1. Introduction

The steering knuckle is a critical component of a vehicle’s suspension system, serving as the main link between the wheel hub and the suspension. It transfers forces from the tires to the suspension, making it subject to high and varying loads [

1,

2]. As a result, its design must prioritize durability and a high safety factor. Additionally, the knuckle should be engineered for robustness, with adequate fatigue life, optimal material selection, and minimized weight, without compromising the overall mechanical performance.

Its geometry changes depending on the specifications of the steering system and the suspension system, including the spatial coordinates of other parts, assembly constraints, and joints [

3,

4]. In particular, the steering knuckle of the MacPherson suspension system [

5,

6], used on several commercial vehicles (i.e., Fiat Siena, Toyota Corolla, Dacia Logan), was considered and is shown in

Figure 1.

However, depending on the classification of the car, different materials (such as cast iron, forged iron, aluminum, and composite materials) are used to manufacture the car’s steering knuckle [

3,

7].

Among the different manufacturing processes available to create parts with complex geometries with medium-high production volumes, one of the best options is investment casting (IC). IC is one of the oldest manufacturing techniques, involving the pouring of molten metal into a mold where it solidifies into a desired shape [

8]. However, a fundamental drawback of the process is the formation of shrinkage cavities, which result from the volumetric contraction that occurs during the liquid-to-solid phase transformation [

9,

10,

11]. A common approach to mitigate this issue involves incorporating excess material in the form of risers, dowels, sprues, and cores [

12,

13]. As a result, the typical material recovery rate in casting, i.e., the ratio of the final product weight to the total molten metal used, is approximately 70%, with around 30% of material wasted. Moreover, additional processing is required to remove this surplus material, leading to increased consumption of both material and energy. With the rise of additive manufacturing (AM) technologies in the last decade, casting processes have benefited due to the spread of rapid tooling (RT). RT is intended for when AM technologies are used to directly manufacture tools or tooling inserts for molding or for any other technology that requires a specific shape to produce a part [

14,

15]. Among the various manufacturing processes supported by rapid tooling (RT)—such as injection molding and die casting—investment casting (IC) has been particularly enhanced by the use of additive manufacturing (AM) to produce meltable patterns. This technique, commonly referred to as rapid investment casting (RIC), allows for the fabrication of complex-shaped sacrificial models made of foundry resin, which are later removed to create the mold cavity [

16,

17]. RIC has proven to be especially effective in applications involving metal foams [

16], reticular or lattice structures [

17,

18], and is increasingly adopted in the production of functional parts for the automotive [

19] and aerospace sectors [

18,

20,

21,

22,

23,

24].

In the automotive industry, weight is always an essential criterion while designing any vehicle component. One of the modern methodologies to reduce the weight without compromising the intended performance of the part is the topological optimization (TO) [

21,

22]. The environmental benefits of topology optimization (TO) have been widely explored in the recent literature, particularly in relation to material savings, weight reduction, and associated improvements in energy efficiency during both production and use phases. Several studies have demonstrated how TO can significantly reduce the environmental footprint of mechanical components by minimizing mass while maintaining or enhancing structural performance [

23,

24,

25].

These works provide a valuable foundation for the current study, which aims to expand on this approach by integrating TO with process-specific simulation and life cycle assessment. TO has its application in the automobile sector for lightweight components and fuel efficiency. For instance, Bajpai et al. [

26] carried out a topology optimization of the steering knuckle of a formula SAE with consideration of boundary conditions and loading conditions acting on the component. After optimization by designing and analysis using the FEA solver, a 40.87% reduction of weight was obtained without compromising the initial performance of the steering knuckle. Zach et al. [

27] performed a topology optimization on a formula SAE steering knuckle and reduced the original mass of the part to only 45.2% (compared for the same materials) and 29.28% of the machined variant from AA 7075. In addition, the safety coefficient is increased by 3.06% compared to the unoptimized AA 7075 and the optimized Ti-6Al-4V design variants.

Due to the different kinds of geometries, manufacturing methodologies, and possibilities of TO, the steering knuckle is a suitable component for a life cycle assessment (LCA) analysis. Current European environmental and raw materials policies emphasize the importance of sustainability and recyclability in tackling urgent ecological and resource-related challenges.

In the scientific literature, LCA has been extensively applied to assess the sustainability of manufacturing technologies across a wide range of industrial sectors. Recent studies have shown that LCA can offer valuable insights for developing lower-impact processes and guiding decision-making in the adoption of new methodologies at the industrial level [

28].

For instance, Venettacci et al. [

20] used LCA to compare the environmental impacts of surface finishing processes in the aerospace sector, demonstrating a 45% reduction in overall impacts when innovative technologies were adopted over traditional methods. Similarly, Müller-Carneiro et al. [

29] highlighted the significance of Ex-Ante LCA in evaluating emerging technologies during the research and development phase, particularly in addressing challenges related to data uncertainty and the modeling of large-scale production. Collectively, these studies underscore the pivotal role of LCA in assessing the sustainability of technological innovations, offering a methodological foundation for studies such as the present one.

This work aims to perform a TO of a SG Iron A536 65-45-12 steering knuckle manufactured by RIC to obtain a component that guarantees similar mechanical responses in terms of displacement under load, Von-Mises’s stress, and safety factors with a lower weight and volume of material.

