Mechanical and Electrical Properties of Injection-Molded MWCNT-Reinforced Polyamide 66 Hybrid Composites

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

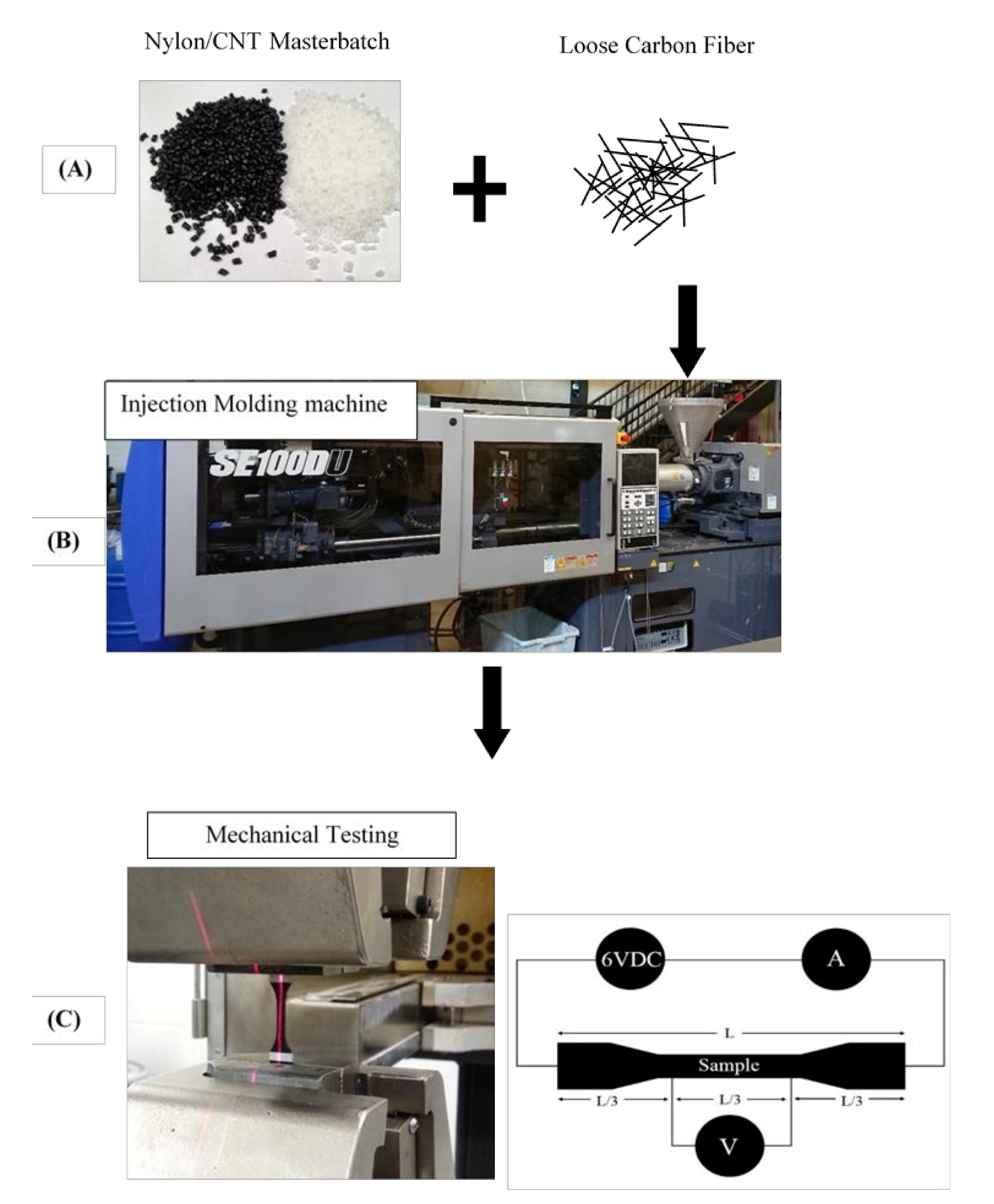

2.2. Manufacturing Process

2.2.1. Material Preparation

2.2.2. Injection Molding Process

2.3. Specimen Geometry

2.4. Mechanical Testing

2.5. Electrical Conductivity Testing

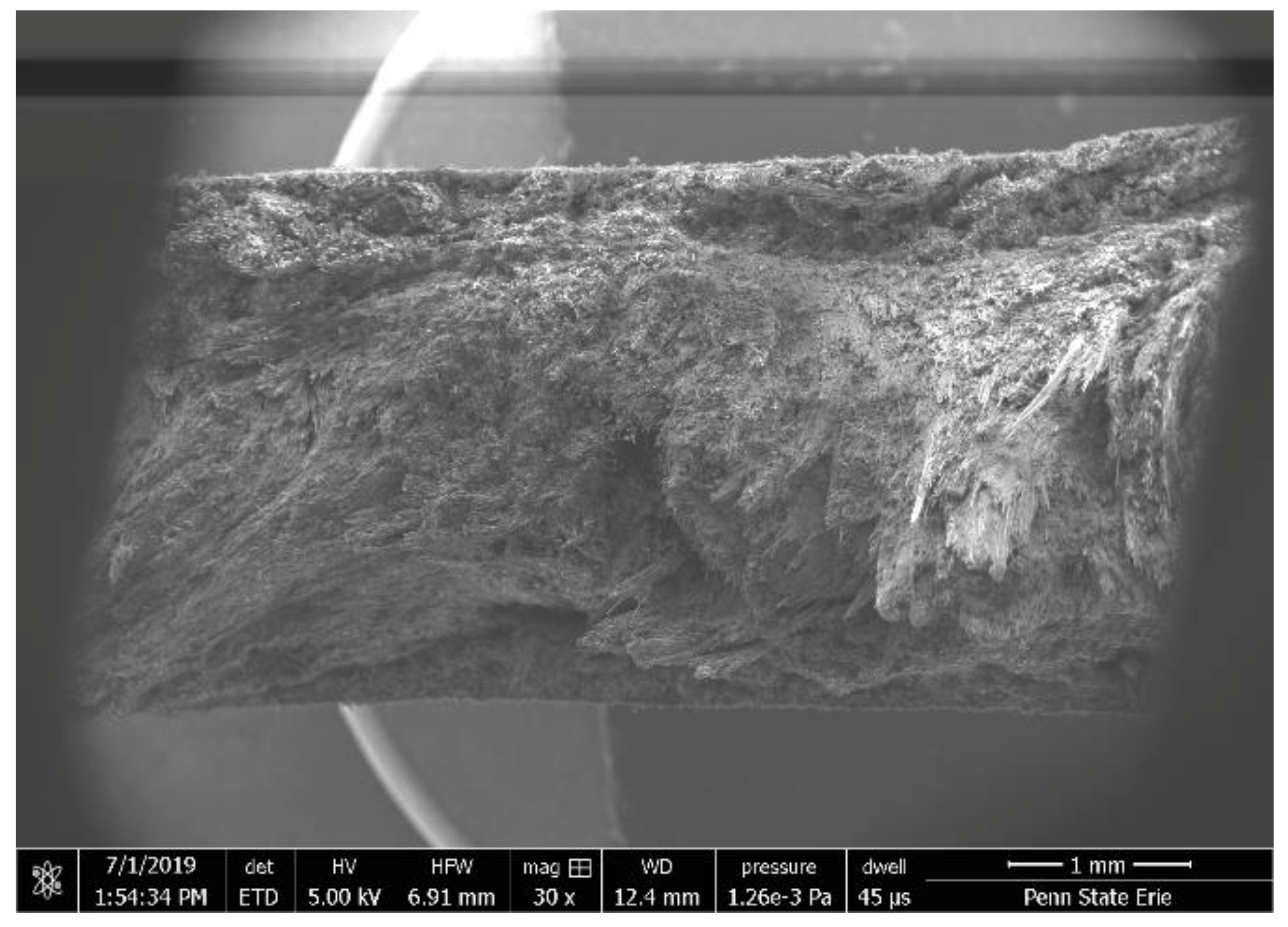

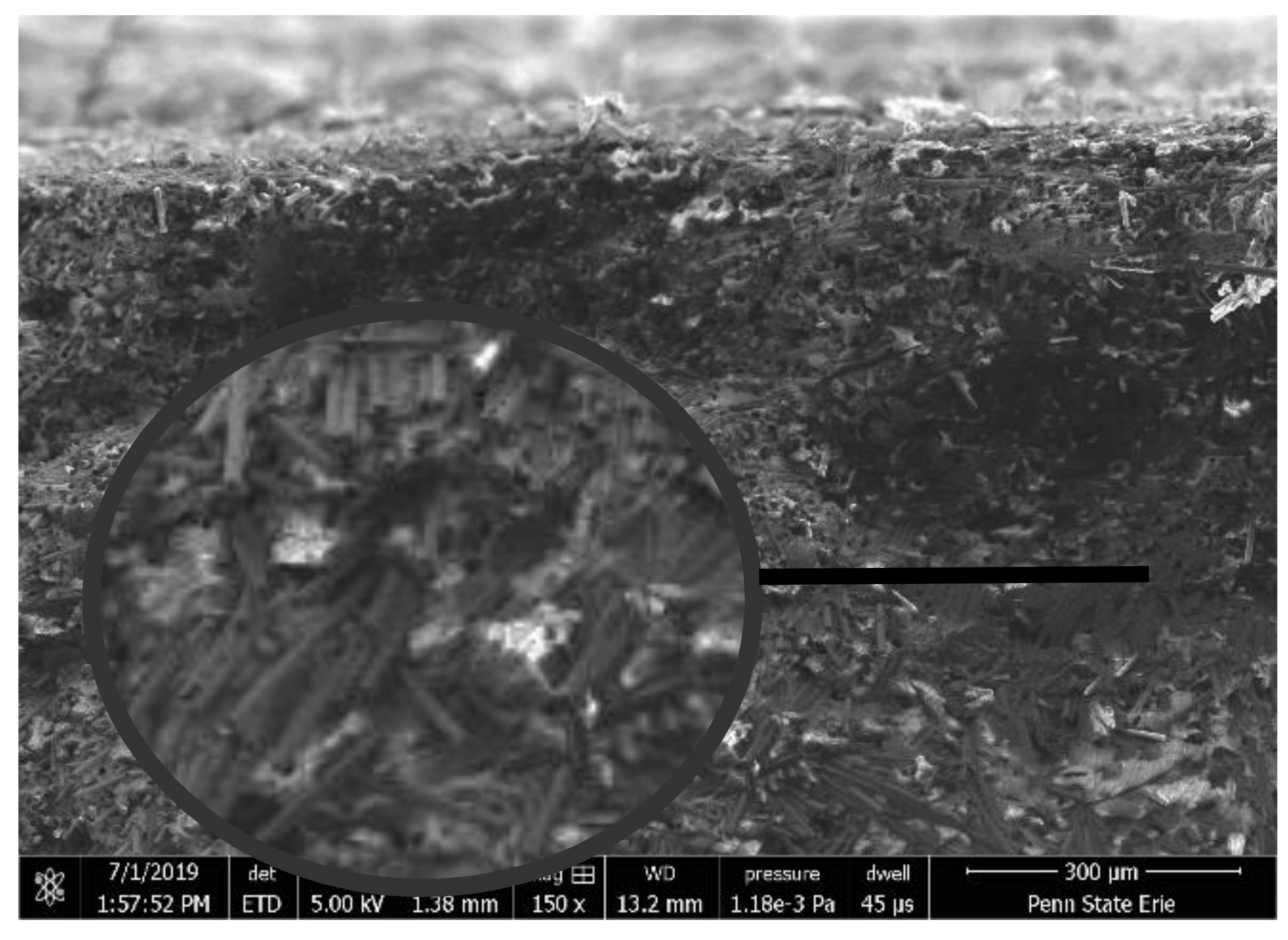

3. Microstructural Analysis

4. Results and Discussion

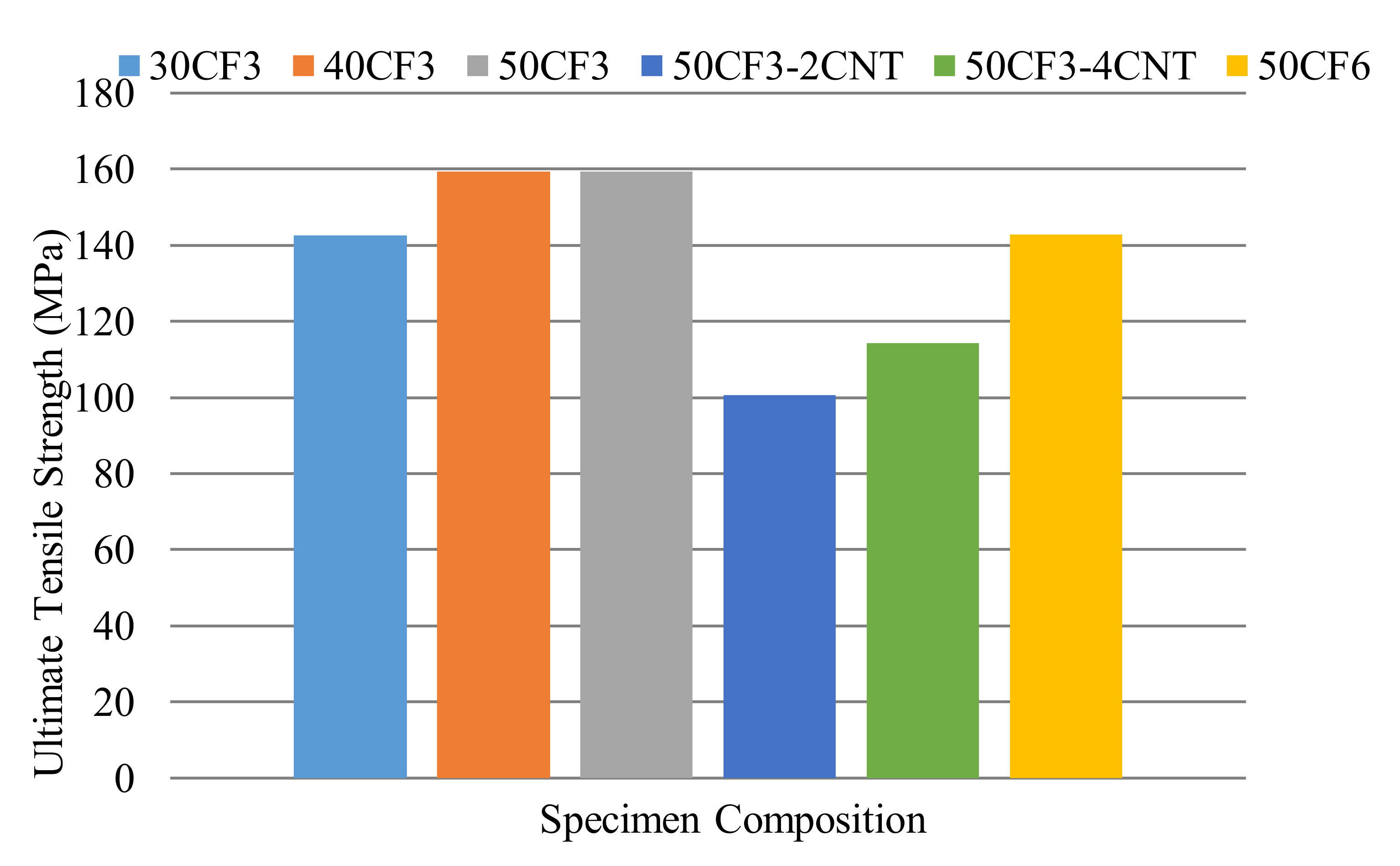

4.1. Ultimate Tensile Strength

4.2. Tensile Modulus of Elasticity

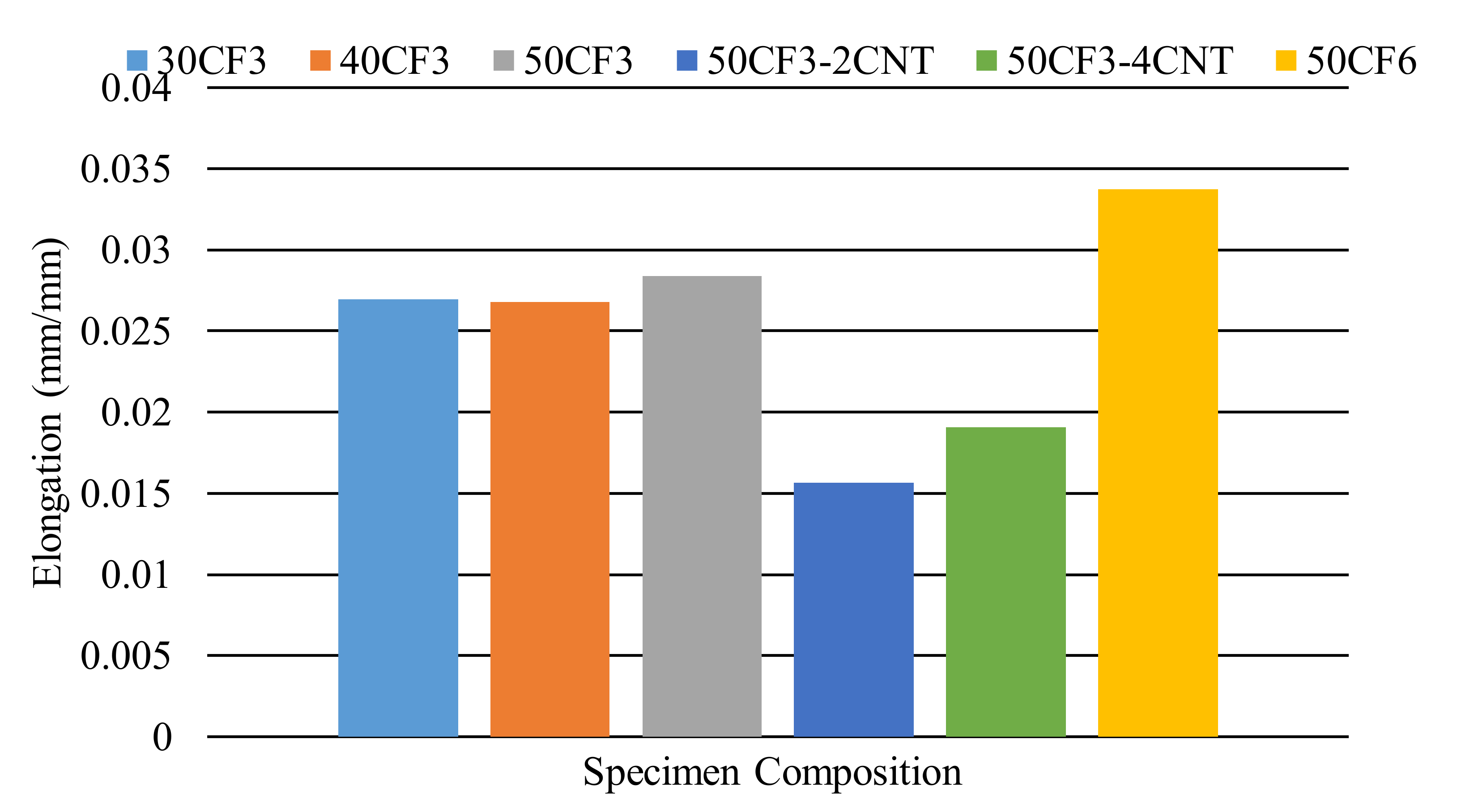

