Effect of Processing-Induced Oxides on the Fatigue Life Variability of 6082 Al-Mg-Si Alloy Extruded Components

Abstract

1. Introduction

2. Materials and Methods

2.1. Microstructural Characterisation

2.2. Surface Roughness Measurements

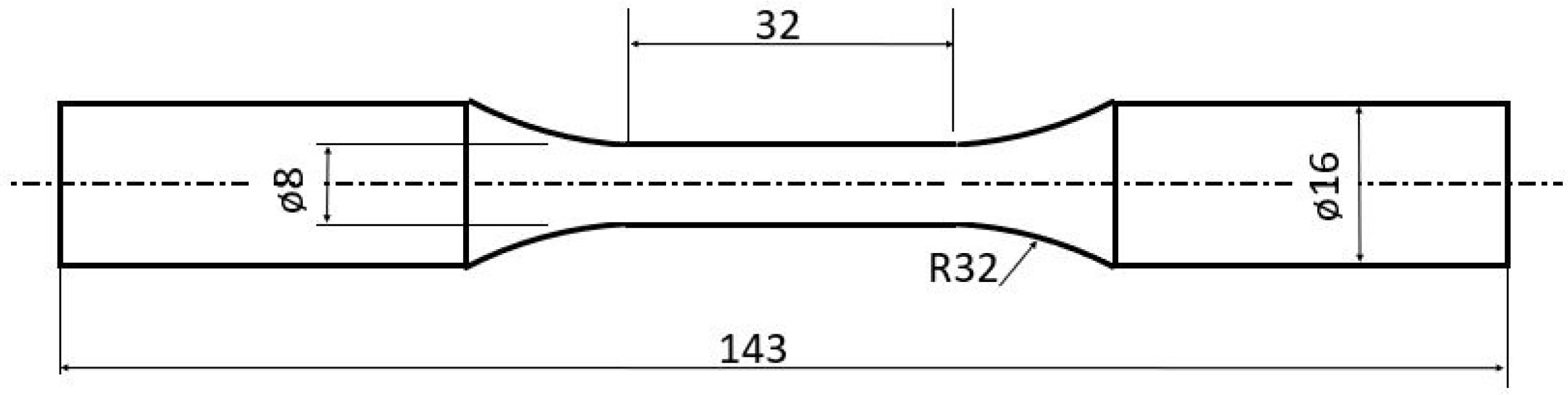

2.3. Mechanical Tests

2.4. Computer Tomography (CT) and 3D Image Analysis

3. Results

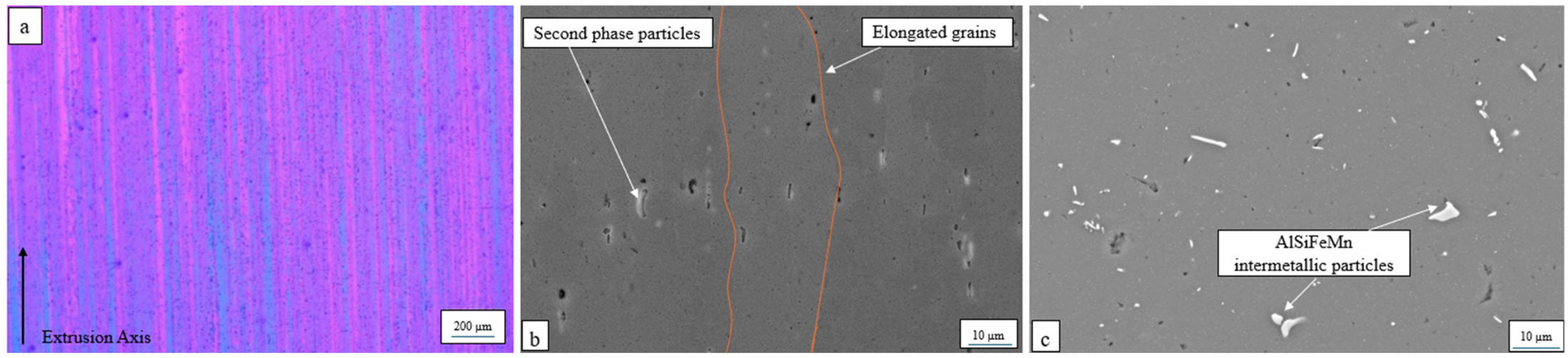

