Cohesive Zone Modeling of the Elastoplastic and Failure Behavior of Polymer Nanoclay Composites

Abstract

1. Introduction

2. Materials and Methods

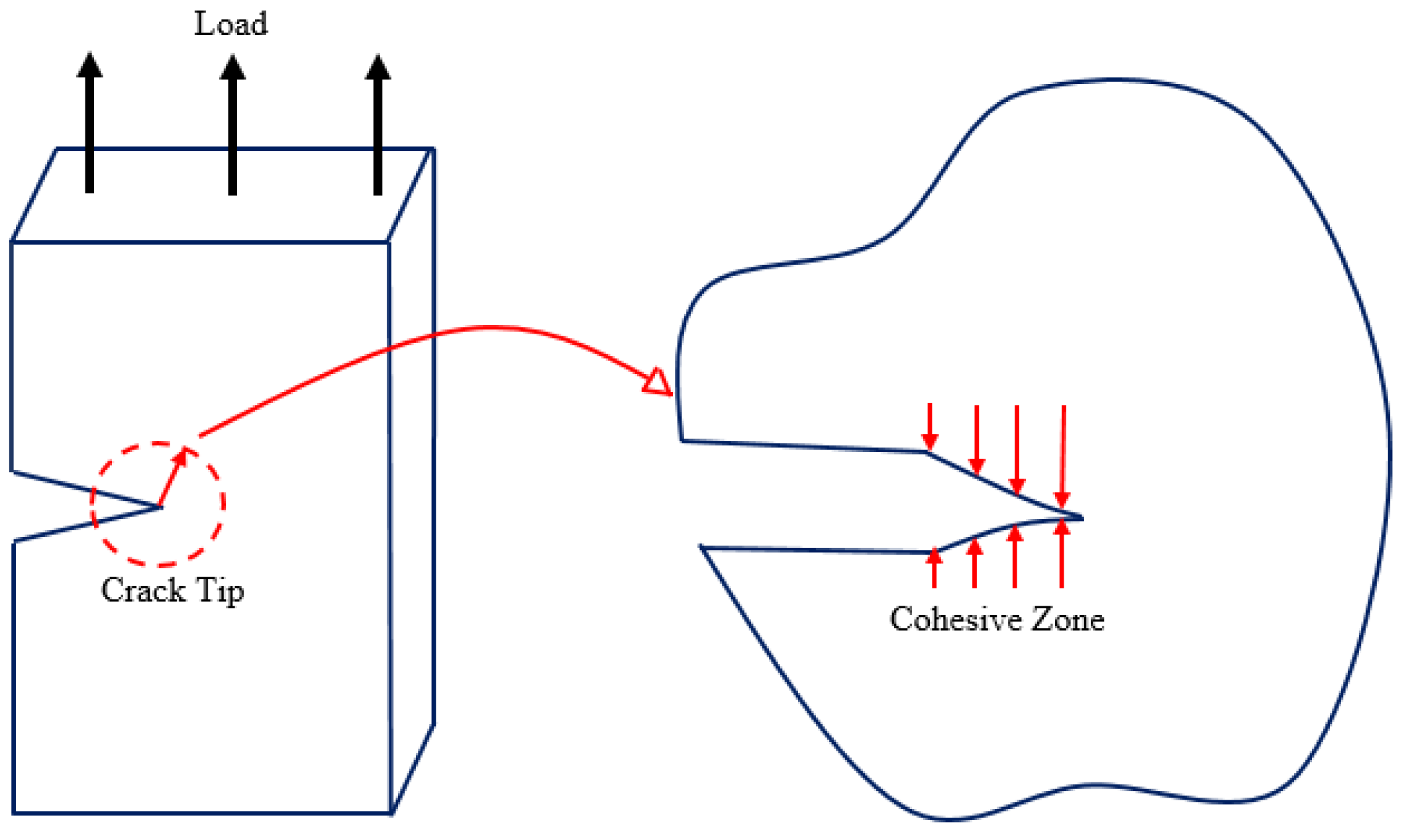

2.1. Cohesive Zone Model (CZM) for PNCs

2.2. CZM-based FEA of the Mechanical Behavior of PNCs

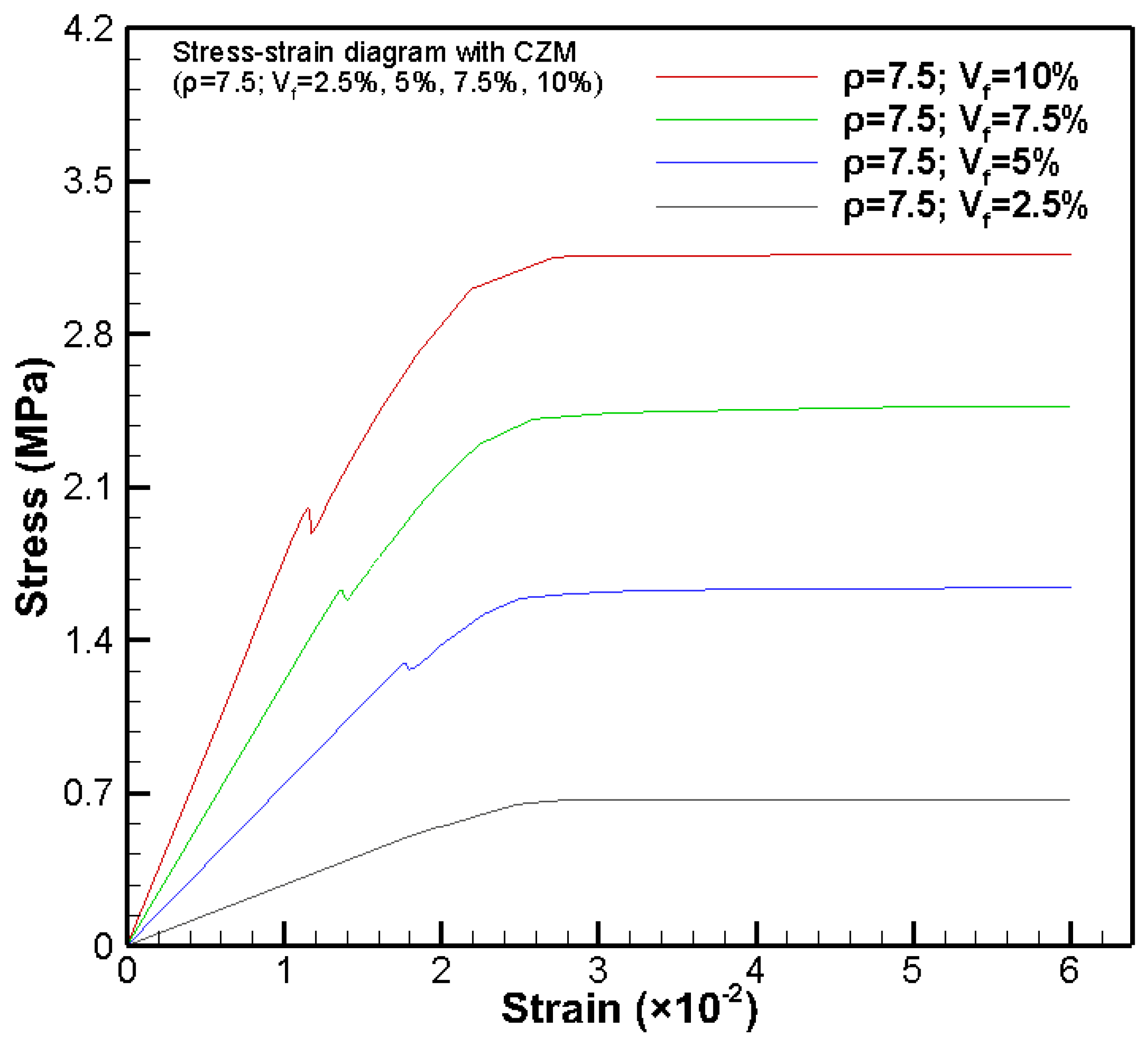

