Fatigue Behavior Comparison of Inter-Ply and Intra-Ply Hybrid Flax-Carbon Fiber Reinforced Polymer Matrix Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Fibers

2.1.1. Unidirectional Flax and Carbon Fiber

2.1.2. Intra-Ply Hybrid (Carbon-Flax Woven Together) Fabric

2.2. Matrix

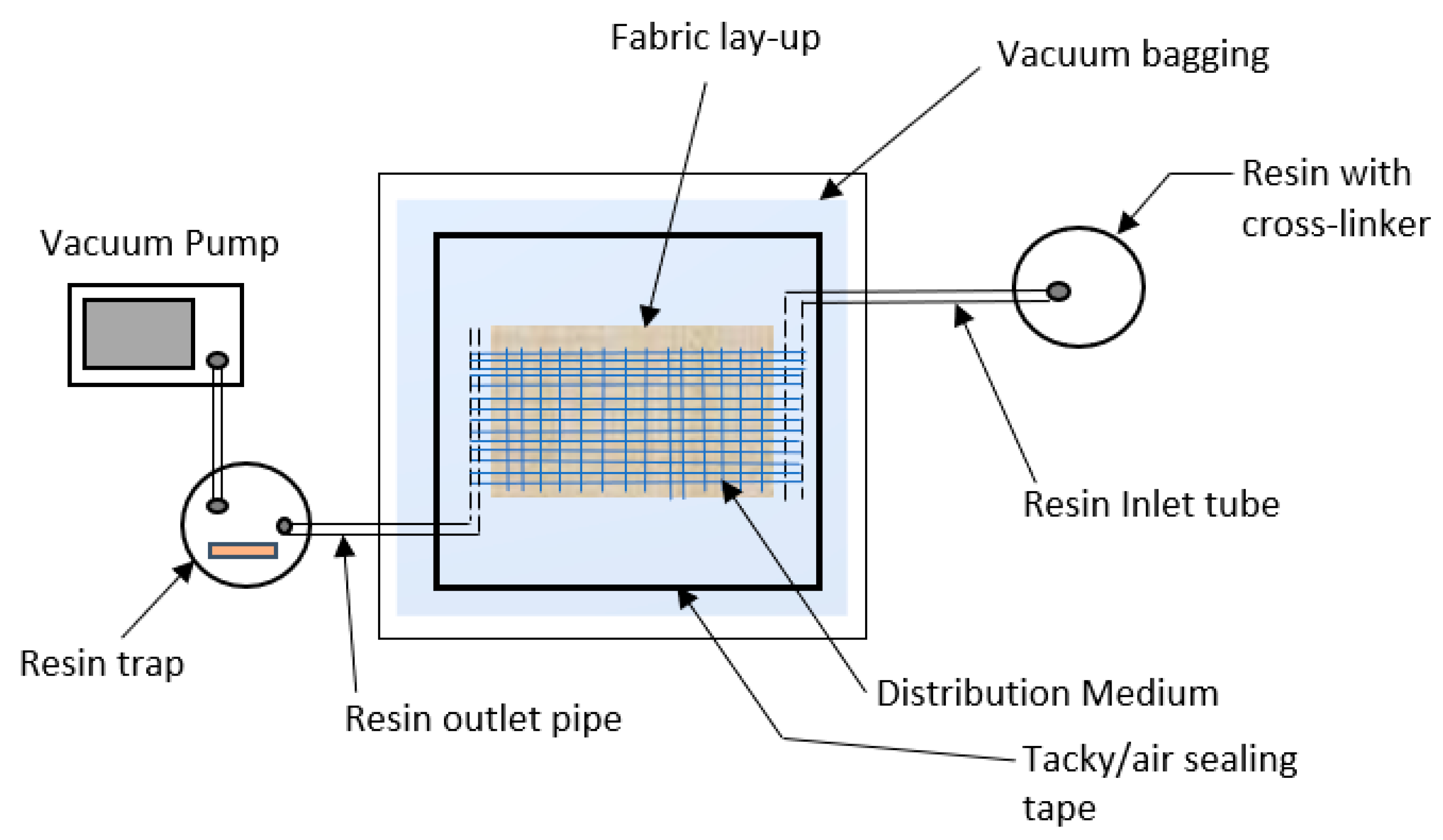

2.3. Manufacturing the Composites

2.4. Test Specimen Fabrication

