Fiber-Reinforced Composite Sandwich Structures by Co-Curing with Additive Manufactured Epoxy Lattices

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

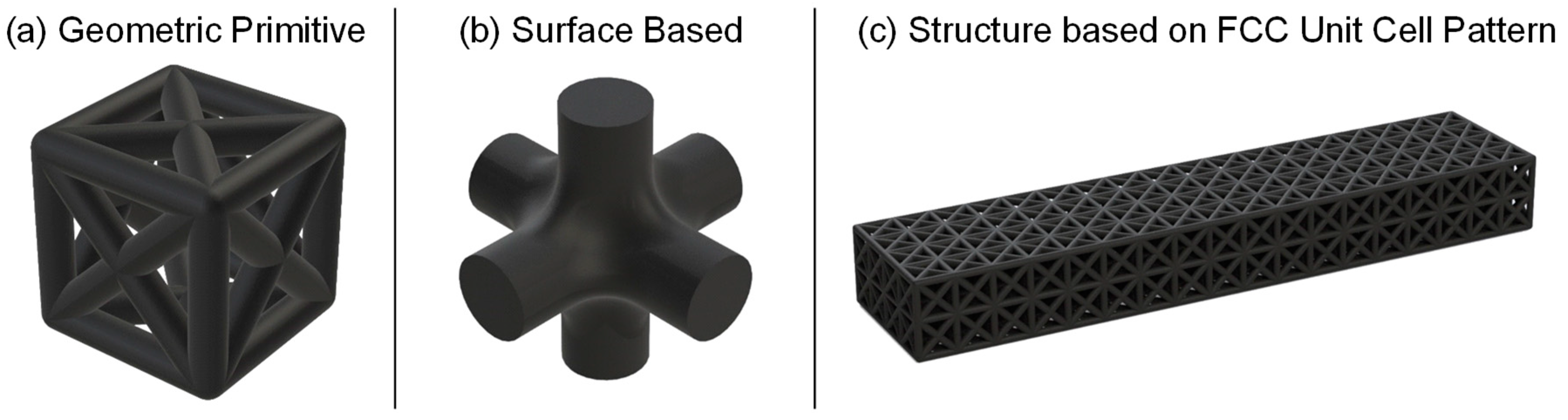

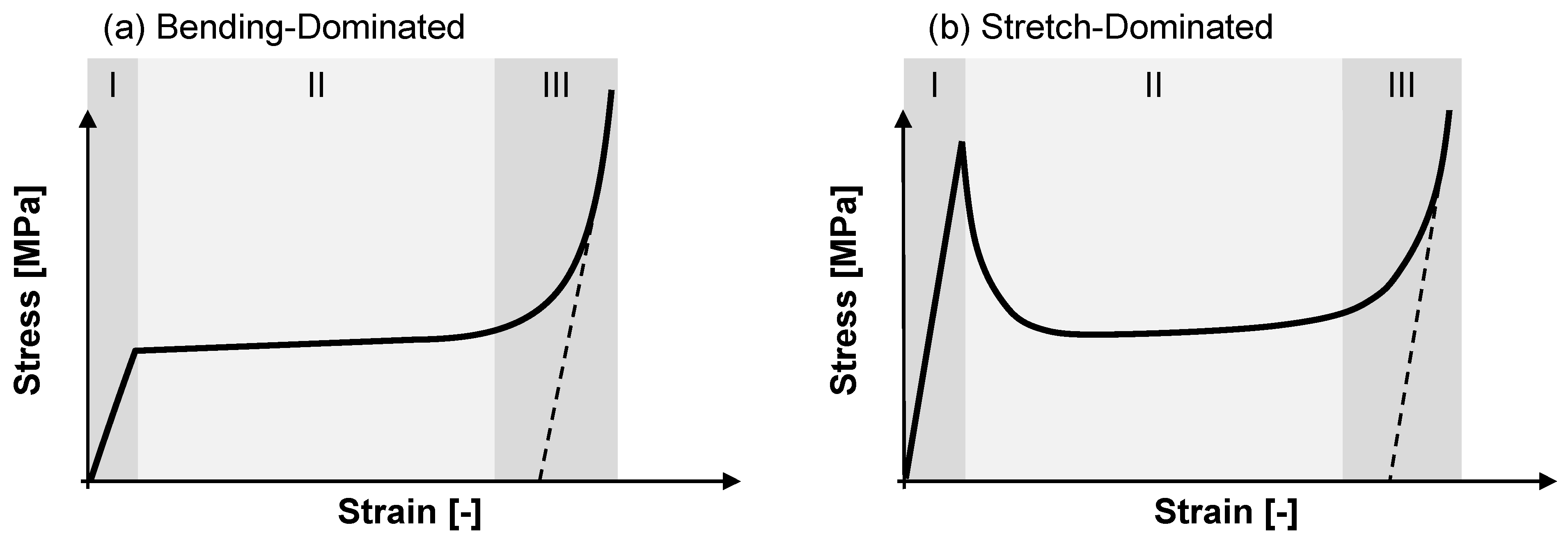

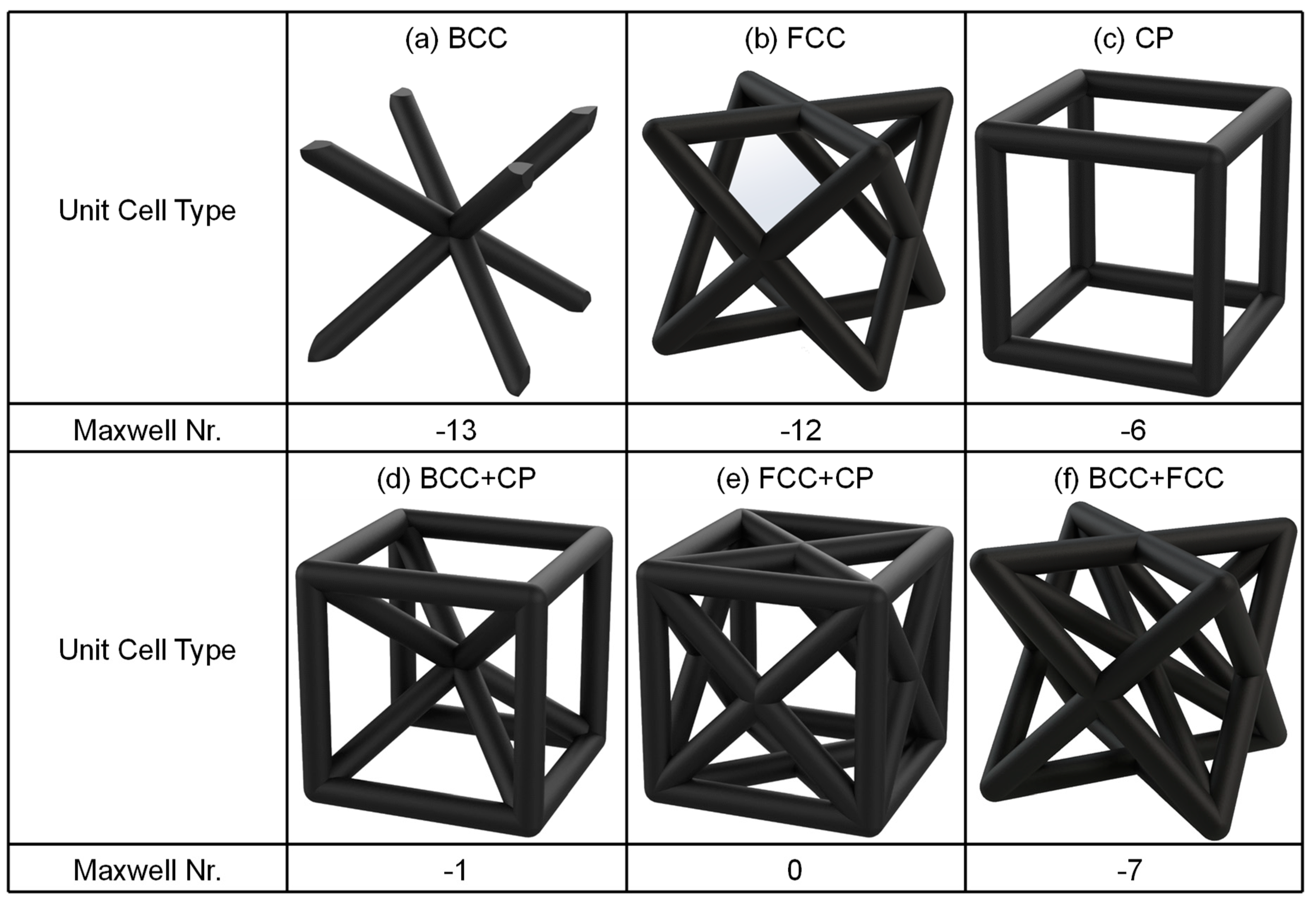

2.2. Lattice Structure Design

2.2.1. Compression Testing

2.2.2. Flexural Beam Testing

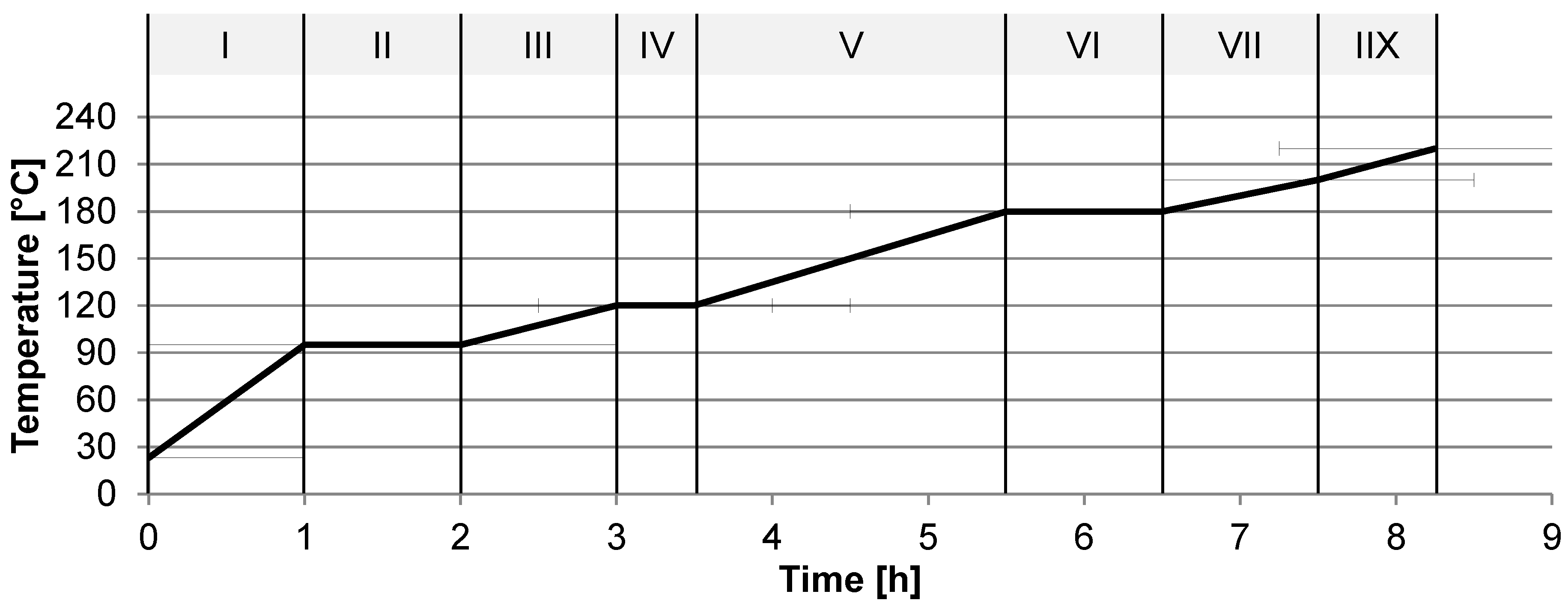

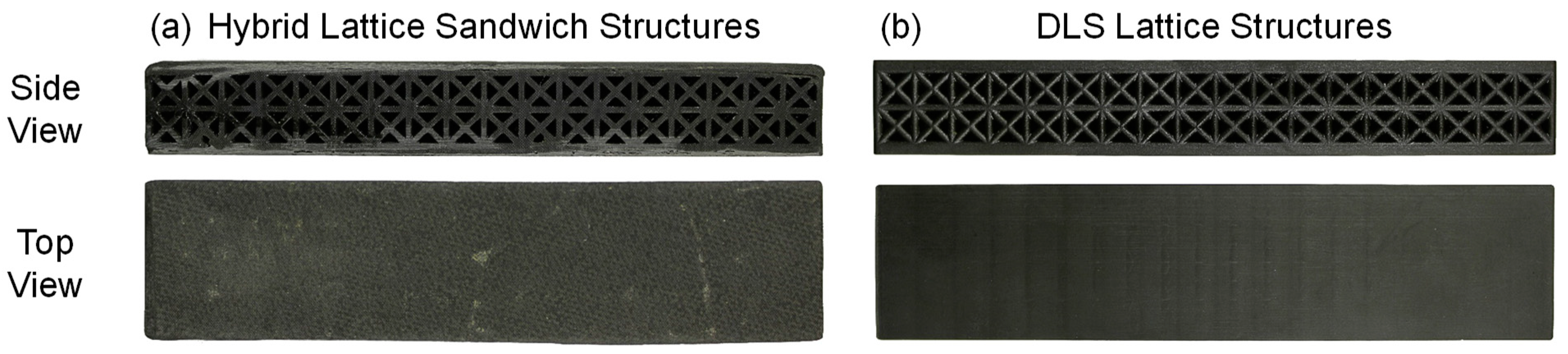

2.3. Manufacturing of Hybrid Lattice Sandwich Structures

3. Results

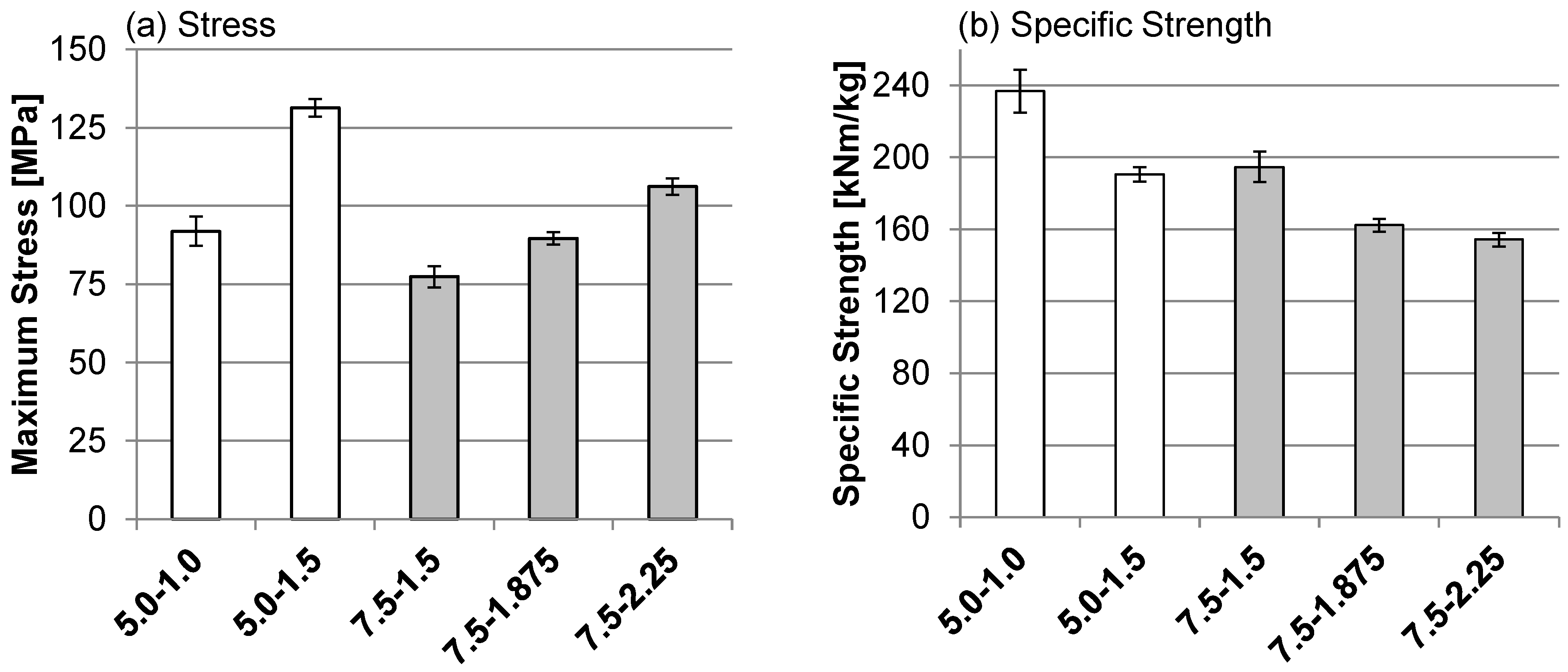

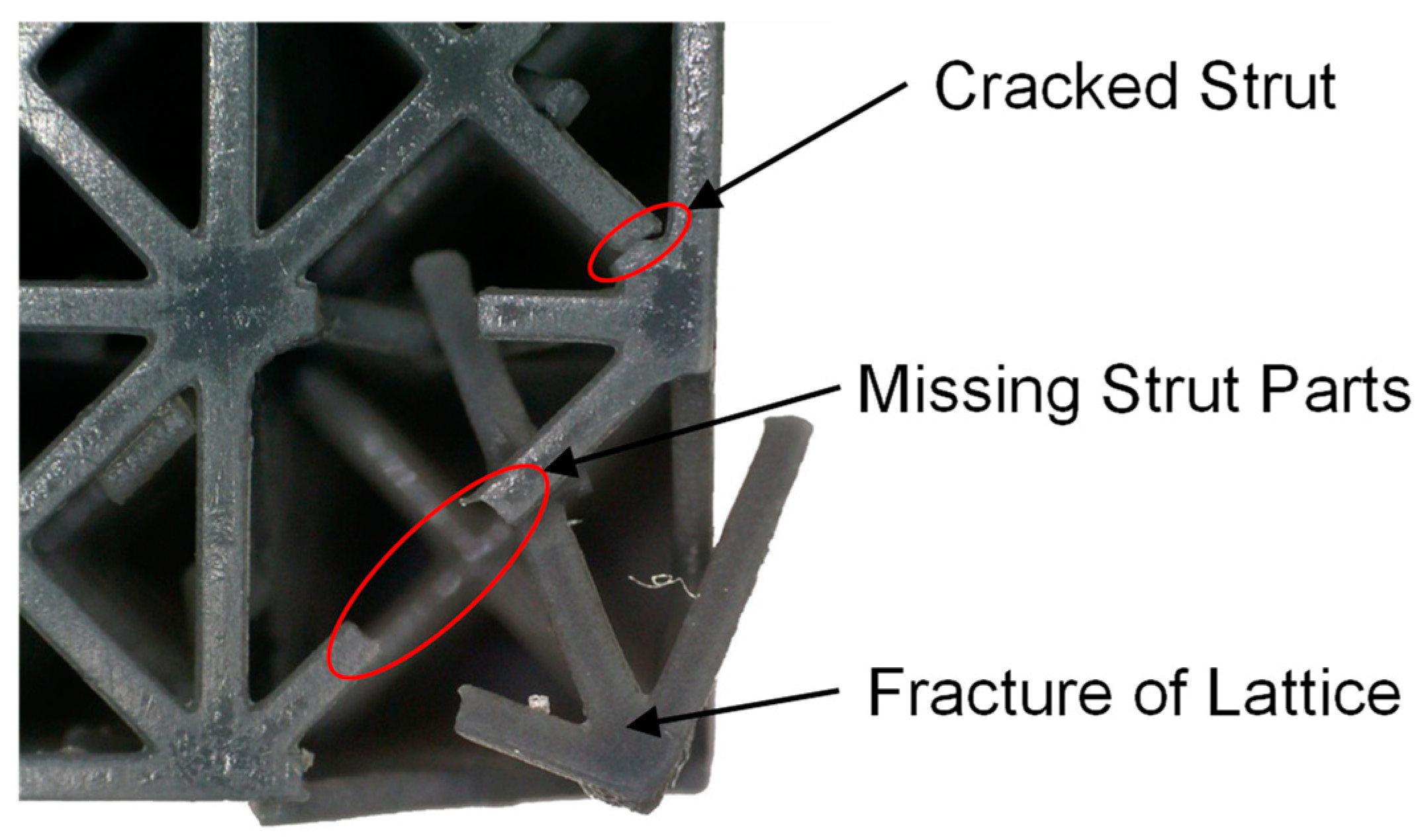