Moreover, an LCA analysis is performed as a comparison between the actual and the optimized geometry to understand the improvements in terms of environmental impact using the Impact 2002+ methodology and indicators. In a context where the sustainability of manufacturing processes is becoming of primary importance due to reasons of legislation compliance and competitiveness, the reduction of the analyzed indicators, in particular those relating to human health, ecosystem quality, climate change, and resources, is totally in line with the objectives of different industrially relevant regulations and standards (i.e., ISO 14001, REACH, and European voluntary declarations such as EMAS) [

30].

The outcomes of this study can guide different steering knuckle manufacturers to use topologically optimized components regardless of the geometry and have a key role in evaluating the best option, jointly considering technical and environmental drivers. This study aims to bridge the gap between topology optimization and sustainable manufacturing by integrating a complete design-to-casting workflow for a structural automotive component. Specifically, it combines topology optimization (TO), rapid investment casting (RIC), and life cycle assessment (LCA) applied to a steering knuckle. This approach enables a comprehensive evaluation of structural performance, manufacturability, and environmental impact within a unified framework—an aspect seldom explored in the current literature.

3. Results and Discussion

3.1. Topology Optimization

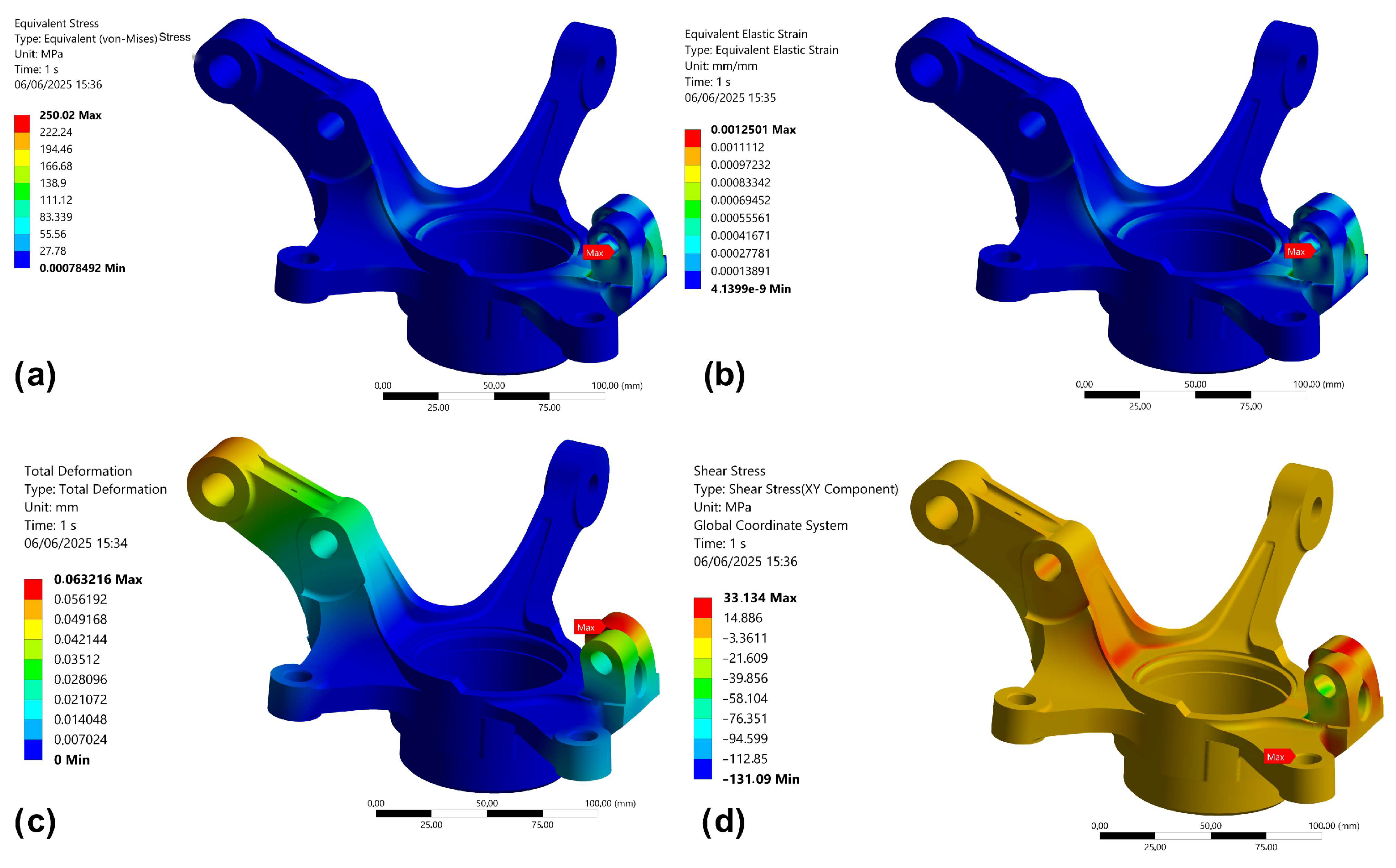

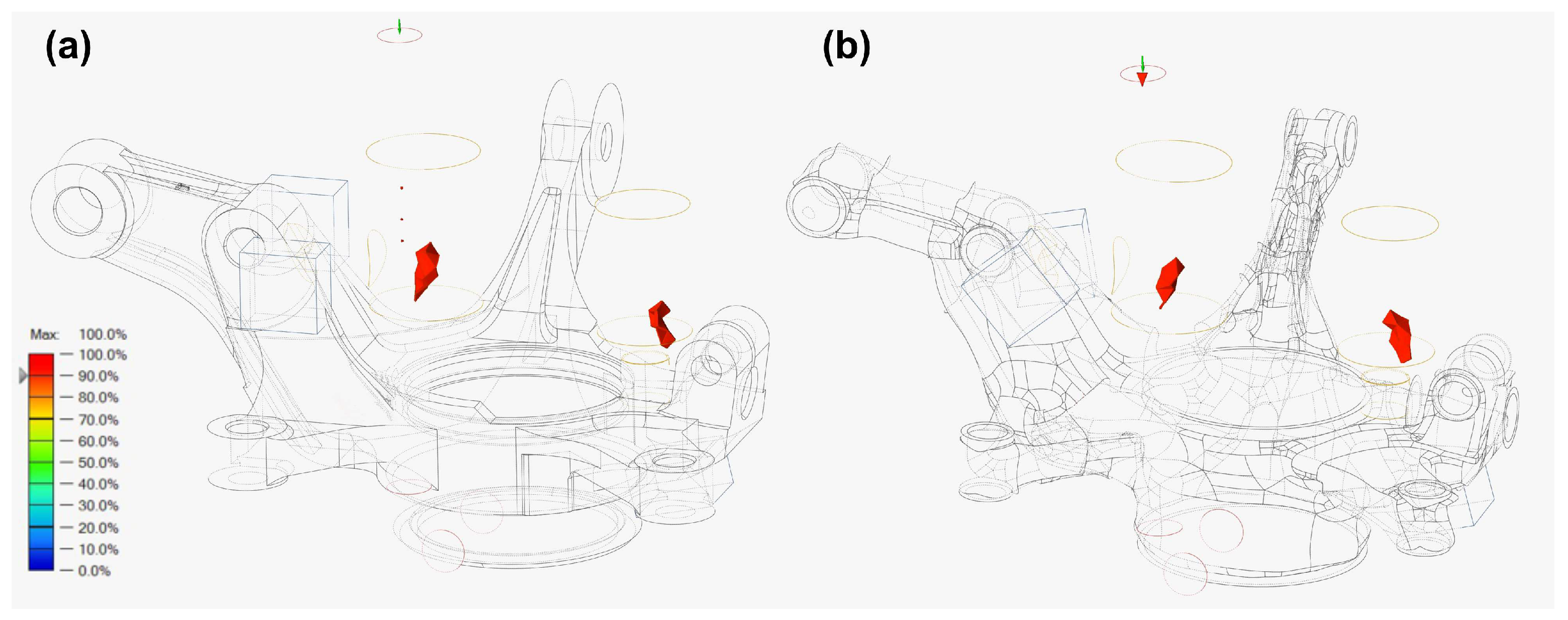

The results of the static structural simulation are shown in

Figure 5. The most stressed region is the region connected with the lower control arm, where we have all the maximum values from the simulation. In particular, the maximum Von Mises stress of 250 MPa is lower than the yield strength of the SG A536 iron alloy used, which is 310 MPa, enabling a safety factor of 1.25 for the load case considered. Also, the results in terms of equivalent elastic strain show that the max values obtained are below the elastic limit of the material (0.002), suggesting there is no plastic deformation involved. Moreover, total deformation reaches a peak of 0.06 mm, and shear stress reaches a peak of 33.13 MPa, which is very compliant with the design limits according to the material used and the given boundary conditions.

Once assured of the goodness of the results obtained from the static analysis, the TO was carried out using the structural optimization tool of Ansys Workbench using the parameters discussed in the previous section in