2.5. Tensile and Fatigue Test Parameters

3. Results and Discussions

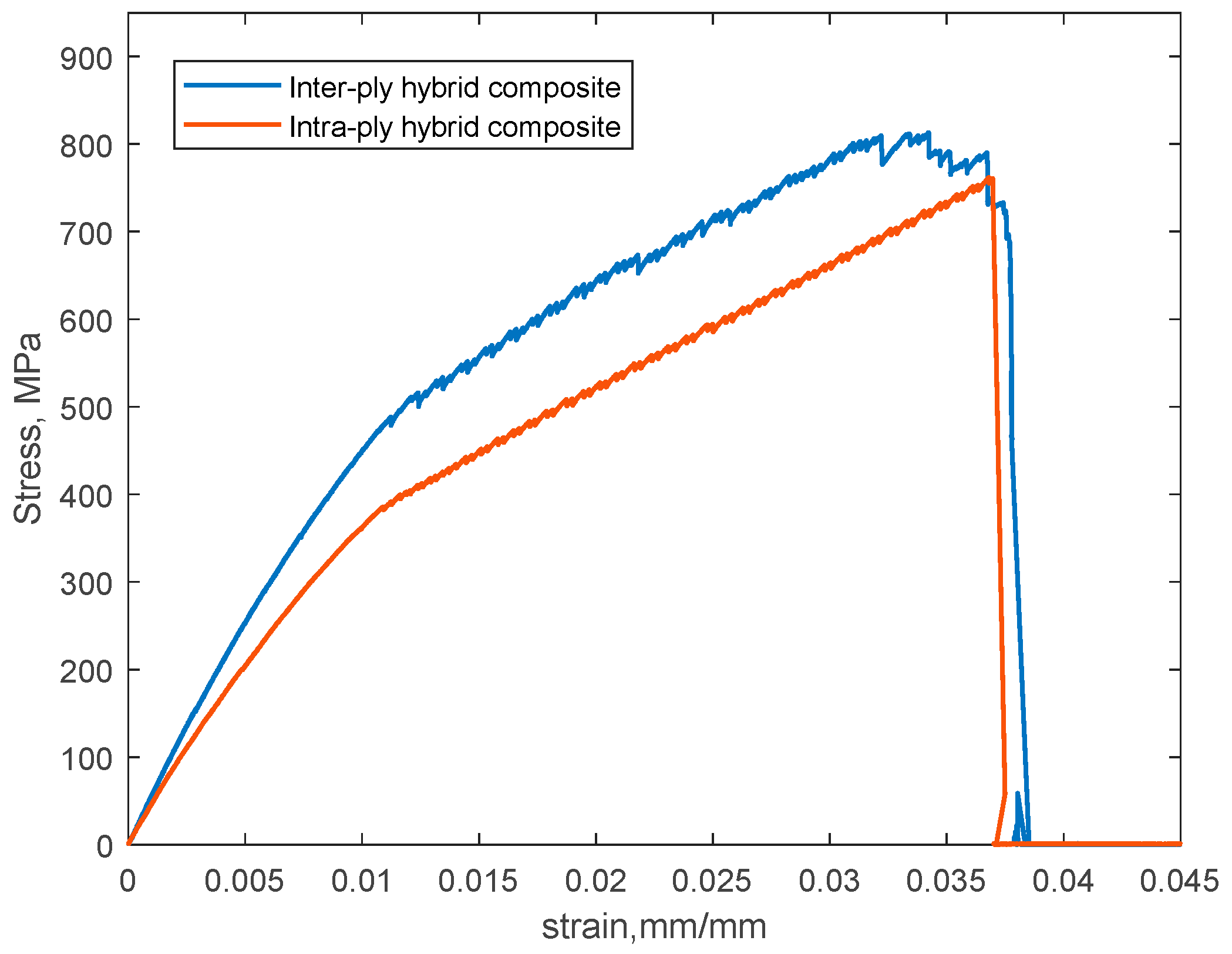

3.1. Tensile Tests

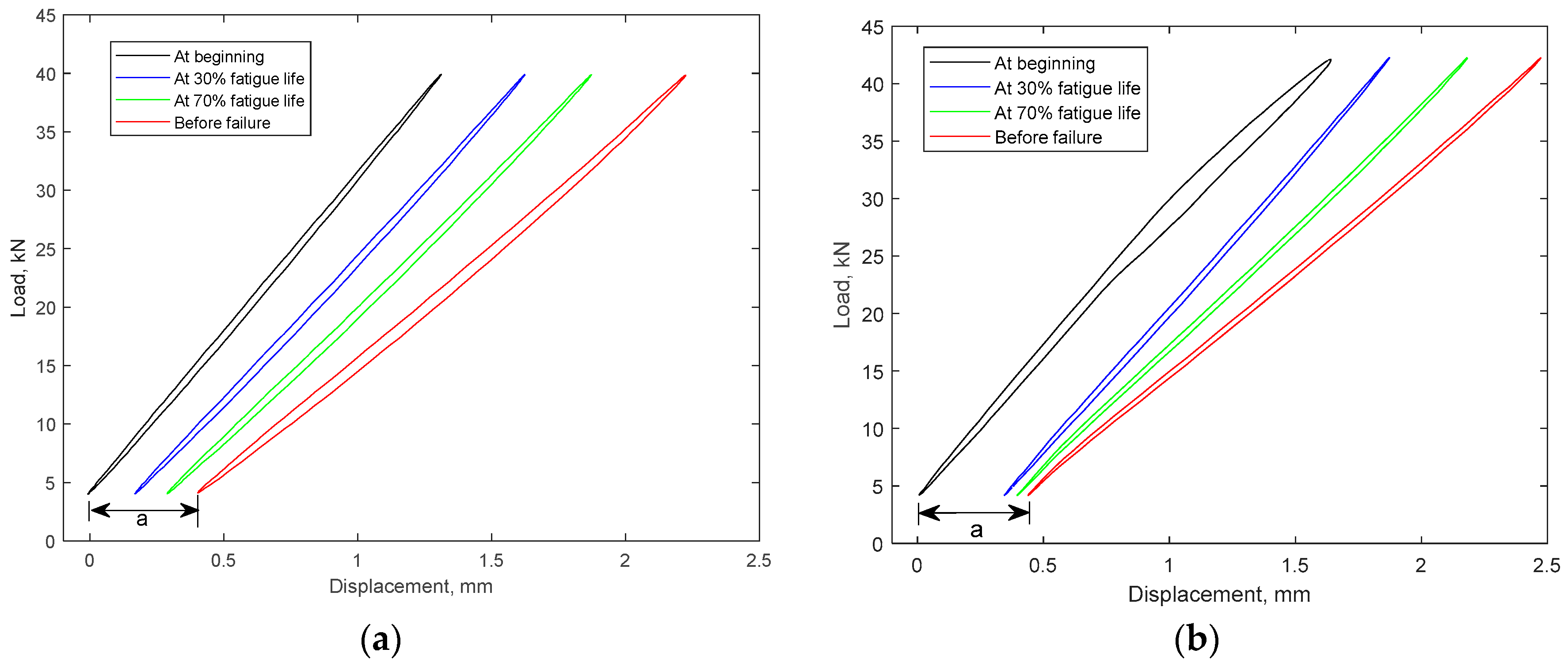

3.2. Fatigue Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kessler, M.R. Polymer matrix composites: A perspective for a special issue of polymer reviews. Polym. Rev. 2012, 52, 229–233. [Google Scholar] [CrossRef]

- González, E.; González, E.V.; Maimí, P.; De Aja, J.S.; Cruz, P.; Camanho, P.P. Effects of interply hybridization on the damage resistance and tolerance of composite laminates. Compos. Struct. 2014, 108, 319–331. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elayaperumal, A.; Sathiya, G. Prediction of tensile properties of hybrid-natural fiber composites. Compos. Part B Eng. 2012, 43, 793–796. [Google Scholar] [CrossRef]

