Mechanical and FEA-Assisted Characterization of Fused Filament Fabricated Triply Periodic Minimal Surface Structures

Abstract

1. Introduction

2. Design and Experimental Methods

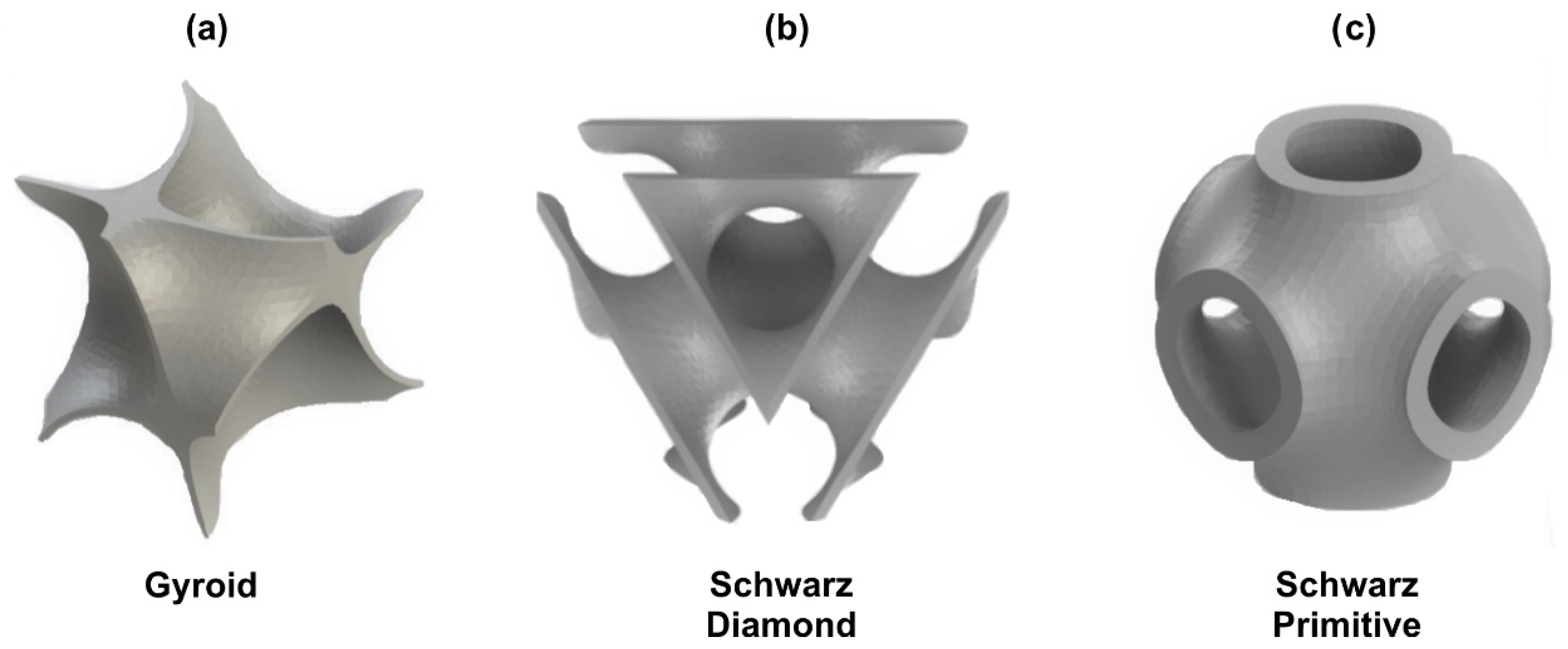

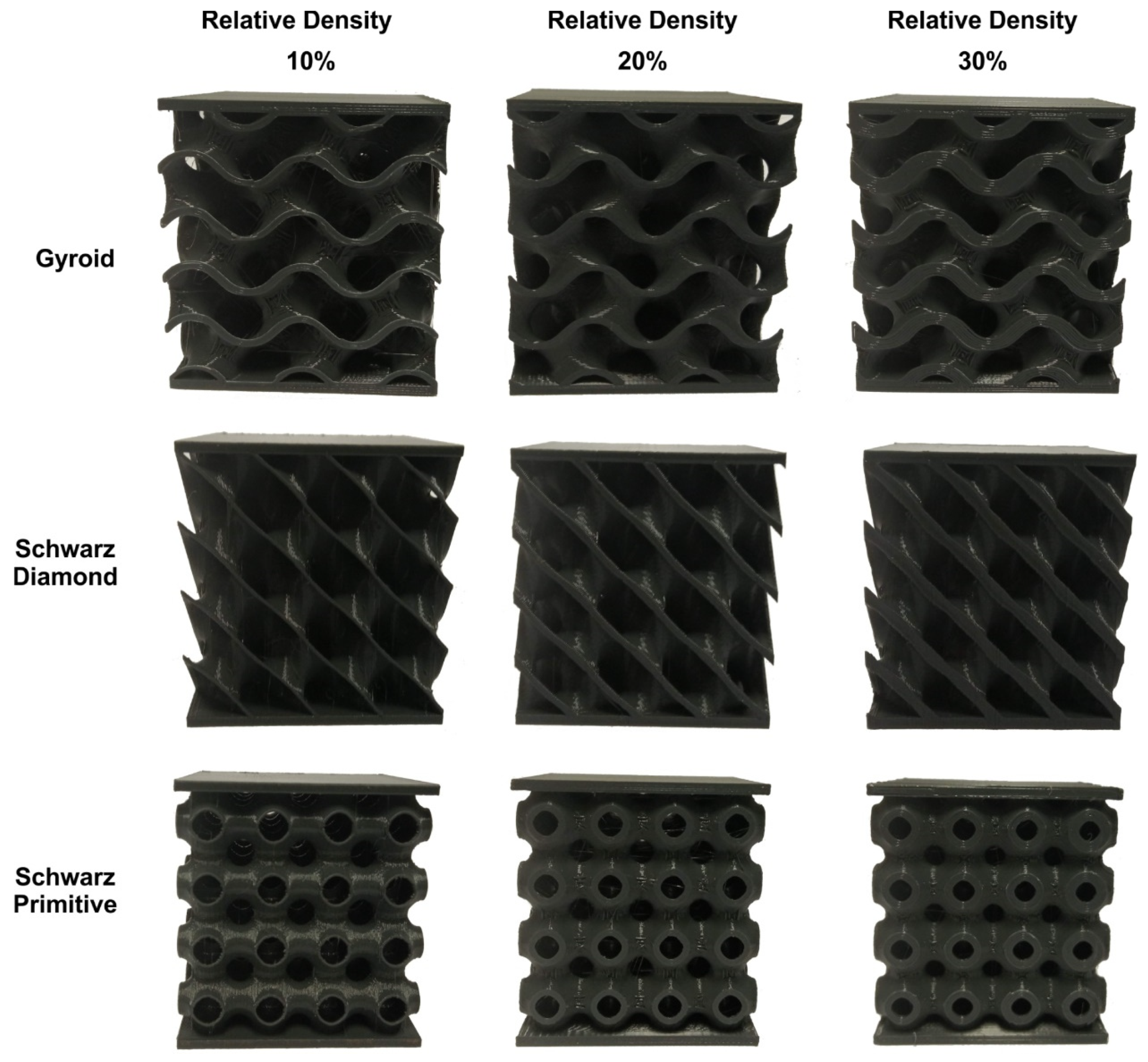

2.1. Procedure of Design and 3D Printing of Lattice Structures

2.2. Microstructure Characterization of the FFF Printed TPMS Structures

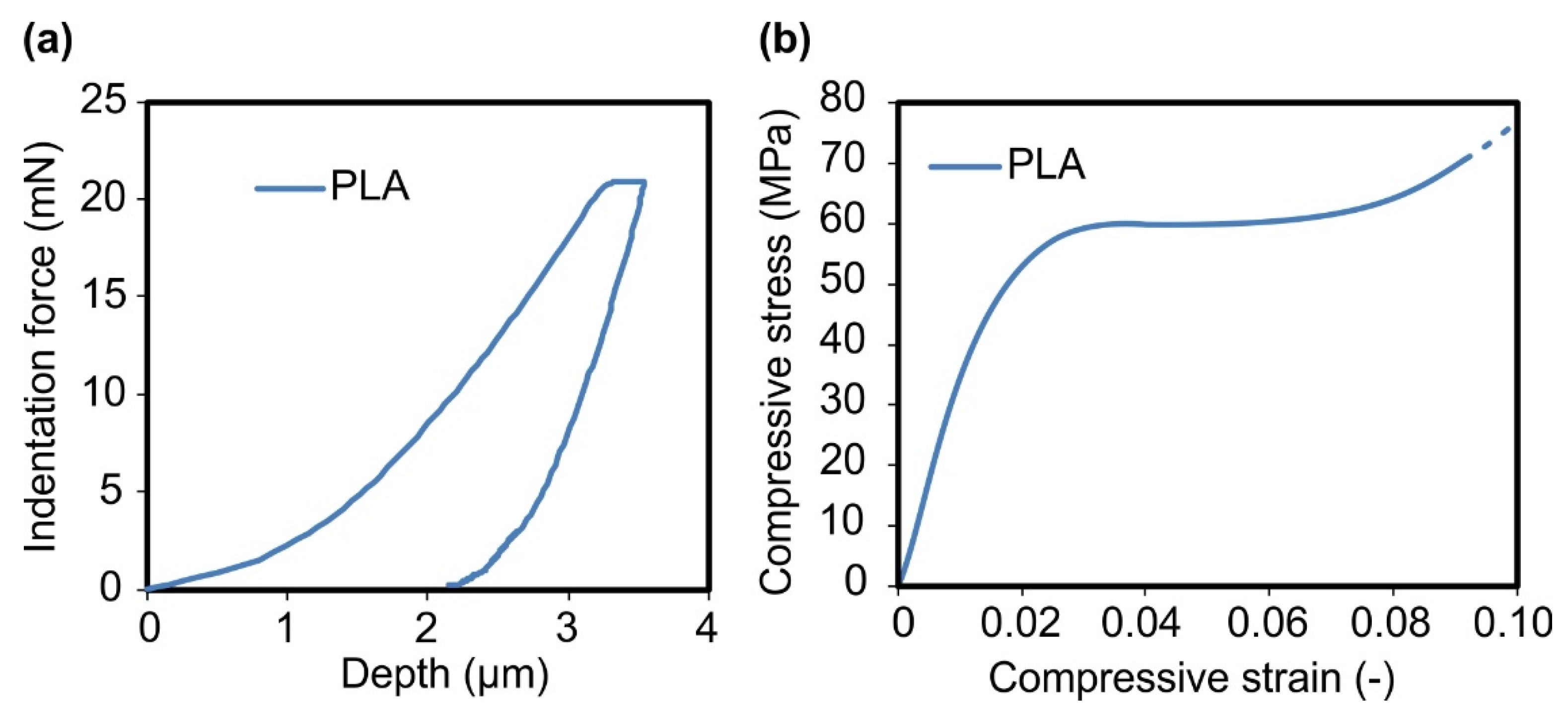

2.3. Nanoindentation and Compression Properties of the Base FFF Material

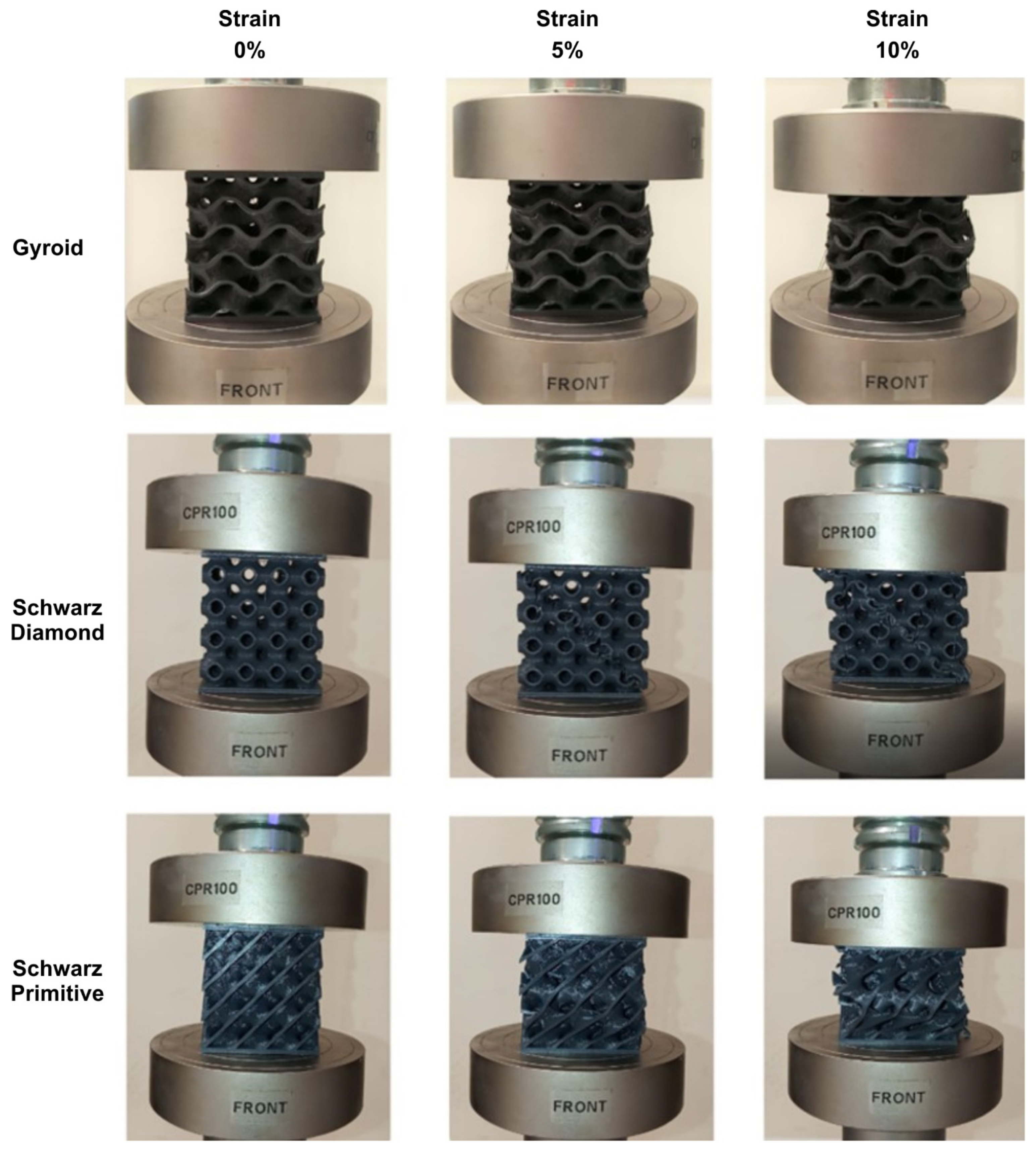

