Abstract

Recently, short basalt fibres (BFs) have been gaining considerable attention in the building materials industry because of their excellent mechanical properties and lower production cost than their counterparts. Reinforcing geopolymer composites with small volumes of fibres has been proven an efficient technique to enhance concrete’s mechanical properties and durability. However, to date, no study has investigated the effect of basalt fibers’ various lengths and volume content on self-compacted geopolymer concrete’s fresh and mechanical properties (SCGC). SCGC is prepared by mixing fly ash, slag, and micro fly ash as the binder with a solid alkali-activator compound named anhydrous sodium metasilicate (Na₂SiO₃). In the present study, a hybrid length of long and short basalt fibres with different weight contents were investigated to reap the benefits of multi-scale characteristics of a single fibre type. A total of 10 mixtures were developed incorporating a single length and a hybrid mix of long (30) mm and short (12) mm basalt fibres, with a weight of 1%, 1.5% and 2% of the total binder content, respectively. The fresh and mechanical properties of SCGC incorporating a hybrid mix of long and short basalt fibres were compared to plain SCGC and SCGC containing a single fibres length. The results indicate that the hybridization of long and short fibres in SCGC mixture yields better mechanical properties than single-length BF-reinforced SCGC. A hybrid fibre coefficient equation will be validated against the mechanical properties results obtained from the current experimental investigation on SCGC to assess its applicability for different concrete mixes.

1. Introduction

Cementitious concrete is the second most extensively used material globally after water, with an average yearly production of 1.4 m3 per capita [1]. The cement manufacturing process generates up to 2.8 billion tons of CO2 emissions [2], forming 7% of the total CO2 emissions [3,4,5], which aggravates the climate change crisis and causes severe harm to the environment and human beings. By 2050, cement production is expected to rise between 12% and 23% [6], with a consequent 4% increase in carbon dioxide emissions [7], aligning with population growth and infrastructure expansion. In that sense, a net zero-project has been set up by the world green building council (WorldGBCs) and the construction sector to achieve a decarbonization approach by 2050. Accordingly, the construction industry has been shifting towards adopting sustainable materials, such as geopolymer concrete, to combat the global climate change dilemma.

In 1979, a geopolymer was firstly introduced by Joseph Davidovits as a new binder polymer family [8]. Since then, extensive research studies have been conducted to develop a broad range of geopolymer resins with distinct properties to suit various applications in the construction, aerospace and automotive industries. In particular, geopolymer concrete is mainly produced as a result of mixing aluminium silicate by-products, such as fly ash, slag and metakaolin, etc., with chemical base alkaline solutions, including Sodium Silicate (Na₂SiO₃) and Sodium hydroxide (NaOH) [9]. Over the last two decades, geopolymer concrete has drawn the attention of many researchers since it produces approximately 80% less CO2 emissions in its manufacture compared to cementitious concrete [10]. Besides, consuming aluminium-silicate by-products, such as fly ash and slag, and geopolymer concrete manufacture contributes to the inhibition of severe damage caused by waste material to the environment and human health. For instance, fly ash is characterised by its small particles and is lightweight, making it easy to carry by air if not stored properly. The prolonged human inhalation of airborne fly ash results in adverse health effects, including respiratory diseases and lung cancer [11]. Geopolymer concrete develops comparable mechanical properties to cementitious concrete, including excellent compressive and tensile strength [12,13], adequate flexural strength [12] as well as a strong bond with steel reinforcement [14,15]. Geopolymer concrete outperforms cementitious concrete for chemical resistance against sulfuric acid [16]. It mainly returns to the stable connection link formed in the geopolymer concrete structure [16]. Geopolymer concrete has superior chemical stability to its counterparts, resulting in improved mechanical characteristics and durability under extreme heat [17]. Furthermore, fly ash/slag-based geopolymer concrete (FSGC) exhibits equivalent freeze-thaw resistance to cementitious concrete [18].

Despite the numerous benefits of geopolymer concrete, its adoption in the building sector is limited, owing to two major hurdles. Geopolymer concrete must be cured 24 h at a temperature between 60 °C and 85 °C [19,20,21,22]. Furthermore, alkali-activator solutions must be produced before casting day, and their highly corrosive nature needs special handling and storage approaches [23,24,25,26]. Rahman and Al-Ameri [13] recently developed a novel self-compacted geopolymer concrete (SCGC), composed of solid anhydrous sodium metasilicate powder (Anhy.Na₂SiO₃) as an alkali-activator, with a fly ash/slag ratio of 60/40 and 5% micro fly ash as the binder, and a water/solid content ratio of 0.45. SCGC has average compressive and indirect tensile strengths of 40 Mpa and 3 Mpa, respectively [13]. The superiority of SCGC over traditional geopolymer concrete is that high heat curing is not required for SCGC production, and solid alkali-activator powder replaces alkali-activator solutions, making it a promising option for general construction applications.

Although the manufacturing simplicity associated with SCGC makes it more practical for in-situ applications, some significant issues concerned with the mechanical properties of fly ash slag-based geopolymer concrete (FASGC) have been observed. FASGC has low indirect tensile and flexural strength and high brittleness [27,28,29]. The likelihood of crack development increases when slag is used in fly ash geopolymer concrete mixtures at a rate greater than 30% of the binder [30], thus weakening the concrete strength and affecting its durability in the long run. Reinforcing geopolymer concrete with discrete short fibres has proven to be an effective way to improve composite ductility and enhance mechanical properties [27,31,32]. Several studies have investigated the effect of employing various types of fibres, including steel, PVA, glass and polypropylene fibres, on the properties of geopolymer composites [33,34,35,36]. Studies [31,32,37,38,39] concluded that including short fibres in geopolymer concrete could reduce composite brittleness and enhance compressive strength, bonding strength, splitting tensile strength and frost resistance. Besides the fibres mentioned above, short basalt fibres, to be deployed for the production of reinforced geopolymer composites, have been attracting researchers due to their sustainability [40,41], low production cost [42], excellent mechanical properties [40,43,44,45] and adequate temperature and chemical stability [42,43,46,47,48,49,50], etc. The impact of short basalt fibres with volume fractions of 0.5% and 1% on the fracture toughness of geopolymer concrete and cementitious concrete was investigated [51]. High-volume fractions of short basalt fibres enhanced the fracture toughness and reduced the crack width of geopolymer and cementitious concrete mixtures compared to plain composites [51]. Notably, incorporating BFs was more effective in toughening geopolymer composites than cementitious concrete [51]. Timakul et al. (2016) [10] reported that adding 10% weight of BFs to geopolymer concrete increased its compressive strength by 37% compared to plain geopolymer concrete. According to a study by Wang et al. (2020) [52], geopolymer concrete reinforced with 6 mm short basalt fibres outperformed geopolymer concretes incorporating 3 mm, 12 mm, and 18 mm, independently, in terms of compressive strength, splitting tensile strength, fracture energy and peak load. Although studies showed that the inclusion of BFs can enhance the mechanical properties of geopolymer concrete, there is still a significant knowledge gap regarding the performance of BF reinforced geopolymer concrete, especially self-compacted geopolymer concrete. Moreover, further research is required to assess the effect of the hybridization of short and long basalt fibers on the fresh and mechanical properties of self-compacted geopolymer concrete.