4.3. Elongation

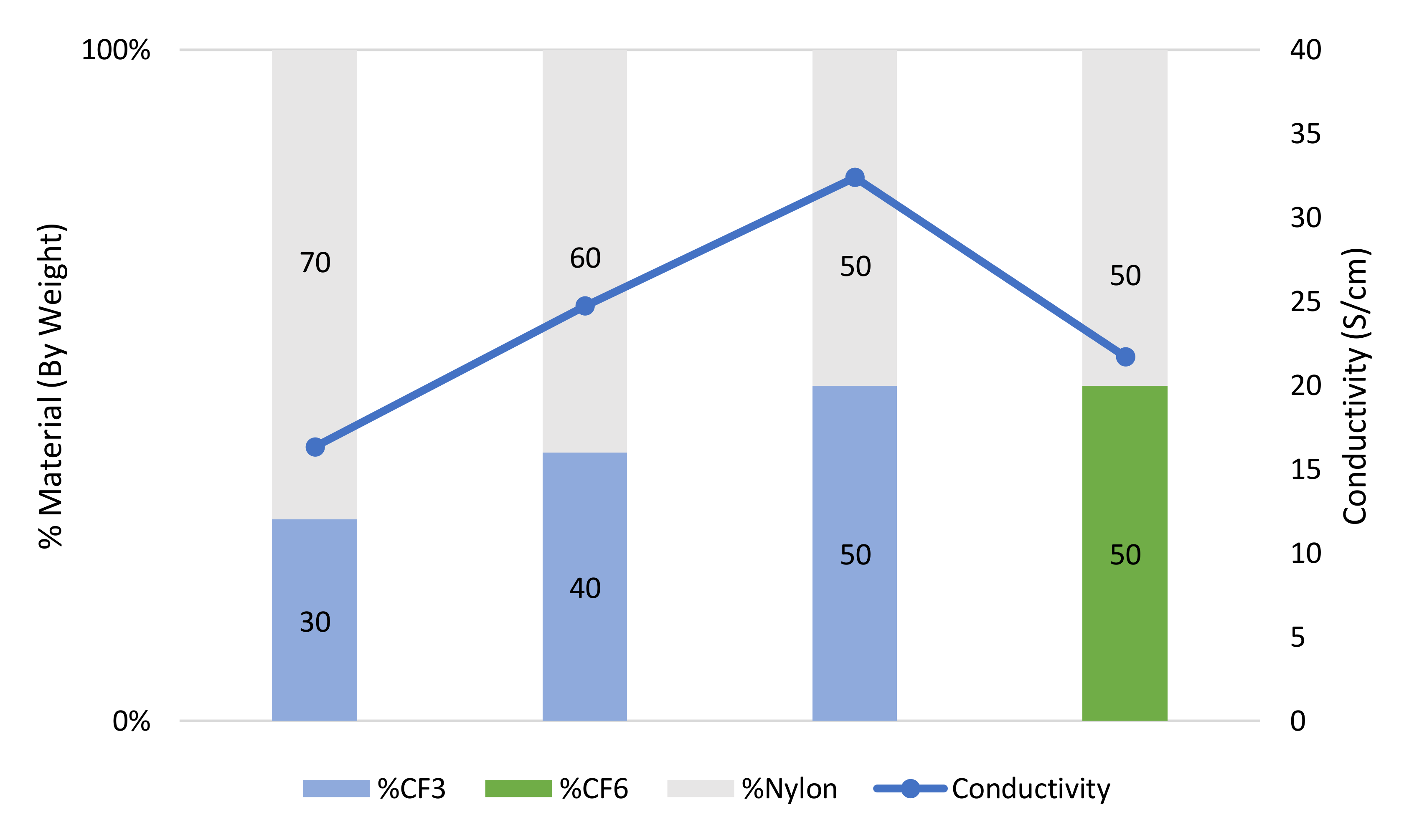

4.4. Electrical Conductivity: Carbon Fibers

4.5. Electrical Conductivity: Carbon Fibers and Carbon Nanotubes

4.6. Core Conductivity

5. Conclusions

- The addition of carbon nanotubes to the CF3 composite specimen decreases the ultimate tensile strength by 20% or more.

- The addition of carbon nanotubes to the CF3 composite specimen decreases elongation by 30% or more.

- Longer carbon fibers at the same loading content have higher elongation.

- The addition of carbon nanotubes increases the variability in testing, indicating an increase in uncertainty in microstructure.