2.4. Compression Testing of FFF Printed TPMS Lattice Structures

2.5. Finite Element Analysis Assisted Simulation of the Mechanical Behavior of the FFF TPMS Structures

3. Results

3.1. Material Properties and Fabrication of FFF TPMS Specimens

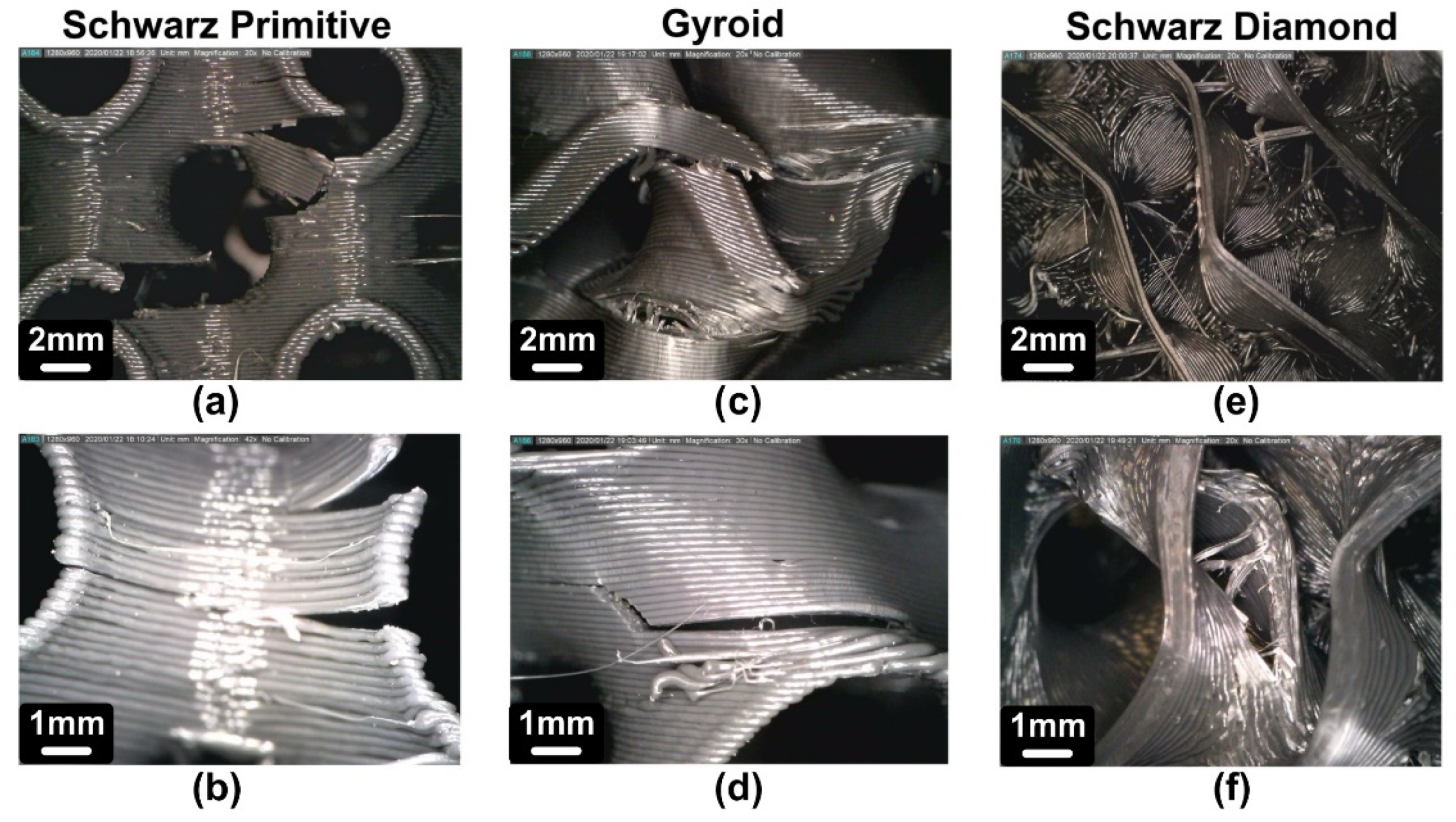

3.2. Morphology Characterization of FFF TPMS Structures

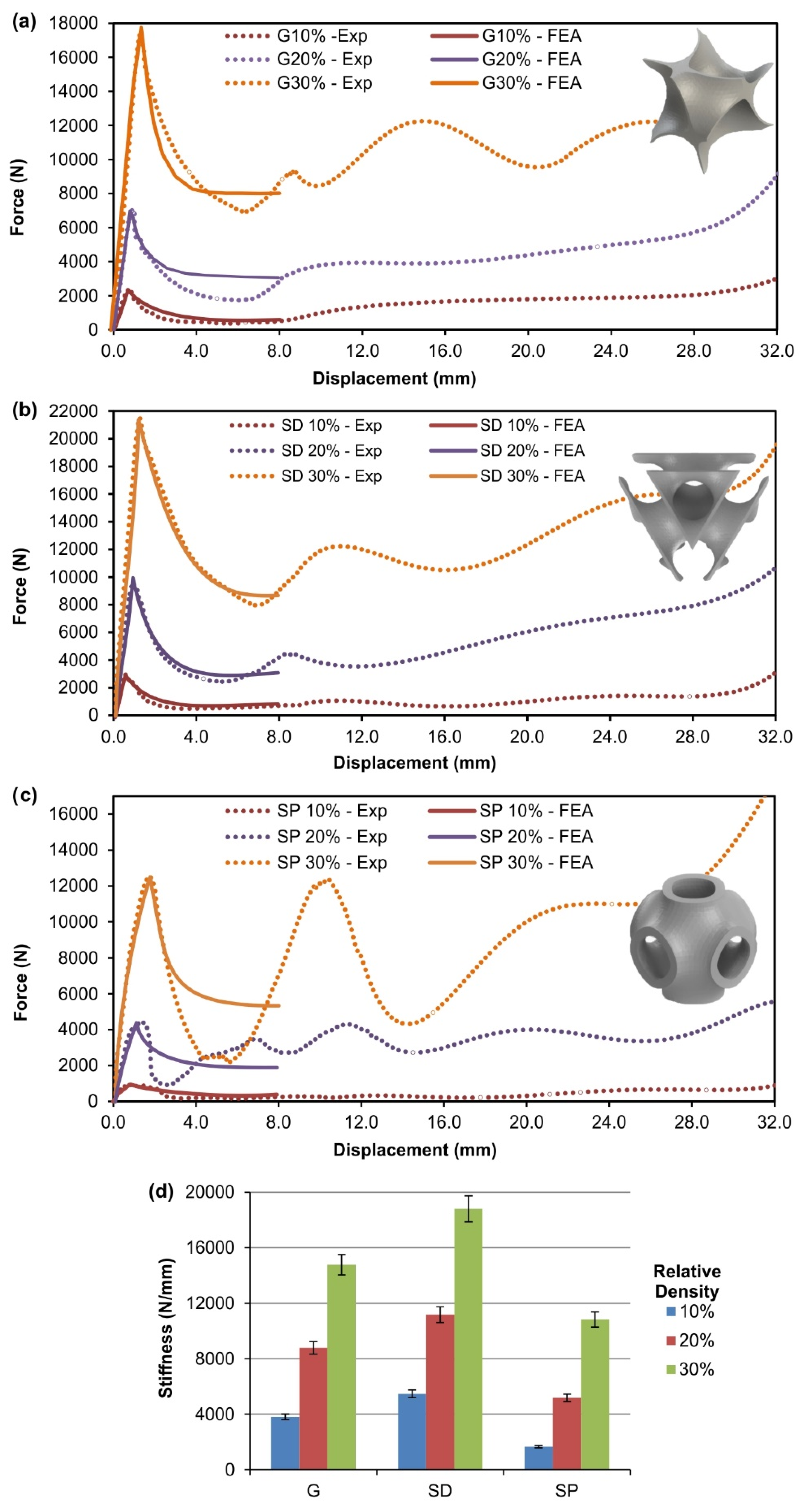

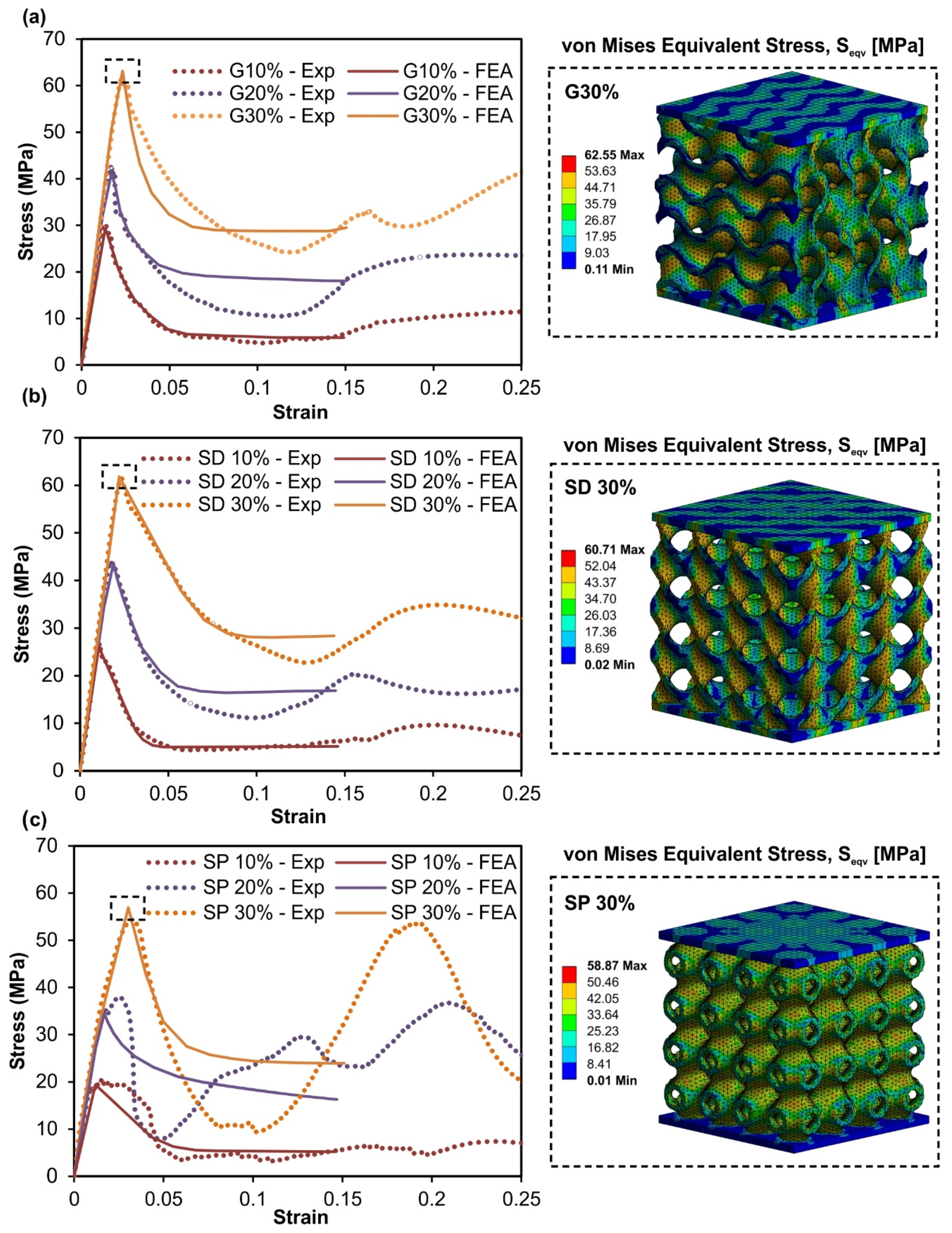

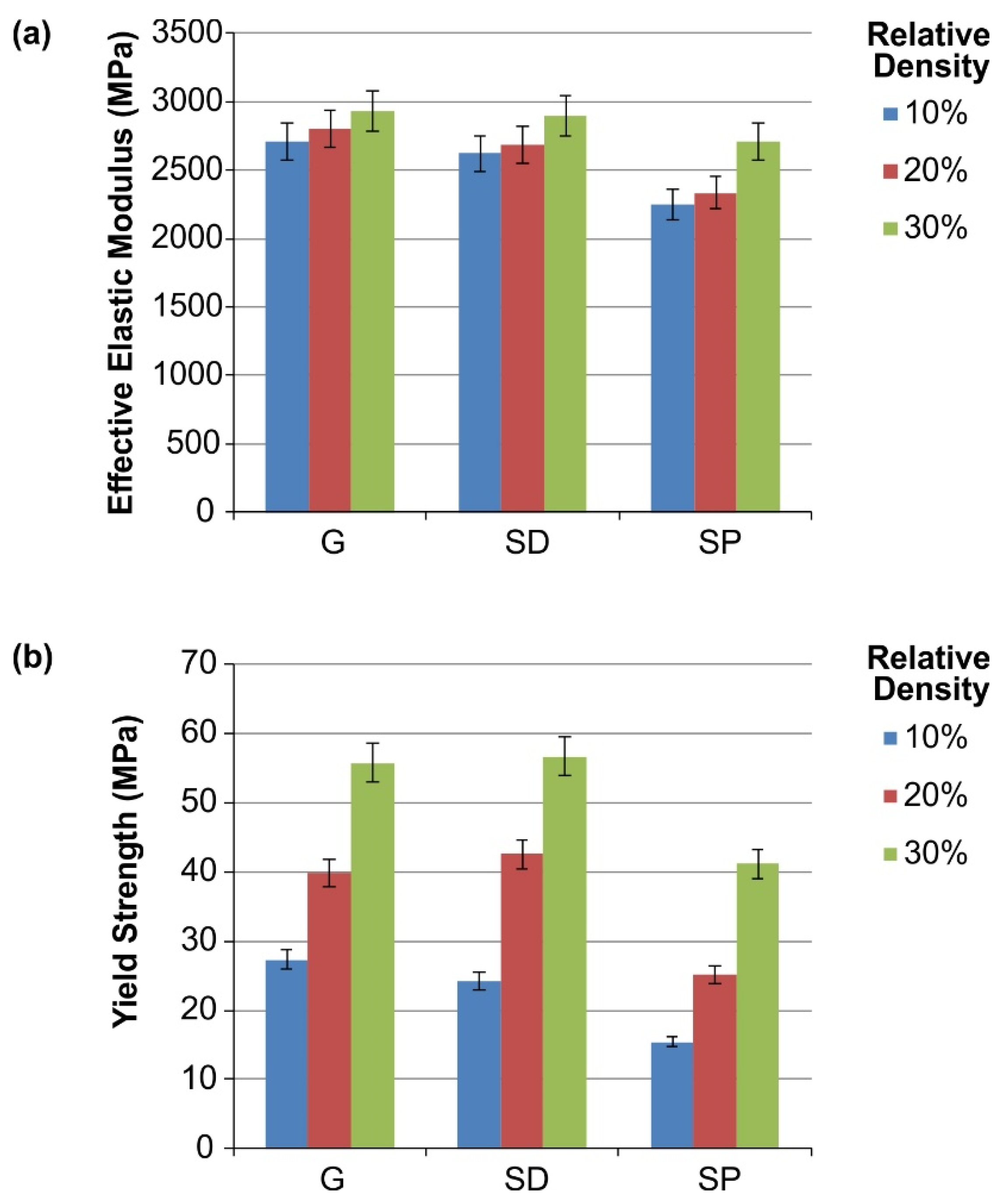

3.3. Mechanical Behavior of FFF TPMS Structures Supported by FEA

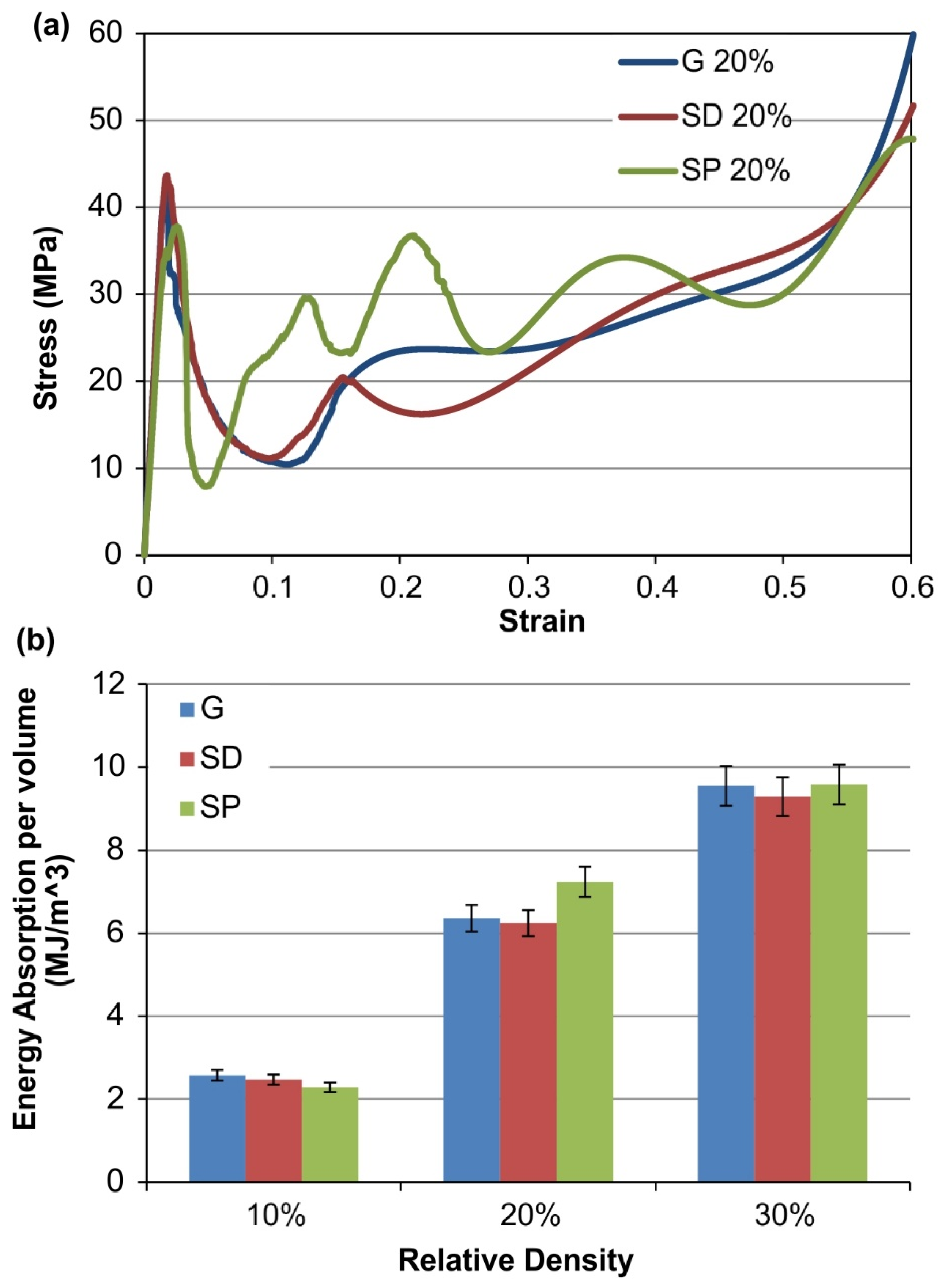