Research Significance

Lately, scholars have conducted extensive research studies into the influence of basalt fibres on concrete’s behaviour, resulting in several advancements [53]. Many studies [40,54,55,56,57,58,59] investigate the effect of discrete short and long basalt fibres on the mechanical properties of cementitious concrete. However, limited research studies examine the mechanical properties of geopolymer concrete reinforced with discrete basalt fibres. No research study has investigated the influence of discrete basalt fibres on the fresh and mechanical properties of self-compacted geopolymer concrete. In recent years, several research studies have focused on reinforcing concrete with different proportions of hybrid fibres [60,61,62,63], where two or more different types of fibres are added to concrete. The aim has been to assess its performance in terms of mechanical properties compared to single fibre reinforced concrete. Cementitious concrete containing steel-polypropylene hybrid fibres has better fracture toughness and stress intensity than mono-fibre systems [62]. High-strength concrete reinforced with hybrid steel-polypropylene fibres of 0.12% volume content has better mechanical properties than mono-fibre high-strength concrete [63]. Strengthening ternary-blend geopolymer concrete with hybrid steel-polypropylene fibres improves the mixture’s mechanical properties and durability [60,61]. Khan and Cao (2021) reported that reinforcing cementitious mortar with four different basalt fibre lengths (3, 6, 12 and 20 mm) generally enhanced the mechanical properties compared to a single-length fibre-reinforced cementitious mortar. Short fibres are more efficient in controlling micro-cracks propagation, while long fibres bridge macro-cracks [60,62,63]. However, the hybridization effect of different lengths of the same fibre type on self-compacted geopolymer concrete’s fresh and mechanical properties has not been explored. Therefore, the primary goal of the current study is to assess the impact of single and hybrid BF lengths with different contents on the fresh and mechanical properties of self-compacted geopolymer concrete. The experimental investigation was carried out on SCGC reinforced with two different lengths of basalt fibres, 12 mm and 30 mm, and a hybrid mix of the two lengths with varying contents. The fresh properties (slump flow, T500 and J-ring tests) and mechanical properties, including compressive and indirect tensile strengths of basalt fiber reinforced SCGC, were investigated. Recently, an equation by Khan and Cao [53] was developed to predict the effect of basalt fiber hybrid lengths on the mechanical properties of cementitious mortar. The set equation was validated against the mechanical properties results obtained from the current experimental investigation on SCGC to assess its applicability for different concrete mixes.

2. Materials and Methods

2.1. Materials and Casting

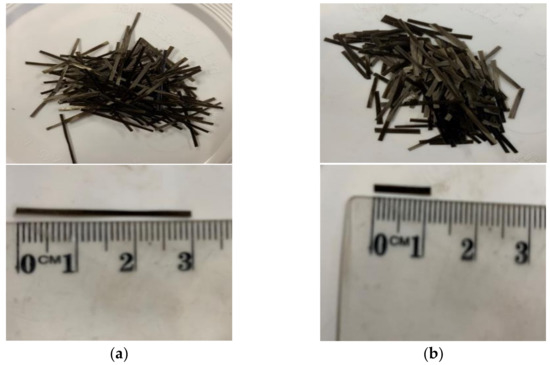

Fly ash and slag, with a 60:40 ratio, are the most significantly used binder constituents for the production of SCGC composite. Fly ash with high silica content, conforming to AS/NZS 3582.1:2016 standard requirements [64], was sourced from Cement Australia Pty Ltd. (Darra, Qld, Australia) Ground slag was sourced from Independent Cement and Lime Pty Ltd. Microash with 3.5 µm fine particle size, sourced from Flyash Australia Pty (Lindfield, NSW, Australia), was added to the mixture to improve the workability and concrete strength [65,66]. Solid anhydrous sodium metasilicate powder sourced from a chemist supplier was used as a single alkali activator to form the geopolymerisation process. Water with 45% of the total binder weight was used in the mix. The chemical composition of binder components is tabulated in Table 1. Short basalt fibres (12 mm) and long basalt fibres (30 mm), as shown in Figure 1, with weight fractions of 1%, 1.5% and 2%, were used for reinforcing the SCGC mixtures. Table 2 presents the physical properties of the basalt fibres used. BFs have a smooth surface and circular cross-sectional area, with high tensile strength of 1000 Mpa. Khan and Cao [53] estimated the weight of a single length of basalt fibres in the hybrid mix based on volume equality for all sizes. However, this method might result in unequal quantifying for the number of single fibres in the hybrid mix, as shorter fibres have a higher count for the number of fibres than longer fibres for the same volume content in the hybrid mix. For better dispersion of the hybrid length of basalt fibres within the SCGC mixture, a 3:1 ratio of long/short fibers was selected in this study. The 30 mm fibers were 2.5 times longer than the 12 mm, and this ratio was chosen to achieve an approximate equal quantification of single fiber length in the hybrid mix.

Table 1.

Chemical composition details of SCGC mixture.

Figure 1.

Short/long basalt fibres with (a) 30 mm and (b) 12 mm were used in the SCGC mixture.

Table 2.

Physical properties of basalt fibres [51,67,68,69].

Ten different SCGC mixtures, as presented in Table 3, were developed, including one control SCGC mix and nine BF-reinforced SCGC mixes. The mix design of the self-compacted geopolymer concrete (SCGC) is presented in Table 4. Reinforced SCGC mixtures were prepared by mixing fine aggregate, coarse aggregates, all binder components and basalt fibres in a concrete mixer drum for 4 min to ensure uniform distribution of fibres within the mix.

Table 3.

Designation of mix composition.

Table 4.

Mix design of SCGC (kg per 1 m3).

Afterwards, water was added to the dry mixture, and mixing was maintained for around 9 min. Fresh properties tests, including slump flow, T500 and J-ring tests, were carried out for all mixes, according to AS 1012.3.5:2015 standards [70], to investigate the effect of short/long BF on the workability of self-compacted geopolymer concrete. A total of 60 cylindrical specimens, with dimensions of 200 mm height and 100 mm diameter, were cast to study the influence of short/long BFs on mechanical properties (compressive strength and indirect tensile strength) of SCGC. Following the completion of the slump test, mixes were poured directly into cylindrical moulds, as shown in Figure 2, which were internally coated with a lanofoam release agent. Two days later, all specimens were demolded, as shown in Figure 3, and kept in a humidity chamber at the structure laboratory of Deakin University for 28 days at 23 °C temperature and 49% relative humidity. The humidity chamber was used to maintain ambient curing for all SCGC specimens, according to AS 3600:2018 Standards [71].

Figure 2.

Freshly poured SCGC specimens.

Figure 3.

Hardened SCGC specimens.

