Manufacturing and Performance of Carbon Short Fiber Reinforced Composite Using Various Aluminum Matrix

Abstract

1. Introduction

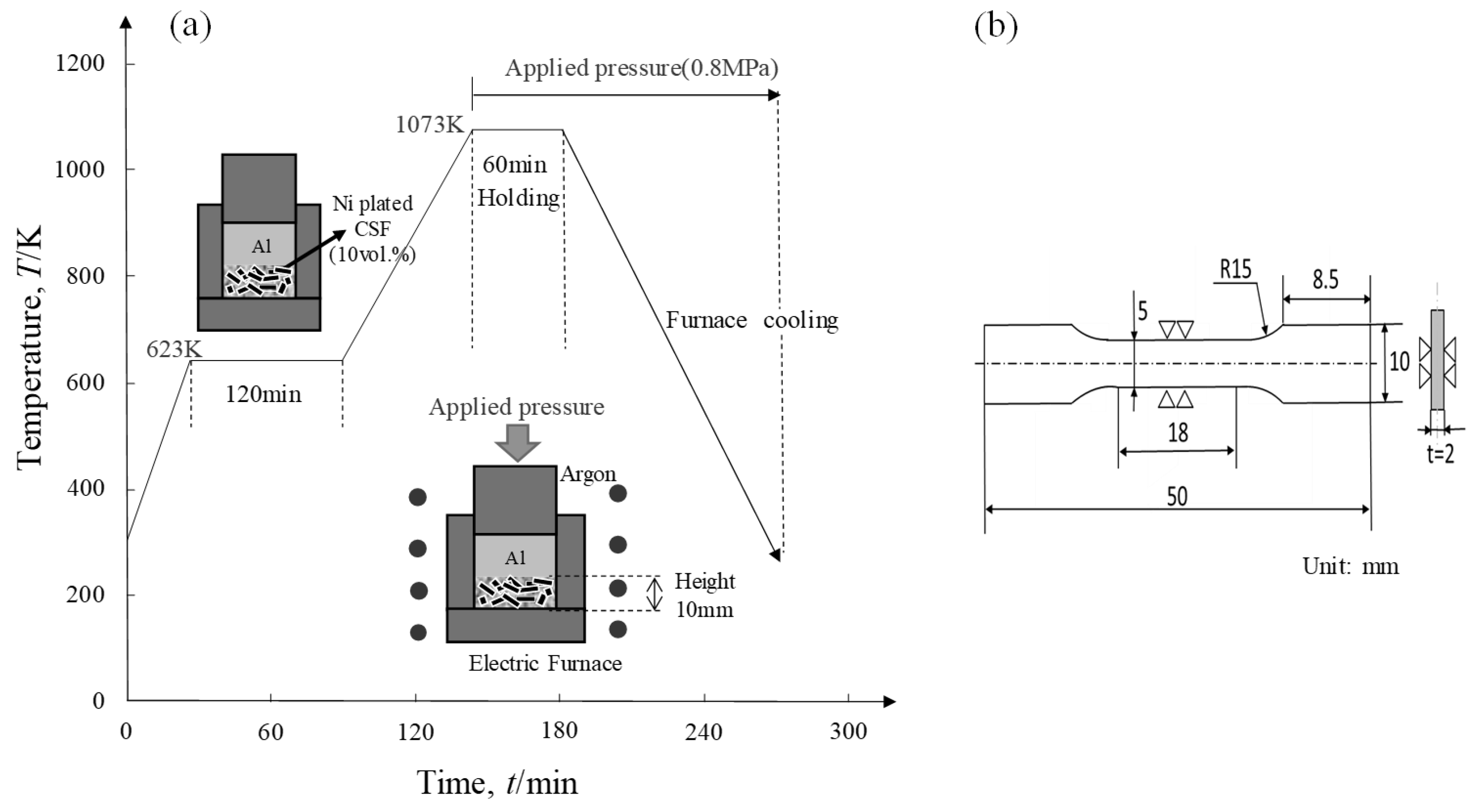

2. Materials and Manufacturing Methods

3. Results

3.1. Thickness of Ni Plated CSFs by Plating Time

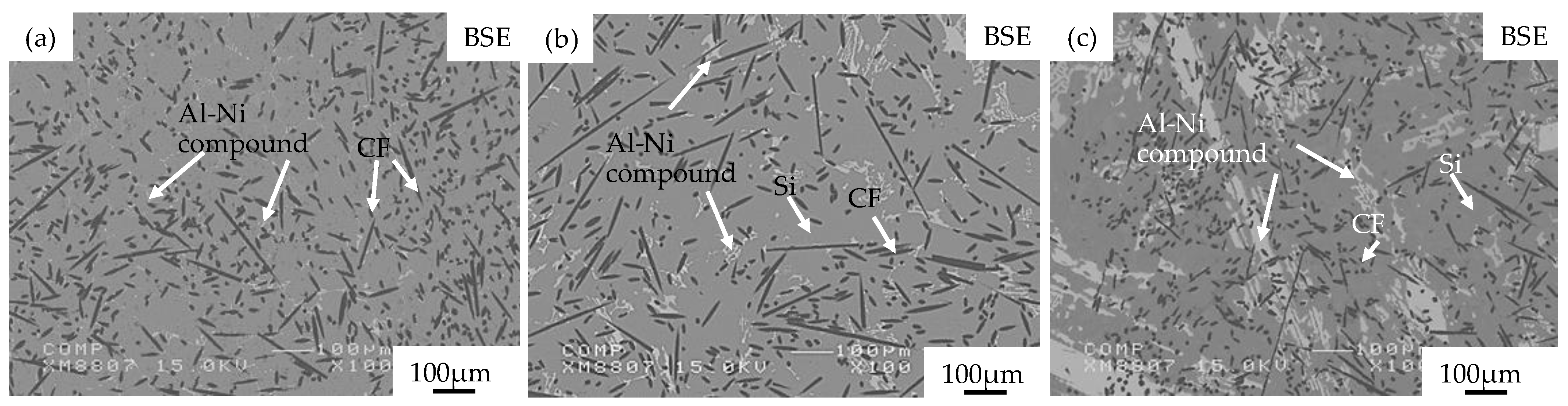

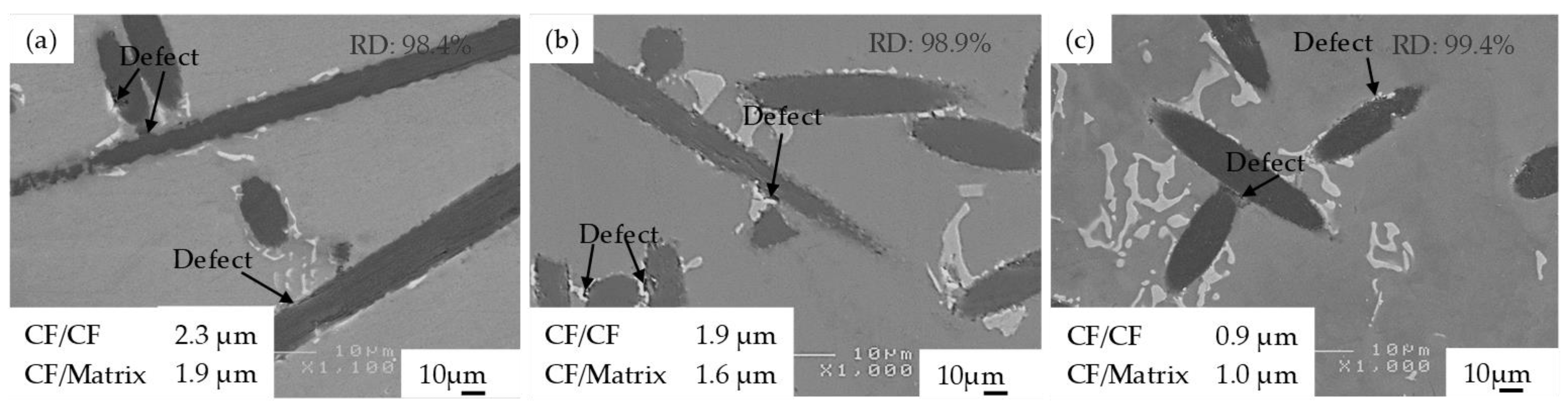

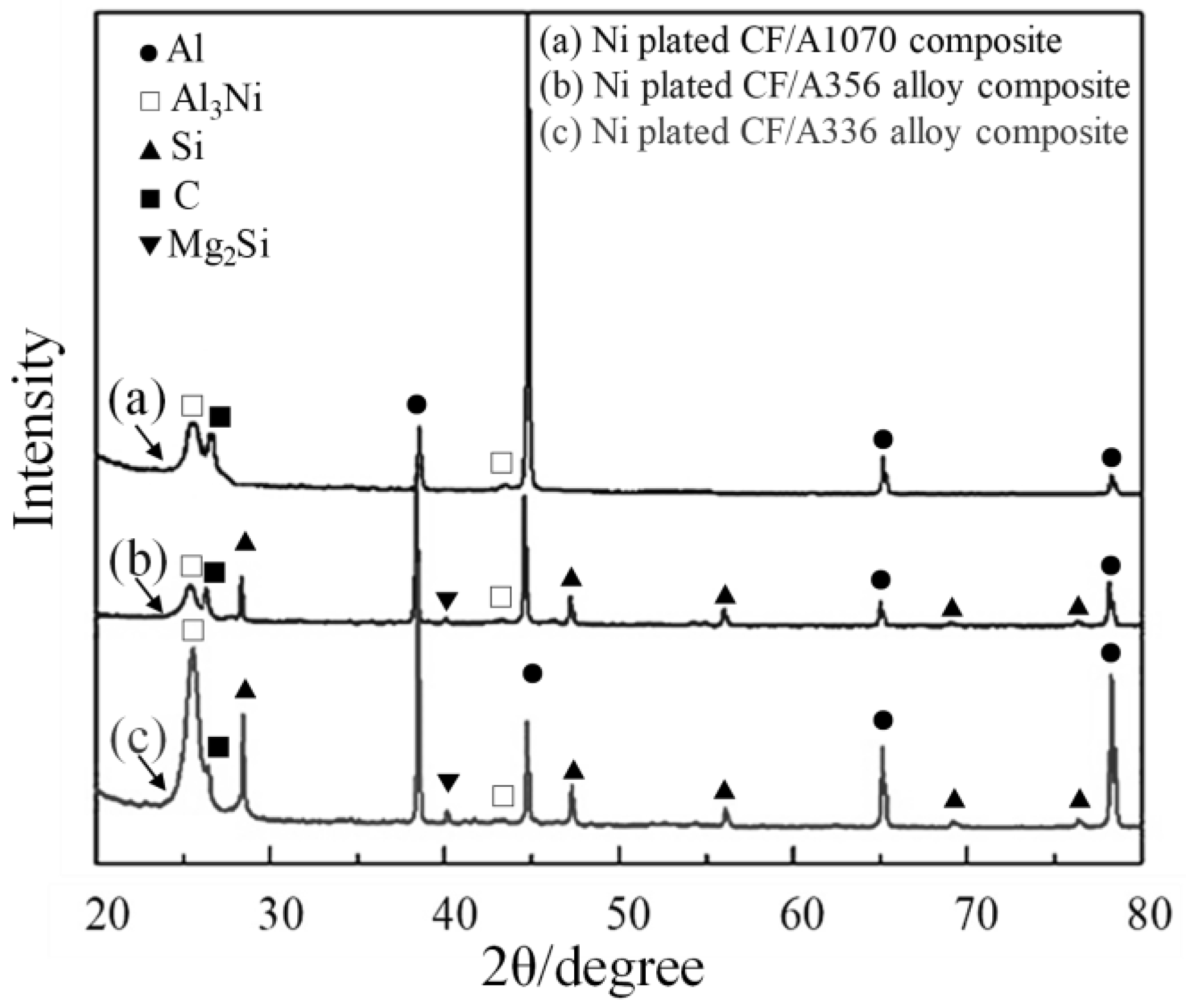

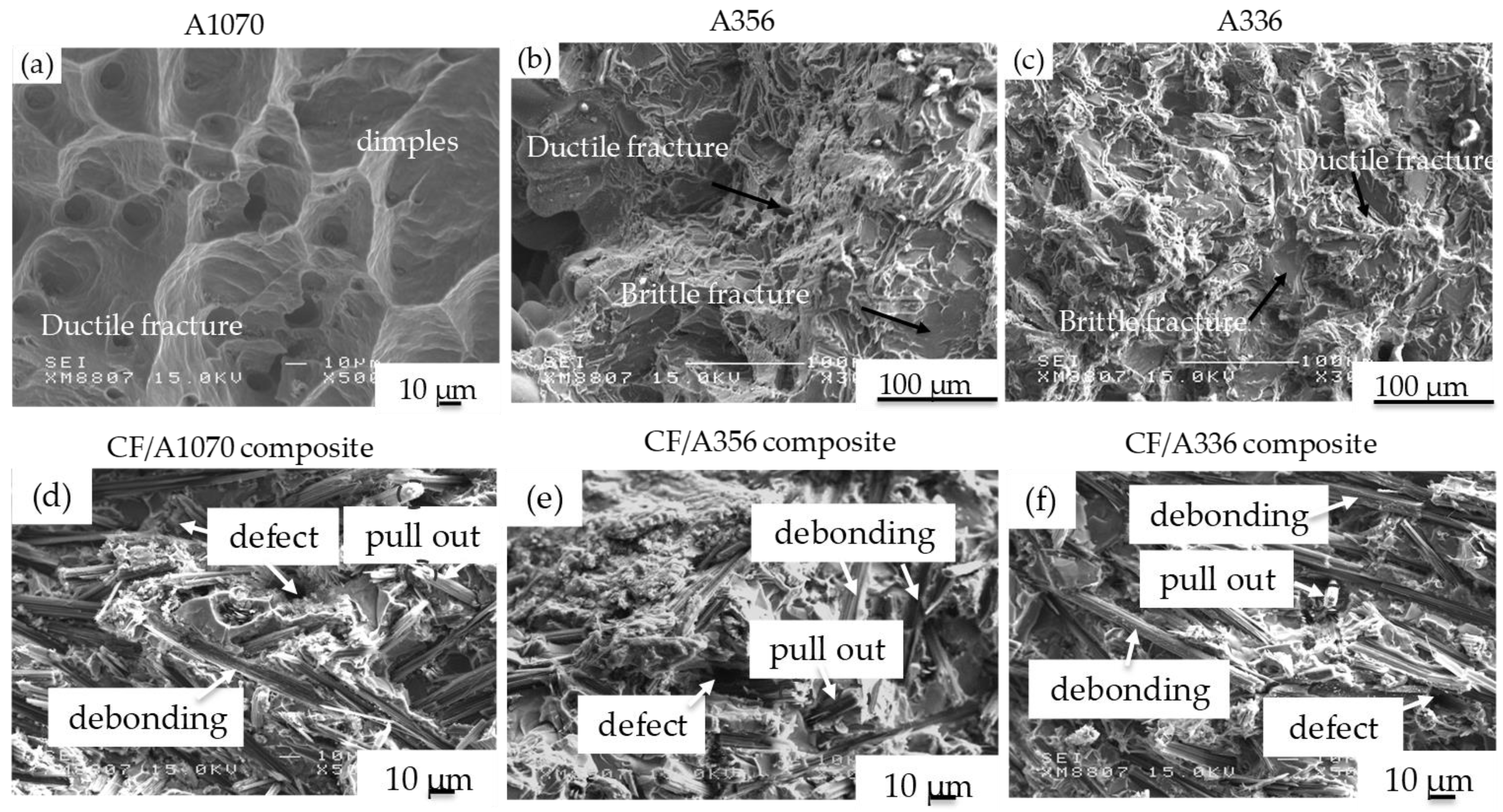

