Poly(ε-Caprolactone)/Brewers’ Spent Grain Composites—The Impact of Filler Treatment on the Mechanical Performance

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Extrusion Grinding of BSG

2.3. Preparation of Polymer Composites

2.4. Measurements

3. Results and Discussion

3.1. Spectroscopic Analysis

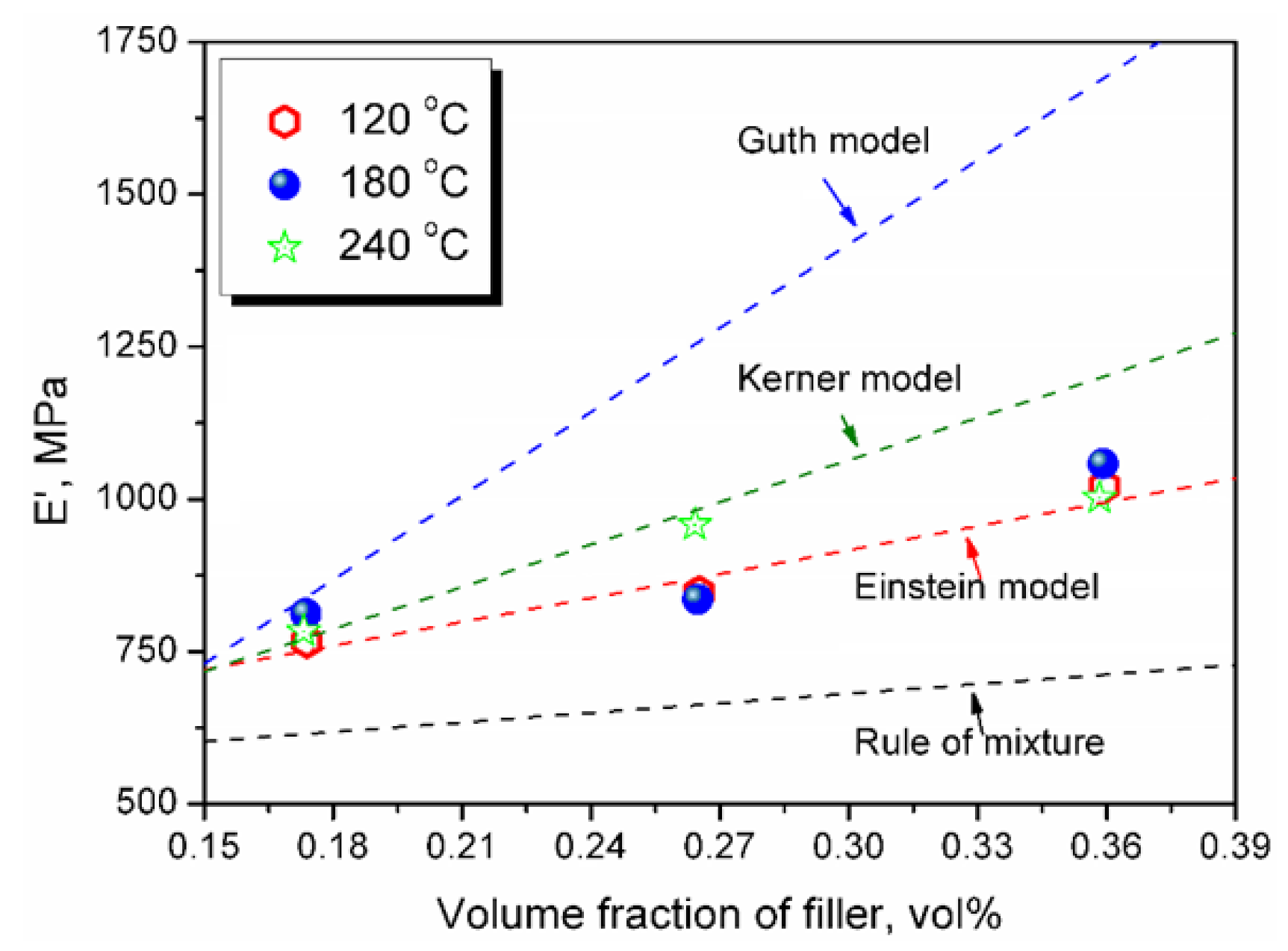

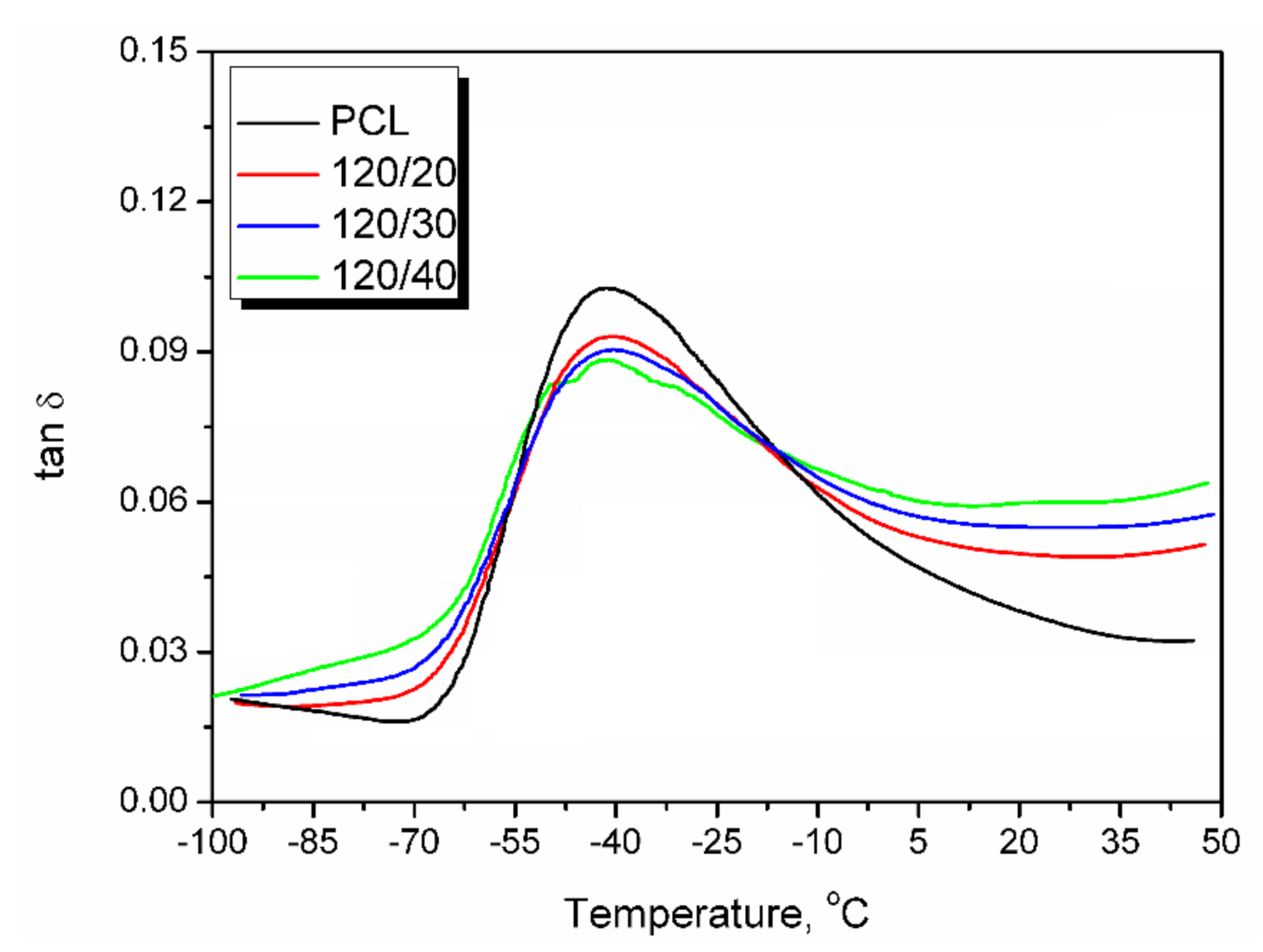

3.2. Physico-Mechanical Properties

4. Conclusions

Funding

Conflicts of Interest

References

- Sultana, T.; Sultana, S.; Nur, H.P.; Khan, M.W. Studies on Mechanical, Thermal and Morphological Properties of Betel Nut Husk Nano Cellulose Reinforced Biodegradable Polymer Composites. J. Compos. Sci. 2020, 4, 83. [Google Scholar] [CrossRef]

- Ates, B.; Koytepe, S.; Ulu, A.; Gurses, C.; Thakur, V.K. Chemistry, Structures, and Advanced Applications of Nanocomposites from Biorenewable Resources. Chem. Rev. 2020, 120, 9304–9362. [Google Scholar] [CrossRef] [PubMed]

- Hejna, A.; Formela, K.; Reza Saeb, M. Processing, mechanical and thermal behavior assessments of polycaprolactone/agricultural wastes biocomposites. Ind. Crop. Prod. 2015, 76, 725–733. [Google Scholar] [CrossRef]