- Composites with 3 mm carbon fiber fillers showed higher conductivity compared to composites with 6 mm carbon fiber, as shorter fibers are more likely to form agglomerated regions, thereby creating a high conductive pathway. Such agglomeration regions may decrease mechanical properties while enhancing electrical conductivity.

- Adding CNTs to the composite matrix further increases electrical conductivity by bridging carbon fibers to form a stronger conductive network.

- Despite the presence of a nylon frozen layer, the conductivity does not change across the thickness and results show that the surface and core of the composite specimen have less than a 3% difference in electrical conductivity.

- Increasing the filler content can have conflicting effects on mechanical and electrical properties; a study on the optimization of filler content is an important future study.

- Evaluating the effect of CNTs with different lengths can be studied in the future to evaluate their effect on both electrical and mechanical properties.

Author Contributions

Funding

Conflicts of Interest

References

- Thostenson, E.T.; Chou, T.-W. Aligned multi-walled carbon nanotube-reinforced composites: Processing and mechanical characterization. J. Phys. D Appl. Phys. 2002, 35, L77–L80. [Google Scholar] [CrossRef]

- Rafii-Tabar, H. Computational modelling of thermo-mechanical and transport properties of carbon nanotubes. Phys. Rep. 2004, 390, 235–452. [Google Scholar] [CrossRef]

- Sanei, S.H.R.; Drozynski, H.; Hetrick, D. Effect of strain rate on tensile properties of injection molded multiwall carbon nanotube reinforced PA6/6 nanocomposites. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition, London, UK, 16–19 November 2020; pp. 1–6. [Google Scholar]

- Moisala, A.; Li, Q.; Kinloch, I.A.; Windle, A.H. Thermal and electrical conductivity of single- and multi-walled carbon nanotube-epoxy composites. Compos. Sci. Technol. 2006, 66, 1285–1288. [Google Scholar] [CrossRef]

- Biercuk, M.J.; Llaguno, M.C.; Radosavljevic, M.; Hyun, J.K.; Johnson, A.T.; Fischer, J.E. Carbon nanotube composites for thermal management. Appl. Phys. Lett. 2002, 80, 2767–2769. [Google Scholar] [CrossRef]

- Yang, K.; Gu, M.; Guo, Y.; Pan, X.; Mu, G. Effects of carbon nanotube functionalization on the mechanical and thermal properties of epoxy composites. Carbon 2009, 47, 1723–1737. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, P.; Du, J.; Zhao, L.; Ajayan, P.M.; Cheng, H.-M. Increasing the electrical conductivity of carbon nanotube/polymer composites by using weak nanotube–polymer interactions. Carbon 2010, 48, 3551–3558. [Google Scholar] [CrossRef]

