Defects Detection and Identification in Adhesively Bonded Joints between CFRP Laminate and Reinforced Concrete Beam Using Acousto-Ultrasonic Technique

Abstract

1. Introduction

2. Materials and Experimental Set-Up

2.1. Samples

- -

- Reference zones with no defect in the adhesive joint (α-type zone). Guaranteed by strict compliance with the surface preparation conditions listed above.

- -

- Zones with voids in the joint (β-type zone).

- -

- Zones with the incorporation of polyurethane resin (8 MPa elastic modulus) on the whole thickness to materialize a poor cure defect or a softening of the resin (γ-type zone), which could be, for example, due to ageing, with the presence of high moisture or poor cure.

- -

- Zones with a lack of adhesion (kissing bond) between the epoxy joint and the composite substrate (δ-type zone). The adherent surfaces were partially contaminated with grease before applying the adhesive to create these weak interfaces.

2.2. Acousto-Ultrasonic Technique

2.3. Defect Detection and Classification Methodology

3. Results and Discussions

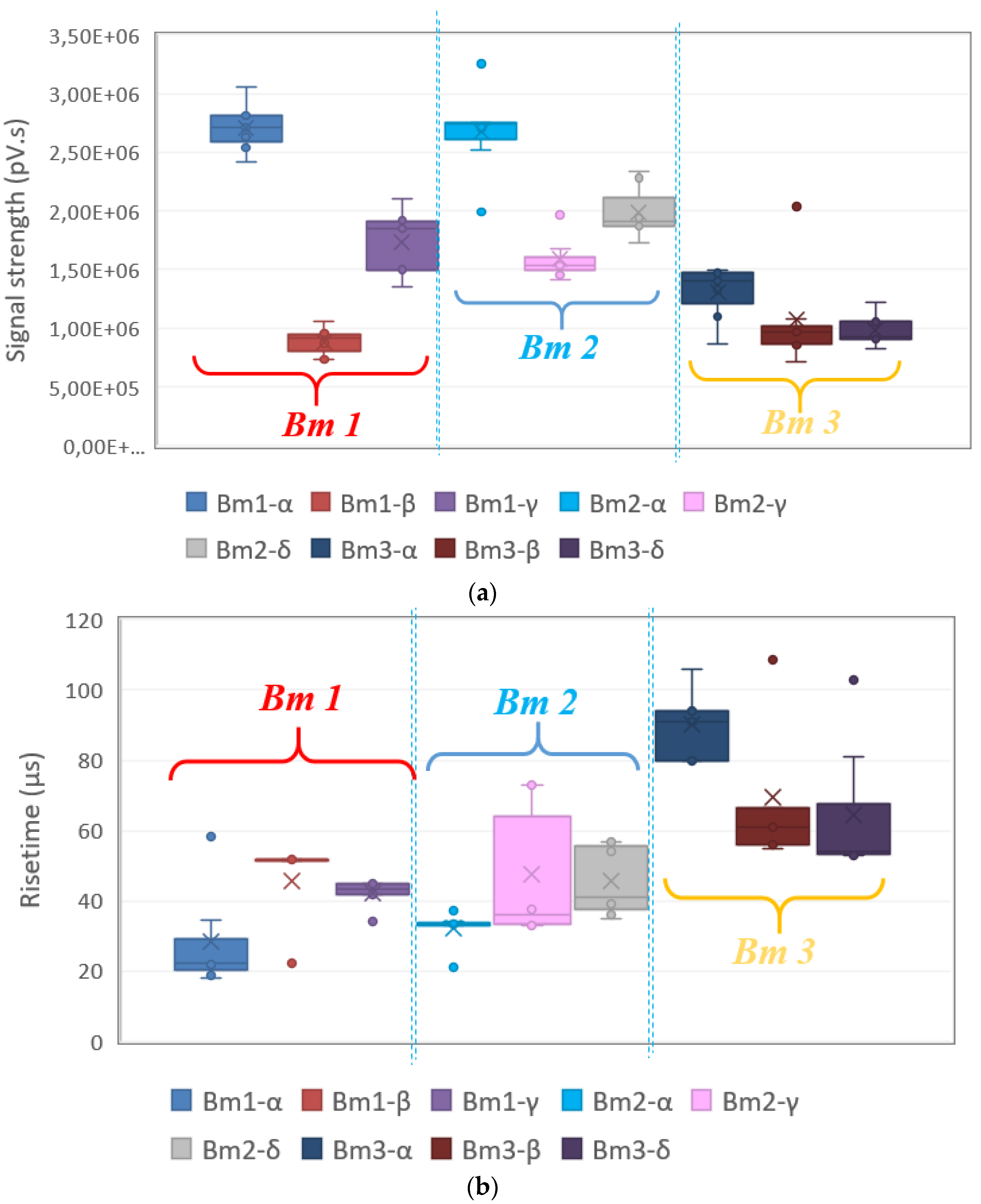

3.1. Detection of the Defects

3.2. Identification of the Defects

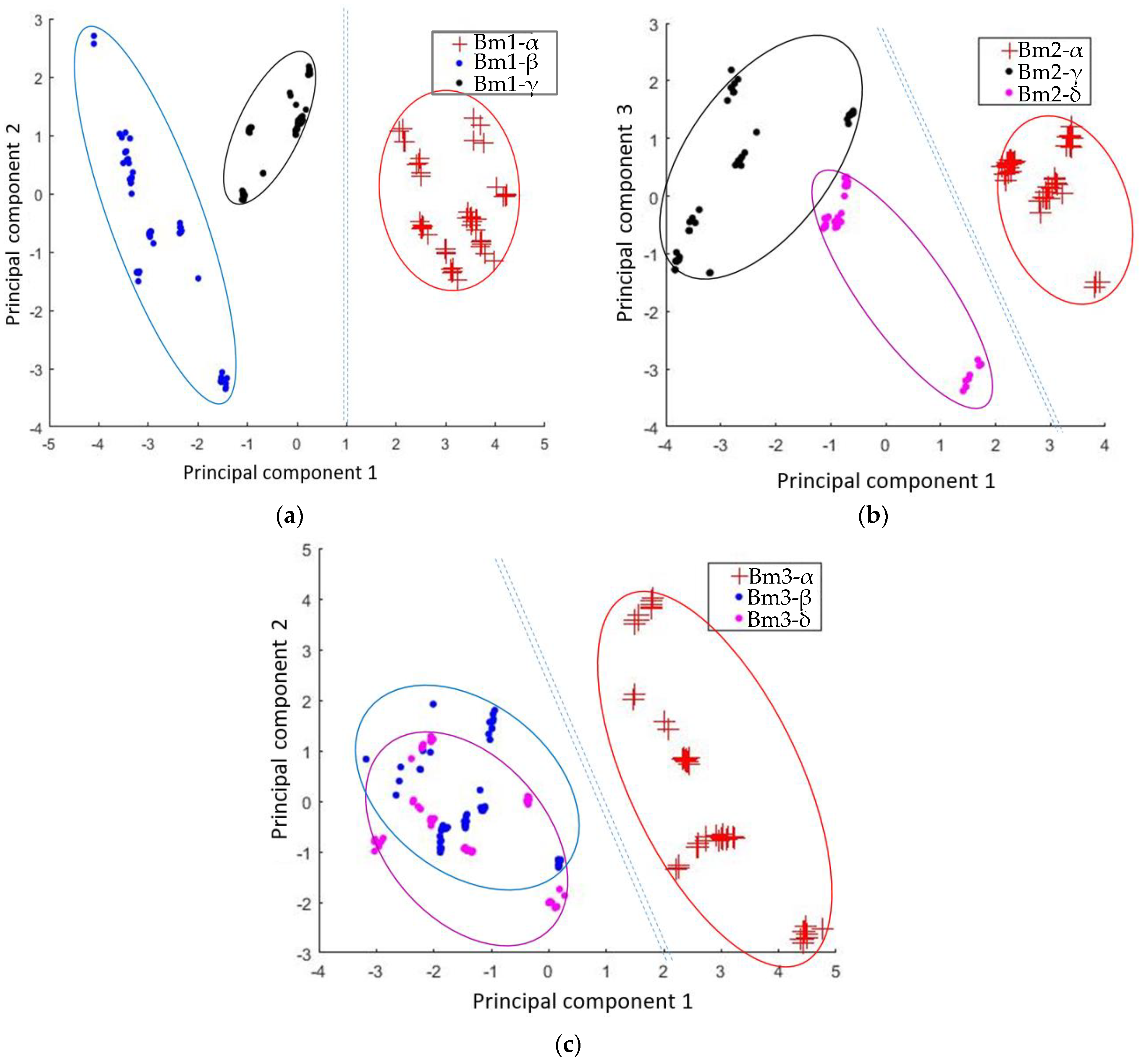

3.2.1. PCA

3.2.2. Random Forest Classification

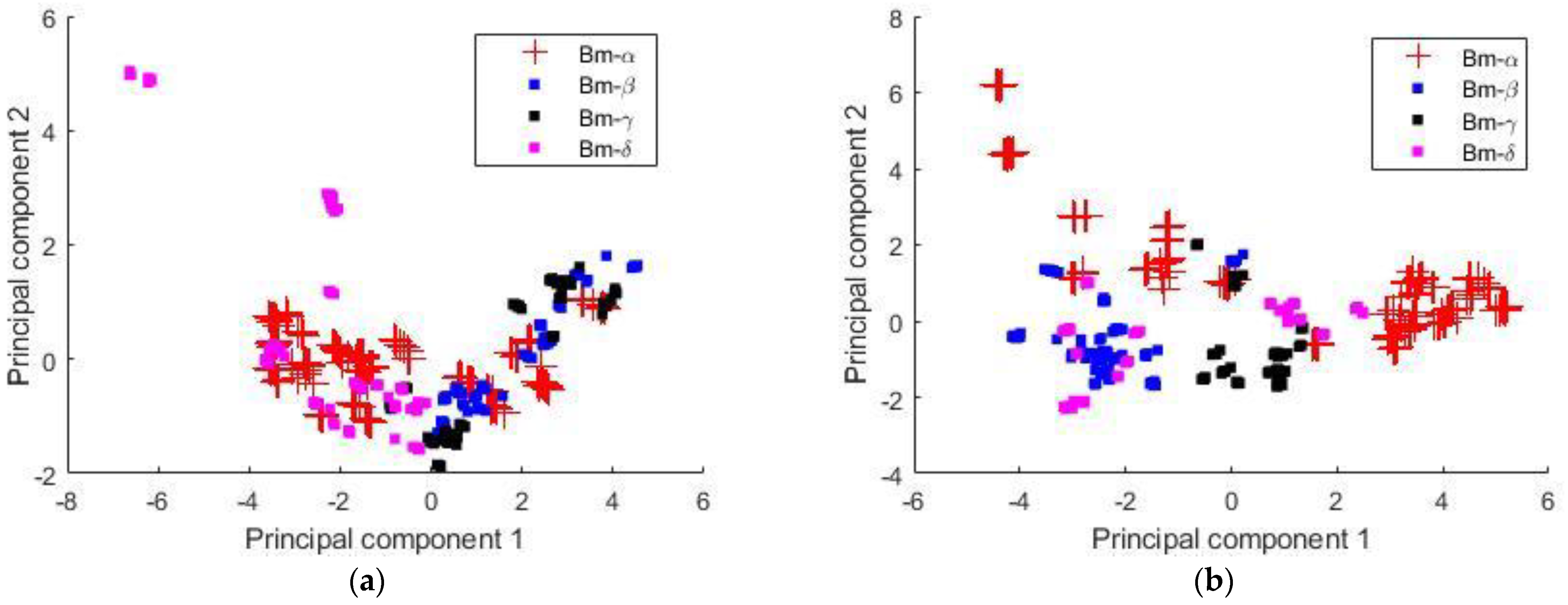

First Campaign of Classification

Second Campaign of Classification

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chataigner, S.; Benzarti, K.; Foret, G.; Caron, J.F.; Gemignani, G.; Brugiolo, M.; Calderon, I.; Pinero, I.; Birtel, V.; Lehmann, F. Design and evaluation of an externally bonded CFRP reinforcement for the fatigue reinforcement of old steel structures. Eng. Struct. 2018, 177, 556–565. [Google Scholar] [CrossRef]

- Lepretre, E.; Chataigner, S.; Dieng, L.; Gaillet, L. Fatigue strengthening of cracked steel plates with CFRP laminates in the case of old steel materials. Constr. Build. Mater. 2018, 174, 421–432. [Google Scholar] [CrossRef]

- Alsayed, S.H.; Al-Salloum, Y.A.; Almusallam, T.H. Fibre-reinforced polymer repair material: Some facts. In Proceedings of the Institution of Civil Engineers-Civil Engineering; Thomas Telford Ltd.: London, UK, 2000; Volume 138, pp. 131–134. [Google Scholar]

- Adams, R.D.; Cawley, P. A review of defect types and nondestructive testing techniques for composites and bonded joints. NDT Int. 1988, 21, 208–222. [Google Scholar]

- Adams, R.D.; Drinkwater, B.W. Nondestructive testing of adhesively-bonded joints. NDT E Int. 1997, 30, 93–98. [Google Scholar] [CrossRef]

