Characterization of Agricultural and Food Processing Residues for Potential Rubber Filler Applications

Abstract

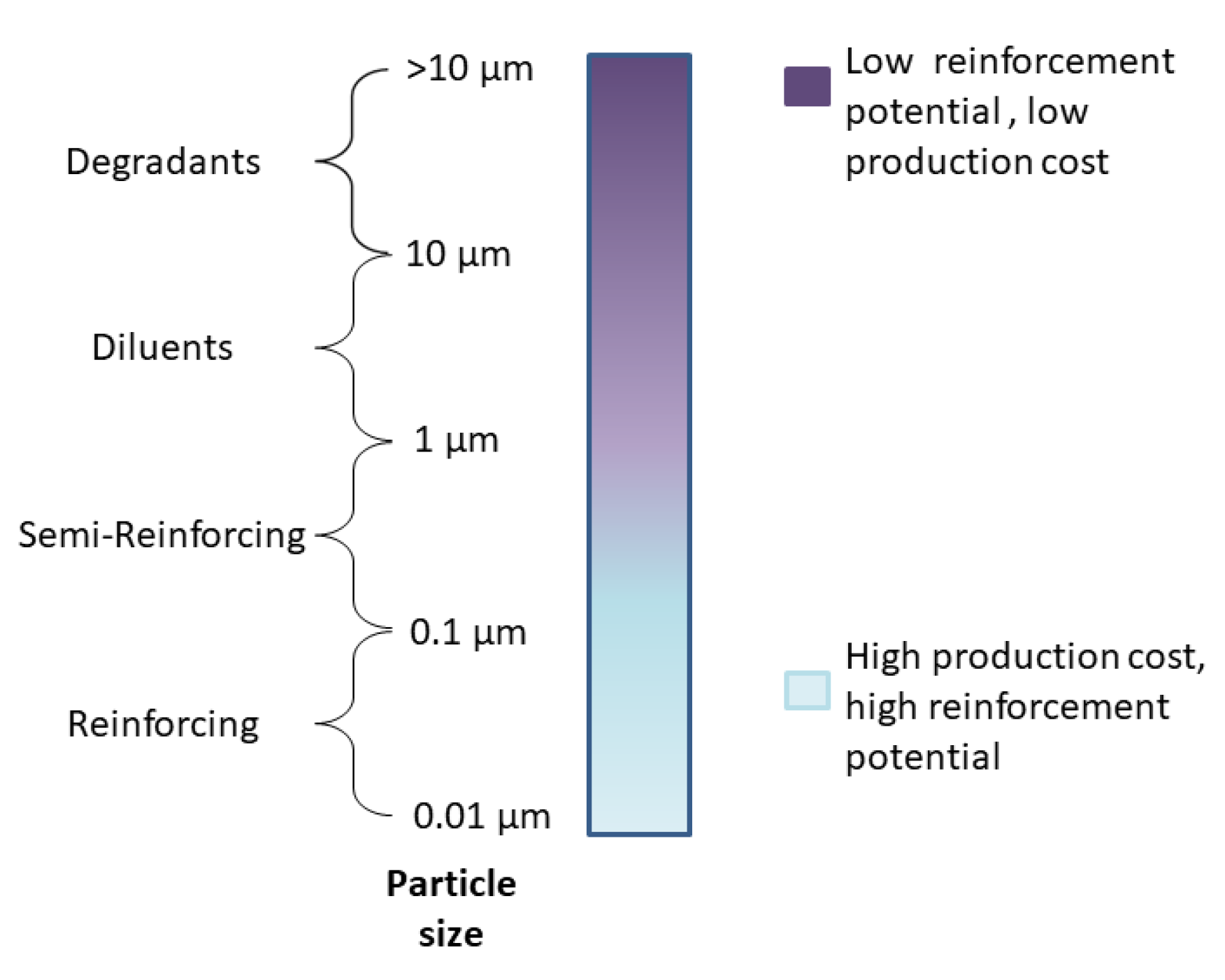

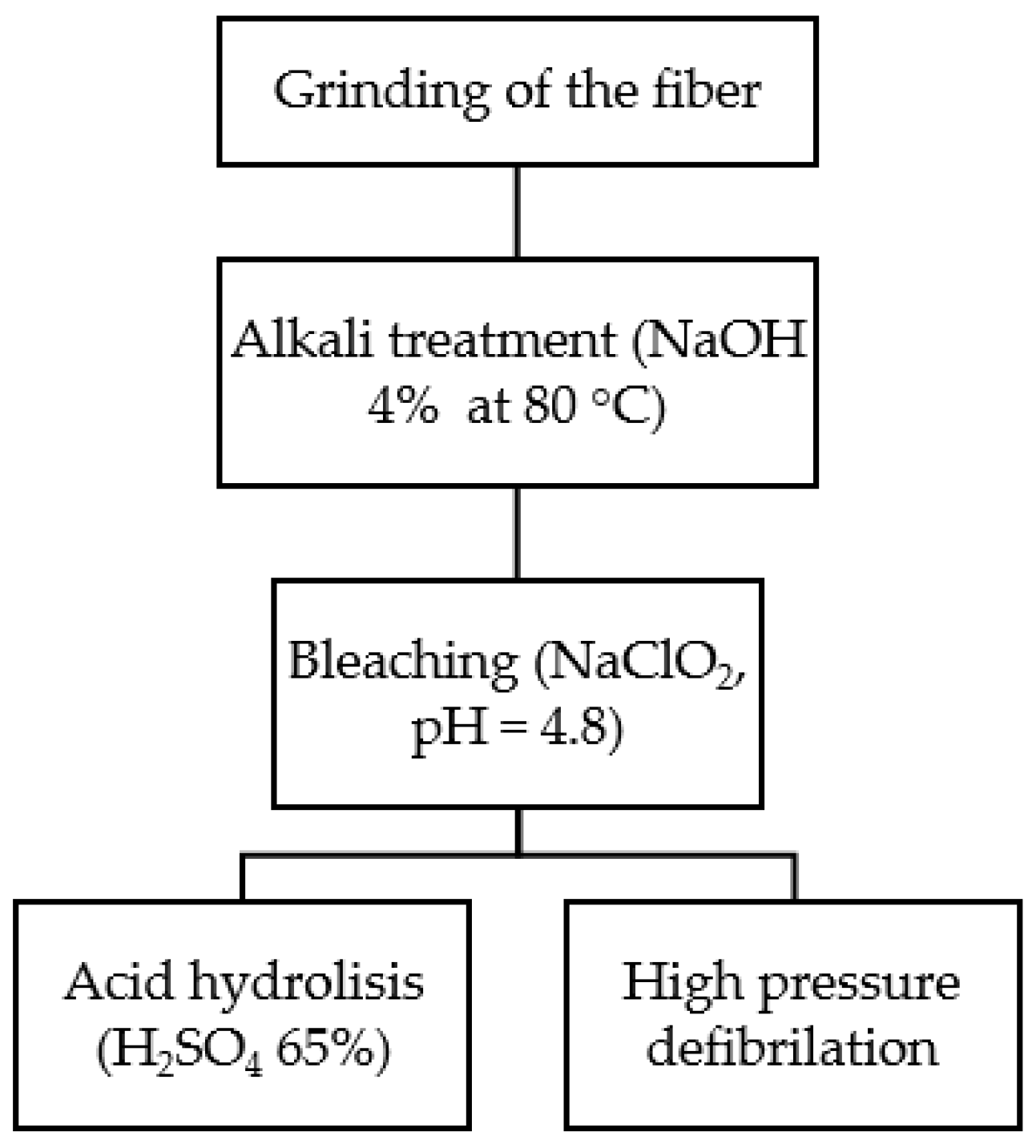

1. Introduction

2. Filler Characterization

2.1. Surface Area

Nitrogen Adsorption

2.2. Surface Activity

2.2.1. Contact Angle

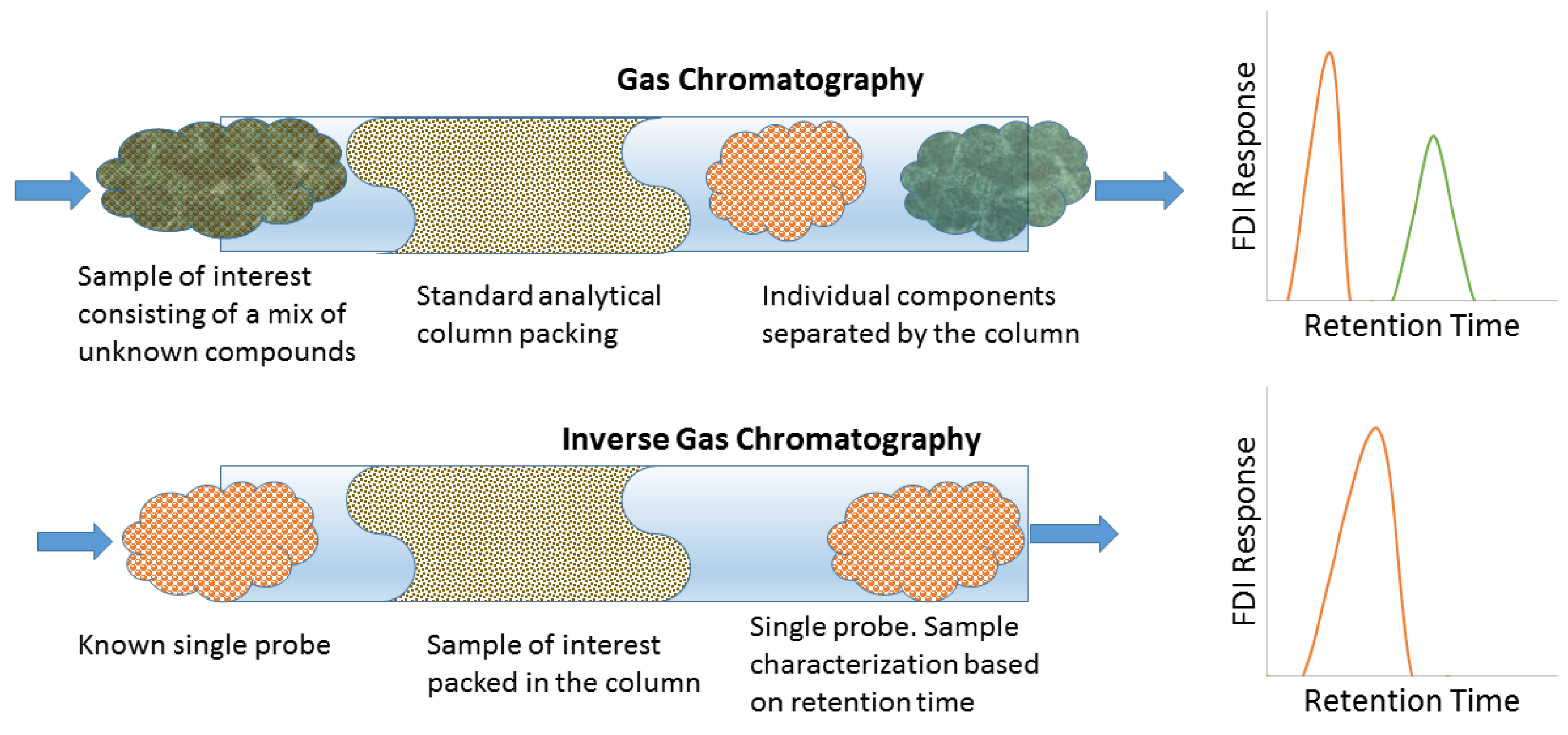

2.2.2. Inverse Gas Chromatography (IGC)

2.3. Filler Chemistry

2.3.1. Fourier Transform Infrared Spectroscopy

2.3.2. X-ray Spectroscopy

2.3.3. Thermogravimetric Analysis (TGA)

2.4. Shape and Structure

2.4.1. Electron Microscopy

2.4.2. Atomic Force Microscopy (AFM)

2.5. Filler Crystallinity

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Pfaltzgraff, L.A.; Cooper, E.C.; Budarin, V.; Clark, J.H. Food waste biomass: A resource for high-value chemicals. Green Chem. 2013, 15, 307–314. [Google Scholar] [CrossRef]