3.2. Microstructures of Ni plated CSF Reinforced Aluminum Matrix Composites

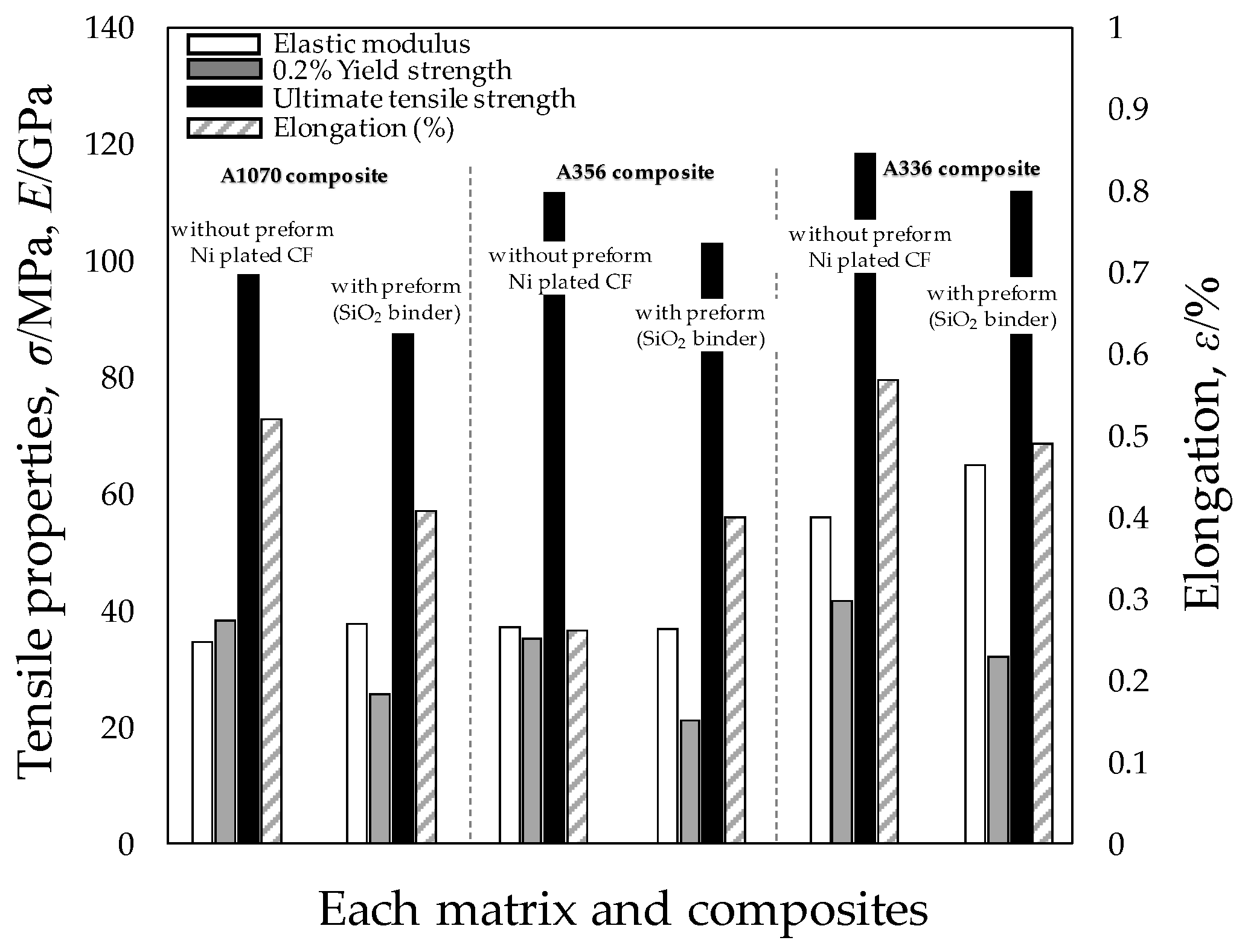

3.3. Hardness and Tensile Strength of Each Matrix and CSF Reinforced Al and Al Alloy Matrix Composites

3.4. Thermal Conductivity of CSF Reinforced Al and Al Alloy Matrix Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Molina, J.; Narciso, J.; Weber, L.; Mortensen, A.; Louis, E. Thermal conductivity of