- Amiri, A.; Krosbakken, T.; Schoen, W.; Theisen, D.; Ulven, C.A. Design and manufacturing of a hybrid flax/carbon fiber composite bicycle frame. Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2018, 232, 28–38. [Google Scholar] [CrossRef]

- Haneefa, A.; Bindu, P.; Aravind, I.; Thomas, S. Studies on tensile and flexural properties of short banana/glass hybrid fiber reinforced polystyrene composites. J. Compos. Mater. 2008, 42, 1471–1489. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Saad, M.; Mirande, C.; Tassin, B. Synthetic fibers in atmospheric fallout: A source of microplastics in environment. Mar. Pollut. Bull. 2016, 104, 290–293. [Google Scholar] [CrossRef]

- Cheung, H.-Y.; Ho, M.-P.; Lau, K.-T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Sargianis, J.J.; Kim, H.-I.; Andres, E.; Suhr, J. Sound and vibration damping characteristics in natural material based sandwich composites. Compos. Struct. 2013, 96, 538–544. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Kureemun, U.; Ravandi, M.; Tran, L.Q.N.; Teo, W.; Tay, T.; Lee, H. Effects of hybridization and hybrid fibre dispersion on the mechanical properties of woven flax-carbon epoxy at low carbon fibre volume fractions. Compos. Part B Eng. 2018, 134, 28–38. [Google Scholar] [CrossRef]

- Karahan, M.; Karahan, N. Investigation of the tensile properties of natural and natural/synthetic hybrid fiber woven fabric composites. J. Reinf. Plast. Compos. 2015, 34, 795–806. [Google Scholar] [CrossRef]

- Shah, N.; Fehrenbach, J.; Ulven, C.A. Hybridization of Hemp Fiber and Recycled-Carbon Fiber in Polypropylene Composites. Sustainability 2019, 11, 3163. [Google Scholar] [CrossRef]

- Nisini, E.; Santulli, C.; Liverani, A. Mechanical and impact characterization of hybrid composite laminates with carbon, basalt and flax fibres. Compos. Part B Eng. 2017, 127, 92–99. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Dehkordi, M.T.; Nosraty, H.; Shokrieh, M.M.; Minak, G.; Ghelli, D. Low velocity impact properties of intra-ply hybrid composites based on basalt and nylon woven fabrics. Mater. Des. 2010, 31, 3835–3844. [Google Scholar] [CrossRef]

- Hashim, N.; Majid, D.L.A.; Mahdi, E.-S.; Zahari, R.; Yidris, N. Effect of fiber loading directions on the low cycle fatigue of intraply carbon-Kevlar reinforced epoxy hybrid composites. Compos. Struct. 2019, 212, 476–483. [Google Scholar] [CrossRef]

- Chung, D.D. Carbon Fiber Composites; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Dhakal, H.; Zhang, Z.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Sarasini, F.; Tirillò, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Zhang, J.; Chaisombat, K.; He, S.; Wang, C.H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater. Des. 2012, 36, 75–80. [Google Scholar] [CrossRef]

- Randjbaran, E.; Zahari, R.; Jalil, A.; Aswan, N.; Majid, A.A.; Laila, D. Hybrid composite laminates reinforced with kevlar/carbon/glass woven fabrics for ballistic impact testing. Sci. World J. 2014, 2014, 413753. [Google Scholar]

- Jung, H.; Kim, Y. Mode I fracture toughness of carbon-glass/epoxy interply hybrid composites. J. Mech. Sci. Technol. 2015, 29, 1955–1962. [Google Scholar] [CrossRef]

- Fariborz, S.; Yang, C.; Harlow, D. The Tensile Behavior of Intraply Hybrid Composites I: Model and Simulation. J. Compos. Mater. 1985, 19, 334–354. [Google Scholar] [CrossRef]