3.4. Energy Absorption of the FFF TPMS Structures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gebisa, A.W.; Lemu, H.G. A case study on topology optimized design for additive manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2017, 276, 12026. [Google Scholar] [CrossRef]

- Rosso, S.; Savio, G.; Uriati, F.; Meneghello, R.; Concheri, G. Optimization Approaches in Design for Additive Manufacturing. Proc. Des. Soc. Int. Conf. Eng. Des. 2019, 1, 809–818. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure & Properties; Pergamon Press: Oxford, UK, 1988; ISBN 0-08-036607-4. [Google Scholar]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Mahmoud, D.; Elbestawi, M.A. Lattice Structures and Functionally Graded Materials Applications in Additive Manufacturing of Orthopedic Implants: A Review. J. Manuf. Mater. Process. 2017, 1, 13. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Finite Element Analysis of Orthopedic Hip Implant with Functionally Graded Bioinspired Lattice Structures. Biomimetics 2020, 5, 44. [Google Scholar] [CrossRef] [PubMed]

- Khanoki, S.A.; Pasini, D. Fatigue design of a mechanically biocompatible lattice for a proof-of-concept femoral stem. J. Mech. Behav. Biomed. Mater. 2013, 22, 65–83. [Google Scholar] [CrossRef]

- Elomaa, L.; Teixeira, S.; Hakala, R.; Korhonen, H.; Grijpma, D.W.; Seppälä, J.V. Preparation of poly(ε-caprolactone)-based tissue engineering scaffolds by stereolithography. Acta Biomater. 2011, 7, 3850–3856. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Chatzidai, N.; Karalekas, D. 3D printing-assisted design of scaffold structures. Int. J. Adv. Manuf. Technol. 2016, 82, 559–571. [Google Scholar] [CrossRef]

- Cabrera, M.S.; Sanders, B.B.; Goor, O.J.; Driessen-Mol, A.A.; Oomens, C.W.; Baaijens, F.P. Computationally Designed 3D Printed Self-Expandable Polymer Stents with Biodegradation Capacity for Minimally Invasive Heart Valve Implantation: A Proof-of-Concept Study. 3D Print. Addit. Manuf. 2017, 4, 19–29. [Google Scholar] [CrossRef]

- Melchiorri, A.J.; Hibino, N.; Best, C.A.; Yi, T.; Lee, Y.U.; Kraynak, C.A.; Kimerer, L.K.; Krieger, A.; Kim, P.; Breuer, C.K.; et al. 3D-Printed Biodegradable Polymeric Vascular Grafts. Adv. Health Mater. 2016, 5, 319–325. [Google Scholar] [CrossRef] [PubMed]