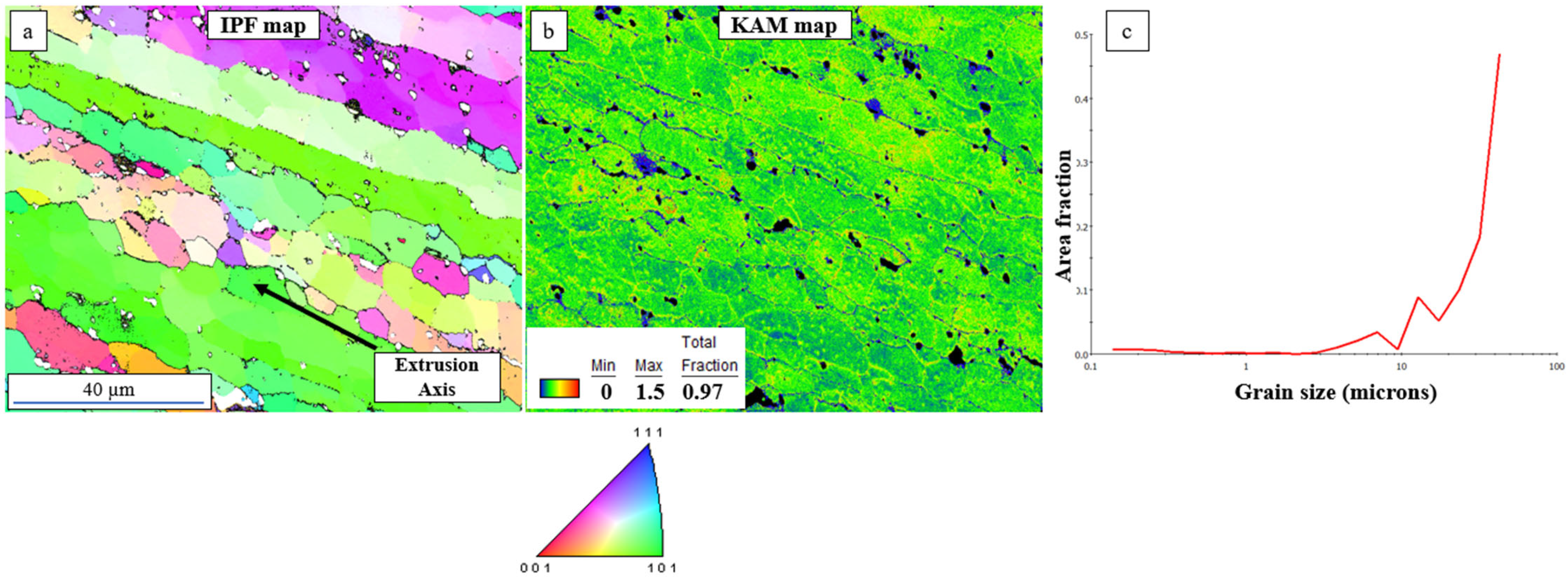

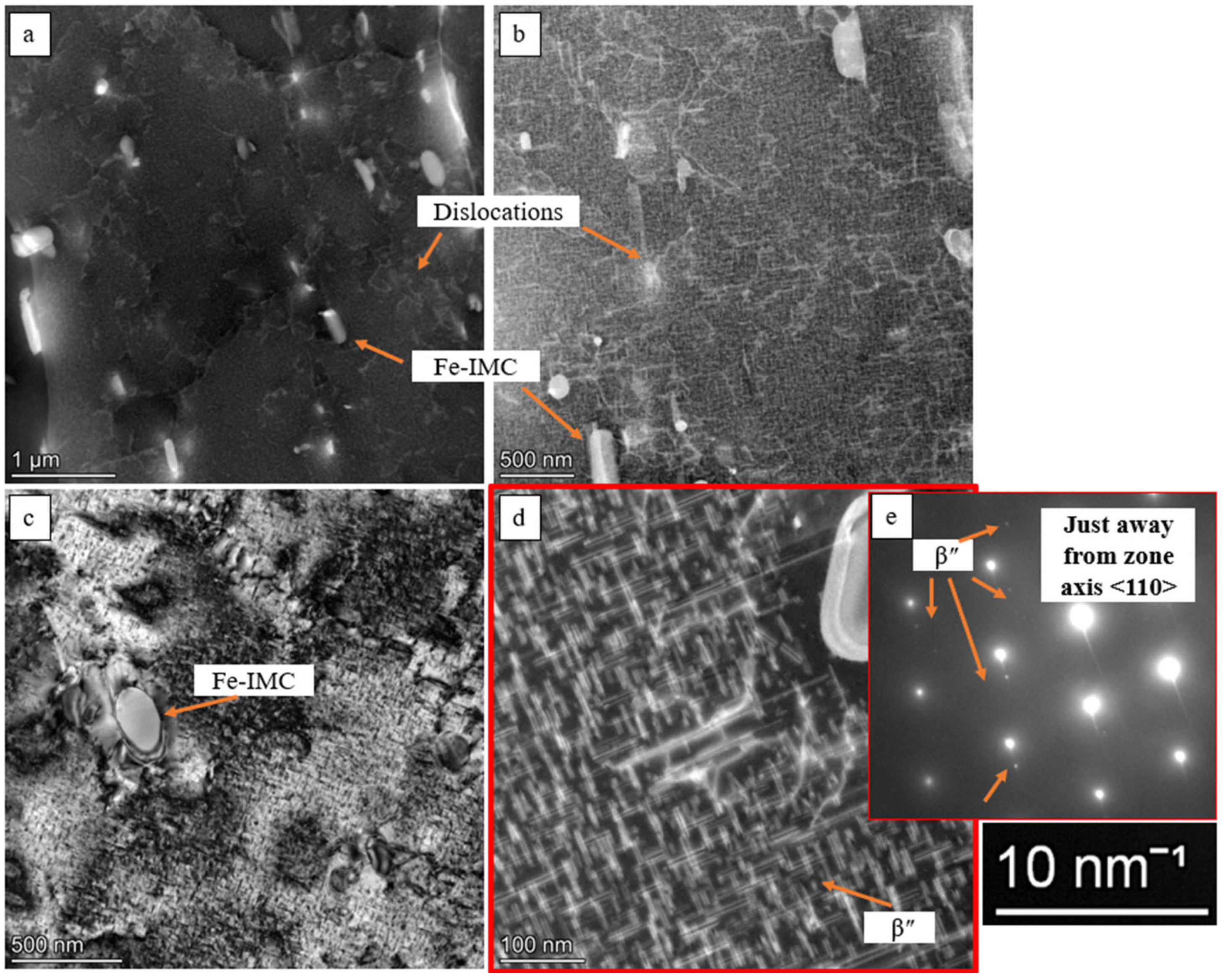

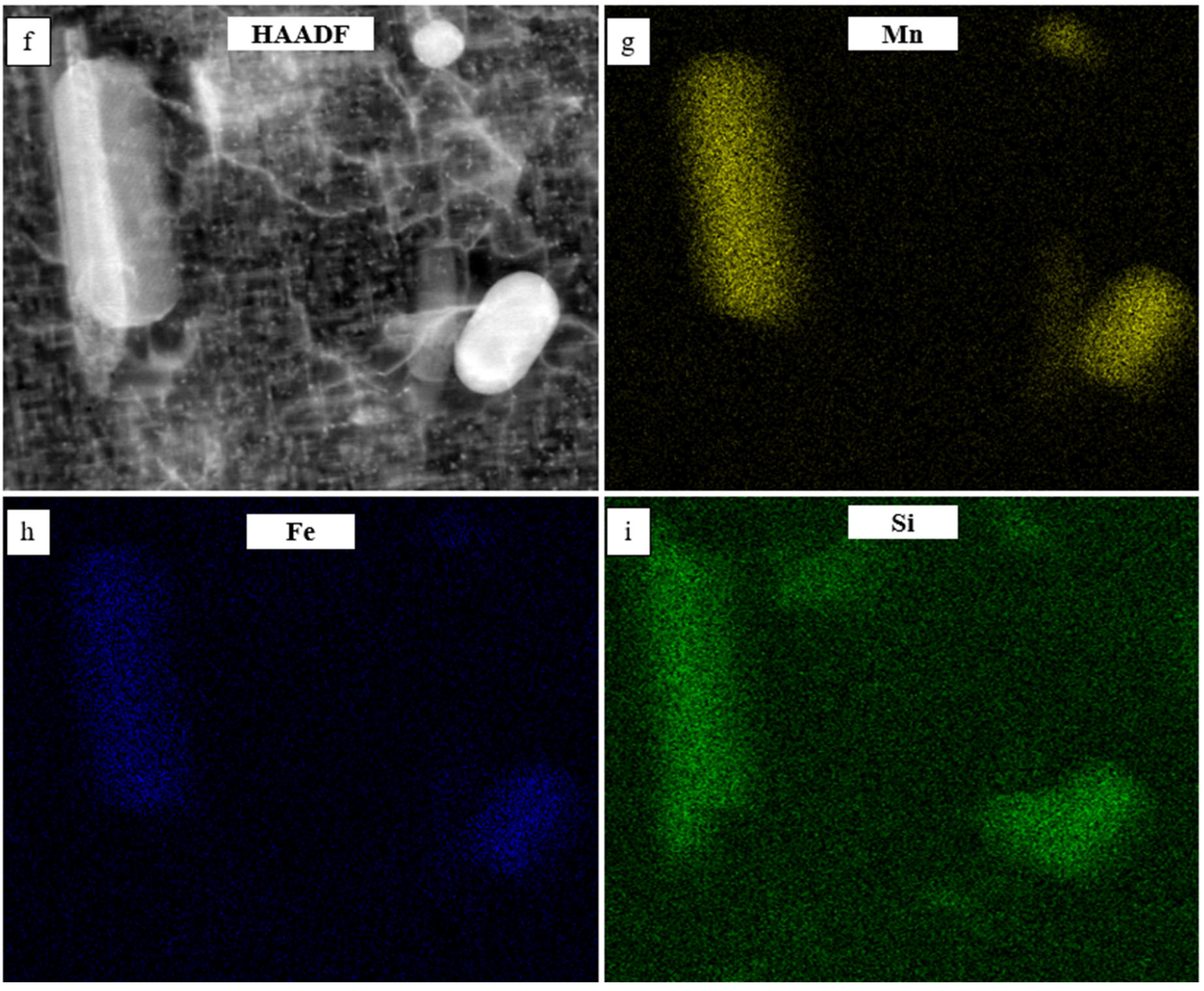

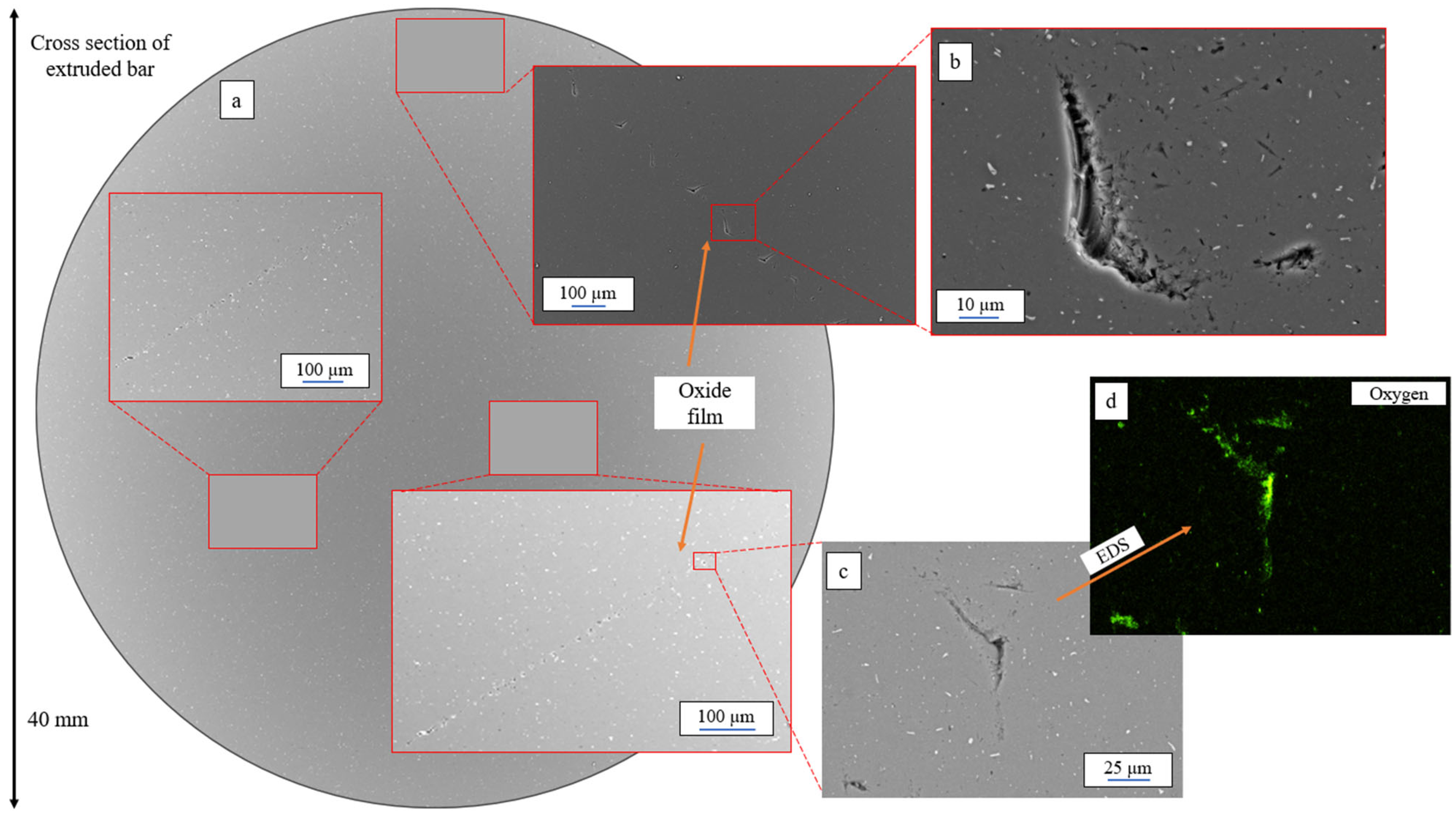

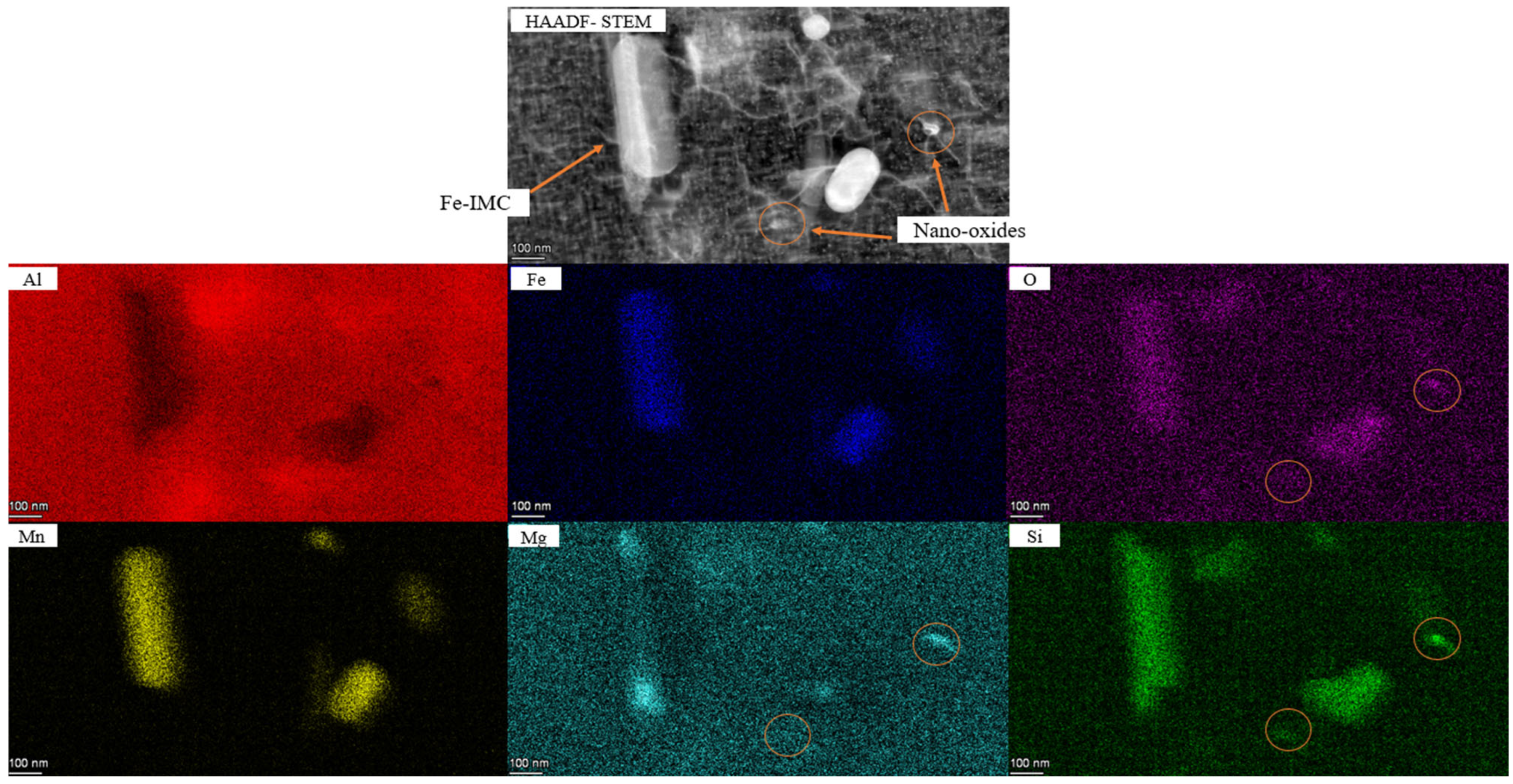

3.1. Initial Microstructural Characterisation of the As-Received Rod Material

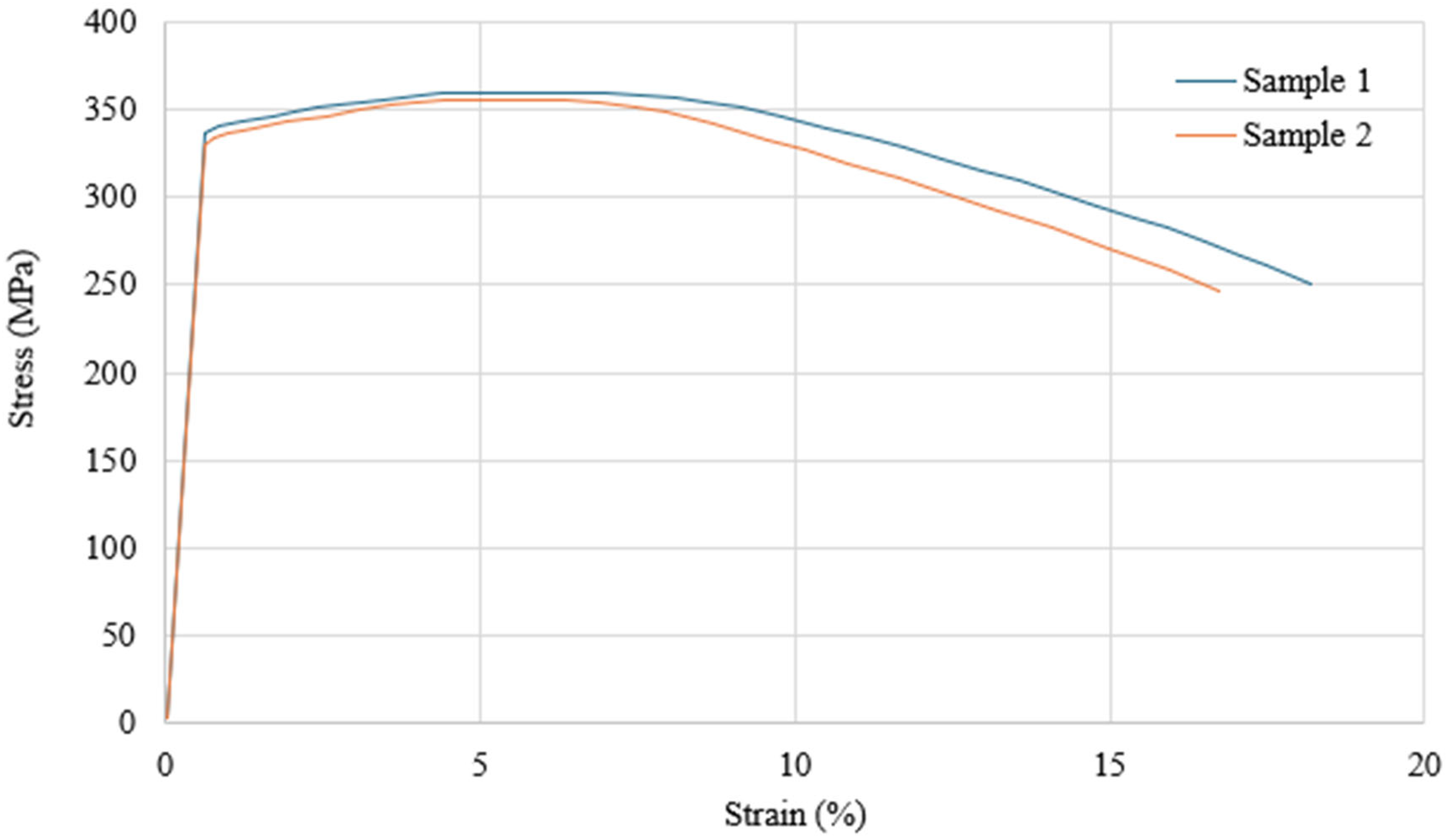

3.2. Tensile Behaviour of Machined Bars

3.3. Fatigue Behaviour

