Recent Advances in Geopolymer Technology. A Potential Eco-Friendly Solution in the Construction Materials Industry: A Review

Abstract

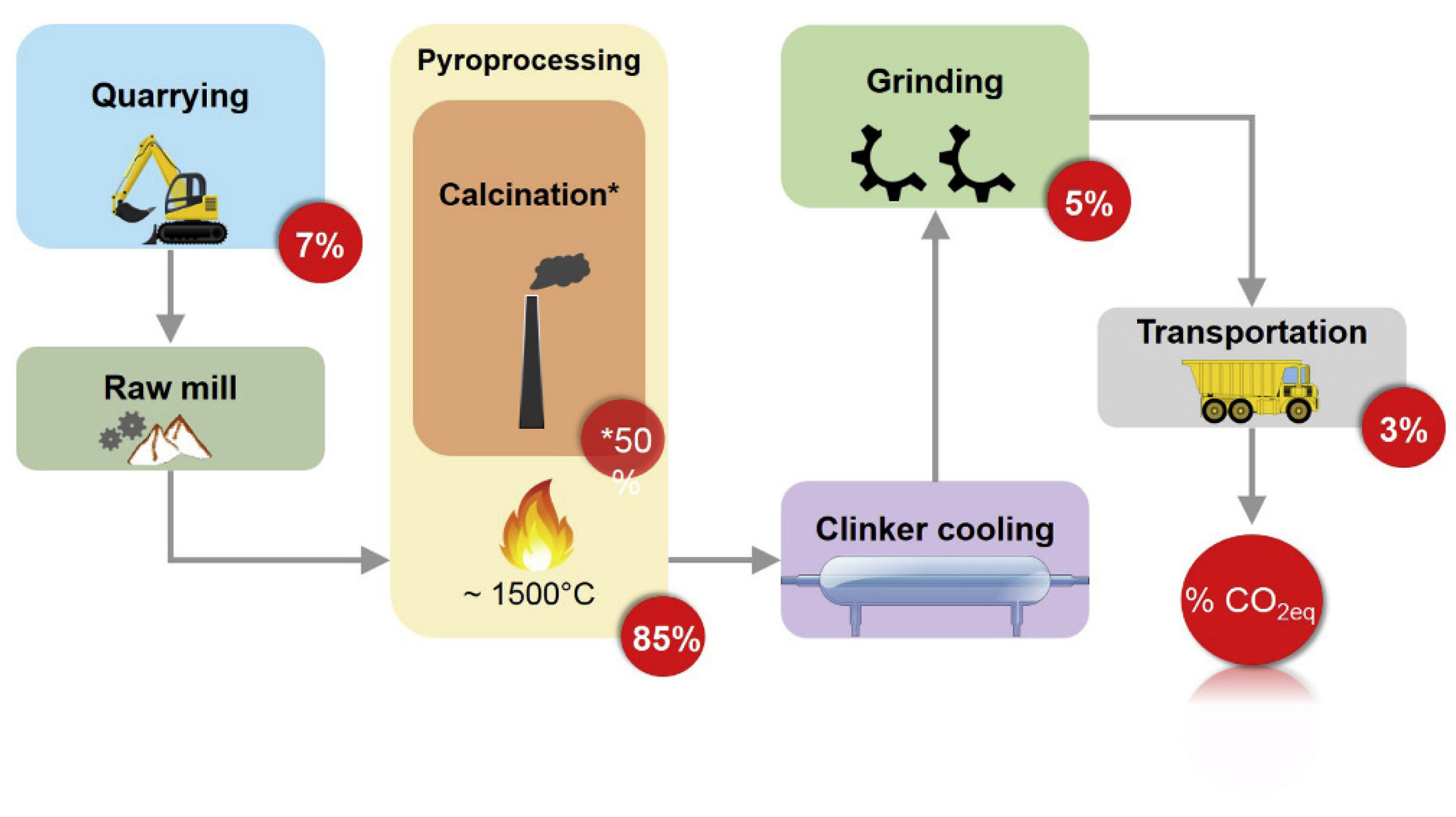

1. Introduction

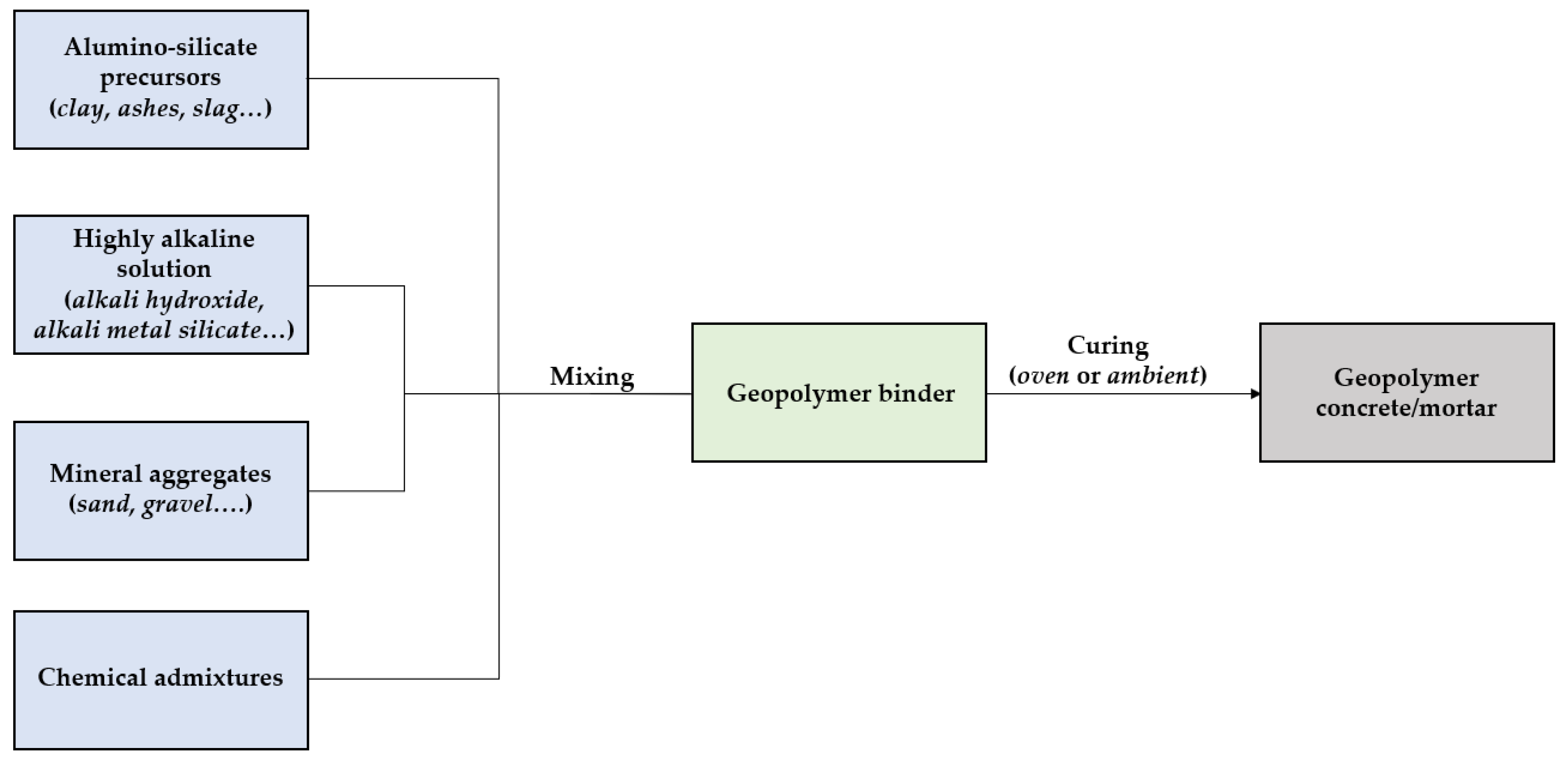

2. Geopolymer Cements (GCs): Chemistry, Raw Materials, and Products

- (1)