- The Brewers of Europe. European Beer Trends. Statistic Report, 2019 Edition. Available online: https://brewersofeurope.org/uploads/mycms-files/documents/publications/2019/european-beer-trends-2019-web.pdf (accessed on 31 August 2020).

- Mussatto, S.I.; Dragone, G.; Roberto, I.C. Brewers’ spent grain: Generation, characteristics and potential applications. J. Cereal Sci. 2006, 43, 1–14. [Google Scholar] [CrossRef]

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ spent grain: A review with an emphasis on food and health. J. I. Brewing 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Rufián-Henares, J.A.; Morales, F.J. Functional properties of melanoidins: In vitro antioxidant, antimicrobial and antihypertensive activities. Food Res. Int. 2007, 40, 995–1002. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crop. Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Cataldo, V.A.; Cavallaro, G.; Lazzara, G.; Milioto, S.; Parisi, F. Coffee grounds as filler for pectin: Green composites with competitive performances dependent on the UV irradiation. Carbohyd. Polym. 2017, 170, 198–205. [Google Scholar] [CrossRef]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of wood and biodegradable thermoplastics: A review. Polym. Rev. 2017, 58, 444–494. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Hejna, A.; Przybysz-Romatowska, M.; Kosmela, P.; Zedler, Ł.; Korol, J.; Formela, K. Recent advances in compatibilization strategies of wood-polymer composites by isocyanates. Wood Sci. Technol. 2020, 54, 1091–1119. [Google Scholar] [CrossRef]

- Formela, K.; Zedler, L.; Hejna, A.; Tercjak, A. Reactive extrusion of bio-based polymer blends and composites—Current trends and future developments. Express Polym. Lett. 2018, 12, 24–57. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Huang, J.; Lin, N.; Ahmad, I.; Mariano, M.; Dufresne, A.; Thomas, S.; Gałęski, A. Recent developments in nanocellulose-based biodegradable polymers, thermoplastic polymers, and porous nanocomposites. Prog. Polym. Sci. 2018, 87, 197–227. [Google Scholar] [CrossRef]

- Hejna, A.; Formela, K. Sposób Suszenia i Rozdrabniania Młóta Browarnianego. Polish Patent Application P.430449, 30 June 2019. [Google Scholar]

- Formela, K.; Hejna, A.; Zedler, Ł.; Przybysz, M.; Ryl, J.; Saeb, M.R.; Piszczyk, Ł. Structural, thermal and physico-mechanical properties of polyurethane/brewers’ spent grain composite foams modified with ground tire rubber. Ind. Crop. Prod. 2017, 108, 844–852. [Google Scholar] [CrossRef]