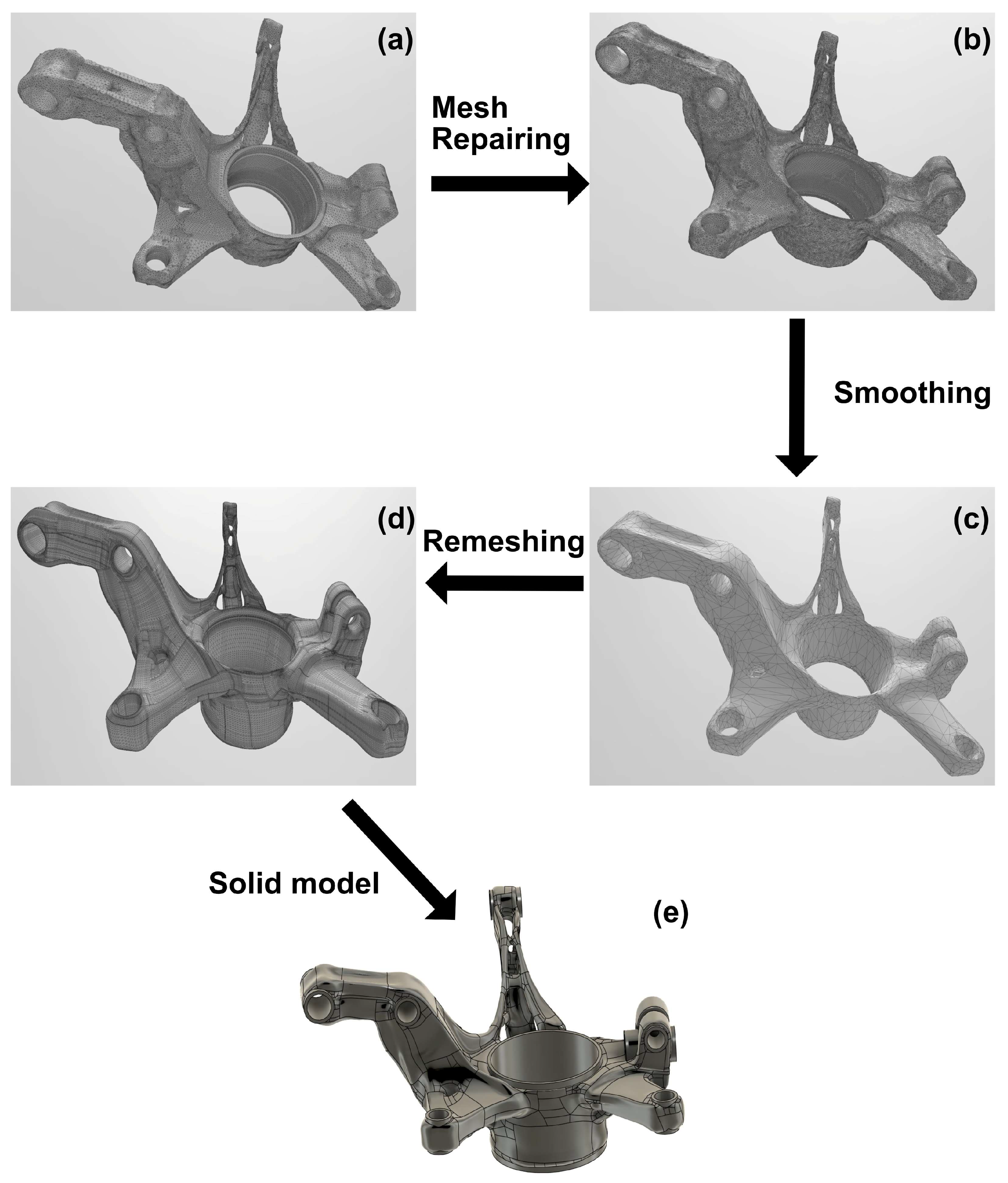

Table 3. The output of the optimization is an STL file of the new model, shown in

Figure 6a, and has some parts of the triangular mesh that were not merged with the others. Thus, using the software Autodesk Fusion, mesh repairing was performed (shown in

Figure 6b) in order to eliminate the missing elements and merge the elements closer to a certain gap of 0.1 mm. The new closed surface was processed to obtain a part with a degree of smoothness that can avoid possible stress concentrations under load. Additionally, support zones had to be recreated to ensure the connection of the optimized component with the other components of the assembly. The surface was then reshaped as a surface body and subsequently converted into a solid body for the subsequent testing and process steps (

Figure 6). The addition of material to make the connection zones resulted in an increase in mass of about 10%.

In

Table 6 and

Figure 7, all the model and mesh properties of the topologically optimized steering knuckle are shown. Compared to the unoptimized geometry, there is a volume and mass reduction of 30%, which would reduce the overall mass of the vehicle by 3.2 kg since the component is installed on each wheel. Although the topology-optimized geometry presents a significant reduction in mass, certain features—such as the rear arm of the knuckle—exhibit slender cross-sections that may pose manufacturability challenges when applying investment casting.

To address this, a post-processing step was performed after the topology optimization phase, during which the geometry was slightly modified to improve castability. This included the elimination of sharp edges, reinforcement of critical thin regions, and verification of minimum wall thicknesses.

These refinements were based on foundry design guidelines and aimed to ensure compatibility with mold filling behavior and ceramic shell stability. While not explicitly illustrated in this study, these adaptations were essential to align the optimized design with the constraints of rapid investment casting.

To validate the optimized design, another static structural simulation was performed with the same boundary conditions as the previous one and its results are shown in

Figure 8. The most stressed region is again the one connected with the lower control arm. The maximum Von Mises stress of 280 MPa is still lower than the yield strength of the used alloy, enabling a safety factor of 1.11 for the load case considered, which is lower than the previous one since part of material was removed. Moreover, the results in terms of equivalent elastic strain show that the obtained max values of 0.0018 are below the elastic limit of the material (0.002), suggesting that even in this case there is no plastic deformation involved. Finally, total deformation reaches a peak of 0.05 mm, and shear stress reaches a peak of 27.49 MPa, which is in line with the design limits.

A comparison of the results of structural analysis on both configurations is shown in

Table 7.