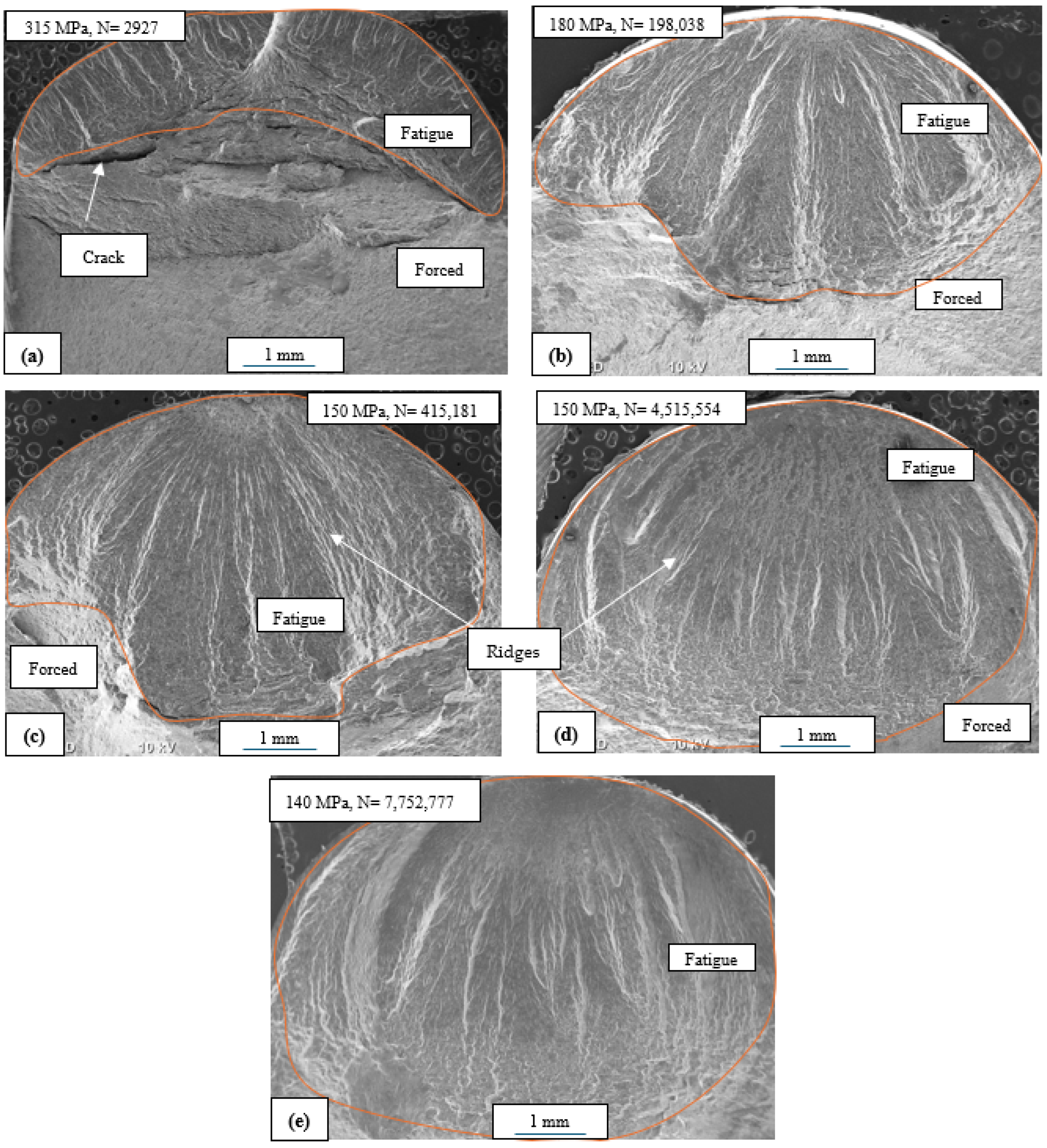

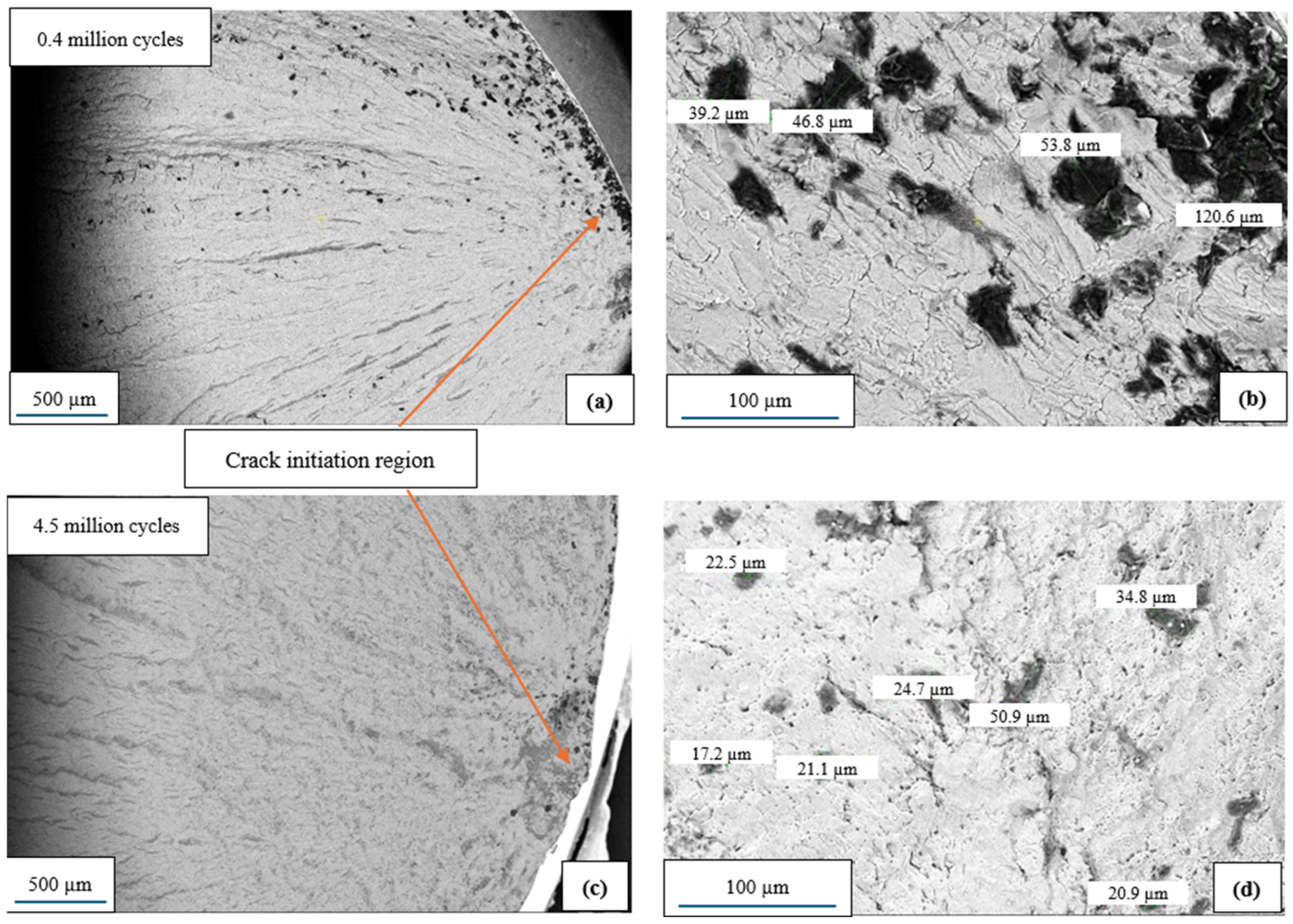

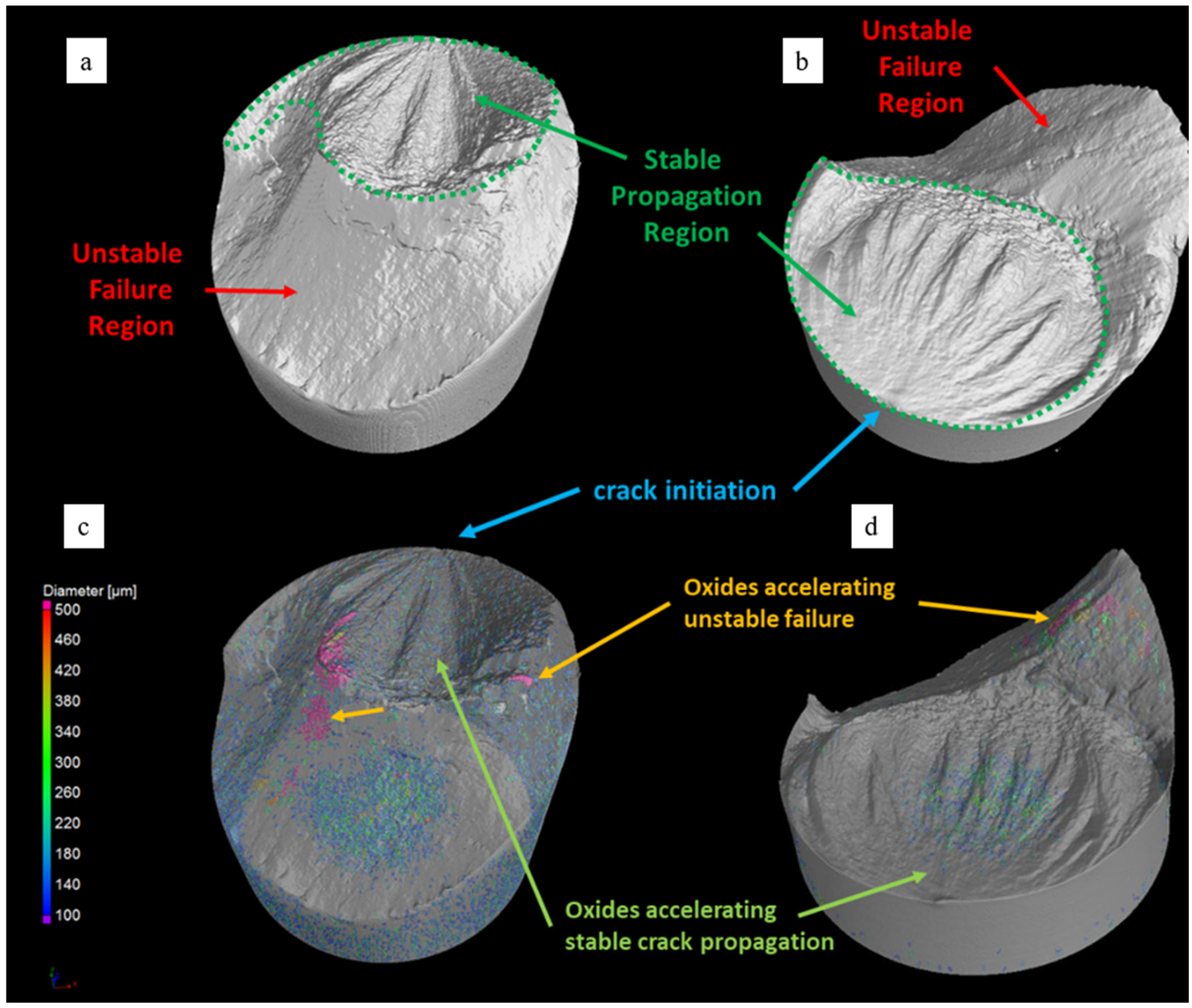

3.4. Fractography of Fatigue Samples

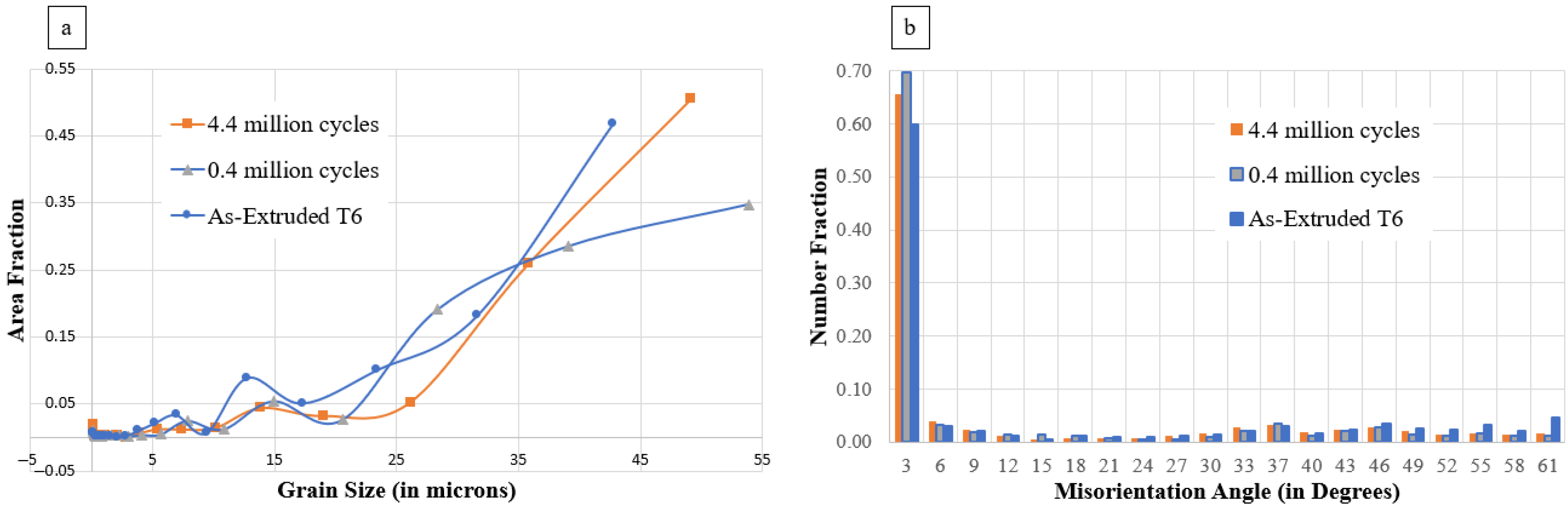

3.5. Variability in the High-Cycle-Fatigue Behaviour

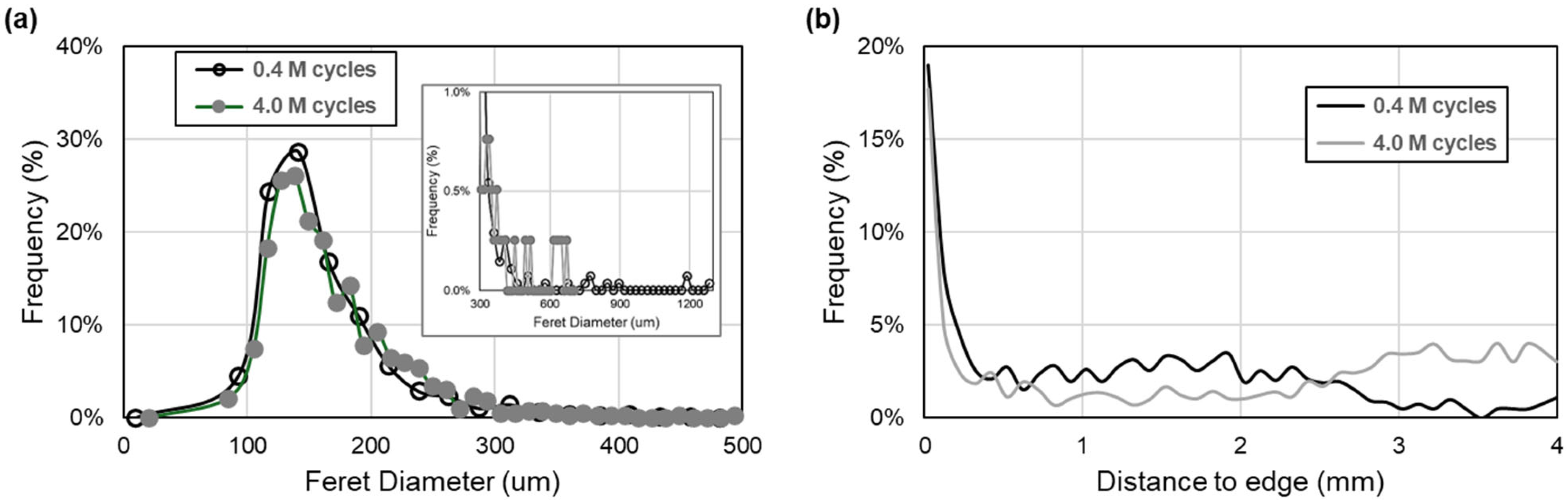

3.6. Distribution of Inclusions on the Fractured Samples

4. Discussion