- Guyott, C.C.H.; Cawley, P.; Adams, R.D. The non-destructive testing of adhesively bonded structure: A review. J. Adhes. 1986, 20, 129–159. [Google Scholar] [CrossRef]

- Srivastava, V.K. Acousto-ultrasonic evaluation of interface bond strength of coated glass fibre-reinforced epoxy resin composites. Compos. Struct. 1995, 30, 281–285. [Google Scholar] [CrossRef]

- Ribeiro, F.; Campilho, R.; Carbas, R.; da Silva, L. Strength and damage growth in composite bonded joints with defects. Compos. Part B Eng. 2016, 100, 91–100. [Google Scholar] [CrossRef]

- Xu, W.; Wei, Y. Strength analysis of metallic bonded joints containing defects. Comput. Mater. Sci. 2012, 53, 444–450. [Google Scholar] [CrossRef]

- Yang, S.; Gu, L.; Gibson, R.F. Nondestructive detection of weak joints in adhesively bonded composite structures. Compos. Struct. 2001, 51, 63–71. [Google Scholar] [CrossRef]

- Shin, P.H.; Webb, S.C.; Peters, K.J. Pulsed phase thermography imaging of fatigue loaded composite adhesively bonded joints. NDT E Int. 2016, 79, 7–16. [Google Scholar] [CrossRef]

- Palumbo, D.; Tamborrino, R.; Galietti, U.; Aversa, P.; Tatì, A.; Luprano, V. Ultrasonic analysis and lock-in thermography for debonding evaluation of composite adhesive joints. NDT E Int. 2016, 78, 1–9. [Google Scholar] [CrossRef]

- Schroeder, J.A.; Ahmed, T.; Choudhry, B.; Shepard, S. Non destructive testing of structural composites and adhesively bonded composite joints: Pulsed thermography. Compos. A 2002, 33, 1511–1517. [Google Scholar] [CrossRef]

- Taillade, F.; Quiertant, M.; Benzarti, K.; Aubagnac, C. Non-destructive evaluation (NDE) of composites: Using shearography to detect bond defects. In Non-Destructive Evaluation (NDE) of Polymer Matrix Composites; Elsevier: Amsterdam, The Netherlands, 2013; pp. 540–557. [Google Scholar]

- Zheng, S.; Vanderstelt, J.; Mcdermid, J.R.; Kish, J.R. Non-destructive investigation of aluminum alloy hemmed joints using neutron radiography and X-ray computed tomography. NDT E Int. 2017, 91, 32–35. [Google Scholar] [CrossRef]

- Santulli, C.; Lucia, A.C. Relation between acoustic emission analysis during cure cycle and bonded joints performances. NDT E Int. 1999, 32, 333–341. [Google Scholar] [CrossRef]

- Yilmaz, B.; Jasiuniene, E. Advanced ultrasonic NDT for weak bond detection in composite-adhesive bonded structures. Int. J. Adhes. Adhes. 2020, 102, 102675. [Google Scholar] [CrossRef]

- Attar, L.; Leduc, D.; el Kettani, M.E.C.; Predoi, M.V.; Galy, J.; Pareige, P. Detection of the degraded interface in dissymmetrical glued structures using Lamb waves. NDT E Int. 2020, 111, 102213. [Google Scholar] [CrossRef]

- Castaings, M. SH ultrasonic guided waves for the evaluation of interfacial adhesion. Ultrasonics 2014, 54, 1760–1775. [Google Scholar] [CrossRef]

- Yilmaz, B.; Asokkumar, A.; Jasiuniene, E.; Kažys, R.J. Air-coupled, contact, and immersion ultrasonic non-destructive testing: Comparison for bonding quality evaluation. Appl. Sci. 2020, 10, 6757. [Google Scholar] [CrossRef]

- Matt, H.; Bartoli, I.; di Scalea, F.L. Ultrasonic guided wave monitoring of composite wing skin-to-spar bonded joints in aerospace structures. J. Acoust. Soc. Am. 2005, 118, 2240–2252. [Google Scholar] [CrossRef]

- Zhang, K.; Li, S.; Zhou, Z. Detection of disbonds in multi-layer bonded structures using the laser ultrasonic pulse-echo mode. Ultrasonics 2019, 94, 411–418. [Google Scholar] [CrossRef]

- Korzeniowski, M.; Piwowarczyk, T.; Maev, R.G. Application of ultrasonic method for quality evaluation of adhesive layers. Arch. Civ. Mech. Eng. 2014, 14, 661–670. [Google Scholar] [CrossRef]

