On the Structure and Mechanical Properties of Multilayered Composite, Obtained by Explosive Welding of High-Strength Titanium Alloys

Abstract

:1. Introduction

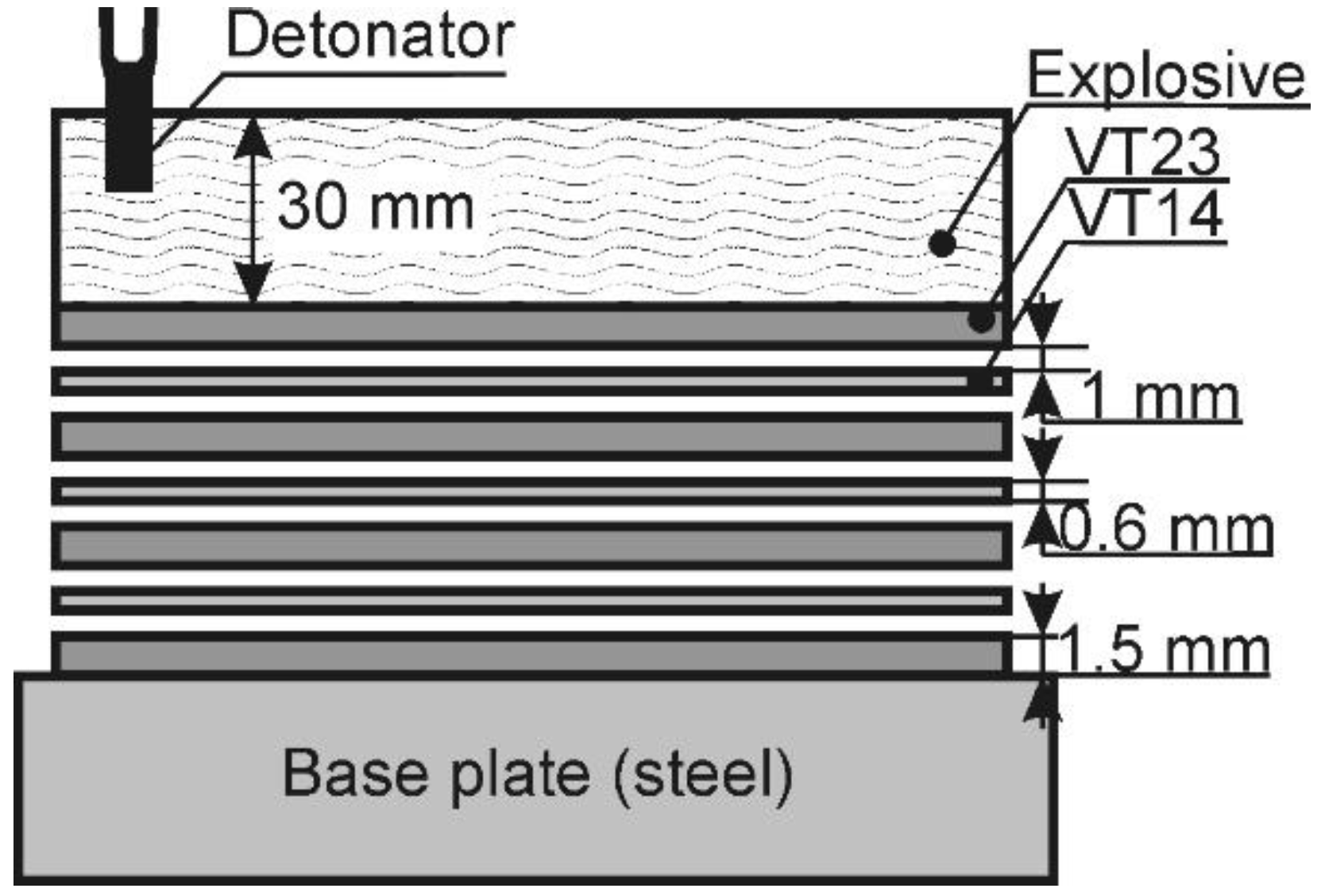

2. Materials and Methods