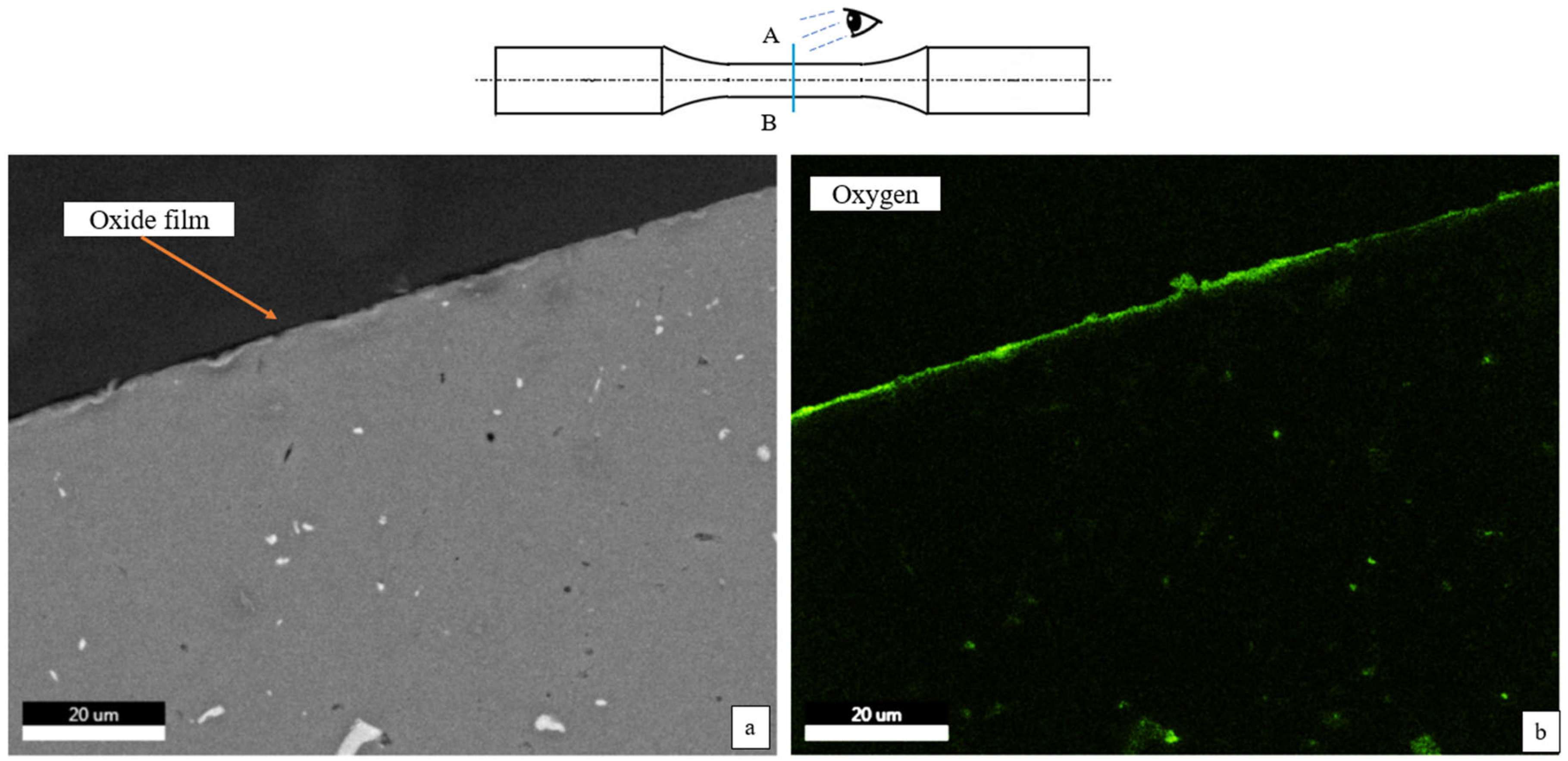

4.1. Origin of Oxides: Influence of Machining

4.2. Origin of Oxides: Influence of Processing

4.3. Mechanism of Oxide Formation

5. Conclusions

- Fatigue tests at similar fatigue conditions (150 MPa, 15 Hz, and R = −1) showed a wide variation in fatigue life, ranging from 0.4 to 4 million cycles, indicating the presence of microstructural defects.