Mixes represent single-length basalt-fibre-reinforced SCGC composites with the ’BF’ abbreviation. The BF lengths are 12 and 30, and the BF weight contents in the SCGC mixes are 1, 1.5 and 2. Mixes with the acronym “HBF represent the hybrid basalt-fibre-reinforced SCGC composites”.

2.2. Test Method

The slump flow test was carried out following the recommendations of the Australian Standard-Method of Testing Concrete, AS 1012.3.5:2015 [70]. The slump flow was determined by averaging the two diameters of the geopolymer concrete spread after the concrete stopped flowing [70], as shown in Figure 4. According to Australian standards, if the slump flow exceeds the spread value of 500 mm, the concrete is deemed self-compacting [70]. The T500 test was carried out following AS 1012.3.5:2015 guidelines, where a slump cone apparatus and timer were used. The required time for the slump to reach a diameter of 500 mm on the baseboard was recorded. The J-ring test was conducted on all mixes, according to AS 1012.3.4:2015 [70], to investigate the effect of short/long fibres on the passing ability of SCGC, as shown in Figure 4.

Figure 4.

Slump flow test done in conjunction with J-ring test.

To measure the compressive strength of the mixes, 3000 KN compression testing equipment, as shown in Figure 5, available at the structural laboratory at Deakin University, was used. A loading rate of 33 Mpa per second, according to AS 1012.14:2018 standards [72], was applied to three specimens for each mix to get the average compressive strength. The indirect tensile strength of the ten mixes was determined according to AS 1012.10-2000 (R2014) [73]. Loading of 785 N/S was applied to the specimens using the testing machine shown in Figure 6. The indirect tensile strength average value of three samples was calculated. The compressive and indirect tensile strength results were valid, as the mechanical property values of the three specimens were within 15% of the mean value; hence, no test repetition was required.

Figure 5.

Compressive strength test specimen.

Figure 6.

Indirect tensile strength test specimen.

Khan and Cao [53] developed a hybrid fibre coefficient equation to predict the effect of basalt fibres’ mixed lengths on the mechanical properties of cement mortar. The cement mortar mechanical properties and the hybrid fibre coefficients were consistent. However, it was necessary to assess the validation of the mixed fibre coefficient equation against other mixtures, such as self-compacted geopolymer concrete. The hybrid fibre coefficient calculation method for concrete mechanical properties is presented in Equation (1).

Hc is the hybrid fibre coefficient of SCGC; M is the property value of hybrid BFs reinforced SCGC. V is the total hybrid BFs content percentage in reinforced SCGC. Mi is the property value of a single reinforced SCGC. Vi is the single BFs content percentage in hybrid fibres SCGC, and i = 1, 2, 3 and so on. If the Hc coefficient value is greater than 1, the hybrid BFs content percentage positively impacted SCGC property performance. On the other hand, if it is less than 1, the mixed BFs content percentage has a negative impact on SCGC properties.

3. Results and Discussions

3.1. Fresh Properties

In this study, the workability parameters of SCGC were compared to regular self-compacted concrete, as no specific regulations are available for geopolymer concrete yet. Three main fresh properties of SCGC were assessed in this study: slump flow test (flowability), T500 (viscosity measurement), and J-ring test (passing ability).

3.1.1. Slump Flow Test

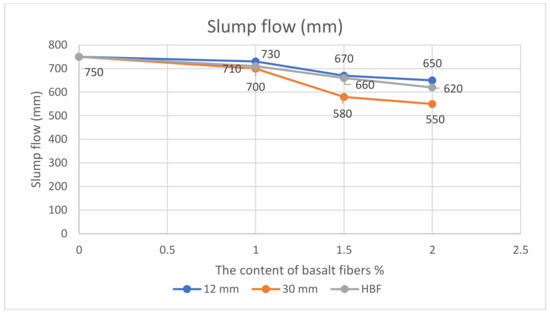

A slump flow test is used to assess the filling ability of concrete to the formwork under its weight [74]. Concrete is considered self-compacted if the slump flow exceeds a 500 mm spread value, according to the Australian Standards AS1012.3.5:2015 [70]. Figure 7 presents the slump flow value for all mixes. As shown in Figure 7, the slump flow results ranged between 550 mm and 750 mm, depending on basalt fibres’ weight content and length. Although adding short and long BFs with different weight contents to the SCGC mix reduced the flowability, all developed mixes were self-compacted, as slump flow results were above 500 mm in diameter. The SCGC mix developed a slump flow of 750 mm, as shown in Figure 4.

Figure 7.

Slump flow value for all mixes.

As shown in Figure 7, increasing the weight content of BFs lowered the slump flow diameter of the reinforced SCGC. Reinforcing SCGC with short BFs (12 mm) and weight content of 1%, 1.5% and 2% resulted in flowability reduction of 2.66%, 10.67% and 13.33%. A 6.66%, 22.66% and 26.66% higher reduction in flowability was observed with the same weight contents for longer BFs (30 mm). The 30 mm BFs have a larger surface area than the 12 mm BFs, which increases its absorption capacity to the moisture content and, consequently, results in a higher reduction of SCGC flowability than SCGC reinforced with 12 mm BFs. Using basalt fibres typically reduces the workability of concrete [75]. This impact is a characteristic of most fibres used [76], which is linked to the additional consumption of mixing water to cover the surface area of the fibres. The slump flow values of HBF-1, HBF-1.5 and HBF-2 were 700 mm, 660 mm and 620 mm, respectively. The slump flow results of SCGC reinforced with a hybrid length of BF were between the slump flow values of 12 mm and 30 mm BF single reinforced SCGC for the same BF weight content. HBF-1, HBF-1.5 and HBF-2 had 1.4%, 12.37% and 11.28% higher flowability than 30 mm BF reinforced SCGC with weight contents of 1%, 1.5% and 2%, respectively, and 2.74%, 1.49% and 4.62% lower flowability than 12 mm BF reinforced SCGC of same weight content. Notably, no segregation was observed with any of the mixtures in the present study.

3.1.2. T500 Test

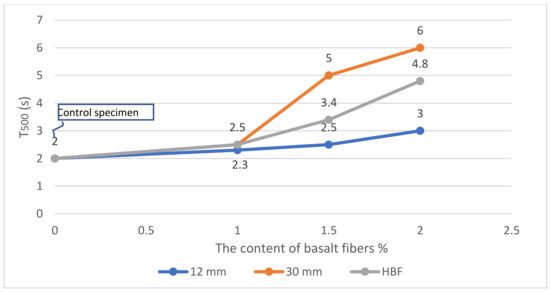

Self-compacted concrete has a higher viscosity than conventional concrete, allowing for long-term creep of self-compacted concrete. According to EFNRC [74] Guidelines, the self-compacted concrete had a T500 value ranging between 2–5 s. The T500 value indicated whether the mixture was suitable for self-compacting concrete applications. Figure 8 presents the T500 values for all mixtures.

Figure 8.

Variation of the T500 flow time with BFs fibre content for different fibre lengths.