3.2. 3D Printing of the Knuckles

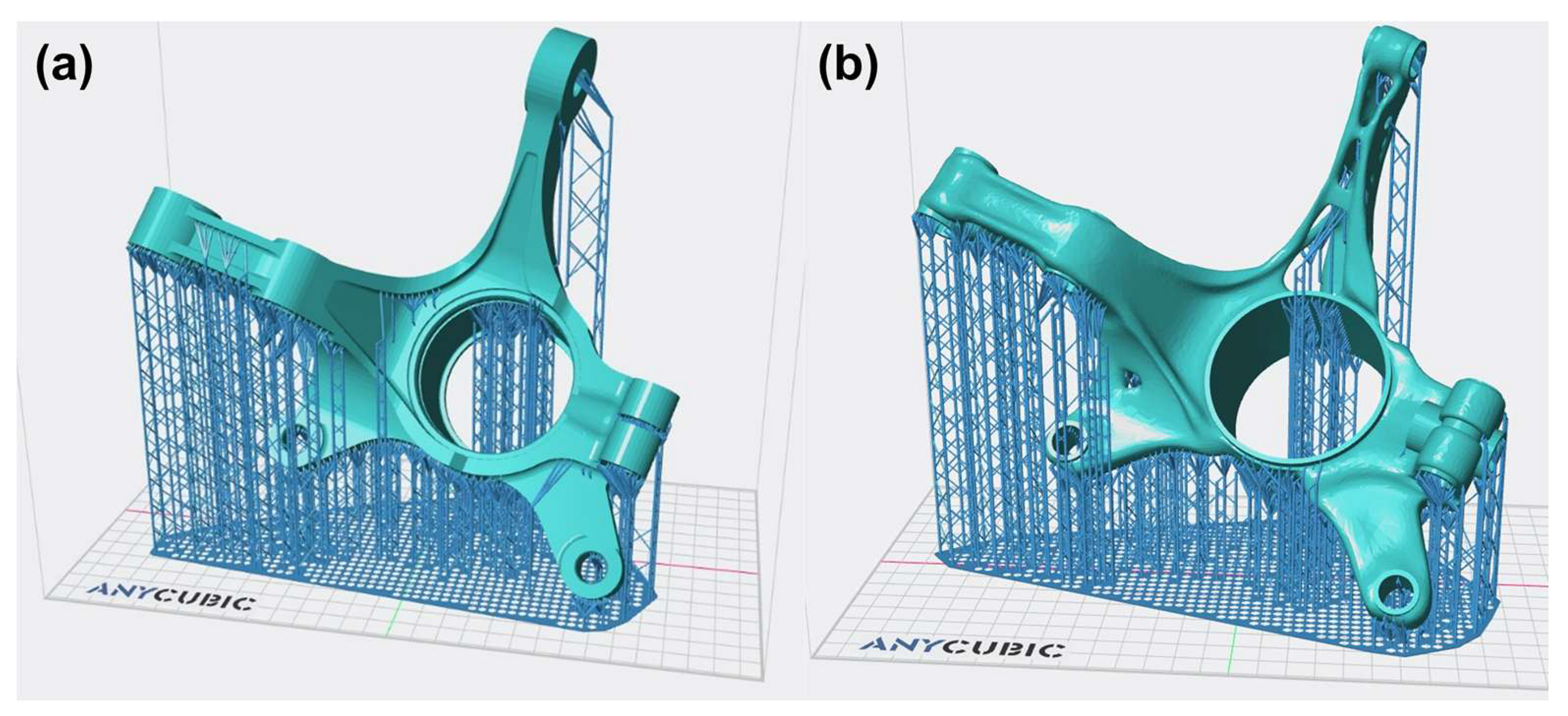

After the validation phase, an evaluation of the printing time and resin usage for the obtained models was performed using the software Anycubic Photon Workshop. The supporting structures and the orientation were optimized using the software tool and shown in

Figure 9.

In particular, the used resin volume for the unoptimized model is 497.27 mL, compared to the 361.89 mL for the TO model, obtaining a material saving of about 27%. Since the cost of the used castable resin is around 150 EUR/L, the saving of the material usage alone is 20 EUR using the optimized model (74.50 EUR vs. 54.28 EUR). Moreover, there is also a reduction of the printing time, which goes down from 575 min to 525 min, also leading savings in terms of electricity used for the process. The UV curing process was supposed to be under the same conditions in the Anycubic Wash and Cure Max, using a temperature of 60 °C for the polymerization for 30 min.