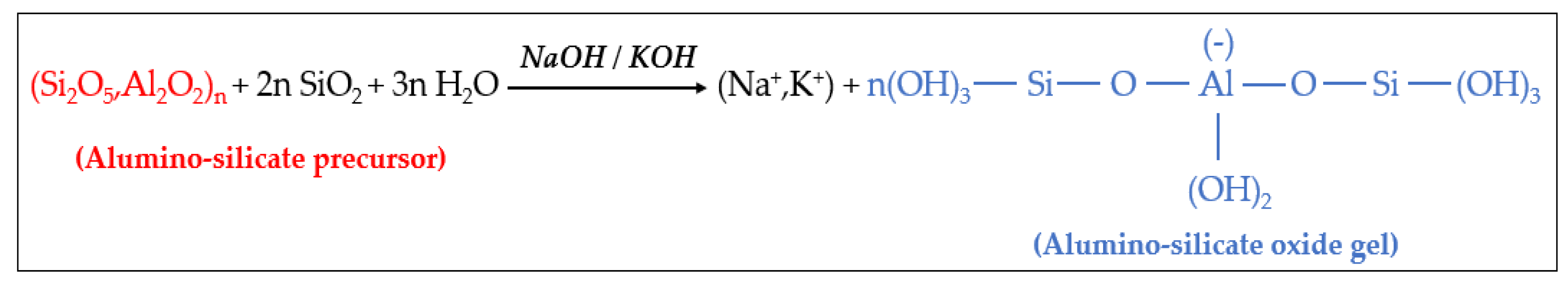

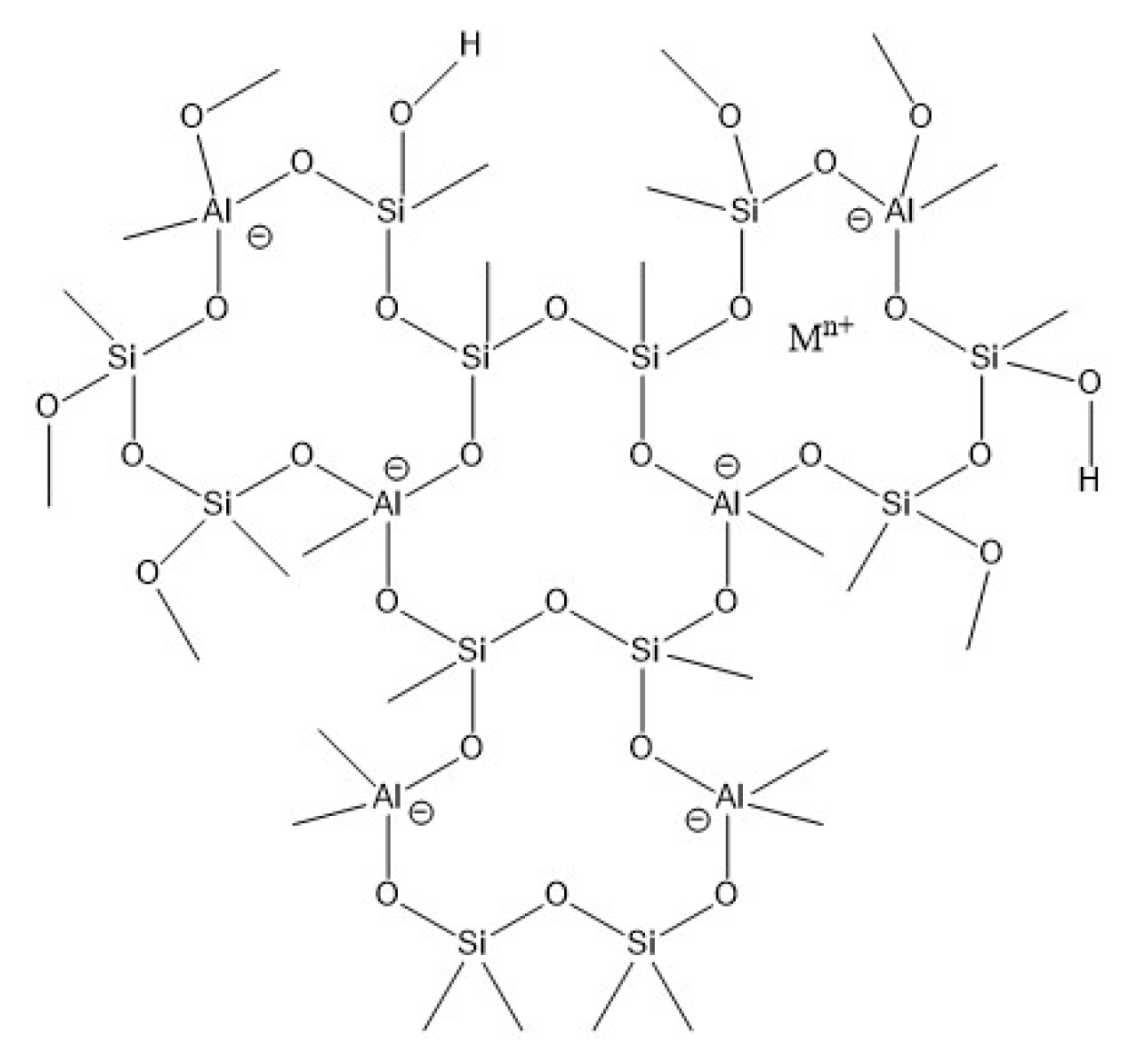

- Alkali activation. An alkaline activator is necessary for the dissolution of Si and Al from the inorganic precursor as well as for the catalysis of the condensation reaction. The reaction of alumino-silicate oxides (Si2O5, Al2O2) in strongly alkaline solution results in a breakdown of Si-O-Si bonds with the subsequent penetration of Al atoms in the original Si-O-Si structure. The resulting alumino-silicate oxide gels, based on Si-O-Al block, are the geopolymer precursor of the polycondensation reaction. The dissolution/hydrolysis reaction is reported in Figure 2.

- (2)

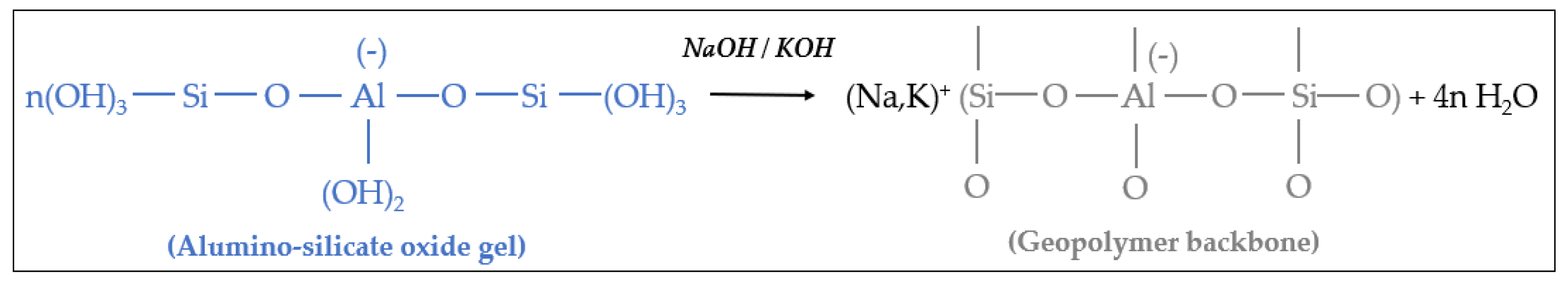

- Polycondensation in Geopolymer network. The alumino-silicate gel phase is a highly reactive product. Under alkaline condition, substantially fast chemical reactions occur, forming a rigid 3D polymeric and ring framework of Si-O-Al bonds (Figure 3). The proper completion of the geopolymerization process and the conferment of adequate mechanical strength properties to the material require heat curing treatment at a thermal range between 25 and 90 °C [11]. The water released by polycondensation is normally consumed during the dissolution process.