The T500 value of the SCGC mix was 2 s, as shown in Figure 4 and Figure 8. The addition of BF to the SCGC mix required more time than plain SCGC for the flowable mix to have a spread value of 500 mm in diameter. T500 values of SCGC mixtures reinforced with 30 mm long BFs were higher than SCGC mixtures reinforced with 12 mm short BFs for the same added weight content of BFs. The T500 values of all mixes ranged between 2 s to 5 s, complying with EFNRC [74] guidelines, except for the BF30-2 mix, as 6 s was reported. Incorporating long BF with high weight content in the SCGC mixture increased the mixture’s viscosity due to the larger surface of BF that absorbed the water content and the binder material.

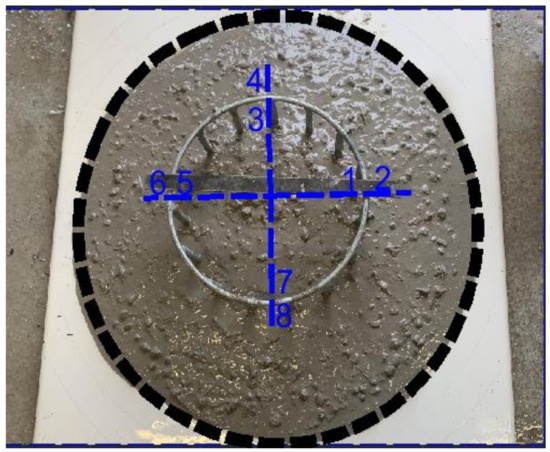

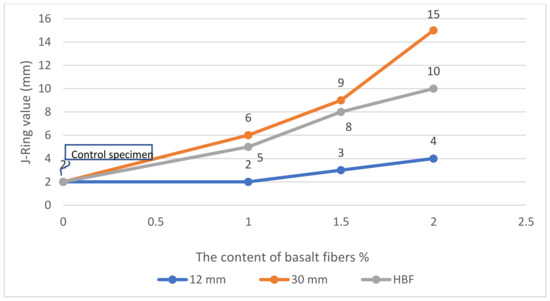

3.1.3. J-Ring Test

According to the EFNRC [74] guidelines, self-compacted geopolymer concrete has a passing ability ranging between 0 mm to 10 mm. The concrete’s height was measured at 8 locations, 4 locations inside and 4 locations outside the J-ring apparatus, at degrees of 0, 90, 180, and 270, as shown in Figure 9. The SCGC mixture smoothly flowed through the narrow opening of the J-ring apparatus with no coarse aggregate piled inside the J-Ring instrument, as shown in Figure 9. J-Ring test results of all mixtures are presented in Figure 10. All mixtures performed well as J-Ring values were between 2 mm to 10 mm, excluding the BF-30 mix type, where a J-Ring value of 15 mm was reported, as shown in Figure 10.

Figure 9.

Locations of SCGC measured heights.

Figure 10.

Variation of the J-ring value with BFs fibre content for different fibre lengths.

3.2. Results of Mechanical Properties

3.2.1. Compressive Strength Parameters

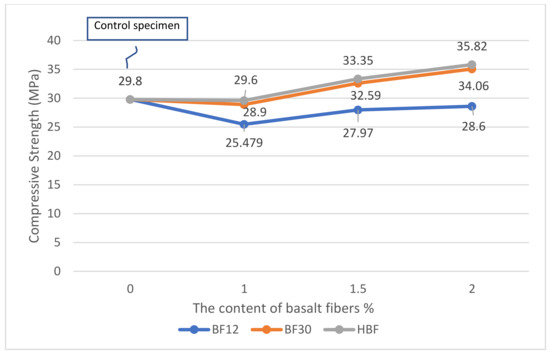

Figure 11 presents the results of a 28-day compressive strength test conducted on plain SCGC and SCGC mixtures reinforced with 12 mm and 30 mm BFs length and weight content ranging between 1% to 2%. The compressive strength of SCGC reinforced with 12 mm and 30 mm BF single and hybrid lengths of 1% weight were lower than plain SCGC. An insignificant decrease of 3% and 0.67% in compressive strength was observed for BF30-1 and HBF-1 mixes, compared to a 14.5% decrease in compressive strength for the BF12-1 mix compared to the plain SCGC. Adding 12 mm BF to SCGC with weight content ranging between 1–2% generally reduced the compressive strength. The inclusion of fibres in cementitious composites may reduce compressive strength due to the increase of poor interface regions in the matrix [77]. Although the reduction of compressive strength is observed, the 12 mm BFs weight content rises from 1% to 2% within the SCGC mix, improving the compressive strength, as shown in Figure 11.

Figure 11.

Variation of the compressive strength for 12 mm, 30 mm, and hybrid BF reinforced SCGC with different weight content.

On the other hand, the compressive strengths of 30 mm single length BFs with total weight contents of 1.5% and 2% were relatively higher than for plain SCGC. The compressive strength of 30 mm BFs reinforced SCGC with weight contents of 1.5% and 2% were increased by 9.36% and 14.29%, respectively, over the plain SCGC. The SCGC reinforced with 30 mm BFs exhibited an improvement in the compressive strength with the increase of BFs weight content from 1% to 2%. The compressive strength of HBF-1.5 and HBF-2 increased by 11.91% and 20.20%, respectively, compared to plain SCGC, but an insignificant decrease of 0.67% in compressive strength was observed for the HBF-1 mix type compared to the plain SCGC. The hybrid fibre reinforced SCGC specimens, HBF-1, HBF-1.5 and HBF-2, showed better results in terms of compressive strength than single-length fibre reinforced SCGC for all BFs weight contents in the present study. Compared to single-length BF reinforced SCGC, HBF-1, HBF-1.5 and HBF-2 showed a compressive strength increase of 16.17%, 19.23% and 25.24% respectively, compared to BF-12-1, BF-12-1.5 and BF-12-2. Furthermore, an insignificant increase of 2.42%, 2.33% and 5.16% in compressive strength of HBF-1, HBF-1.5 and HBF-2, compared to BF30-1, BF30-1.5 and BF30-2, respectively, was observed. The compressive strength results were in relatively good agreement with the study conducted by Algin and Ozen (2018) [76] to assess the effect of basalt fibres length and volume content on the compressive strength of self-compacted cementitious concrete. A decrease in compressive strength was observed for specimens reinforced with 12 mm and 24 mm BFs for volume content ranging between 0.1–0.3% (approximately (0.5–1.4)% of binder weight), followed by an increase in compressive strength for specimens reinforced with 12 mm and 24 mm BFs up to 0.5% volume content of concrete [76]. Palchik (2011) [78] reported a 25% and 58% increase in compressive strength of geopolymer composites reinforced with 12 mm and 24 mm basalt fibres, respectively (as cited in Farhan, Johari and Demirboğa (2021) [79]). Hassani Niaki, Fereidoon and Ghorbanzadeh Ahangari (2018) [69] reported an increase in compressive strength of ternary epoxy-based polymer concrete reinforced with a basalt fibres content of up to 2%.

