Application of Laser Thermal Deformation Sintering in the Manufacture of Drum-Type Diamond Tools

Abstract

1. Introduction

2. Theoretical and Empirical Research

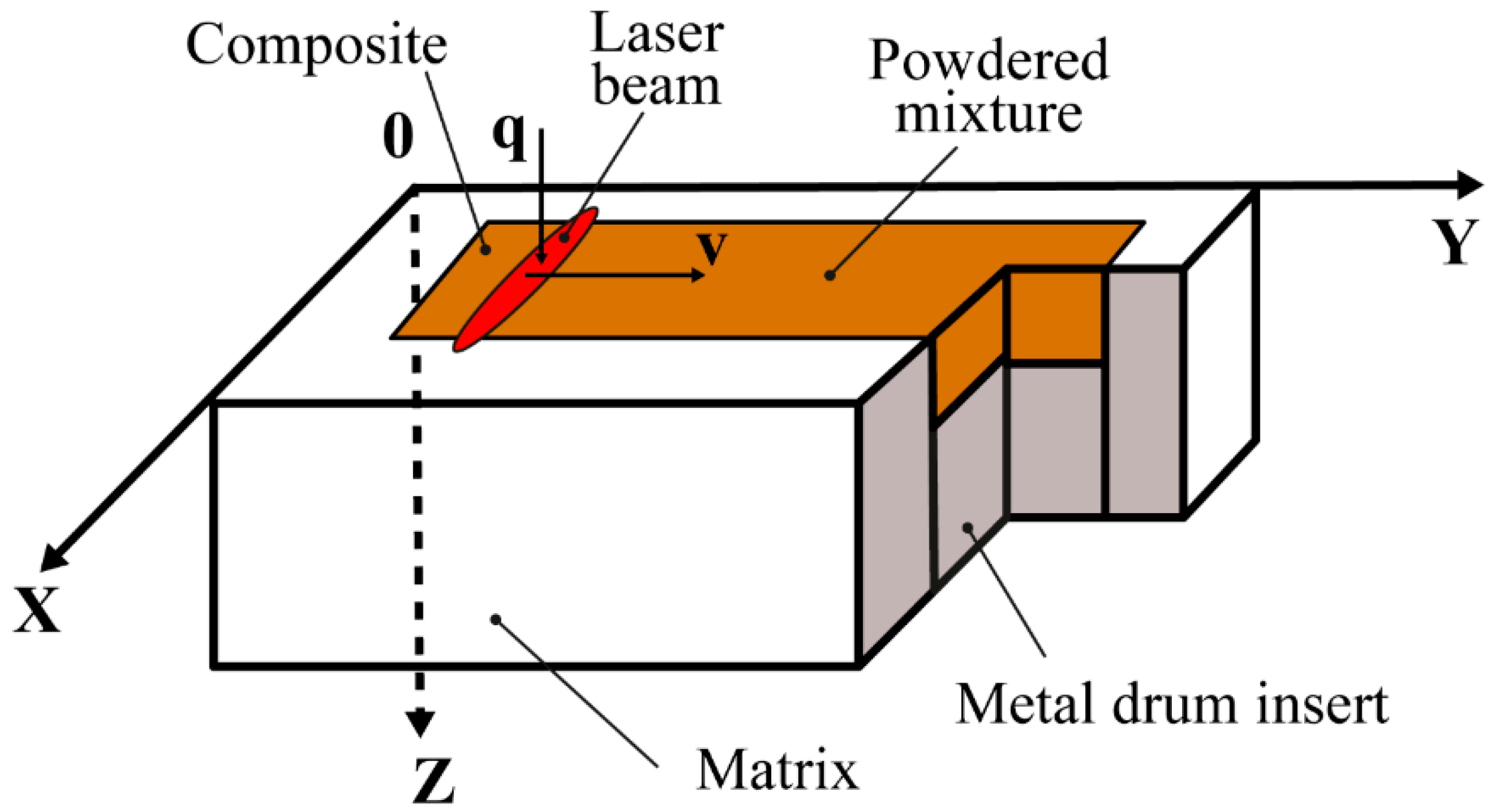

2.1. Problem Statement

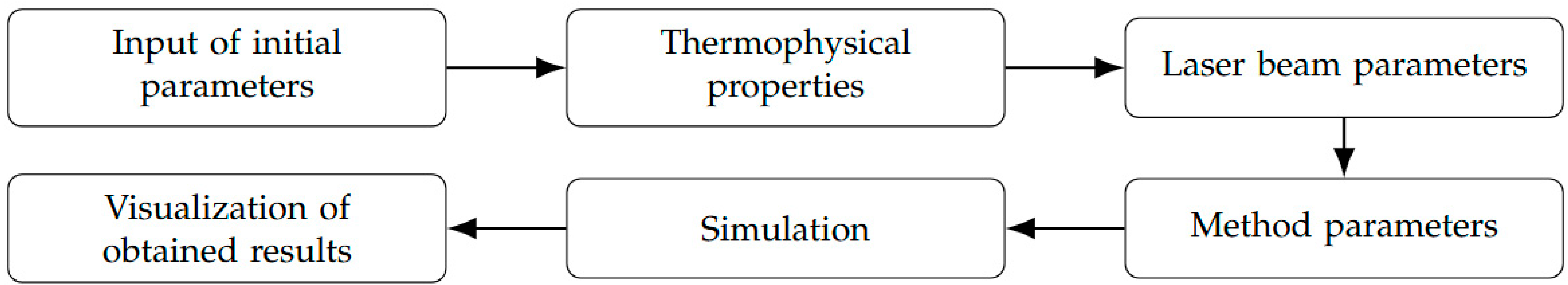

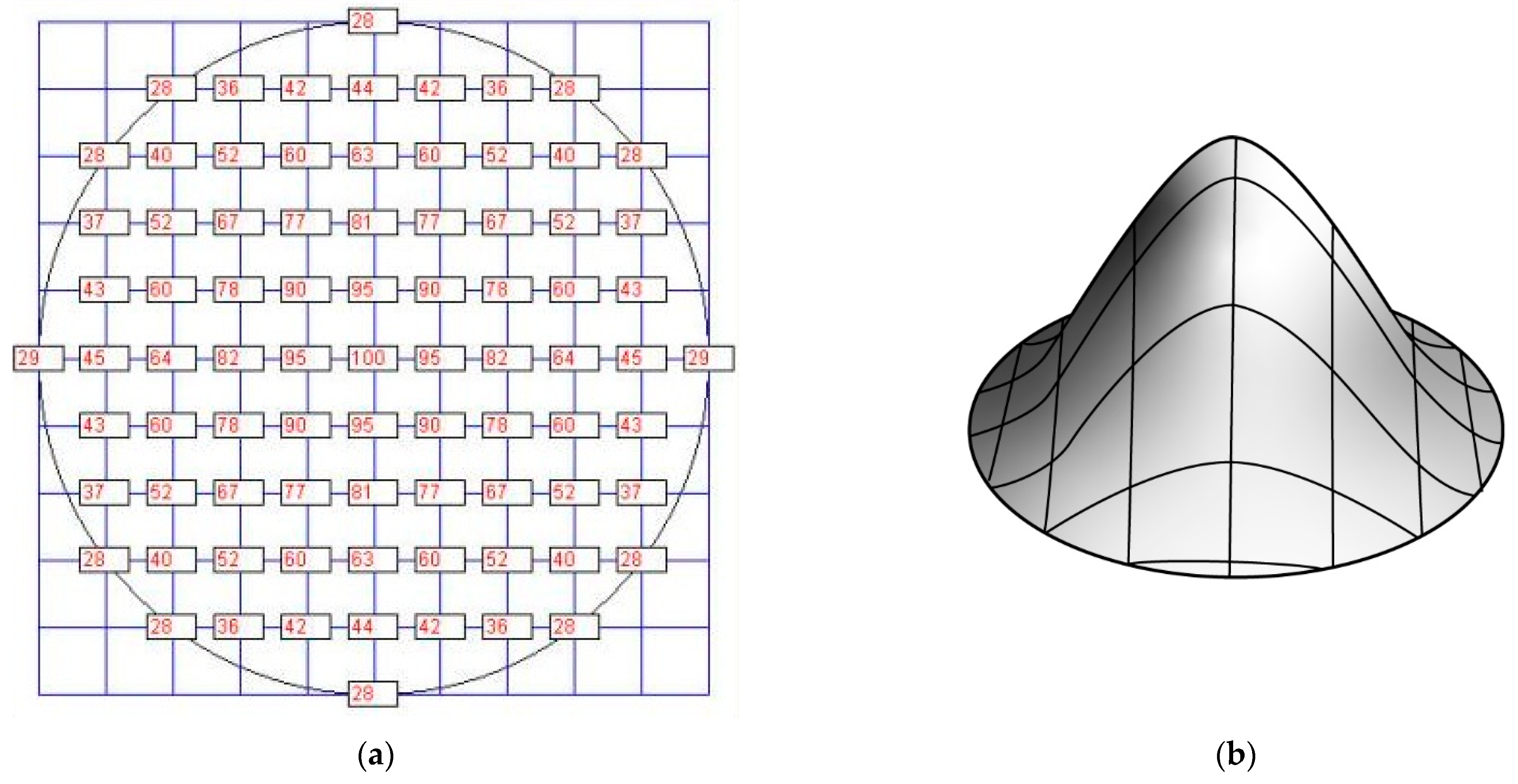

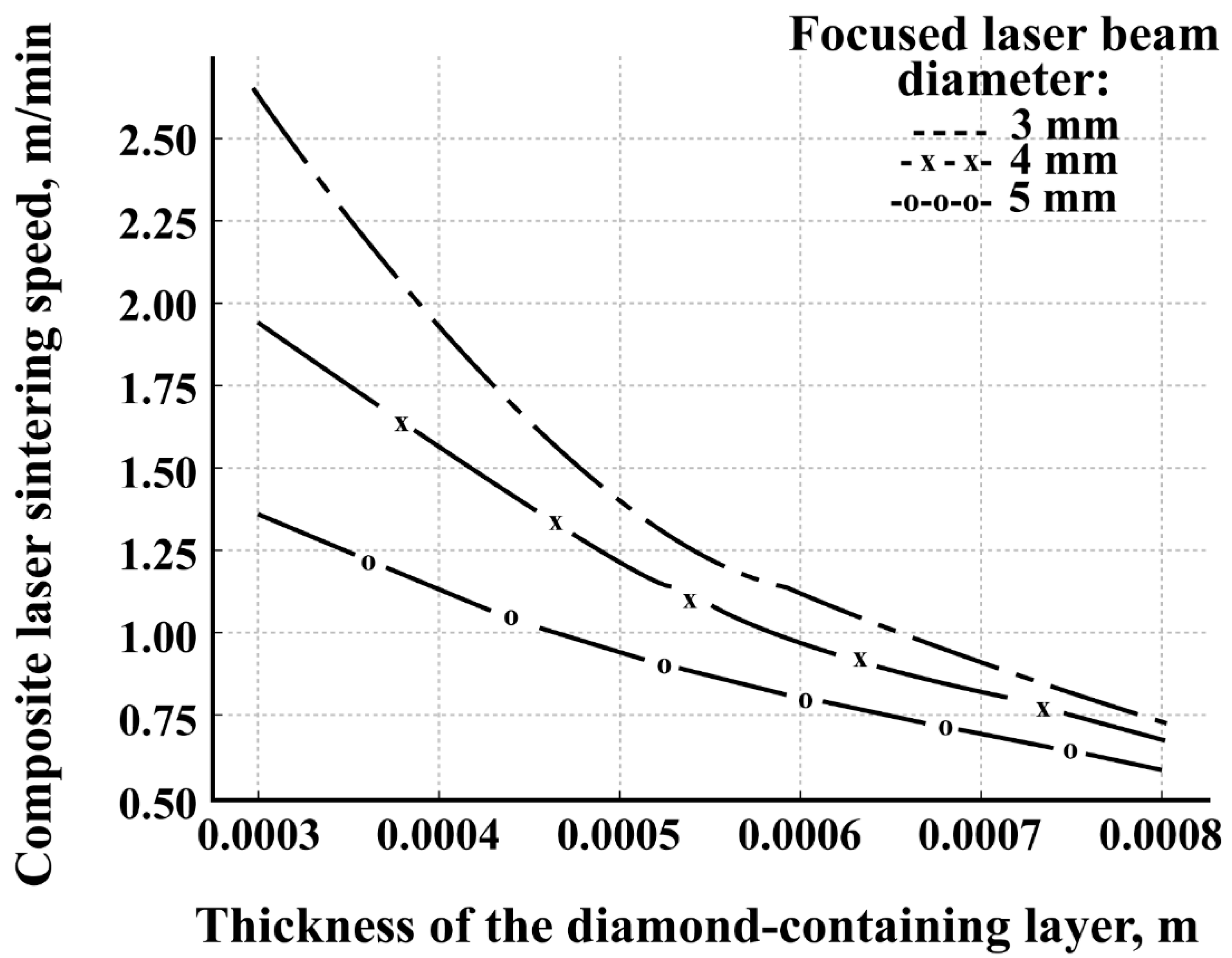