2.1. Metakaolin-Based Geopolymer Cements (MGCs)

2.2. Fly Ash-Based Geopolymer Cements (FGCs)

2.3. Natural Minerals-Based Geopolymer Cements (NCs)

2.4. Hybrid Geopolymer Cements (HGCs)

3. Recent Research Findings of Geopolymer-Based Concrete Properties

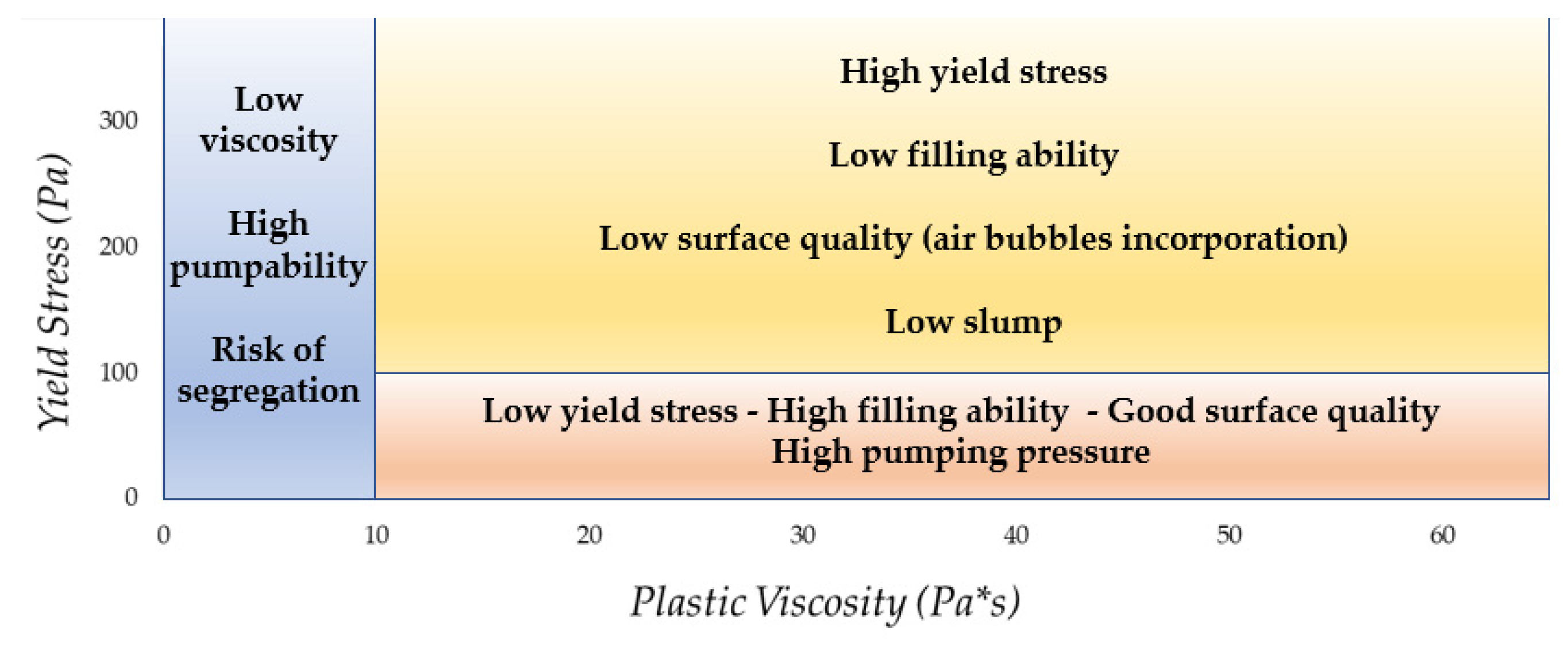

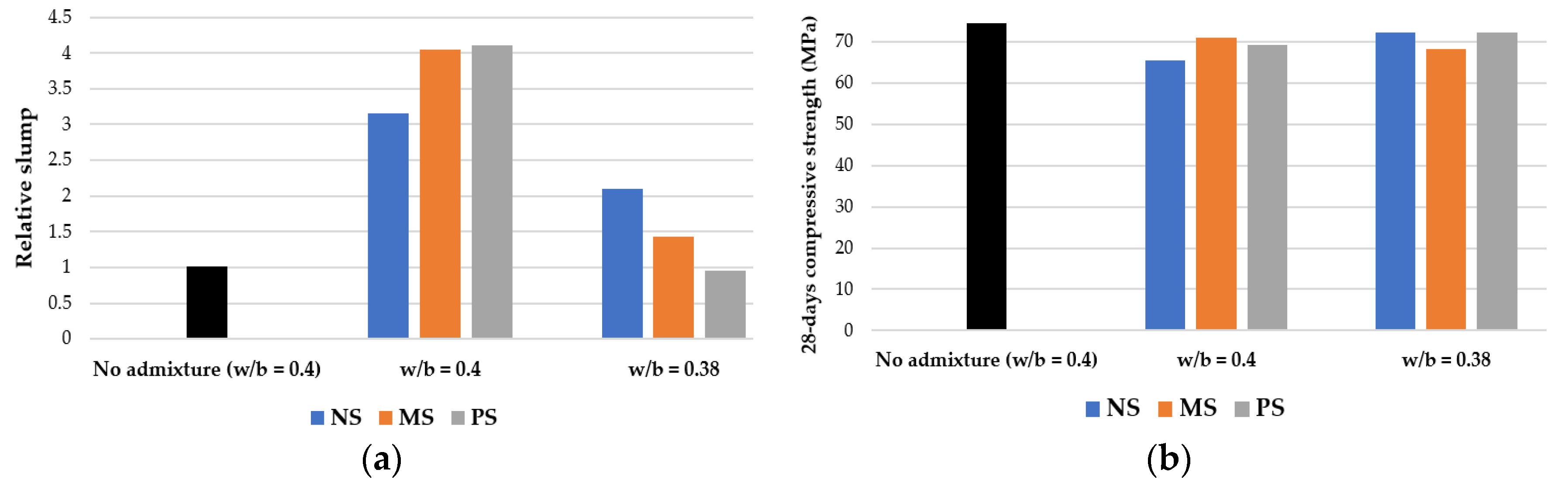

3.1. Rheological Properties

3.2. Microstructural Properties

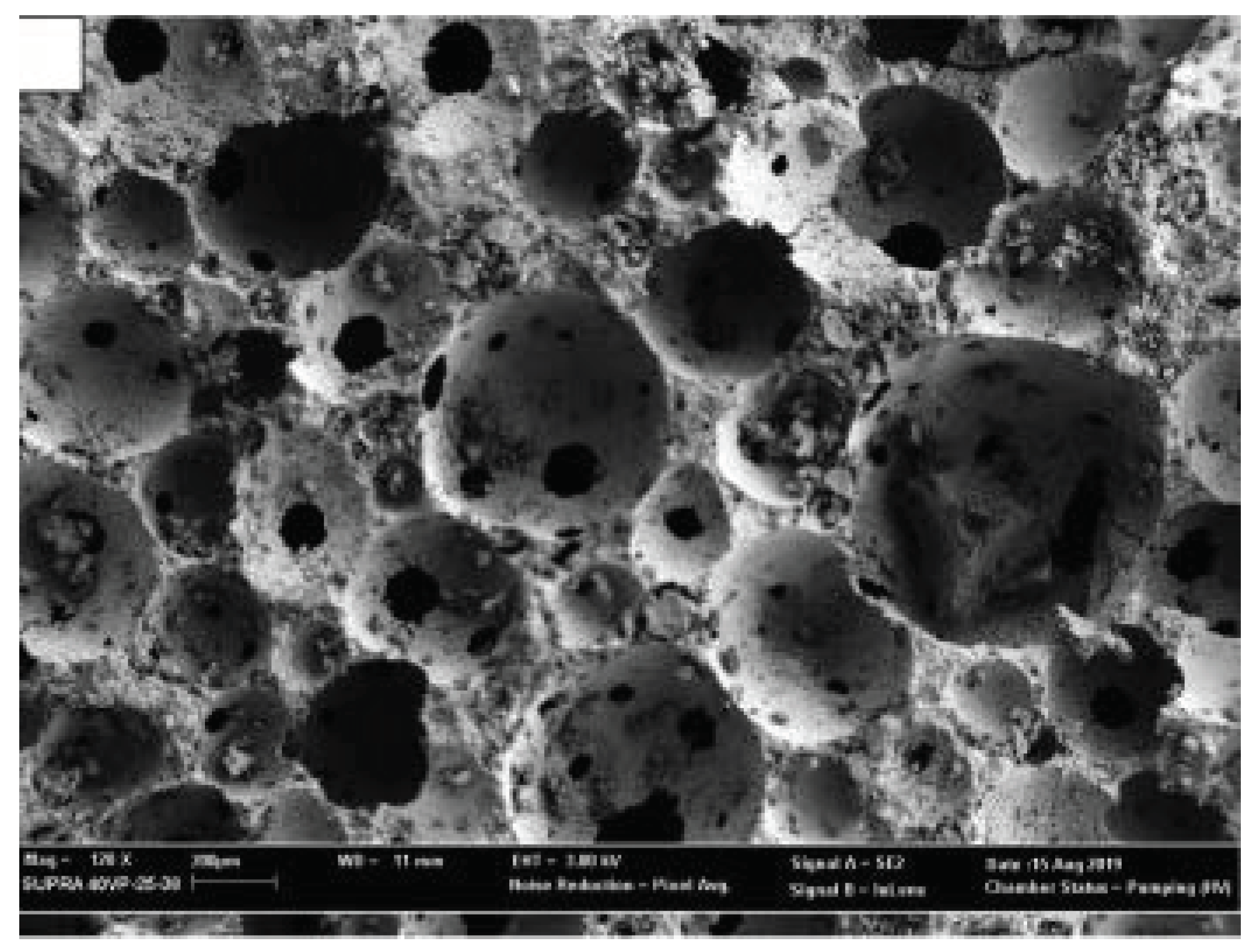

- Particle size distribution of alumino-silicate precursors. Assi et al. [40] investigated the influence of three different FA particle grades (38.8, 17.9, and 4.78 μm) on the microstructural properties of geopolymer concrete. The finer the average FA particle size distribution, the denser and stronger the geopolymer matrix. In this regard, the increase in surface area is crucial in terms of high reactivity to alkaline dissolution, the preferential formation of geopolymer products, the high ability to fill structural micro-voids, and less free water that evaporates during the curing, causing a decrease in the formation of microcracks.