Compared to the plain specimen, basalt fibres could enhance the failure mechanism of the SCGC mixture under the compression load [53]. However, the addition of 12 mm BF with weight contents ranging between 1% to 2% to the SCGC mixture did not show a different failure mechanism from SCGC’s brittle failure. On the other hand, SCGC incorporated with 30 mm BF and BF hybrid length developed a ductile failure mode and fewer cracks, with less crack width, were visually observed than plain SCGC. It could be attributed to the fact that 30 mm longer BF had a higher bridging effect than 12 mm shorter BF, which efficiently limited crack propagation and yielded a better destructive energy consumption than the plain SCGC mixture and 12 mm reinforced SCGC mixture.

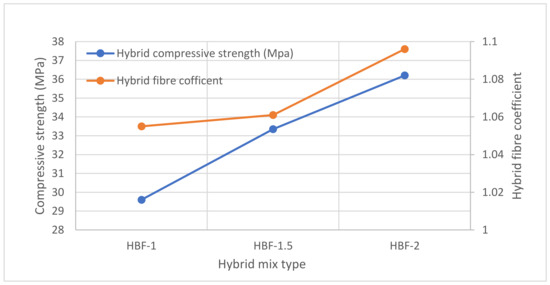

The developed hybrid coefficient equation was used to predict the effect of the BFs hybrid mix on the mechanical properties of cementitious mortar [53]. This study validated the hybrid fibre coefficient equation against the SCGC mixture incorporating BFs. Figure 12 presents the calculated hybrid fibre coefficients of SCGC compressive strength based on Equation (1) for HBF-1, HBF-1.5 and HBF-2. The hybrid fibre coefficient for all HBF mixes is above 1, and the highest hybrid coefficient is for the HBF-2 mix with 2% BFs weight content. The calculated hybrid fibre coefficient trend showed good consistency with BFs hybrid-length compressive strength results. Regarding the hybrid fibre coefficient equation, the predicted compressive strength of HBF-1, HBF-1.5 and HBF-2 were 31.44 MPa, 31.61 MPa and 32.66 MPa, respectively. The anticipated compressive strength results are within 10% of compressive strength results obtained from the experimental investigation, which indicates the validation of the hybrid equation to assess the compressive strength performance of SCGC incorporated hybrid Length of BFs.

Figure 12.

Hybrid fibre coefficient of SCGC’s compressive strength.

3.2.2. Indirect Tensile Strength Parameters

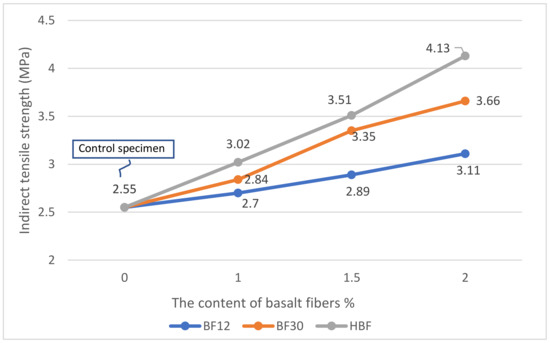

Figure 13 illustrates the indirect tensile strength of SCGC incorporated BF with weight content between 1% to 2%. Previous studies [40,53,76,80] acknowledged that adding BFs to a concrete mixture resulted in improving the indirect tensile strength. In the present study, the increase of 12 mm and 30 mm BF up to 2% weight content in the SCGC mix resulted in the enhancement of SCGC indirect tensile strength. The indirect tensile strength of BF12-1, BF12-1.5 mixes and BF12-2 were higher than plain SCGC by 5.55%, 13.70% and 22%, respectively. On the other hand, the indirect tensile strength of BF30-1, BF30-1.5 and BF30-2 were higher than plain SCGC by 11.37%, 31.50% and 43.50%, respectively. SCGC incorporated with 30 mm BF showed a better indirect tensile strength performance than SCGC reinforced with 12 mm BF. BF30-1, BF30-1.5 and BF30-2 had 4.92%, 16% and 17.70%, respectively, better indirect tensile strength than BF12-1, BF12-1.5 and BF12-2. The indirect tensile strength findings of the current study were in good agreement with earlier studies that assessed the effect of short and long basalt fibres with different volume contents on the indirect tensile strength of self-compacted cementitious concrete [76] and cementitious concrete [54]. Concrete reinforced with longer basalt fibres showed better indirect tensile performance than concrete reinforced with short fibres for the same volume content [54,76]. The dispersion of basalt fibres within a concrete mix stimulates the bridging action across the cracks, which limits the propagation of cracks and, consequently, improves the indirect tensile strength [76].

Figure 13.

The indirect tensile strength variation for 12 mm, 30 mm, and hybrid BFs reinforced SCGC with different weight content.

SCGC reinforced with BFs hybrid length had a much better indirect tensile strength performance than plain SCGC. The indirect tensile strength of HBF-1, HBF-1.5, and HBF-2 mixes were higher than plain SCGC by 18.43%, 37.64% and 61.96%, respectively. HBF-1, HBF-1.5 and HBF-2 mixes had 11.85%, 21.45% and 32.80%, respectively, higher indirect tensile strength than BF12-1, BF12-1.5 and BF12-2. In comparison to SCGC incorporated with 30 mm, HBF-1, HBF-1.5 and HBF-2 had higher indirect tensile strengths than BF30-1, BF30-1.5 and BF30-2 by 6.34%, 4.77% and 12.84%, respectively. HBF-2 has the highest indirect tensile strength of 4.13 MPa.

A brittle failure was observed with SCGC specimens, and they were split into two halves after approaching the failure load. SCGC specimens incorporated with single-length and hybrid length of BF showed some ductile failure mechanism, as the specimens were not directly split into two halves after approaching the failure load. The dispersion of 30 mm BF in the SCGC mix could have a better bridging effect than 12 mm BF and, consequently, consume additional destructive energy and has better indirect tensile strength properties than plain SCGC and 12 mm BF reinforced SCGC.

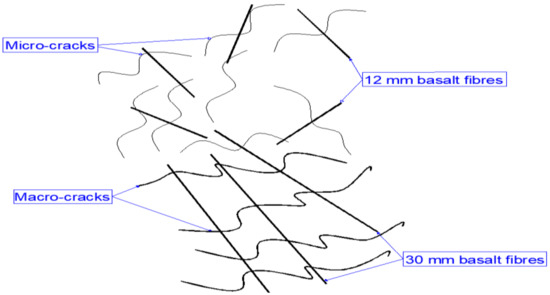

Micro-cracks and voids are formed in the SCGC matrix during the geo-polymerization process. Under the applied tensile stresses on SCGC, the crack’s width and length grow to macro-cracks, as shown in Figure 14. Adding hybrid lengths of BFs to the SCGC mix improves the indirect tensile strength of the matrix, as 12 mm BF hindered the propagation of micro-cracks. As the tensile stresses increase, the 12 mm BFs are broken, and the role of 30 mm BFs emerge through arresting macro-crack propagation and enhancing the destructive energy absorption of the matrix till it becomes unable to withstand any further stresses. The indirect tensile strength of hybrid-length BF reinforced mixes is higher than single-length BF mixes of the same BFs weight content, as shown in Figure 13. An optical microscope image was captured for a hybrid-length BF-reinforced SCGC specimen, as shown in Figure 15. Hybrid-length BFs are homogenously embedded and bound to the SCGC matrix. A synergetic interaction under tensile stresses was formed, and better destructive energy absorption through the friction between the SCGC constituents and BF was exhibited.