3.3. Rapid Investment Casting Simulation

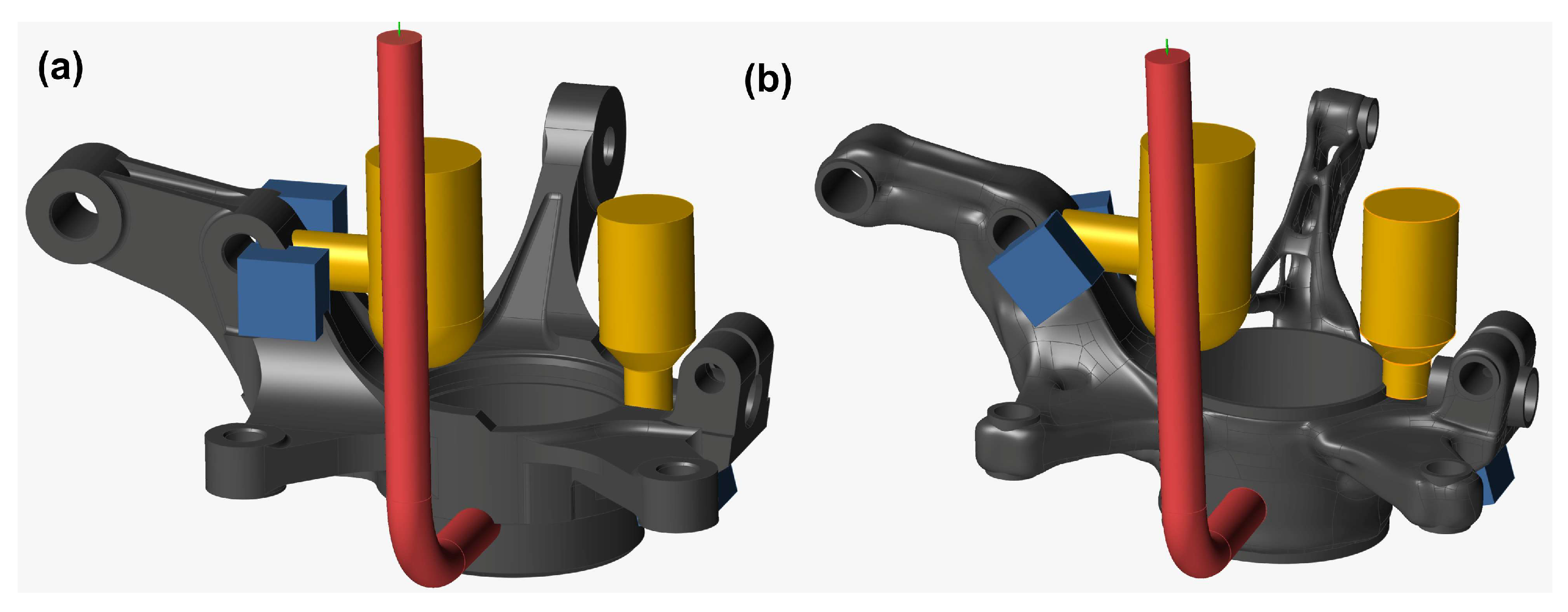

Subsequently, the gating system was designed using the Autodesk Fusion software for both configurations, considering the different thermal modules of the zones and the corresponding cylindrical matrices increased by 30% concerning the thermal module value of the connecting zones. Two different risers were identified and added, with the dimensions, volumes, and weights described in

Table 8.

For the inlet gate design, according to the equations defined in sub-paragraph 2.4, the filling speed was equally imposed at 2 m/s. The inlet gate section S

a is 706.5 mm

2 (D = 30.0 mm) for the initial geometry, while it is 637.5 mm

2 for the TO model (D = 28.5 mm). In addition, copper chillers were added in both configurations in the area below riser number 1, and near the neck of number 2, to promote directional solidification in the most critical zones and bring that part of the component within the radius of influence of the risers. The overall gating system for both configurations is shown in

Figure 10.

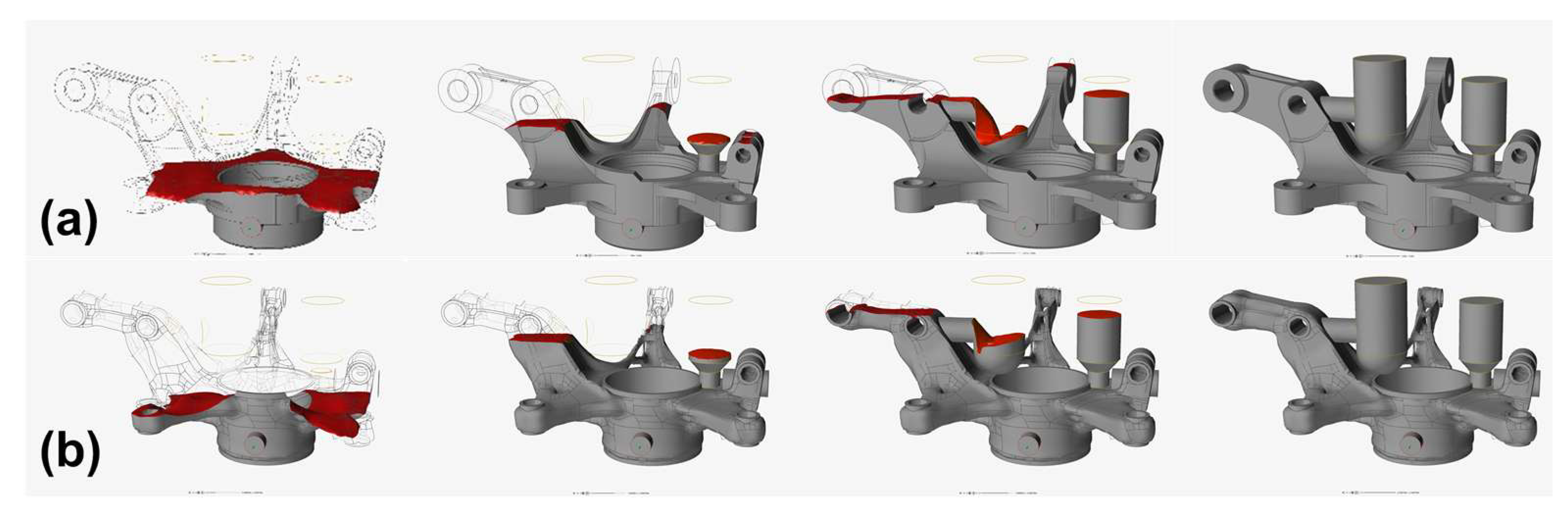

Successively, the RIC simulation was performed with the software Altair Inspire Cast, using the gating systems, models, and filling speed previously defined and a casting temperature of 1300 °C in accordance with material properties.

Figure 11 shows the filling of both models at different percentages. In particular, the filling time it takes for the molten metal front to fill the entire model and risers is 3.06 s for the MacPherson steering knuckle and 2.37 s for the TO knuckle model. Both calculated times are in the ideal filling time range (0.5–5 s) for components with a mass higher than 1 kg produced with this process [

36], since higher times would increase the risks of cold joints. The different filling time obtained depends on the smaller amount of molten metal required to fill the cavity, considering the same imposed filling velocity (2 m/s), even if the inlet section for the second case slightly decreases (thus, the volumetric flow rate).