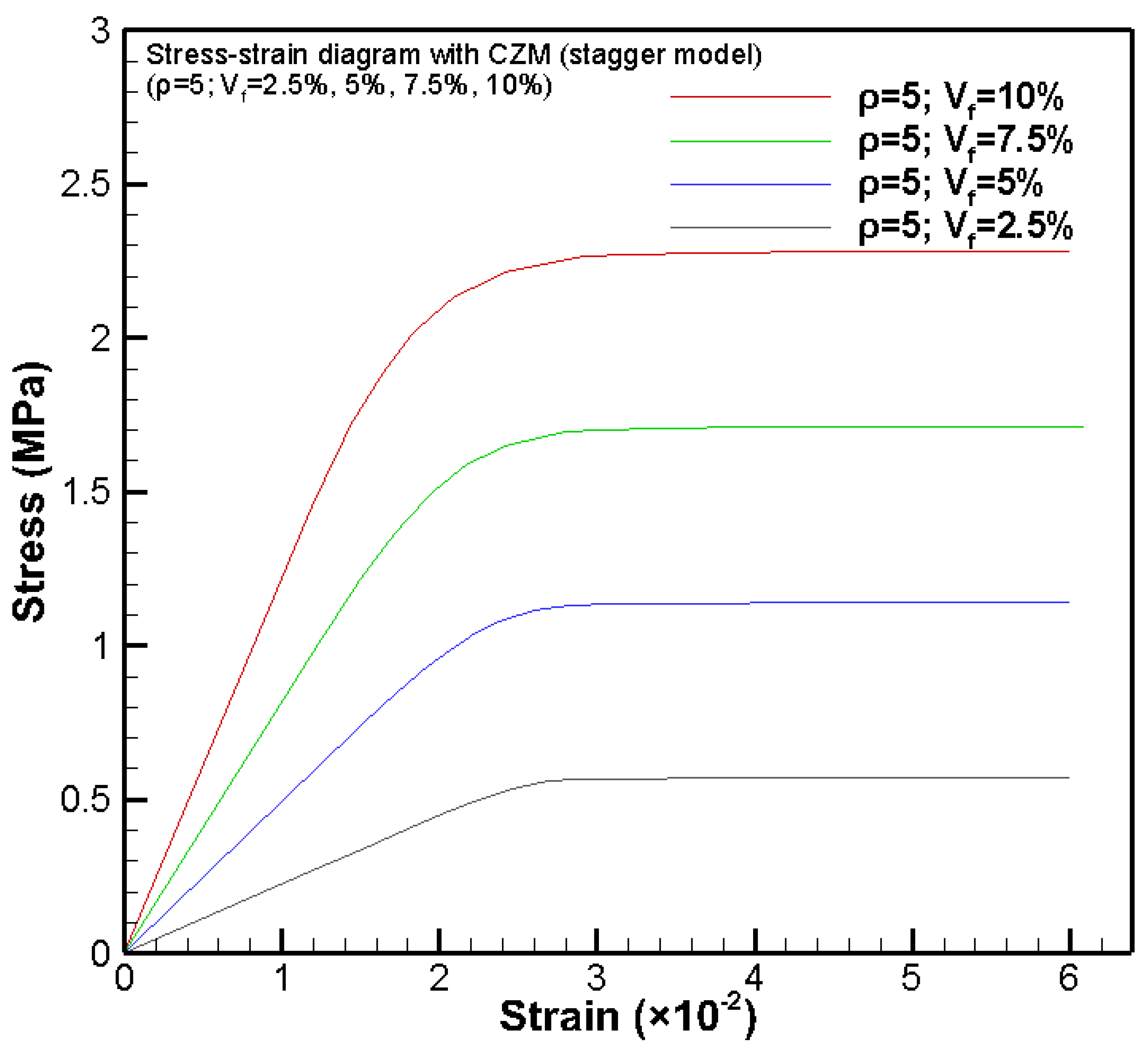

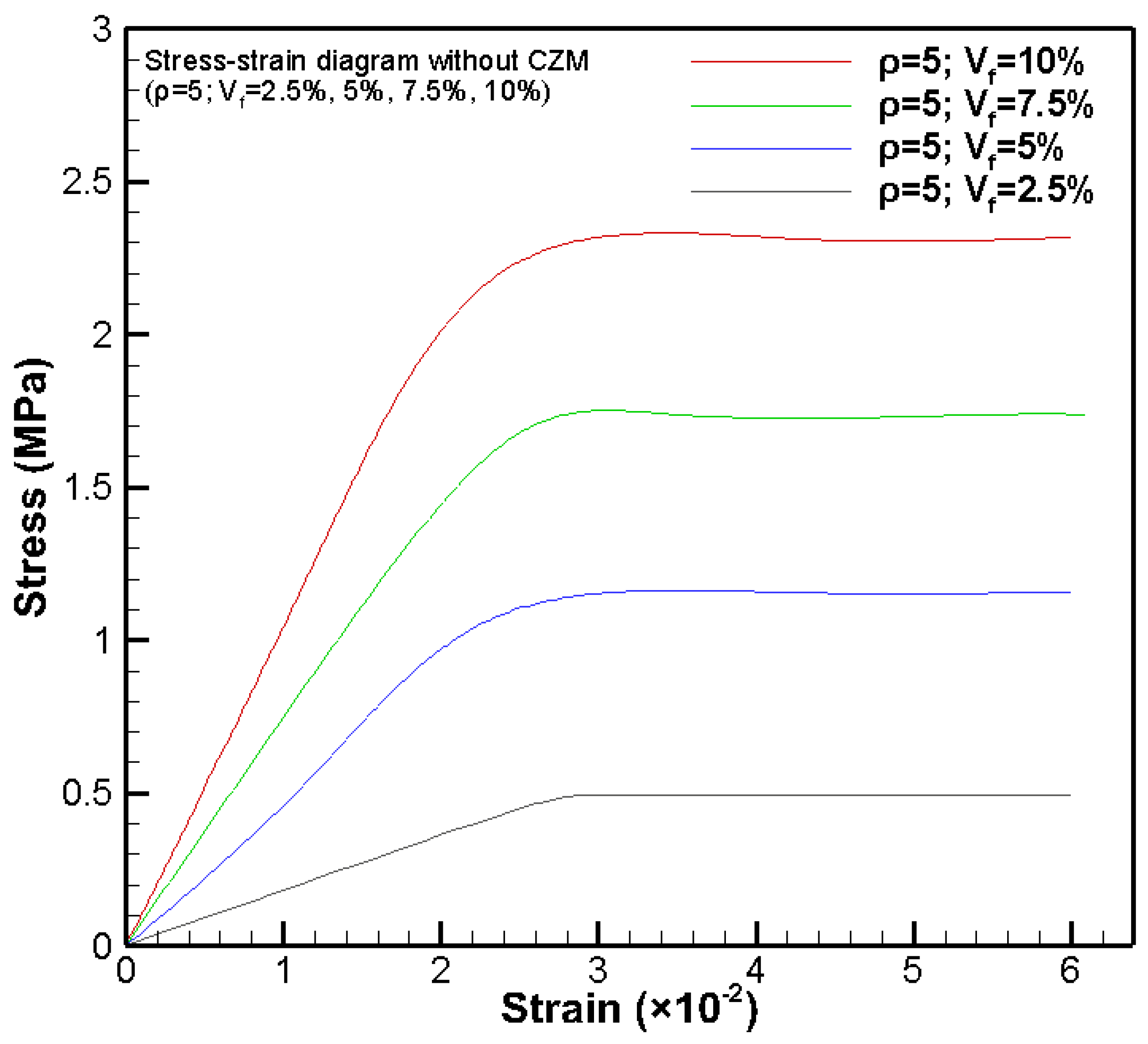

3. Results and Discussion

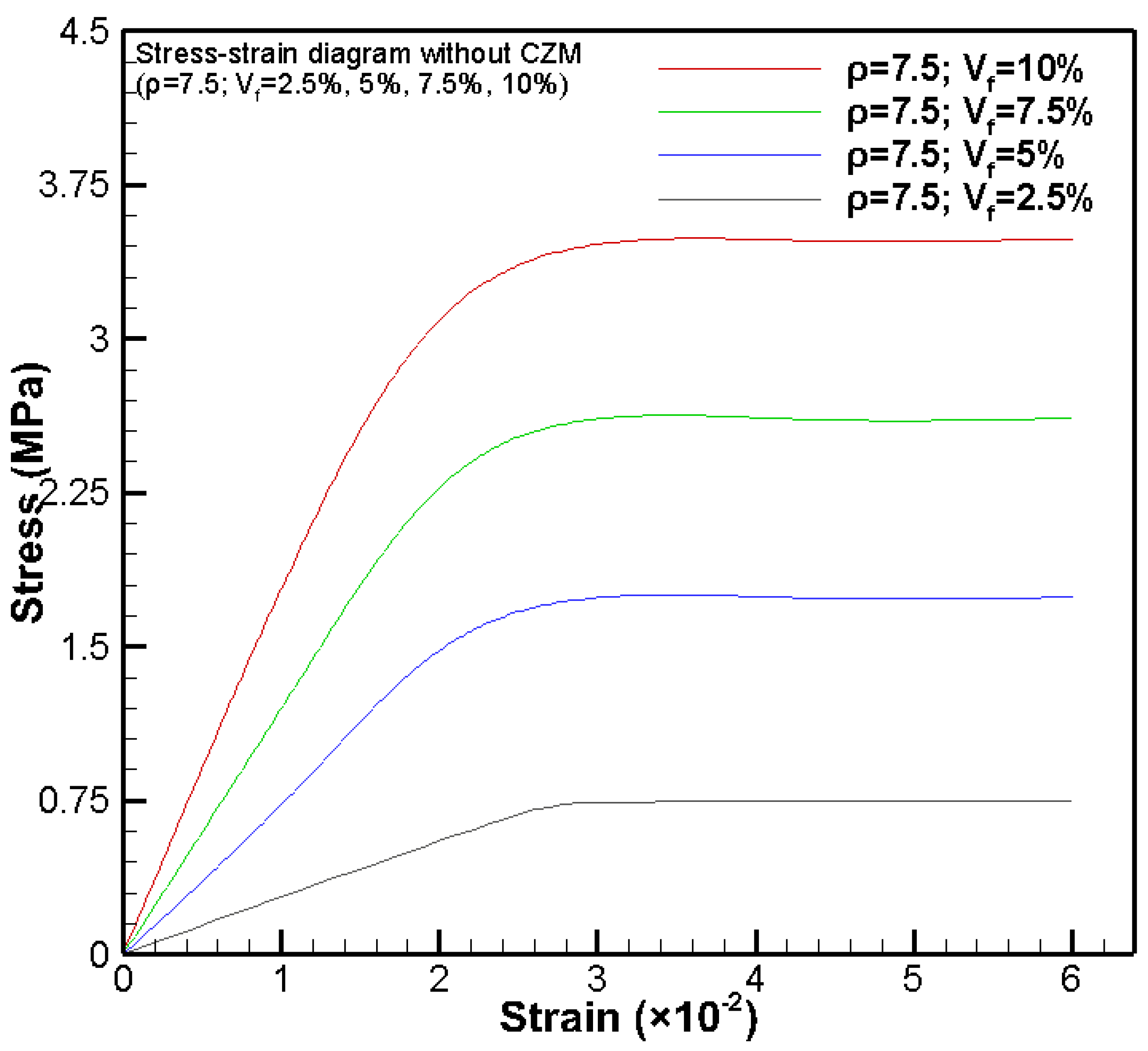

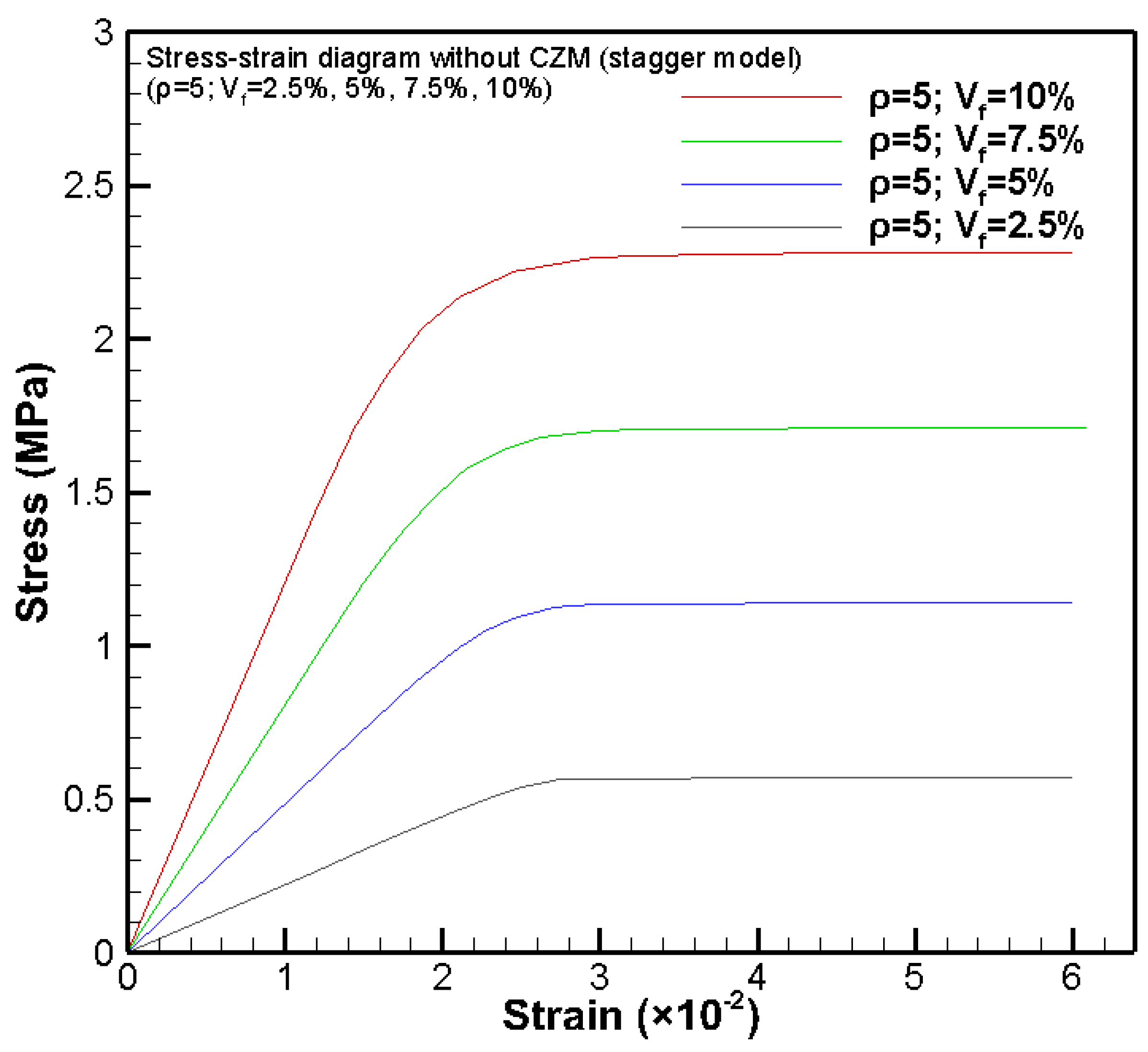

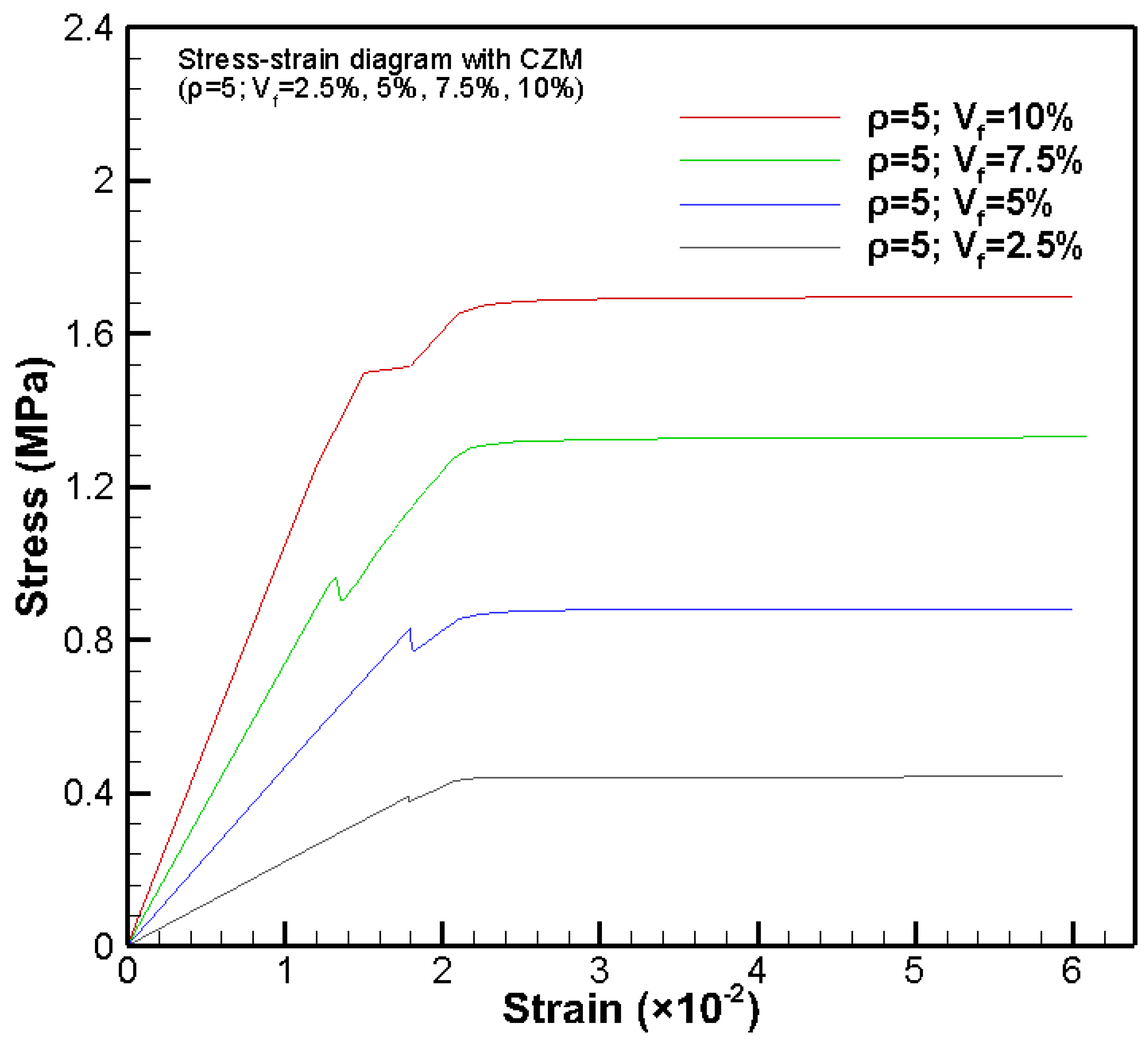

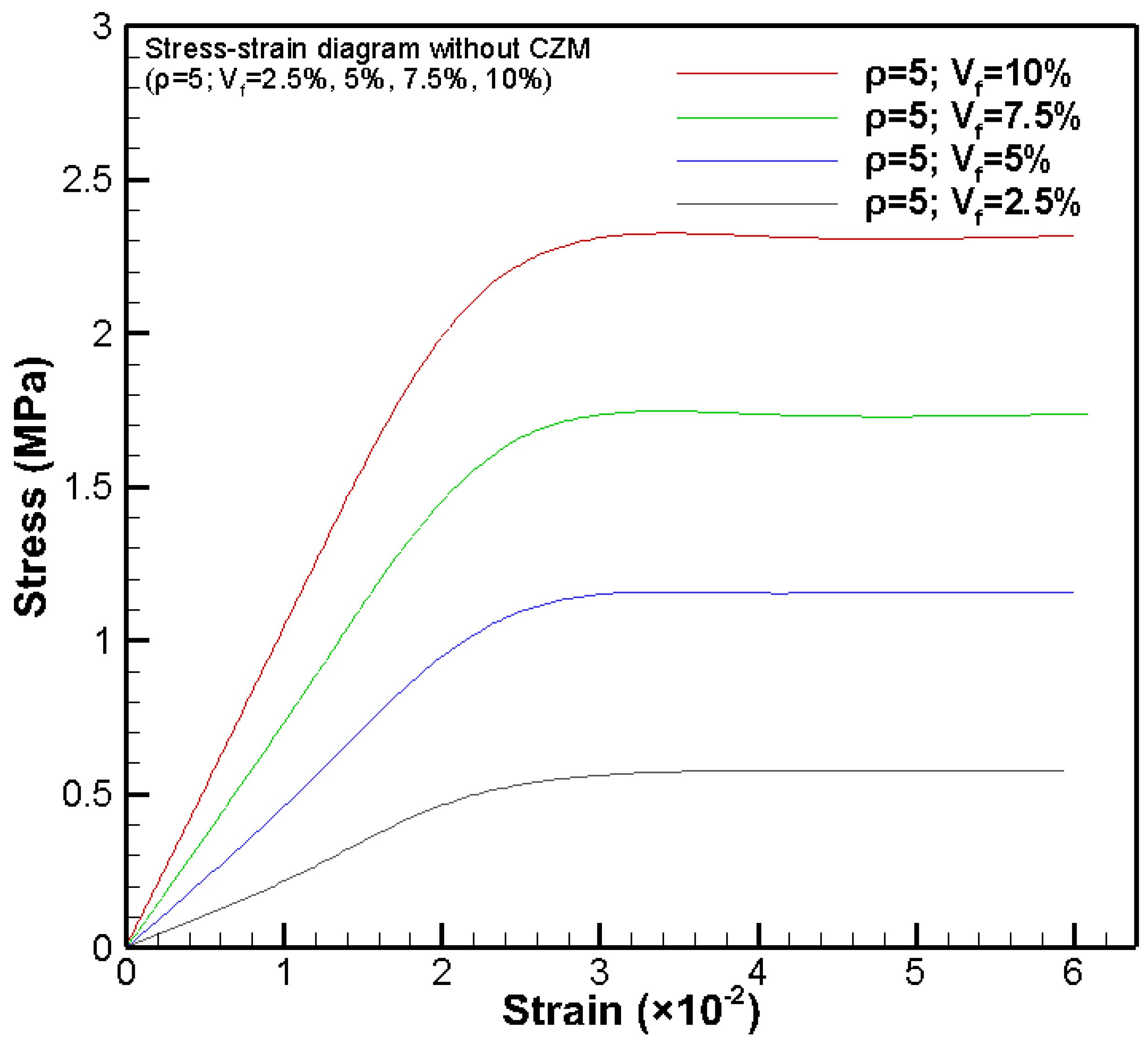

Scaling Analysis of the Effective Stress-Strain Behaviors of PNCs