Figure 14.

Cracks arresting mechanism of hybrid basalt fibres reinforced SCGC.

Figure 15.

Optical microscope image of hybrid basalt fibres reinforced SCGC.

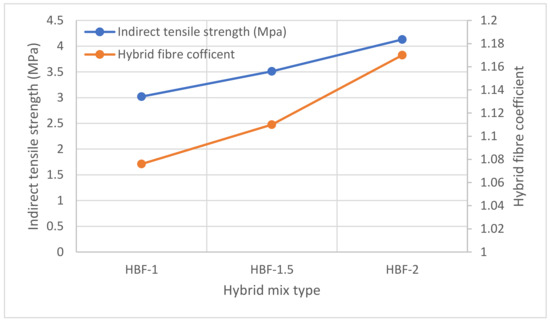

Figure 16 presents the calculated hybrid fibre coefficient of SCGC indirect tensile strength for HBF-1, HBF-1.5 and HBF-2 mixes. The hybrid fibre coefficient for all HBF mixes is above 1, and the highest hybrid fibre coefficient is for the HBF-2 mix with 2% BF content. Based on hybrid fibre coefficient values, the predicted indirect tensile strength of HBF-1, HBF-1.5 and HBF-2 were 2.74 MPa, 2.83 MPa and 2.98 MPa, respectively. Although the mixed fibre coefficient trend showed good consistency with the indirect tensile strength results, as shown in Figure 16, the predicted results from the hybrid coefficient equation for HBF-1.5 and HBF-2 were not within 10% of the obtained results from the experimental investigation. Thus, the hybrid fibre coefficient equation may not be recommended for assessing the effect of BF hybrid length on SCGC’s indirect tensile strength.

Figure 16.

Hybrid fibre coefficient of SCGC’s indirect tensile strength.

4. Conclusions

In this study, the fresh and mechanical properties of self-compacted geopolymer concrete, incorporated with 12 mm and 30 mm single and hybrid lengths of BFs, and with weight contents of 1%, 1.5% and 2%, were investigated. The assessed parameters of fresh properties included flowability, viscosity measurement and passing ability, and the mechanical parameters were compressive strength and indirect tensile strength. A developed equation to calculate the hybrid fibre coefficient of cementitious mortar incorporated with hybrid-length BFs was validated against SCGC. The critical findings are listed as follows:

- Increased BF length and weight directly reflected the fresh properties of SCGC. All developed mixes showed a flowability above 500 mm, which complied with Australian standards. However, the SCGC containing 30 mm single-length BF with a weight content of 2% had viscosity measurement and passing ability values that were not within the recommended range of the EFNRC guidelines.

- The highest reported compressive strength was 35.82 MPa for the HBF-2 mix, which was incorporated with hybrid-length BF and had a weight content of 2%. HBF-2 had 20.20% higher compressive strength than plain SCGC. The SCGC containing 30 mm single-length and hybrid-length BF showed an increase in compressive strength with an increase in BF weight content up to 2%.

- The highest reported indirect tensile strength was 4.13 MPa for the HBF-2 mix. HBF-2 had 61.96% higher indirect tensile strength than plain SCGC. The SCGC incorporated with hybrid-length BFs showed better indirect tensile strength performance than single-length BF-reinforced SCGC for the same BFs weight content.

- The hybrid fibre coefficient trend showed good consistency with compressive and indirect tensile strength results. However, it might not be recommended regarding the indirect tensile strength property, as the calculated results from the hybrid fibre equation were not within 10% of the obtained results from the experimental investigation.

Author Contributions

Conceptualization, M.H. and R.A.-A.; Data curation, M.H.; Investigation, M.H.; Methodology, M.H.; Supervision, B.K. and R.A.-A.; Writing—original draft, M.H.; Writing—review & editing, M.H., B.K. and R.A.-A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Available on request from authors.

Acknowledgments

The authors would like to acknowledge the support of Deakin University in carrying out the present study. Moreover, the assistance of Leanne Farago, Lube Veljanoski and Michael Shanahan during the experimental phase of the study is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Droege, S. Pricing and Its Future Role for Energy-Intensive Industries. Key Features of Steel, Cement, Aluminium, Basic Chemicals, Pulp & Paper; Synthesis Report; Climate Strategies: London, UK, March 2013. [Google Scholar]

- Law, D.W.; Adam, A.A.; Molyneaux, T.K.; Patnaikuni, I.; Wardhono, A. Long term durability properties of class F fly ash geopolymer concrete. Mater. Struct. 2015, 48, 721–731. [Google Scholar] [CrossRef]

- Deb, P.S.; Sarker, P.K.; Barbhuiya, S. Sorptivity and acid resistance of ambient-cured geopolymer mortars containing nano-silica. Cem. Concr. Compos. 2016, 72, 235–245. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G. Damage behavior of geopolymer composites exposed to elevated temperatures. Cem. Concr. Compos. 2008, 30, 986–991. [Google Scholar] [CrossRef]

- Ofosu-Adarkwa, J.; Xie, N.; Javed, S.A. Forecasting CO2 emissions of China’s cement industry using a hybrid Verhulst-GM (1, N) model and emissions’ technical conversion. Renew. Sustain. Energy Rev. 2020, 130, 109945. [Google Scholar] [CrossRef]

- IEA. Cement Technology Roadmap Plots Path to Cutting CO2 Emissions 24% by 2050—News; IEA: Paris, France, 2018; pp. 1–3. [Google Scholar]

- Davidovits, J.; Cordi, S. Synthesis of new high temperature geo-polymers for reinforced plastics/composites. Spe Pactec 1979, 79, 151–154. [Google Scholar]

- Ma, C.-K.; Awang, A.Z.; Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Timakul, P.; Rattanaprasit, W.; Aungkavattana, P. Improving compressive strength of fly ash-based geopolymer composites by basalt fibers addition. Ceram. Int. 2016, 42, 6288–6295. [Google Scholar] [CrossRef]

- Whiteside, M.; Herndon, J.M. Aerosolized coal fly ash: Risk factor for COPD and respiratory disease. J. Adv. Med. Med. Res. 2018, 26, 1–13. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. A newly developed self-compacting geopolymer concrete under ambient condition. Constr. Build. Mater. 2021, 267, 121822. [Google Scholar] [CrossRef]

- Sarker, P.K. Bond strength of reinforcing steel embedded in fly ash-based geopolymer concrete. Mater. Struct. 2011, 44, 1021–1030. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J. Bond strength between blended slag and Class F fly ash geopolymer concrete with steel reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- Ariffin, M.; Bhutta, M.; Hussin, M.; Tahir, M.M.; Aziah, N. Sulfuric acid resistance of blended ash geopolymer concrete. Constr. Build. Mater. 2013, 43, 80–86. [Google Scholar] [CrossRef]