3. Results and Discussion

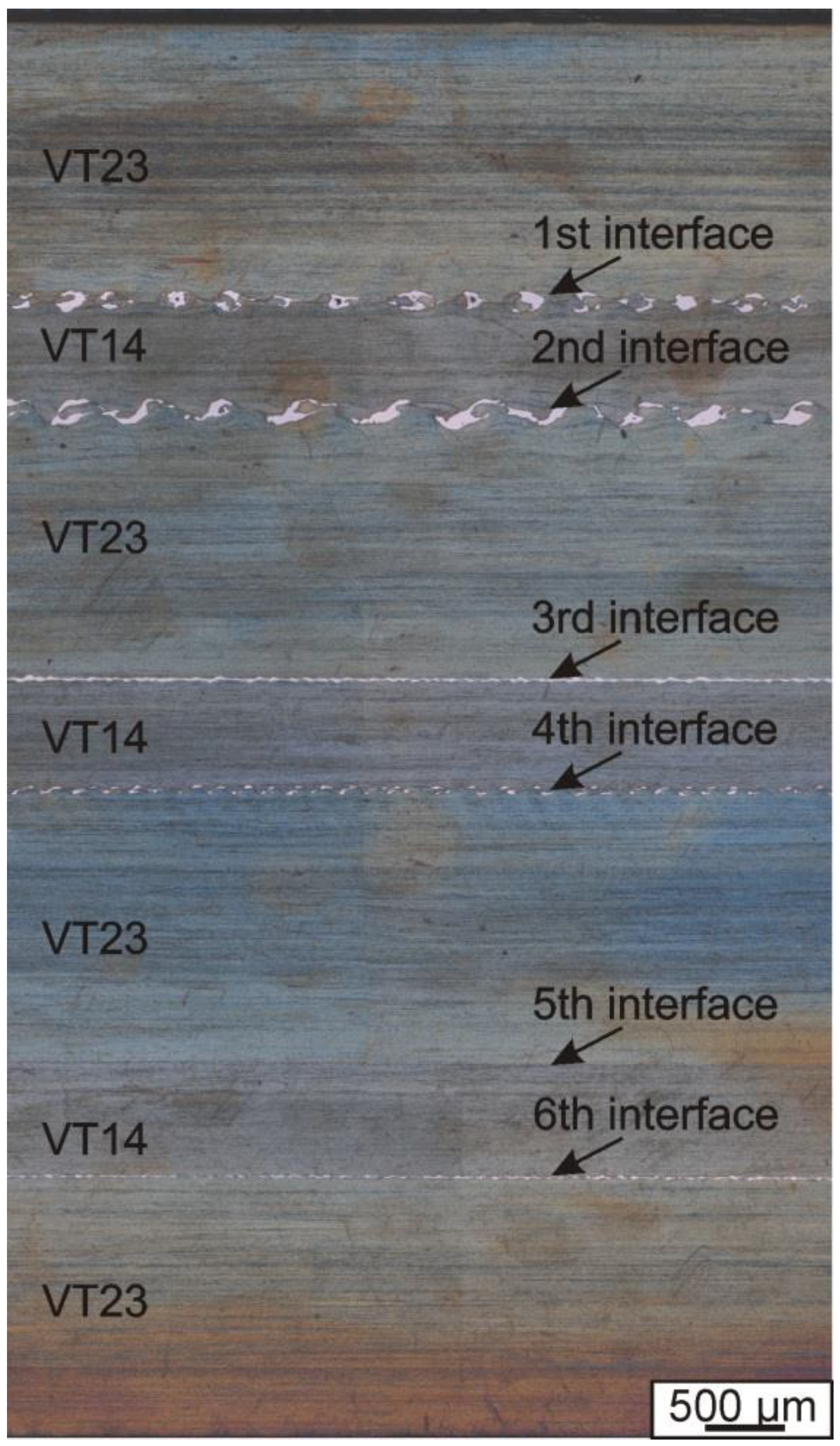

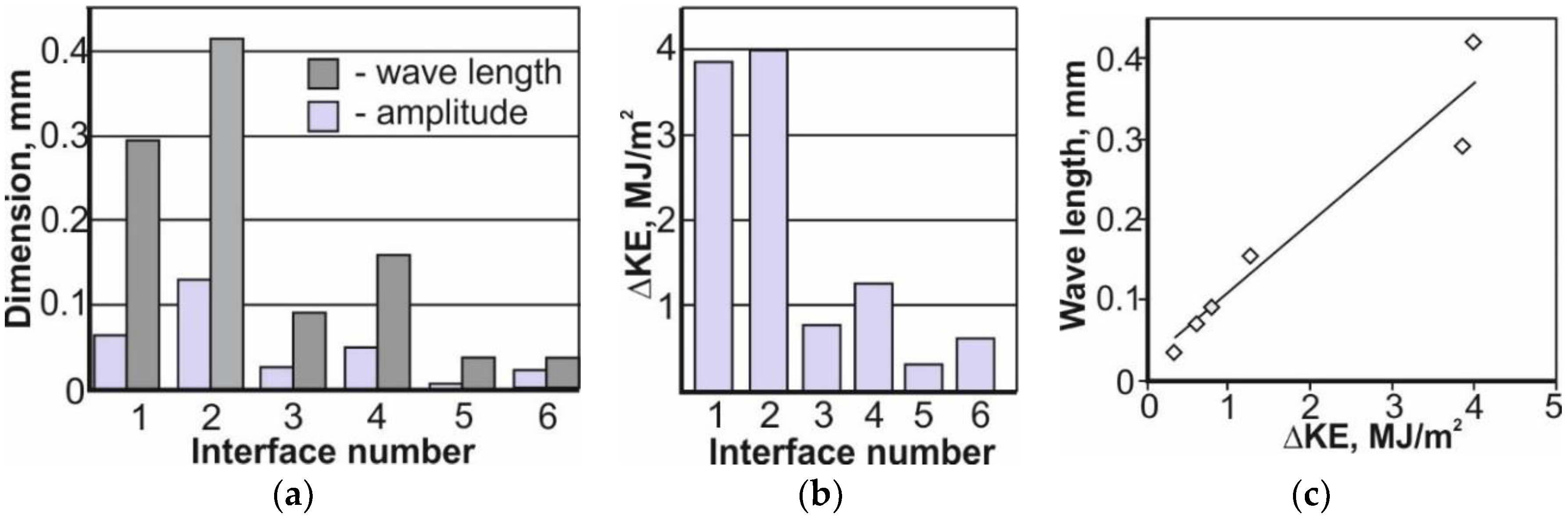

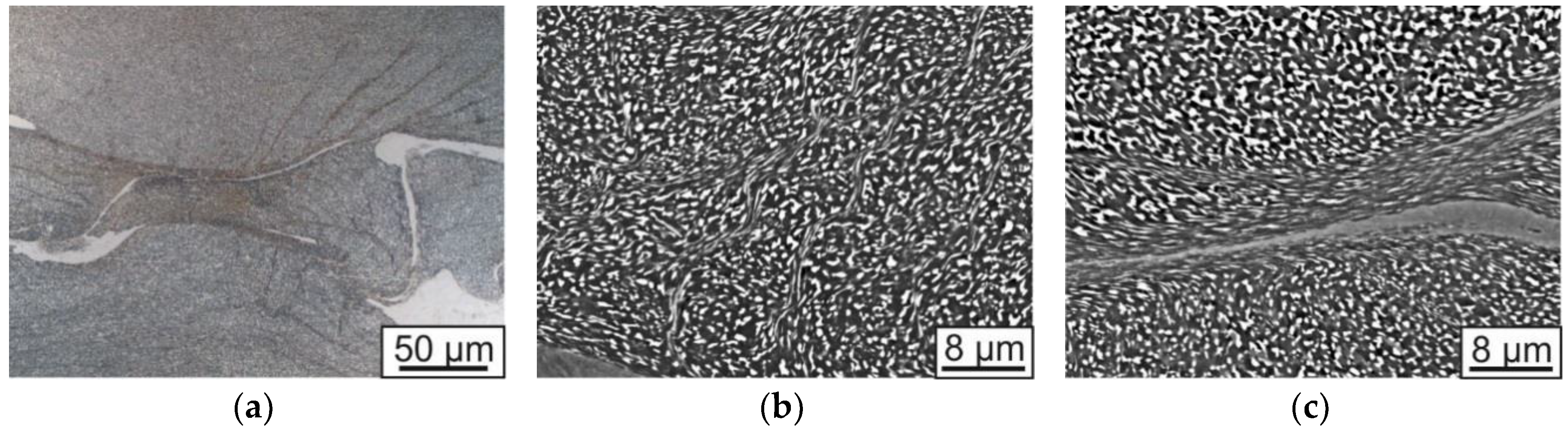

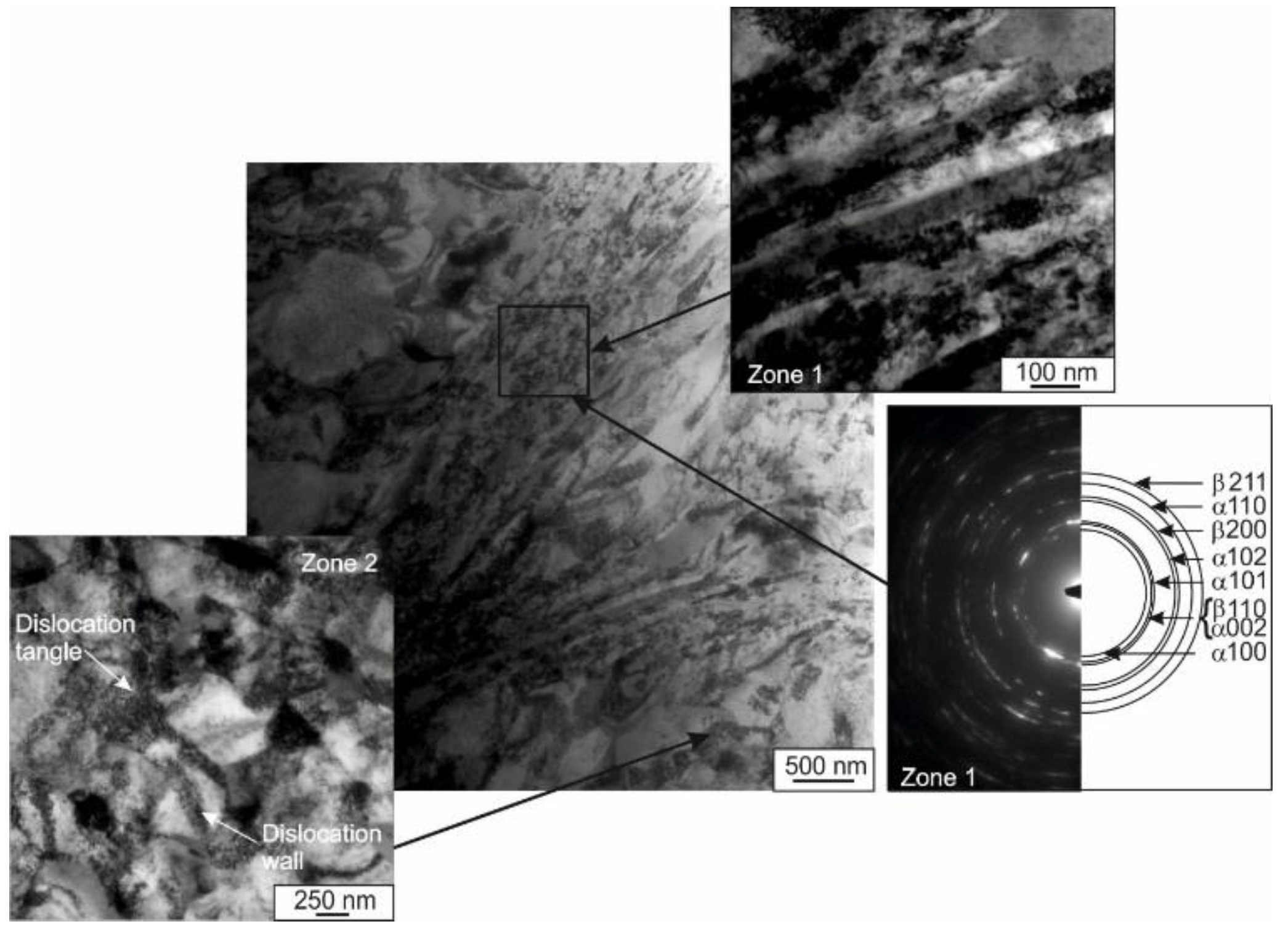

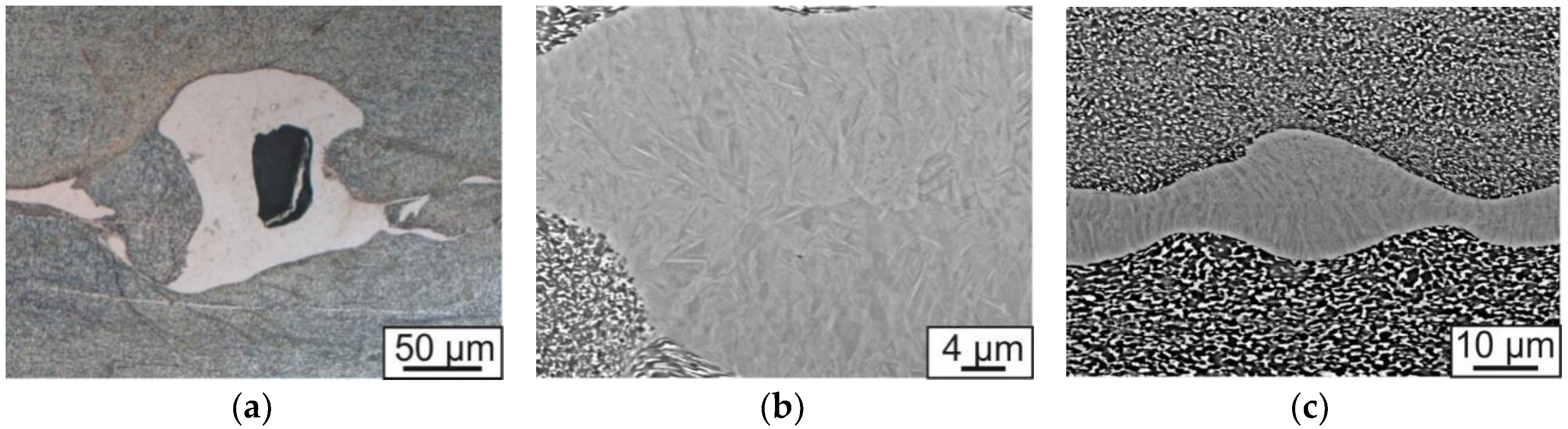