- Li, J.; Lu, Y.; Lee, Y.F. Debonding detection in CFRP-reinforced steel structures using anti-symmetrical guided waves. Compos. Struct. 2020, 253, 112813. [Google Scholar] [CrossRef]

- Spadea, G.; Bencardino, F.; Sorrenti, F.; Swamy, R.N. Structural effectiveness of FRP materials in strengthening RC beams. Eng. Struct. 2015, 99, 631–641. [Google Scholar] [CrossRef]

- Li, D.; Zhou, J.; Ou, J. Damage, nondestructive evaluation and rehabilitation of FRP composite-RC structure: A review. Constr. Build. Mater. 2021, 27, 121551. [Google Scholar] [CrossRef]

- Guo, J.; Doitrand, A.; Sarr, C.; Chataigner, S.; Gaillet, L.; Godin, N. Numerical voids detection in bonded metal/composite assemblies using acousto-ultrasonic method. Appl. Sci. 2022, 12, 4153. [Google Scholar] [CrossRef]

- Sarr, C.A.T.; Chataigner, S.; Gaillet, L.; Godin, N. Nondestructive evaluation of FRP-reinforced structures bonded joints using acousto-ultrasonic: Towards diagnostic of damage state. Constr. Build. Mater. 2021, 313, 125499. [Google Scholar] [CrossRef]

- Sarr, C.; Chataigner, S.; Gaillet, L.; Godin, N. Assessment of steel-composite and concrete-composite adhesively bonded joints by acousto-ultrasonic technique. In International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering; Springer: Cham, Switzerland, 2021; pp. 1806–1816. [Google Scholar]

- Wang, R.; Wu, Q.; Xiong, K.; Zhang, H.; Okabe, Y. Evaluation of the matrix crack number in carbon fiber reinforced plastics using linear and nonlinear acousto-ultrasonic detections. Compos. Struct. 2021, 255, 112962. [Google Scholar] [CrossRef]

- Tanary, S.; Haddad, M.; Fahr, A.; Lee, S. Nondestructive evaluation of adhesively bonded joints in graphite/epoxy composites using acousto-ultrasonics. J. Press. Vessel Technol. 1992, 114, 344–352. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Prakash, R. Acousto-ultrasonic evaluation of the strength of composite material adhesive joints. In Acousto-Ultrasonics: Theory and Application; Springer Science Business Media, LLC.: Boston, MA, USA, 1988; pp. 345–353. [Google Scholar]

- Vary, A.; Lark, R.F. Correlation of fiber composite tensile strength with the ultrasonic stress wave factor. J. Test. Eval. 1979, 7, 185–191. [Google Scholar]

- Kwon, O.Y.; Lee, S.H. Acousto-ultrasonic evaluation of adhesively bonded CFRP-aluminum joints. NDT E Int. 1999, 32, 153–160. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Acousto-ultrasonic evaluation of interlaminar strength on CFRP laminates. Compos. Struct. 2019, 208, 796–805. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Pappalettere, C.; Vimalathithan, P.K. Detection of damage in CFRP by wavelet packet transform and empirical mode decomposition: An hybrid approach. Appl. Compos. Mater. 2020, 27, 641–655. [Google Scholar] [CrossRef]

- Janapati, V.; Kopsaftopoulos, F.; Li, F.; Lee, S.J.; Chang, F.K. Damage detection sensitivity characterization of acousto-ultrasound-based SHM techniques. Struct. Health Monit. 2016, 15, 143–161. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Q.; Xu, W.; Xiong, K. Damage evaluation of complex composite structures using acousto-ultrasonic detection combined with phase-shifted fiber Bragg grating and dual-frequency based data processing. Compos. Struct. 2022, 281, 115000. [Google Scholar] [CrossRef]

- Morizet, N.; Godin, N.; Tang, J.; Maillet, E.; Fregonese, M.; Normand, B. Classification of acoustic emission signals using wavelets and random forests: Application to localized corrosion. Mech. Syst. Signal Process. 2019, 70–71, 1026–1037. [Google Scholar] [CrossRef]

| Longitudinal Young’s Modulus (GPa) | Transversal Young’s Modulus (GPa) | Longitudinal Poisson’s Ratio | Longitudinal Shear Modulus (GPa) | Transverse Poisson’s Ratio | Density (g/cm3) | |