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dzenis, A. Structural nanocomposites. Science 1998, 319, 419–420. [Google Scholar] [CrossRef]

- Wu, X.F.; Yarin, A.L. Recent progress in interfacial toughening and damage self-healing of polymer composites based on electrospun and solution-blown nanofibers. J. Appl. Polym. Sci. 2013, 130, 2225–2237. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, L.; Yoon, M.K.; Wu, X.F.; Arefin, R.H.; Fong, H. Preparation and evaluation of nano-epoxy composite resins containing electrospun glass nanofibers. J. Appl. Polym. Sci. 2012, 124, 444–451. [Google Scholar] [CrossRef]

- Wu, X.F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toughening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Wu, X.F.; Zholobko, O.; Zhou, Z.; Rahman, A. Electrospun nanofibers for interfacial toughening and damage self-healing of polymer composites and surface coatings. In Electrospun Polymers and Composites: Ultrafine Materials, High Performance Fibers and Wearables; Woodhead Publishing: Oxford, UK, 2020. [Google Scholar]

- Usuki, A.; Kojima, Y.; Kawasumi, M.; Okada, A.; Fukushima, Y.; Kurauchi, T.; Kamigaito, O. Synthesis of nylon 6-clay hybrid. J. Mater. Res. 1993, 8, 1179–1184. [Google Scholar] [CrossRef]

- Chan, M.; Lau, K.; Wong, T.; Ho, M.; Hui, D. Mechanism of reinforcement in a nanoclay/polymer composite. Composites B Eng. 2011, 42, 1708–1712. [Google Scholar] [CrossRef]

- Almansoori, A.; Majewski, C.; Rodenburg, C. Nanoclay/polymer composite powders for use in laser sintering applications: Effects of nanoclay plasma treatment. J. Mater. 2017, 69, 2278–2285. [Google Scholar] [CrossRef] [PubMed]