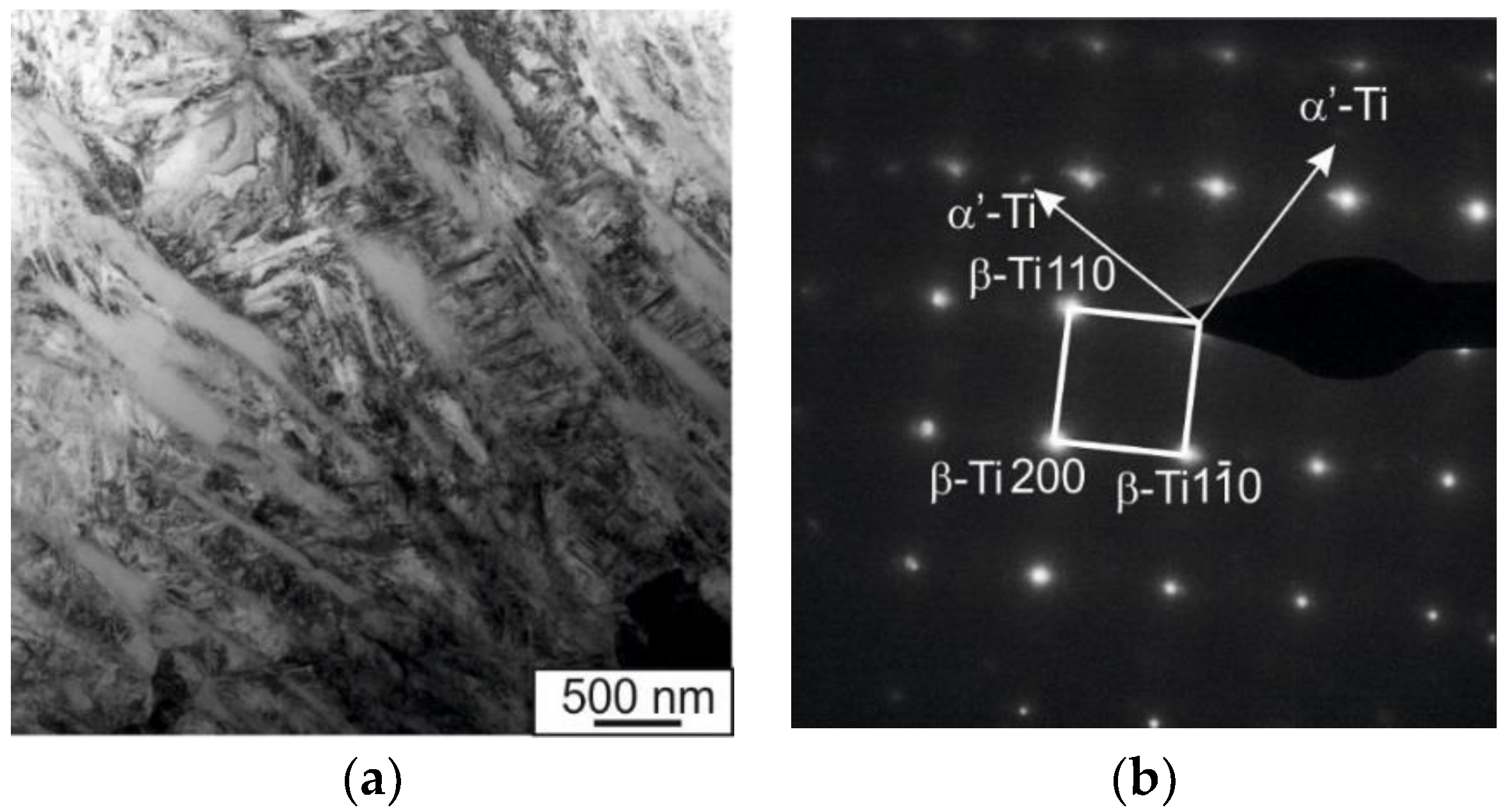

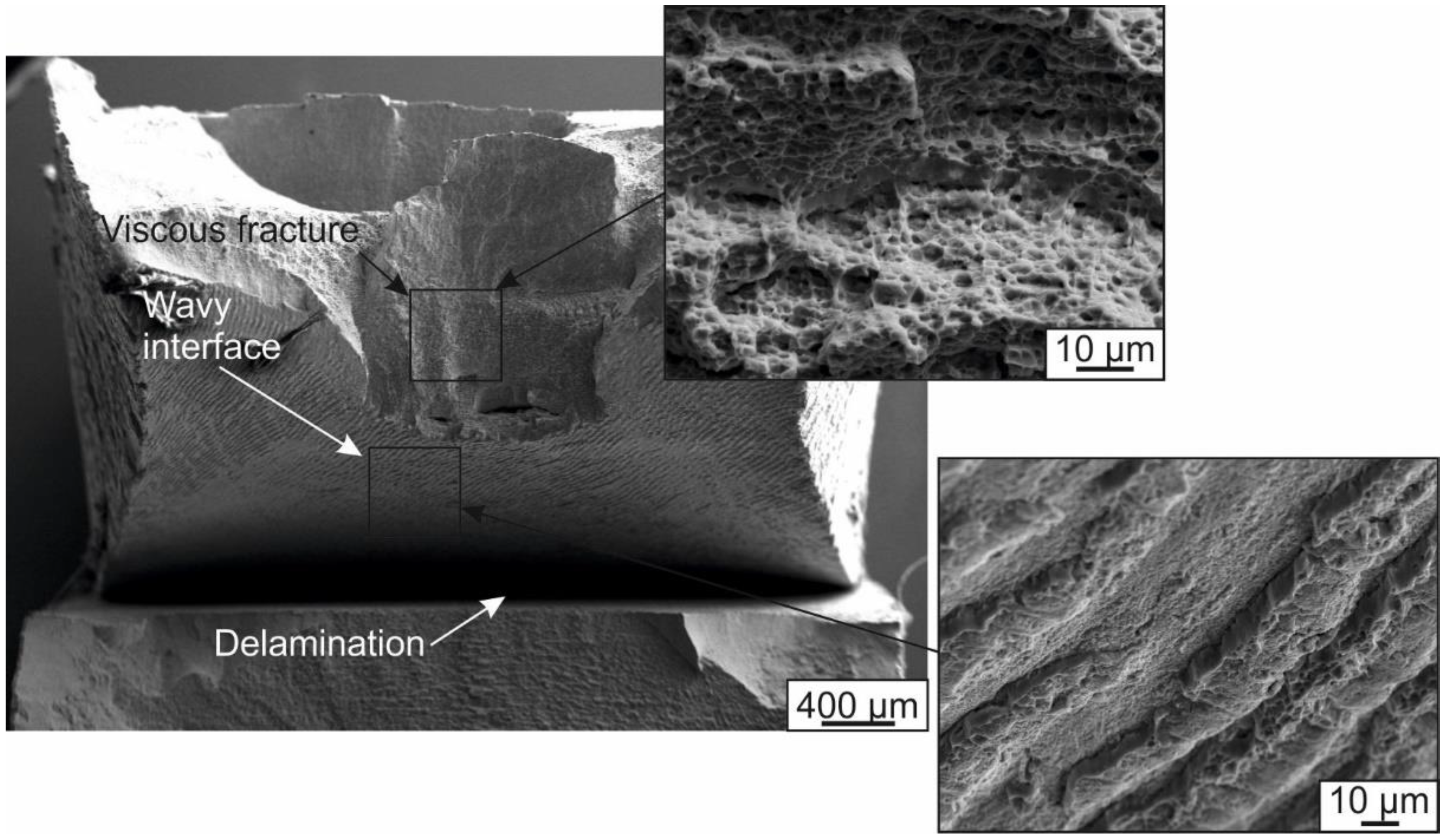

3.1. Structural Investigations of the Interfaces Between Titanium Alloys

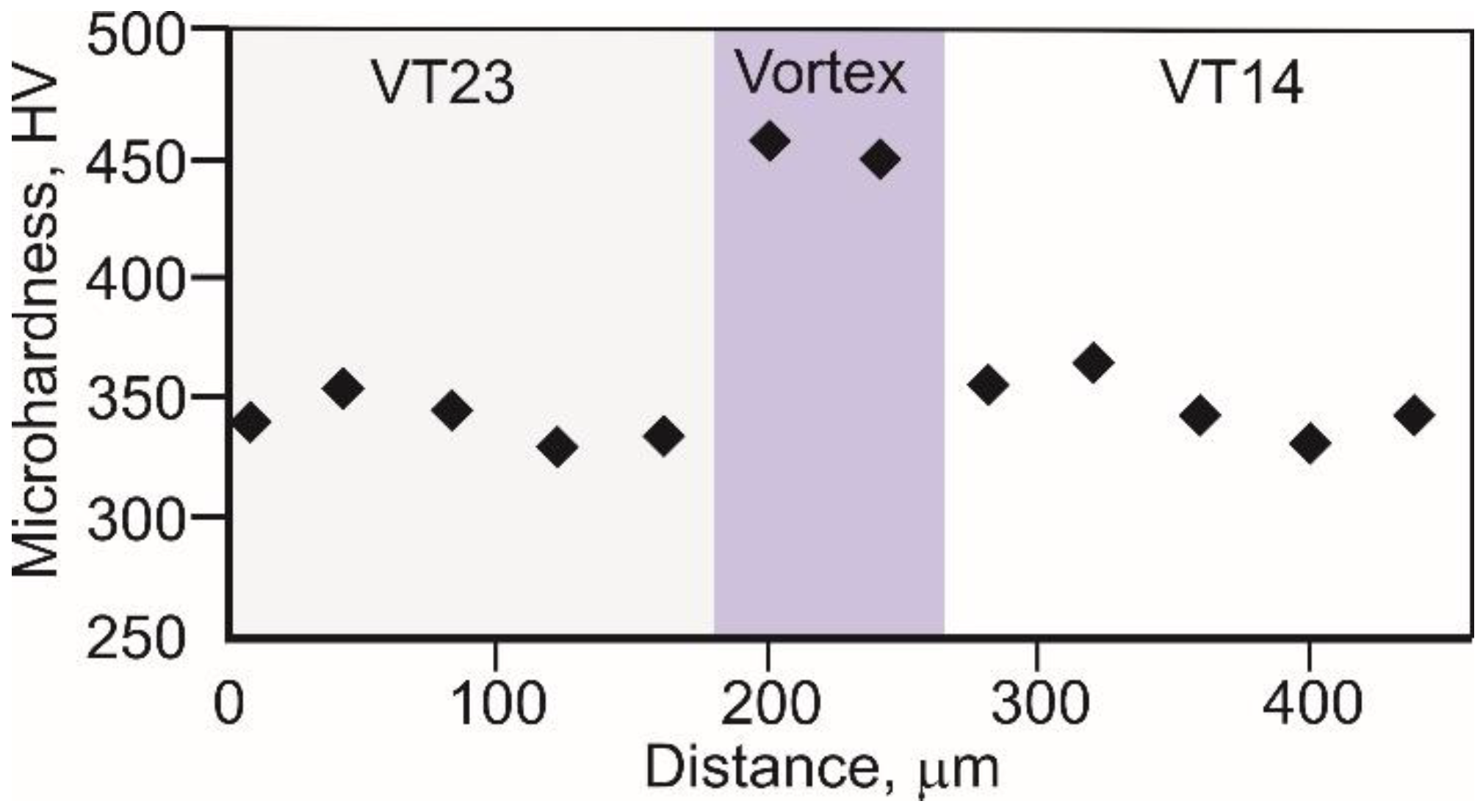

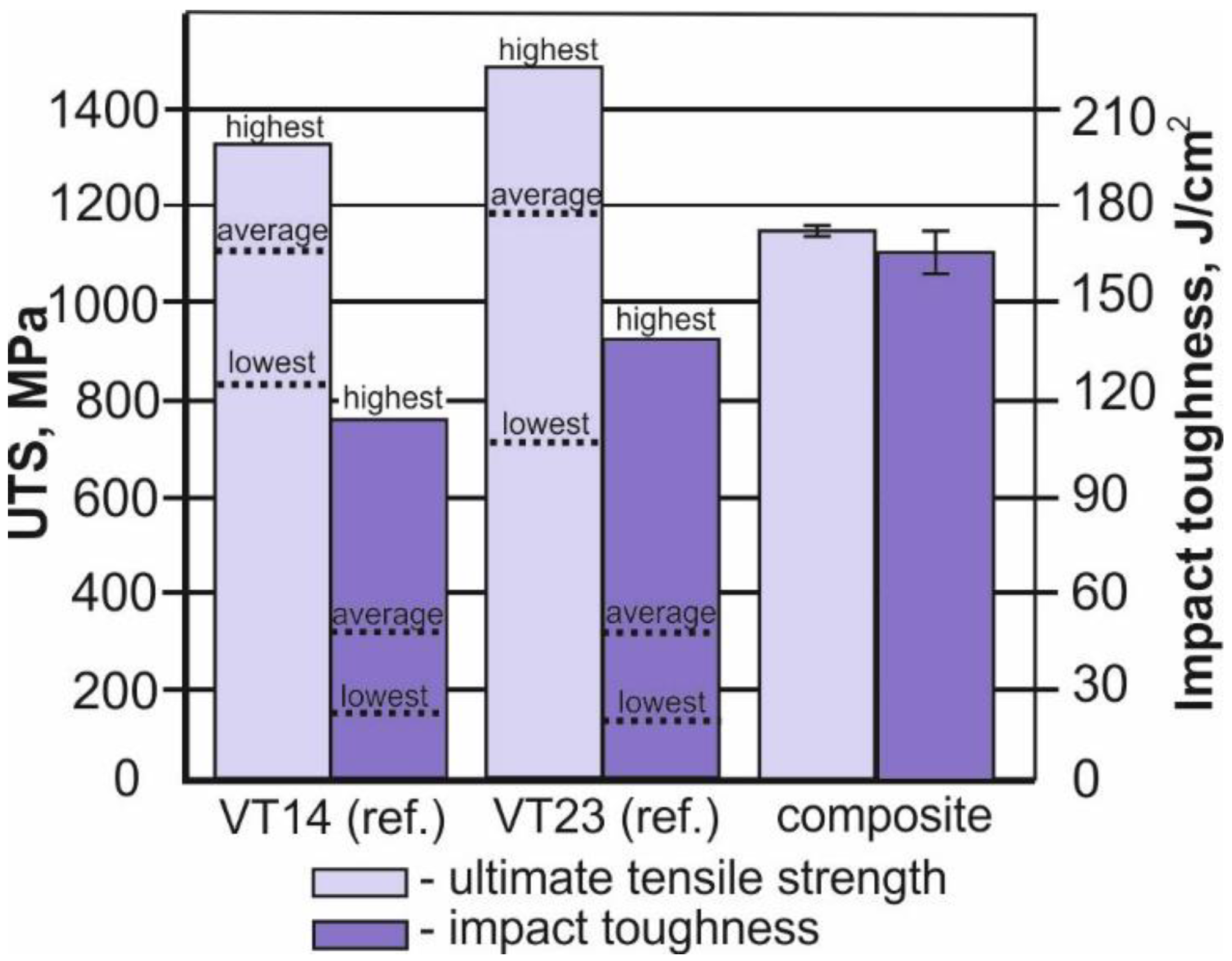

3.2. Mechanical Properties of the Composite

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003; p. 532. [Google Scholar]

- Donachie, M.J. Titanium: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000; p. 381. [Google Scholar]

- Grabovetskaya, G.P.; Kolobov, G.P.; Ivanov, K.V.; Zabudchenko, O.V. The effect of cold severe plastic deformation on structure, deformation behavior and mechanical properties of ultrafine-grained titanium. Phys. Mesomech. 2004, 7, 22–25. [Google Scholar]

- Grabovetskaya, G.P.; Chernova, L.V.; Kolobov, Y.R.; Girsova, N.V. Structure and deformation behavior of submicrocrystalline titanium at creep. Phys. Mesomech. 2002, 5, 87–94. [Google Scholar]