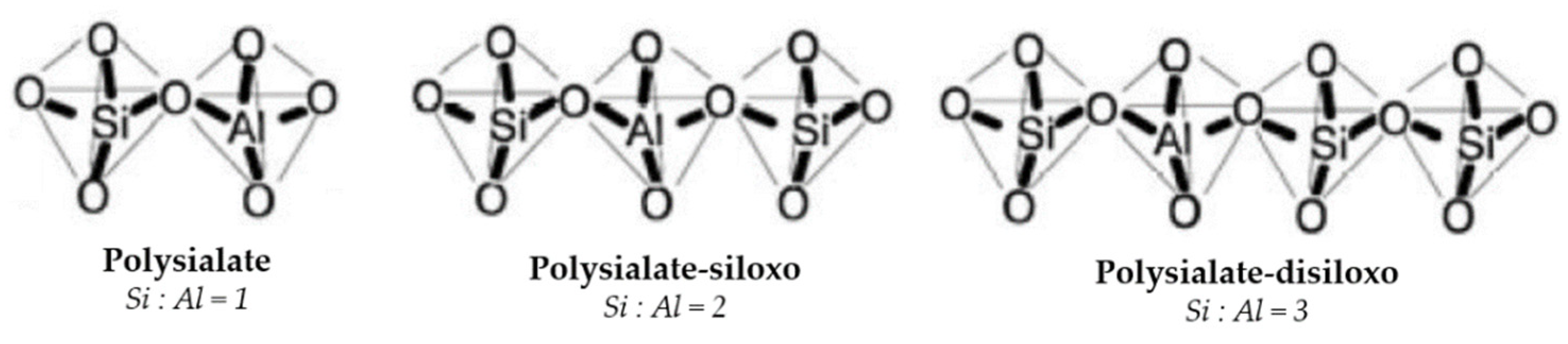

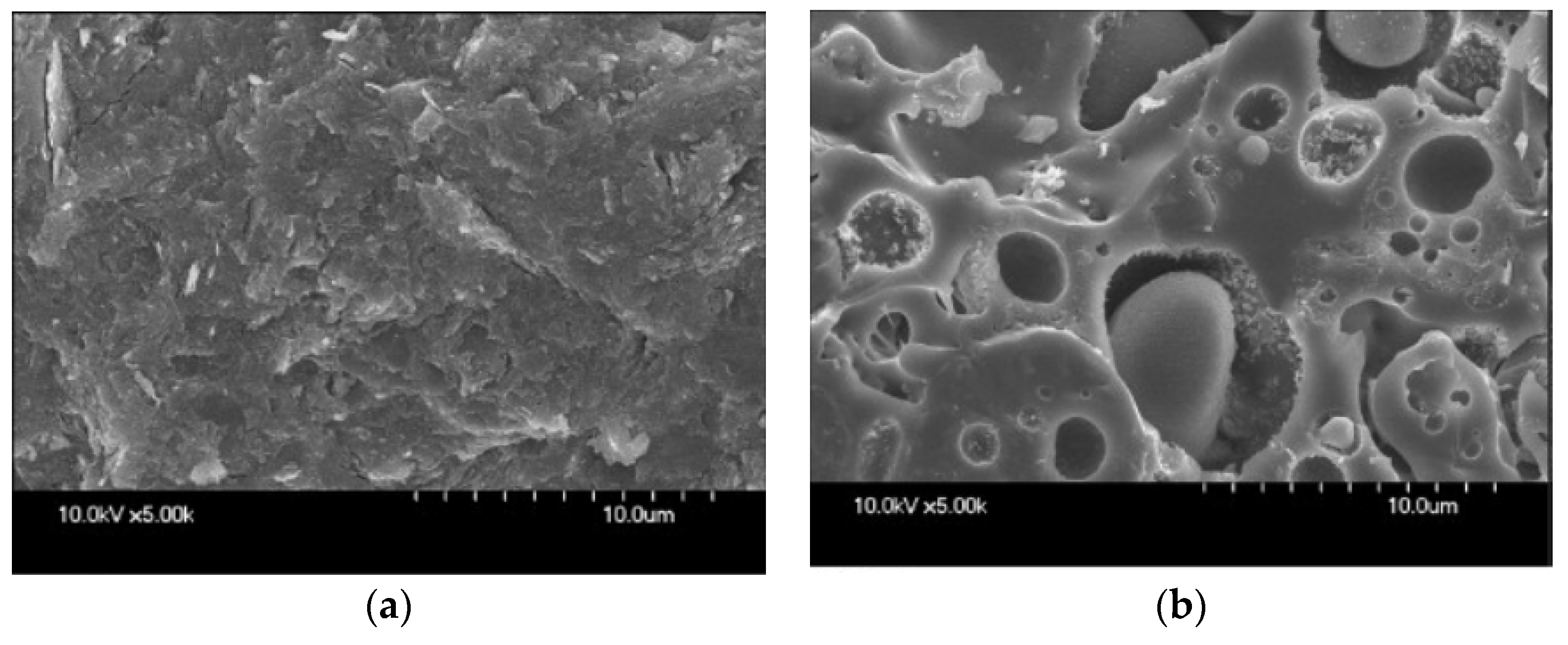

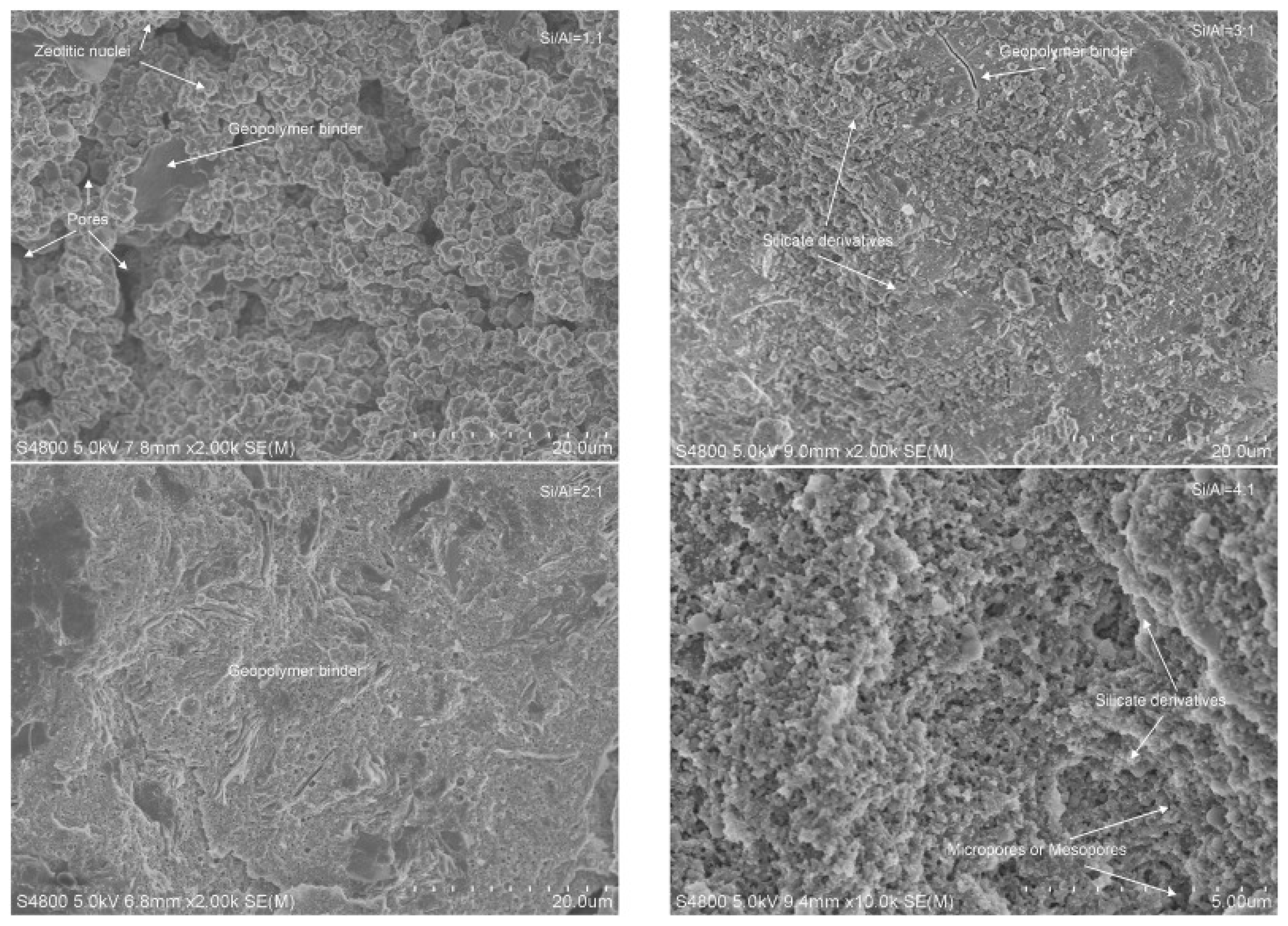

- Type of mineral precursor and Si/Al ratio. Cherki El Idrissi et al. [41] proved how the Si/Al ratio, brought by several mineral precursors, is intimately linked with the porosity distribution in GCs. In this research, three different precursors were analyzed: MK (Si/Al ratio: 2.5), GBFS (Si/Al ratio: 3.5), and FA (Si/Al ratio: 5.9). Experimental pore volume distribution, conducted by mercury intrusion porosimetry (MIP), revealed that the pore distribution of geopolymer medium shifted into smaller voids as the Si/Al ratio increases. This result is consistent with the work of Wan et al. [42]. Geopolymer compounds synthesized at a low Si/Al ratio (Si/Al ratio of 1:1) present a high content of undispersed crystalline zeolitic nuclei into a little geopolymeric binder and macropores. At a Si/Al ratio of 2:1, a proper concentration of aluminate and silicate monomers is involved in a homogeneous geopolymer binder. At a Si/Al ratio of 4:1, many micropores or mesopores are formed due to an insufficient amount of dissolved aluminosilicate monomers. SEM micrographs of GCs synthesized at various Si/Al ratios are reported in Figure 10.

- Molarity of alkali-activator. Huseien et al. [43] researched the influence of NaOH molarity (from 2 to 16M) on the water absorption tendency of GBFS-FA-based geopolymer mortars. High NaOH molarity improves the microstructure of samples in terms of density increasing and air voids reduction. The increased concentration of alkali-activator enhances the geopolymerization mechanism in terms of precursors solubility, resulting in a high compactness of the network structure and good interfacial adhesion between the geopolymer paste and mineral aggregates. However, very high alkaline solutions (generally > 16 M) can be deleterious on the microstructural and mechanical properties of geopolymer concrete. Higher NaOH concentrations hinder the polycondensation process due to the accelerated dissolution of the alumino-silicate raw materials. The excess of hydroxyls anion (OH−) in the alkali-activated matrix results in premature precipitation of geopolymeric gels, deteriorating the mechanical properties of the geopolymer produced.

- Curing time and temperature. Recent findings of the effect of curing treatment on the pore system of FGC-based materials are reported in the research of Zhang et al. [44]. The authors investigated the relationship of microstructural properties development of FGCs and its dependence on curing conditions (room temperature, 50 °C and 80 °C for 7, 28, and 49 days). For each curing temperature, the porosity rate of the samples decreased with the heat curing period. Macro-pores (50–100 μm) constituted the geopolymer matrix under 7 days curing time. As the heat treatment increased, the percentage of large pores tended to decrease, but a more significant contribution of microcracks due to the material’s drying occurred. In this regard, the greater the temporal extension of the thermal treatment, the higher the geopolymer reaction degree, increasing the inorganic gel formation that constructed a more compact microstructure [39]. Curing temperature is crucial to the overall pore volume. Similar pore content was observed at room and middle curing temperatures (about 5% and 4.5%, respectively, while a higher pore fraction (about 8%) was detected in the samples cured at 80 °C. Faster water evaporation and hardening process at higher curing temperature results in a less ordered medium of poorer quality having larger pores and defects. On the other hand, lower curing temperatures help the material densification, as the geopolymer gel tends to saturate the microstructural voids [45].

Effects of Mineral Aggregates: Interfacial Transition Zone (ITZ) Porosity

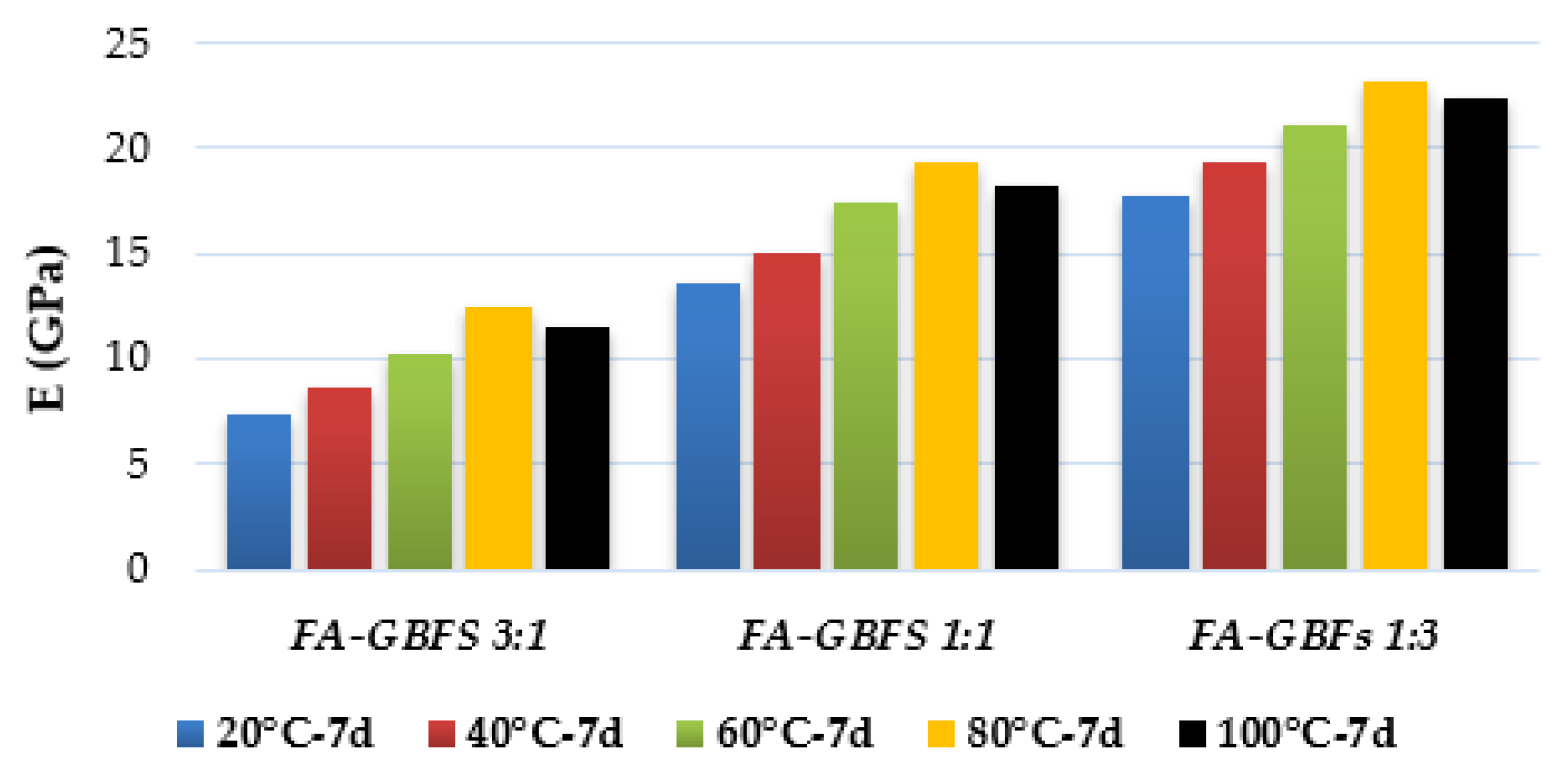

3.3. Mechanical Properties

Mechanical Strength Properties Optimization of GC-Based Concrete: Recent Developments