- Rahman, A.; Wu, X.F. Computational study of the effects of processing parameters on the nonlinear elastoplastic behavior of polymer nanoclay composites. J. Compos. Sci. 2017, 1, 16. [Google Scholar] [CrossRef]

- Rahman, A. Fabrication and Mechanical Characterization of Novel Hybrid Carbon-fiber/Epoxy Composites Reinforced with Toughening/Self-Repairing Nanofibers at Interfaces. Ph.D. Thesis, North Dakota State University, Fargo, ND, USA, 2012. [Google Scholar]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. Synthesis of nylon 6–clay hybrid by montmorillonite intercalated with ϵ-caprolactam. J. Polym. Sci. A Polym. Chem. 1993, 31, 983–986. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-layered silicate nanocomposites: Preparation, properties and uses of a new class of materials. Mater. Sci. Eng. R Rep. 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, H.; Shi, J. In vivo bio-safety evaluations and diagnostic/therapeutic applications of chemically designed mesoporous silica nanoparticles. Adv. Mater. 2013, 25, 3144–3176. [Google Scholar] [CrossRef]

- Tjong, S.C. Structural and mechanical properties of polymer nanocomposites. Mater. Sci. Eng. R Rep. 2006, 53, 73–197. [Google Scholar] [CrossRef]

- Schadler, L.; Brinson, L.; Sawyer, W. Polymer nanocomposites: A small part of the story. J. Mater. 2007, 59, 53–60. [Google Scholar] [CrossRef]

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef]

- Tucker, C.L., III.; Liang, E. Stiffness predictions for unidirectional short-fiber composites: Review and evaluation. Compos. Sci. Technol. 1999, 59, 655–671. [Google Scholar] [CrossRef]

- Weon, J.I.; Sue, H.J. Effects of clay orientation and aspect ratio on mechanical behavior of nylon-6 nanocomposite. Polymer 2005, 46, 6325–6334. [Google Scholar] [CrossRef]

- Tsai, J.; Sun, C. Effect of platelet dispersion on the load transfer efficiency in nanoclay composites. J. Compos. Mater. 2004, 38, 567–579. [Google Scholar] [CrossRef]

- Dong, Y.; Bhattacharyya, D. A simple micromechanical approach to predict mechanical behaviour of polypropylene/organoclay nanocomposites based on representative volume element (RVE). Comput. Mater. Sci. 2010, 49, 1–8. [Google Scholar] [CrossRef]

- Hu, H.; Onyebueke, L.; Abatan, A. Characterizing and modeling mechanical properties of nanocomposites-review and evaluation. J. Miner. Mater. Character. Eng. 2010, 9, 275–319. [Google Scholar] [CrossRef]

- Barenblatt, G.I. The formation of equilibrium cracks during brittle fracture: General ideas and hypotheses, axially symmetric cracks. Appl. Math. Mech. 1959, 23, 622–636. [Google Scholar] [CrossRef]

- Barenblatt, G.I. The mathematical theory of equilibrium in brittle fracture. Adv. Appl. Mech. 1962, 7, 55–129. [Google Scholar]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H. Cohesive zone models: A critical review of traction-separation relationships across fracture surfaces. Appl. Mech. Rev. 2011, 64, 060802. [Google Scholar] [CrossRef]

- ANSYS® Theory Reference (Version 16); ANSYS, Inc.: Canonsburg, PA, USA, 2016.

- Wu, X.F.; Chowdhury, U. Computational analysis of the mechanical strength and debonding process of adhesively bonded joints. Int. J. Solid Mater. 2019, 1, 171–225. [Google Scholar]

- Chowdhury, U. Theoretical and Computational Studies of the Strength and Fracture Toughness of Adhesively Bonded Joints and Polymer Nanoclay Composites. Ph.D. Thesis, North Dakota State University, Fargo, ND, USA, 2018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, U.; Wu, X.-F. Cohesive Zone Modeling of the Elastoplastic and Failure Behavior of Polymer Nanoclay Composites. J. Compos. Sci. 2021, 5, 131. https://doi.org/10.3390/jcs5050131

Chowdhury U, Wu X-F. Cohesive Zone Modeling of the Elastoplastic and Failure Behavior of Polymer Nanoclay Composites. Journal of Composites Science. 2021; 5(5):131. https://doi.org/10.3390/jcs5050131

Chicago/Turabian StyleChowdhury, Uraching, and Xiang-Fa Wu. 2021. "Cohesive Zone Modeling of the Elastoplastic and Failure Behavior of Polymer Nanoclay Composites" Journal of Composites Science 5, no. 5: 131. https://doi.org/10.3390/jcs5050131

APA StyleChowdhury, U., & Wu, X.-F. (2021). Cohesive Zone Modeling of the Elastoplastic and Failure Behavior of Polymer Nanoclay Composites. Journal of Composites Science, 5(5), 131. https://doi.org/10.3390/jcs5050131