- Valença, S.L.; Griza, S.; De Oliveira, V.G.; Sussuchi, E.M.; Cunha, F. Evaluation of the mechanical behavior of epoxy composite reinforced with Kevlar plain fabric and glass/Kevlar hybrid fabric. Compos. Part B Eng. 2015, 70, 1–8. [Google Scholar] [CrossRef]

- Felipe, R.C.T.d.S.; Felipe, R.N.B.; Batista, A.C.d.M.C.; Aquino, E.M.F. Polymer composites reinforced with hybrid fiber fabrics. Mater. Res. 2017, 20, 555–567. [Google Scholar] [CrossRef][Green Version]

- Sivakumar, D.; Ng, L.; Lau, S.; Lim, K. Fatigue life behaviour of glass/kenaf woven-ply polymer hybrid biocomposites. J. Polym. Environ. 2018, 26, 499–507. [Google Scholar] [CrossRef]

- Asgarinia, S.; Viriyasuthee, C.; Phillips, S.; Dube, M.; Baets, J.; Van Vuure, A.; Verpoest, I.; Lessard, L. Tension–tension fatigue behaviour of woven flax/epoxy composites. J. Reinf. Plast. Compos. 2015, 34, 857–867. [Google Scholar] [CrossRef]

- El Sawi, I.; Fawaz, Z.; Zitoune, R.; Bougherara, H. An investigation of the damage mechanisms and fatigue life diagrams of flax fiber-reinforced polymer laminates. J. Mater. Sci. 2014, 49, 2338–2346. [Google Scholar] [CrossRef]

- Montesano, J.; Fawaz, Z.; Bougherara, H. Use of infrared thermography to investigate the fatigue behavior of a carbon fiber reinforced polymer composite. Compos. Struct. 2013, 97, 76–83. [Google Scholar] [CrossRef]

- Islam, M.Z.; Ulven, C.A. A thermographic and energy based approach to define high cycle fatigue strength of flax fiber reinforced thermoset composites. Compos. Sci. Technol. 2020, 196, 108233. [Google Scholar] [CrossRef]

- Ben Ameur, M.; El Mahi, A.; Rebiere, J.-L.; Beyaoui, M.; Abdennadher, M.; Haddar, M. Experimental fatigue behavior of carbon/flax hybrid composites under tensile loading. J. Compos. Mater. 2021, 55, 581–596. [Google Scholar] [CrossRef]

- Jeannin, T.; Gabrion, X.; Ramasso, E.; Placet, V. About the fatigue endurance of unidirectional flax-epoxy composite laminates. Compos. Part B Eng. 2019, 165, 690–701. [Google Scholar] [CrossRef]

- Islam, M.Z.; Ulven, C.A. Influence of loading frequency on thermal and micro-mechanical damage during fatigue of flax fiber reinforced composites. In Proceedings of the International Manufacturing Science and Engineering Conference, Virtual, Online, 3 September 2020; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2020; p. V001T02A002. [Google Scholar] [CrossRef]

- Derbali, I.; Terekhina, S.; Guillaumat, L.; Ouagne, P. Rapid manufacturing of woven comingled flax/polypropylene composite structures. Int. J. Mater. Form. 2019, 12, 927–942. [Google Scholar] [CrossRef]

- Ueki, Y.; Lilholt, H.; Madsen, B. Fatigue behaviour of uni-directional flax fibre/epoxy composites. In Proceedings of the 20th International Conference on Composite Materials (ICCM20), ICCM20 Secretariat, Copenhagen, Danemark, 19–24 July 2015. [Google Scholar]

- Zhao, X.; Wang, X.; Wu, Z.; Keller, T.; Vassilopoulos, A. Temperature effect on fatigue behavior of basalt fiberreinforced polymer composites. Polym. Compos. 2019, 40, 2273–2283. [Google Scholar] [CrossRef]

- Liang, S.; Gning, P.; Guillaumat, L. A comparative study of fatigue behaviour of flax/epoxy and glass/epoxy composites. Compos. Sci. Technol. 2012, 72, 535–543. [Google Scholar] [CrossRef]