3.4. Durability Properties

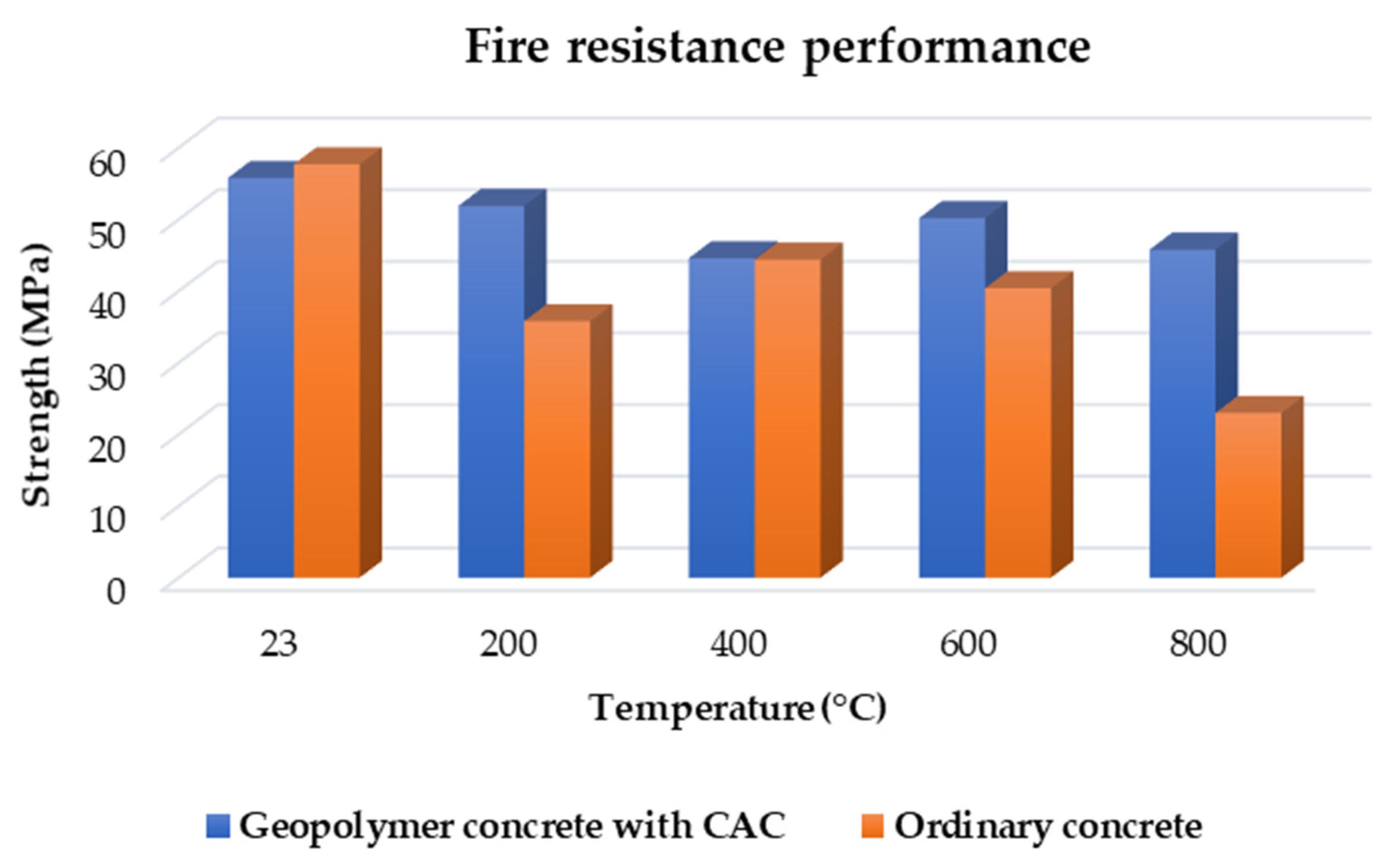

3.5. Thermal and Acoustic Properties

4. Recent Applications and Upgrading of Geopolymer Technology in Construction Sector

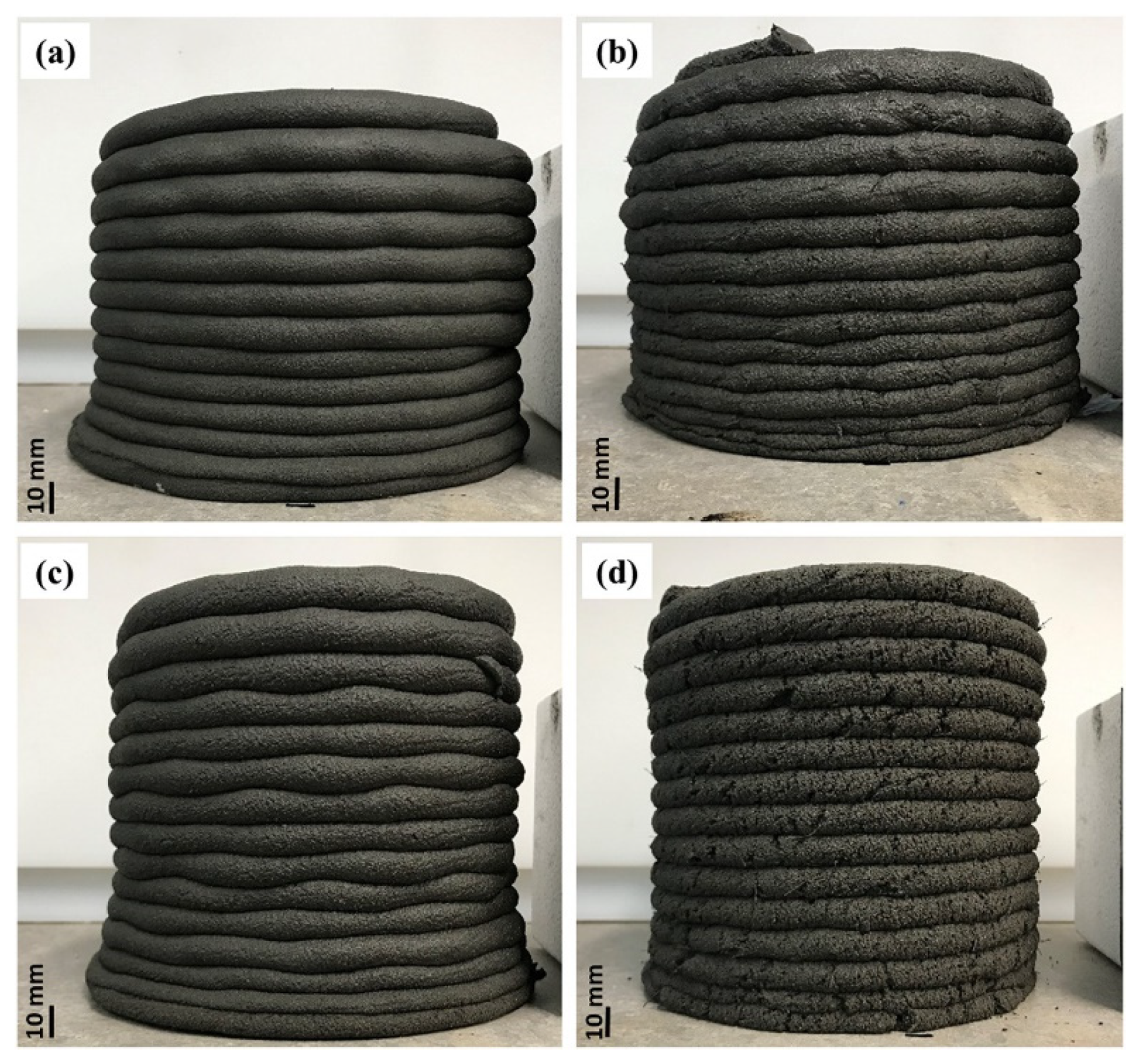

4.1. GC-Based Mixes for 3D Printing Fabrication Technologies

4.1.1. Muthukrishnan et al. Research

4.1.2. Chougan et al. Research

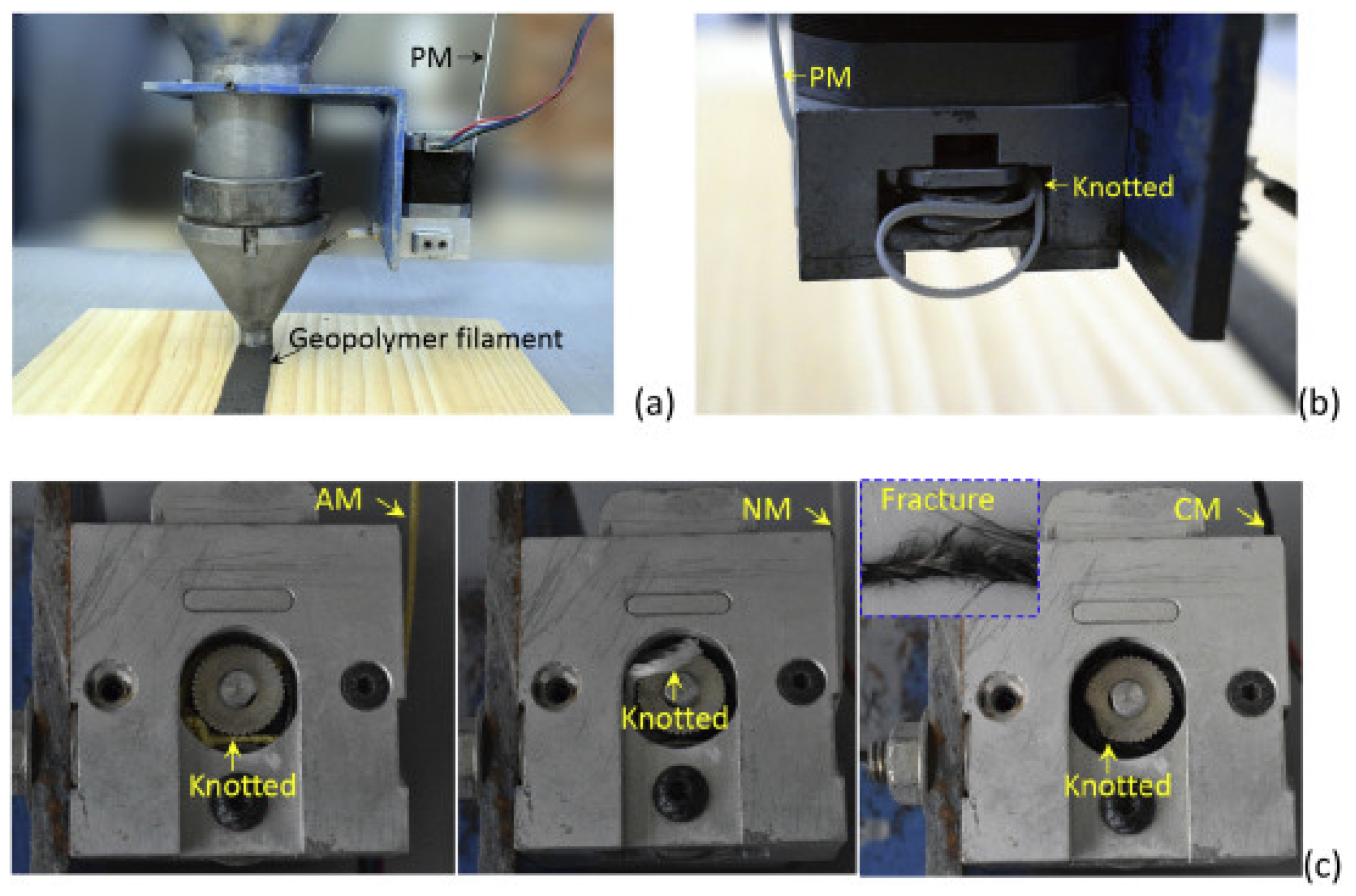

4.1.3. Li et al. Research

4.1.4. Voney et al. Research

4.1.5. Xia et al. Research

4.2. Adopting Geopolymer Technology: Companies and Applications

4.3. InnoWEE Project

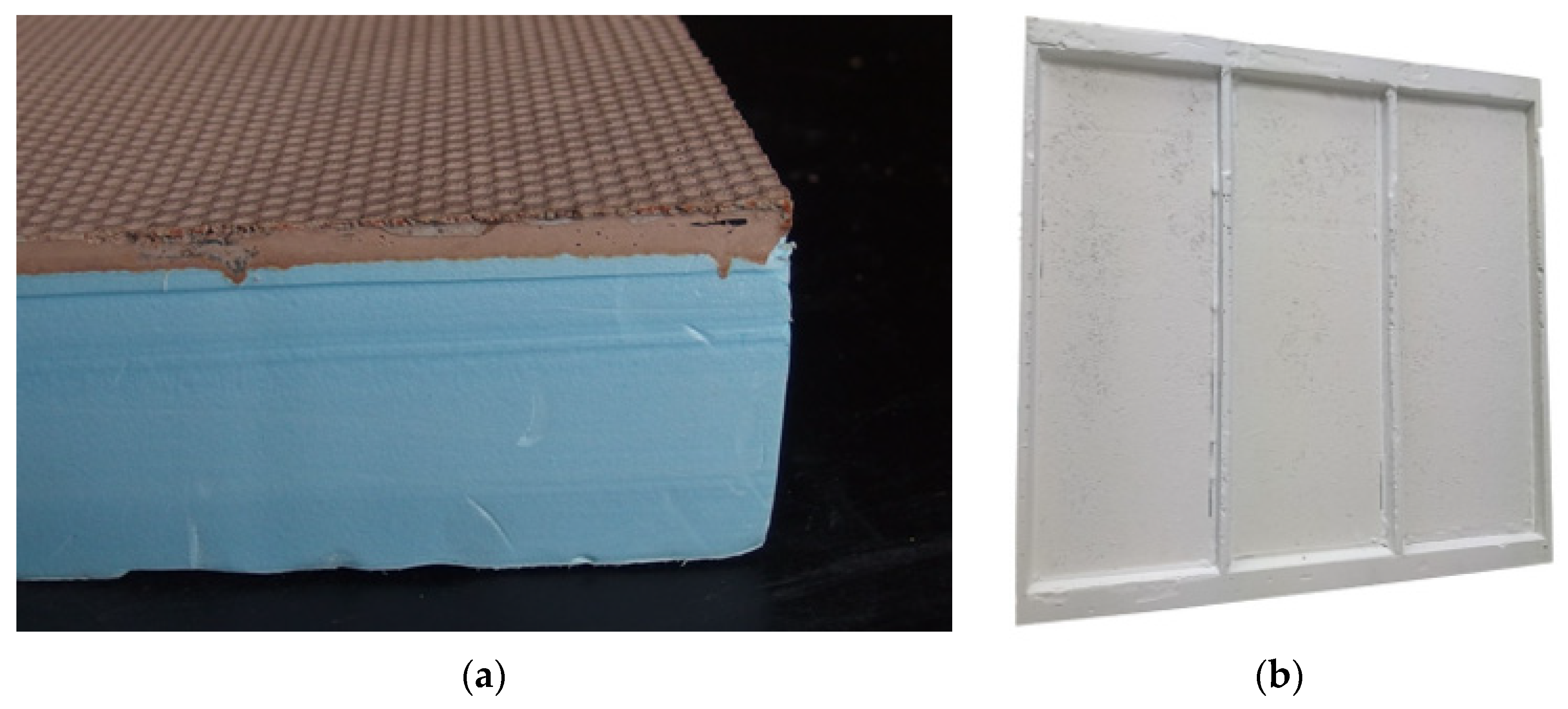

- ETICs-like panels. ETICs-like panels (Figure 19a) consist of sandwich panels (400 mm × 900 mm) composed of an outer high-density geopolymer layer (8 mm thin) and 70 mm-thick expanded polystyrene (EPS) insulating core. The geopolymeric binder is an FA-MK blend implemented with 50 wt % of inorganic aggregates consisting in a mixture of fired clay and concrete waste. A preliminary thermal insulation performance analysis was performed by installing these panels in some residential and urban buildings located in various European countries, such as “Don Orione” residential assistance center (Bucharest, Romania), Volua municipal building (Athens, Greece), and pilot eco-buildings (Padova, Italy). In terms of energy efficiency, the results demonstrated an annual energy saving of over 400 kW/h per year, meeting the new building efficiency requirements imposed by the EU.