- SEM and EDS analysis confirmed the existence of oxide inclusions on the fracture surface and edges of the material.

- Larger oxide particles ranging from 39 µm to 120 µm in thickness, and up to 1300 µm in length, were present in the samples with a shorter fatigue life.

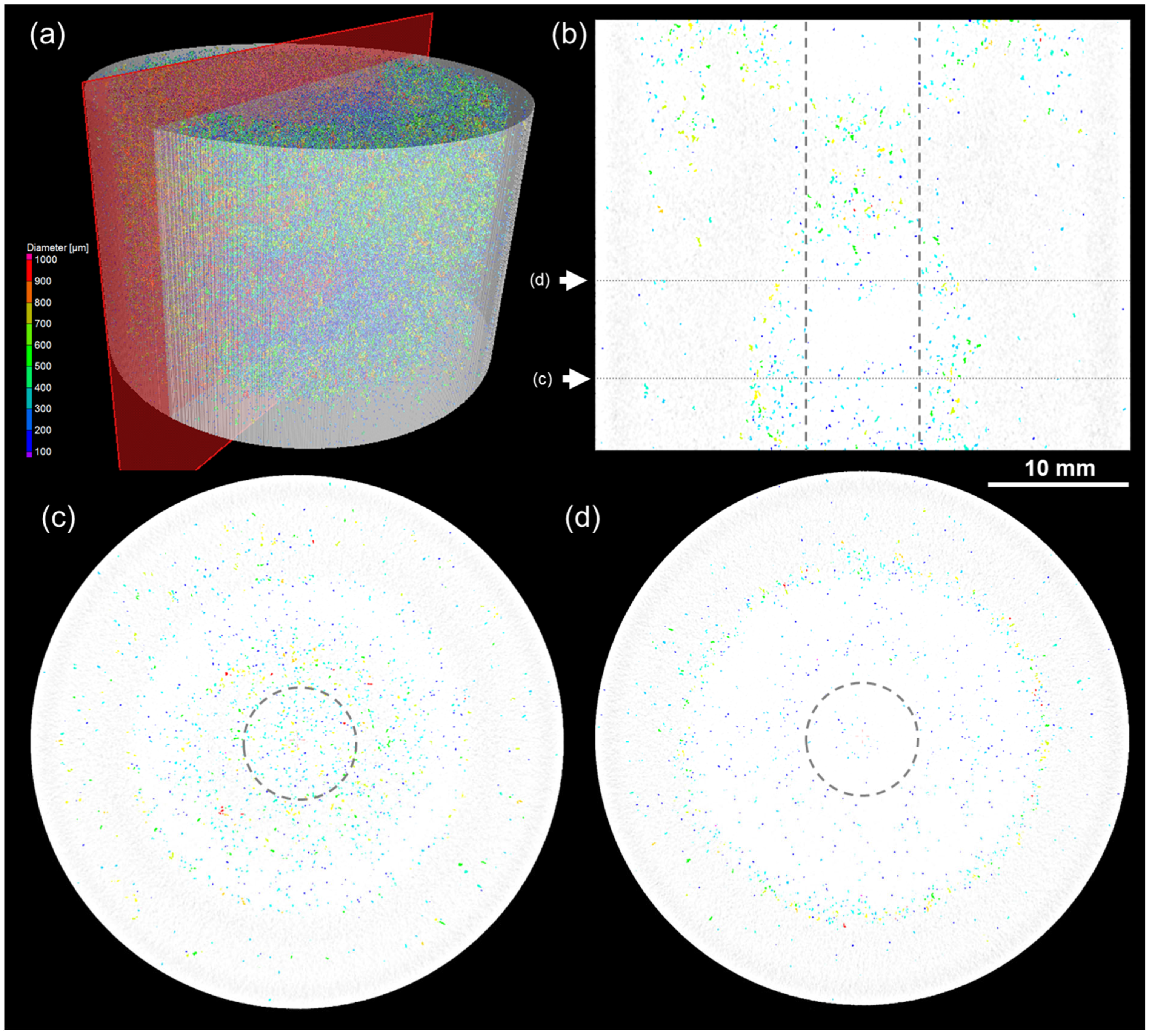

- The sample with lower fatigue life exhibited an oxide volume fraction of 0.35% with a particle of 10/mm3, whereas the sample with higher fatigue life presented an oxide fraction of 0.22% and a particle density of only 6/mm3.

- The presence of oxides acted as stress concentrators and contributed to faster crack growth and premature fatigue failure.

- A sample exhibiting low fatigue life presented more defects closer to the surface, leading to a higher crack propagation rate at early stages.