|---|---|---|---|---|---|---|

| Beam (C35/45) | 34.1 | 34.1 | 0.2 | - | - | 2.5 |

| Composite (FLT S512) | 160 | 12.3 | 0.25 | 5.02 | 0.25 | 1.6 |

| Adhesive joint- epoxy (Sikadur 30) | 12.8 | 12.8 | 0.29–0.34 | - | - | 1.95 at 20 °C |

| Voids: β-Type Zone | PU: γ-Type Zone | Kissing Bond: δ-Type Zone | Adhesive Average Thickness (mm) | ||

|---|---|---|---|---|---|

| 1st campaign | Beam #1 | 50 × 50 mm2 | 50 × 50 mm2 | - | 0.94 |

| Beam #2 | - | 50 × 50 mm2 | 50 × 50 mm2 | 0.9 | |

| Beam #3 | 50 × 50 mm2 | - | 50 × 50 mm2 | 1 | |

| 2nd campaign | Beam #4 | 50 × 50 mm2 | 50 × 50 mm2 | 50 × 50 mm2 | 0.79 |

| Beam #5 | - | - | - | 0.86 | |

| Beam #6 | 25 × 25 mm2 | 25 × 25 mm2 | 25 × 25 mm2 | 0.84 |

| Class “Healthy” | Class “Void” | Class “PU” | Class “Kissing Bond” | ||

|---|---|---|---|---|---|

| Testing data set from beam #1 | Healthy α | 70 | 27 | 3 | - |

| Void β | - | 61 | 18 | 2 | |

| PU γ | - | 20 | 64 | - | |

| Testing data set from beam #2 | Healthy α | 89 | - | - | 15 |

| PU γ | - | 10 | 50 | 20 | |

| Kissing bond δ | 17 | - | - | 65 | |

| Testing data set from beam #3 | Healthy α | 52 | 15 | 10 | 24 |

| Void β | - | 78 | - | 4 | |

| Kissing bond δ | 9 | 14 | 19 | 40 | |

| Classification Rate | Error Rate | ||

|---|---|---|---|

| Testing data set from beam #1 | Healthy α | 70% | 30% |

| Void β | 75% | 25% | |

| PU γ | 76% | 24% | |

| Testing data set from beam #2 | Healthy α | 86% | 14% |

| PU γ | 63% | 37% | |

| Kissing bond δ | 79% | 21% | |

| Testing data set from beam #3 | Healthy α | 51% | 49% |

| Void β | 95% | 5% | |

| Kissing bond δ | 49% | 51% | |

| Class “Healthy” | Class “Void” | Class “PU” | Class “Kissing Bond” | ||

|---|---|---|---|---|---|

| Testing data set from beam #4 | Void β | - | 78 | 84 | 7 |

| PU γ | 62 | 11 | 75 | 11 | |

| Kissing bond δ | 56 | - | 98 | - | |

| Testing data set from beam #5 | Healthy α | 72 | - | - | 72 |

| Testing data set from beam #6 | ¼ Void β | 3 | 48 | - | 98 |

| ¼ PU γ | 10 | 75 | 46 | 11 | |

| ¼ Kissing bond δ | 116 | 1 | 18 | 6 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarr, C.A.T.; Chataigner, S.; Gaillet, L.; Godin, N. Defects Detection and Identification in Adhesively Bonded Joints between CFRP Laminate and Reinforced Concrete Beam Using Acousto-Ultrasonic Technique. J. Compos. Sci. 2022, 6, 334. https://doi.org/10.3390/jcs6110334

Sarr CAT, Chataigner S, Gaillet L, Godin N. Defects Detection and Identification in Adhesively Bonded Joints between CFRP Laminate and Reinforced Concrete Beam Using Acousto-Ultrasonic Technique. Journal of Composites Science. 2022; 6(11):334. https://doi.org/10.3390/jcs6110334

Chicago/Turabian StyleSarr, Cheikh A. T., Sylvain Chataigner, Laurent Gaillet, and Nathalie Godin. 2022. "Defects Detection and Identification in Adhesively Bonded Joints between CFRP Laminate and Reinforced Concrete Beam Using Acousto-Ultrasonic Technique" Journal of Composites Science 6, no. 11: 334. https://doi.org/10.3390/jcs6110334

APA StyleSarr, C. A. T., Chataigner, S., Gaillet, L., & Godin, N. (2022). Defects Detection and Identification in Adhesively Bonded Joints between CFRP Laminate and Reinforced Concrete Beam Using Acousto-Ultrasonic Technique. Journal of Composites Science, 6(11), 334. https://doi.org/10.3390/jcs6110334