3.1. Mechanical Characterization of DLS Lattice Structures

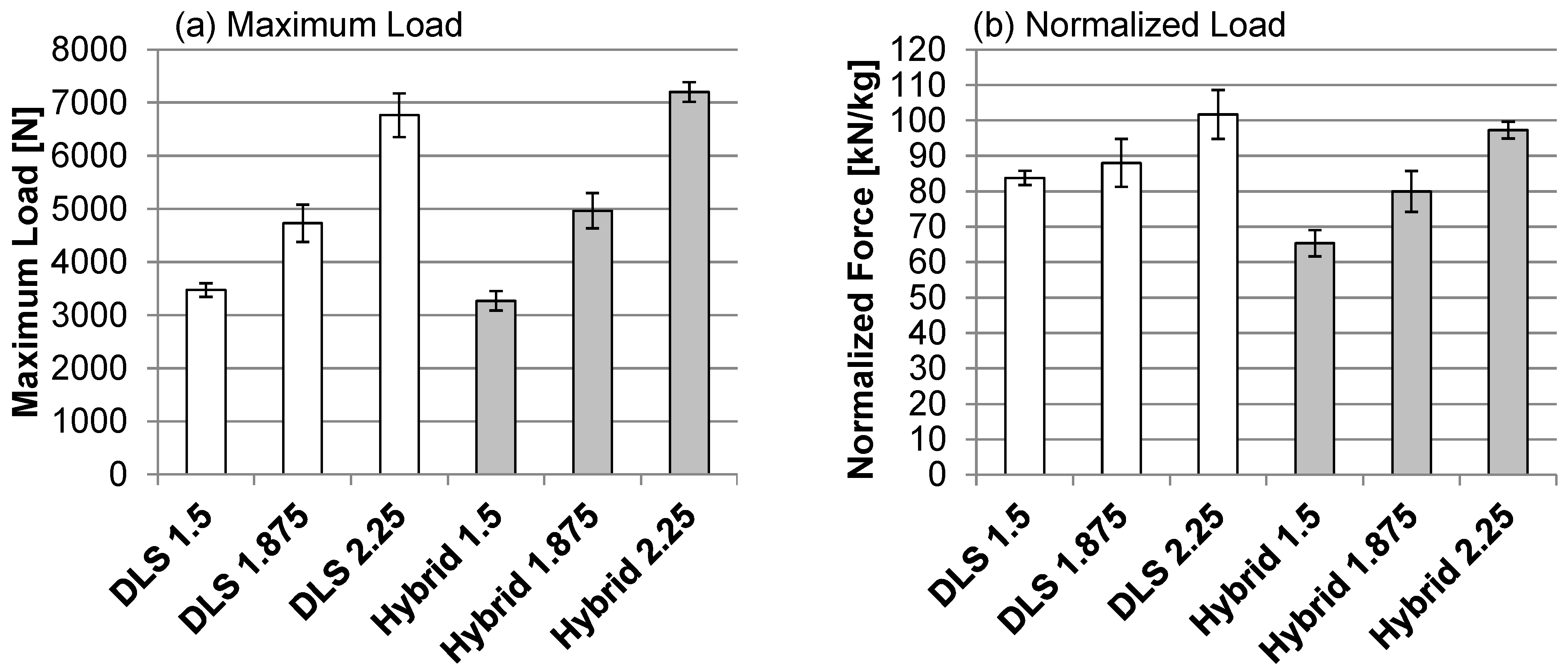

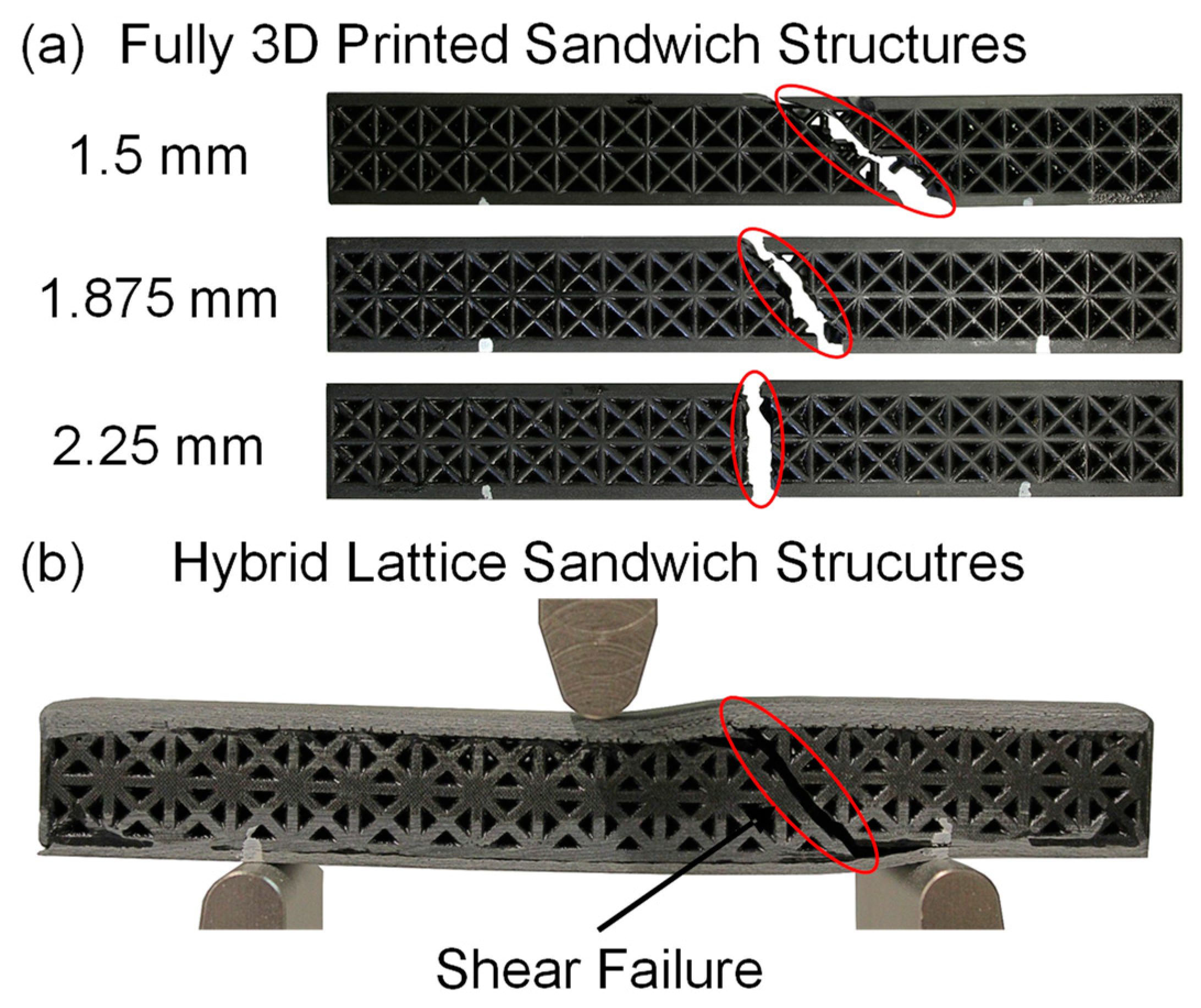

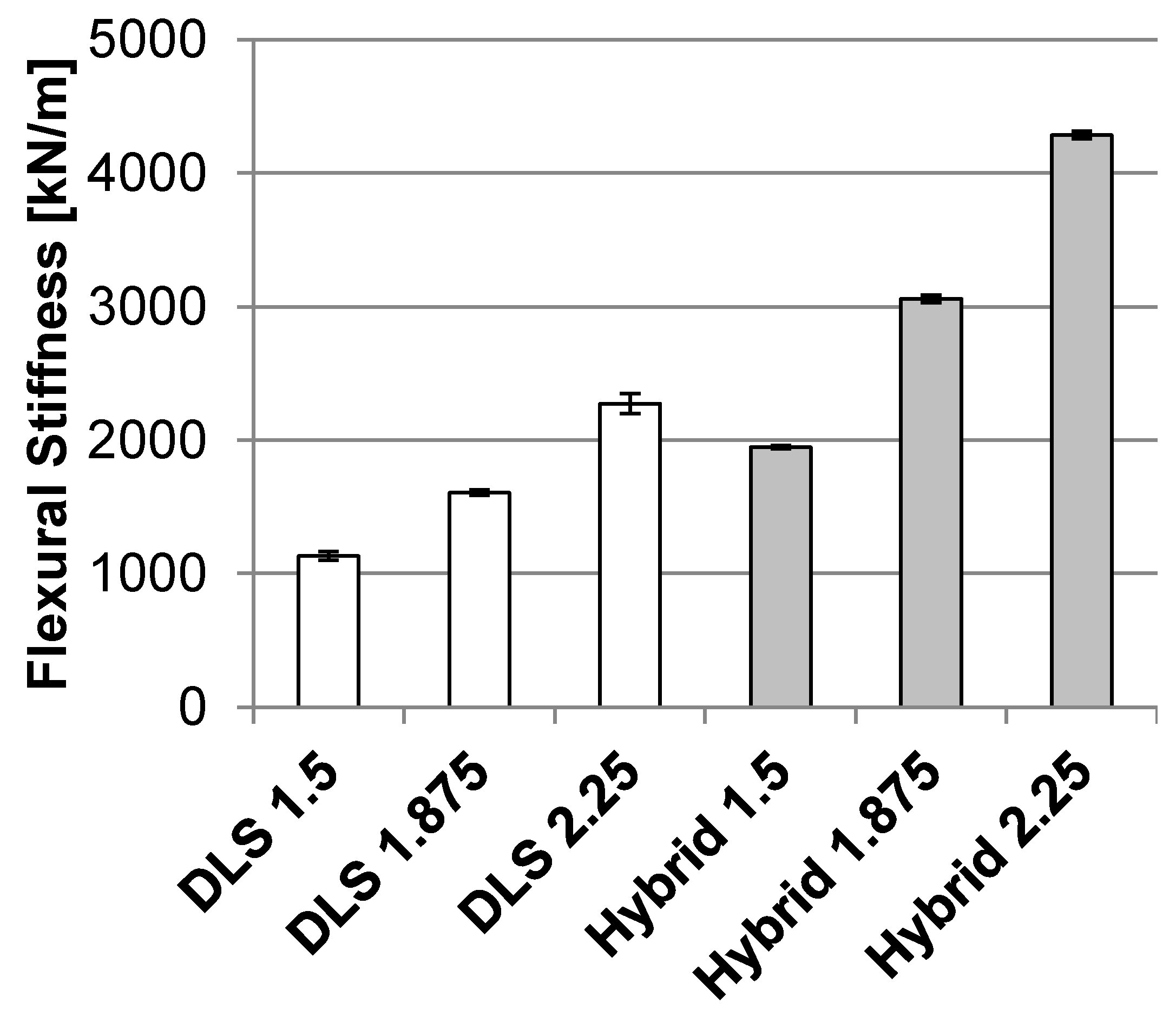

3.2. Flexural Testing of Hybrid Lattice Sandwich Structure

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Herrmann, A.T.; Zahlen, P.C.; Zuardy, I. Sandwich Structures Technology in Commercial Aviation; Springer: Dordrecht, The Netherlands, 2005; ISBN 1-4020-3444-X. [Google Scholar]

- Eckstein, L.; Schmitt, F.; Hartmann, B. Leichtbau bei Elektrofahrzeugen. ATZ-Automob. Z. 2010, 112, 788–795. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union Regulation (EU) No 333/2014 of the European Parliament and of the Council of 11 March 2014 Amending Regulation (EC) No 443/2009 to Define the Modalities for Reaching the 2020 Target to Reduce CO2 Emissions from New Passenger Cars; European Union: Strassburg, France, 2014.

- Xiong, J.; Du, Y.; Mousanezhad, D.; Eydani Asl, M.; Norato, J.; Vaziri, A. Sandwich Structures with Prismatic and Foam Cores: A Review. Adv. Eng. Mater. 2019, 21, 1800036. [Google Scholar] [CrossRef]

- Allen, H.G. Analysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics Division; Pergamon: Oxford, UK, 1969; ISBN 978-0-08-012870-2. [Google Scholar]

- SAND.CORe Co-ordination Action on. Best Practice Guide for Sandwich Structures in Marine Applications; Newcastle University: Newcastle upon Tyne, UK, 2013. [Google Scholar]

- Türk, D.-A.; Kussmaul, R.; Zogg, M.; Klahn, C.; Spierings, A.; Könen, H.; Ermanni, P.; Meboldt, M. Additive manufacturing with composites for integrated aircraft structures. In Proceedings of the SAMPE, Long Beach, CA, USA, 23–26 May 2016. [Google Scholar]

- Osswald, T.A. Understanding Polymer Processing: Processes and Governing Equations, 2nd ed.; Hanser Publishers and Hanser Publications: Munich, Germany; Cincinnati, OH, USA, 2017; ISBN 978-1-56990-647-7. [Google Scholar]