Al-SiC composites with monomodal and bimodal particle size distribution. Mater. Sci. Eng. A 2008, 480, 483–488. [Google Scholar] [CrossRef]

- Euh, K.J.; Kang, S.B. Effect of rolling on the thermon-physical properteis of SiCp/Al composites fabricated by plasma spraying. Mater. Sci. Eng. A 2005, 395, 47–52. [Google Scholar] [CrossRef]

- Ames, W.; Alpas, A.T. Wear mechanisms in hybrid composites of graphite-20 Pct SiC in A 356 alumium alloy. Metall. Mater. Trans. A 1995, 26, 85–98. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C.; Wu, S.Q. Wear of al-badsed hybird composites contating BN and SiC particulates. Metall. Mater. Trans. A 1999, 30, 2551–2555. [Google Scholar] [CrossRef]

- Laffont, L.; Monthioux, M.; Serin, V. Plasmon as a tool for in situ evaluation of physical properties for carbon materials. Carbon 2002, 40, 767–780. [Google Scholar] [CrossRef]

- Chang, K.C.; Matsugi, K.; Sasaki, G.; Yanagisawa, O. Infiluence of fiber surface structure on interface reaction between carbon and alumminum. J. Jpn. Institure Met. 2005, 48, 205–209. [Google Scholar]

- Choi, Y.B.; Sasaki, G.; Matsugi, K.; Yanagisawa, O. Mater. Effect of ultrasonic vibration on infiltration of nickel porous preform with molten aluminum alloy. Mater. Trans. 2005, 46, 2156–2158. [Google Scholar] [CrossRef]