- Luhar, S.; Nicolaides, D.; Luhar, I. Fire resistance behaviour of geopolymer concrete: An overview. Buildings 2021, 11, 82. [Google Scholar] [CrossRef]

- Zhao, R.; Yuan, Y.; Cheng, Z.; Wen, T.; Li, J.; Li, F.; Ma, Z.J. Freeze-thaw resistance of Class F fly ash-based geopolymer concrete. Constr. Build. Mater. 2019, 222, 474–483. [Google Scholar] [CrossRef]

- Fan, Y.; Yin, S.; Wen, Z.; Zhong, J. Activation of fly ash and its effects on cement properties. Cem. Concr. Res. 1999, 29, 467–472. [Google Scholar] [CrossRef]

- Puertas, F.; Martínez-Ramírez, S.; Alonso, S.; Vázquez, T. Alkali-activated fly ash/slag cements: Strength behaviour and hydration products. Cem. Concr. Res. 2000, 30, 1625–1632. [Google Scholar] [CrossRef]

- Somna, K.; Jaturapitakkul, C.; Kajitvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar] [CrossRef]

- Heweidak, M.; Kafle, B.; Al-Ameri, R. Shear-Bond Behaviour of Profiled Composite Slab Incorporated with Self-Compacted Geopolymer Concrete. Appl. Sci. 2022, 12, 8512. [Google Scholar] [CrossRef]

- Ardalan, R.B.; Emamzadeh, Z.N.; Rasekh, H.; Joshaghani, A.; Samali, B. Physical and mechanical properties of polymer modified self-compacting concrete (SCC) using natural and recycled aggregates. J. Sustain. Cem.-Based Mater. 2020, 9, 1–16. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J. Efficiency of different superplasticizers and retarders on properties of ’one-Part’ Fly ash-slag blended geopolymers with different activators. Materials 2019, 12, 3410. [Google Scholar] [CrossRef] [PubMed]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Synthesis of heat and ambient cured one-part geopolymer mixes with different grades of sodium silicate. Ceram. Int. 2015, 41, 5696–5704. [Google Scholar] [CrossRef]

- Zannerni, G.M.; Fattah, K.P.; Al-Tamimi, A.K. Ambient-cured geopolymer concrete with single alkali activator. Sustain. Mater. Technol. 2020, 23, e00131. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. Fiber-reinforced one-part alkali-activated slag/ceramic binders. Ceram. Int. 2018, 44, 8963–8976. [Google Scholar] [CrossRef]

- Korniejenko, K.; Frączek, E.; Pytlak, E.; Adamski, M. Mechanical Properties of Geopolymer Composites Reinforced with Natural Fibers. Procedia Eng. 2016, 151, 388–393. [Google Scholar] [CrossRef]

- Shah, S.F.A.; Chen, B.; Oderji, S.Y.; Aminul Haque, M.; Ahmad, M.R. Comparative study on the effect of fiber type and content on the performance of one-part alkali-activated mortar. Constr. Build. Mater. 2020, 243, 118221. [Google Scholar] [CrossRef]

- Lee, N.; Jang, J.G.; Lee, H.-K. Shrinkage characteristics of alkali-activated fly ash/slag paste and mortar at early ages. Cem. Concr. Compos. 2014, 53, 239–248. [Google Scholar] [CrossRef]

- Gülşan, M.E.; Alzeebaree, R.; Rasheed, A.A.; Niş, A.; Kurtoğlu, A.E. Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber. Constr. Build. Mater. 2019, 211, 271–283. [Google Scholar] [CrossRef]

- Kumar, R.; Suman, S.K.; Sharma, M. Laboratory investigation on the synthesis and mechanical characterization of fiber reinforced geopolymer concrete. Mater. Today Proc. 2020, 32, 268–273. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Mastali, M.; Dalvand, A. Comparative study on the effects of recycled glass–fiber on drying shrinkage rate and mechanical properties of the self-compacting mortar and fly ash–slag geopolymer mortar. J. Mater. Civ. Eng. 2017, 29, 04017076. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Dai, J.-G. Tensile behavior and microstructure of hybrid fiber ambient cured one-part engineered geopolymer composites. Constr. Build. Mater. 2018, 184, 419–431. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. High ductile behavior of a polyethylene fiber-reinforced one-part geopolymer composite: A micromechanics-based investigation. Arch. Civ. Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Comparative deflection hardening behavior of short fiber reinforced geopolymer composites. Constr. Build. Mater. 2014, 70, 54–64. [Google Scholar] [CrossRef]

- Sathanandam, T.; Awoyera, P.O.; Vijayan, V.; Sathishkumar, K. Low carbon building: Experimental insight on the use of fly ash and glass fibre for making geopolymer concrete. Sustain. Environ. Res. 2017, 27, 146–153. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, T.; Zheng, X.; Liu, Y.; Darkwa, J.; Zhou, G. Thermo-mechanical and moisture absorption properties of fly ash-based lightweight geopolymer concrete reinforced by polypropylene fibers. Constr. Build. Mater. 2020, 251, 118960. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, R.; Li, R.; Wang, Y.; Cheng, Z.; Li, F.; John Ma, Z. Frost resistance of fiber-reinforced blended slag and Class F fly ash-based geopolymer concrete under the coupling effect of freeze-thaw cycling and axial compressive loading. Constr. Build. Mater. 2020, 250, 118831. [Google Scholar] [CrossRef]

- Adesina, A. Performance of cementitious composites reinforced with chopped basalt fibres—An overview. Constr. Build. Mater. 2021, 266, 120970. [Google Scholar] [CrossRef]

- Kogan, F.; Nikitina, O. Solubility of chrysotile asbestos and basalt fibers in relation to their fibrogenic and carcinogenic action. Environ. Health Perspect. 1994, 102, 205–206. [Google Scholar]

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Luo, X.; Xu, J.-Y.; Bai, E.-L.; Li, W. Study on the effect of basalt fiber on the energy absorption characteristics of porous material. Constr. Build. Mater. 2014, 68, 384–390. [Google Scholar] [CrossRef]

- Xin, L.; Jin-Yu, X.; Weimin, L.; Zhi-Kun, W. Comparative Study of the Effect of Basalt Fiber on Dynamic Damage Characteristics of Ceramics Cement—Based Porous Material. J. Mater. Civ. Eng. 2015, 27, 04014224. [Google Scholar] [CrossRef]

- Bheel, N. Basalt fibre-reinforced concrete: Review of fresh and mechanical properties. J. Build. Pathol. Rehabil. 2021, 6, 12. [Google Scholar] [CrossRef]