- Ventilated façade cladding panels. Innovative lightweight façade panels (Figure 19b), with dimensions of 595 mm × 595 mm, were developed by bonding an outer high-density geopolymer (such as the ETICs-like one) layer to an inner wood–geopolymer panel (incorporating 40 wt % of crushed wood. The element combines the specific behavior of its components. The geopolymer layer acts as a barrier to protect the structure from adverse weather phenomena (wind load, rain, and ice). The wood–geopolymer panel provides additional strength and lightweight. As for ETICs, insulating and durability studies were performed both in the laboratory and on site by the installation of prefabricated cladding panels in European pilot buildings.

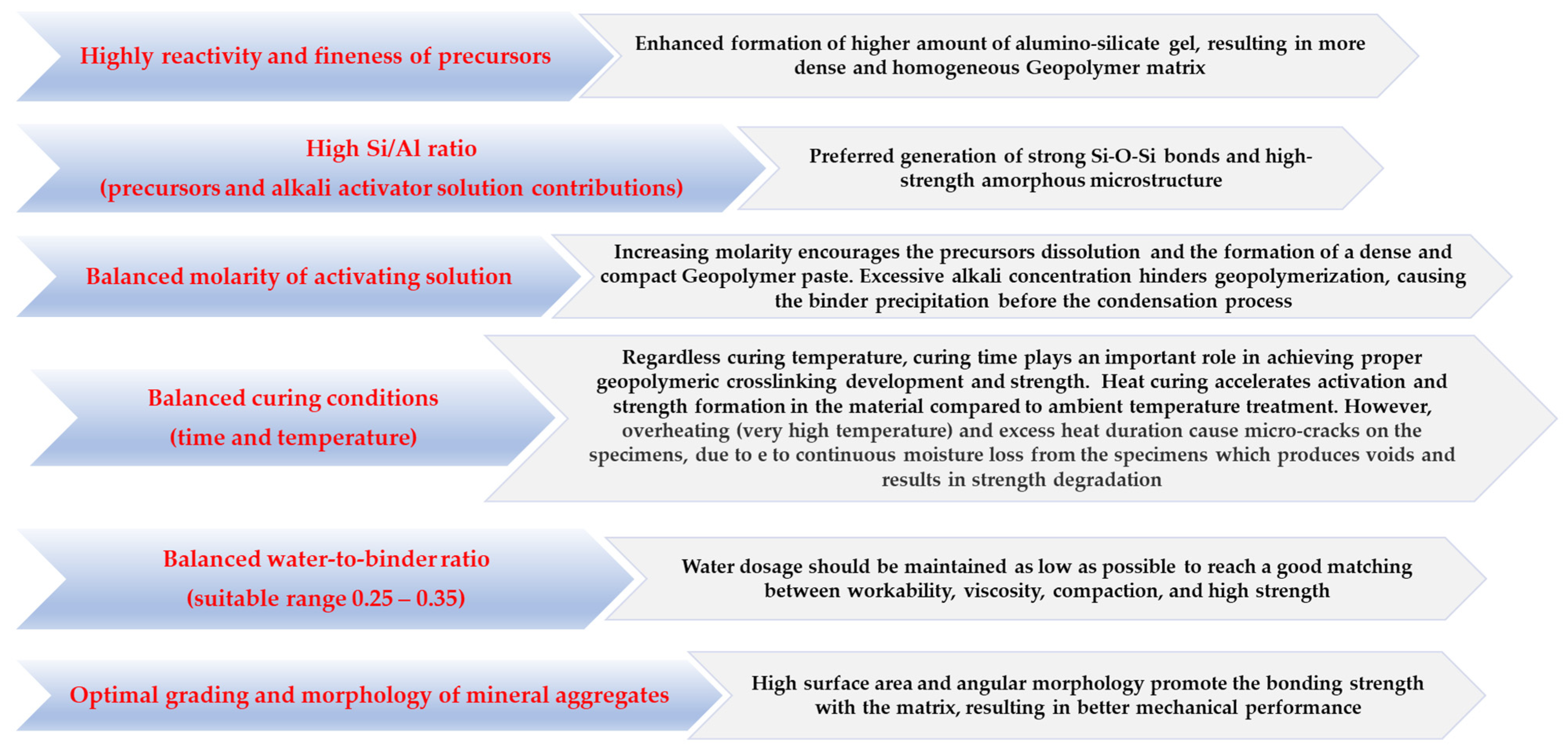

5. Discussion and Conclusions

- Reactivity, SiO2 and Al2O3 monomers concentration, and the morphological finesse of the precursors are crucial for the compaction and microstructural features of a geopolymer matrix. A finer size gradation and a high (but balanced) Si/Al ratio are favorable conditions to ensure the formation of a less porous and dense geopolymer gel, promoting the mechanical strength properties.

- Activating solution molarity should be properly balanced to obtain an efficient dissolution of the alumino-silicate precursors and proper rheology of the fresh paste in terms of setting time and slump. The addition of superplasticizers reduces the water requirement, preserving optimal mechanical properties.

- Curing at room temperature or thermal-induced provides similar performance in terms of long-term mechanical strength. High curing temperatures promote the geopolymerization process but, on the other hand, they can negatively affect the microstructure and strength of the material due to the micro-crack generation deriving from accelerated water evaporation.

- The Si-content and the specific surface of the natural inert incorporated in the geopolymer compounds affect the microstructure and mechanical properties. The very Si-rich and finer mineral aggregates promote a more compact and cohesive ITZ.

- The incorporation of reinforcement fibers and micro and nano-fillers is a novel and viable approach to improve the mechanical strength and stiffness of geopolymer concrete and mortars.

- Some current investigations on the durability performance of geopolymeric compounds revealed better characteristics than PC-based materials in terms of water sorptivity, permeability, long-term resistance to corrosion, and fireproofing.

- GFCs are an emerging class of geopolymer formulations with improved thermal insulation and sound absorption properties, resulting in attractive technologies to optimize the energy-efficiency for building application. However, the sound insulation performances of geopolymers concrete are poorly covered in the literature, and therefore, more investigations need to be conducted in this field.

- The high sensitivity of the geopolymerization process to environmental factors and synthesis parameters requires skilled and highly trained labor to obtain materials of suitable quality. The instability in the chemical composition of precursors can be another severely limiting factor.

- High costs and toxicity of activating alkaline solutions. In this regard, the study of more eco-friendly and cheap activators could be a possible way of research to optimize the geopolymer technology.

- Long-term availability of raw materials. The stringent environmental regulations adopted in many industrialized countries on the use of renewable resources as primary energy supplies have led to a slight decline in many power plants, from which geopolymeric raw materials are extracted (for example, coal-fired power stations for FA supply). If this trend continues, it may further affect the diffusion of GC as a replacement of ordinary PC. However, in accordance with current production rates, availability, and costs, possible replacements of PC concrete with geopolymer aggregates of at least 75% are feasible [100].

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- BBC. Available online: https://www.bbc.com/news/science-environment-46455844 (accessed on 17 March 2021).

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Maddalena, R.; Roberts, J.J.; Hamilton, A. Can Portland cement be replaced by low-carbon alternative materials? A study on the thermal properties and carbon emissions of innovative cements. J. Clean. Prod. 2018, 186, 933–942. [Google Scholar] [CrossRef]

- World Green Building Council. Available online: https://www.worldgbc.org/news-media/WorldGBC-embodied-carbon-report-published (accessed on 18 March 2021).

- Van Chanh, N.; Trung, B.D.; Van Tuan, D. Recent research geopolymer concrete. In Proceedings of the 3rd ACF International Conference-ACF/VCA, Ho Chi Minh City, Vietnam, 11–13 November 2008; Volume 18, pp. 235–241. [Google Scholar]

- Nuaklong, P.; Jongvivatsakul, P.; Pothisiri, T.; Sata, V.; Chindaprasirt, P. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 2020, 252, 119797. [Google Scholar] [CrossRef]

- Ahdaya, M.; Imqam, A. Investigating geopolymer cement performance in presence of water based drilling fluid. J. Pet. Sci. Eng. 2019, 176, 934–942. [Google Scholar] [CrossRef]

- Ji, Z.; Pei, Y. Bibliographic and visualized analysis of geopolymer research and its application in heavy metal immobilization: A review. J. Environ. Manag. 2019, 231, 256–267. [Google Scholar] [CrossRef] [PubMed]

- Davidovits, J. Geopolymer cement. A Rev. Geopolymer Inst. Tech. Pap. 2013, 21, 1–11. [Google Scholar]

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Kani, E.N.; Allahverdi, A. Effects of curing time and temperature on strength development of inorganic polymeric binder based on natural pozzolan. J. Mater. Sci. 2009, 44, 3088–3097. [Google Scholar] [CrossRef]

- Ozer, I.; Soyer-Uzun, S. Relations between the structural characteristics and compressive strength in metakaolin based geopolymers with different molar Si/Al ratios. Ceram. Int. 2015, 41, 10192–10198. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.; Hussin, K.; Bnhussain, M.; Ismail, K.N.; Ibrahim, W.M.W. Mechanism and chemical reaction of fly ash geopolymer cement-a review. Int. J. Pure Appl. Sci. Technol 2011, 6, 35–44. [Google Scholar]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Calcestruzzo&Prefabbricazione International. Available online: https://www.cpi-worldwide.com/it/journals/artikel/44107/metacaolino-nel-calcestruzzo-una-breve-panoramica (accessed on 2 January 2021).