- Tao, W.; Leu, M.C. Design of lattice structure for additive manufacturing. In Proceedings of the 2016 International Symposium on Flexible Automation (ISFA), Cleveland, OH, USA, 1–3 August 2016; pp. 325–332. [Google Scholar] [CrossRef]

- Hurt, C.; Brandt, M.; Priya, S.S.; Bhatelia, T.; Patel, J.; Selvakannan, P.; Bhargava, S. Combining additive manufacturing and catalysis: A review. Catal. Sci. Technol. 2017, 7, 3421–3439. [Google Scholar] [CrossRef]

- Boomsma, K.; Poulikakos, D.; Zwick, F. Metal foams as compact high performance heat exchangers. Mech. Mater. 2003, 35, 1161–1176. [Google Scholar] [CrossRef]

- Simone, A.; Gibson, L. Effects of solid distribution on the stiffness and strength of metallic foams. Acta Mater. 1998, 46, 2139–2150. [Google Scholar] [CrossRef]

- Maskery, I.; Sturm, L.; Aremu, A.; Panesar, A.; Williams, C.; Tuck, C.; Wildman, R.; Ashcroft, I.; Hague, R. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Kaur, M.; Yun, T.G.; Han, S.M.; Thomas, E.L.; Kim, W.S. 3D printed stretching-dominated micro-trusses. Mater. Des. 2017, 134, 272–280. [Google Scholar] [CrossRef]

- Bauer, J.; Meza, L.R.; Schaedler, T.A.; Schwaiger, R.; Zheng, X.; Valdevit, L. Nanolattices: An Emerging Class of Mechanical Metamaterials. Adv. Mater. 2017, 29, 1701850. [Google Scholar] [CrossRef]

- Zhao, M.; Liu, F.; Fu, G.; Zhang, D.Z.; Zhang, T.; Zhou, H. Improved Mechanical Properties and Energy Absorption of BCC Lattice Structures with Triply Periodic Minimal Surfaces Fabricated by SLM. Materials 2018, 11, 2411. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Abu Al-Rub, R.K. Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Li, D.; Liao, W.; Dai, N.; Xie, Y.M. Comparison of Mechanical Properties and Energy Absorption of Sheet-Based and Strut-Based Gyroid Cellular Structures with Graded Densities. Materials 2019, 12, 2183. [Google Scholar] [CrossRef] [PubMed]

- Abueidda, D.W.; Elhebeary, M.; Shiang, C.-S.A.; Pang, S.; Abu Al-Rub, R.K.; Jasiuk, I.M. Mechanical properties of 3D printed polymeric Gyroid cellular structures: Experimental and finite element study. Mater. Des. 2019, 165, 107597. [Google Scholar] [CrossRef]

- Zheng, X.; Fu, Z.; Du, K.; Wang, C.; Yi, Y. Minimal surface designs for porous materials: From microstructures to mechanical properties. J. Mater. Sci. 2018, 53, 10194–10208. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rezgui, R.; Rowshan, R.; Du, H.; Fang, N.X.; Abu Al-Rub, R.K. Microarchitected Stretching-Dominated Mechanical Metamaterials with Minimal Surface Topologies. Adv. Eng. Mater. 2018, 20, 1800029. [Google Scholar] [CrossRef]

- Chua, C.K.; Yeong, W.Y.; Tan, M.J.; Liu, E.J.; Tor, S.B. Study of the influence of 3D printing parameters on the mechanical properties of PLA. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing, Nanyang Executive Centre, Singapore, 14–17 May 2018; pp. 547–552. [Google Scholar]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Zhang, J.W.; Peng, A.H. Process-Parameter Optimization for Fused Deposition Modeling Based on Taguchi Method. Adv. Mater. Res. 2012, 538, 444–447. [Google Scholar] [CrossRef]

- Ang, K.C.; Leong, K.F.; Chua, C.K.; Chandrasekaran, M. Investigation of the mechanical properties and porosity relationships in fused deposition modelling-fabricated porous structures. Rapid Prototyp. J. 2006, 12, 100–105. [Google Scholar] [CrossRef]

- Da Silva, D.; Kaduri, M.; Poley, M.; Adir, O.; Krinsky, N.; Shainsky-Roitman, J.; Schroeder, A. Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem. Eng. J. 2018, 340, 9–14. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Abu Al-Rub, R.K. Multifunctional Mechanical Metamaterials Based on Triply Periodic Minimal Surface Lattices: A review. Adv. Eng. Mater. 2019, 21, 1900524. [Google Scholar] [CrossRef]

- Lord, E.A.; Mackay, A.L. Periodic minimal surfaces of cubic symmetry. Curr. Sci. 2003, 85, 346–362. [Google Scholar]

- Panesar, A.; Abdi, M.; Hickman, D.; Ashcroft, I. Strategies for functionally graded lattice structures derived using topology optimisation for Additive Manufacturing. Addit. Manuf. 2018, 19, 81–94. [Google Scholar] [CrossRef]

- Mansour, G.; Tsongas, K.; Tzetzis, D.; Tzikas, K. Dynamic Mechanical Characterization of Polyurethane/Multiwalled Carbon Nanotube Composite Thermoplastic Elastomers. Polym. Plast. Technol. Eng. 2017, 56, 1505–1515. [Google Scholar] [CrossRef]

- Mansour, M.; Tsongas, K.; Tzetzis, D.; Antoniadis, A. Mechanical and Dynamic Behavior of Fused Filament Fabrication 3D Printed Polyethylene Terephthalate Glycol Reinforced with Carbon Fibers. Polym. Technol. Eng. 2018, 57, 1715–1725. [Google Scholar] [CrossRef]

- Mansour, M.; Tsongas, K.; Tzetzis, D. Measurement of the mechanical and dynamic properties of 3D printed polylactic acid reinforced with graphene. Polym. Plast. Technol. Eng. 2018, 58, 1234–1244. [Google Scholar] [CrossRef]

- Tsongas, K.; Tzetzis, D.; Mansour, G. Mechanical and vibration isolation behaviour of acrylonitrile-butadiene rubber/multi-walled carbon nanotube composite machine mounts. Plast. Rubber Compos. 2017, 46, 458–468. [Google Scholar] [CrossRef]