- Deniel, M.; Haarlemmer, G.; Roubaud, A.; Weiss-Hortala, E.; Fages, J. Energy valorisation of food processing residues and model compounds by hydrothermal liquefaction. Renew. Sustain. Energy Rev. 2016, 54, 1632–1652. [Google Scholar] [CrossRef]

- FAO. The Food Systems of the Future Need to be Smarter, More Efficiente, (n.d.). Available online: http://www.fao.org/news/story/en/item/275009/icode/ (accessed on 19 September 2019).

- ASTM International. Standard Terminology for Composite Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Kalaprasad, G.; Groeninckx, G.; Thomas, S. Dynamic mechanical behavior of short coir fiber reinforced natural rubber composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1499–1506. [Google Scholar] [CrossRef]

- Jacob, M.; Thomas, S.; Varughese, K.T. Mechanical properties of sisal/oil palm hybrid fiber reinforced natural rubber composites. Compos. Sci. Technol. 2004, 64, 955–965. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.A.; John, M.; Narine, S.S.; Thomas, S. Physicomechanical properties of nanocomposites based on cellulose nanofibre and natural rubber latex. Cellulose 2013, 20, 417–427. [Google Scholar] [CrossRef]

- Barrera, C.S.; Cornish, K. Novel mineral and organic materials from agro-industrial residues as fillers for natural rubber. J. Polym. Environ. 2015, 23, 437–448. [Google Scholar] [CrossRef]

- Barrera, C.S.; Cornish, K. High performance waste-derived filler/carbon black reinforced guayule natural rubber composites. Ind. Crops Prod. 2016, 86, 132–142. [Google Scholar] [CrossRef]

- Neto, W.P.F.; Mariano, M.; Da Silva, I.S.V.; Silvério, H.A.; Putaux, J.L.; Otaguro, H. Mechanical properties of natural rubber nanocomposites reinforced with high aspect ratio cellulose nanocrystals isolated from soy hulls. Carbohydr. Polym. 2016, 153, 143–152. [Google Scholar] [CrossRef]

- Intharapat, P.; Kongnoo, A.; Kateungngan, K. The Potential of Chicken Eggshell Waste as a Bio-filler Filled Epoxidized Natural Rubber (ENR) Composite and its Properties. J. Polym. Environ. 2013, 21, 245–258. [Google Scholar] [CrossRef]

- Poompradub, S.; Ikeda, Y.; Kokubo, Y.; Shiono, T. Cuttlebone as reinforcing filler for natural rubber. Eur. Polym. J. 2008, 44, 4157–4164. [Google Scholar] [CrossRef]

- Sae-Oui, P.; Rakdee, C.; Thanmathorn, P. Use of rice husk ash as filler in natural rubber vulcanizates: In comparison with other commercial fillers. J. Appl. Polym. Sci. 2002, 83, 2485–2493. [Google Scholar] [CrossRef]

- Samsuri, A.B. Theory and Mechanisms of Filler Reinforcement in Natural Rubber. In Natural Rubber Materials: Volume 2: Composites and Nanocomposites; Thomas, H.M.S., Chan, C.H., Pothen, L., Joy, J., Eds.; The Royal Society of Chemistry: London, UK, 2013; pp. 73–111. [Google Scholar] [CrossRef]

- Donnet, J.B.; Custodero, E. Reinforcement of Elastomers by Particulate Fillers. In The Science and Technology of Rubber, 4th ed.; Mark, J.E., Erman, B., Roland, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 383–416. [Google Scholar] [CrossRef]

- Rattanasom, N.; Saowapark, T.A.; Deeprasertkul, C. Reinforcement of natural rubber with silica/carbon black hybrid filler. Polym. Test. 2007, 26, 369–377. [Google Scholar] [CrossRef]

- Fröhlich, J.; Niedermeier, W.; Luginsland, H.D. The effect of filler-filler and filler-elastomer interaction on rubber reinforcement. Compos. Part A Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Leblanc, J. Rubber–filler interactions and rheological properties in filled compounds. Prog. Polym. Sci. 2002, 27, 627–687. [Google Scholar] [CrossRef]

- Hamed, G.R. Reinforcement of Rubber. Rubber Chem. Technol. 2000, 73, 524–533. [Google Scholar] [CrossRef]

- Rader, C.P. Vulcanization of rubber-Sulfur and non-peroxides. In Basic Elastomer Technol; Baranwal, K.C., Stephens, H.L., Eds.; American Chemical Society, Rubber Division: Akron, OH, USA, 2001; pp. 165–190. [Google Scholar]

- Coran, A.Y. Vulcanization. In The Science and Technology of Rubber, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 337–381. [Google Scholar] [CrossRef]

- Notch Consulting Inc. Carbon black and silica in the tire markets challenges and opportunities. In Proceedings of the Tire Technology Expo, Cologne, Germany, 7 February 2015. [Google Scholar]

- Malaysian Rubber Board. Natural Rubber Statistics. 2016. Available online: http://www.lgm.gov.my/nrstat/nrstats.pdf (accessed on 24 October 2019).

- International Carbon Black Association. Carbon Black User’s Guide. 2004. Available online: http://www.carbon-black.org/files/carbonblackuserguide.pdf (accessed on 18 September 2019).