- Sanei, S.H.R.; Barsotti, E.J.; Leonhardt, D.; Fertig, R.S. Characterization, synthetic generation, and statistical equivalence of composite microstructures. J. Compos. Mater. 2016, 51, 1817–1829. [Google Scholar] [CrossRef]

- Sanei, S.H.R.; Fertig, R.S. Uncorrelated volume element for stochastic modeling of microstructures based on local fiber volume fraction variation. Compos. Sci. Technol. 2015, 117, 191–198. [Google Scholar] [CrossRef]

- Sanei, S.H.; Doles, R.; Ekaitis, T.; Sanei, S.H.R. Effect of Nanocomposite Microstructure on Stochastic Elastic Properties: An Finite Element Analysis Study. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B Mech. Eng. 2019, 5, 1–6. [Google Scholar] [CrossRef]

- Park, J.P.; Mohanty, S.; Bahn, C.B.; Majumdar, S.; Natesan, K. Weibull and Bootstrap Based Data-Analytics Framework for Fatigue Life Prognosis of Pressurized Water Nuclear Reactor Component under Harsh Reactor Coolant Environment. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2019, 142, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Dotchev, P.; Sanei, S.H.R.; Steinmetz, E.; Williams, J. Nanocomposites: Manufacturing, Microstructural Characterization and Mechanical Testing. Am. Soc. Compos. 2018. [Google Scholar] [CrossRef]

- Xu, X.; Sanei, S.H.R.; Steinmetz, E.; Gohn, A.; Williams, J. Effect of microstructure uncertainty and testing frequency on storage and loss moduli of injection molded MWCNT reinforced polyamide 66 nanocomposites. Polym. Test. 2020, 85, 106455. [Google Scholar] [CrossRef]

- Thongruang, W.; Spontak, R.J.; Balik, C.M. Correlated electrical conductivity and mechanical property analysis of high-density polyethylene filled with graphite and carbon fiber. Polymer 2002, 43, 2279–2286. [Google Scholar] [CrossRef]

- Xu, J.; Donohoe, J.P.; Pittman, C.U. Preparation, electrical and mechanical properties of vapor grown carbon fiber (VGCF)/vinyl ester composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 693–701. [Google Scholar] [CrossRef]

- Wu, M.; Shaw, L.L. On the improved properties of injection-molded, carbon nanotube-filled PET/PVDF blends. J. Power Sources 2004, 136, 37–44. [Google Scholar] [CrossRef]

- Wu, M.; Shaw, L. Electrical and mechanical behaviors of carbon nanotube-filled polymer blends. J. Appl. Polym. Sci. 2005, 99, 477–488. [Google Scholar] [CrossRef]

- Liang, J.-Z.; Yang, Q.-Q. Effects of carbon fiber content and size on electric conductive properties of reinforced high density polyethylene composites. Compos. Part B Eng. 2017, 114, 457–466. [Google Scholar] [CrossRef]

- Dweiri, R.; Sahari, J. Electrical properties of carbon-based polypropylene composites for bipolar plates in polymer electrolyte membrane fuel cell (PEMFC). J. Power Sources 2007, 171, 424–432. [Google Scholar] [CrossRef]

- Heiser, J.A.; King, J.A.; Konell, J.P.; Sutter, L.L. Electrical conductivity of carbon filled nylon 6,6. Adv. Polym. Technol. 2004, 23, 135–146. [Google Scholar] [CrossRef]

- Mighri, F.; Huneault, M.A.; Champagne, M.F. Electrically conductive thermoplastic blends for injection and compression molding of bipolar plates in the fuel cell application. Polym. Eng. Sci. 2004, 44, 1755–1765. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, H.; Li, G.; Dai, K.; Zheng, G.; Liu, C.; Shen, C. Synergistic effect of carbon fibers on the conductive properties of a segregated carbon black/polypropylene composite. Mater. Lett. 2014, 129, 72–75. [Google Scholar] [CrossRef]

- Wen, M.; Sun, X.; Su, L.; Shen, J.; Li, J.; Guo, S. The electrical conductivity of carbon nanotube/carbon black/polypropylene composites prepared through multistage stretching extrusion. Polymer 2012, 53, 1602–1610. [Google Scholar] [CrossRef]

