https://doi.org/10.3390/jcs6120353

APA StyleSchuster, A., Degenhardt, R., Willberg, C., & Wille, T. (2022). Influence of Spatially Distributed Out-of-Plane CFRP Fiber Waviness on the Estimation of Knock-Down Factors Based on Stochastic Numerical Analysis. Journal of Composites Science, 6(12), 353. https://doi.org/10.3390/jcs6120353