- Studebaker, M. The chemistry of carbon black and reinforcement. Rubber Chem. Technol. 1957, 30, 1401–1483. [Google Scholar] [CrossRef]

- Gerspacher, M.; Wampler, W. Fillers—Carbon black. In Basic Elastomer Technol; Baranwal, K.C., Stephens, H., Eds.; American Chemical Society, Rubber Division: Akron, OH, USA, 2001; pp. 57–81. [Google Scholar]

- Barrera, C.S.; Cornish, K. Waste-derived Reinforcing Fillers in Guayule and Hevea Natural Rubber. In Proceedings of the 190th Technical Meeting Rubber Division American Chemical Society, Pittsburg, PA, USA, 10 October 2016. [Google Scholar]

- Moore, M. Exec: Expect Carbon Black Shortage in Five Years. 2015. Available online: http://www.rubbernews.com/article/20150717/NEWS/307139999 (accessed on 16 Auguest 2016).

- Afiq, M.M.; Azura, A.R. Effect of sago starch loadings on soil decomposition of Natural Rubber Latex (NRL) composite films mechanical properties. Int. Biodeterior. Biodegrad. 2013, 85, 139–149. [Google Scholar] [CrossRef]

- Nunes, R.C.R. Natural Rubber (NR) Composites Using Cellulosic Fiber Reinforcements in Chemistry, Manufacture and Applications of Natural Rubber; Elsevier: Amsterdam, The Netherlands, 2014; pp. 284–302. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Angellier, H.; Molina-Boisseau, S.; Dufresne, A. Mechanical properties of waxy maize starch nanocrystal reinforced natural rubber. Macromolecules 2005, 38, 9161–9170. [Google Scholar] [CrossRef]

- Parambath Kanoth, B.; Claudino, M.; Johansson, M.; Berglund, L.A.; Zhou, Q. Biocomposites from natural rubber: Synergistic effects of functionalized cellulose nanocrystals as both reinforcing and crosslinking agents via free-radical thiol–ene chemistry. ACS Appl. Mater. Interfaces. 2015, 7, 16303–16310. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Shao, Y.; Jia, D. Chemically modified starch reinforced natural rubber composites. Polymer 2008, 49, 2176–2181. [Google Scholar] [CrossRef]

- Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Mihajlović, S.R.; Vučinić, D.R.; Sekulić, Ž.T.; Milićević, S.Z.; Kolonja, B.M. Mechanism of stearic acid adsorption to calcite. Powder Technol. 2013, 245, 208–216. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.E.; Simon, F.; Panayiotou, C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

- Chenal, J.M.; Gauthier, C.; Chazeau, L.; Guy, L.; Bomal, Y. Parameters governing strain induced crystallization in filled natural rubber. Polymer 2007, 48, 6893–6901. [Google Scholar] [CrossRef]

- Byers, J.T. Filler—Non-black. In Basic Elastomer Technol; Baranwal, K.C., Stephens, H.L., Eds.; American Chemical Society, Rubber Division: Akron, OH, USA, 2001; pp. 82–111. [Google Scholar]

- Kohls, D.J.; Beaucage, G. Rational design of reinforced rubber. Curr. Opin. Solid State Mater. Sci. 2002, 6, 183–194. [Google Scholar] [CrossRef]

- Bendahou, A.; Kaddami, H.; Dufresne, A. Investigation on the effect of cellulosic nanoparticles’ morphology on the properties of natural rubber based nanocomposites. Eur. Polym. J. 2010, 46, 609–620. [Google Scholar] [CrossRef]

- Khan, I.; Bhat, A. Micro and Nano Calcium Carbonate Filled Natural Rubber Composites and Nanocomposites. In Natural Rubber Materials; Thomas, H.M.S., Chan, C.H., Pothen, L., Joy, J., Eds.; The Royal Society of Chemistry: London, UK, 2014; pp. 467–487. [Google Scholar] [CrossRef]

- Szeluga, U.; Kumanek, B.; Trzebicka, B. Synergy in hybrid polymer/nanocarbon composites. A review. Compos. Part A Appl. Sci. Manuf. 2015, 73, 204–231. [Google Scholar] [CrossRef]

- Peddini, S.K.; Bosnyak, C.P.; Henderson, N.M.; Ellison, C.J.; Paul, D.R. Nanocomposites from styrene-butadiene rubber (SBR) and multiwall carbon nanotubes (MWCNT) part 1: Morphology and rheology. Polymer 2014, 55, 258–270. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.A.; Jacob, M.; Thomas, S.; Cvelbar, U. Extraction of nanocellulose fibrils from lignocellulosic fibres: A novel approach. Carbohydr. Polym. 2011, 86, 1468–1475. [Google Scholar] [CrossRef]

- Fang, Q.; Song, B.; Tee, T.T.; Sin, L.T.; Hui, D.; Bee, S.T. Investigation of dynamic characteristics of nano-size calcium carbonate added in natural rubber vulcanizate. Compos. Part B Eng. 2014, 60, 561–567. [Google Scholar] [CrossRef]

- Galimberti, M.; Cipolletti, V.; Kumar, V. Nanofillers in Natural Rubber. In Natural Rubber Materials Volume 2 Composites Nanocomposites; Thomas, S., Chan, C.H., Pothen, L., Joy, J., Maria, H., Eds.; The Royal Society of Chemistry: London, UK, 2014; pp. 34–72. [Google Scholar] [CrossRef]

- Bandyopadhyay-Ghosh, S.; Ghosh, S.B.; Sain, M. The use of biobased nanofibres in composites. In Biofiber Reinforcements in Composite Materials; Faruk, O., Sain, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 571–647. [Google Scholar] [CrossRef]