- CT scanning revealed that the internal distribution and size of the oxides play an important role in the crack propagation and final unstable failure. It also confirms that these defects are heterogeneously distributed in the as-received extruded rod, suggesting that they originated during the material processing stage.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, J.; Cui, J.; Wang, Y.; Huang, M.; Dong, J.; Yan, J. Effect of T6 heat treatment on microstructure and mechanical properties of 6082 aluminum alloy automotive flange components formed by squeeze casting. Mater. Sci. Eng. A 2024, 912, 146974. [Google Scholar] [CrossRef]

- Klemenc, J.; Glodež, S.; Steinacher, M.; Zupanič, F. LCF behaviour of high strength aluminium alloys AA 6110A and AA 6086. Int. J. Fatigue 2023, 177, 107971. [Google Scholar] [CrossRef]

- Stojanovic, B.; Bukvic, M.; Epler, I. Application of Aluminum and Aluminum Alloys in Engineering. Appl. Eng. Lett. 2018, 3, 52–62. [Google Scholar] [CrossRef]

- Zupanič, F.; Klemenc, J.; Steinacher, M.; Glodež, S. Microstructure, mechanical properties and fatigue behaviour of a new high-strength aluminium alloy AA 6086. J. Alloys Compd. 2023, 941, 168976. [Google Scholar] [CrossRef]

- Bannantine, J.A.; Comer, J.J.; Handrock, J.L. Fundamentals of Metal Fatigue Analysis; Prentice Hall: Englewood Cliffs, NJ, USA, 1990. [Google Scholar]

- Schijve, J. Fatigue of Structures and Materials, 2nd ed.; [Nachdr.]; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, MA, USA; New York, NY, USA, 1998. [Google Scholar]

- Avner, S.H. Introduction to Physical Metallurgy, 2nd ed.; McGraw-Hill Book Co: New York, NY, USA, 1974. [Google Scholar]

- Siddesh Kumar, N.M.; Dhruthi; Pramod, G.K.; Samrat, P.; Sadashiva, M. A Critical Review on Heat Treatment of Aluminium Alloys. Mater. Today Proc. 2022, 58, 71–79. [Google Scholar] [CrossRef]

- Chauhan, K. Influence of Heat Treatment on the Mechanical Properties of Aluminium Alloys (6xxx Series): A Literature Review. Int. J. Eng. Res. 2017, 6, IJERTV6IS030301. Available online: https://www.ijert.org/research/influence-of-heat-treatment-on-the-mechanical-properties-of-aluminium-alloys-6xxx-series-a-literature-review-IJERTV6IS030301.pdf (accessed on 17 July 2025).

- Di Sabatino, M.; Arnberg, L.; Rørvik, S.; Prestmo, A. The influence of oxide inclusions on the fluidity of Al–7wt.%Si alloy. Mater. Sci. Eng. A 2005, 413–414, 272–276. [Google Scholar] [CrossRef]

- Liu, L.; Samuel, F.H. Effect of inclusions on the tensile properties of Al–7% Si–0.35% Mg (A356.2) aluminium casting alloy. J. Mater. Sci. 1998, 33, 2269–2281. [Google Scholar] [CrossRef]

- Zhang, L.; Lv, X.; Torgerson, A.T.; Long, M. Removal of Impurity Elements from Molten Aluminum: A Review. Miner. Process. Extr. Metall. Rev. 2011, 32, 150–228. [Google Scholar] [CrossRef]

- Poletti, C.; Bureau, R.; Loidolt, P.; Simon, P.; Mitsche, S.; Spuller, M. Microstructure Evolution in a 6082 Aluminium Alloy during Thermomechanical Treatment. Materials 2018, 11, 1319. [Google Scholar] [CrossRef]

- Kumar, N.; Goel, S.; Jayaganthan, R.; Owolabi, G.M. The influence of metallurgical factors on low cycle fatigue behavior of ultra-fine grained 6082 Al alloy. Int. J. Fatigue 2018, 110, 130–143. [Google Scholar] [CrossRef]

- Nanninga, N.; White, C. The relationship between extrusion die line roughness and high cycle fatigue life of an AA6082 alloy. Int. J. Fatigue 2009, 31, 1215–1224. [Google Scholar] [CrossRef]

- Wang, P.; Wang, B.; Liu, Y.; Zhang, P.; Luan, Y.K.; Li, D.Z.; Zhang, Z.F. Effects of inclusion types on the high-cycle fatigue properties of high-strength steel. Scr. Mater. 2022, 206, 114232. [Google Scholar] [CrossRef]

- Gopalan, R.; Prabhu, N.K. Oxide bifilms in aluminium alloy castings—A review. Mater. Sci. Technol. 2011, 27, 1757–1769. [Google Scholar] [CrossRef]

- Wang, Q.S.; Crepeau, P.N.; Davidson, C.J.; Griffiths, J.R. Oxide films, pores and the fatigue lives of cast aluminum alloys. Metall. Mater. Trans. B 2006, 37, 887–895. [Google Scholar] [CrossRef]

- Tahmasbi, K.; Yaghoobi, M.; Shao, S.; Shamsaei, N.; Haghshenas, M. Simulated effect of defect volume and location on very high cycle fatigue of laser beam powder bed fused AlSi10Mg. Int. J. Fatigue 2025, 197, 108926. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Analysis of the effect of surface roughness on fatigue performance of powder bed fusion additive manufactured metals. Theor. Appl. Fract. Mech. 2020, 108, 102638. [Google Scholar] [CrossRef]

- Rodopoulos, C. Optimisation of the fatigue resistance of 2024-T351 aluminium alloys by controlled shot peening—Methodology, results and analysis. Int. J. Fatigue 2004, 26, 849–856. [Google Scholar] [CrossRef]

- Trško, L.; Fintová, S.; Nový, F.; Bokůvka, O.; Jambor, M.; Pastorek, F.; Florková, Z.; Oravcová, M. Study of Relation between Shot Peening Parameters and Fatigue Fracture Surface Character of an AW 7075 Aluminium Alloy. Metals 2018, 8, 111. [Google Scholar] [CrossRef]

- ASTM E466-15; Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM E8/E8M-09; Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2009. [CrossRef]

- Negendank, M.; Taparli, U.A.; Gall, S.; Müller, S.; Reimers, W. Microstructural evolution of indirectly extruded seamless 6xxx aluminum tubes with axial variable wall thickness. J. Mater. Process. Technol. 2016, 230, 187–197. [Google Scholar] [CrossRef]

- Qiu, S.; Xia, E.; Liu, L.; Ye, T.; Liu, J.; Tang, J.; Liu, W.; Wu, Y. Tensile Behavior and Microstructure Evolution of an Extruded 6082 Aluminum Alloy Sheet at High Temperatures. Metals 2023, 14, 7. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Fernández, R.; Saliwan-Neumann, R.; González-Doncel, G.; Bruno, G. Dislocation substructures in pure aluminium after creep deformation as studied by electron backscatter diffraction. J. Appl. Crystallogr. 2022, 55, 860–869. [Google Scholar] [CrossRef]

- Bouquerel, J.; Diawara, B.; Dubois, A.; Dubar, M.; Vogt, J.-B.; Najjar, D. Investigations of the microstructural response to a cold forging process of the 6082-T6 alloy. Mater. Des. 2015, 68, 245–258. [Google Scholar] [CrossRef]

- Borrego, L.P.; Abreu, L.M.; Costa, J.M.; Ferreira, J.M. Analysis of low cycle fatigue in AlMgSi aluminium alloys. Eng. Fail. Anal. 2004, 11, 715–725. [Google Scholar] [CrossRef]

- Hua, L.; Yuan, P.; Zhao, N.; Hu, Z.; Ma, H. Microstructure and mechanical properties of 6082 aluminum alloy processed by preaging and hot forging. Trans. Nonferrous Met. Soc. China 2022, 32, 790–800. [Google Scholar] [CrossRef]

- Xu, X.; Zhu, W.; Guo, X.; Liang, C.; Deng, Y. Effect of ageing treatment process on the microstructure development and mechanical properties of 6082 Al alloy. J. Alloys Compd. 2023, 935, 167892. [Google Scholar] [CrossRef]

- Hamada, A.S.; Järvenpää, A.; Ahmed, M.M.Z.; Jaskari, M.; Wynne, B.P.; Porter, D.A.; Karjalainen, L.P. The microstructural evolution of friction stir welded AA6082-T6 aluminum alloy during cyclic deformation. Mater. Sci. Eng. A 2015, 642, 366–376. [Google Scholar] [CrossRef]

- Joshi, S.S.; Lefebvre, W.; Duval, Y.; Folton, C.; Hug, E.; Fazzini, M.; Keller, C. Impact of laser powder bed fusion processing on the cyclic and fatigue properties of Ni20Cr alloy. Mater. Sci. Eng. A 2024, 890, 145915. [Google Scholar] [CrossRef]

- Niu, Z.; Que, Z.; Patel, J.B.; Fan, Z. Assessment and Improvement of Melt Quality of Recycled Secondary A357 Alloy by Application of the High Shear Melt Conditioning (HSMC) Technology. Crystals 2024, 14, 1044. [Google Scholar] [CrossRef]