- Dudarev, E.F.; Bakach, G.P.; Grabovetskaya, G.P.; Kolobov, Y.R.; Kashin, O.A.; Chernova, L.V. Plastic deformation behavior and localization in submicrocrystalline titanium at meso- and macroscale levels. Phys. Mesomech. 2001, 4, 97–104. [Google Scholar]

- Dudarev, E.F.; Pochivalova, G.P.; Kolobov, Y.R.; Galkina, I.G.; Kashin, O.A.; Girsova, N.V. Influence of severe plastic deformation and subsequent annealing on true grain-boundary sliding in coarse-grained and ultrafine-grained titanium. Phys. Mesomech. 2004, 7, 30–33. [Google Scholar]

- Il’in, A.A.; Kolachev, B.A.; Pol’kin, I.S. Titanovye Splavy. Sostav, Structura, Svoystva; VILS-MATI: Moscow, Russia, 2009; p. 519. [Google Scholar]

- Çetin, A.; Krebs, J.; Durussel, A.; Rossoll, A.; Inoue, J.; Koseki, T.; Nambu, S.; Mortensen, A. Laminated metal composites by infiltration. Metall. Mater. Trans. A 2011, 42, 3509–3520. [Google Scholar] [CrossRef]

- Wadsworth, J.; Lesuer, D.R. Ancient and modern laminated composites—From the great pyramid of gizeh to Y2K. Mater. Charact. 2000, 45, 289–313. [Google Scholar] [CrossRef]

- Chaudhari, G.P.; Acoff, V. Cold roll bonding of multi-layered bi-metal laminate composites. Compos. Sci. Technol. 2009, 69, 1667–1675. [Google Scholar] [CrossRef]

- Luo, J.G.; Acoff, V.L. Using cold roll bonding and annealing to process Ti/Al multi-layered composites from elemental foils. Mater. Sci. Eng. A 2004, 379, 164–172. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; Carreño, F.; Ruano, O.A.; Sarkeeva, A.A.; Kruglov, A.A.; Lutfullin, R. Influence of interfacial defects on the impact toughness of solid state diffusion bonded Ti-6Al-4V alloy based multilayer composites. Mater. Sci. Eng. A 2013, 563, 28–35. [Google Scholar] [CrossRef]

- Alizadeh, M.; Samiei, M. Fabrication of nanostructured Al/Cu/Mn metallic multilayer composites by accumulative roll bonding process and investigation of their mechanical properti. Mater. Des. 2014, 56, 680–684. [Google Scholar] [CrossRef]

- Eslami, A.H.; Mojtaba Zebarjad, S.; Moshksar, M.M. Study on mechanical and magnetic properties of Cu/Ni multilayer composite fabricated by accumulative roll bonding process. Mater. Sci. Technol. 2013, 29, 1000–1005. [Google Scholar] [CrossRef]

- Jia, N.; Zhu, M.W.; Zheng, Y.R.; He, T.; Zhao, X. Inhomogeneous deformation of multilayered roll-bonded Brass/Cu composites. Acta Metall. Sin. (Engl. Lett.) 2015, 28, 600–607. [Google Scholar] [CrossRef]

- Korzhov, V.P.; Kiiko, V.M.; Karpov, M.I. Structure of multilayer microcomposite Ni/Al obtained by diffusion welding. Inorg. Mater. 2012, 3, 314–318. [Google Scholar] [CrossRef]

- Harach, D.J.; Vecchio, K.S. Microstructure evolution in metal-intermetallic laminate (MIL) composites synthesized by reactive foil sintering in air. Metall. Mater. Trans. A 2001, 32, 1493–1505. [Google Scholar] [CrossRef]

- Ege, E.S.; Inal, O.T.; Zimmerly, C.A. Response surface study on production of explosively-welded aluminum-titanium laminates. J. Mater. Sci. 1998, 33, 5327–5338. [Google Scholar] [CrossRef]

- Mal’tseva, L.A.; Tyushlyaeva, D.S.; Mal’tseva, T.V.; Pastukhov, M.V.; Lozhkin, N.N.; Inyakin, D.V.; Marshuk, L.A. Metallic layered composite materials produced by explosion welding: Structure, properties, and structure of the transition zone. Russ. Metall. 2014, 10, 817–825. [Google Scholar] [CrossRef]

- Prikhodko, E.A.; Bataev, I.A.; Bataev, A.A.; Lozhkin, V.S.; Mali, V.I.; Esikov, M.A. The effect of heat treatment on microstructure and mechanical properties of multilayered composites welded by explosion. Adv. Mater. Res. 2012, 535–537, 231–234. [Google Scholar] [CrossRef]

- Bataev, I.; Bataev, A.; Mali, V.; Burov, V.; Golovin, E.; Smirnov, A.; Prikhodko, E. Structure and fatigue crack resistance of multilayer materials produced by explosive welding. Adv. Mater. Res. 2011, 287–290, 108–111. [Google Scholar] [CrossRef]

- Bataev, I.; Bataev, A.; Mali, V.; Esikov, M.; Batawv, V. Peculiarities of weld seams and adjacent zones structures formed in process of explosive welding of sheet steel plates. Mater. Sci. Forum 2011, 673, 95–100. [Google Scholar] [CrossRef]

- Akbari Mousavi, S.A.A.; Al-Hassani, S.T.S.; Atkins, A.G. Bond strength of explosively welded specimens. Mater. Des. 2008, 29, 1334–1352. [Google Scholar] [CrossRef]

- Hokamoto, K.; Chiba, A.; Fujita, M.; Izuma, T. Single-shot explosive welding technique for the fabrication of multilayered metal base composites: Effect of welding parameters leading to optimum bonding condition. Compos. Eng. 1995, 5, 1069–1079. [Google Scholar] [CrossRef]