- Paul, K.T.; Satpathy, S.K.; Manna, I.; Chakraborty, K.K.; Nando, G.B. Preparation and characterization of nano structured materials from fly ash: A waste from thermal power stations, by high energy ball milling. Nanoscale Res. Lett. 2007, 2, 397–404. [Google Scholar] [CrossRef]

- Hassan, T.A.; Rangari, V.K.; Rana, R.K.; Jeelani, S. Sonochemical effect on size reduction of CaCO3 nanoparticles derived from waste eggshells. Ultrason. Sonochem. 2013, 20, 1308–1315. [Google Scholar] [CrossRef] [PubMed]

- Chao, H.; Riggleman, R.A. Effect of particle size and grafting density on the mechanical properties of polymer nanocomposites. Polymer 2013, 54, 5222–5229. [Google Scholar] [CrossRef]

- Kueseng, K.; Jacob, K.I. Natural rubber nanocomposites with SiC nanoparticles and carbon nanotubes. Eur. Polym. J. 2006, 42, 220–227. [Google Scholar] [CrossRef]

- Siqueira, G.; Bras, J.; Dufresne, A. Cellulosic bionanocomposites: A review of preparation, properties and applications. Polymers 2010, 2, 728–765. [Google Scholar] [CrossRef]

- Barrera, C.S.; Cornish, K. Processing and mechanical properties of natural rubber/waste-derived nano fi ller composites compared to macro and micro filler composites. Ind. Crop. Prod. 2017, 107, 217–231. [Google Scholar] [CrossRef]

- Fagerlund, G. Determination of specific surface by the BET method. Matériaux Constr. 1973, 6, 239–245. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Carbon Black—Total and External Surface Area by Nitrogen; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Barrera, C.S.; Soboyejo, A.B.O.; Cornish, K. Quantification of the contribution of filler characteristics to natural rubber reinforcement using principal componentanalysis. Rubber Chem. Technol. 2018, 91, 79–96. [Google Scholar] [CrossRef]

- Chaudhary, D.S.; Jollands, M.C. Characterization of rice hull ash. J. Appl. Polym. Sci. 2004, 93, 1–8. [Google Scholar] [CrossRef]

- Papirer, E.; Schultz, J.; Turchi, C. Surface properties of a calcium carbonate filler treated with stearic acid. Eur. Polym. J. 1984, 20, 1155–1158. [Google Scholar] [CrossRef]

- Stöckelhuber, K.W.; Svistkov, A.S.; Pelevin, A.G.; Heinrich, G. Impact of filler surface modification on large scale mechanics of styrene butadiene/silica rubber composites. Macromolecules 2011, 44, 4366–4381. [Google Scholar] [CrossRef]

- Papirer, E.; Balard, H.; Vidal, A. Inverse gas chromatography: A valuable method for the surface characterization of fillers for polymers (glass fibres and silicas). Eur. Polym. J. 1988, 24, 783–790. [Google Scholar] [CrossRef]

- Hole, B.B.; Keller, D.S.; Burry, W.M.; Schwarz, J.A. Surface energetics of bone mineral and synthetic hydroxyapatite using inverse gas chromatography. J. Chromatogr. B 2011, 879, 1847–1850. [Google Scholar] [CrossRef]

- Cordeiro, N.; Gouveia, C.; Moraes, A.G.O.; Amico, S.C. Natural fibers characterization by inverse gas chromatography. Carbohydr. Polym. 2011, 84, 110–117. [Google Scholar] [CrossRef]

- Burry, W.M.; Keller, D.S. Effects of dehydration on the apolar surface energetics of inorganic paper fillers. J. Chromatogr. A 2002, 972, 241–251. [Google Scholar] [CrossRef]

- Papirer, E.; Brendle, E.; Ozil, F.; Balard, H. Comparison of the surface properties of graphite, carbon black and fullerene samples, measured by inverse gas chromatography. Carbon 1999, 37, 1265–1274. [Google Scholar] [CrossRef]

- Cordeiro, N.; Gouveia, C.; John, M.J. Investigation of surface properties of physico-chemically modified natural fibres using inverse gas chromatography. Ind. Crops Prod. 2011, 33, 108–115. [Google Scholar] [CrossRef]

- Nardin, M.; Balard, H.; Papirer, E. Surface characteristics of commercial carbon fibres determined by inverse gas chromatography. Carbon 1990, 28, 43–48. [Google Scholar] [CrossRef]

- Voelkel, A.; Strzemiecka, B.; Adamska, K.; Milczewska, K. Inverse gas chromatography as a source of physiochemical data. J. Chromatogr. A 2009, 1216, 1551–1566. [Google Scholar] [CrossRef] [PubMed]

- Stöckelhuber, K.W.; Das, A.; Jurk, R.; Heinrich, G. Contribution of physico-chemical properties of interfaces on dispersibility, adhesion and flocculation of filler particles in rubber. Polymer 2010, 51, 1954–1963. [Google Scholar] [CrossRef]

- Strzemiecka, B.; Voelkel, A.; Donate-Robles, J.; Martín-Martínez, J.M. Assessment of the surface chemistry of carbon blacks by TGA-MS, XPS and inverse gas chromatography using statistical chemometric analysis. Appl. Surf. Sci. 2014, 316, 315–323. [Google Scholar] [CrossRef]

- Mohammadi-Jam, S.; Waters, K.E. Inverse gas chromatography applications: A review. Adv. Colloid Interface Sci. 2014, 212, 21–44. [Google Scholar] [CrossRef]

- Gamble, J.F.; Leane, M.; Olusanmi, D.; Tobyn, M.; Šupuk, E.; Khoo, J. Surface energy analysis as a tool to probe the surface energy characteristics of micronized materials—A comparison with inverse gas chromatography. Int. J. Pharm. 2012, 422, 238–244. [Google Scholar] [CrossRef]