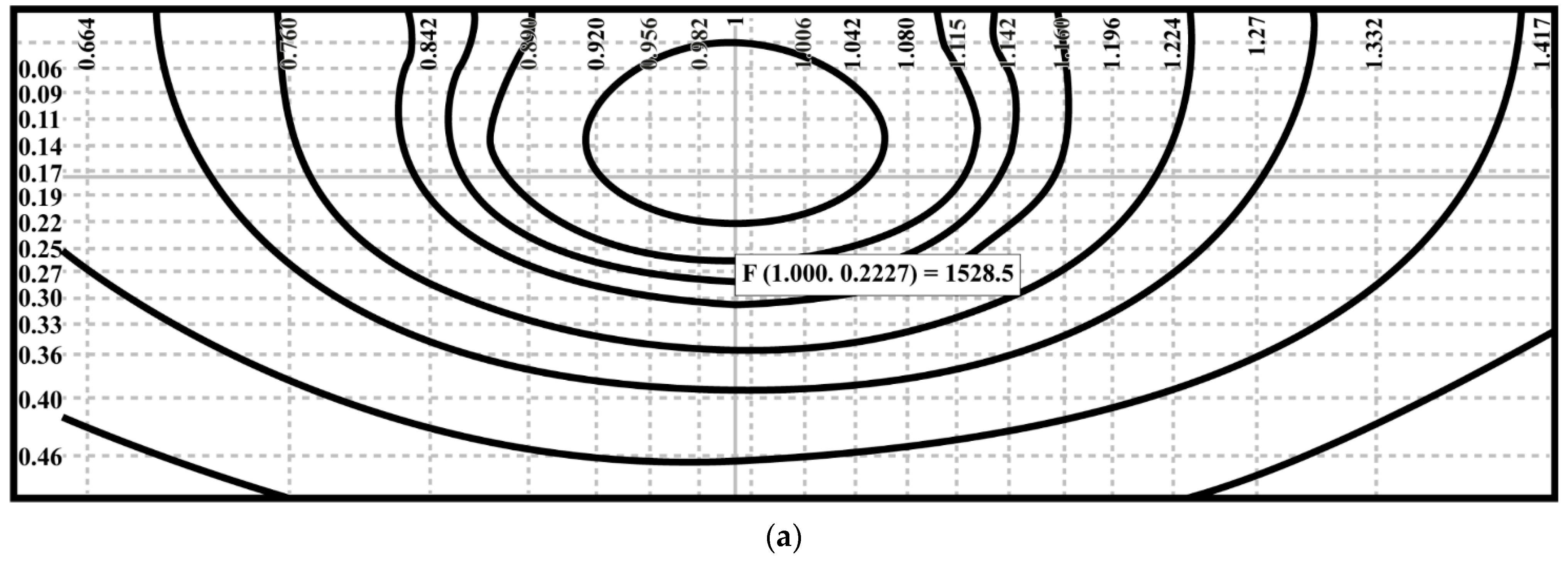

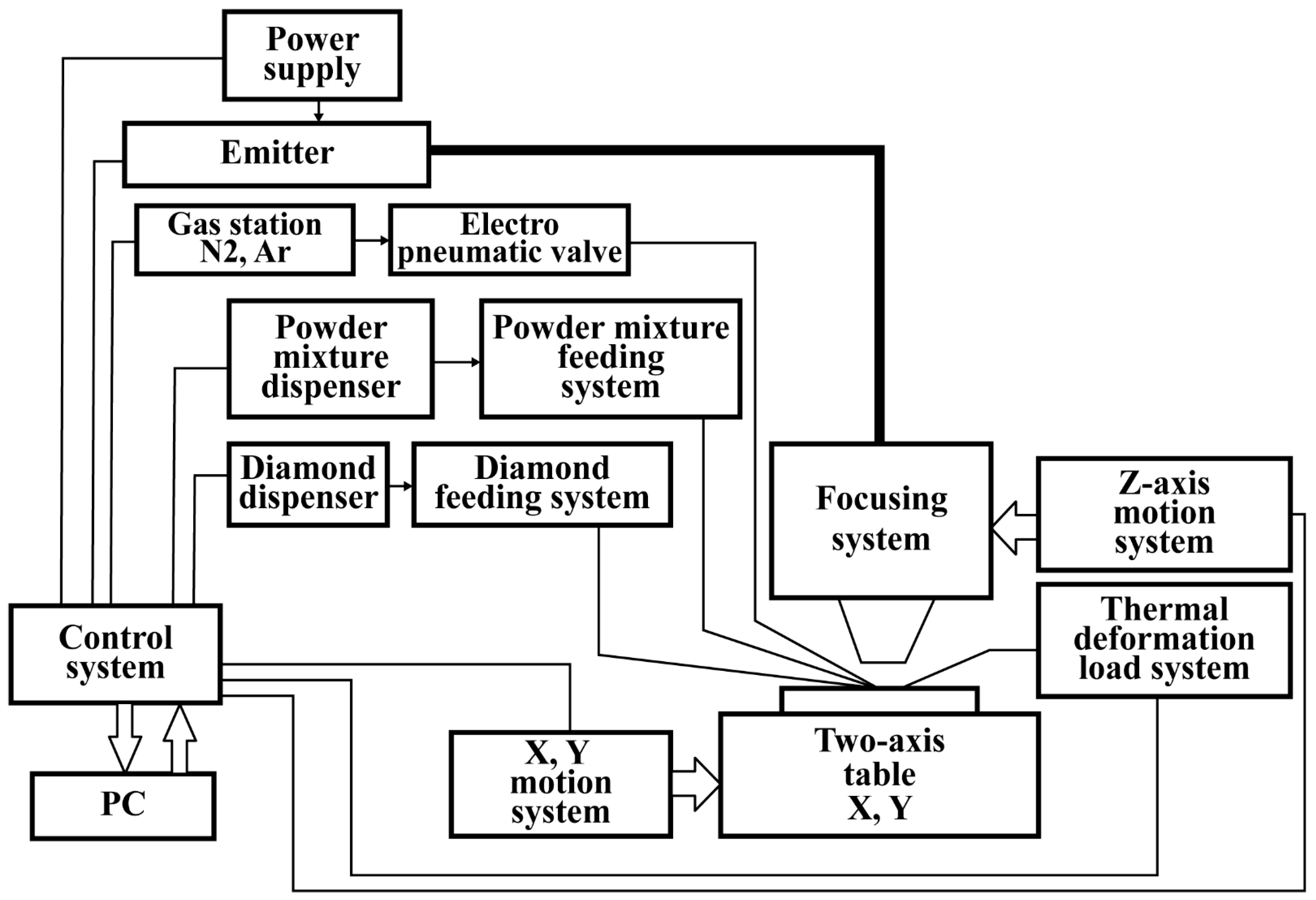

2.2. Calculation Results

3. Materials and Methods

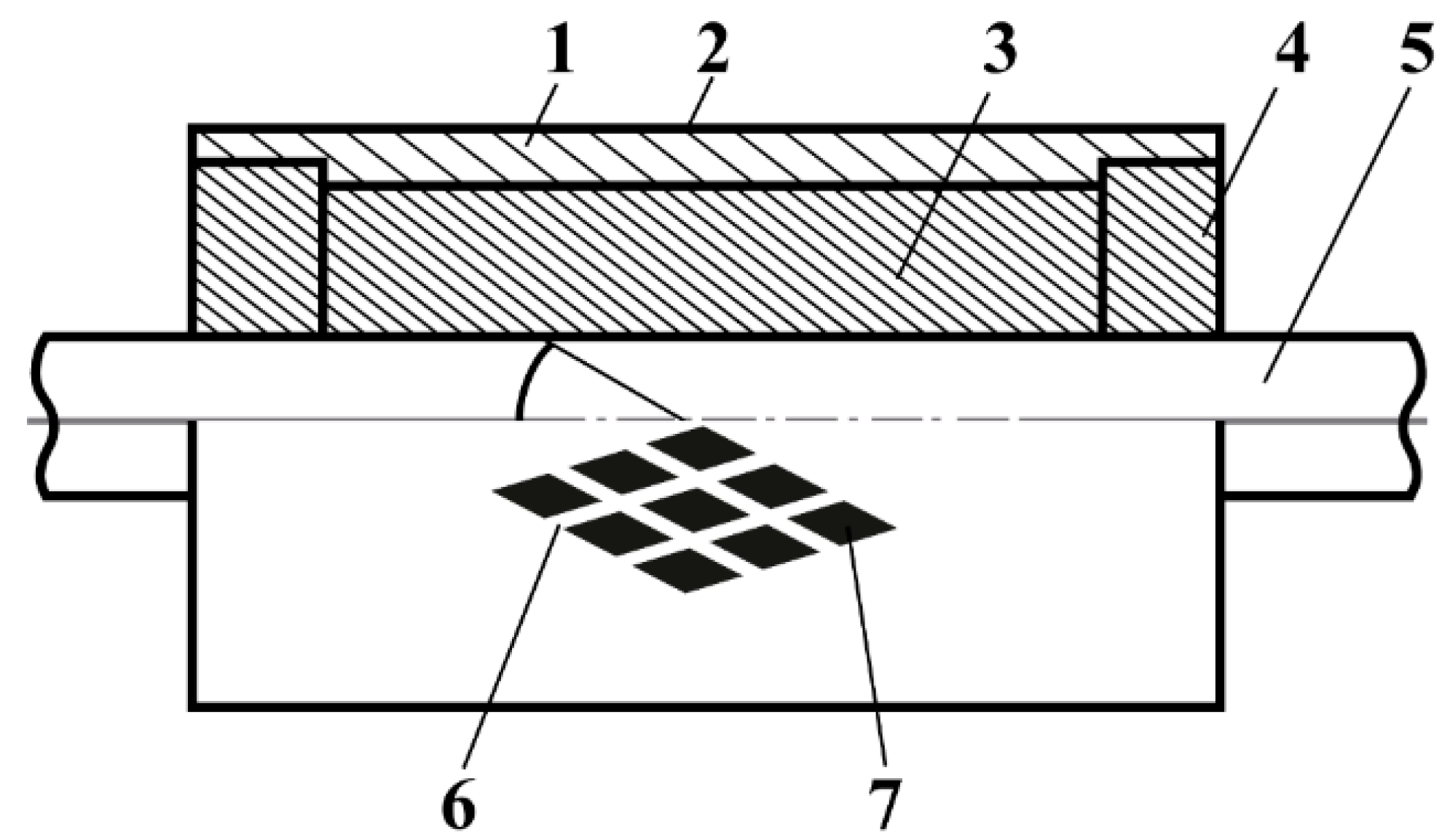

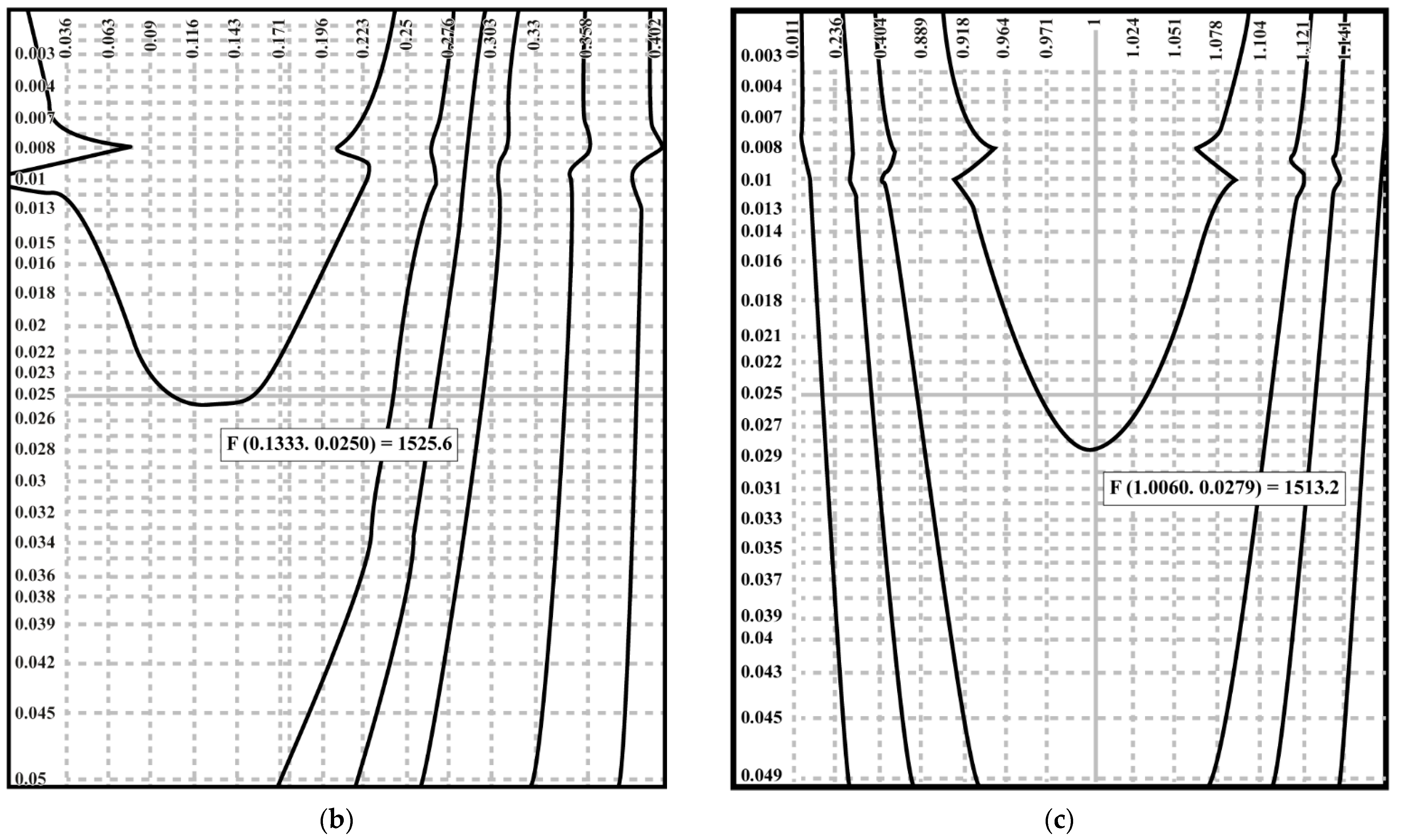

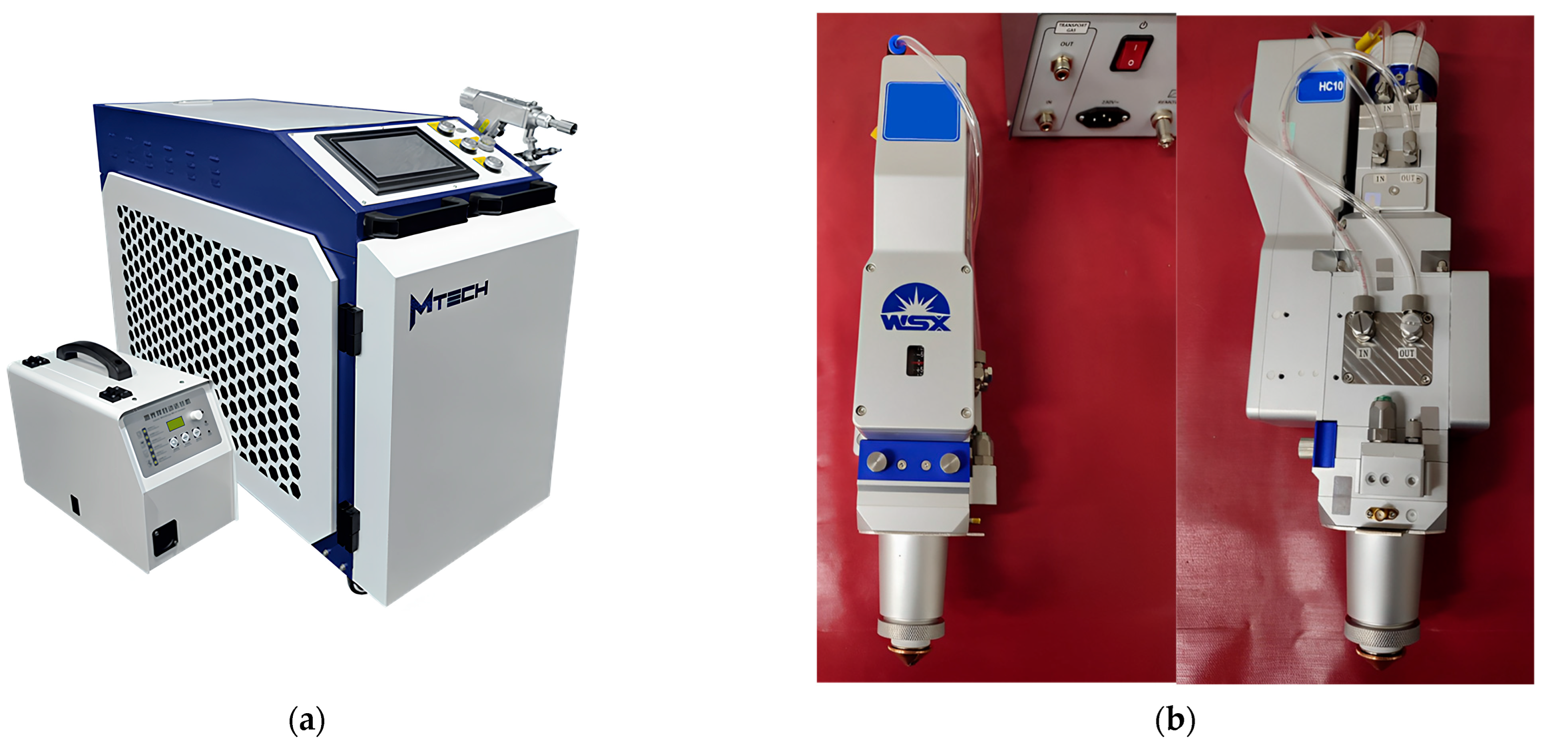

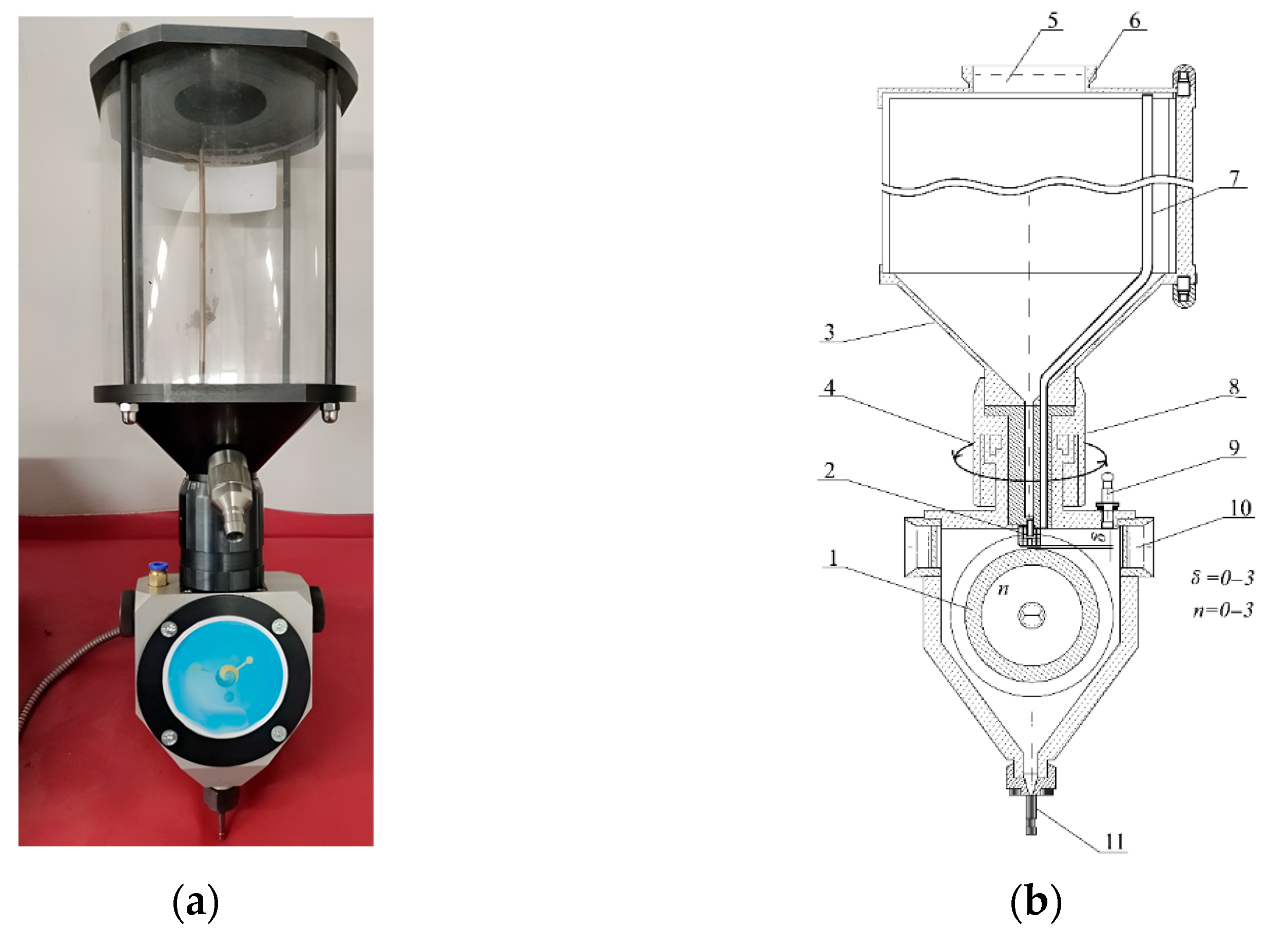

3.1. Experimental Equipment

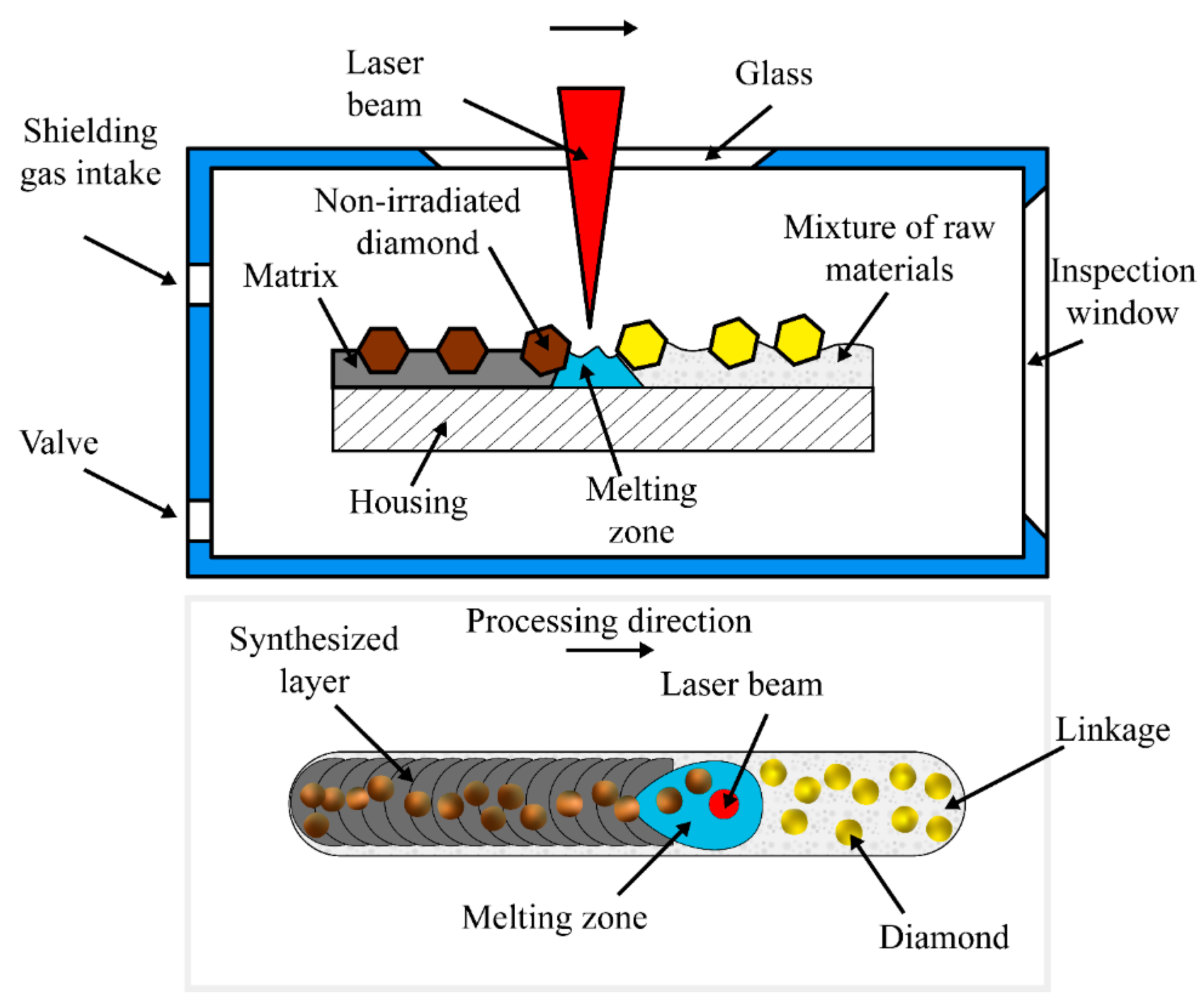