- Tate, J.S.; Kelkar, A.D. Stiffness degradation model for biaxial braided composites under fatigue loading. Compos. Part B Eng. 2008, 39, 548–555. [Google Scholar] [CrossRef]

| Material-1: Inter-Ply Unidirectional Flax-Carbon Hybrid Composites |

| Fabric lay-up: 1C/2F/1C/2F/1C [C—carbon, F—flax], |

| Total number of layers = 7 [three layers of carbon fiber fabric and four layers of flax fiber fabric] |

| Thickness of the produced plate = 2.8 mm. |

| Density of the plate (1C/2F/1C/2F/1C) = 1436 kg/m3 |

| Material-2: Intra-Ply Hybrid Composites (Unidirectional Flax-Carbon Fiber Woven Together) |

| Fabric lay-up: 14 layers of unidirectional fabric, flax and carbon fiber woven together (51% flax and 49% carbon fiber by mass) |

| Thickness of the produced plate = 3.1 mm |

| Density of the plate = 1324 kg/m3 |

| Material-1: Inter-Ply Flax-Carbon Hybrid Composites (1C/2F/1C/2F/1C) | Material-2: Intra-Ply Flax-Carbon Hybrid Composites 14-Layer | |

|---|---|---|

| Overall mass of fabric per square meter, (g/m2) | (470 × 3) + (280 × 4) = 2530 | 175 × 14 = 2450 |

| Mass of carbon and flax fiber separately, (g/m2) | Carbon fiber = 470 × 3 = 1410 Flax fiber = 280 × 4 = 1120 | Carbon fiber = 2450 × 0.49 = 1200 Flax fiber = 2450 × 0.51 = 1250 (51% Carbon, 49% Flax) |

| Inter-Ply Flax-Carbon Hybrid Composite (1C/2F/1C/2F/1C) | Intra-Ply Flax-Carbon Hybrid Composite (14 Layers, Flax-Carbon Co-Woven) |

|---|---|

| 16,578 cycle to failure | 324,534 cycle to failure |

| 12,739 cycle to failure | 223,057 cycle to failure |

| 21,785 cycle to failure | 547,227 cycle to failure |

| (Mean = 17,034 cycle, Standard deviation = 3707 cycle) | (Mean = 365,939 cycle, Standard deviation = 137,390 cycle) |

| Materials | Average Fatigue Life (Cycles) (At 70% UTS) |

|---|---|

| Flax fiber reinforced composites | 32,407 cycles (loading frequency = 5 Hz) [30] |

| Carbon fiber reinforced composites (triaxially braided) | 1,000,000 cycles (loading frequency = 5 Hz) [29] |

| Flax-carbon hybrid (inter-ply) | 17,034 cycles (loading frequency = 3 Hz) |

| Flax-Carbon hybrid (intra-ply) | 364,939 cycles (loading frequency = 3 Hz) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, M.Z.; Amiri, A.; Ulven, C.A. Fatigue Behavior Comparison of Inter-Ply and Intra-Ply Hybrid Flax-Carbon Fiber Reinforced Polymer Matrix Composites. J. Compos. Sci. 2021, 5, 184. https://doi.org/10.3390/jcs5070184

Islam MZ, Amiri A, Ulven CA. Fatigue Behavior Comparison of Inter-Ply and Intra-Ply Hybrid Flax-Carbon Fiber Reinforced Polymer Matrix Composites. Journal of Composites Science. 2021; 5(7):184. https://doi.org/10.3390/jcs5070184

Chicago/Turabian StyleIslam, Md Zahirul, Ali Amiri, and Chad A. Ulven. 2021. "Fatigue Behavior Comparison of Inter-Ply and Intra-Ply Hybrid Flax-Carbon Fiber Reinforced Polymer Matrix Composites" Journal of Composites Science 5, no. 7: 184. https://doi.org/10.3390/jcs5070184

APA StyleIslam, M. Z., Amiri, A., & Ulven, C. A. (2021). Fatigue Behavior Comparison of Inter-Ply and Intra-Ply Hybrid Flax-Carbon Fiber Reinforced Polymer Matrix Composites. Journal of Composites Science, 5(7), 184. https://doi.org/10.3390/jcs5070184