- Riedl, B.; Matuana, L.M. Inverse Gas Chromatography of Fibers and Polymers, (2006). In Encyclopedia of Surface and Colloid Science; CRC Press: Boca Raton, FL, USA, 2015; pp. 3352–3364. [Google Scholar] [CrossRef]

- Grimsey, I.M.; Feeley, J.C.; York, P. Analysis of the surface energy of pharmaceutical powders by inverse gas chromatography. J. Pharm. Sci. 2002, 91, 571–583. [Google Scholar] [CrossRef]

- Thielmann, F. Introduction into the characterisation of porous materials by inverse gas chromatography. J. Chromatogr. A 2004, 1037, 115–123. [Google Scholar] [CrossRef]

- Charmas, B.; Leboda, R. Effect of surface heterogeneity on adsorption on solid surfaces: Application of inverse gas chromatography in the studies of energetic heterogeneity of adsorbents. J. Chromatogr. A 2000, 886, 133–152. [Google Scholar] [CrossRef]

- Rückriem, M.; Inayat, A.; Enke, D.; Gläser, R.; Einicke, W.-D.; Rockmann, R. Inverse gas chromatography for determining the dispersive surface energy of porous silica. Colloids Surf. A Physicochem. Eng. Asp. 2010, 357, 21–26. [Google Scholar] [CrossRef]

- Van Asten, A.; van Veenendaal, N.; Koster, S. Surface characterization of industrial fibers with inverse gas chromatography. J. Chromatogr. A 2000, 888, 175–196. [Google Scholar] [CrossRef]

- Thielmann, F.; Levoguer, C. Inverse Gas Chromatography i GC—A New Instrumental Technique for Characterising the Phyisco-Chemical Properties of Pharmaceutical Materials; Surface Measurement Systems Ltd.: London, UK, 2001; pp. 1–9. [Google Scholar]

- Cordeiro, N.; Ornelas, M.; Ashori, A.; Sheshmani, S.; Norouzi, H. Investigation on the surface properties of chemically modified natural fibers using inverse gas chromatography. Carbohydr. Polym. 2012, 87, 2367–2375. [Google Scholar] [CrossRef]

- Nair, K.G.; Dufresne, A. Crab shell chitin whisker reinforced natural rubber nanocomposites. 1. Processing and swelling behavior. Biomacromolecules 2003, 4, 657–665. [Google Scholar] [CrossRef]

- Pasquini, D.; Teixeira, E.D.M.; Curvelo, A.A.D.S.; Belgacem, M.N.; Dufresne, A. Extraction of cellulose whiskers from cassava bagasse and their applications as reinforcing agent in natural rubber. Ind. Crops Prod. 2010, 32, 486–490. [Google Scholar] [CrossRef]

- Kutchko, B.G.; Kim, A.G. Fly ash characterization by SEM-EDS. Fuel 2006, 85, 2537–2544. [Google Scholar] [CrossRef]

- Sombatsompop, N.; Thongsang, S.; Markpin, T.; Wimolmala, E. Fly ash particles and precipitated silica as fillers in rubbers. I. Untreated fillers in natural rubber and styrene-butadiene rubber compounds. J. Appl. Polym. Sci. 2004, 93, 2119–2130. [Google Scholar] [CrossRef]

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T.; Vandenberghe, L.P.S.; Mohan, R. Biotechnological potential of agro-industrial residues. II: Cassava bagasse. Bioresour. Technol. 2000, 74, 81–87. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Thomas, S. Diffusion of water and artificial seawater through coir fiber reinforced natural rubber composites. Polym. Compos. 2005, 26, 136–143. [Google Scholar] [CrossRef]

- Shinoj, S.; Visvanathan, R.; Panigrahi, S.; Kochubabu, M. Oil palm fiber (OPF) and its composites: A review. Ind. Crops Prod. 2011, 33, 7–22. [Google Scholar] [CrossRef]

- Ismail, H.; Haw, F.S. Effects of palm ash loading and maleated natural rubber as a coupling agent on the properties of palm-ash-filled natural rubber composites. J. Appl. Polym. Sci. 2008, 110, 2867–2876. [Google Scholar] [CrossRef]

- Ooi, Z.X.; Ismail, H.; Bakar, A.A. Synergistic effect of oil palm ash filled natural rubber compound at low filler loading. Polym. Test. 2013, 32, 38–44. [Google Scholar] [CrossRef]

- Johar, N.; Ahmad, I.; Dufresne, A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind. Crops Prod. 2012, 37, 93–99. [Google Scholar] [CrossRef]

- Khalf, A.I.; Ward, A.A. Use of rice husks as potential filler in styrene butadiene rubber/linear low density polyethylene blends in the presence of maleic anhydride. Mater. Des. 2010, 31, 2414–2421. [Google Scholar] [CrossRef]

- Ismail, H.; Nizam, J.M.; Khalil, H.P.S.A. Effect of a compatibilizer on the mechanical properties and mass swell of white rice husk ash filled natural rubber/linear low density polyethylene blends. Polym. Test. 2001, 20, 125–133. [Google Scholar] [CrossRef]

- Rashid, A.A.; Yahya, S.R. Mechanical Properties of Natural Rubber Composites Filled with Macro and Nanofillers. In Natural Rubber Materials; Thomas, S., Chan, C.H., Pothen, L., Joy, J., Maria, H., Eds.; The Royal Society of Chemistry: London, UK, 2013; Volume 2, pp. 550–573. [Google Scholar] [CrossRef]

- Poompradub, S. Soft bio-composites from natural rubber (NR) and marine products. In Chemistry, Manufacture and Applications of Natural Rubber; Elsevier: Amsterdam, The Netherlands, 2014; pp. 303–324. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Isolation and characterization of nanofibers from agricultural residues—Wheat straw and soy hulls. Bioresour. Technol. 2008, 99, 1664–1671. [Google Scholar] [CrossRef]