- Manikandan, P.; Hokamoto, K.; Deribas, A.A.; Raghukandan, K.; Tomoshige, R. Explosive welding of titanium/stainless steel by controlling energetic conditions. Mater. Trans. 2006, 47, 2049–2055. [Google Scholar] [CrossRef]

- Stelly, M.; Dormeval, R. Adiabatic Shearing. In Metallurgical Application of Shock-Wave and High-Strain-Rate Phenomena; Murr, L.E., Staudhammer, K.P., Mayers, M.A., Eds.; Marcel Dekker: New York City, NY, USA, 1986; pp. 607–632. [Google Scholar]

- Cho, K.; Chi, Y.C.; Duffy, J. Microscopic observations of adiabatic shear bands in three different steel. Mater. Trans. A 1990, 21, 1167–1675. [Google Scholar]

- Peirs, J.; Tirry, W.; Amin-Ahmadi, B.; Coghe, F.; Verleysen, P.; Rabet, L.; Schryvers, D.; Degrieck, J. Microstructure of adiabatic shear bands in Ti6Al4V. Mater. Charact. 2013, 75, 79–92. [Google Scholar] [CrossRef]

- Meyers, M.A.; Nesterenko, V.F.; LaSalvia, J.C.; Xue, Q. Shear localization in dynamic deformation of materials: Microstructural evolution and self-organization. Mater. Sci. Eng. A 2001, 317, 204–225. [Google Scholar] [CrossRef]

- Bataev, I.A. Structure of explosively welded materials: Experimental study and numerical simulation. Obrab. Metallov: Metal. Work. Mater. Sci. 2017, 4, 55–67. [Google Scholar] [CrossRef]

- Bataev, I.A.; Lazurenko, D.V.; Tanaka, S.; Hokamoto, K.; Bataev, A.A.; Guo, Y.; Jorge, A.M., Jr. High cooling rates and metastable phases at the interfaces of explosively welded materials. Acta Mater. 2017, 135, 277–289. [Google Scholar] [CrossRef]

- Cowan, G.R.; Holtzman, A.H. Flow configurations in colliding plates: Explosive bonding. J. Appl. Phys. 1963, 34, 928–939. [Google Scholar] [CrossRef]

- Deribas, A.A. Fizika Uprochneniya I Svarki Vzryvom; Nauka: Novosibirsk, Russia, 1980; p. 221. [Google Scholar]

- Fizika Vzryva; Fizmatlit: Moscow, Russia, 2004; Volume 2, p. 656.

- Kum, D.W.; Oyama, T.; Wadsworth, J.; Sherby, O.D. The impact properties of laminated composites containing ultrahigh carbon (UHC) steels. J. Mech. Phys. Solids 1983, 31, 133–137. [Google Scholar] [CrossRef]

- Lee, S.; Oyama, T.; Wadsworth, J.; Sherby, O.D. Impact properties of a laminated composite based on ultrahigh carbon steel and brass. Mater. Sci. Eng. A 1992, 154, 133–137. [Google Scholar] [CrossRef]

- Lee, S.; Wadsworth, J.; Sherby, O.D. Impact properties of a laminated composite based on ultrahigh carbon steel and a Ni-Si-Steel. J. Eng. Mater. Technol. 1992, 114, 278–281. [Google Scholar] [CrossRef]

- Lesuer, D.R.; Wadsworth, J.; Riddle, R.A.; Syn, C.K.; Lewandowski, J.J.; Hunt, W.H. Toughening mechanisms in Al/Al-SiC laminated metal composites. MRS Proc. 2011, 434, 205. [Google Scholar] [CrossRef]

| Titanium Alloy | Ti | Fe | Cr | Mo | V | Al | Others |

|---|---|---|---|---|---|---|---|

| VT23 | Bal. | 0.56 | 0.85 | 1.74 | 4.58 | 4.54 | 0.43 |

| VT14 | Bal. | 0.29 | - | 3.10 | 1.45 | 4.91 | 0.76 |

| Zone of Analysis | Ti | Al | V | Cr | Fe | Mo |

|---|---|---|---|---|---|---|

| VT23 | 86.12 | 4.68 | 4.81 | 1.1 | 0.6 | 2.7 |

| VT14 | 91.04 | 4.2 | - | - | - | 4.76 |

| Mixing zone | 89.55 | 4.47 | 2.3 | 0.4 | - | 3.28 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazurenko, D.V.; Bataev, I.; Maliutina, I.; Kuz’min, R.; Mali, V.; Esikov, M.; Kornienko, E. On the Structure and Mechanical Properties of Multilayered Composite, Obtained by Explosive Welding of High-Strength Titanium Alloys. J. Compos. Sci. 2018, 2, 39. https://doi.org/10.3390/jcs2030039

Lazurenko DV, Bataev I, Maliutina I, Kuz’min R, Mali V, Esikov M, Kornienko E. On the Structure and Mechanical Properties of Multilayered Composite, Obtained by Explosive Welding of High-Strength Titanium Alloys. Journal of Composites Science. 2018; 2(3):39. https://doi.org/10.3390/jcs2030039

Chicago/Turabian StyleLazurenko, Daria V., Ivan Bataev, Iulia Maliutina, Ruslan Kuz’min, Vyacheslav Mali, Maksim Esikov, and Elena Kornienko. 2018. "On the Structure and Mechanical Properties of Multilayered Composite, Obtained by Explosive Welding of High-Strength Titanium Alloys" Journal of Composites Science 2, no. 3: 39. https://doi.org/10.3390/jcs2030039

APA StyleLazurenko, D. V., Bataev, I., Maliutina, I., Kuz’min, R., Mali, V., Esikov, M., & Kornienko, E. (2018). On the Structure and Mechanical Properties of Multilayered Composite, Obtained by Explosive Welding of High-Strength Titanium Alloys. Journal of Composites Science, 2(3), 39. https://doi.org/10.3390/jcs2030039