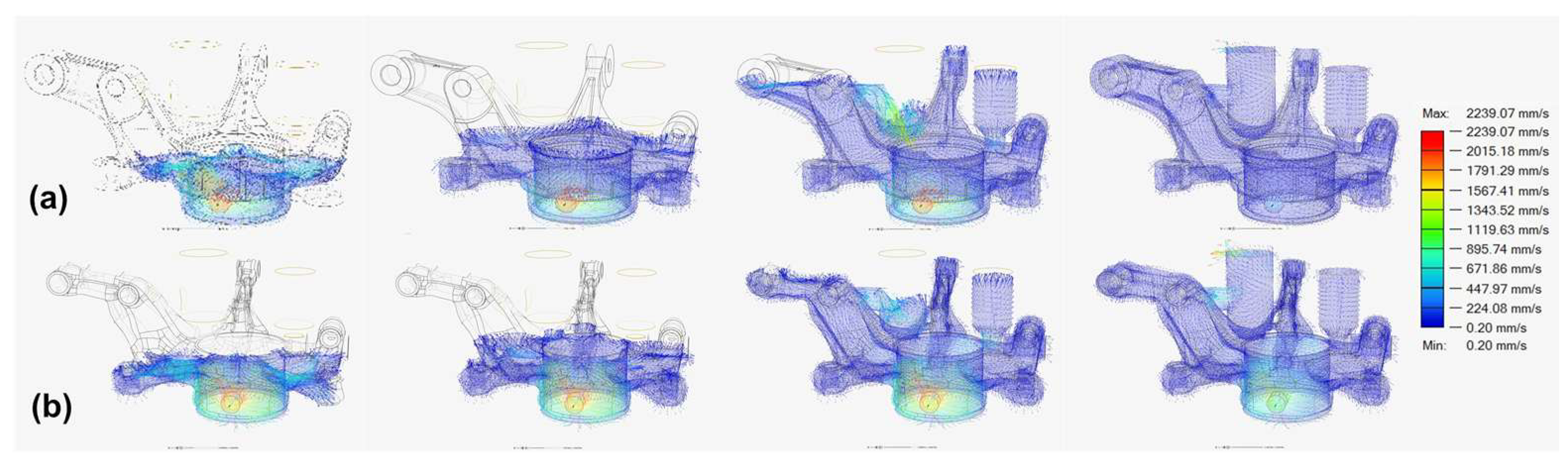

The velocity vectors at different filling percentages for both models are shown in

Figure 12. It can be noticed that, for the two cases considered, the maximum filling speed over time is always in correspondence of the inlet gate. However, inside the cavity, the velocity is between 0.5 and 2 m/s, which is the ideal filling velocity range for a RIC process to avoid turbulences, gaseous inclusions, and improve the overall surface quality [

36,

39].

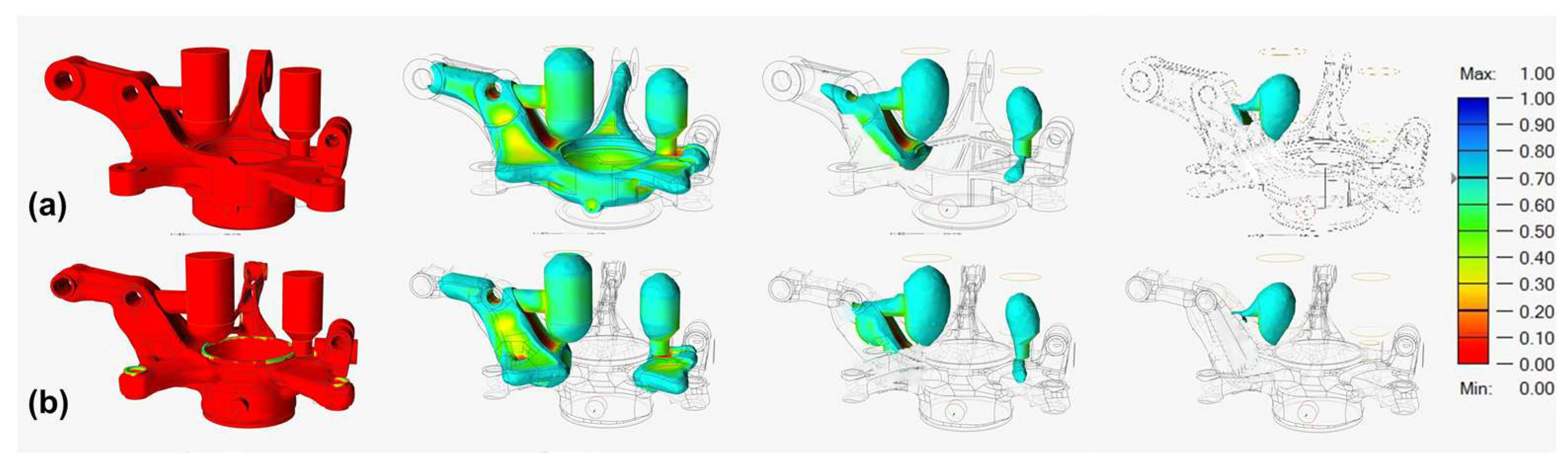

After the filling phase, computed solidification times for both models are 1370 s for the initial one and 1250 s for the topologically optimized.

Figure 13 shows the analysis of the solid fraction at different times. It can be noticed that even in the initial seconds, the TO steering knuckle starts to solidify in the thin-walled zones (2 mm), compared to the unoptimized counterpart. Particular attention was paid to the castability of geometrically critical regions, such as the rear arm of the knuckle. Minor geometric refinements were introduced post-optimization to avoid shell failure and misruns during the filling process. Moreover, going forward with the solidification of both models, it is notable that the last part of the casting to solidify is in the risers, causing them to be able to absorb any shrinkage cones or cavities.

Figure 14 shows the largest porosities inside the model at the end of the solidification phase (90%). In both cases, the largest porosities are inside the designed risers, which means that the observed ones do not affect the structural strength and surface finish of both models produced. It can be noted that the porosities in the optimized model are greater, even though they are contained in the risers that will later be removed during post-processing and are therefore not influential.