- Neto, W.P.F.; Silvério, H.A.; Dantas, N.O.; Pasquini, D. Extraction and characterization of cellulose nanocrystals from agro-industrial residue—Soy hulls. Ind. Crops Prod. 2013, 42, 480–488. [Google Scholar] [CrossRef]

- Kolattukudy, P.E. Biopolyester membranes of plants: Cutin and suberin. Science 1980, 208, 990–1000. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Sun, G.; Li, D.; Pan, Z. A comparison of dynamic mechanical properties of processing-tomato peel as affected by hot lye and infrared radiation heating for peeling. J. Food Eng. 2014, 126, 27–34. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- George, N.; Chandra, J.; Mathiazhagan, A.; Joseph, R. High performance natural rubber composites with conductive segregated network of multiwalled carbon nanotubes. Compos. Sci. Technol. 2015, 116, 33–40. [Google Scholar] [CrossRef]

- Hao, D.; Shou-ci, L.; Yan-xi, D.; Gao-xiang, D. Mechano-activated surface modification of calcium carbonate in wet stirred mill. Trans. Nonferrous. Met. Soc. China. 2007, 17, 1100–1104. [Google Scholar]

- Faix, O. Fourier Transform Infrared Spectroscopy. In Methods in Lignin Chemistry; Springer: Berlin/Heidelberg, Germany, 1992; pp. 83–109. [Google Scholar] [CrossRef]

- Mayers, J.J.; Flynn, K.J.; Shields, R.J. Rapid determination of bulk microalgal biochemical composition by Fourier-Transform Infrared spectroscopy. Bioresour. Technol. 2013, 148, 215–220. [Google Scholar] [CrossRef]

- Barrios, V.; Méndez, J.; Aguilar, N. FTIR–An Essential Characterization Technique for Polymeric Materials, Cdn. Intechopen. Com. 2003. Available online: http://cdn.intechopen.com/pdfs/36174/InTech-Ftir_an_essential_characterization_technique_for_polymeric_materials.pdf (accessed on 19 September 2019).

- Knutson, K.; Lyman, D.J. Surface Infrared Spectroscopy. In Surface and Interfacial Aspects of Biomedical Polymers; Springer: Boston, MA, USA, 1985; pp. 197–247. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Grady, B.P.; Cooper, S.L.; Robertson, C.G. Thermoplastic Elastomers. In The Science and Technology of Rubber; Elsevier: Amsterdam, The Netherlands, 2013; pp. 591–652. [Google Scholar] [CrossRef]

- Fombuena, V.; Bernardi, L.; Fenollar, O.; Boronat, T.; Balart, R. Characterization of green composites from biobased epoxy matrices and bio-fillers derived from seashell wastes. J. Mater. 2014, 57, 168–174. [Google Scholar] [CrossRef]

- Bello, M.O.; Abdus-Salam, N.; Adekola, F.A. Utilization of Guinea corn (Sughurm vulgare) Husk for Preparation of Bio-based Silica and its Characterization Studies. Int. J. Environ. Agric. Biotechnol. 2018, 3, 670–675. [Google Scholar] [CrossRef]

- Kibel, M.H. X-Ray Photoelectron Spectroscopy. In Surface Analysis Methods in Materials Science; O’Connor, D.J., Sexton, B.A., Smart, R.S.C., Eds.; Springer: Berlin/Heidelberg, Germany, 2003; pp. 175–201. [Google Scholar] [CrossRef]

- Mettler-Toledo GmbH Analytical, Thermal Analysis Information for Users—User Com 45, Thermogravimetry and Gas Analysis, Part 1: Basic Principles and Overview (2017). Available online: https://www.mt.com/us/en/home/library/usercoms/lab-analytical-instruments/thermal-analysis-usercom-45.html (accessed on 12 November 2019).

- Mettler-Toledo GmbH Analytical, Thermal Analysis Information for Users—User Com 47, Thermogravimetry and Gas Analysis, Part 3: TGA/DSC-FTIR (2018). Available online: https://www.mt.com/us/en/home/library/usercoms/lab-analytical-instruments/thermal-analysis-usercom-47.html (accessed on 12 November 2019).

- Li, S.; Lyons-Hart, J.; Banyasz, J.; Shafer, K. Real-time evolved gas analysis by FTIR method: An experimental study of cellulose pyrolysis. Fuel 2001, 80, 1809–1817. [Google Scholar] [CrossRef]

- Bitinis, N.; Verdejo, R.; Bras, J.; Fortunati, E.; Kenny, J.M.; Torre, L. Poly(lactic acid)/natural rubber/cellulose nanocrystal bionanocomposites Part, I. Processing and morphology. Carbohydr. Polym. 2013, 96, 611–620. [Google Scholar] [CrossRef]

- Xie, W.; Pan, W.P. Thermal characterization of materials using evolved gas analysis. J. Therm. Anal. Calorim. 2001, 65, 669–685. [Google Scholar] [CrossRef]

- Kim, H.-Y.; Park, S.S.; Lim, S.-T. Preparation, characterization and utilization of starch nanoparticles. Colloids Surf. B Biointerfaces 2015, 126, 607–620. [Google Scholar] [CrossRef]

- Conzatti, L.; Galimberti, M. Microscopy of Natural Rubber Composites and Nanocomposites. In Natural Rubber Materials; Thomas, S., Chan, C.H., Pothen, L., Joy, J., Maria, H., Eds.; The Royal Society of Chemistry: London, UK, 2014; Volume 2, pp. 649–682. [Google Scholar] [CrossRef]

- Visakh, P.M.; Thomas, S.; Oksman, K.; Mathew, A.P. Crosslinked natural rubber nanocomposites reinforced with cellulose whiskers isolated from bamboo waste: Processing and mechanical/thermal properties. Compos. Part A Appl. Sci. Manuf. 2012, 43, 735–741. [Google Scholar] [CrossRef]