- Gebhardt, A.; Hötter, J.-S. Additive Manufacturing: 3D Printing for Prototyping and Manufacturing; Hanser Publishers and Hanser Publications: Munich, Germany; Cincinnati, OH, USA, 2016; ISBN 978-1-56990-582-1. [Google Scholar]

- Li, T.; Wang, L. Bending behavior of sandwich composite structures with tunable 3D-printed core materials. Compos. Struct. 2017, 175, 46–57. [Google Scholar] [CrossRef]

- Beyer, C.; Figueroa, D. Design and Analysis of Lattice Structures for Additive Manufacturing. J. Manuf. Sci. Eng. 2016, 138, 121014. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Carter, W.B. Architected Cellular Materials. Annu. Rev. Mater. Res. 2016, 46, 187–210. [Google Scholar] [CrossRef]

- Tao, W.; Leu, M.C. Design of lattice structure for additive manufacturing. In Proceedings of the International Symposium on Flexible Automation: ISFA 2016, Cleveland, OH, USA, 1–3 August 2016. [Google Scholar]

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Dong, G.; Zhou, Q.; Zhao, Y.F. Lattice Structure Design and Optimization with Additive Manufacturing Constraints. IEEE Trans. Autom. Sci. Eng. 2017, 15, 1546–1562. [Google Scholar] [CrossRef]

- Wadley, H.N.G. Multifunctional periodic cellular metals. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2006, 364, 31–68. [Google Scholar] [CrossRef] [PubMed]

- Rashed, M.G.; Ashraf, M.; Mines, R.A.W.; Hazell, P.J. Metallic microlattice materials: A current state of the art on manufacturing, mechanical properties and applications. Mater. Des. 2016, 95, 518–533. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; McMillan, M.; Sun, S.; Shidid, D.; Brandt, M. Mechanical properties of Ti6Al4V and AlSi12Mg lattice structures manufactured by Selective Laser Melting (SLM). In Laser Additive Manufacturing; Woodhead Publishing: Cambridge, UK, 2017; pp. 119–161. [Google Scholar]