- Kim, D.; Jiang, R.; Reed, P.A.S. Microstructural and oxidation effects on fatigue crack initiation mechanisms in a turbine disc alloy. J. Mater. Sci. 2023, 58, 1869–1885. [Google Scholar] [CrossRef]

- Gerhard, N.; Göttlich, T.; Schraknepper, D.; Bergs, T. Experimental investigation on friction under machining conditions with cutting fluid supply. Procedia CIRP 2022, 108, 378–383. [Google Scholar] [CrossRef]

- Grzesik, W.; Nieslony, P. Prediction of friction and heat flow in machining incorporating thermophysical properties of the coating–chip interface. Wear 2004, 256, 108–117. [Google Scholar] [CrossRef]

- Scamans, G.M.; Frolish, M.F.; Rainforth, W.M.; Zhou, Z.; Liu, Y.; Zhou, X.; Thompson, G.E. The ubiquitous Beilby layer on aluminium surfaces. Surf. Interface Anal. 2010, 42, 175–179. [Google Scholar] [CrossRef]

- Liu, B.; Zhou, X.; Zhang, X. Orthogonal machining introduced microstructure modification in AA7150-T651 aluminium alloy. Mater. Charact. 2017, 123, 91–98. [Google Scholar] [CrossRef]

- Li, X.; Huang, C.; Yang, J.; Liu, D.; Li, T.; Tan, C.; Jia, W.; Wan, M. Effect of multilevel lamellar microstructures on notch high cycle fatigue damage micromechanism of TC21 alloy. Int. J. Fatigue 2025, 199, 109013. [Google Scholar] [CrossRef]

- Tan, C.; Sun, Q.; Xiao, L.; Zhao, Y.; Sun, J. Cyclic deformation and microcrack initiation during stress controlled high cycle fatigue of a titanium alloy. Mater. Sci. Eng. A 2018, 711, 212–222. [Google Scholar] [CrossRef]

- Campbell, J. Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design, 1st ed.; Elsevier Butterworth-Heinemann: Oxford, UK; Waltham, MA, USA, 2011. [Google Scholar]

- Cao, X.; Campbell, J. Effect of melt superheating on convection-free precipitation and sedimentation of primary α-Fe phase in liquid Al-11.5Si-0.4Mg alloy. Int. J. Cast Met. Res. 2003, 15, 595–608. [Google Scholar] [CrossRef]

- El-Sayed, M.A.; Essa, K.; Hassanin, H. Influence of Bifilm Defects Generated during Mould Filling on the Tensile Properties of Al–Si–Mg Cast Alloys. Metals 2022, 12, 160. [Google Scholar] [CrossRef]

- Osoba, L.O.; Owolabi, O.B.; Talabi, S.I.; Adeosun, S.O. Review on Oxide Formation and Aluminum Recovery Mechanism during Secondary Smelting. Mater. Eng. 2018, 2, 45–51. [Google Scholar]

- Song, H.; Zhang, L.; Cao, F.; Gu, X.; Sun, J. Oxide bifilm defects in aluminum alloy castings. Mater. Lett. 2021, 285, 129089. [Google Scholar] [CrossRef]

- Akaberi, N.; Taghiabadi, R.; Razaghian, A. Effect of Bifilm Oxides on the Dry Sliding Wear Behavior of Fe-Rich Al–Si Alloys. J. Tribol. 2017, 139, 051602. [Google Scholar] [CrossRef]

- El-Sayed, M.A.; Salem, H.A.G.; Kandeil, A.Y.; Griffiths, W.D. Effect of Holding Time Before Solidification on Double-Oxide Film Defects and Mechanical Properties of Aluminum Alloys. Metall. Mater. Trans. B 2011, 42, 1104–1109. [Google Scholar] [CrossRef]

- Uludağ, M.; Çetin, R.; Gemi, L.; Dispinar, D. Change in Porosity of A356 by Holding Time and Its Effect on Mechanical Properties. J. Mater. Eng. Perform. 2018, 27, 5141–5151. [Google Scholar] [CrossRef]

- Li, D.Z.; Campbell, J.; Li, Y.Y. Filling system for investment cast Ni-base turbine blades. J. Mater. Process. Technol. 2004, 148, 310–316. [Google Scholar] [CrossRef]

- Raza, M.H.; Wasim, A.; Sajid, M.; Hussain, S. Investigating the effects of gating design on mechanical properties of aluminum alloy in sand casting process. J. King Saud Univ. Eng. Sci. 2021, 33, 201–212. [Google Scholar] [CrossRef]

- Nayhumwa, C.; Green, N.R.; Campbell, J. Influence of casting technique and hot isostatic pressing on the fatigue of an Al-7Si-Mg alloy. Metall. Mater. Trans. A 2001, 32, 349–358. [Google Scholar] [CrossRef]

- Lazaro-Nebreda, J.; Patel, J.B.; Fan, Z. Improved degassing efficiency and mechanical properties of A356 aluminium alloy castings by high shear melt conditioning (HSMC) technology. J. Mater. Process. Technol. 2021, 294, 117146. [Google Scholar] [CrossRef]

- Lazaro-Nebreda, J.; Patel, J.B.; Lordan, E.; Zhang, Y.; Karakulak, E.; Al-Helal, K.; Scamans, G.M.; Fan, Z. Degassing of Aluminum Alloy Melts by High Shear Melt Conditioning Technology: An Overview. Metals 2022, 12, 1772. [Google Scholar] [CrossRef]

| Element | Mg | Si | Mn | Fe | Cr | Al |

|---|---|---|---|---|---|---|

| Measured | 0.61 | 1.02 | 0.42 | 0.18 | 0.01 | Balance |

| From manufacturer (Aalco) | 0.6–1.20 | 0.7–1.30 | 0.4–1.00 | 0.0–0.50 | 0.0–0.25 | Balance |

| Properties | Values |

|---|---|

| Yield strength (MPa) | 334 ± 2 |

| Ultimate tensile strength (MPa) | 360 ± 3 |

| Young’s modulus (GPa) | 72 |

| Elongation (%) | 18.1 ± 0.6 |

| Tests | Stress (MPa) | Frequency (Hz) | Stress Ratio (R) | No. of Tests | Average Life (Cycles) | Standard Deviation |

|---|---|---|---|---|---|---|

| 1 | 315 | 5 | −0.5 | 3 | 3446 | 1257 |

| 2 | 180 | 15 | −1 | 3 | 196,217 | 4595 |

| 3 | 150 | 15 | −1 | 6 | 468,404 | 184,647 |

| 4 | 150 | 15 | −1 | 4 | 4,541,861 | 608,998 |

| 5 | 140 | 15 | −1 | 2 | 5,701,053 | 2,051,723 |

| No. | Stress (MPa) | Frequency (Hz) | Stress Ratio (R) | Fatigue Life (Cycles) | Area of the Stable Propagation (mm2) | Percentage of the Total Area |

|---|---|---|---|---|---|---|

| 1 | 315 | 5 | −0.5 | 2297 | 9.9 | 19.7 |

| 2 | 180 | 15 | −1 | 198,038 | 17.4 | 34.6 |

| 3 | 150 | 15 | −1 | 415,181 | 24.2 | 48.1 |

| 4 | 150 | 15 | −1 | 4,515,554 | 26.7 | 53.3 |

| 5 | 140 | 15 | −1 | 7,752,777 | 30.1 | 59.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vivekanandam, V.; Joshi, S.S.; Lazaro-Nebreda, J.; Fan, Z. Effect of Processing-Induced Oxides on the Fatigue Life Variability of 6082 Al-Mg-Si Alloy Extruded Components. J. Manuf. Mater. Process. 2025, 9, 247. https://doi.org/10.3390/jmmp9070247

Vivekanandam V, Joshi SS, Lazaro-Nebreda J, Fan Z. Effect of Processing-Induced Oxides on the Fatigue Life Variability of 6082 Al-Mg-Si Alloy Extruded Components. Journal of Manufacturing and Materials Processing. 2025; 9(7):247. https://doi.org/10.3390/jmmp9070247

Chicago/Turabian StyleVivekanandam, Viththagan, Shubham Sanjay Joshi, Jaime Lazaro-Nebreda, and Zhongyun Fan. 2025. "Effect of Processing-Induced Oxides on the Fatigue Life Variability of 6082 Al-Mg-Si Alloy Extruded Components" Journal of Manufacturing and Materials Processing 9, no. 7: 247. https://doi.org/10.3390/jmmp9070247

APA StyleVivekanandam, V., Joshi, S. S., Lazaro-Nebreda, J., & Fan, Z. (2025). Effect of Processing-Induced Oxides on the Fatigue Life Variability of 6082 Al-Mg-Si Alloy Extruded Components. Journal of Manufacturing and Materials Processing, 9(7), 247. https://doi.org/10.3390/jmmp9070247