- Turner, P.S.; Nockolds, C.E.; Bulcock, S. Electron Microscope Techniques for Surface Characterization. In Surface Analysis Methods in Materials Science; O’connor, D.J., Sexton, B.A., Smart, R.S.C., Eds.; Springer: Berlin/Heidelberg, Germany, 2003; pp. 85–105. [Google Scholar] [CrossRef]

- Karimi, K.; Taherzadeh, M.J. A critical review of analytical methods in pretreatment of lignocelluloses: Composition, imaging, and crystallinity. Bioresour. Technol. 2016, 200, 1008–1018. [Google Scholar] [CrossRef] [PubMed]

- Kohjiya, S.; Katoh, A.; Suda, T.; Shimanuki, J.; Ikeda, Y. Visualisation of carbon black networks in rubbery matrix by skeletonisation of 3D-TEM image. Polymer 2006, 47, 3298–3301. [Google Scholar] [CrossRef]

- Rebouillat, S.; Pla, F. State of the Art Manufacturing and Engineering of Nanocellulose: A Review of Available Data and Industrial Applications. J. Biomater. Nanobiotechnol. 2013, 4, 165–188. [Google Scholar] [CrossRef]

- Bras, J.; Viet, D.; Bruzzese, C.; Dufresne, A. Correlation between stiffness of sheets prepared from cellulose whiskers and nanoparticles dimensions. Carbohydr. Polym. 2011, 84, 211–215. [Google Scholar] [CrossRef]

- Bras, J.; Hassan, M.L.; Bruzesse, C.; Hassan, E.A.; El-Wakil, N.A.; Dufresne, A. Mechanical, barrier, and biodegradability properties of bagasse cellulose whiskers reinforced natural rubber nanocomposites. Ind. Crops Prod. 2010, 32, 627–633. [Google Scholar] [CrossRef]

- Nunes, C.; Mahendrasingam, A.; Suryanarayanan, R. Quantification of crystallinity in substantially amorphous materials by synchrotron X-ray powder diffractometry. Pharm. Res. 2005, 22, 1942–1953. [Google Scholar] [CrossRef]

- Visakh, P.M.; Thomas, S. Preparation of bionanomaterials and their polymer nanocomposites from waste and biomass. Waste Biomass Valorization 2010, 1, 121–134. [Google Scholar] [CrossRef]

- Abdou, E.S.; Nagy, K.S.A.; Elsabee, M.Z. Extraction and characterization of chitin and chitosan from local sources. Bioresour. Technol. 2008, 99, 1359–1367. [Google Scholar] [CrossRef]

- Filho, G.R.; de Assunção, R.M.N.; Vieira, J.G.; Meireles, C.D.; Cerqueira, D.A.; Barud, H.D. Characterization of methylcellulose produced from sugar cane bagasse cellulose: Crystallinity and thermal properties. Polym. Degrad. Stab. 2007, 92, 205–210. [Google Scholar] [CrossRef]

- Cao, J.; Billows, C.A. Crystallinity determination of native and stretched wool by X-ray diffraction. Polym. Int. 1999, 48, 1027–1033. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1958, 29, 786–794. [Google Scholar] [CrossRef]

- Jiang, F.; Hsieh, Y.-L. Cellulose nanocrystal isolation from tomato peels and assembled nanofibers. Carbohydr. Polym. 2015, 122, 60–68. [Google Scholar] [CrossRef]

| Agricultural and Food Processing Residues | Main Composition | Reference |

|---|---|---|

| Banana fiber | Cellulose, hemicellulose, lignin | [8,46] |

| Carbon fly ash | Alumino-silicate, unburned carbon, iron oxide, calcium, potassium, magnesium, sodium, and sulfur compounds | [60,86,87] |

| Cassava bagasse | Starch and cellulose | [85,88] |

| Coir fiber | Lignin, cellulose and pectin | [6,89] |

| Eggshells | Calcium carbonate, proteins | [9,51] |

| Oil palm fiber | Cellulose, lignin and hemicellulose | [7,90] |

| Oil palm ash | Silicon dioxide, calcium oxide, potassium oxide, magnesium oxide and phosphorus pentoxide and unburned carbon | [91,92] |

| Rice husk | Cellulose, hemicellulose, lignin and Silicon dioxide | [93,94] |

| Rice husk ash | Silicon dioxide and unburned carbon | [14,95,96] |

| Shellfish | Chitin, calcium carbonate, protein | [13,84,97] |

| Soy hulls | Cellulose, hemicellulose, lignin, protein and pectin | [11,98,99] |

| Tomato peels | Cutin, pectin, cellulose and hemicellulose | [86,100,101] |

| Material | Index of Refraction | Hardness (Kg/mm2) |

|---|---|---|

| Diamond | 2.40 | 5700 |

| Germanium | 4.00 | 550 |

| Silicon | 3.42 | 1150 |

| Zinc selenide | 2.42 | 120 |

| Thallium bromide | 2.35 | 40 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrera, C.S.; Cornish, K. Characterization of Agricultural and Food Processing Residues for Potential Rubber Filler Applications. J. Compos. Sci. 2019, 3, 102. https://doi.org/10.3390/jcs3040102

Barrera CS, Cornish K. Characterization of Agricultural and Food Processing Residues for Potential Rubber Filler Applications. Journal of Composites Science. 2019; 3(4):102. https://doi.org/10.3390/jcs3040102

Chicago/Turabian StyleBarrera, Cindy S., and Katrina Cornish. 2019. "Characterization of Agricultural and Food Processing Residues for Potential Rubber Filler Applications" Journal of Composites Science 3, no. 4: 102. https://doi.org/10.3390/jcs3040102

APA StyleBarrera, C. S., & Cornish, K. (2019). Characterization of Agricultural and Food Processing Residues for Potential Rubber Filler Applications. Journal of Composites Science, 3(4), 102. https://doi.org/10.3390/jcs3040102