- Hejna, A.; Haponiuk, J.; Piszczyk, Ł.; Klein, M.; Formela, K. Performance properties of rigid polyurethane-polyisocyanurate/brewers’ spent grain foamed composites as function of isocyanate index. e-Polymers 2017, 17, 427–437. [Google Scholar] [CrossRef]

- Zedler, Ł.; Colom, X.; Cañavate, J.; Saeb, M.R.; Haponiuk, J.T.; Formela, K. Investigating the Impact of Curing System on Structure-Property Relationship of Natural Rubber Modified with Brewery By-Product and Ground Tire Rubber. Polymers 2020, 12, 545. [Google Scholar] [CrossRef] [PubMed]

- Zedler, Ł.; Colom, X.; Saeb, M.R.; Formela, K. Preparation and characterization of natural rubber composites highly filled with brewers’ spent grain/ground tire rubber hybrid reinforcement. Compos. Part B Eng. 2018, 145, 182–188. [Google Scholar] [CrossRef]

- Revert, A.; Reig, M.; Seguí, V.J.; Boronat, T.; Fombuena, V.; Balart, R. Upgrading brewer’s spent grain as functional filler in polypropylene matrix. Polym. Compos. 2015, 38, 40–47. [Google Scholar] [CrossRef]

- Cunha, M.; Berthet, M.A.; Pereira, R.; Covas, J.A.; Vicente, A.A.; Hilliou, L. Development of polyhydroxyalkanoate/beer spent grain fibers composites for film blowing applications. Polym. Compos. 2014, 36, 1859–1865. [Google Scholar] [CrossRef]

- Berthet, M.A.; Angellier-Coussy, H.; Machado, D.; Hilliou, L.; Staebler, A.; Vicente, A.; Gontard, N. Exploring the potentialities of using lignocellulosic fibres derived from three food by-products as constituents of biocomposites for food packaging. Ind. Crop. Prod. 2015, 69, 110–122. [Google Scholar] [CrossRef]

- Oracz, J.; Zyzelewicz, D. In Vitro Antioxidant Activity and FTIR Characterization of High-Molecular Weight Melanoidin Fractions from Different Types of Cocoa Beans. Antioxidants 2019, 8, 560. [Google Scholar] [CrossRef]

- Ji, Y.; Yang, X.; Ji, Z.; Zhu, L.; Ma, N.; Chen, D.; Jia, X.; Tang, J.; Cao, Y. DFT-Calculated IR Spectrum Amide I, II, and III Band Contributions of N-Methylacetamide Fine Components. ACS Omega 2020, 5, 8572–8578. [Google Scholar] [CrossRef]

- Huang, A.; Jiang, Y.; Napiwocki, B.; Mi, H.; Peng, X.; Turng, L.S. Fabrication of poly(ε-caprolactone) tissue engineering scaffolds with fibrillated and interconnected pores utilizing microcellular injection molding and polymer leaching. RSC Adv. 2017, 7, 43432–43444. [Google Scholar] [CrossRef]

- Barth, A. Infrared spectroscopy of proteins. BBA Bioenergetics 2007, 1767, 1073–1101. [Google Scholar] [CrossRef]

- Hejna, A.; Sulyman, M.; Przybysz, M.; Saeb, M.R.; Klein, M.; Formela, K. On the correlation of lignocellulosic filler composition with the performance properties of poly(ε-caprolactone) based biocomposites. Waste Biomass Valori. 2020, 11, 1467–1479. [Google Scholar] [CrossRef]