- Deák, T.; Czigány, T. Chemical composition and mechanical properties of basalt and glass fibers: A comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- Scheffler, C.; Förster, T.; Mäder, E.; Heinrich, G.; Hempel, S.; Mechtcherine, V. Aging of alkali-resistant glass and basalt fibers in alkaline solutions: Evaluation of the failure stress by Weibull distribution function. J. Non-Cryst. Solids 2009, 355, 2588–2595. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Tensile behavior contrast of basalt and glass fibers after chemical treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Zhu, L.; Sun, B.; Gu, B. Frequency features of basalt filament tows under quasi-static and high strain rate tension. J. Compos. Mater. 2012, 46, 1285–1293. [Google Scholar] [CrossRef]

- Dias, D.P.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; He, Z. Mechanical and fracture properties of geopolymer concrete with basalt fiber using digital image correlation. Theor. Appl. Fract. Mech. 2021, 112, 102909. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M. Effect of hybrid basalt fibre length and content on properties of cementitious composites. Mag. Concr. Res. 2021, 73, 487–498. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Sun, X.; Gao, Z.; Cao, P.; Zhou, C. Mechanical properties tests and multi-scale numerical simulations for basalt fiber reinforced concrete. Constr. Build. Mater. 2019, 202, 58–72. [Google Scholar] [CrossRef]

- Wang, D.; Wang, H.; Larsson, S.; Benzerzour, M.; Maherzi, W.; Amar, M. Effect of basalt fiber inclusion on the mechanical properties and microstructure of cement-solidified kaolinite. Constr. Build. Mater. 2020, 241, 118085. [Google Scholar] [CrossRef]

- Du, Q.; Cai, C.; Lv, J.; Wu, J.; Pan, T.; Zhou, J. Experimental Investigation on the Mechanical Properties and Microstructure of Basalt Fiber Reinforced Engineered Cementitious Composite. Materials 2020, 13, 3796. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ai, H.; Hussain, A. Basalt Fibers in Modified Whisker Reinforced Cementitious Composites. Period. Polytech. Civ. Eng. 2022, 66, 344–354. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Prota, A.; Manfredi, G. Structural Upgrade Using Basalt Fibers for Concrete Confinement. J. Compos. Constr. 2010, 14, 541–552. [Google Scholar] [CrossRef]

- Sathish Kumar, V.; Ganesan, N.; Indira, P.V. Engineering Properties of Hybrid Fibre Reinforced Ternary Blend Geopolymer Concrete. J. Compos. Sci. 2021, 5, 203. [Google Scholar] [CrossRef]

- Sathish Kumar, V.; Ganesan, N.; Indira, P.V. Effect of Hybrid Fibres on the Durability Characteristics of Ternary Blend Geopolymer Concrete. J. Compos. Sci. 2021, 5, 279. [Google Scholar] [CrossRef]

- Qian, C.; Stroeven, P. Fracture properties of concrete reinforced with steel–polypropylene hybrid fibres. Cem. Concr. Compos. 2000, 22, 343–351. [Google Scholar] [CrossRef]

- Sivakumar, A.; Santhanam, M. Mechanical properties of high strength concrete reinforced with metallic and non-metallic fibres. Cem. Concr. Compos. 2007, 29, 603–608. [Google Scholar] [CrossRef]

- AS/NZS 3582.1:2016; Supplementary Cementitious Materials Fly Ash. Standards Australia: Sydney, NSW, Australia, 2016; 11. Available online: https://infostore.saiglobal.com/en-us/standards/as-nzs-3582-1-2016-101026_saig_as_as_212259/ (accessed on 28 September 2022).

- Zhang, J.; Tan, H.; Bao, M.; Liu, X.; Luo, Z.; Wang, P. Low carbon cementitious materials: Sodium sulfate activated ultra-fine slag/fly ash blends at ambient temperature. J. Clean. Prod. 2021, 280, 124363. [Google Scholar] [CrossRef]

- Krishnaraj, L.; Ravichandran, P.T. Characterisation of ultra-fine fly ash as sustainable cementitious material for masonry construction. Ain Shams Eng. J. 2021, 12, 259–269. [Google Scholar] [CrossRef]

- Banibayat, P.; Patnaik, A. Variability of mechanical properties of basalt fiber reinforced polymer bars manufactured by wet-layup method. Mater. Des. 2014, 56, 898–906. [Google Scholar] [CrossRef]

- Masi, G.; Rickard, W.D.A.; Bignozzi, M.C.; van Riessen, A. The effect of organic and inorganic fibres on the mechanical and thermal properties of aluminate activated geopolymers. Compos. Part B Eng. 2015, 76, 218–228. [Google Scholar] [CrossRef]

- Hassani Niaki, M.; Fereidoon, A.; Ghorbanzadeh Ahangari, M. Experimental study on the mechanical and thermal properties of basalt fiber and nanoclay reinforced polymer concrete. Compos. Struct. 2018, 191, 231–238. [Google Scholar] [CrossRef]

- AS 1012.3.1:2014; Methods of Testing Concrete Determination of Properties Related to the Consistency of Concrete—Slump Flow, T500 and J-Ring Test. Standards Australia: Sydney, NSW, Australia, 2015; p. 9. Available online: https://infostore.saiglobal.com/en-us/standards/as-1012-3-5-2015-111337_saig_as_as_232905/ (accessed on 14 August 2022).

- AS 3600: 2018; Concrete Structures. Standards Australia Limited: Sydney, NSW, Australia, 2018. Available online: https://infostore.saiglobal.com/en-au/standards/as-3600-2018-98877_saig_as_as_207930/ (accessed on 12 August 2022).

- AS 1012.14:2018; Methods of Testing Concrete Method for Securing and Testing Cores from Hardened Concrete for Compressive Strength and Mass per Unit. Standards Australia: Sydney, NSW, Australia, 2018; 11. Available online: https://infostore.saiglobal.com/en-us/standards/as-1012-14-2018-99136_saig_as_as_208448/ (accessed on 12 August 2022).

- AS 1012.10:2000; Methods of Testing Concrete Determination of Indirect Tensile Strength of Concrete Cylinders (’Brazil’ or Splitting Test) (Reconfirmed 2014). Standards Australia: Sydney, NSW, Australia, 2014; 5. Available online: https://infostore.saiglobal.com/en-us/standards/as-1012-10-2000-129179_saig_as_as_273253/ (accessed on 17 August 2022).

- EFNARC. Guidelines for Self-Compacting Concrete; Association House: London, UK, 2002; Volume 32, p. 34. [Google Scholar]

- Kabay, N. Abrasion resistance and fracture energy of concretes with basalt fiber. Constr. Build. Mater. 2014, 50, 95–101. [Google Scholar] [CrossRef]

- Algin, Z.; Ozen, M. The properties of chopped basalt fibre reinforced self-compacting concrete. Constr. Build. Mater. 2018, 186, 678–685. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Palchik, P. On control testing of fiber-concrete samples to determine their compression and tensile strength at bending; Protocol No 64-1-11; Kyiv National University of Construction and Architecture: Kyiv, Ukraine, 2011; p. 11. [Google Scholar]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Impact of fiber reinforcements on properties of geopolymer composites: A review. J. Build. Eng. 2021, 44, 102628. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).