- Janusziewicz, R.; Tumbleston, J.R.; Quintanilla, A.L.; Mecham, S.J.; DeSimone, J.M. Layerless fabrication with continuous liquid interface production. Proc. Natl. Acad. Sci. USA 2016, 113, 11703–11708. [Google Scholar] [CrossRef] [PubMed]

- De Simone, J.M.; Ermoshkin, A.; Samulski, E.T. Method and Apperatus for Three-Dimensional Fabrication. US Patent 9,498,920, 22 November 2016. [Google Scholar]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Additive manufacturing. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Epoxy Technology Inc. B-Stage Epoxy; Epoxy Technology Inc.: Billerica, MA, USA, 2012. [Google Scholar]

- Carbon, Inc. CarbonResin EPX 81; Carbon, Inc.: Redwood, CA, USA, 2017. [Google Scholar]

- Carbon, Inc. CarbonResin EPX 81 Biocompatibility; Carbon, Inc.: Redwood, CA, USA, 2017. [Google Scholar]

- Mitsubishi Chemical Carbon Fiber and Composites, Inc. EP4030 Epoxy Resin System; Mitsubishi Chemical Carbon Fiber and Composites, Inc.: Irvine, CA, USA, 2017. [Google Scholar]

- ASTM D1621 Test Method for Compressive Properties of Rigid Cellular Plastics; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D7249 Test Method for Facing Properties of Sandwich Constructions by Long Beam Flexure; ASTM International: West Conshohocken, PA, USA, 2016.

- www18 Carbon Hardware. Available online: https://www.carbon3d.com/hardware (accessed on 18 February 2018).

- Deshpande, V.S.; Fleck, N.A.; Ashby, M.F. Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 2001, 49, 1747–1769. [Google Scholar] [CrossRef]

- Dong, L.; Deshpande, V.; Wadley, H. Mechanical response of Ti-6Al-4V octet-truss lattice structures. Int. J. Solids Struct. 2015, 60–61, 107–124. [Google Scholar] [CrossRef]

- Saigal, A.; Tumbleston, J.; Vogel, H.; Fox, C.; Mackay, N. Mechanical Response of Octahedral and Octet-Truss Lattice Structures Fabricated Using the CLIP Technology; DEStech Publications, Inc.: Lancaster, PA, USA, 2016. [Google Scholar]

| Material Property | EPX81 | EP4030 |

|---|---|---|

| Tensile Strength (MPa) | 88 ± 3 | 2370 |

| Tensile Modulus (GPa) | 3140 ± 105 | 146 |

| Flexural Strength (MPa) | 119 ± 21 | 1720 |

| Flexural Modulus (MPa) | 3250 ± 45 | 140 |

| Specimen Designation | Unit Cell Size (mm) | Strut Diameter (ds) (mm) | Ratio of Strut Diameter and Unit Cell Size |

|---|---|---|---|

| 5-0.5 | 5 | 0.500 | 0.10 |

| 5-1.0 | 1.000 | 0.20 | |

| 5-1.5 | 1.500 | 0.30 | |

| 7.5-1.5 | 7.5 | 1.500 | 0.20 |

| 7.5-1.875 | 1.875 | 0.25 | |

| 7.5-2.25 | 2.250 | 0.30 |

| Specimen Designation | Face Sheet Material | Strut Diameter (ds) (mm) | Ratio of Strut Diameter and Unit Cell Size |

|---|---|---|---|

| Hybrid 1.5 | 5 layers CF prepreg | 1.500 | 0.20 |

| Hybrid 1.875 | 1.875 | 0.25 | |

| Hybrid 2.25 | 2.250 | 0.30 | |

| DLS 1.5 | EXP81 | 1.500 | 0.20 |

| DLS 1.875 | 1.875 | 0.25 | |

| DLS 2.25 | 2.250 | 0.30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Austermann, J.; Redmann, A.J.; Dahmen, V.; Quintanilla, A.L.; Mecham, S.J.; Osswald, T.A. Fiber-Reinforced Composite Sandwich Structures by Co-Curing with Additive Manufactured Epoxy Lattices. J. Compos. Sci. 2019, 3, 53. https://doi.org/10.3390/jcs3020053

Austermann J, Redmann AJ, Dahmen V, Quintanilla AL, Mecham SJ, Osswald TA. Fiber-Reinforced Composite Sandwich Structures by Co-Curing with Additive Manufactured Epoxy Lattices. Journal of Composites Science. 2019; 3(2):53. https://doi.org/10.3390/jcs3020053

Chicago/Turabian StyleAustermann, Johannes, Alec J. Redmann, Vera Dahmen, Adam L. Quintanilla, Sue J. Mecham, and Tim A. Osswald. 2019. "Fiber-Reinforced Composite Sandwich Structures by Co-Curing with Additive Manufactured Epoxy Lattices" Journal of Composites Science 3, no. 2: 53. https://doi.org/10.3390/jcs3020053

APA StyleAustermann, J., Redmann, A. J., Dahmen, V., Quintanilla, A. L., Mecham, S. J., & Osswald, T. A. (2019). Fiber-Reinforced Composite Sandwich Structures by Co-Curing with Additive Manufactured Epoxy Lattices. Journal of Composites Science, 3(2), 53. https://doi.org/10.3390/jcs3020053