- Hong, J.I.; Schadler, L.S.; Siegel, R.W.; Mårtensson, E. Rescaled electrical properties of ZnO/low density polyethylene nanocomposites. Appl. Phys. Lett. 2003, 82, 1956–1958. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Viscoelastic Behavior and Reinforcement Mechanism in Rubber Nanocomposites in the Vicinity of Spherical Nanoparticles. J. Phys. Chem. B 2013, 117, 12632–12648. [Google Scholar] [CrossRef]

- Nelson, J.K.; Hu, Y. The Impact of Nanocomposite Formulations on Electrical Voltage Endurance. In Proceedings of the 2004 IEEE International Conference of Solid Dielectrics, ICSD 2004, Toulouse, France, 5–9 July 2004; pp. 832–835. [Google Scholar] [CrossRef]

- Siqueira, D.D.; Luna, C.B.B.; Ferreira, E.S.B.; Araújo, E.M.; Wellen, R.M.R. Tailored PCL/Macaíba fiber to reach sustainable biocomposites. J. Mater. Res. Technol. 2020, 9, 9691–9708. [Google Scholar] [CrossRef]

- Waters, D.M.; Jacob, F.; Titze, J.; Arendt, E.K.; Zannini, E. Fibre, protein and mineral fortification of wheat bread through milled and fermented brewer’s spent grain enrichment. Eur. Food Res. Technol. 2012, 235, 767–778. [Google Scholar] [CrossRef]

- Maillard, L.C. Action des acides amines sur les sucres; formation de melanoidines par voie méthodique. Compt. Rend. 1912, 154, 66–68. [Google Scholar]

- Martins, S.I.F.; Jongen, W.M.; van Boekel, M.A.J. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Tech. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Villamiel, M.; del Castillo, M.D.; Corzo, N. Browning Reactions. In Food Biochemistry and Food Processing; Hui, Y.H., Nip, W.K., Nollet, L.M.L., Paliyath, G., Simpson, B.K., Eds.; Wiley-Blackwell: New York, NY, USA, 2006; pp. 71–100. [Google Scholar] [CrossRef]

- Aguiar, C.; Rocha, A.L.B.; Jambassi, J.R.; Baptista, A.S.; Lima, R.B. Factors Affecting Color Formation During Storage of White Crystal Sugar. Focus. Modern Food Ind. 2015, 4, 1–10. [Google Scholar] [CrossRef]

- Wang, Z.H.; Liu, J.; Wu, S.Z.; Wang, W.C.; Zhang, L.Q. Novel percolation phenomena and mechanism of strengthening elastomers by nanofillers. Phys. Chem. Chem. Phys. 2010, 12, 3014–3030. [Google Scholar] [CrossRef] [PubMed]

- Svärd, A.; Brännvall, E.; Edlund, U. Modified and thermoplastic rapeseed straw xylan: A renewable additive in PCL biocomposites. Ind. Crop Prod. 2018, 119, 73–82. [Google Scholar] [CrossRef]

- Einstein, A. Ueber die von der molekularkinetischen fluessigkeiten suspendierten teilchen. Ann. Phys. (Leipzig) 1905, 17, 549–560. [Google Scholar] [CrossRef]

- Kerner, E.H. The Elastic and Thermoelastic Properties of Composite Media. Proc. Phys. Soc. B 1956, 69, 808–813. [Google Scholar] [CrossRef]

- Lu, L.; Zhang, Q.; Wootton, D.M.; Chiou, R.; Li, D.; Lu, B.; Lelkes, P.I.; Zhou, J. Mechanical study of polycaprolactone-hydroxyapatite porous scaffolds created by porogen-based solid freeform fabrication method. J. Appl. Biomater. Func. 2014, 12, 145–154. [Google Scholar] [CrossRef]

- Guth, E. Theory of filler reinforcement. J. Appl. Phys. 1945, 16, 20–25. [Google Scholar] [CrossRef]