3.4. Life Cycle Assessment

Once the goodness of the systems designed for manufacturing both components was assessed, a life cycle assessment (LCA) analysis was performed to evaluate the advantages in terms of environmental impact of the optimized component. The LCA analysis was performed by comparing the two RIC scenarios for the standard steering knuckle and the TO variant. The comparison was conducted both on the manufacturing processes and the life cycle of a full set of knuckles (four specimens) considering the environmental impacts calculated using the IMPACT 2002+ method, which evaluates four main categories of damage: human health, ecosystem quality, climate change, and resources.

In

Table 9, the percentage of environmental impact for the rapid investment casting sub-processes of both components is shown. The casting process is dominant in terms of energy consumption in both scenarios, accounting for over 60% of the total. However, the environmental impact of the sub-process is significantly lower for the TO scenario because of a reduction in the needed casting metal. The percentage differences between the energy used for manufacturing the two components are marginal overall, with a slight decrease in the total energy consumption associated with 3D printing and casting in the optimized component due to the volume reduction. An increase is observed in “curing and cleaning” (+1.17%), while the environmental impact of the sub-process is perfectly comparable. All the observed variations for the model and 3D printing, mold preparation, casting, and post-processing can be attributed to the reduction of the materials involved in those processes (resin, plaster, and iron alloy), meanwhile the higher percentage impact of the curing and cleaning process might be attributed to the higher water and acetone consumption due to the complexity of the geometry. Although these variations are small in percentage, they generate non-negligible effects on cumulative environmental impacts, especially when multiplied on an industrial scale.

Table 10 presents the results for the four main damage categories obtained from the chosen LCA methodology, which allows a direct comparison between the different impact categories. It is possible to confront, for both scenarios, the impact of the manufacturing of four knuckles and their life cycle considering 200,000 km installed in a commercial car.

Appendix A contains the complete table without the grouping of the thirteen impact categories, not included in the text for the sake of briefness. It is worth noting that the TO scenario obtained a reduced environmental impact compared to the standard scenario for both manufacturing and life cycle, with savings of 27% and 31%, respectively. The bigger reduction in the environmental impact of the whole life cycle compared to manufacturing is attributable to the lightweighting of the car that reduces fuel consumption and vehicle wear. The benefit is uniformly reflected across all damage areas, with relevance to the human health and climate change categories, suggesting that the TO optimization is associated with a cleaner energy mix or greater efficiency in key processes. The reduction in the consumption of resin, steel, sand, electricity, and fuel causes a reduction in the consumed resources as well as the reduction in climate change due to less raw materials transformations.

The analysis suggests that, despite marginal differences in the percentage distribution of environmental impact in the sub-processes, the TO process achieves a significant reduction in overall environmental impact, as measured using the IMPACT 2002+ method. This can be attributed to several factors, such as the reduction in absolute energy consumption and the improved efficiencies of the most impactful processes, such as casting and 3D printing.

4. Conclusions and Future Developments

This study demonstrated the effectiveness of topology optimization in improving the structural and environmental performance of commercial vehicle steering knuckles. The main contribution of this work lies in the methodological integration of TO, RIC, and LCA applied to a real-world safety-critical component. By performing both cradle-to-gate and cradle-to-grave environmental assessments and validating the results with detailed structural and process simulations, the study offers a holistic evaluation that advances current practices in sustainable component design.

Using finite element analysis and static structural simulations, the optimized design showed improved material efficiency while maintaining mechanical integrity. The maximum Von Mises stress remained below the yield strength of the SG A536 iron alloy in both configurations, ensuring a 1.11 safety factor.

The topology optimized component exhibited a 30% reduction in volume and mass, which translated into significant benefits during downstream processes. Specifically, the 3D printing phase yielded 27% savings in resin usage and 9% shorter printing times, reducing both material cost and energy demand.

In the rapid investment casting simulations, the TO model filled faster and solidified more efficiently due to its reduced volume and optimized geometry. Porosity was confined to non-critical regions (risers), affirming the reliability of the optimized design from a manufacturing standpoint.

Life cycle assessment further confirmed the environmental advantages of the TO approach. When scaled to a full vehicle set of four knuckles and assessed over a service life of 200,000 km, the TO configuration achieved a 27% reduction in the environmental impact of manufacturing and a 31% reduction over the full life cycle. These savings were especially notable in the impact categories on human health and climate change, indicating a tangible benefit of lightweighting in terms of fuel economy and reduced resource use.

In general, the integration of topology optimization with advanced manufacturing techniques, such as additive manufacturing and RIC, presents a viable path to producing high-performance automotive components that are both structurally resistant and environmentally sustainable. While this study focused on compliance minimization as a primary optimization objective, future work will explore alternative criteria such as fatigue performance or dynamic behavior to further enhance component reliability. Future work will involve the manufacturing and metallurgical characterization of real castings based on the optimized design. This will enable experimental verification of the microstructural integrity, specifically regarding the potential formation of carbides in 2 mm thin-walled sections and the retention of spheroidal graphite in areas subject to prolonged solidification. Such validation is crucial to ensure that the optimized component meets both mechanical and microstructural requirements for automotive applications. Future work will focus on incorporating additive manufacturing constraints (e.g., overhang angles) directly within the topology optimization process, enabling more production-oriented design outputs. Future work may explore different materials, fatigue behavior, and further design refinements to extend these findings to a wider range of automotive components.