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si+ Ca) and metakaolin (Si+ Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H.; Zhu, Y.; Reid, A.; Provis, J.L.; Bullen, F. Using fly ash to partially substitute metakaolin in geopolymer synthesis. Appl. Clay Sci. 2014, 88, 194–201. [Google Scholar] [CrossRef]

- Swanepoel, J.C.; Strydom, C.A. Utilisation of fly ash in a geopolymeric material. Appl. Geochem. 2002, 17, 1143–1148. [Google Scholar] [CrossRef]

- Vargas, J.; Halog, A. Effective carbon emission reductions from using upgraded fly ash in the cement industry. J. Clean. Prod. 2015, 103, 948–959. [Google Scholar] [CrossRef]

- Arnon, C.; Thanongsak, N. Thermal analysis and microstructure of Portland cement-fly ash-silica fume pastes. J. Therm. Anal. Calorim. 2009, 99, 487–493. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G.L.; Sagoe-Crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Mehrotra, S.P. Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer. J. Mater. Sci. 2010, 45, 607–615. [Google Scholar] [CrossRef]

- Ekmen, Ş.; Mermerdaş, K.; Algın, Z. Effect of oxide composition and ingredient proportions on the rheological and mechanical properties of geopolymer mortar incorporating pumice aggregate. J. Build. Eng. 2020, 101893. [Google Scholar] [CrossRef]

- Binici, H. Engineering properties of geopolymer incorporating slag, fly ash, silica sand and pumice. Adv. Civ. Env. Eng. 2013, 1, 108–123. [Google Scholar]

- Papa, E.; Medri, V.; Amari, S.; Manaud, J.; Benito, P.; Vaccari, A.; Landi, E. Zeolite-geopolymer composite materials: Production and characterization. J. Clean. Prod. 2018, 171, 76–84. [Google Scholar] [CrossRef]

- Nikolov, A.; Rostovsky, I.; Nugteren, H. Geopolymer materials based on natural zeolite. Case Stud. Constr. Mater. 2017, 6, 198–205. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Elimbi, A.; Tchakouté, H.K.; Kumar, S. Mechanical activation of volcanic ash for geopolymer synthesis: Effect on reaction kinetics, gel characteristics, physical and mechanical properties. RSC Adv. 2016, 6, 39106–39117. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Elimbi, A.; Tchakouté, H.K.; Kumar, S. Mechanical properties and durability of volcanic ash based geopolymer mortars. Constr. Build. Mater. 2016, 124, 606–614. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Tungsten mine waste geopolymeric binder: Preliminary hydration products investigations. Constr. Build. Mater. 2009, 23, 200–209. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; de Gutiérrez, R.M.; Gordillo, M.; Provis, J.L. Mechanical and thermal characterisation of geopolymers based on silicate-activated metakaolin/slag blends. J. Mater. Sci. 2011, 46, 5477–5486. [Google Scholar] [CrossRef]

- Ferraris, C.F.; Billberg, P.; Ferron, R.; Feys, D.; Hu, J.; Kawashima, S.; Koehler, E.; Sonebi, M.; Tanesi, J.; Tregger, N. Role of rheology in achieving successful concrete performance. ACI Commun. 2017, 238, 43–51. [Google Scholar]

- Roussel, N. Rheology of fresh concrete: From measurements to predictions of casting processes. Mater. Struct. 2007, 40, 1001–1012. [Google Scholar] [CrossRef]

- Rifaai, Y.; Yahia, A.; Mostafa, A.; Aggoun, S.; Kadri, E.H. Rheology of fly ash-based geopolymer: Effect of NaOH concentration. Constr. Build. Mater. 2019, 223, 583–594. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D.; Mendis, P. The effects of precursors on rheology and self-compactness of geopolymer concrete. Mag. Concr. Res. 2019, 71, 557–566. [Google Scholar] [CrossRef]

- Xie, J.; Kayali, O. Effect of superplasticiser on workability enhancement of Class F and Class C fly ash-based geopolymers. Constr. Build. Mater. 2016, 122, 36–42. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Wang, Y.S.; Dai, J.G. The effectiveness of different superplasticizers in ambient cured one-part alkali activated pastes. Cem. Concr. Compos. 2019, 97, 166–174. [Google Scholar] [CrossRef]

- Gunasekara, C.M. Influence of Properties of Fly Ash from Different Sources on the Mix Design and Performance of Geopolymer Concrete. Ph.D. Thesis, School of Engineering College of Science, Engineering and Health RMIT University Melbourne, Melbourne, Australia, July 2016. [Google Scholar]

- Assi, L.N.; Deaver, E.E.; Ziehl, P. Effect of source and particle size distribution on the mechanical and microstructural properties of fly Ash-Based geopolymer concrete. Constr. Build. Mater. 2018, 167, 372–380. [Google Scholar] [CrossRef]

- Cherki El Idrissi, A.; Roziere, E.; Loukili, A.; Darson, S. Design of geopolymer grouts: The effects of water content and mineral precursor. Eur. J. Environ. Civ. Eng. 2016, 22, 628–649. [Google Scholar] [CrossRef]

- Wan, Q.; Rao, F.; Song, S.; García, R.E.; Estrella, R.M.; Patino, C.L.; Zhang, Y. Geopolymerization reaction, microstructure and simulation of metakaolin-based geopolymers at extended Si/Al ratios. Cem. Concr. Compos. 2017, 79, 45–52. [Google Scholar] [CrossRef]

- Huseien, G.F.; Ismail, M.; Khalid, N.H.A.; Hussin, M.W.; Mirza, J. Compressive strength and microstructure of assorted wastes incorporated geopolymer mortars: Effect of solution molarity. Alex. Eng. J. 2018, 57, 3375–3386. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, M.; Zhang, G.; Sietins, J.M.; Granados-Focil, S.; Pepi, M.S.; Xun, Y.; Tao, M. Reaction kinetics of red mud-fly ash based geopolymers: Effects of curing temperature on chemical bonding, porosity, and mechanical strength. Cem. Concr. Compos. 2018, 93, 175–185. [Google Scholar] [CrossRef]

- Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Leemann, A.; Münch, B.; Gasser, P.; Holzer, L. Influence of compaction on the interfacial transition zone and the permeability of concrete. Cem. Concr. Res. 2006, 36, 1425–1433. [Google Scholar] [CrossRef]

- Chuah, S.; Duan, W.H.; Pan, Z.; Hunter, E.; Korayem, A.H.; Zhao, X.L.; Collins, F.; Sanjayan, J.G. The properties of fly ash based geopolymer mortars made with dune sand. Mater. Des. 2016, 92, 571–578. [Google Scholar] [CrossRef]

- Zhu, P.; Hua, M.; Liu, H.; Wang, X.; Chen, C. Interfacial evaluation of geopolymer mortar prepared with recycled geopolymer fine aggregates. Constr. Build. Mater. 2020, 259, 119849. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment–A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Chithambaram, S.J.; Kumar, S.; Prasad, M.M. Thermo-mechanical characteristics of geopolymer mortar. Constr. Build. Mater. 2019, 213, 100–108. [Google Scholar] [CrossRef]

- Hu, Y.; Tang, Z.; Li, W.; Li, Y.; Tam, V.W. Physical-mechanical properties of fly ash/GGBFS geopolymer composites with recycled aggregates. Constr. Build. Mater. 2019, 226, 139–151. [Google Scholar] [CrossRef]

- Mermerdaş, K.; Manguri, S.; Nassani, D.E.; Oleiwi, S.M. Effect of aggregate properties on the mechanical and absorption characteristics of geopolymer mortar. Eng. Sci. Technol. Int. J. 2017, 20, 1642–1652. [Google Scholar] [CrossRef]

- Azarsa, P.; Gupta, R. Comparative Study Involving Effect of Curing Regime on Elastic Modulus of Geopolymer Concrete. Buildings 2020, 10, 101. [Google Scholar] [CrossRef]

- Yan, D.; Chen, S.; Zeng, Q.; Xu, S.; Li, H. Correlating the elastic properties of metakaolin-based geopolymer with its composition. Mater. Des. 2016, 95, 306–318. [Google Scholar] [CrossRef]

- Yoo, S.Y.; Jeon, J.Y. Investigation of the effects of different types of interlayers on floor impact sound insulation in box-frame reinforced concrete structures. Build. Environ. 2014, 76, 105–112. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- Aboulayt, A.; Jaafri, R.; Samouh, H.; El Idrissi, A.C.; Roziere, E.; Moussa, R.; Loukili, A. Stability of a new geopolymer grout: Rheological and mechanical performances of metakaolin-fly ash binary mixtures. Constr. Build. Mater. 2018, 181, 420–436. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; He, Z. Mechanical and fracture properties of fly ash geopolymer concrete addictive with calcium aluminate cement. Materials 2019, 12, 2982. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wang, C.; Zhao, J.; Liu, F.; Fang, C. Study on the optimum initial curing condition for fly ash and GGBS based geopolymer recycled aggregate concrete. Constr. Build. Mater. 2020, 247, 118540. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Maegawa, A.; Mishima, N.; Hatanaka, S.; Chindaprasirt, P. Effects of sodium hydroxide and sodium silicate solutions on compressive and shear bond strengths of FA–GBFS geopolymer. Constr. Build. Mater. 2015, 91, 1–8. [Google Scholar] [CrossRef]

- Gülşan, M.E.; Alzeebaree, R.; Rasheed, A.A.; Niş, A.; Kurtoğlu, A.E. Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber. Constr. Build. Mater. 2019, 211, 271–283. [Google Scholar] [CrossRef]

- Al-Rawi, S.; Taysi, N. Performance of self-compacting geopolymer concrete with and without GGBFS and steel fiber. Adv. Concr. Constr. 2018, 6, 323. [Google Scholar] [CrossRef]

- Deb, P.S.; Sarker, P.K.; Barbhuiya, S. Effects of nano-silica on the strength development of geopolymer cured at room temperature. Constr. Build. Mater. 2015, 101, 675–683. [Google Scholar] [CrossRef]

- Bellum, R.R.; Muniraj, K.; Indukuri, C.S.R.; Madduru, S.R.C. Investigation on Performance Enhancement of Fly ash-GGBFS Based Graphene Geopolymer Concrete. J. Build. Eng. 2020, 32, 101659. [Google Scholar] [CrossRef]

- Liu, C.; Huang, X.; Wu, Y.Y.; Deng, X.; Liu, J.; Zheng, Z.; Hui, D. Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide. Nanotechnol. Rev. 2020, 9, 155–169. [Google Scholar] [CrossRef]

- Pham, T.M. Enhanced properties of high-silica rice husk ash-based geopolymer paste by incorporating basalt fibers. Constr. Build. Mater. 2020, 245, 118422. [Google Scholar] [CrossRef]

- Gunasekara, C.; Setunge, S.; Law, D.W.; Willis, N.; Burt, T. Engineering properties of geopolymer aggregate concrete. J. Mater. Civ. Eng. 2018, 30, 04018299. [Google Scholar] [CrossRef]

- Morla, P.; Gupta, R.; Azarsa, P.; Sharma, A. Corrosion Evaluation of Geopolymer Concrete Made with Fly Ash and Bottom Ash. Sustainability 2021, 13, 398. [Google Scholar] [CrossRef]

- Cao, Y.; Tao, Z.; Pan, Z.; Murphy, T.; Wuhrer, R. Fire Resistance of Fly Ash-Based Geopolymer Concrete Blended with Calcium Aluminate Cement. In Proceedings of the 1st International Conference on Structural Engineering Research, Sydney, Australia, 20–22 November 2017; pp. 210–220. [Google Scholar]

- Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014, 72, 238–245. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Mendis, P.; Sanjayan, J. Regulating the chemical foaming reaction to control the porosity of geopolymer foams. Mater. Des. 2017, 120, 255–265. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Enhancing the mechanical and thermal properties of aerated geopolymer concrete using porous lightweight aggregates. Constr. Build. Mater. 2020, 264, 120713. [Google Scholar] [CrossRef]

- Senff, L.; Novais, R.M.; Carvalheiras, J.; Labrincha, J.A. Eco-friendly approach to enhance the mechanical performance of geopolymer foams: Using glass fibre waste coming from wind blade production. Constr. Build. Mater. 2020, 239, 117805. [Google Scholar] [CrossRef]