- Tzetzis, D.; Tsongas, K.; Mansour, G. Determination of the Mechanical Properties of Epoxy Silica Nanocomposites through FEA-Supported Evaluation of Ball Indentation Test Results. Mater. Res. 2017, 20, 1571–1578. [Google Scholar] [CrossRef]

- Walley, S.M.; Field, J.E. Strain rate sensitivity of polymers in compression from low to high rates. DYMAT J. 1994, 1, 211–227. [Google Scholar]

- Khan, K.A.; Abu Al-Rub, R.K. Viscoelastic properties of architected foams based on the Schoen IWP triply periodic minimal surface. Mech. Adv. Mater. Struct. 2020, 27, 775–788. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Granta Material Intelligence. Granta’s CES EduPack; Granta Design Limited: Cambridge, UK, 2007. [Google Scholar]

- Tzetzis, D.; Mansour, G.; Tsiafis, I.; Pavlidou, E. Nanoindentation measurements of fumed silica epoxy reinforced nanocomposites. J. Reinf. Plast. Compos. 2013, 32, 160–173. [Google Scholar] [CrossRef]

- ASTM. ISO/ASTM 52921: 2013 Standard Terminology for Additive Manufacturing–Coordinate Systems and Test Methodologies; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar] [CrossRef]

- Meza, L.R.; Das, S.; Greer, J.R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 2014, 345, 1322–1326. [Google Scholar] [CrossRef] [PubMed]

- Bauer, J.; Hengsbach, S.; Tesari, I.; Schwaiger, R.; Kraft, O. High-strength cellular ceramic composites with 3D microarchitecture. Proc. Natl. Acad. Sci. USA 2014, 111, 2453–2458. [Google Scholar] [CrossRef] [PubMed]

- Mahshid, R.; Hansen, H.N.; Højbjerre, K.L. Strength analysis and modeling of cellular lattice structures manufactured using selective laser melting for tooling applications. Mater. Des. 2016, 104, 276–283. [Google Scholar] [CrossRef]

- Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals; ISO 13314:2011; International Organization for Standardization: Geneva, Switzerland, 2011–2012.

- Sychov, M.; Lebedev, L.; Dyachenko, S.; Nefedova, L. Mechanical properties of energy-absorbing structures with triply periodic minimal surface topology. Acta Astronaut. 2018, 150, 81–84. [Google Scholar] [CrossRef]

| TPMS Structure | Relative Density | ||

|---|---|---|---|

| 10% | 20% | 30% | |

| Thickness Gyroid | 0.65 mm | 1.3 mm | 1.95 mm |

| Thickness Schwarz Diamond | 0.67 mm | 1.33 mm | 2 mm |

| Thickness Schwarz Primitive | 0.54 mm | 1.07 mm | 1.61 mm |

| Printing Parameters | Values |

|---|---|

| Layer Height | 0.2 mm |

| Wall Thickness | 0.54–2 mm (depending on applied unit cell) |

| Infill | 100% |

| Printing Temperature | 210 °C |

| Printing Speed | 60 mm/s |

| Properties PLA | Density (g/cm3) | Elastic Modulus from Nanoindentation Test (MPa) | Elastic Modulus from Compression Tests (MPa) | Compressive Yield Strength (MPa) |

|---|---|---|---|---|

| 1.25 | 3700 ± 115 | 3400 ± 130 | 60 ± 5 |

| TPMS | Relative Density of Lattice Volume | Actual Relative Density | Weight of Specimen (gr.) | Time of Printing |

|---|---|---|---|---|

| Gyroid | 10% | 16.7% | 28.18 | ~4 h |

| 20% | 26.1% | 44.04 | ~5 h and 30 min. | |

| 30% | 35% | 59.06 | ~7 h and 30 min. | |

| Schwarz Diamond | 10% | 16.7% | 28.18 | ~4 h |

| 20% | 26.1% | 44.04 | ~5 h and 30 min. | |

| 30% | 35% | 59.06 | ~7 h and 30 min. | |

| Schwarz Primitive | 10% | 16.7% | 28.18 | ~4 h |

| 20% | 26.1% | 44.04 | ~5 h and 30 min. | |

| 30% | 35% | 59.06 | ~7 h and 30 min. |

| Type of Specimen | Effective Elastic Modulus Elat (MPa) | Compressive Yield Strength (Experimental) σexp (MPa) | Compressive Yield Strength (FEA) σfea (MPa) |

|---|---|---|---|

| Gyroid (ρ = 10%) | 2708 | 27.33 | 27.11 |

| Gyroid (ρ = 20%) | 2804 | 39.82 | 39.89 |

| Gyroid (ρ = 30%) | 2928 | 55.76 | 53.55 |

| Schwarz Diamond (ρ = 10%) | 2624 | 24.17 | 25.83 |

| Schwarz Diamond (ρ = 20%) | 2685 | 42.52 | 39.32 |

| Schwarz Diamond (ρ = 30%) | 2896 | 56.67 | 51.71 |

| Schwarz Primitive (ρ = 10%) | 2250 | 15.44 | 17.61 |

| Schwarz Primitive (ρ = 20%) | 2334 | 25.15 | 33.63 |

| Schwarz Primitive (ρ = 30%) | 2713 | 41.11 | 47.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Mechanical and FEA-Assisted Characterization of Fused Filament Fabricated Triply Periodic Minimal Surface Structures. J. Compos. Sci. 2021, 5, 58. https://doi.org/10.3390/jcs5020058

Kladovasilakis N, Tsongas K, Tzetzis D. Mechanical and FEA-Assisted Characterization of Fused Filament Fabricated Triply Periodic Minimal Surface Structures. Journal of Composites Science. 2021; 5(2):58. https://doi.org/10.3390/jcs5020058

Chicago/Turabian StyleKladovasilakis, Nikolaos, Konstantinos Tsongas, and Dimitrios Tzetzis. 2021. "Mechanical and FEA-Assisted Characterization of Fused Filament Fabricated Triply Periodic Minimal Surface Structures" Journal of Composites Science 5, no. 2: 58. https://doi.org/10.3390/jcs5020058

APA StyleKladovasilakis, N., Tsongas, K., & Tzetzis, D. (2021). Mechanical and FEA-Assisted Characterization of Fused Filament Fabricated Triply Periodic Minimal Surface Structures. Journal of Composites Science, 5(2), 58. https://doi.org/10.3390/jcs5020058