- Chua, P.S. Dynamic mechanical analysis studies of the interphase. Polym. Compos. 1987, 8, 308–313. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E.; Narkis, M. Sliding wear, viscoelasticity, and brittleness of polymers. J. Mater. Res. 2006, 21, 2422–2428. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E.; Khoja, S. Brittleness and toughness of polymers and other materials. Mater. Lett. 2015, 159, 478–480. [Google Scholar] [CrossRef]

- Galeja, M.; Hejna, A.; Kosmela, P.; Kulawik, A. Static and Dynamic Mechanical Properties of 3D Printed ABS as a Function of Raster Angle. Materials 2020, 13, 297. [Google Scholar] [CrossRef]

- Hejna, A.; Zedler, Ł.; Przybysz-Romatowska, M.; Cañavate, J.; Colom, X.; Formela, K. Reclaimed Rubber/Poly(ε-caprolactone) Blends: Structure, Mechanical, and Thermal Properties. Polymers 2020, 12, 1204. [Google Scholar] [CrossRef]

- Cowie, J.M.G. Polymers: Chemistry and Physics of Modern Materials, 2nd ed.; Nelson Thornes Ltd.: Cheltenham, UK, 2000; pp. 375–390. [Google Scholar]

- Abdalla, M.; Dean, D.; Adibempe, D.; Nyairo, E.; Robinson, P.; Thompson, G. The effect of interfacial chemistry on molecular mobility and morphology of multiwalled carbon nanotubes epoxy nanocomposite. Polymer 2007, 48, 5662–5670. [Google Scholar] [CrossRef]

- Kubát, J.; Rigdahl, M.; Welander, M. Characterization of interfacial interactions in high density polyethylene filled with glass spheres using dynamic-mechanical analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

| Parameter | PCL | 120/20 | 120/30 | 120/40 | 180/20 | 180/30 | 180/40 | 240/20 | 240/30 | 240/40 |

|---|---|---|---|---|---|---|---|---|---|---|

| Theoretical density, g/cm3 | 1.151 | 1.189 | 1.208 | 1.229 | 1.189 | 1.209 | 1.229 | 1.190 | 1.210 | 1.231 |

| Experimental density, g/cm3 | 1.151 | 1.182 | 1.199 | 1.214 | 1.185 | 1.201 | 1.217 | 1.183 | 1.203 | 1.223 |

| Porosity, % | 0.000 | 0.542 | 0.782 | 1.207 | 0.364 | 0.634 | 0.979 | 0.574 | 0.545 | 0.687 |

| Filler volume fraction, % | 0.00 | 17.39 | 26.52 | 35.95 | 17.37 | 26.49 | 35.92 | 17.31 | 26.42 | 35.83 |

| Average particle distance, µm | - | 99 | 57 | 30 | 73 | 42 | 22 | 70 | 40 | 21 |

| Interface surface area, nm−1 | - | 4.7 | 7.1 | 9.7 | 6.4 | 9.7 | 13.1 | 6.6 | 10.1 | 13.7 |

| Tensile strength, MPa | 34.6 ± 1.5 | 11.1 ± 0.1 | 10.5 ± 0.3 | 9.8 ± 0.2 | 12.8 ± 0.3 | 10.9 ± 0.7 | 10.8 ± 0.3 | 11.8 ± 0.7 | 9.9 ± 0.7 | 9.1 ± 0.4 |

| Elongation at break, % | 1061 ± 82 | 33.2 ± 9.7 | 13.5 ± 1.8 | 5.9 ± 0.2 | 33.5 ± 1.8 | 12.9 ± 4.5 | 6.1 ± 1.0 | 37.2 ± 9.7 | 13.2 ± 0.8 | 9.0 ± 0.4 |

| Young’s modulus, MPa | 289 ± 18 | 469 ± 6 | 502 ± 40 | 615 ± 27 | 512 ± 11 | 599 ± 63 | 677 ± 44 | 536 ± 63 | 640 ± 35 | 735 ± 39 |