- Ahmed, M.F.; Khalil, W.I.; Frayyeh, Q.J. Thermal Insulation Enhancement of Metakaolin-Based Geopolymer Concrete Using Waste Clay Brick. In Proceedings of the 4th International Conference on Manufacturing Technologies (ICMT), Seattle, WA, USA, 17–19 January 2020. [Google Scholar] [CrossRef]

- Tekin, I.; Gencel, O.; Gholampour, A.; Oren, O.H.; Koksal, F.; Ozbakkaloglu, T. Recycling zeolitic tuff and marble waste in the production of eco-friendly geopolymer concretes. J. Clean. Prod. 2020, 268, 122298. [Google Scholar] [CrossRef]

- Leiva, C.M.; Luna-Galiano, Y.; Arenas, C.; Alonso-Fariñas, B.; Fernández-Pereira, C. A porous geopolymer based on aluminum-waste with acoustic properties. Waste Manag. 2019, 95, 504–512. [Google Scholar] [CrossRef]

- Gao, H.; Liu, H.; Liao, L.; Mei, L.; Zhang, F.; Zhang, L.; Li, S.; Lv, G. A bifunctional hierarchical porous kaolinite geopolymer with good performance in thermal and sound insulation. Constr. Build. Mater. 2020, 251, 118888. [Google Scholar] [CrossRef]

- Stolz, J.; Boluk, Y.; Bindiganavile, V. Mechanical, thermal and acoustic properties of cellular alkali activated fly ash concrete. Cem. Concr. Compos. 2018, 94, 24–32. [Google Scholar] [CrossRef]

- Tudor, E.M.; Dettendorfer, A.; Kain, G.; Barbu, M.C.; Reh, R.; Krišťák, Ľ. Sound-absorption coefficient of bark-based insulation panels. Polymers 2020, 12, 1012. [Google Scholar] [CrossRef] [PubMed]

- Gandoman, M.; Kokabi, M. Sound barrier properties of sustainable waste rubber/geopolymer concretes. Iran. Polym. J. 2015, 24, 105–112. [Google Scholar] [CrossRef]

- Sambucci, M.; Valente, M.; Sibai, A.; Marini, D.; Quitadamo, A.; Musacchi, E. Rubber-Cement Composites for Additive Manufacturing: Physical, Mechanical and Thermo-Acoustic Characterization. In Second RILEM International Conference on Concrete and Digital Fabrication: Digital Concrete 2020; Bos, F., Lucas, S., Wolfs, R., Salet, T., Eds.; RILEM Bookseries; Springer: Cham, Switzerland, 2020; Volume 28. [Google Scholar] [CrossRef]

- Valente, M.; Sibai, A.; Sambucci, M. Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry. J. Compos. Sci. 2019, 3, 88. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.; Flatt, R.J. Digital concrete: A review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Al-Qutaifi, S.; Nazari, A.; Bagheri, A. Mechanical properties of layered geopolymer structures applicable in concrete 3D-printing. Constr. Build. Mater. 2018, 176, 690–699. [Google Scholar] [CrossRef]

- Sambucci, M.; Marini, D.; Sibai, A.; Valente, M. Preliminary Mechanical Analysis of Rubber-Cement Composites Suitable for Additive Process Construction. J. Compos. Sci. 2020, 4, 120. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I. Additive Manufacturing in the Geopolymer Construction Technology: A Review. Open Constr. Build. Technol. J. 2020, 14, 150–161. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of microwave heating on interlayer bonding and buildability of geopolymer 3D concrete printing. Constr. Build. Mater. 2020, 265, 120786. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Sikora, P.; Chung, S.Y.; Rucinska, T.; Stephan, D.; Albar, A.; Swash, M.R. Investigation of additive incorporation on rheological, microstructural and mechanical properties of 3D printable alkali-activated materials. Mater. Des. 2021, 109574. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G. Mechanical improvement of continuous steel microcable reinforced geopolymer composites for 3D printing subjected to different loading conditions. Compos. Part B Eng. 2020, 187, 107796. [Google Scholar] [CrossRef]

- Voney, V.; Odaglia, P.; Schenker, F.; Brumaud, C.; Dillenburger, B.; Habert, G. Powder bed 3D printing with quarry waste. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042056. [Google Scholar] [CrossRef]

- Xia, M.; Nematollahi, B.; Sanjayan, J. Printability, accuracy and strength of geopolymer made using powder-based 3D printing for construction applications. Autom. Constr. 2019, 101, 179–189. [Google Scholar] [CrossRef]

- Zhou, Z.; Buchanan, F.; Mitchell, C.; Dunne, N. Printability of calcium phosphate: Calcium sulfate powders for the application of tissue engineered bone scaffolds using the 3D printing technique. Mater. Sci. Eng. C 2014, 38, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Wagners. Available online: https://www.wagner.com.au/ (accessed on 2 March 2021).

- Glasby, T.; Day, J.; Genrich, R.; Aldred, J. EFC geopolymer concrete aircraft pavements at Brisbane West Wellcamp Airport. In Proceedings of the Concrete 2015 Conference, Melbourne, Australia, 31 August–2 September 2015. [Google Scholar]

- Zeobond. Available online: http://www.zeobond.com/ (accessed on 2 March 2021).

- Geopolymer Solutions. Available online: https://www.geopolymertech.com/ (accessed on 2 March 2021).

- Renca. Available online: https://www.renca.org/ (accessed on 2 March 2021).

- Agma Geopolimeri. Available online: https://www.agmageopolimeri.com/ (accessed on 2 March 2021).

- InnoWEE. Available online: https://innowee.eu/it/ (accessed on 2 March 2021).

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of availability of source materials for geopolymer/sustainable concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

| Oxides (%) | Yangzi Power Plant (China) [18] | Secunda Power Plant (South Africa) [19] | Mae Mao Power Plant (Thailand) [22] |

|---|---|---|---|

| SiO2 | 55.86 | 46.28 | 39.82 |

| Al2O3 | 31.74 | 21.27 | 21.52 |

| Fe2O3 | 3.28 | 4.29 | 13.68 |

| CaO | 1.67 | 9.82 | 15.24 |

| MgO | 0.39 | 2.62 | 2.78 |

| other | 7.06 | 15.72 | 6.96 |

| Formulation | FA(%) | GBFS (%) | Micro-FA (%) | d (μm) | Dry Packing Density (0–1) |

|---|---|---|---|---|---|

| M 1 | 5 | 25 | 10 | 33.1 | 0.483 |

| M 2 | 10 | 20 | 10 | 37.7 | 0.505 |

| M 3 | 15 | 15 | 10 | 42.8 | 0.517 |

| M 4 | 15 | 20 | 5 | 43.5 | 0.515 |

| M 5 | 20 | 15 | 5 | 48.6 | 0.528 |

| Type | Variable | Investigated Range | Compressive Strength (MPa) | Flexural Strength (MPa) | Density (g/cm3) | Primary Findings |

|---|---|---|---|---|---|---|

| FA-based lightweight mortar [25] | Activator molarity | 10–14 M | 19–30 | 3–4 | 1.88–1.92 | 14 M optimal |

| FA-GBFS-based concrete [36] | Precursors size distribution | 33.1–48.6 μm | 48–67 | / | / | Finest size gradation optimal |

| FA-GBFS-based mortar [50] | Heat curing | Ambient–100 °C | 40–53 | / | 1.88–1.96 | Ambient (28 days) and 90 °C (1 h) curing similar improvement effect |

| FA-GBFS-based concrete [51] | FA-GBFS replacement | 0–30% by weight of GBFS | 26–52 | 3.5–5 | 2.38–2.43 | 30% GBFS replacement optimal |

| FA-based mortar [52] | Mineral aggregates grading (limestone sand) | 0–4 mm; 2–4 mm; 1–2 mm; 0–1 mm | 42–49 | 6.7 -6.9 | 2.03–2.07 | 2–4 mm gradation optimal |

| Method | Process Parameter | Mix Composition | Primary Findings |

|---|---|---|---|

| EP | 3-axis extruder, 25 mm × 15 mm rectangular nozzle, 12 mm/s printing speed, 15 mm nozzle height | FA-GBFS geopolymer mix, coarse, and fine silica sand, PVA fibers, Na2SiO3 activating solution, no chemical admixtures | Use of microwave heating as a rapid and efficient mode to increase the filaments bond strength and improve the buildability of 3D printed elements |

| Method | Process Parameter | Mix Composition | Primary Findings |

|---|---|---|---|

| EP | Gantry-type extruder, 20 mm circular nozzle, 20 mm/s printing speed, 10 mm nozzle height | FA-GBFS geopolymer mix, fine river sand, silica fume, KOH-Na2SiO3 activating solution, no chemical admixtures | Addition of nano additive reinforcements (attapulgite nano-clay) and PVA fibers to increase the printability and mechanical strength properties |

| Method | Process Parameter | Mix Composition | Primary Findings |

|---|---|---|---|

| EP | 3-axis extruder, 12 mm circular nozzle, 10 mm/s printing speed, 50 mm nozzle height | FA-GBFS geopolymer mix, fine river sand, silica fume, penta-Na2SiO3, no chemical admixtures | Implementation of printing device with an automated micro-cable reinforcing method to incorporate steel fibers into the printed filaments for mechanical bearing capacity optimization |

| Method | Process Parameter | Mix Composition | Primary Findings |

|---|---|---|---|

| PP | Powder-based system, 0.2 mm circular nozzle, 0.8 mm line spacing, 2.5 mm layer height, 0.5–1 μL/mm injection volume | MK reactive powder, silica sand, ground quarry waste, K2SiO3 activating solution | The replacement of natural aggregates with ground quarry waste preserves the print quality and the structural properties of the printed elements, resulting in a more eco-sustainable approach |

| Method | Process Parameter | Mix Composition | Primary Findings |

|---|---|---|---|

| PP | Powder-based system, 2.5 pL drop volume, 0.1 mm layer height, 2–4 layers/min printing speed | FA-GBFS powder blend, silica sand, anhydrous Na2SiO3 activating solution | The use of GBFS in the mix design (min. 50 wt %) is always necessary to ensure an adequate material setting at room temperature and higher mechanical properties. The exclusive use of FA does not allow to reach adequate green strength due to the low reactivity of the particles. The increase in FA amount increases the binder droplet penetration time. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sambucci, M.; Sibai, A.; Valente, M. Recent Advances in Geopolymer Technology. A Potential Eco-Friendly Solution in the Construction Materials Industry: A Review. J. Compos. Sci. 2021, 5, 109. https://doi.org/10.3390/jcs5040109

Sambucci M, Sibai A, Valente M. Recent Advances in Geopolymer Technology. A Potential Eco-Friendly Solution in the Construction Materials Industry: A Review. Journal of Composites Science. 2021; 5(4):109. https://doi.org/10.3390/jcs5040109

Chicago/Turabian StyleSambucci, Matteo, Abbas Sibai, and Marco Valente. 2021. "Recent Advances in Geopolymer Technology. A Potential Eco-Friendly Solution in the Construction Materials Industry: A Review" Journal of Composites Science 5, no. 4: 109. https://doi.org/10.3390/jcs5040109

APA StyleSambucci, M., Sibai, A., & Valente, M. (2021). Recent Advances in Geopolymer Technology. A Potential Eco-Friendly Solution in the Construction Materials Industry: A Review. Journal of Composites Science, 5(4), 109. https://doi.org/10.3390/jcs5040109