- Zhu, X.-D.; Zang, C.-G.; Jiao, Q.-J. High electrical conductivity of nylon 6 composites obtained with hybrid multiwalled carbon nanotube/carbon fiber fillers. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Sulong, A.B.; Sahari, J. A review of electrical conductivity models for conductive polymer composite. Int. J. Hydrog. Energy 2017, 42, 9262–9273. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Simplification and development of McLachlan model for electrical conductivity of polymer carbon nanotubes nanocomposites assuming the networking of interphase regions. Compos. Part B Eng. 2019, 156, 64–71. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y.; Park, S.-J. A developed equation for electrical conductivity of polymer carbon nanotubes (CNT) nanocomposites based on Halpin-Tsai model. Results Phys. 2019, 14, 102406. [Google Scholar] [CrossRef]

- Sander, M.L.; Pritts, J.T.; Young, B.A.; Santamaria, A.D.; Hollinger, A.S. Electrically Conductive Polymer Composites for Injection-Molded Bipolar Plates. Eur. Fuel Cell Technol. Appl. Conf. 2017, 361–362. [Google Scholar] [CrossRef]

| Specimen Name | Reinforcement | Matrix (Nylon 6,6) Content | ||

|---|---|---|---|---|

| MWCNT Content | Carbon Fiber Content | Carbon Fiber Length | ||

| 30CF3 | 0% | 30% | 3 mm | 70% |

| 40CF3 | 0% | 40% | 3 mm | 60% |

| 50CF3 | 0% | 50% | 3 mm | 50% |

| 50CF3-2CNT | 2% | 50% | 3 mm | 48% |

| 50CF3-4CNT | 4% | 50% | 3 mm | 46% |

| 50CF6 | 0% | 50% | 6 mm | 50% |

| Composition | 30% CF3 | 40% CF3 | 50% CF3 | 50% CF3 + 2% CNT | 50% CF3 + 4% CNT | 50% CF6 |

|---|---|---|---|---|---|---|

| Average (MPa) | 142.67 | 159.50 | 159.27 | 100.70 | 114.23 | 142.78 |

| Coeff. of Variation (%) | 20.1 | 4.1 | 15.5 | 23.3 | 27.7 | 8.8 |

| Composition | 30% CF3 | 40% CF3 | 50% CF3 | 50% CF3 + 2% CNT | 50% CF3 + 4% CNT | 50% CF6 |

|---|---|---|---|---|---|---|

| Mean (MPa) | 9379.5 | 9812.9 | 9875.4 | 10,322 | 9771.1 | 9845.9 |

| Coeff. of Variation (%) | 19.2 | 8.3 | 9.5 | 2.9 | 18.6 | 8.7 |

| Composition | 30% CF3 | 40% CF3 | 50% CF3 | 50% CF3 + 2% CNT | 50% CF3 + 4% CNT | 50% CF6 |

|---|---|---|---|---|---|---|

| Mean (mm/mm) | 0.026957 | 0.02677 | 0.028407 | 0.01567 | 0.019068 | 0.033723 |

| Coeff. of Variation (%) | 1.2 | 1.2 | 1.5 | 27.8 | 20.1 | 3.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zameroski, R.; Kypta, C.J.; Young, B.A.; Sanei, S.H.R.; Hollinger, A.S. Mechanical and Electrical Properties of Injection-Molded MWCNT-Reinforced Polyamide 66 Hybrid Composites. J. Compos. Sci. 2020, 4, 177. https://doi.org/10.3390/jcs4040177

Zameroski R, Kypta CJ, Young BA, Sanei SHR, Hollinger AS. Mechanical and Electrical Properties of Injection-Molded MWCNT-Reinforced Polyamide 66 Hybrid Composites. Journal of Composites Science. 2020; 4(4):177. https://doi.org/10.3390/jcs4040177

Chicago/Turabian StyleZameroski, Ross, Chadwick J. Kypta, Brian A. Young, Seyed Hamid Reza Sanei, and Adam S. Hollinger. 2020. "Mechanical and Electrical Properties of Injection-Molded MWCNT-Reinforced Polyamide 66 Hybrid Composites" Journal of Composites Science 4, no. 4: 177. https://doi.org/10.3390/jcs4040177

APA StyleZameroski, R., Kypta, C. J., Young, B. A., Sanei, S. H. R., & Hollinger, A. S. (2020). Mechanical and Electrical Properties of Injection-Molded MWCNT-Reinforced Polyamide 66 Hybrid Composites. Journal of Composites Science, 4(4), 177. https://doi.org/10.3390/jcs4040177