3.2. Research Methods

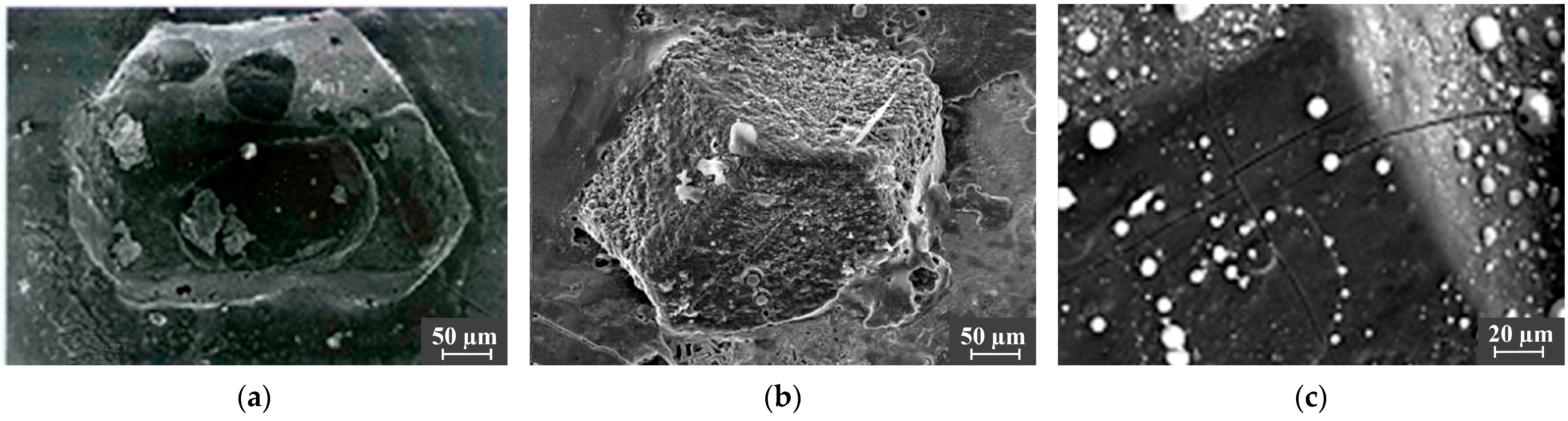

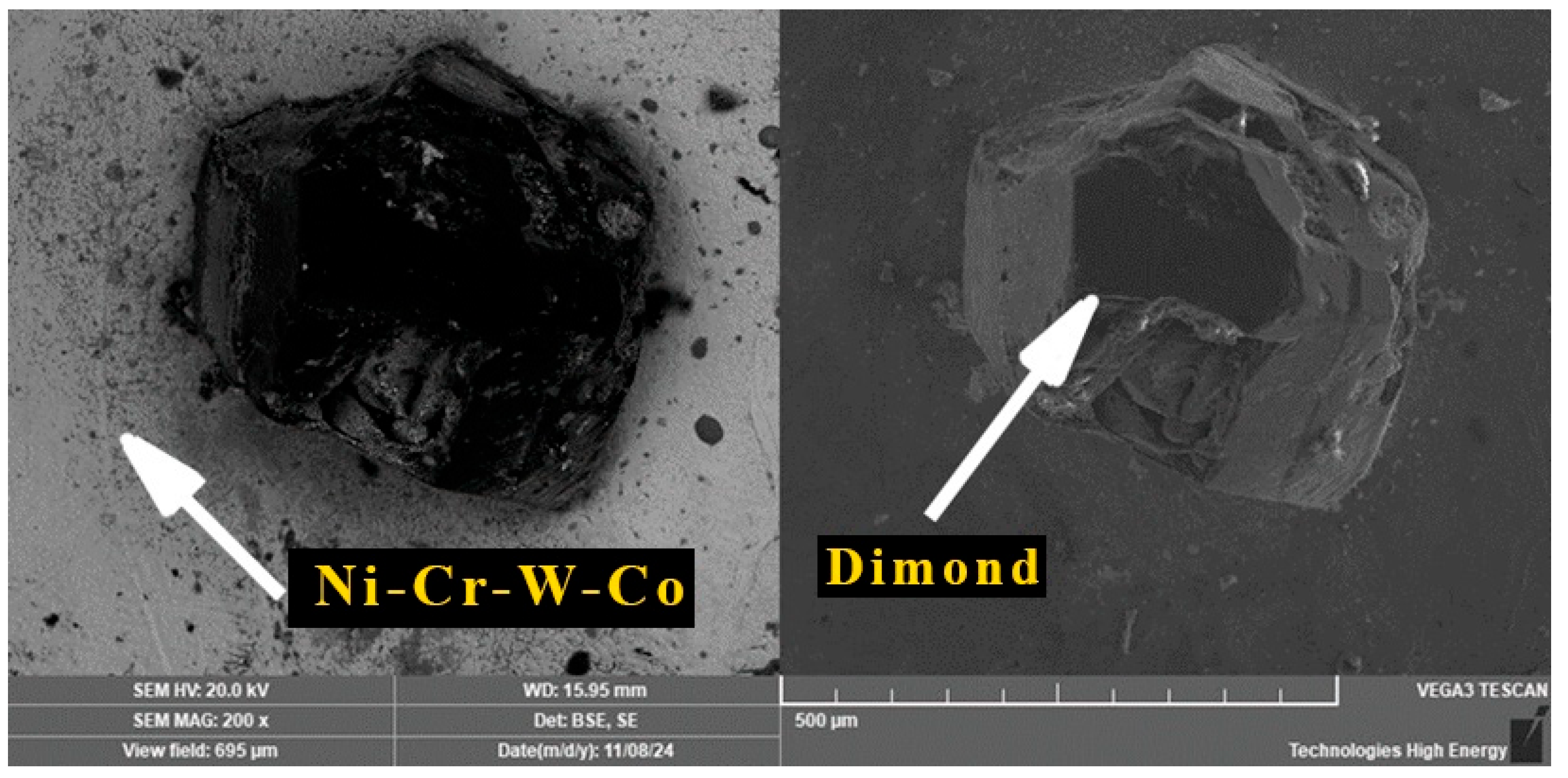

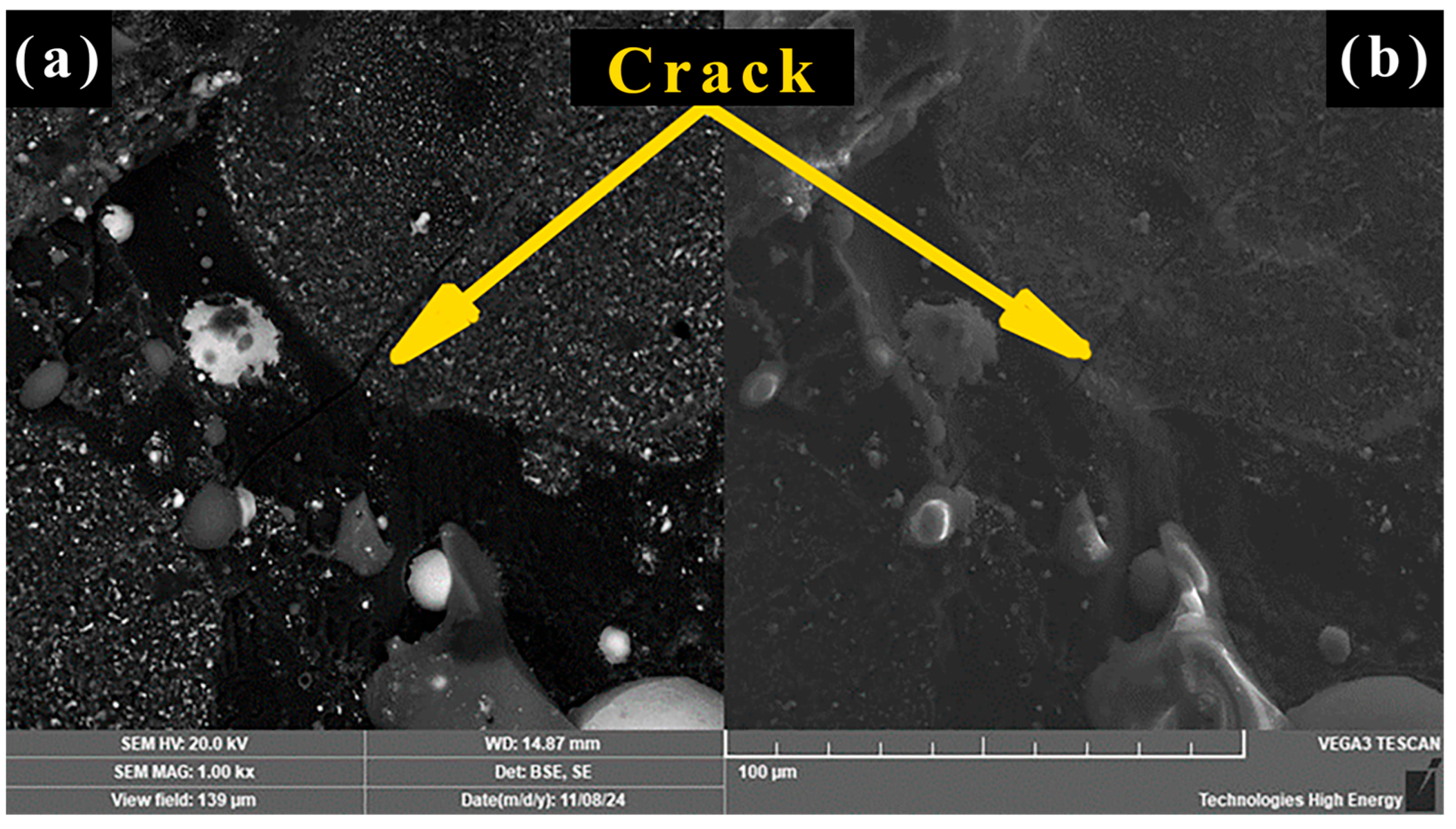

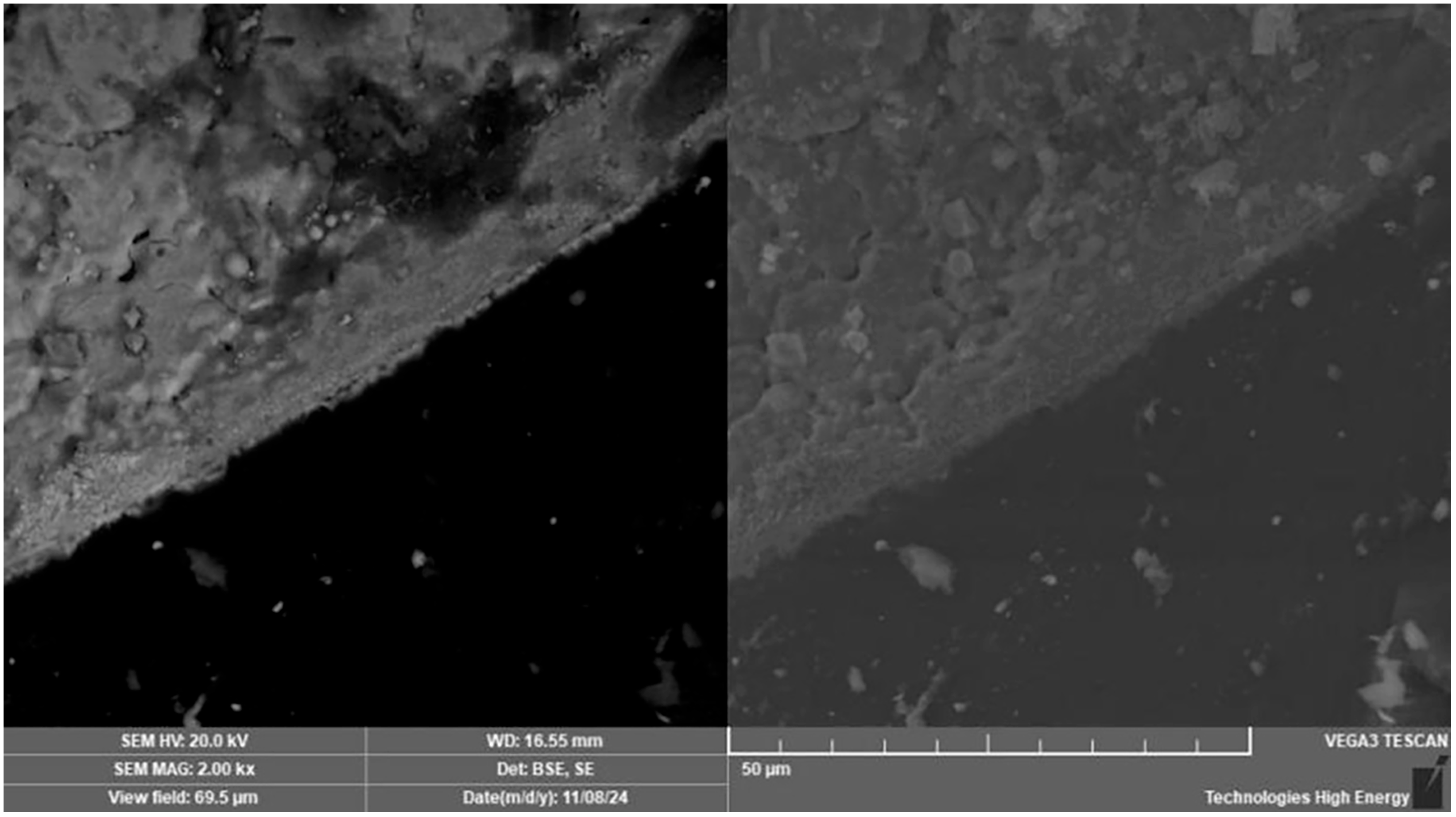

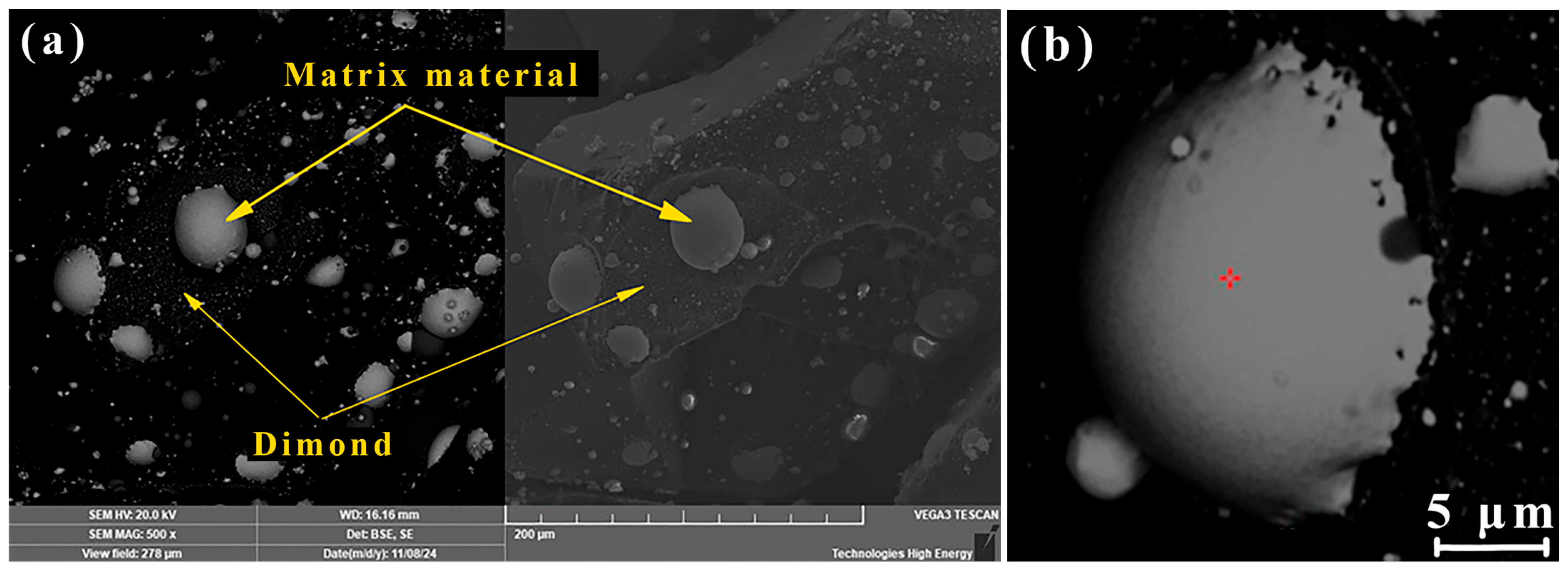

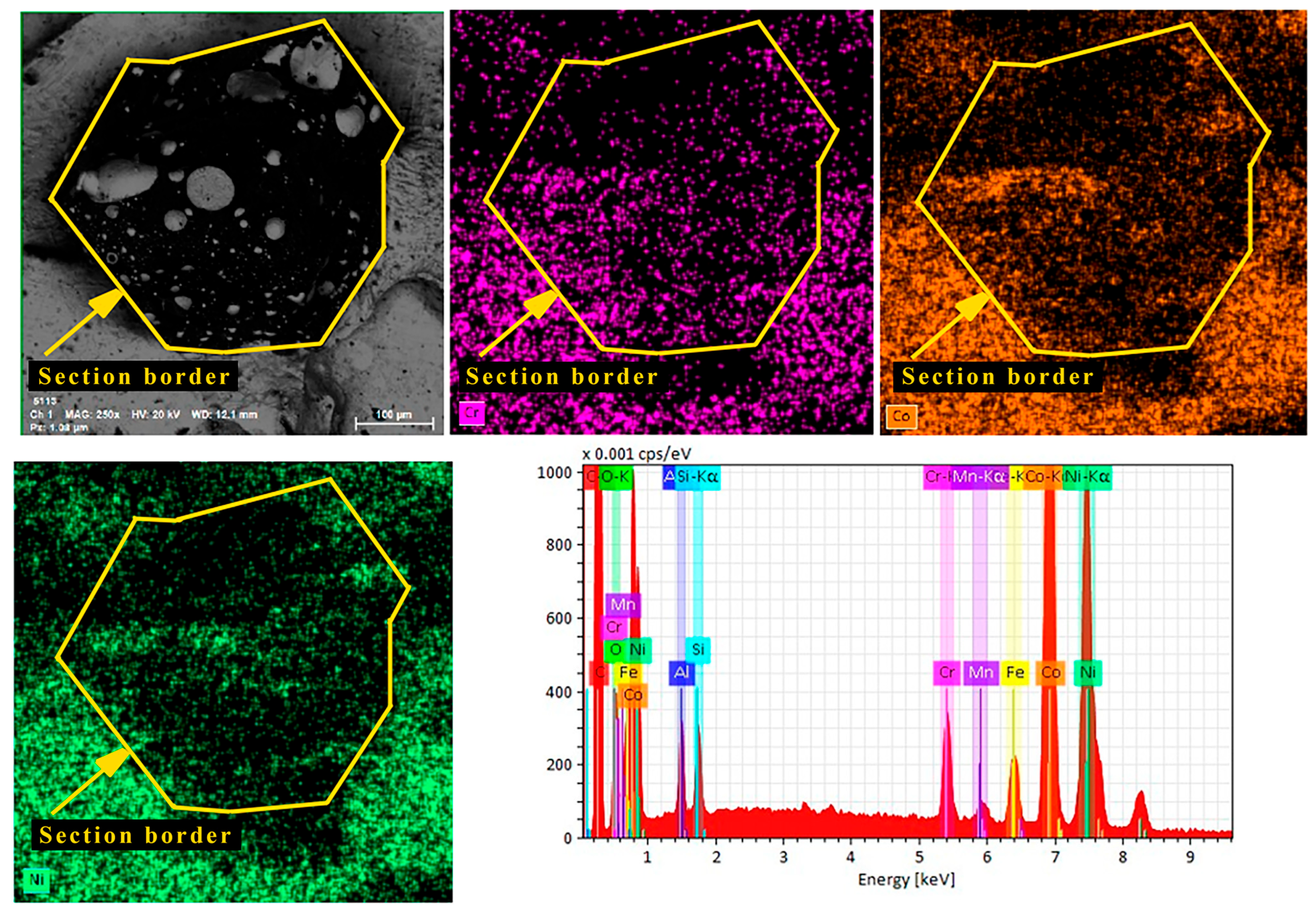

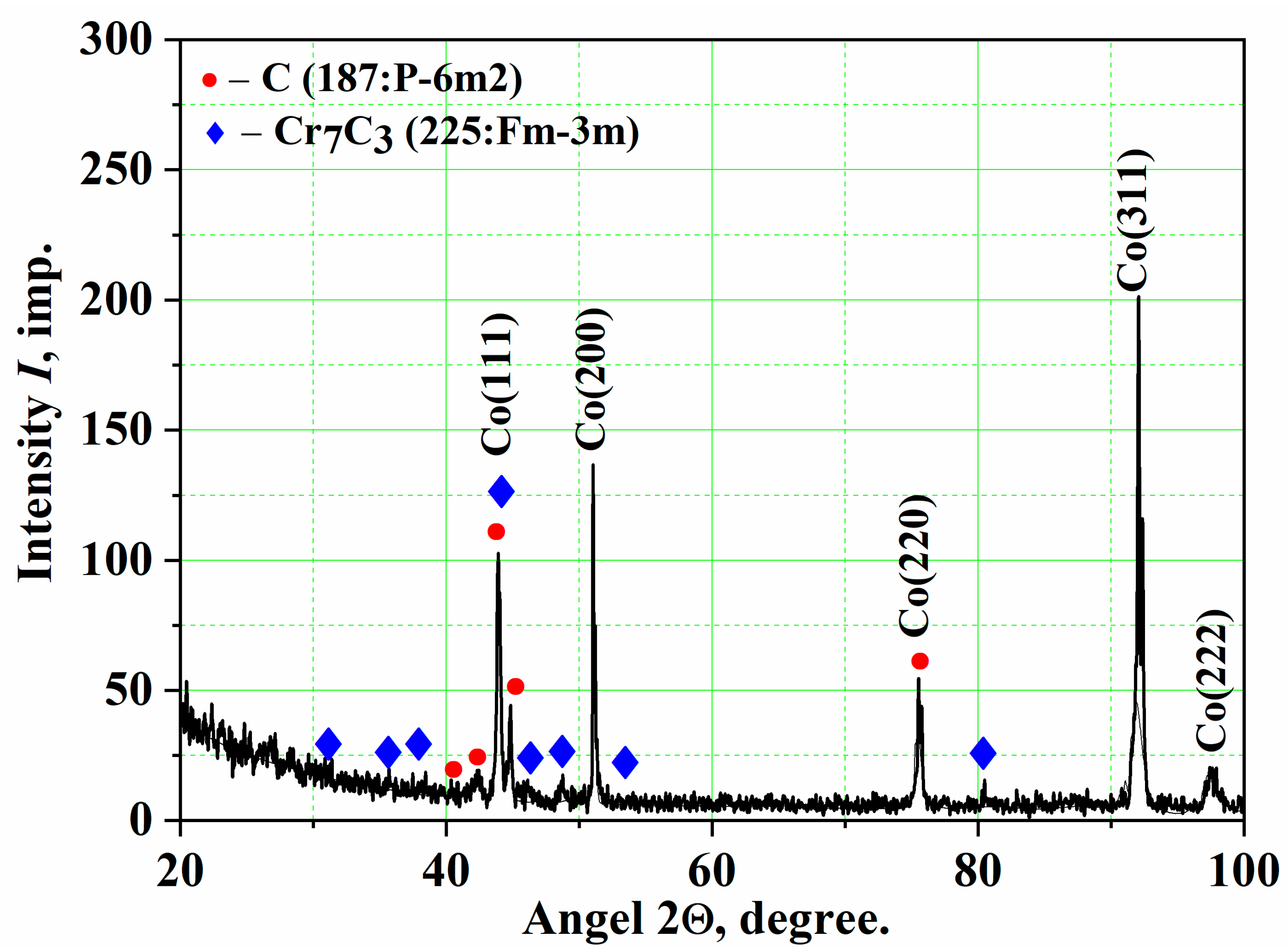

4. Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lavrynenko, V.I.; Novikov, M.R. Nadtverdi Abrazyvni Materialy v Mekhanoobrobtsi: Entsyklopedychnyi Dovidnyk; INM im. V.M. Bakulia: Nanu, Ukraine, 2013; p. 456. [Google Scholar]

- Huang, C.A.; Shen, C.H.; Li, P.Y.; Lai, P.L. Effect of fabrication parameters on grinding performances of electroplated ni-B-diamond tools with D150-Diamond Particles. J. Manuf. Process. 2022, 80, 374–381. [Google Scholar] [CrossRef]

- Huang, C.A.; Shen, C.H.; Huang, W.Z. Grinding performance of electroplated diamond tools strengthened with Cr-C deposit using D-150 diamond particles. Int. J. Adv. Manuf. Technol. 2022, 121, 4549–4558. [Google Scholar] [CrossRef]

- Chattopadhyay, A.K.; Chollet, L.; Hintermann, H.E. On performance of brazed bonded monolayer diamond grinding wheel. CIRP Ann. 1991, 40, 347–350. [Google Scholar] [CrossRef]

- Zhang, L. Filler metals, brazing processing and reliability for Diamond Tools Brazing: A Review. J. Manuf. Process. 2021, 66, 651–668. [Google Scholar] [CrossRef]

- Sun, B.-J.; Xiao, B. Effects of process parameters on interfacial microstructure, residual stresses, and properties of tunnel furnace Brazed Diamonds. Diam. Relat. Mater. 2018, 85, 98–103. [Google Scholar] [CrossRef]

- Twomey, B.; Breen, A.; Byrne, G.; Hynes, A.; Dowling, D.P. Rapid discharge sintering of nickel–Diamond Metal Matrix Composites. J. Mater. Process. Technol. 2011, 211, 1210–1216. [Google Scholar] [CrossRef]