| Toughness, J/cm3 | 25215 ± 3359 | 283 ± 81 | 95 ± 16 | 44 ± 1 | 317 ± 27 | 106 ± 18 | 49 ± 10 | 342 ± 38 | 125 ± 14 | 58 ± 6 |

| Brittleness, 1010 %·Pa | 0.0180 | 0.3932 | 0.8741 | 1.6562 | 0.3678 | 0.9309 | 1.5404 | 0.3435 | 0.7907 | 1.1125 |

| E’ at 25 °C, MPa | 523.7 | 766.2 | 847.0 | 1021.1 | 812.2 | 835.4 | 1058.2 | 782.8 | 958.1 | 1002.1 |

| E’ at −90 °C, MPa | 3372.6 | 3917.8 | 3846.4 | 4468.2 | 3990.0 | 3915.8 | 4522.0 | 3843.1 | 4110.0 | 4060.8 |

| C factor | 1.00 | 0.79 | 0.71 | 0.68 | 0.76 | 0.73 | 0.66 | 0.76 | 0.67 | 0.63 |

| E’ rule of mixture, MPa | - | 614.8 | 662.6 | 712.0 | 614.6 | 662.4 | 711.8 | 614.4 | 662.0 | 711.3 |

| E’ Einstein model, MPa | - | 751.4 | 870.9 | 994.4 | 751.1 | 870.5 | 993.9 | 750.4 | 869.5 | 992.8 |

| E’ Kerner model, MPa | - | 781.4 | 965.5 | 1211.0 | 781.0 | 964.8 | 1209.9 | 780.1 | 963.2 | 1207.4 |

| E’ Guth model, MPa | - | 860.8 | 1216.5 | 1713.5 | 860.1 | 1215.1 | 1711.3 | 858.4 | 1211.8 | 1706.3 |

| tan δ at 25 °C | 0.0360 | 0.0494 | 0.0551 | 0.0596 | 0.0466 | 0.0490 | 0.0522 | 0.0414 | 0.0455 | 0.0481 |

| tan δ at Tg | 0.1027 | 0.0932 | 0.0904 | 0.0885 | 0.0921 | 0.0902 | 0.0863 | 0.0906 | 0.0872 | 0.0838 |

| Tg, °C | −41.42 | −41.12 | −40.41 | −40.02 | −41.31 | −40.15 | −39.24 | −41.41 | −41.38 | −40.52 |

| Area under tan δ peak, °C | 6.136 | 6.318 | 6.742 | 7.515 | 6.396 | 6.992 | 7.573 | 6.270 | 6.702 | 7.547 |

| Adhesion factor | - | 0.658 | 1.079 | 1.582 | 0.565 | 0.849 | 1.258 | 0.390 | 0.716 | 1.081 |

| Constrained chain volume, % | 0.00 | 7.17 | 9.33 | 10.83 | 8.01 | 9.47 | 12.55 | 9.19 | 11.87 | 14.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hejna, A. Poly(ε-Caprolactone)/Brewers’ Spent Grain Composites—The Impact of Filler Treatment on the Mechanical Performance. J. Compos. Sci. 2020, 4, 167. https://doi.org/10.3390/jcs4040167

Hejna A. Poly(ε-Caprolactone)/Brewers’ Spent Grain Composites—The Impact of Filler Treatment on the Mechanical Performance. Journal of Composites Science. 2020; 4(4):167. https://doi.org/10.3390/jcs4040167

Chicago/Turabian StyleHejna, Aleksander. 2020. "Poly(ε-Caprolactone)/Brewers’ Spent Grain Composites—The Impact of Filler Treatment on the Mechanical Performance" Journal of Composites Science 4, no. 4: 167. https://doi.org/10.3390/jcs4040167

APA StyleHejna, A. (2020). Poly(ε-Caprolactone)/Brewers’ Spent Grain Composites—The Impact of Filler Treatment on the Mechanical Performance. Journal of Composites Science, 4(4), 167. https://doi.org/10.3390/jcs4040167