- Choi, Y.B.; Sasaki, G.; Matsugi, K.; Sorida, N.; Kondoh, S.; Fujii, T.; Yanagisawa, O. Simulation of infiltration of molten alloy to porous prefrom using low pressure. Jpn. Soc. Mecahnical Eng. A 2006, 49, 20–24. [Google Scholar]

- Choi, Y.B.; Matsugi, K.; Sasaki, G.; Arita, K.; Yanagisawa, O. Analysis of manufacturing process for metal fiver reinforced aluminum alloy composite fabricated by low pressure casting. Mater. Trans. 2006, 47, 1227–1231. [Google Scholar] [CrossRef][Green Version]

- Bakshi, S.R.; Keshri, A.K.; Singh, V.; Seal, S.; Agarwal, A. Inerface in carbon nanotube reinforced aluminum silicon composites: Thermodynamic analysis and experimental verification. J. Alloys Compouds 2009, 481, 207–213. [Google Scholar] [CrossRef]

- Cui, G.F.; Li, N.; Li, D.; Zheng, J.; Wu, Q.L. The physical and electrochemical properties of eletroless deposited nickel-phosphorus black coating. Surf. Coat. Technol. 2006, 200, 6808–6814. [Google Scholar] [CrossRef]

- Ashassi-Sorkhabi, H.; Rafizadeh, S.H. Effect of coating time and heat treatment on structures and corrosion characteristics of electroless Ni-P alloy deposits. Surf. Coat. Technol. 2004, 176, 318–326. [Google Scholar] [CrossRef]

- Meng, X.; Choi, Y.B.; Matsugi, K.; Liu, W. Development of carbon short fiber reinforced al based composite without preform manufacturing. Mater. Trans. 2020, 61, 1041–1044. [Google Scholar] [CrossRef]

- Terada, Y.; Ohkubo, K.; Mohri, T.; Suzuki, T. Thermal conductivity. Metall. Mater. Trans. A 2003, 34, 3167–3176. [Google Scholar] [CrossRef]

| Plating Time (s) | Ni/CSF (Vol.%) | Ni/CSF (Wt.%) | Density of Ni Plated CSF (g/cm3) | Ni Plated Thickness (μm) |

|---|---|---|---|---|

| 0 | — | — | — | — |

| 60 | 2.8 | 11.5 | 2.37 | |

| 90 | 4.3 | 17.5 | 2.47 | |

| 120 | 5.3 | 22.5 | 2.53 | |

| 180 | 7.9 | 32.0 | 2.70 |

| CSF/Al1070 Composite | CSF/A356 Composite | CSF/A336 Composite | |||||

|---|---|---|---|---|---|---|---|

| CSFs Vol.% | Al-Ni Compounds Vol.% | CSFs vol.% | Al-Ni Compounds Vol.% | Si Vol.% | CSFs vol.% | Al-Ni Compounds Vol.% | Si Vol.% |

| 13.7 | 3.6 | 13.0 | 3.6 | 8.0 | 13.5 | 8.4 | 15.2 |

| Position | Composition (at%) | Al:Ni | Al-Ni Phase | |

|---|---|---|---|---|

| Al | Ni | |||

| 1 | 72.45 | 23.36 | 03:01 | Al3Ni |

| 2 | 74.86 | 22.58 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, Y.; Meng, X.; Xu, Z. Manufacturing and Performance of Carbon Short Fiber Reinforced Composite Using Various Aluminum Matrix. J. Compos. Sci. 2021, 5, 307. https://doi.org/10.3390/jcs5120307

Choi Y, Meng X, Xu Z. Manufacturing and Performance of Carbon Short Fiber Reinforced Composite Using Various Aluminum Matrix. Journal of Composites Science. 2021; 5(12):307. https://doi.org/10.3390/jcs5120307

Chicago/Turabian StyleChoi, Yongbum, Xuan Meng, and Zhefeng Xu. 2021. "Manufacturing and Performance of Carbon Short Fiber Reinforced Composite Using Various Aluminum Matrix" Journal of Composites Science 5, no. 12: 307. https://doi.org/10.3390/jcs5120307

APA StyleChoi, Y., Meng, X., & Xu, Z. (2021). Manufacturing and Performance of Carbon Short Fiber Reinforced Composite Using Various Aluminum Matrix. Journal of Composites Science, 5(12), 307. https://doi.org/10.3390/jcs5120307