- Shepelev, A.A.; Sorochenko, V.G.; Prydnikov, E.L. Grinding of polymer composite materials with single-layer diamond wheels and drums. Instrum. World 2003, 1, 4–8. [Google Scholar]

- Tillmann, W.; Kronholz, C.; Ferreira, M.P.; Knote, A.; Theisen, W.; Schütte, P.; Schmidt, J. Diamond-metal matrix interaction in tools fabricated by conventional and current-induced sintering. Int. J. Powder Metall. 2011, 47, 29–36. [Google Scholar]

- Goncharuk, O.; Zhuk, R.; Kaglyak, O. Laser Sintering of Abrasive Layers with Inclusions of Cubic Boron Nitride Grains. Lasers Manuf. Mater. Process. 2018, 5, 298–316. [Google Scholar] [CrossRef]

- Krivtsun, I.; Khoshnaw, F.; Polishko, G.; Schwab, S.; Selin, R. Welding and Related Technologies; CRC Press: London, UK, 2025. [Google Scholar] [CrossRef]

- Novikov, N.V.; Sepelev, A.A.; Kovalenko, V.S.; Golovko, L.F.; Sorochenko, V.G. Application of laser technology for the production of diamond disk tools. Superhard Mater. 2004, 1, 52–63. [Google Scholar]

- Kovalenko, V.; Golovko, L.; Meijer, J.; Anyakin, M. New developments in laser sintering of Diamond Cutting Disks. CIRP Ann. 2007, 56, 189–192. [Google Scholar] [CrossRef]

- Rommel, D.; Scherm, F.; Kuttner, C.; Glatzel, U. Laser cladding of diamond tools: Interfacial reactions of diamond and molten metal. Surf. Coat. Technol. 2016, 291, 62–69. [Google Scholar] [CrossRef]

- Goncharuk, O.; Golovko, L.; Kaglyak, O. Laser-assisted Manufacturing of CBN-contained grinding tools. Mech. Adv. Technol. 2020, 1, 108–123. [Google Scholar] [CrossRef]

- Feldshtein, E.E.; Devojno, O.G.; Kardapolava, M.A. Tribological characteristics of composite coatings formed by laser cladding of powders of nickel self-fluxing alloy and bronze. J. Frict. Wear 2016, 37, 454–461. [Google Scholar] [CrossRef]

- Devoino, O.G.; Feldshtein, E.É.; Kardapolova, M.A. Structure-Phase Condition and Tribological Properties of Coatings Based on Self-Fluxing Nickel Alloy PG-12N-01 After Laser Surfacing. Met. Sci. Heat. Treat. 2017, 58, 748–752. [Google Scholar] [CrossRef]

- Nadtoka, V.M.; Husarova, I.O.; Kraiev, M.V.; Borysenko, A.Y.; Bondar, D.M.; Osinovyy, G.G. Vacuum arc coatings for combustion chambers of rocket engines. Space Mater. Technol. 2024, 30, 20–28. [Google Scholar] [CrossRef]

- Kolekar, A.; Chopade, B.G.; Salvi, I.R. Effect of Heat Treatment Process on Mechanical Property of 40Cr4 Material. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 1718–1724. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, M.; Zhang, Z.; Liu, A.; Yang, R.; Liu, S. A study on diamond grinding wheels with regular grain distribution using additive manufacturing (AM) technology. Mater. Des. 2016, 104, 292–297. [Google Scholar] [CrossRef]

- Karayel, E.; Bozkurt, Y. Additive Manufacturing Method and different welding applications. J. Mater. Res. Technol. 2020, 9, 11424–11438. [Google Scholar] [CrossRef]

- Denkena, B.; Krödel, A.; Harmes, J. Additive manufacturing of metal-bonded grinding tools. Int. J. Adv. Manuf. Technol. 2020, 107, 2387–2395. [Google Scholar] [CrossRef]

- Shepelev, A.A.; Sorochenko, V.G. Diamond abrasive processing of polymer composite materials. Collect. Sci. Artic. Mod. Technol. Mech. Eng. 2006, 1, 248–256. [Google Scholar]

- Goncharuk, O.; Golovko, L.; Voloshko, S.; Kaglyak, O.; Burmak, A.; Kliuchnikov, Y. Mathematical Modeling of Laser Synthesis of the Working Layer of an Abrasive Tool. Technol. Tech. Typogr. (Tekhnolohiia I Tekhnika Druk.) 2024, 3, 51–68. [Google Scholar] [CrossRef]

- Berdnikova, O.; Pozniakov, V.; Bernatskyi, A.; Alekseienko, T.; Sydorets, V. Effect of the structure on the mechanical properties and cracking resistance of welded joints of low-alloyed high-strength steels. Procedia Struct. Integr. 2019, 16, 89–96. [Google Scholar] [CrossRef]

- Bernatskyi, A.V.; Berdnikova, O.M.; Klochkov, I.M.; Sydorets, V.M.; Chinakhov, D.A. Laser welding in different spatial positions of T-joints of austenitic steel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 582, 012048. [Google Scholar] [CrossRef]

| Grade | C, % | B, % | Si, % | Cr, % | Fe, % | Ni, % | Hardness |

|---|---|---|---|---|---|---|---|

| PS-12N-VK (PG-10N-01 65% + WC 35%) [15] | 0.6–1.0 | 2.8–4.5 | 4.0–4.5 | 14–20 | 3.0–7.0 | - | HRC 56–63 |

| PG-12N-01 [16,17] | 0.3–0.6 | 1.7–2.5 | 1.2–3.2 | 8–14 | 1.2–1.3 | - | HRC 35–40 |

| 12KH18N10T (AISI 304) [18] | ≤0.12 | - | ≤0.8 | 17–19 | base | 9–11 | BHN 123 |

| 40Cr4 [19] | 0.35–0.45 | - | 0.10–0.35 | 0.9–1.2 | - | ≤0.3 | BHN 229–277 |

| Metal parameters | |

| Specific heat C, J/g · °C | 0.62 |

| Density ρ, kg/m3 | 7800 |

| Thermal conductivity λ, W/m · °C | 24 |

| Powder parameters | |

| Specific heat C, J/g · °C | 0.65 |

| Density ρ, kg/m3 | 8000 |

| Thermal conductivity λ, W/m · °C | 24.5 |

| Heat transfer coefficient | |

| Metal | 50 |

| Powder | 45 |

| Temperature | |

| Outside, °C | 20 |

| Required, °C | 800 |

| Laser system parameters | |

| Laser power, W/cm2 | 100 |

| Laser speed, cm/s | 10 |

| Material | 40Cr4 |

| Binding | 12KH18N10T + TiB2 + CrB2 |

| Thickness of the composite layer | 0.3–0.6 mm |

| Laser beam diameter | 3, 4, 5 mm |

| Melting point of the bond | 1250 °C |

| Laser power | 1500 W |

| Thermal conduction | 29 W/(m-K) |

| Thermal diffusivity | 3.4 × 10−6 m2/s |

| Absorption capacity of the bond | 0.7 |

| Diameter of the Focusing Area, mm | Composite Layer Thickness, mm | Feed Rate, m/min |

|---|---|---|

| 3 | 0.3 | 1.922 |

| 0.4 | 1.436 | |

| 0.5 | 1.113 | |

| 0.6 | 0.888 | |

| 0.7 | 0.725 | |

| 0.8 | 0.603 | |

| 4 | 0.3 | 1.287 |

| 0.4 | 1.042 | |

| 0.5 | 0.861 | |

| 0.6 | 0.723 | |

| 0.7 | 0.616 | |

| 0.8 | 0.531 | |

| 5 | 0.3 | 0.851 |

| 0.4 | 0.728 | |

| 0.5 | 0.630 | |

| 0.6 | 0.551 | |

| 0.7 | 0.485 | |

| 0.8 | 0.431 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaglyak, O.; Golovko, L.; Goncharuk, O.; Voloshko, S.; Kapustynskyi, O.; Višniakov, N. Application of Laser Thermal Deformation Sintering in the Manufacture of Drum-Type Diamond Tools. J. Manuf. Mater. Process. 2025, 9, 251. https://doi.org/10.3390/jmmp9080251

Kaglyak O, Golovko L, Goncharuk O, Voloshko S, Kapustynskyi O, Višniakov N. Application of Laser Thermal Deformation Sintering in the Manufacture of Drum-Type Diamond Tools. Journal of Manufacturing and Materials Processing. 2025; 9(8):251. https://doi.org/10.3390/jmmp9080251

Chicago/Turabian StyleKaglyak, Oleksii, Leonid Golovko, Oleksii Goncharuk, Svitlana Voloshko, Oleksandr Kapustynskyi, and Nikolaj Višniakov. 2025. "Application of Laser Thermal Deformation Sintering in the Manufacture of Drum-Type Diamond Tools" Journal of Manufacturing and Materials Processing 9, no. 8: 251. https://doi.org/10.3390/jmmp9080251

APA StyleKaglyak, O., Golovko, L., Goncharuk, O., Voloshko, S., Kapustynskyi, O., & Višniakov, N. (2025). Application of Laser Thermal Deformation Sintering in the Manufacture of Drum-Type Diamond Tools. Journal of Manufacturing and Materials Processing, 9(8), 251. https://doi.org/10.3390/jmmp9080251